Abstract

Biopolymers have been the focus of intense research because of their wide applicability. The thermophysical properties of solutions containing biopolymers have fundamental importance for engineering calculations, as well as for thermal load calculations, energy expenditure, and development of new products. In this work, the thermophysical properties of binary and ternary solutions of carboxymethylcellulose and/or high methoxylation pectin and water at different temperatures have been investigated taking into consideration different biopolymer concentrations. The experimental data related to the thermophysical properties were correlated to obtain empirical models that can describe the temperature–concentration combined effect on the density, refractive index, and dynamic viscosity. From data obtained from the experiments, the density, refractive index, and dynamic viscosity increase with increasing biopolymer concentration and decrease with increasing temperature. The polynomial models showed a good fit to the experimental data and high correlation coefficients (\(R^{2}\ge \) 0.98) for each studied system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Knowing the thermophysical properties of solutions containing polymers is of fundamental importance for engineering calculations involving selection and sizing of equipment related to heat, mass, and/or momentum transfer processes, knowledge of the iteration with electromagnetic radiation, and implementation of control process strategies [1], as well as for thermal load calculations, energy expenditure, and development of new products. The thermophysical behavior of polymers may be influenced by several factors, such as molecular weight, temperature, solute concentration, and the presence of salts [2]. Several studies have been performed with the aim of determining the thermophysical properties of solutions containing biopolymers [3–6].

Carboxymethylcellulose (CMC) is obtained by the reaction between cellulose and sodium monochloroacetate. It is a hydrocolloid that aids in gel formation and water retention [7]. The CMC structure is based on the cellulose \(\beta \)-(1,4)-d-glucopyranose polymer. This polymer exhibits solubility in cold and hot water, high viscosity, the ability to form films, and adhesiveness, as well as providing features to suspensions, water retention, and resistance to oils, fats, and organic solvents. Thus, it has wide applications in formulation of food products and improvement of their processing [8, 9].

Pectin belongs to the heteropolysaccharides group, and it is found in the primary cell walls of plants [10]. It is a polysaccharide with approximately 150–500 galacturonic acid units partially esterified with methoxylic groups linked by \(\alpha \)-1,4 glycosidic linkages in a long molecular chain [11]. Pectins used in the food industry are categorized as high methoxylation (60 % to 90 % esterified carboxylic groups) and low methoxylation (5 % to 50 % esterified carboxylic groups) [12]. The most important raw materials for commercial extraction of pectin are apple pomace, citrus peels, and by-products from the juice industry [13]. Pectins are used in industry as thickeners, texturizers, emulsifiers, and stabilizers [14]. Studies also suggest that pectin can be used in the pharmaceutical industry owing to its ability to reduce cholesterol levels in human blood [15].

The current study aims to determine the thermophysical properties of binary and ternary solutions containing CMC and/or high methoxylation pectin and water.

2 Materials and Methods

2.1 Materials

Solutions were prepared with medium viscosity sodium carboxymethylcellulose (C4888, purity \(\approx \) 0.995) and high methoxylation pectin obtained from citrus peels (P9135, galacturonic acid \(\ge \)74.0 %) purchased from Sigma-Aldrich (St. Louis, MO, USA) and ultrapure water with a conductivity of 0.05 \(\upmu \)S/cm (Master System R&D, Gehaka, Brazil).

2.2 Methods

Aqueous solutions were prepared by diluting an appropriate amount of biopolymer with ultrapure water (Tables 1, 2, 3). An analytical scale (AY220, Shimadzu, Japan) with accuracy of 0.0001 g was used in the preparation of the solutions. The solutions were subjected to magnetic stirring (78 HW-1, Biomixer, Curitiba, Brazil) for 3 h. Ultrasound treatment was then applied for 30 min (ultrasonic processor UP100H, Hielscher, Teltow, Germany) to homogenize the systems. The combined expanded uncertainty, u(Y), of the density, refractive indices, and dynamic viscosities (Y) is given by [16–18]

where N is the number of input parameters and \(u(X_{i})\) are the experimental uncertainties of all of the measured quantities \((X_{i})\).

