Abstract

Enhanced biofuel production strategies from microalgae by employing affordable bio-waste usage are fetching significance, nowadays. This study examines the effect of VWE for enhanced biomass from new indigenous microalgal isolates, Asterarcys sp. SPC, Scenedesmus sp. KT-U, Scenedesmus sp. KTWL-A, Coelastrum sp. T–E, and Chlorella sp. TWL-B. The growth of microalgae in VWE-treated growth media showed considerable increase (1.14–2.3 folds) than control medium (without VWE). Further, two effective native microalgae were selected based on growth in VWE treatment, biomass productivity, and TAG accumulation through statistical clustering analysis. Mixotrophic batch cultivation of Scenedesmus sp. KT-U and Asterarcys sp. SPC cultivated using VWE treatment in the optimum concentration had produced significant average increase in BP (1.8 and 1.4 folds, respectively) than control (without VWE). Whereas in the lipid production phase, there was a noticeable increase in lipid yield in VWE-treated cells of lipid phase (231.8 ± 17.9 mg/L and 243.5 ± 25 mg/L) in Scenedesmus sp. KT-U and Asterarcys sp. SPC, respectively, than in control (140.5 ± 28 mg/L and 166.4 ± 23 mg/L) with considerable TAG accumulation. Thus, this study imparts strain selection process of native microalgae based on vegetable waste usage for improved yield of biomass and lipid amenable for cost-effective biodiesel production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Globally food loss and waste levels are high. For instance, in developing countries around 15% to 50% of all fruit and vegetable wastages occur during post-harvest stage, whereas in Switzerland, around 47% of all vegetables produced are wasted in the food supply chain, and in Germany, fruits and vegetable wastages account for 43% of all household waste [1]. It is worth mentioning that, India produces large amount of municipal solid waste (MSW), and it is projected that about 300 million tons per annum of MSW will be generated in the near future [2]. Among the waste generated in India, the biodegradable portion is higher than the estimate of 51% [3]. Vegetable waste occupies the bulk portion of the biodegradable wastes generated from processing, packaging, and post-harvest losses including rotten vegetables, peels and scrapped portions [4]. The segregation and utilization of these biodegradable—municipal solid waste from hotels and houses are the major highlights of Solid waste management rules notified by Union Ministry of Environment, Forest, and Climate Change [5]. Substantially, the global production of vegetable waste has been estimated to be 70.2 MMT [6]. In fact, an estimated average of 6.03 million tons of unavoidable vegetable waste has been generated from the consumption of fresh vegetables in households of European Union [7]. It was reported that the vegetable wastes are rich in nutrients, however on dumping these biodegradable wastes in land-filling site generate GHG emissions such as methane emissions [8]. Recently, a comprehensive estimate proposes that the annual global methane emissions are around 570 million tons [9]. Therefore, recycling and proper utilization of vegetable waste for bioenergy applications paves the way for energy generation which can also gratifies the environmental concern [10]. It is worth mentioning that the procurement of vegetable waste from hotels, restaurants, big kitchens or food industries is easier. Biowastes such as vegetable waste is considered as one of the best raw materials to obtain energy (biogas, bioelectricity, and biofuels) due to high organic composition with good biodegradable nature, and most importantly, vegetable wastes have the potential to enhance the microbial growth due to its high protein, vitamins, minerals and other trace elements [11].

Microalgae are the potent candidates for biodiesel production owing to its capability of higher lipid accumulation. Moreover, microalgae are highly efficient in waste and CO2 remediation [12, 13]. Biodiesel (FAME) can be produced from lipids of oleaginous microalgal feedstock [14]. Transesterification is the most common reaction employed for the conversion of lipids/oil into biodiesel [15, 16]. In addition to biodiesel production, microalgal biomass are the potent feedstock for the production of bioethanol, biogas, carotenoids, and other value-added chemicals [13]. Nevertheless, the cost of production of microalgae is one of the major hindrances to commercial production [17]. Combinatorial approaches for microalgal biomass cultivation and waste utilization are considered to be sustainable for microalgae-based biofuel production which facilitate microalgal cultivation in a cost-effective manner [13, 18,19,20]. Subsequently, growth media for microalgae has been produced using biowastes such as kitchen effluent [21], waste molasses [22], food waste [23], rice husks [24], dairy waste [25], etc., for frugal biomass cultivation. Mixotrophic cultivation using biodegradable waste is one of the suitable cultivation mode for overall enhanced lipid yield appropriate for biodiesel application with economic viability as well [26]. In fact, anaerobically digested kitchen waste-based media for Chlorella sorokiniana SDEC-18 and Scenedesmus sp. SDEC-8 [27], fruit waste hydrolysates for C. vulgaris had shown increased biomass and lipid production [28]. Moreover, growth medium derived from diluted vegetable waste hydrolysate, and diluted fruit waste hydrolysate had increased the biomass growth in Chlorella vulgaris [28]. This kind of cultivation system coupled with waste utilization improves resource recovery and the economics of sustainable bioenergy production from microalgae [13, 29]. But at the same time, reports on imparting vegetable waste in the process of screening of new indigenous microalgal isolates are scarce.

Therefore, this current study was aimed to evaluate five new indigenous microalgal isolates for biodiesel application through statistical clustering analysis based on the key parameters such as (i) growth in various VWE concentrations, (ii) biomass productivity, and (iii) TAG production. Thus, the purpose of this study is to enable the strain selection process as well as ascertaining the suitability of new indigenous microalgal isolates for mixotrophic cultivation employing vegetable wastes. Furthermore, TAG accumulation, biomass, and lipid yield of VWE-treated biomass of lipid phase and the control cells (untreated) of the selected indigenous microalgal isolates were examined under batch cultivation.

