Abstract

A series of new fluorine-containing polyamides were prepared directly by polycondensation of 2-(4-trifluoromethylphenoxy)terephthalic acid with four trifluoromethyl-substituted aromatic bis(ether amine)s in N-methyl-2-pyrrolidone (NMP) solution containing dissolved calcium chloride using triphenyl phosphite and pyridine as condensing agents. All the polymers showed excellent solubility in solvents such as NMP, N,N-dimethylacetamide, N,N-dimethylformamide, dimethyl sulfoxide, pyridine, tetrahydrofuran, and acetone at room temperature. These polymers had inherent viscosities between 0.67 and 1.09 dL/g, and their weight-average molecular weights and number-average molecular weights were in the range of 48,200–68,000 and 29,500–39,400, respectively. The resulting polymers showed glass-transition temperatures between 189 and 214 °C and 10% weight loss temperatures ranging from 475 to 483 °C, and char yields at 800 °C higher than 50% in nitrogen. All polymers were amorphous and could be cast into transparent, flexible, and strong films from DMAc solutions with tensile strengths of 71–115 MPa, elongations at break of 6–9%, and tensile moduli of 2.7–3.2 GPa. These polymers had low dielectric constants of 3.14–3.31 (1 MHz), low moisture absorption in the range of 0.88–1.60%, and high transparency with an ultraviolet–visible absorption cut-off wavelength in the 320–340 nm range.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wholly aromatic polyamides are one of the families of high-performance engineering thermoplastics because of their good thermal stability, chemical resistance, and excellent mechanical properties [1]. However, the poor solubility and high melting temperature caused by the high crystallinity and stiffness of the polymer backbones lead to processing difficulty, thus restricting their applications. Therefore, several modification of the chemical structure have been made to enhance their processability and solubility without compromising their other desired properties either by introducing of flexible linkages [2–4], bulky pendant [5–8] or cardo groups [9–11], as well as non-coplanar structures [12, 13] into polymer backbone. Another attractive method is the incorporation of geometrically unsymmetrical units into the polymer backbone [14–17]. This method is quite effective to improve the solubility of polyamides without much deteriorating their inherent excellent properties because close chain stacking and intermolecular interactions are restricted while the main-chain rigidity of the polyamide can also be maintained. Recently, considerable attention has been paid to the fluorine-containing aromatic polyamides, especially trifluoromethyl-containing polyamides [18–23]. It has been demonstrated that the incorporation of bulky trifluoromethyl pendant groups into the polyamide backbone resulted in great benefits for improving polymer solubility as well as optical transparency and dielectric performance, which attributed to the low polarisability of the C–F bond and the increase in free volume. In continuing our interest in preparing easily processable high-performance polyamides bearing trifluoromethyl substituents [22], we herein report another four new organosoluble aromatic polyamides with pendant trifluoromethylphenoxy groups, derived from a unsymmetrically aromatic dicarboxylic acid, 2-(4-trifluoromethylphenoxy)terephthalic acid (TFPA) with four kinds of trifluoromethyl-substituted aromatic bis(ether amine)s by solution polycondensation. The solubility, crystallinity, thermal stability, and mechanical property as well as optical and dielectric behaviors of the newly fluorinated polyamides were investigated.