The densities (\(\rho \)) of the binary and ternary solutions were measured using a digital density meter (DMA 4500M, Anton Paar, Graz, Austria) with an accuracy of 5.0 \(\times \) 10\(^{-5}\) g\(\cdot \)cm\(^{-3}\) at T = (298.15 to 308.15) K with an accuracy of 0.01 K. The digital density meter was coupled to an automatic sampler (Xsample 122, Anton Paar, Graz, Austria). The estimated combined expanded uncertainty of the density measurements at the 95 % confidence level with a coverage factor of k \(\approx \) 2 is 0.02 kg\(\cdot \)m\(^{-3}\) to 0.08 kg\(\cdot \)m\(^{-3}\) depending on the mass fraction and temperature range.

The refractive indices (n) of the binary and ternary solutions were obtained using an ABBEMAT RXA170 digital refractometer integrated with a DMA 4500M digital density meter (Anton Paar) and an automatic sampler (Xsample 122, Anton Paar) at T = (298.15 to 308.15) K with an accuracy of 0.03 K. The digital refractometer accuracy was of 4.0 \(\times \) 10\(^{-5}\) nD. The estimated combined expanded uncertainty of the refractive indices measurements at the 95 % confidence level with a coverage factor of k \(\approx \) 2 is 2 \(\times \) 10\(^{-5}\) nD to 9 \(\times \) 10\(^{-5}\) nD depending mass fraction and temperature range.

The dynamic viscosities (\(\eta \)) of the binary and ternary solutions were determined by tests performed with a rotational rheometer (HAAKE MARS III, Thermo Scientific, Waltham, MA, USA) with cone (C60/1 \(^{\circ }\) TiL) and plate (MPC 60) geometry at a shear rate of 200 s\(^{-1}\) and T = (298.15 to 308.15) K with an accuracy of 0.01 K. The cone and plate were fabricated from titan with diameter (60.0 ± 0.5) mm and plate–cone angle 1 \(^{\circ }\). The data were visualized with HAAKE RheoWin software. The estimated combined expanded uncertainty of the dynamic viscosities measurements at the 95 % confidence level with a coverage factor of k \(\approx \) 2 is 0.01 mPa\(\cdot \)s (0.2 %) to 0.06 mPa\(\cdot \)s (1.2 %) depending on the mass fraction and temperature range.

The experimental data were analyzed using the Statistical Analysis System (SAS) statistical package (version 9.1, SAS Institute Inc., Cary, NC, USA). Quadratic multiple regression models were adjusted according to the experimental data to describe how the studied properties are influenced by temperature and biopolymer concentration. The models were selected and the lack of parameter adjustment was evaluated by a t-test and by the analysis of residues among the observed data and those generated by the models.

The experimental data from the binary and ternary solutions were combined in a single equation for each thermophysical property. A significance level of 5 % (\(p<\)0.05) was used as the criterion for analysis of the model parameters. The general quadratic model used in the current study is

where \(\varPsi \) is the thermophysical property, \(\beta _{1}\), \(\beta _{2}\), \(\beta _{3}\), \(\beta _{4}\), \(\beta _{5}\), \(\beta _{6,}\beta _{7}\), \(\beta _{8}\), and \(\beta _{9}\) are constants determined from experimental data adjustments, T is temperature (K), \(T_{R}\) is the reference temperature (298.15 K), and \(w_{1}\) and \(w_{2}\) are the mass fraction of pectin and CMC, respectively.

