Abstract

A novel electrogenic bacterial species, Kluyvera georgiana MCC 3673, was isolated by enrichment in microbial fuel cells (MFC) using oilseed cake as a growth substrate. CHNS analyses showed that oilseed cakes are rich in carbon and nitrogen content. Utilization of these compounds by bacteria was evident from 50% reduction in chemical oxygen demand. The maximum power density of 379 ± 8 mW/m2 was produced from sesame seed cake media with mixed consortia inoculum from lake sediment. Enrichment was carried out for over 15 cycles by renewing the media periodically on drop of the voltage. A pure culture of enriched electrogen was isolated by dilution plate technique. Physiological and biochemical studies were performed on the isolate as per standard methods. Genetic analysis by 16S rDNA sequencing revealed that this organism is closely related to Kluyvera georgiana. When inoculated in MFC as pure culture, the maximum power density of 158 ± 11 mW/m2 and 172 ± 13 mW/m2 was produced with sesame and groundnut oilseed cake media, respectively. The performance increased in LB media producing maximum power density of 394 ± 6 mW/m2. This bacterium has also scope for application in wide range of MFC as it can produce electricity even in suspended culture. To our knowledge, this is the first report on bio-electricity generation using oilseed cake as substrate in MFC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microorganisms are known to play numerous beneficial roles in human welfare. One such application of microbes trending in recent times is the generation of electricity (bio-electricity). The process of electricity generation by microorganisms was observed for the first time by Potter over a century ago [1]. But the true mechanism of electricity generation was studied extensively in recent times under the broad concept microbial fuel cell (MFC) due to its numerous applications. In MFC, microorganisms catalyze the conversion of the chemical energy into electrical energy by oxidizing the organic compounds. The protons generated are passed through the selective proton exchange membrane, and the accumulated electrons are collected by the electrode and transferred through the circuit [2]. The bio-electrogenic process in MFC largely depends on the kind of inocula fed in anode chamber. Mixed consortia of microorganisms have been a prime choice in many cases due to the diverse microbial community and the symbiotic relation among them. But the main drawback with the mixed consortia is an unstable microbial community which keeps changing with time and other conditions like nutrient load, temperature, pH, etc. The metagenome analysis of enriched microbes in MFC reveals the presence of a various classes of bacteria depending on the source and site of inoculation. The dominant microbes belong to the class Gammaproteobacteria and Deltaproteobacteria of the phylum Proteobacteria [3]. They are obligate or facultative anaerobes which, under anoxic conditions, tend to find an alternate electron acceptor to oxygen. This enables them to reduce metals in the environment and generate electricity in MFC by donating electrons to the electrode either directly or indirectly by the aid of mediators like neutral red, methylene red, riboflavin, etc. Some electrogenic bacteria like Pseudomonas can produce their own mediator [4] for electron transfer, while some mediator-less microbes have a special mechanism for electron transportation through cell-bound enzymes and cytochromes [5]. Shewanella oneidensis produces a set of cell-bound proteins dedicated to exo-electron transfer [6], whereas Geobacter species form conductive extracellular filaments called nanowires [5].

MFCs are widely employed for treating wastewater [7], reducing metals [8], dyes [9], production of bio-hydrogen [10], methane [11], etc. Apart from the physiology of the species, the choice of growth substrate plays an important role in output generation in MFC. Acetate is a simple two-carbon compound used extensively due to its rapid metabolism by bacteria in MFC. Other simple monomers like lactate, pyruvate, glucose, and higher polysaccharides such as starch and cellulose have also been used [12]. Apart from these, complex natural agro by-product residues like wheat straw [13], rice straw [14] have been explored to power MFC. Complex compounds like oilseed cakes are wastes generated during extraction of cooking oil from edible and biofuel from non-edible oilseeds. Oilseed cakes are rich in nutrient content [15]. They are commonly used as nutrient supplement to animal feed for poultry, swine, dairy due to the presence of vitamins, proteins, dietary fibers, and essential minerals [16]. They are ideal sources of proteinaceous nutrients and support matrix for cost reduction in various fermentative processes for value addition such as enzymes, vitamins, mushrooms, and biochemical products. Oilseed production in India was 32.87 million tonnes in 2013–2014 and is the seventh largest oil crop producer accounting for 10% of global oilseeds production (http://farmersfortune.com). Oilseed cake residues have attracted attention for the production of bio-oil fuels or biogas as environmentally friendly green process for energy [17]. However, interestingly to our knowledge, so far, there are no reports on the use of oilseed cakes in MFC. Thus, it was of interest to explore nature of electrochemically active bacteria enriched in a MFC powered by oilseed cake and to characterize them.