Materials and Methods

Chemicals and Reagents

Analytical grade chemicals (minimum assay ≥ 98%) were used. The following are the list of chemicals, sodium nitrate (NaNO3), sodium carbonate (Na2CO3), disodium magnesium EDTA (Na2MgEDTA), calcium chloride (CaCl2·2H2O), ferric chloride (FeCl3), ammonium sulfate (NH4)2SO4, citric acid (C6H8O7), magnesium sulfate (MgSO4·7H2O), dipotassium hydrogen phosphate (K2HPO4), boric acid (H3BO3), manganese chloride (MnCl2·4H2O), Zinc sulfate (ZnSO4·7H2O), Copper sulfate (CuSO4·5H2O), Cobaltous chloride (CoCl2·6H2O), Sodium molybdate (NaMoO4·2H2O); TEN buffer (10 mmol/L Tris–HCl, 10 mmol/L Na2EDTA, 150 mmol/L NaCl); SDS-EB buffer (2% SDS, 400 mmol/L NaCl, 40 mmol/L Na2EDTA, 100 mmol/L Tris–HCl); phenol, chloroform, hexane, diethyl ether, isoamyl alcohol, isopropanol, ethanol, Bovine Serum Albumin (BSA), Coomassie brilliant blue-G250, Carbinol/ Methanol, 85% orthophosphoric acid, D-glucose; 3,5-dinitrosalicylic acid (DNSA), sodium potassium tartrate, potassium sulfate, sodium acetate, glacial acetic acid, silver nitrate, gum acacia, sulfuric acid, hydrochloric acid, disodium hydrogen phosphate, ammonium chloride, barium chloride, ammonium oxalate, ammonium hydroxide, methyl red, potassium permanganate, and sodium hydroxide.

Sampling, Isolation and Growth of Microalgae

Fresh water sample was collected for the isolation of indigenous microalgae from Sulur lake, Coimbatore, Tamil Nadu, India (11.0295 N 77.1208 E). Further, soil samples were collected from Tamil Nadu Agricultural University (TNAU) campus, Coimbatore, Tamil Nadu, India (11.0129 N 76.938 E); wetland TNAU, Coimbatore, Tamil Nadu, India (11.0018 N 76.9242 E & 11.0022 N 76.9247 E). Each sample was serially diluted, inoculated on modified BG-11 agar medium [30], and incubated at 25 °C for 14–20 days. The plates were maintained under the average light intensity of 3500 lx (Lux meter: HTC-LX101A, India) with the alternate photoperiod of light: dark cycle-10:14 h. The purity of the isolates was monitored under light microscope. Based on the pure colonial existence, the microalgal isolates, namely SPC (from Sulur lake), KT-U (from TNAU campus, Coimbatore), KTWL-A, T-E, and TWL-B (from wetland, TNAU) of the above-mentioned geographical locations were cultured, and maintained as pure cultures in modified BG-11 medium (pH 7.0 ± 0.2) under the average light intensity of 3500 lx in Erlenmeyer’s flask with alternate photoperiod (light: dark cycle-10:14 h) at 28 ± 3 °C. The pure microalgal isolates were monitored under light microscope (Labomed, Germany) with 1000X magnification.

Molecular Identification, Phylogeny and Taxonomy

Genomic DNA was extracted from the pure microalgal isolates. Briefly, cell pellets were collected; washed with TEN buffer; resuspended in 150 µL ice cold water, and vortexed for two min. Further, 350 µL SDS-EB buffer was added; cells were lysed through agitation using tissue lyser (Qiagen, Germany) at a frequency of 28 s−1 for 10 min, and incubated for 3 min. After cell lysis, genomic DNA was then extracted following phenol: chloroform method. DNA amplification of partial 18S rRNA /ITS regions were performed using genomic DNA as the template by PCR. The ITS1-5.8S-ITS2 region was amplified with the following primer sequences 5ʹ-ACCTAGAGGAAGGAGAAGTCGTAA-3ʹ, 5ʹ-TTCCTCCGCTTATTGATATGC-3ʹ as forward and reverse primer, respectively [31], whereas the partial small subunit 18S rRNA region was amplified with the following primers, 5ʹ- TCTAGAGCTAATACGTGCG -3ʹ, 5ʹ-GTGGTGCCCTTCCGTCAAT-3ʹ as forward and reverse primer, respectively [this study]. PCR products were sequenced by Sanger’s dideoxy method of sequencing and the sequences were subjected to Nucleotide BLAST analysis. Phylogenetic trees were constructed (phylogeny test by neighbor joining tree method) with 1000 bootstrap replications using MEGA 6 software using the multiple sequence alignment (Clustal W) of the ITS1- 5.8 S- ITS2 regions (Asterarcys sp. SPC, Scenedesmus sp. KT-U, Scenedesmus sp. KTWL-A, Coelastrum sp. T-E) and partial small subunit 18S rRNA regions (Chlorella sp. TWL-B, Scenedesmus sp. KTWL-A) with the existing Asterarcys sp., Scenedesmus sp., Coelastrum sp., and Chlorella sp. The sequences of small subunit rRNA (partial 18S rRNA) and ITS1-5.8S-ITS2 regions of the above-mentioned indigenous microalgal isolates were submitted to GenBank (Accession nos. MN508368.1; MN450293.1; MN472749; MN472748.1; MN508367, and MN450294) (www.ncbi.nlm.nih.gov). The taxonomic lineage in the hierarchical arrangement, i.e., Superkingdom, Kingdom, Phylum, Class, Order, Family, Genus of the indigenous microalgal isolates were retrieved from NCBI Taxonomy.

Preparation of VWE and its Characterization

Vegetable wastes were collected from the kitchen of a local hostel at Coimbatore, Tamil Nadu, India. Briefly, onion peels, brinjal waste, garlic peels, and pumpkin wastes were dried in oven at 60 °C; ground; mixed in the ratio of 2:1:0.1:1, respectively (20 g powdered waste in 200 mL of distilled water); autoclaved twice (at 121 °C for 20 min at 15 psi); filtered, and this aqueous extract (VWE) was used for the waste supplementation studies. The total dissolved solids (TDS) present in VWE were calculated by gravimetric method. The protein concentration present in VWE (mg/mL) was estimated using bovine serum albumin standard calibration curve by Bradford reaction, at 595 nm [32]. The amount of reducing sugar present in VWE (mg/mL) was quantified using the standard glucose graph by DNSA method [33]. The spectrum of dried VWE was obtained from FT–IR spectroscopy (FT/IR-6800 type A) and the interpretation of functional groups present in the sample was performed by ID Expert software. Moreover, Ca, Mg, Na, K, Cl, and S content were estimated for ground water and VWE [34].