3 Results and Discussion

The density, refractive index, and dynamic viscosity of binary aqueous solutions of the pectin–CMC system were investigated in the range \(w_{1}\) = (0.0010 to 0.0100) for the pectin binary aqueous solution and \(w_{2}\) = (0.0005 to 0.0060) for the CMC binary aqueous solution. Pectin and CMC combinations of \(w_{1}\) = 0.0010 and \(w_{2}\) = 0.0005 to 0.010 were investigated for ternary aqueous solutions. All of the measurements were evaluated at five different temperatures between T = (298.15 to 308.15) K.

The results obtained from the experiments and their respective standard deviations are shown in Tables 1, 2, and 3. Newtonian behavior of the viscosities was assumed for analysis of these biopolymeric solutions after previous analysis in the rheometer. Analysis of the experimental data considering the density, refractive index, and dynamic viscosity shows that the thermophysical properties increase with increasing polymer concentration and decrease with increasing temperature.

According to Santos et al. [19], the refractive index behavior is related to the polymer concentration owing to the fact that higher polymer concentration makes light propagation more difficult and leads to an increase in this thermophysical property. In turn, the refractive index is expected to decrease as the temperature increases because the ease of passage of light increases with particle disorder.

The increase in the viscosity with increasing polymer concentration in the solution can be attributed to entanglement and intermolecular interactions because of the effective increase in the dimensions of macromolecules and the molecular weight [20]. The viscosity of a polysaccharide aqueous solution is directly related to molecule stiffness, which depends on its structure, especially the primary and secondary structures [21]. Felix et al. [22] explained the temperature influence on viscosity with respect to fluids. The transfer of momentum resulting from the molecular activity is small compared with the cohesive forces among molecules, Therefore, the shear stress and viscosity are mainly dependent on the order of magnitude of these cohesive forces, which tend to hold adjacent molecules in a fixed position and resist movement. Because these forces rapidly decrease with increasing temperature, the viscosity of the fluid decreases with increasing temperature.

The same behavior found in this study has also been reported in other studies. Guimarães et al. [3] investigated the density and kinematic viscosity of pectin binary aqueous solutions. They found that the density and dynamic viscosity increased with increasing concentration, whereas both thermophysical properties decreased with increasing temperature. Assis et al. [4] found that the densities and dynamic viscosities of binary and ternary solutions containing xanthan gum, carboxymethylcellulose, sodium chloride, and water increased with increasing concentration and decreased with increasing temperature. Ramos et al. [5] investigated the density and viscosity of ternary solutions of \(\kappa \)-carrageenan, sodium chloride, and water at different pHs and temperatures. They found that the density and viscosity decreased with increasing temperature for all of the pH values studied. Costa et al. [6] found that the density, refractive index, and dynamic viscosity of aqueous solutions of polyethylene glycol 1500 decreased with increased temperature and increased with addition of solute.

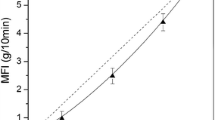

The experimental data from analysis of the thermophysical properties of the binary and ternary systems were correlated with the SAS 9.1 statistical software, and equations were determined to describe the combined effect of temperature and concentration on variation of the density, index refraction, and dynamic viscosity. The equation parameters shown in Table 4 were obtained with the polynomial model (Eq. 1). The significance level used to evaluate the effects of the parameters was 5 %. The high determination coefficients (\(R^{2} \,>\,\) 0.98) indicate a good fit of the models to the experimental data. Costa et al. [6] and Ramos et al. [5] also constructed general quadratic polynomial models to express the effect of temperature and polymer concentration on the thermophysical properties of PEG1500 solutions, binary and ternary solutions of \(\kappa \)-carrageenan, sodium chloride, and water, respectively. Figures 1, 2 and 3 show plots of the predicted values versus the observed values for all of the models obtained using Eq. 1 for each thermophysical property.

In general, taking into consideration the high determination coefficient values and the good adjustment of the experimental data to the calculated data according to temperature, the models proposed in the current study express the data well for the studied temperature range and biopolymer concentrations, indicating their applicability to engineering calculations.