The objectives of the present study were to test oilseed cakes as substrate for powering MFC, to enrich electrogenic microbes, isolate in pure culture, and screen for ability to produce bio-electricity in MFC. A novel electrogenic bacterium was isolated and the electrogenic ability of the organism is reported here.

Materials and Methods

Microbial Inoculant

Lake sediment was collected from IIT Madras (13°00′N, 80°14′E) and stored at 4 °C until processed. This mixed consortia with the diverse microbial community served as inoculum in MFC. Different media having oilseed cakes as substrate were used because of their high carbon and nitrogen content. Three different oilseed cakes, cotton, groundnut, and sesame were obtained from a local oil mill in Chennai, finely ground into powder, washed, and dried in an oven. Oilseed cake media were prepared by dissolving 1% w/v of oilseed cake in distilled water and adjusting the pH to 7.2 and salinity to 1% using 0.1 N sodium hydroxide and sodium chloride, respectively. Enrichment was done by inoculating 1 ml of sludge in oilseed cakes media for 15 cycles until a stable voltage was observed for repetitive batches in MFC. The growth media were renewed whenever a drop in voltage was observed, which was after 96 h of operation in all the cycles operated at room temperature (25 ± 2 °C).

Pure Culture Isolation

The efficient electrogens enriched in MFC were diluted and transferred into LB broth (Himedia, India) and incubated at 30 °C and 150 rpm overnight. The overnight grown mixed culture was diluted in sterile 1% saline solution and streaked on agar plates using dilution plating method. Plates were incubated at 30 °C until visible colonies appeared. Isolated colonies were transferred several times on agar plate to ensure purity of the culture. The morphological and physiological analysis of the isolate was done by standard cultivation procedure.

Biochemical Test

The biochemical tests were done as per the method reported elsewhere [18]. The biochemical tests performed include indole production, citrate utilization, and acid production, production of the enzymes catalase, oxidase, amylase, and lipase enzyme, gelatine hydrolase, hydrogen sulfide gas production, and motility. Apart from that, Vitek 2 GP card (Biomerieux, France) having 43 different biochemical tests were used, which includes tests for utilization of sugars, secretion of enzymes, resistance and susceptibility towards antibiotics, etc. [19]. The wells in the test chemical and reagent were filled with the bacterial culture and the card was loaded into the cassette, placed in a Vitek 2, incubated at 35 °C and subjected to spectroscopic measurement automatically at every 15 min for a period of 6 h. The tests results are indicated by a change in color of the well, which were analyzed from the reference card provided.

16S rDNA Identification of the Isolate

Identification of the bacterium was done by 16S rDNA analysis. The genomic DNA was extracted using the phenol–chloroform method as per literature [20]. Amplification of 16S rDNA was done using 27F (5′ AGAGTTTGATCCTGGCTCAG 3′) and 1492R (5′ CGGTTACCTTGTTACGACTT 3′) forward and reverse primers, respectively [21], in a thermocycler (Eppendorf, Germany). Briefly, 0.5 µl of template DNA was added to 1 µl of each primer and 5 µl of PCR master mix (Ampliqon, Denmark) containing dNTPs, Mg2+, DNA polymerase, and reaction buffer. PCR reaction was performed by initial denaturation at 96 °C for 5 min, followed by cycling conditions set as denaturation at 96 °C for 30 s, primers annealing at 56 °C for 45 s, elongation at 72 °C for 150 s, for 35 cycles, and a final elongation for 10 min. Amplified PCR product was analyzed on 2% agarose gel electrophoresis and confirmed the product size with a DNA ladder (GenedireX, US).