Effect of VWE at Different Concentrations on Biomass Growth

The indigenous microalgal isolates, Asterarcys sp. SPC, Scenedesmus sp. KT-U, Chlorella sp. TWL-B, Scenedesmus sp. KTWL-A, and Coelastrum sp. T-E with the initial inoculum of 0.68 mL [containing DCW of 3 mg, 4.9 mg, 1.7 mg, 3.5 mg, and 2.5 mg, respectively] were inoculated in culture tubes containing 20 mL of control growth medium (modified BG-11 media made using ground water instead of distilled water). After 5 days of growth, VWE was added to the cultures at different VWE concentrations of 5 µL/mL, 10 µL/mL, 15 µL/mL, and 20 µL/mL growth media. The control growth media was maintained in the experiment without VWE addition which was served as control, i.e., untreated. Independent triplicate culture tubes were maintained for each condition. To estimate the growth of microalgal biomass in control (untreated) and VWE-treated cultures, Chl a (µg/mL) was estimated from the cell pellets harvested at regular intervals for up to 20 days of cultivation, based on the following equation [35].

Analysis of Biomass and TAG Accumulation

To assess the production of biomass, the pure biomass of the five indigenous microalgal isolates, Asterarcys sp. SPC, Scenedesmus sp. KT-U, Chlorella sp. TWL-B, Scenedesmus sp. KTWL-A, and Coelastrum sp. T-E were cultivated with the initial inoculums of DCW, 30.5 ± 0.5 mg; 34 ± 1.0 mg; 17.5 ± 1.5 mg; 33.5 ± 2.5 mg; and 23.5 ± 3.5 mg, respectively in 250 mL Erlenmeyer’s flasks containing 50 mL of modified BG-11 media made using distilled water (complete nutrient condition) for 25 days. Biomass was harvested in late log phase after 25 days of cultivation from the day of inoculation; washed; dried; weighed gravimetrically, and the BP was expressed as DCW (mg/L) [it is worth mentioning that BP was calculated after excluding the dry weight of respective initial inoculum sizes]. To get crude lipid extracts, wet pellets of equal biomass concentration from the above-mentioned cells of complete nutrient condition (cultivated for up to 25 days from the day of inoculation) was suspended in 1 mL of chloroform–methanol (2:1, v/v) [36]; agitated in tissue lyser (Qiagen, Germany) at a frequency of 17 per second for 10 min; centrifuged, and supernatant was collected. To assess TAG accumulation under N starvation, nutrient stress condition was created by culturing the early log phase cells of microalgae in N starved medium (modified BG-11 medium without NaNO3) for 15 days and total crude lipid was extracted from these cells as mentioned above. Then the crude lipid extracts were separated by TLC using developing solvent (hexane; diethyl ether; acetic acid in the ratio of 70:30:1, respectively) (v/v). TLC plate (Merck, Germany) was sprayed with 10% copper sulfate (in 8% phosphoric acid) (w/v); charred at 150 °C for 12 min, to develop the bands of lipid moieties and reference TAG standard. To analyze relative TAG production among five isolates, intensities of each TAG band were documented; measured using Image J software, and (i) relative TAG production under complete nutrient condition and (ii) relative TAG band production under N starvation were represented in terms of relative TAG band intensity (as percentage distribution among five indigenous microalgae).

Validation of VWE Treatment-Mixotrophic Batch Cultivation of Scenedesmus sp. KT-U and Asterarcys sp. SPC Using VWE

The biomass of indigenous microalgal isolates, Scenedesmus sp. KT-U and Asterarcys sp. SPC with the initial inoculum of DCW, 82 mg and 80 mg, respectively, were cultivated as batch cultures in 500 mL Erlenmeyer flask containing 250 mL of VWE-treated growth media (modified BG-11 medium was made using ground water instead of distilled water; adjusted to pH 7.0 ± 0.2; sterilized by autoclaving, and VWE at a concentration of 10 µL/mL was added into it). Control growth media (without VWE addition) was also maintained. After 25 days of biomass growth, BP (mg/L) was estimated for control and VWE treatment (represented as Ctrl and VWE, respectively) as biomass phase. To allow lipid induction i.e., as a lipid phase condition, VWE-treated cells of biomass phase was harvested, washed, cultured in N starved media for 25 days, and these VWE-treated cells of lipid phase were represented as VWE-II. On the other hand, control cells of lipid phase were the control cells (without VWE) with the total incubation time was 50 days, represented as Ctrl-II. Total crude lipid was extracted from Ctrl-II and VWE-II using chloroform: methanol (2:1, v/v), and the crude LC (%) was then calculated gravimetrically [36]. Lipid yield (mg/L) of Scenedesmus sp. KT-U and Asterarcys sp. SPC at lipid phase conditions was then estimated from LC and BP [37, 38]. Further, the crude lipids were separated through TLC as mentioned above.

Statistical Analysis

All the above experiments were performed in independent repeat experiments (duplicates/triplicates). Data were analyzed through student t test through a statistical tool (http://vassarstats.net/). Statistical Clustering analysis using PCA was carried out for the following six parameters evaluated for the five microalgae (i) biomass fold increase [in terms of Chl a] in VWE treatment at 10 μL/mL concentration, relative to the control [without VWE] (ii) biomass fold increase in VWE treatment at 15 μL/mL concentration, relative to the control (iii) biomass fold increase in VWE treatment at 20 μL/mL concentration, relative to the control (iv) BP (mg/L) (v) relative TAG production under complete nutrient condition (% distribution), and (vi) relative TAG production under N starvation (% distribution). PCA was carried out by applying unit variance scaling to the data. Singular value decomposition with imputation was used to calculate the principal components (PC), and clustering heat maps were generated using correlation distance and average linkage using a web-based statistical tool, ClustVis [39].

Results

Molecular Identification and Phylogenetic Analysis of the Indigenous Microalgal Isolates