Experimental

Materials

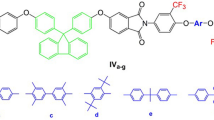

2-(4-Trifluoromethylphenoxy)terephthalic acid (TFPA) [22] was prepared by the nucleophilic chloro displacement of 1-chloro-4-trifluoromethylbenzene with the potassium phenolate of 2,5-dimethylphenol, followed by oxidation. 2,2-Bis[4-(4-aminophenoxy) phenyl]hexafluoropropane (2b, m.p. 162–163 °C) [18] was prepared by the aromatic nucleophilic substitution reaction of 2,2-bis(4-hydroxyphenyl)hexafluoropropane and 4-chloronitrobenzene in the presence of potassium carbonate and by the subsequent reduction of the intermediate dinitro compound with hydrazine as reducing agent and palladium on active carbon as catalyst. The other aromatic diamines with trifluoromethyl substituents such as 4-(4-aminophenoxy)-3-trifluoromethylphenyl-amine (2a, m.p. 67–68 °C) [24], 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene (2c, m.p. 132–133 °C) [25], 2,2-bis [4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane (2d, m.p. 65–66 °C) [26], were prepared from the corresponding phenol or bisphenol precursors with 2-chloro-5-nitrobenzotrifluoride using similar methods as preparation of trifluoromethyl-containing bis(ether amine) monomer 2b. Anhydrous potassium carbonate was dried in vacuum at 100 °C before use. Anhydrous calcium chloride (CaCl2) was dried under vacuum at 200 °C for 10 h. Triphenyl phosphite (TPP) was purified by fractional distillation under reduced pressure. Pyridine (Py) was refluxed in an inert atmosphere in the presence of KOH for 6 h, distilled and stored over 4 Å molecular sieves. N-Methyl-2-pyrrolidone (NMP) was distilled over calcium hydride under reduced pressure and stored over 4 Å molecular sieves.

Polymer synthesis

A representative polymerization procedure under nitrogen atmosphere for the synthesis of polyamide (3c) was described as follows. The mixture of 0.4078 g (1.25 mmol) of TFPA, 0.5354 g (1.25 mmol) of diamine 2c, 0.3 g of CaCl2, 1.0 mL of TPP, 0.8 mL of Py, and 3.5 mL of NMP was heated with stirring at 110 °C for 4 h. After cooling, the obtained viscous polymer solution was poured slowly into 300 mL of stirring methanol to precipitate a white fiber-like product, which was isolated by filtration, thoroughly washed first with methanol and then with hot water, and dried at 150 °C under vacuum for 5 h to give polyamide 3c (0.88 g, yield 98%). The inherent viscosity of 3c was 1.09 dL/g, as measured at a concentration of 0.5 g/dL in DMAc at 30 °C. The FTIR spectrum exhibited absorptions at 3310 (N–H stretching), 1663 (C=O stretching), 1235 (C–O–C stretching), and 1131 cm−1 (C–F stretching). The other polyamides were prepared by an analogous procedure.

Preparation of the polyamide films

A solution of polymer was made by dissolving about 0.8 g of the polyamide sample in 8 mL of DMAc to afford an approximate 10 wt% solution. The homogeneous solution was poured into a 9-cm diameter glass culture dish, which was placed overnight in an oven at 120 °C for the slow release of the solvent. The polyamide film was released from the glass substrate and further dried in vacuo at 150 °C for 24 h. The obtained films showed about 0.05–0.07 mm in thick and were used for their corresponding properties such as WAXD measurement, solubility test, tensile test, and thermal analysis.

Measurements

1H (400 MHz) and 13C (100 MHz) NMR spectra were recorded on Bruker AVANCE 400 MHz spectrometer in dimethyl sulfoxide-d6 (DMSO-d6) or chloroform (CDCl3). FTIR spectra of the monomer and polymers in KBr pellets were determined on a Perkin-Elmer SP One FTIR spectrophotometer. Microanalyses were performed with a Carlo Erba 1106 Elemental Analyzer. Differential scanning calorimetry (DSC) analyses were performed on a Perkin Elmer Pyris 1 DSC at a scanning rate of 20 °C/min from 50 to 400 °C in flowing nitrogen (20 mL/min). The glass-transition temperatures (Tg’s) were read at the midpoint of the transition in the heat capacity and were taken from the second heating scan after quick cooling from 400 °C at a cooling rate of 200 °C/min. Thermogravimetric analysis (TGA) was carried out on approximately 6–8 mg film samples with a Perkin Elmer Pyris 1 TGA in nitrogen (40 mL/min) at a heating rate of 10 °C/min from 50 to 800 °C. Wide-angle X-ray diffraction patterns were recorded at room temperature (ca. 25 °C) on a Shimadzu XRD-6000 X-ray diffractometer (operating at 40 kV and 30 mA) with graphite-monochromatized CuK α radiation (λ = 1.5418 Å); the scanning rate was 2°/min over a range of 2θ = 5–40°). Molecular weights were determined by a gel permeation chromatography (GPC) with polystyrene calibration using a Waters 510 HPLC equipped with 5-μm Styragel HR-2 and HR-4 columns (7.8 mm i.d. × 300 mm) connected in series and a UV detector at 254 nm using tetrahydrofuran as eluent. The inherent viscosities were measured at 0.5 g/dL concentration in DMAc with an Ubbelohde viscometer at 30 °C, in which the polyamides were pretreated by drying in oven at 120 °C for 1 h to remove the adsorbed moisture. The mechanical properties of the polymer films were measured on an Instron 1122 testing instrument with a 5-kg load cell at a crosshead speed of 5 mm/min on strips (0.5 cm wide, 6 cm long, and ca. 0.05 mm thick), and an average of at least three replicas was used. Ultraviolet–visible (UV–vis) spectra of the polymer films were recorded on a Shimadzu UV-1601 UV–vis spectrophotometer with the wavelength range of 200–800 nm. Dielectric constants were measured using a dielectric analyzer (TA Instruments DEA 2970).