Phylogenetic Analysis

To determine the evolutionary relationship of the 16S rDNA gene sequence, phylogenetic analysis was carried out by the Maximum likelihood (ML) method. First local alignment (SW algorithm) as implemented by BLASTn (https://blast.ncbi.nlm.nih.gov) was performed to select sequences of high similarity with the query against the NCBI nucleotide (nr/nt) database. The putative homologous sequences were chosen based on overall identity, E-value, and query coverage. Sequence alignment was done by the progressive method using the CLUSTAL W program [22] and BioEdit program [23]. Before commencing phylogenetic analysis, the preferred model of evolution on this dataset was tested using the model selection program available in the MEGA 7 software suite [24]. Finally, the phylogenetic analysis was carried out using the aforementioned ML method in MEGA 7 with 500 bootstrap replicates under the K2 + G + I model. The resultant trees were visualized using Figtree 1.7 program.

Pure Culture Performance in MFC

A 20 µl of culture was inoculated into the LB media from frozen stock and incubated at 35 °C with agitating speed of 150 rpm for 12 h, and optical density (OD) was 0.96 measured at 600 nm in a spectrometer. 20 µl of active culture was inoculated into MFC with LB media filled in the anode compartment and sealed tightly with electrodes placed in it. Similarly, to observe the growth and electrogenic character, 20 µl of active culture was inoculated into the MFC with oilseed cake media.

MFC Setup Configuration

Two chambered MFC was used in this study [25]. The working volume of each compartment was 100 ml separated by a selectively permeable membrane supported by silicon gasket on either side. CMI 7000 (Membrane International, US) was used as proton permeable membrane. Prior to use in MFC, the membrane was pre-treated by dissolving in 5% sodium chloride solution for at least 12 h as instructed by the supplier. Carbon cloth with the surface area of 1.4 cm2 was used as an anode material. Carbon cloth was treated by sonication in 0.1 N hydrochloric acid to free from contaminants adhered on the surface before employing in MFC. Graphite rods with a surface area of 14 cm2 connected to a 2-mm-thick copper wire were used as electrode material at cathode. The setup was sterilized by autoclaving at 121 °C for 20 min. Freshly prepared 0.05 M potassium ferricyanide in 0.1 M sodium phosphate buffer (pH 7.2) was used as a catholyte.

Scanning Electron Microscope Analysis

The scanning electron microscopy (SEM) analysis was done for anode to observe the microbial aggregation on the electrode surface. A small piece of the anode was taken and washed with phosphate buffer thrice to remove the undesired particles and contaminants. Fixation was done by overnight incubation at 4 °C in 2.5% glutaraldehyde, followed by gradient ethanol wash (30, 50, 70, 80, 90, and 99%) and air dry. Prior to SEM sputtering was done with gold ion for 120 s for improving the resolution of the image.

Data Acquisition System

The MFC setup was connected to a data acquisition system, ADC 20 Picolog (Pico technologies, UK) for recording the voltage. The data acquisition system was adjusted by programming software to record the output at a regular time interval. The voltage generated in MFC was measured without external resistance to observe the maximum OCV. After the MFC attained maximum OCV, polarization analysis was done to understand the voltage against the current by varying the resistance in the circuit. A resistor from 10 to 50,000 Ω was connected and the voltage was measured against the specific resistor and the current was calculated by applying Ohms law. Similarly, current densities and power densities were calculated by normalizing to the geometric surface area of the electrode with current and power produced, respectively.

Results and Discussion

Oilseed Cake as Substrate in MFC

The analysis of various growth media by CHNS analyzer (LECO True spec, US) is shown in Table 1. The carbon content of oilseed cakes was two times higher compared to LB media. The highest carbon content was found in groundnut with 45% followed by 42% of each in sesame and cotton seed cakes. Only 25% of carbon was found to present in LB media, while the other essential elements nitrogen, hydrogen, and sulfur were in almost similar proportion. The high carbon content in oilseed cakes is due to the presence of long hydrocarbon chains of fats and lipid molecules. The C/N ratio which plays an important role in growth of microorganisms was higher in oilseed cake as compared to LB media. The utilization of oilseed cake was evident from reduction of chemical oxygen demand (COD), shown in Fig. S1 (Supplementary Information). Nearly 50% reduction in organic content was observed with increasing positive voltage in all the MFCs, which is due to the oxidation of oilseed cakes by bacteria resulting in free electrons that are collected by the electrode for bio-electricity generation.