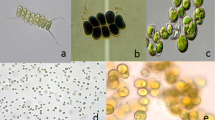

Five freshwater microalgae prevailing predominantly in the lake and wet soil of the Coimbatore regions (of the above-mentioned geographical locations), Tamil Nadu, India were isolated based on their pure colonial existence. Morphological identification by microscopic analysis showed that the isolates, SPC, KT-U, T–E, and KTWL-A were solitary to cluster of few cells of coenobium, oval to ellipsoidal cell shape that resembles Scenedesmaceae-like microalgae [40], whereas, TWL-B cells were smaller, spherical, smooth, and mostly found solitary which were similar to Chlorella [41]. All the isolates were unicellular green eukaryotic microalgal cells devoid of spines or flagella of Phylum: Chlorophyta. Microscopic images of the pure microalgal isolates were given in the Supplementary Fig. 1. Moreover, the isolates SPC, KT-U, T-E, and KTWL-A were further confirmed by ITS1-5.8S-ITS2 gene region sequencing and identified as Asterarcys sp. (maximum identity 99%; similarity to Asterarcys sp. MS3), Scenedesmus sp., (maximum identity 99%; similarity to Scenedesmus sp. CCNM 1077); Coelastrum sp. (maximum identity 99%; similarity to Coelastrum proboscideum) and Scenedesmus sp. (maximum identity 99%; similarity to Scenedesmus sp. SM 15_4), respectively. Whereas microalgal isolate TWL-B was identified as Chlorella sp. (maximum identity 99%; similarity to Chlorella sp. YACCYB105 based on partial 18S rRNA sequence analysis). To further confirm the identity of the indigenous isolates, phylogenetic analysis was performed with the other related microalgal species revealing definite clade (Fig. 1). The indigenous microalgal isolates, KT-U, SPC, T-E, KTWL-A, and TWL-B were submitted to GenBank with the accession numbers: MN508368.1; MN450293.1; MN472749; MN472748.1, and MN450294, respectively. Further, the taxonomic lineages of the microalgal isolates are designated in the hierarchical arrangement, i.e., Superkingdom, Kingdom, Phylum, Class, Order, Family, Genus, respectively, as Eukaryota, Viridiplantae, Chlorophyta, Chlorophyceae, Sphaeropleales, Scenedesmaceae, Scenedesmus (NCBI:txid2617489) for Scenedesmus sp. KT-U; (II) taxonomic lineage of Coelastrum sp. T-E is determined as Superkingdom: Eukaryota, Kingdom: Viridiplantae, Phylum: Chlorophyta, Class: Chlorophyceae, Order: Sphaeropleales, Family: Scenedesmaceae, Genus: Coelastrum (NCBI:txid2613536); (III) taxonomic lineage of Chlorella sp. TWL-B is determined as Superkingdom: Eukaryota, Kingdom: Viridiplantae, Phylum: Chlorophyta, Class: Trebouxiophyceae, Order: Chlorellales, Family: Chlorellaceae, Genus: Chlorella (NCBI:txid2609506); (IV) taxonomic lineage of Asterarcys sp. SPC is as follows, Superkingdom: Eukaryota, Kingdom: Viridiplantae, Phylum: Chlorophyta, Class: Chlorophyceae, Order: Sphaeropleales; Family: Scenedesmaceae, Genus: Asterarcys (NCBI:txid2609505), and the (V) taxonomic lineage of Scenedesmus sp. KTWL-A is designated as Superkingdom: Eukaryota, Kingdom: Viridiplantae, Phylum: Chlorophyta, Class: Chlorophyceae, Order: Sphaeropleales, Family: Scenedesmaceae, Genus: Scenedesmus (NCBI:txid2613535).

Phylogenetic tree constructed by neighborhood joining method. a Sequences containing ITS1-5.8S-ITS2 region. b Sequences containing 18S rRNA region. Bootstrap values are indicated as percentage at the nodes of the tree (with 1000 bootstrap replications). The distances between the indigenous microalgal isolates to the other related species are being measured through the scale bar

Effect of VWE at Different Concentrations on Biomass Growth

To study the influence of VWE in the production of microalgal biomass for the above-mentioned new native microalgal isolates, different concentrations of VWE (5 µL/mL, 10 µL/mL, 15 µL/mL, and 20 µL/mL of growth media) were added and the biomass growth was estimated in terms of Chl a concentration at regular interval till 20 days of cultivation (Fig. 2). The chlorophyll a is the primary chlorophyll pigment and the biomass growth of green microalgae is directly proportional to Chl a concentration [42]. Subsequently, this study revealed that the VWE supplementation at the concentrations of 10 µL/mL, 15 µL/mL, and 20 µl/mL had resulted in increased biomass growth when compared to control (without VWE) and VWE supplementation at the concentration of 5 µL/mL. However, the optimum increase in Chl a for all the five isolates was observed at either 10 µL/mL or 15 µL/mL concentration (Fig. 2). In case of Scenedesmus sp. KT-U, considerable increase in biomass concentrations (1.47 ± 0.09 and 1.38 ± 0.07 folds) was observed in VWE supplementations of 10 µL/mL and 15 µL/mL, respectively, than the control (untreated). Coelastrum sp. T-E had also shown considerable increase in biomass concentration of 1.36 ± 0.08 and 1.23 ± 0.11 folds than control, respectively, in 10 µL/mL and 15 µL/mL VWE supplementation. Chlorella sp. TWL-B and Asterarcys sp. SPC also exhibited considerable increase in Chl a content with VWE supplementation. The results of this study clearly depicted that VWE provided as supplementation to the inorganic growth media encouraged the microalgal biomass growth, which was revealed through increased Chl a for most of the indigenous isolates, Scenedesmus sp. KT-U, Coelastrum sp. T–E, Chlorella sp. TWL-B, and Asterarcys sp. SPC (Fig. 2). On the other hand, Scenedesmus KTWL-A displayed mild increase on Chl a concentration with VWE treatment (at the VWE concentration of 15 µL/mL) than control (untreated). The effect of VWE at different concentrations on biomass growth (in terms of Chl a) of Scenedesmus sp. KTWL-A was given in supplementary Fig. 2. The physico-chemical properties of VWE and ground water used for media preparation are given in Table 1. It is noteworthy to mention that ground water with modified BG-11 nutrients was used as the control growth media in this study to substantiate the suitability of these native strains for large scale cultivation. The physiochemical analysis of ground water showed considerable quantities of elements such as Ca, Mg, Na, K, Cl, and S (Table 1). In terms of nutrient aspects of VWE, the extract used had enriched organic C and organic N content substantiated by the presence of high reducing sugar (19.6 ± 0.9 mg/mL) and protein (8.5 ± 1.6 mg/mL) content, respectively, with the noticeable levels of nutrients such as Cl, Mg, and S (Table 1). The functional group analysis of VWE by FT–IR spectrum substantiated the presence of C–C, C = O, -OH, C–O, C–H, -NH3, -NH2 absorption peaks corresponding to sugars and proteins; in addition to the absorption peaks corresponding to the functional groups, C–Cl, P, and S were also detected (Supplementary Fig. 3A). Further, nutrient utilization from VWE by the microalgae was substantiated from the peak shifts and peak intensity variations from the FT–IR spectra of media containing fresh/unused VWE, and used VWE (Supplementary Fig. 3B). The nutrient-rich aspect of VWE had increased the biomass growth of microalgae evident through increase in Chl a concentration with VWE treatment than control (untreated) (Fig. 2).