4 Conclusions

Binary and ternary systems were investigated at different temperatures with different biopolymer concentrations. From the data obtained from the experiments, the density, refractive index, and dynamic viscosity increased with increasing biopolymer concentration and decreased with increasing temperature. These results are satisfactory because of the small standard deviation and their consistency with the literature. The mathematical models obtained in this study have high determination coefficients and can be used in engineering calculations.

References

W.L. Mccabe, J.C. Smith, P. Harriot, Unit Operations of Chemical Engineering, 5th edn. (McGraw-Hill, New York, 1993)

G. Li, K.C.J. Chang, Agric. Food Chem. 45, 4785 (1997)

G.C. Guimarães, M.C. Coelho Jr., E.E.G. Rojas, J. Chem. Eng. Data 54, 662 (2009)

T.F. Assis, E.E.G. Rojas, G.C. Guimarães, M.C. Coelho, A.V. Ramos, B.S. Costa, J.S.R. Coimbra, Int. J. Thermophys. 31, 513 (2010)

A.V. Ramos, E.E.G. Rojas, A.D. Giraldo-Zuniga, Int. J. Thermophys. 34, 240 (2013)

B.S. Costa, E.E.G. Rojas, J.S.R. Coimbra, J.A. Teixeira, J.T. Romero, J. Chem. Eng. Data 59, 339 (2014)

U. Käistner, H. Hoffmann, R. Dönges, J. Hilbig, Colloids Surf. A 307, 123 (1997)

A. Alhamdan, S.K. Sastry, J. Food Process Eng. 13, 113 (1990)

V. Pilizota, D. Subaric, T. Lovric, Food Tech. Biotechnol. 34, 87 (1996)

G.O. Philips, P.A. Willians, Handbook of Hydrocolloids, 2nd edn. (Woodhead Publishing Ltd, Cambridge, 2009)

P.A. Bobbio, F.O. Bobbio, Introdução à química de alimentos, 2nd edn. (Varela, São Paulo, 1995)

A.J. Gava, C.A.B. Silva, J.R.F. Gava, Tecnologia de alimentos: princípios e aplicações (Nobel, São Paulo, 2008)

M.T. Coelho, Pectina: características e aplicações em alimentos (Universidade Federal de Pelotas, Pelotas, Brasil, Thesis, 2008)

J. Bowers, Food Theory and Aplications, 2nd edn. (Macmillan Publishing Company, New York, 1992), p. 411

J.M. Ros, H.A. Schol, A.G.J. Voragen, Carbohydr. Polym. 37, 159 (1998)

B.N. Taylor, C.E. Kuyatt, Guidelines for evaluating and expressing the uncertainty of NIST measurement results (NIST, Gaithersburg, 1994)

Q. Dong, R.D. Chirico, X. Yan, X. Hong, M. Frenkel, J. Chem. Eng. Data 50, 546 (2005)

GUM, Evaluation of measurement data—-guide to the expression of uncertainty in measurement (JCGM, Switzerland, 2008)

I.J.B. Santos, R.M.M. Carvalho, M.C.H. Silva, L.H.M. Silva, J. Chem. Eng. Data 57, 274 (2012)

F. Garcia-Ochoa, V.E. Santos, A. Casa, E. Gómez, Biotechnol. Adv. 18, 549 (2000)

P.S. Diaz, C.T. Vendruscolo, J.L.S. Vendruscolo, Semina 25, 15 (2004)

T.F. Félix, E.L.F. Vidal, R.B. Garcia, M. Costa, J.H.S. Girão, 4\(^{o}\) PDPETRO (2007)

Acknowledgments

The authors thank CNPq and FAPERJ for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, B.L.L.D., Costa, B.S. & Garcia-Rojas, E.E. Binary and Ternary Mixtures of Biopolymers and Water: Viscosity, Refractive Index, and Density. Int J Thermophys 37, 79 (2016). https://doi.org/10.1007/s10765-016-2084-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-016-2084-7