Enrichment of Electro-active Microbes

The inoculum of lake sludge in MFC resulted in high voltage output due to the presence of the diverse microbial community. The positive potential due to growth of microbial consortium in MFC gradually increased over the time. An OCV of 0.6 V was observed in all the MFCs inoculated with different oilseed cake media. The spent media were replaced with the fresh one whenever there was a drop in voltage, which occurred after 4–5 days in each cycle. A faster increase in voltage was observed after three successive transfers due to the adaptation of the inoculum to the MFC conditions. The enriched microbial community was found to be stable and unaffected while renewing the media. The constant OCV of 0.6 V was produced in every batch, which confirmed the establishment of an electrogenic microbial community. The maximum OCV of 0.7 V was achieved within 12 h of operation. Sesame seed cake served as a better substrate and produced 379 ± 8 mW/m2 of power density compared to 324 ± 11 mW/m2 and 203 ± 9 mW/m2 by cotton- and groundnut-fed MFC, respectively. Though the decrease in COD was less for sesame seed cake, the power density was higher compared to cotton and groundnut seed cake. This could be due to the dominance of electrogenic microbial community favoring sesame seed cake for their metabolism. The coulombic efficiency, which is defined as the extent to which the substrate is metabolized by microorganism to produce bio-electricity [26] was higher with sesame seed cake-fed MFC, which resulted in the maximum conversion of the substrate. The coulombic efficiency for sesame, cotton, and groundnut oilseed cake was 60, 42, and 32%, respectively. Hence, further enrichment was continued with sesame seed cake media.

Isolation and Characterization of Electrogenic Bacteria

Thirty different pure cultures were obtained. Each isolate, when tested in MFC, exhibited electrogenic property with their ability to generate voltage in MFC. The OCV produced ranged from 0.2 to 0.7 V with different isolates. The highest output was achieved with the isolate K. georgiana MCC 3673, producing 0.72 V within 12 h of inoculation.

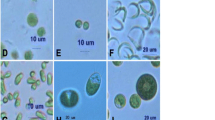

Physiological Characterization

The bacterium K. georgiana MCC 3673 was found to produce maximum voltage compared to other electrogenic isolates. K. georgiana MCC 3673 is a facultative anaerobe, Gram-negative, non-spore forming, non-motile, rod-shaped, measuring 0.3–0.6 µm × 1–2 µm under a microscope. Growth is rapid in LB broth at a temperature range of 25–37 °C. Small circular, yellowish, smooth colonies with a diameter of 0.2–0.3 mm were formed on LB agar after 12 h of incubation.

Biochemical Characterization

The biochemical test results are summarized in Table T1 (Supplementary Information). Briefly, the bacterium can metabolize amino acid tryptophan to indole, metabolize glucose to produce acids but cannot ferment to 2,3-butanediol, and can utilize citrate as a carbon source. No clearing zone in tributyrin agar indicated the absence of lipase, and did not hydrolyze gelatine, but hydrolysis of starch in agar plate indicated amylase production. Oxidase is produced but not catalase. Growth was observed only in the stab line of inoculation with no black precipitation of SIM (sulfide, indole, motility) agar tubes indicating non-motile and no hydrogen sulfide production but gas bubbles of hydrogen were formed. The test results from Biomerieux GP card indicated the ability of the isolate to utilize carbon source as galactose, mannitol, mannose, raffinose, ribose, trehalose, xylose, lactose, sucrose, salicin, methyl glucopyranoside, and N-acetyl glucosamine. Bacterium could not metabolize cyclodextrin, amygdalin, maltose, pullulan, and sorbitol. It is susceptible to antibiotic polymyxin B and resistant to bacitracin, novobiocin, Vibrio toxin O/129, and optochin.

16S rDNA Sequencing and Identification

The PCR product of 16S rDNA was 1.5 kb in size indicating successful amplification covering all the variable regions of the 16S rDNA. The BLAST analysis of 16S rDNA sequence resulted in 99.72% similarity with the bacterium K. georgiana. The phylogenetic analysis performed using ML method with 500 bootstrap repeat checks showed this bacterium closely related to K. georgiana ATCC 51603, shown in Fig. 1. This isolate was deposited at the Microbial Culture Collection (MCC) Pune, India with the accession number MCC 3673, and at Microbial Type Culture Collection Centre (MTCC) Chandigarh, India with accession number MTCC 12866. K. georgiana was first isolated and reported by Muller et al. [27]. They are known to inhabit lake, sewage, and wastewater. Some clinical reports on this bacterium have shown its ability to resist antibiotics due to the secretion of enzyme beta-lactamase due to CTX gene encoded by chromosomal DNA [28]. The resistance towards different antibiotic was observed with K. georgiana MCC 3673 from biochemical test.