Effect of VWE treatment at various concentrations on the biomass growth of indigenous microalgal isolates in terms of Chl a concentration (μg/mL) at regular intervals, a Scenedesmus sp. KT-U, b Coelastrum sp. T-E, c Chlorella sp. TWL-B, d Asterarcys sp. SPC. Control represents growth media without VWE. i.e., untreated. Data represent the mean of independent triplicate experiments and the error bar denotes the standard error

Clustering Analysis of Parameters Influencing Biodiesel Production Employing Vegetable Waste

To identify suitable isolates for biodiesel production in the perspective of vegetable waste usage ability, critical parameters of five indigenous microalgae such as biomass growth in VWE, biomass, and TAG accumulation were determined. The results revealed maximum BP of 734.4 ± 53 mg/L in Scenedesmus sp. KT-U under complete nutrient culture conditions employed, among five indigenous microalgal isolates (Supplementary Table 1). The relative TAG level for mentioned five microalgae under N starvation showed higher TAG in Asterarcys sp. SPC, Scenedesmus sp. KTWL-A, and Chlorella sp. TWL-B (Supplementary Fig. 4) (Supplementary Table 1). Further, PCA performed for the above-mentioned parameters for five indigenous microalgal substantiated the influence of the most variances, PC1 and PC2 at 64.9% and 25.5%, respectively (Fig. 3b). Clustering heat maps generated through the analysis clearly depicted that the indigenous microalgae, Scenedesmus sp. KTWL-A and Chlorella sp. TWL-B exhibited less positive influence in biomass growth with VWE treatment, when compared to other isolates (Fig. 3a). At the same time their relative TAG accumulation under N starvation is higher among other strains, next to Asterarcys sp. SPC (Supplementary Table 1). In this study of TAG accumulation under N starvation (for 15 days), Scenedesmus sp. KT-U exhibited less TAG production among all the isolates; however, prolonged N starvation for 25 days caused higher TAG accumulation in Scenedesmus sp. KT-U (Supplementary Fig. 5). Pertaining to biodiesel production ability, all the five indigenous microalgae are potent candidates that can be appropriately cultivated through suitable cultivation strategies. At the same time, it is important to observe that the more positive influence was obtained for Asterarcys sp. SPC in terms of all the parameters considered, especially based on its growth in bio-waste i.e., in VWE supplementation. Also, Scenedesmus sp. KT-U had shown positive influence by better growth response with VWE treatment (Fig. 3). Hence the indigenous microalgal isolates, Asterarcys sp. SPC and Scenedesmus sp. KT-U were used for further evaluation of biomass, lipid, and TAG production in mixotrophic batch cultivation in two phases, viz. Biomass phase and Lipid phase.

PCA for five indigenous microalgal isolates for the following six parameters. (i) relative increase in biomass (in folds) upon VWE addition (at 10 μL/mL); (ii) relative increase in biomass upon VWE addition (at 15 μL/mL); (iii) relative increase in biomass upon VWE addition (at 20 μL/mL); (iv) biomass productivity (mg/L) under complete nutrient condition; (v) relative TAG production under complete nutrient condition (as % distribution), and (vi) relative TAG production under N starvation (as % distribution) (Culture conditions are detailed in “Materials and Methods” section). a Clustering heat map, b PC 1 and PC2 are the principal components

Biomass, Lipid, and TAG Production Under Mixotrophic Batch Cultivation Using VWE

Biomass yield of Scenedesmus sp. KT-U and Asterarcys sp. SPC was validated in batch culture of 25 days of cultivation in control (untreated) and VWE-treated media conditions. The results showed significant increase in BP (956 ± 70 mg/L & 964 ± 70 mg/L) for both Scenedesmus sp. KT-U and Asterarcys sp. SPC, respectively, in the VWE-treated growth media [at the standardized VWE concentration of 10 µL/mL growth media] than in control (untreated) (535 ± 70 mg/L and 704 ± 0.4 mg/L, respectively) (Fig. 4a). It is clear that the less TAG accumulation occurred in biomass phase during VWE treatment (Fig. 4c), since the nutrients in VWE are assimilated for biomass growth evident through significant increase in Chl a concentration (supplementary Table 2), and increased biomass yield (Fig. 4a). Higher Chl a content in green microalgae is negatively correlated to storage lipid accumulation level, on the other hand, N depletion nutrient status allow for storage lipid accumulation with decreased Chl a [43], since the nitrogen-rich chlorophyll compounds could serve as intracellular nitrogen pool to facilitate microalgal cellular growth and enhance biomass [44]. Moreover, nitrogen starved microalgae can serve as an appropriate biodiesel feedstock due to substantial amounts of TAG possessing optimum fuel properties [45]. Subsequently, as a lipid phase, VWE-treated microalgae of biomass phase was subjected to N starvation and analyzed for lipid production after 25 days in this study. It is remarkable to mention that the control cells at that time had completed 50 days of cultivation period (represented as Ctrl-II, control of lipid phase). The results showed noticeable increase in lipid yield in VWE-treated cells of lipid phase (231.8 ± 17.9 and 243.5 ± 25 mg/L) in Scenedesmus sp. KT-U and Asterarcys sp. SPC, respectively, than in control (140.5 ± 28 mg/L and 166.4 ± 23 mg/L) cells of lipid phase (Fig. 4b). This increase corresponds to average increase of lipid production of 1.65 and 1.46-folds, respectively, with more or less equivalent lipid content (%) and relative TAG accumulation level in lipid phase for both control and N starved-VWE-treated microalgae. It is because the control cells at that time of harvest had entered lipid phase, due to 50 days of growth. This is also evident with the increase in TAG band intensity in the control with prolonged culturing time of 50 days [Fig. 4d represented as KT-U (Ctrl) –II and SPC (Ctrl)-II)] than in control of biomass phase with culturing time of only 25 days [Fig. 4c represented as KT-U (Ctrl) & SPC (Ctrl)]. This study shows indigenous microalgal cultivation in two phases with vegetable waste usage for the biomass phase led to benefit of significant enhancement in BP and concomitant lipid yield in lipid phase.