Results and discussion

Polymer synthesis

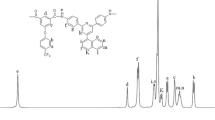

Several new fluorine-containing aromatic polyamides 3a–d were prepared from TFPA 1 with four aromatic diamines containing trifluoromethyl substituents 2a–d based on Yamazaki–Higashi reaction conditions [27] using TPP and pyridine as condensing agents (Scheme 1).

Synthesis conditions and inherent viscosities of polyamides 3a–d were summarized in Table 1. All the polymerizations proceeded homogeneously throughout the reaction and afforded clear, highly viscous polymer solutions. These polyamides were obtained in almost quantitative yields, with inherent viscosities in the range of 0.67–1.09 dL/g. As can be seen from Table 1, the GPC data obtained for the resulting polyamides indicated that the weight-averaged molecular weights (M w) and number-average molecular weights (M n) were in the range of 48,200–68,700 and 29,500–39,400, respectively, relative to polystyrene standards. All the polymers had sufficiently high molecular weights to permit the casting of tough and flexible films.

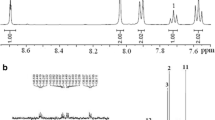

The formation of polyamides was verified by elemental analysis, FTIR, and NMR spectroscopy. A typical FTIR spectrum for the polyamide 3c is shown in Fig. 1. The FTIR spectra of all polymers showed the characteristic absorptions of the amide group at around 3310–3300 cm−1 (N–H stretching), 1660–1664 cm−1 (amide C=O stretching), and 1530–1537 cm−1 (N–H bending). The polymers also exhibited characteristic absorptions bands of aryl ether stretching at around 1235–1246 cm−1, along with the characteristic absorption bands of C–F stretching at around 1128–1131 cm−1. The formation of the amide group was also confirmed by the resonance signals of amide protons at around δ 10.8–10.6 in the 1H NMR spectra and amide carbons at around δ 168 in the 13C NMR spectra.

The results of elemental analysis were also reported in Table 2, which showed that the polymers had slight moisture absorptions in the range of 0.88–1.60% because of their amide groups [28]. The observed values were corrected by the elimination of the amount of absorbed water, and the corrected values were generally in agreement with the calculated ones. Generally, fluorine substitution almost resulted in lower water absorption. As shown in Table 2, the polyamides 3d showed the lowest water uptake of 0.88%, which can be due to the presence of more fluorine atoms as trifluoromethyl groups compared to the other polymers.

Thermal properties

The thermal properties of all the polyamides evaluated by DSC and TGA were summarized in Table 3. Quenching from an elevated temperature of about 400 °C to room temperature in air gave predominantly amorphous samples so that T g’s of all the polymers could be easily revealed in the subsequent DSC scans. Figure 2 displayed DSC thermograms for these polymers. It was found that there was no melting peak (T m) detected in DSC and the absence of peak in DSC supported the generally amorphous nature of the polymer. The T g values of these polyamides were in the range of 189–214 °C, which followed the decreasing order of the chain flexibility and steric hindrance of the polymer backbones. Among the polyamides, polymer 3a showed the highest T g value probably owing to the presence of less flexible ether linkage in the polymer backbones than those of the other analogous. In contrast, polyamide 3d exhibited a lower T g value than 3b, which might be a result of increasing in free volume caused by the introduction of the bulky trifluoromethyl substituents.