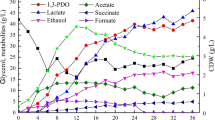

Performance of K. georgiana in MFC

The electrogenic character of K. georgiana MCC 3673 was studied in MFC fed with LB media. Carbon cloth was used as an anode material because of its rough and larger surface area that favors adhesion and colonization of bacterial cells. Since the growth media were rich in nutrient source and other growth factors, OCV of 0.75 V was observed within 12 h of operation. The maximum power density of 394 ± 6 mW/m2 and a current density of 2.16 ± 0.07 mA/cm2 were produced (Fig. 2). In oilseed cake media, the performance was comparatively less, producing 0.5 V of OCV. Similarly, power densities of 172 ± 13 mW/m2 and 158 ± 11 mW/m2 were produced with groundnut and sesame oilseed cake media (Fig. 3). The maximum current densities of 1.25 ± 0.02 mA/cm2 and 1.08 ± 0.07 mA/cm2 were generated with groundnut and sesame seed cake, respectively. Sesame oil seed cake has a protein content of 35% and is richest in ash (11.8%), calcium (2.45%), phosphorus (1.11%) with low fiber compared to many other seed cakes [17], and this could have aided in its better utilization in MFC.

Bio-electricity generation in MFC using various agro-by-products which are complex substrates are summarized in Table 2. The maximum power density of 622 mW/m2 was reported with palm oil millet effluent which is due to enriched and acclimatized habitat of the microbial inocula [29]. The oilseed cake-fed MFC reported in this study, producing 379 ± 8 mW/m2 of power density with mixed culture is higher to other complex substrates reported in the literature.

SEM analysis of the anode after growth of the isolate is shown in Fig. S2 (Supplementary Information). The carbon fibers before MFC were smooth and plain, which turned thick and rough due to the colonization of bacterial cells forming biofilm-like structure on the surface of the electrode. The bacterial cells adhered on the surface of carbon fiber indicating direct contact of the bacterium with the electrode for electron transfer.

The wide application of MFC can be practically achieved by understanding the microbial ecology and exploring the diverse microbial community behind it [11]. The electrogen isolated in this study has potential for generating bio-electricity simultaneous to reducing the environmental waste. The pure culture of electrogenic bacterium, K. georgiana MCC 3673 produced higher power density in oilseed cake media as compared to other cultures (Table 2). A study on wheat straw biomass-powered MFC reported that suspended bacteria and biofilm ferment the complex fuel into simple fermentation products, which can subsequently be utilized by electrogenic bacteria to generate electricity [34]. The electrogenic isolate reported in the present study is the first report on K. georgiana in MFC. The bacterium can ferment oilseed cakes as suspended culture in MFC as well as produce electricity forming biofilms on the electrode. The ability of this bacterium to ferment wide range of compounds and resistance towards different antibiotics proves its metabolic versatility. Hence, this bacterium has much potential for application as single culture or in defined mixed culture with other electrogens which will enable better control over the microbial community function in MFCs for treating, dyes, wastewater and sludge, desalination, metal recovery, etc.

The electrode material used in the present study was graphite, which had no adverse effect on microbial growth during enrichment. The carbonaceous materials (graphite, graphite brush, carbon cloth, etc.) are commonly used as electrode material for enrichment process and favors bacterial colonization [35, 36]. However, use of catalyst-modified electrode has resulted in increased performance of MFC [25, 37, 38]. Wang et al. reported the use of FeS2 nanoparticles decorated graphene anode not only benefited bacterial adhesion and enrichment on the electrode surface but also promoted efficient extracellular electron transfer [39]. A good anodic material should have properties of high electrical conductivity, strong bio-compatibility, chemical stability and anti-corrosion, large surface area, and appropriate mechanical strength and toughness [40]. Hence, the use of non-toxic and stable nanocatalyst or nanomaterial modified anode may further improve the performance in MFC.