Validation of VWE treatment: a Biomass productivity (mg/L) of Scenedesmus sp. KT-U, Asterarcys sp. SPC under control (untreated) [represented as KT-U (Ctrl) & SPC (Ctrl), respectively] and VWE-treated conditions [represented as KT-U (VWE) and SPC-(VWE), respectively]. b Total crude LC (%) and total lipid yield (mg/L) of Scenedesmus sp. KT-U, Asterarcys sp. SPC during lipid phase under control [represented as KT-U (Ctrl)-II & SPC (Ctrl-II, respectively] and in VWE-treated cells subjected to N starvation for 25 days [represented as KT-U (VWE)-II & SPC(VWE)-II, respectively]. [Culture conditions employed are detailed in “Materials and Methods” section]. Data represent the mean of independent duplicate experiments and the error bars denotes the standard error (*P < 0.05; **P < 0.01). c Separation of lipids by TLC in BP phase. d Separation of lipids by TLC in lipid phase

Discussion

Technoeconomic studies have clearly shown that algal biofuel production through the inclusion of nutrients from the available waste resources along with multiple microalgal production technologies are needed for gaining the economic feasibility of microalgal production [46]. Assessment of microalgal biomass growth improvement via vegetable waste supplementation is one of the most reliable approach of cheaper cultivation mode. Subsequently, in this current study, evaluation of biomass growth of new five indigenous microalgal isolates performed under VWE treatment showed improved biomass growth. Likewise, food waste hydrolysate as growth medium in heterotrophic microalgae, Schizochytrium mangrovei and Chlorella pyrenoidosa showed increased production of biomass than conventional medium, and the produced biomass was rich in carbohydrates, lipids, proteins, saturated and polyunsaturated fatty acids [23]. In yet another study, usage of rice husk solution at 6 mL/L concentration in growth medium produced enhanced microalgal biomass in case of Phaeodactylum tricornutum with higher Chl c content (8.48 ± 0.13 μg/mL) than control (6.25 ± 0.99 μg/mL) [24]. In another study, vegetable waste growth media for Chlorella vulgaris (CPCC 90) showed positive effect in increasing lipid and carbohydrate content, though decreased biomass was obtained than control [11]. It was also reported that the lesser production of biomass of Chlorella vulgaris (CPCC 90) in the vegetable waste media than control inorganic base medium was probably due to the lesser nutrient assimilation efficiency of complex organic molecules by microalgae than inorganic carbon and nitrogen source [11]. This suggests the proper and efficient bio-waste pretreatment so as to derive less complex nutrient molecules for facilitating better nutrient assimilation by the microalgal cells. Hence in this study VWE was prepared through thermal hydrolysis by autoclaving twice for better nutrient recovery. The better nutrient assimilation ability from VWE by the microalgae was substantiated by FT–IR and physiochemical analyses in this study. Moreover, based on the statistical clustering analysis of critical parameters such as (i) growth in VWE, (ii) biomass productivity, and (iii) TAG accumulation of five new indigenous microalgal isolates, Asterarcys sp. SPC and Scenedesmus sp. KT-U were selected. This paved the way for strain selection employing vegetable waste in this current study. These selected microalgal isolates were cultivated under mixotrophic batch cultivation employing VWE at the standardized concentration. Increased lipid yield was obtained from VWE-treated cells of lipid phase (231.8 ± 17.9 mg/L and 243.5 ± 25 mg/L) in Scenedesmus sp. KT-U and Asterarcys sp. SPC, respectively, than in control (140.5 ± 28 mg/L and 166.4 ± 23 mg/L). Likewise, in a study on cultivation in food wastewater effluent in Scenedesmus bijuga had improved lipid production in the range of 13.81–15.59 mg/L/day which was higher than in synthetic medium [47]. It was reported that, anaerobically digested effluent from kitchen waste (ADE-KW) for the cultivation of Chlorella sorokiniana SDEC-18 and Scenedesmus SDEC-8 showed optimal BPs of 0.42 g/L and 0.55 g/L, respectively, with 1/15 diluted ADE-KW [27]. It was reported that in microalgae, Chlorella vulgaris, in addition to increased lipid content, higher carbohydrate content was obtained in diluted vegetable waste medium than control [11]. Increase in lipid production was obtained in Chlorella SDEC-11 and Scenedesmus SDEC-13 in ADW-KW added with brassinolide [21]. It is important that the nutrient-rich biowastes such as agricultural wastes, food wastes, vegetable wastes, and fruit wastes are to be exploited effectively for the microalgal cultivation that can pave the way for feasible improved production with proven efficient nutrient recovery [28, 48, 49].

Conclusion

New indigenous microalgae identified as Asterarcys sp. SPC, Scenedesmus sp. KT-U, Scenedesmus sp. KTWL-A, Coelastrum sp. T-E, and Chlorella sp. TWL-B had showcased improved biomass growth in VWE-treated media with at least one of the VWE concentration. Mixotrophic cultivation of the selected microalgae, Scenedesmus sp. KT-U and Asterarcys sp. SPC cultivated using VWE treatment in the optimum concentration of 10 µL/mL growth medium during biomass phase had produced increased biomass (1.8 and 1.4 folds, respectively) than control (medium without VWE). Enhanced lipid yield of 231.8 ± 17.9 mg/L and 243.5 ± 25 mg/L in Scenedesmus sp. KT-U and Asterarcys sp. SPC, respectively, were obtained with considerable TAG accumulation. Thus, this study employed new indigenous microalgae which imparted vegetable waste in the strain assortment and cultivation process for enhanced lipid yield for biodiesel application.

Abbreviations

- VWE:

-

Vegetable waste extract

- FAO:

-

Food and Agriculture Organization

- µL/mL:

-

Microliters per milliliter

- μg/mL:

-

Micrograms per milliliter

- mEq/L:

-

Milliequivalents per liter

- mmol/L:

-

Millimoles per liter

- mg/L:

-

Milligrams per liter

- DCW:

-

Dry cell weight

- TDS:

-

Total dissolved solids

- TAG:

-

Triacylglycerol

- PCA:

-

Principal Component Analysis

- MMT:

-

Million metric tons

- GHG:

-

Greenhouse gas

- FAME:

-

Fatty acid methyl esters

- TLC:

-

Thin Layer Chromatography

- DNA:

-

Deoxyribonucleic acid

- ITS:

-

Internal Transcribed Spacer

- PCR:

-

Polymerase chain reaction

- Chl a:

-

Chlorophyll a

- LC:

-

Lipid content

- BP:

-

Biomass production

References

Ghosh PR, Fawcett D, Sharma SB, Poinern GEJ (2016) Progress towards sustainable utilisation and management of food wastes in the global economy. Int J Food Sci. https://doi.org/10.1155/2016/3563478