The fluorinated polyamides had the onset decomposition temperatures in the range of 412–431 °C, the temperatures at 5 and 10% weight loss in the range of 430–446 and 475–483 °C, respectively. In addition, All the fluorinated polyamides exhibited good thermal stability without significant weight loss up to temperature of approximately 412 °C in nitrogen atmosphere, and the char yields at 800 °C for all polymers were in the range of 50–55%.

The DSC and TGA data for the similar structural polyamide 3c′ derived from a diamine without trifluoromethyl substituents [22] (Scheme 2) were also presented in Table 3. As observed, the resent polyamide 3c exhibited a T g of 200 °C, which was lower than that of 3c′ analogue (228 °C). This might be a result of a significant reduction in the density of hydrogen bonding among chains, and the introduction of a trifluoromethyl substituent apparently renders the molecular structure in the polymer chain more asymmetric. However, polyamide 3c had relatively lower T d than the corresponding analogue 3c′, which might be a result of poor packing and weaker chain–chain interactions because of the presence of the trifluoromethyl groups.

Solubilities

The solubilities of the fluorine-containing polyamides in various organic solvents at 3.0% (m/v) are presented in Table 4. All the polymers could readily dissolved in both polar solvents such as N-methyl-2-pyrrolidone, N,N-dimethylformamide, N,N-dimethylacetamide, dimethyl sulfoxide, pyridine, m-cresol, and some common organic solvents such as THF and acetone at room temperature. Obviously, their good solubilities are due to the fact that the aromatic diacid (TFPA) containing a bulky pendant trifluoromethylphenoxy group and the aromatic diamines bearing trifluoromethyl groups and ether linkages all exhibit steric hindrance, which prevent close chain-packing and allow the solvent molecules to diffuse into the polymer chains.

Crystal and mechanical properties

All polyamides were characterized by WAXD studies in the film form. As expected, all the polyamides displayed a nearly completely amorphous pattern (Fig. 3). This can be attributed to the combined effects of the bulky pendant trifluoromethylphenoxy groups and flexible ether linkages in the polymer backbone, which produced wider separation of polymer chains, weakening intermolecular hydrogen bonding, lowering chain-packing efficiency with a gain of free volume, thus resulting in a decrease in crystallinity. The amorphous structure of these polyamides also reflected in their excellent solubility and good film forming ability.

All fluorine-containing polyamides films with highly transparent, flexible and very light yellow characteristics were easily formed via the casting of polymer solutions in DMAc. The mechanical properties of the polyamide films are summarized in Table 5. The values of the tensile strength varied in the range of 71–115 MPa, the elongation at break varied in the range of 6–9%, and the initial modulus varied in the range of 2.7–3.0 GPa. All the polyamides possessed good mechanical properties, and this suggested that these polyamides could be considered as engineering plastics and photoelectric materials.

Optical and dielectric properties

The fluorinated polyamide films were measured for optical transparency using UV–vis spectroscopy. Figure 4 depicted the UV–vis spectra of all polyamide films and their cut-off wavelength values were also listed in Table 6. These polyamides had high average transmittances in the visible region (>80%), and the cut-off wavelengths were between 320 and 340 nm. Polyamide 3d exhibited the lowest cut-off wavelength (320 nm) because of its more trifluoromethyl groups. In comparison, polyamide 3c exhibited a cut-off wavelength at 322 nm, 13 nm lower than that of polyamide 3c′ (335 nm) [22], which might be a result of polyamide 3c had more fluorine content in the polymer backbone.