References

Potter MC (1911) Electrical effects accompanying the decomposition of organic compounds. Proc R Soc Lond 84(571):260–276. https://doi.org/10.1098/rspb.1911.0073

Logan BE, Hamelers B, Rozendal R, Schröder U, Keller J, Freguia S, Aelterman P, Verstraete W, Rabaey K (2006) Microbial fuel cells: methodology and technology. Environ Sci Technol 40(17):5181–5192. https://doi.org/10.1021/es0605016

Bretschger O, Osterstock JB, Pinchak WE, Ishii S, Nelson KE (2010) Microbial fuel cells and microbial ecology: applications in ruminant health and production research. Microb Ecol 59(3):415–427. https://doi.org/10.1007/s00248-009-9623-8

Rabaey K, Boon N, Siciliano SD, Verstraete W, Verhaege M (2004) Biofuel cells select for microbial consortia that self-mediate electron transfer biofuel cells select for microbial consortia that self-mediate electron transfer. Appl Environ Microbiol 70(9):5373–5382. https://doi.org/10.1128/AEM.70.9.5373

Reguera G, McCarthy KD, Mehta T, Nicoll JS, Tuominen MT, Lovley DR (2005) Extracellular electron transfer via microbial nanowires. Nature 435(7045):1098–1101. https://doi.org/10.1038/nature03661

Shi L, Chen B, Wang Z, Elias DA, Mayer MU, Gorby YA, Ni S, Lower BH, Kennedy DW, Wunschel DS, Mottaz HM, Marshall MJ, Hill EA, Beliaev AS, Zachara JM, Fredrickson JK, Squier TC (2006) Isolation of a high-affinity functional protein complex between OmcA and MtrC: Two outer membrane decaheme c-type cytochromes of Shewanella oneidensis MR-1. J Bacteriol 188(13):4705–4714. https://doi.org/10.1128/JB.01966-05

Liu H, Ramnarayanan R, Logan BE (2004) Production of electricity during wastewater treatment using a single chamber microbial fuel cell. Environ Sci Technol 38(7):2281–2285. https://doi.org/10.1021/es034923g

Kim HJ, Park HS, Hyun MS, Chang IS, Kim M, Kim BH (2002) A mediator-less microbial fuel cell using a metal reducing bacterium, Shewanella putrefaciens. Enzyme Microb Technol 30(2):145–152. https://doi.org/10.1016/S0141-0229(01)00478-1

Mani P, Kumar VTF, Keshavarz T, Chandra TS, Kyazze G (2018) The role of natural laccase redox mediators in simultaneous dye decolorization and power production in microbial fuel cells. Energies 11(12):3455. https://doi.org/10.3390/en11123455

Rozendal RA, Hamelers HVM, Euverink GJW, Metz SJ, Buisman CJN (2006) Principle and perspectives of hydrogen production through biocatalyzed electrolysis. Int J Hydrogen Energy 31(12):1632–1640. https://doi.org/10.1016/j.ijhydene.2005.12.006

Wagner RC, Regan JM, Oh SE, Zuo Y, Logan BE (2009) Hydrogen and methane production from swine wastewater using microbial electrolysis cells. Water Res 43(5):1480–1488. https://doi.org/10.1016/j.watres.2008.12.037

Pant D, Van Bogaert G, Diels L, Vanbroekhoven K (2010) A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresour Technol 101(6):1533–1543. https://doi.org/10.1016/j.biortech.2009.10.017

Zhang Y, Min B, Huang L, Angelidaki I (2009) Generation of electricity and analysis of microbial communities in wheat straw biomass-powered microbial fuel cells. Appl Environ Microbiol 75(11):3389–3395. https://doi.org/10.1128/AEM.02240-08

Wang Z, Lee T, Lim B, Choi C, Park J (2014) Microbial community structures differentiated in a single-chamber air-cathode microbial fuel cell fueled with rice straw hydrolysate. Biotechnol Biofuels 7(1):1–10. https://doi.org/10.1186/1754-6834-7-9

Sunil L, Prakruthi A, Prashant Kumar PK, Gopala Krishna AG (2016) Development of health foods from oilseed cakes. J Food Process Technol 7(11):1–6. https://doi.org/10.4172/2157-7110.1000631

Sunil L, Appaiah P, Prasanth Kumar PK, Gopala Krishna AG (2015) Preparation of food supplements from oilseed cakes. J Food Sci Technol 52(5):2998–3005. https://doi.org/10.1007/s13197-014-1386-7