Asnani PU (2009) Position paper on the solid waste management sector in India. Department of Economic Affairs, Government of India. http://www.indiaenvironmentportal.org.in/files/ppp_position_paper_solid_waste_mgmt.pdf

Ahluwalia IJ, Patel U (2018) Solid waste management in India: an assessment of resource recovery and environmental impact. Indian Council for Research on International Economic Relations. http://hdl.handle.net/11540/8143

Singh A, Kuila A, Adak S et al (2012) Utilization of vegetable wastes for bioenergy generation. Agric Res 1:213–222. https://doi.org/10.1007/s40003-012-0030-x

Javadekar (2016) Solid waste management rules revised after 16 years; rules now extend to urban and industrial areas. Press Information Bureau Government of India. Ministry of Environment, Forests and Climate Change. https://pib.gov.in/newsite/PrintRelease.aspx?relid=138591

Sagar NA, Pareek S, Sharma S et al (2018) Fruit and vegetable waste: bioactive compounds, their extraction, and possible utilization. Compr Rev Food Sci Food Saf 17:512–531. https://doi.org/10.1111/1541-4337.12330

De Laurentiis V, Corrado S, Sala S (2018) Quantifying household waste of fresh fruit and vegetables in the EU. Waste Manag 77:238–251. https://doi.org/10.1016/j.wasman.2018.04.001

Das NG, Huque KS, Amanullah SM et al (2018) Study of chemical composition and nutritional values of vegetable wastes in Bangladesh. Vet Anim Sci 5:31–37. https://doi.org/10.1016/j.vas.2018.02.003

IEA (2020) Methane Tracker 2020, International Energy Agency, Paris. https://www.iea.org/reports/methane-tracker-2020. Accessed 12 June 2021.

Yang Z, Koh SK, Ng WC et al (2016) Potential application of gasification to recycle food waste and rehabilitate acidic soil from secondary forests on degraded land in Southeast Asia. J Environ Manage 172:40–48. https://doi.org/10.1016/j.jenvman.2016.02.020

de Jesus SS, Santana A, Ponce GHSF, Maciel Filho R (2017) Potential use of vegetable waste for biofuel production. J Chem Technol Biotechnol 92:90–99. https://doi.org/10.1002/jctb.5002

Mustafa S, Bhatti HN, Maqbool M, Iqbal M (2021) Microalgae biosorption, bioaccumulation and biodegradation efficiency for the remediation of wastewater and carbon dioxide mitigation: prospects, challenges and opportunities. J Water Process Eng 41:3–5. https://doi.org/10.1016/j.jwpe.2021.102009

Karpagam R, Jawaharraj K, Gnanam R (2021) Review on integrated biofuel production from microalgal biomass through the outset of transesterification route: a cascade approach for sustainable bioenergy. Sci Total Environ 766:144236. https://doi.org/10.1016/j.scitotenv.2020.144236

Aslam A, Thomas-Hall SR, Manzoor M et al (2018) Mixed microalgae consortia growth under higher concentration of CO2 from unfiltered coal fired flue gas: fatty acid profiling and biodiesel production. J Photochem Photobiol B Biol 179:126–133. https://doi.org/10.1016/j.jphotobiol.2018.01.003

Noreen S, Khalid K, Iqbal M et al (2021) Eco-benign approach to produce biodiesel from neem oil using heterogeneous nano-catalysts and process optimization. Environ Technol Innov 22:1–4. https://doi.org/10.1016/j.eti.2021.101430

Hiwot T (2016) Determination of oil and biodiesel content, physicochemical properties of the oil extracted from avocado seed (Persea americana) grown in Wonago and Dilla (Gedeo zone), Southern Ethiopia. World Sci News 58:133–147

Avila-león IA, Ferreira-camargo LS, Marcelo C, Carvalho JCM (2020) Neochloris oleoabundans growth evaluation under different nitrogen; phosphorus; carbon feeding strategies. Curr Microbiol 77:3270–3277. https://doi.org/10.1007/s00284-020-02149-2

Nur MMA, Buma AGJ (2019) Opportunities and challenges of microalgal cultivation on wastewater, with special focus on palm oil mill effluent and the production of high value compounds. Waste and Biomass Valorization 10:2079–2097. https://doi.org/10.1007/s12649-018-0256-3

Dubey KK, Kumar S, Dixit D et al (2015) Implication of industrial waste for biomass and lipid production in Chlorella minutissima under autotrophic, heterotrophic, and mixotrophic grown conditions. Appl Biochem Biotechnol 176:1581–1595. https://doi.org/10.1007/s12010-015-1663-6

Hussain F, Shah SZ, Ahmad H et al (2021) Microalgae an ecofriendly and sustainable wastewater treatment option: biomass application in biofuel and bio-fertilizer production. A review Renew Sustain Energy Rev 137:110603. https://doi.org/10.1016/j.rser.2020.110603

Pei H, Jiang L, Hou Q, Yu Z (2017) Toward facilitating microalgae cope with effluent from anaerobic digestion of kitchen waste: the art of agricultural phytohormones. Biotechnol Biofuels 10:1–18. https://doi.org/10.1186/s13068-017-0759-3

Dong X, Huang L, Li T et al (2019) The enhanced biomass and lipid accumulation in algae with an integrated treatment strategy by waste molasses and Mg2+ addition. J Energy Sources, Part A Recover Util Environ Eff 42:1183–1192. https://doi.org/10.1080/15567036.2019.1602227

Pleissner D, Lam WC, Sun Z, Lin CSK (2013) Food waste as nutrient source in heterotrophic microalgae cultivation. Bioresour Technol 137:139–146. https://doi.org/10.1016/j.biortech.2013.03.088

Anto S, Karpagam R, Renukadevi P et al (2019) Biomass enhancement and bioconversion of brown marine microalgal lipid using heterogeneous catalysts mediated transesterification from biowaste derived biochar and bionanoparticle. Fuel 255:115789. https://doi.org/10.1016/j.fuel.2019.115789

Shu Q, Qin L, Yuan Z et al (2018) Comparison of dairy wastewater and synthetic medium for biofuels production by microalgae cultivation. Energy Sources Part A Recover Util Environ Eff. https://doi.org/10.1080/15567036.2014.907847