The electrical insulating properties of these polymers were evaluated on the basis of dielectric constants, measured by the parallel plate capacitor method and the results were reported in Table 6. As can been seen from Table 6, these polyamides showed a lower dielectric constant in the range of 3.14–3.31 (1 MHz) than commercial Nylatron (ca. 3.7 at 1 MHz). The low dielectric constants could be attributed to the presence of bukyl trifluoromethylphenoxy pendant groups, which led to efficient chain packing and increased free volume in the polymer backbone. Additionally, the strong electronegativity of fluorine and associated low polarisability of the C–F bonds resulted in decreasing the dielectric constants. Likewise, polyamide 3d showed some what lower dielectric constant value in this series of analogous polyamides because of a combination of factors as above.

Conclusions

A series of highly organosoluble and optically transparent fluorine-containing polyamides were synthesized by direct polycondensation from 2-(4-trifluoromethylphenoxy)terephthalic acid and trifluoromethyl-containing aromatic bis(ether amine)s using the Yamazak–Higashi phosphorylation technique. The introduction of more fluorine atoms such as trifluoromethylphenoxy and substituted trifluoromethyl pendant groups into the polyamides resulted in dramatic changes in their properties, especially in the improvement of solubility and lowered moisture uptakes. The obtained polyamides exhibited amorphous nature, excellent optical properties, low dielectric constants, good thermal stabilities, and mechanical properties. These characteristics indicated that these new fluorine-containing polyamides could be considered as new candidates for processable high-performance engineering plastic and photoelectric materials.

References

Cassidy PE (1980) Thermally stable polymers. Dekker, New York

Bellomo MR, Pasquale GD, Rosa AL, Pollicino A, Siracusa G (1996) New aromatic polyamide materials containing sulfone, ether and ketone linkages. Polymer 37:2877–2881

Mehdipour-Ataei S, Heidari H (2003) Synthesis and characterization of novel soluble and thermally stable polyamides based on pyridine monomer. Macromol Symp 193:159–168

Hsiao SH, Chang YH (2004) New soluble aromatic polyamides containing ether linkages and laterally attached p-terphenyls. Eur Polym J 40:1749–1759

Chen SH, Shiau CS, Tsai LR, Chen Y (2006) Poly(9,9-dihexylfluorene) derivatives containing electron-transporting aromatic triazole segments: synthesis, optical and electrochemical properties. Polymer 47:8436–8443

Chang CW, Chung CH, Liou GS (2008) Novel anodic polyelectrochromic aromatic polyamides containing pendent dimethyltriphenylamine moieties. Macromolecules 41:8441–8451

Zeng K, Hong HB, Zhou SH, Wu DM, Miao P, Huang ZF, Yang G (2009) A new soluble aramide with pendant phthalonitrile units and polymer property enhancement by nitrile cure reactions. Polymer 50:5002–5006

Mallakpour S, Dinari M (2009) Preparation of thermally stable and optically active organosoluble aromatic polyamides containing l-leucine amino acid under green conditions. Polym Bull 63:623–635

Yang CP, Lin JH (1993) Syntheses and properties of aromatic polyamides and polyimides derived from 9,9-bis[4-(p-aminophenoxy)phenyl]fluorine. J Polym Sci A 31:2153–2163

Liaw DJ, Liaw BY, Chung CY (2000) Synthesis and characterization of new cardo polyamides and polyimides containing tert-butylcyclohexylidene units. Macromol Chem Phys 201:1887–1893

Sheng SR, Ma CX, Jiang JW, Huang ZZ, Song CS (2010) Synthesis and properties of novel aromatic polyamides with xanthene cardo groups. J Appl Polym Sci 116:1650–1659

Liou GS, Hsiao SH, Ishida M, Kakimoto M, Imai Y (2002) Synthesis and characterization of novel soluble triphenylamine-containing aromatic polyamides based on N,N′-bis(4-aminophenyl)-N,N′-diphenyl-1,4-phenylenediamine. J Polym Sci A 40:2810–2818

Liaw DJ, Chang FC, Leung MK, Chou MY, Muellen K (2005) High thermal stability and rigid rod of novel organosoluble polyimides and polyamides based on bulky and noncoplanar naphthalene-biphenyldiamine. Macromolecules 38:4024–4029

Cheng L, Jian XG, Mao SZ (2002) Aromatic polyamides derived from unsymmetrical diamines containing the phthalazinone moiety. J Polym Sci A 40:3489–3496

Wu SC, Shu CF (2003) Synthesis and properties of soluble aromatic polyamides derived from 2,2′-bis(4-carboxyphenoxy)-9,9′-spirobifluorene. J Polym Sci A 41:1160–1166

Pal RR, Patil PS, Salunkhe MM, Maldar NN, Wadgaonkar PP (2009) Synthesis, characterization and constitutional isomerism study of new aromatic polyamides containing pendant groups based on asymmetrically substituted meta-phenylene diamines. Eur Polym J 45:953–959

Ghaemy M, Amini-Nasab SM, Alizadeh R (2010) Synthesis and characterization of new soluble polyamides from an unsymmetrical diamine bearing a bulky triaryl pyridine pendent group. J Appl Polym Sci 116:3725–3731

Liaw DJ, Wang KL (1996) Synthesis and characterization of fluorine-containing polyamides derived from 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane by direct polycondensation. J Polym Sci A 34:1209–1217

Ge ZY, Yang SY, Tao ZQ, Liu JG, Fan L (2004) Synthesis and characterization of novel soluble fluorinated aromatic polyamides derived from fluorinated isophthaloyl dichlorides and aromatic diamines. Polymer 45:3627–3635

Liaw DJ, Huang CC, Hu CK, Lee KR, Lai JY (2007) High optical transparency, low dielectric constant and light color of novel organosoluble polyamides with bulky alicyclic pendent group. Polymer 48:6571–6580

Maji S, Banerjee S (2008) Synthesis, characterization, and properties of novel fluorine containing aromatic polyamides. J Appl Polym Sci 108:1356–1364

Sheng SR, Pei XL, Liu XL, Song CS (2009) Novel soluble fluorinated aromatic polyamides derived from 2-(4-trifluoromethylphenoxy)terephthalyol chloride with various aromatic diamines. Eur Polym J 45:230–236

Li PH, Wang CY, Li G, Jiang JM (2010) Synthesis and characterization of novel polyamides derived from 1,4-bis((4-amino-2-(trifluoromethyl)phenoxy)methyl)cyclohexane and aromatic dicarboxylic acids. Polym Bull 64:127–140

Chung IM, Kim SY (2000) Soluble polyimides from unsymmetrical diamine with trifluoromethyl pendent group. Macromolecules 33:3190–3193

Yang CP, Chen YP, Woo EM (2004) Fluorinated polyamides and poly(amide imide)s based on 1,4-bis(4-amino-2-trifluromethylphenoxy)benzene, aromatic dicarboxylic acids, and various monotrimellitimides and bistrimellitimides: syntheses and properties. J Polym Sci A 42:3116–3129

Yang CP, Chen RS, Chen KH (2003) Effects of diamines and their fluorinated groups on the color lightness and preparation of organosoluble aromatic polyimides from 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]-hexafluoropropane. J Polym Sci A 41:922–938

Yamazaki N, Matsumoto M, Higashi F (1975) Studies on reactions of the N-phosphonium salts of pyridines. XIV. Wholly aromatic polyamides by the direct polycondensation reaction by using phosphites in the presence of metal salts. J Polym Sci Polym Chem Ed 13:1373–1380

Liaw DJ, Liaw BY (1998) Synthesis and characterization of new poly(amide–imide)s from 1,4-bis(4-trimellitimidophenoxy)-2-tert-butylbenzene with various diamines. J Polym Sci A 36:2301–2307

Acknowledgments

The financial support for this work provided by the National Natural Science Foundation of China (No. 20664001, 21064003) and the Research Program of Jiangxi Province Department of Education (No. 2007–123, GJJ08166 and GJJ09138) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, JW., Pei, XL., Sheng, SR. et al. Novel soluble fluorine-containing polyamides derived from 2-(4-trifluoromethylphenoxy)terephthalic acid and trifluoromethyl-substituted aromatic bis(ether amine)s. Polym. Bull. 67, 263–274 (2011). https://doi.org/10.1007/s00289-010-0414-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-010-0414-7