Zhan J, Rong J, Wang Q (2017) Mixotrophic cultivation, a preferable microalgae cultivation mode for biomass/bioenergy production, and bioremediation, advances and prospect. Int J Hydrogen Energy 42:8505–8517. https://doi.org/10.1016/j.ijhydene.2016.12.021

Zhang L, Cheng J, Pei H et al (2018) Cultivation of microalgae using anaerobically digested effluent from kitchen waste as a nutrient source for biodiesel production. Renew Energy 115:276–287. https://doi.org/10.1016/j.renene.2017.08.034

Pratap A, Kumar M, Sibi G (2017) Fruit and vegetable waste hydrolysates as growth medium for higher biomass and lipid production in Chlorella vulgaris. J Environ Waste Manag 4:204–210

Bhatia SK, Mehariya S, Bhatia RK et al (2021) Wastewater based microalgal biorefinery for bioenergy production: progress and challenges. Sci Total Environ 751:141599. https://doi.org/10.1016/j.scitotenv.2020.141599

Rippka R, Deruelles J, Waterbury JB et al (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61. https://doi.org/10.1099/00221287-111-1-1

Hu CW, Te CL, Yu PC, Chen CNN (2013) Pigment production by a new thermotolerant microalga Coelastrella sp. F50. Food Chem 138:2071–2078. https://doi.org/10.1016/j.foodchem.2012.11.133

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Santhi R, Natesan R, Bhaskaran A, Murugappan V (2003) Procedures for soil testing and water quality appraisal. Tamil Nadu Agricultural University, India

Ritchie RJ (2006) Consistent sets of spectrophotometric chlorophyll equations for acetone, methanol and ethanol solvents. Photosynth Res 89:27–41. https://doi.org/10.1007/s11120-006-9065-9

Folch J, Lees M, Sloane Stanely GH (1957) A simple method for the isolation and purification of total lipides from animal tissues. J Biol Chem 226:497–509. https://doi.org/10.1016/S0021-9258(18)64849-5

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21:493–507. https://doi.org/10.1007/s10811-008-9392-7

Karpagam R, Jawaharraj K, Ashokkumar B, Varalakshmi P (2015) Characterization and fatty acid profiling in two fresh water microalgae for biodiesel production: lipid enhancement methods and media optimization using response surface methodology. Bioresour Technol 188:177–184. https://doi.org/10.1016/j.biortech.2015.01.053

Metsalu T, Vilo J (2015) ClustVis: a web tool for visualizing clustering of multivariate data using Principal Component Analysis and heatmap. Nucleic Acids Res 43:W566–W570. https://doi.org/10.1093/nar/gkv468

Akgül F, Tüne I, Kizilkaya AR, Erduğan H (2017) Morphological and molecular characterization of Scenedesmus-like species from Ergene River Basin (Thrace, Turkey). Turkish J Fish Aquat Sci 17:609–618. https://doi.org/10.4194/1303-2712-v17_3_17

Luo W, Pröschold T, Bock C, Krienitz L (2010) Generic concept in Chlorella-related coccoid green algae (Chlorophyta, Trebouxiophyceae). Plant Biol 12:545–553. https://doi.org/10.1111/j.1438-8677.2009.00221.x

Johan F, Jafri MZ, Lim HS, Wan Maznah WO (2014) Laboratory measurement: Chlorophyll-a concentration measurement with acetone method using spectrophotometer. Proc Int Conf Indust Eng Eng Manag. https://doi.org/10.1109/IEEM.2014.7058737

Zhu S, Huang W, Xu J et al (2014) Metabolic changes of starch and lipid triggered by nitrogen starvation in the microalga Chlorella zofingiensis. Bioresour Technol 152:292–298. https://doi.org/10.1016/j.biortech.2013.10.092

Li Y, Horsman M, Wang B et al (2008) Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl Microbiol Biotechnol 81:629–636. https://doi.org/10.1007/s00253-008-1681-1

Andeden EE, Ozturk S, Aslim B (2021) Evaluation of thirty microalgal isolates as biodiesel feedstocks based on lipid productivity and triacylglycerol (TAG) content. Curr Microbiol 78:775–788. https://doi.org/10.1007/s00284-020-02340-5

Allen J, Unlu S, Demirel Y et al (2018) Integration of biology, ecology and engineering for sustainable algal-based biofuel and bioproduct biorefinery. Bioresour Bioproc 5:1–28. https://doi.org/10.1186/s40643-018-0233-5

Shin DY, Cho HU, Utomo JC et al (2015) Biodiesel production from Scenedesmus bijuga grown in anaerobically digested food wastewater effluent. Bioresour Technol 184:215–221. https://doi.org/10.1016/j.biortech.2014.10.090

Cai T, Park SY, Li Y (2013) Nutrient recovery from wastewater streams by microalgae: status and prospects. Renew Sustain Energy Rev 19:360–369. https://doi.org/10.1016/j.rser.2012.11.030

Markou G, Wang L, Ye J, Unc A (2018) Using agro-industrial wastes for the cultivation of microalgae and duckweeds: Contamination risks and biomass safety concerns. Biotechnol Adv 36:1238–1254. https://doi.org/10.1016/j.biotechadv.2018.04.003

Acknowledgements

Authors thankfully acknowledge Department of Science and Technology, New Delhi, India for the financial support to R. Karpagam [DST/INSPIRE/04/2018/001484] (File No. DST/INSPIRE Faculty Award/Batch-14/2018 dated 24.1.2019). The authors are grateful to the Centre for Plant Molecular Biology and Biotechnology (CPMB & B), and the Department of Soil sciences, Tamil Nadu Agricultural University, Coimbatore, Tamil Nadu, India for instrumentation facilities and analytical services, respectively, for this study. We also acknowledge the biocatalysis lab of the Department of Agricultural Microbiology, Tamil Nadu Agricultural University, Coimbatore, Tamil Nadu, India for the FT–IR analysis service.

Author information

Authors and Affiliations

Contributions

Conceptualization, RK; Investigation, RK, NA, and RG; Methodology and data analysis, RK and NA; Writing of the original draft, RK; Reviewing, Editing & Supervision, RK and RG. All authors have read and approved the published version of manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

Authors declare no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Karpagam, R., Abinaya, N. & Gnanam, R. Assortment of Native Microalgae for Improved Biomass and Lipid Production on Employing Vegetable Waste as a Frugal Cultivation Approach for Biodiesel Application. Curr Microbiol 78, 3770–3781 (2021). https://doi.org/10.1007/s00284-021-02643-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-021-02643-1