Ramachandran S, Singh SK, Larroche C, Soccol CR, Pandey A (2007) Oil cakes and their biotechnological applications—a review. Bioresour Technol 98(10):2000–2009. https://doi.org/10.1016/j.biortech.2006.08.002

Prescott H (2002) Laboratory exercises in microbiology, 5th edn. The McGraw-Hill, New York

Funke G, Funke-Kissling P (2005) Performance of the new VITEK 2 GP card for identification of medically relevant gram-positive cocci in a routine clinical laboratory. J Clin Microbiol 43(1):84–88. https://doi.org/10.1128/JCM.43.1.84-88.2005

Green MR, Sambrook J (2012) Molecular cloning. A laboratory manual, 4th edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor

Frank JA, Reich CI, Sharma S, Weisbaum JS, Wilson BA, Olsen GJ (2008) Critical evaluation of two primers commonly used for amplification of bacterial 16S rRNA genes. Appl Environ Microbiol 74(8):2461–2470. https://doi.org/10.1128/AEM.02272-07

Thompson JD, Higgins DG, Gibson TJ (1994) CLUSTAL W: improving the sensitivity of progressive multiple sequence alignment through sequence weighting, position-specific gap penalties and weight matrix choice. Nucleic Acids Res 22(22):4673–4680. https://doi.org/10.1093/nar/22.22.4673

Hall TA (1999) Bio Edit: a user-friendly biological sequence alignment editor and analysis program for windows 95/98/NT. Nucleic Acid Symposium, vol. 41, Oxford University Press, pp. 95–8

Kumar S, Stecher G, Tamura K (2016) MEGA7: molecular evolutionary genetics analysis version 7.0 for bigger datasets. Mol Biol Evol 33(7):1870–1874. https://doi.org/10.1093/molbev/msw054

Thapa BS, Seetharaman S, Chetty R, Chandra TS (2019) Xerogel based catalyst for improved cathode performance in microbial fuel cells. Enzyme Microb Technol 124:1–8. https://doi.org/10.1016/j.enzmictec.2019.01.007

Kim JR, Min B, Logan BE (2005) Evaluation of procedures to acclimate a microbial fuel cell for electricity production. Appl Microbiol Biotechnol 68(1):23–30. https://doi.org/10.1007/s00253-004-1845-6

Müller HE, Brenner DJ, Fanning GR, Grimont PA, Kämpfer P (1996) Emended description of Buttiauxella agrestis with recognition of six new species of Buttiauxella and two new species of Kluyvera: Buttiauxella ferragutiae sp. nov., Buttiauxella gaviniae sp. nov., Buttiauxella brennerae sp. nov., Buttiauxella izardii sp. Int J Syst Bacteriol 46(1):50–63. https://doi.org/10.1099/00207713-46-1-50

Rodríguez MM, Power P, Sader H, Galleni M, Gutkind G (2010) Novel chromosome-encoded CTX-M-78 β-lactamase from a Kluyvera georgiana clinical isolate as a putative origin of CTX-M-25 subgroup. Antimicrob Agents Chemotherapy 54(7):3070–3071. https://doi.org/10.1128/AAC.01615-09

Jong BC, Liew PWY, Juri ML, Kim BH, Mohd. Dzomir AZ, Leo KW, Awang MR (2011) Performance and microbial diversity of palm oil mill effluent microbial fuel cell. Lett Appl Microbiol 53(6):660–667. https://doi.org/10.1111/j.1472-765X.2011.03159.x

Wang M, Yan Z, Huang B, Zhao J, Liu R (2013) Electricity generation by microbial fuel cells fuelled with Enteromorpha prolifera hydrolysis. Int J Electrochem Sci 8(2):2104–2111. https://doi.org/10.1016/j.biombioe.2011.09.026

Ren Z, Ward TE, Regan JM (2007) Electricity production from cellulose in a microbial fuel cell using a defined binary culture. Environ Sci Technol 41(13):4781–4786. https://doi.org/10.1021/es070577h

Niessen J, Schröder U, Scholz F (2004) Exploiting complex carbohydrates for microbial electricity generation—a bacterial fuel cell operating on starch. Electrochem Commun 6(9):955–958. https://doi.org/10.1016/j.elecom.2004.07.010

Zuo Y, Maness P-C, Logan BE (2006) Electricity production from steam exploded corn stover biomass. Energy Fuels 20(12):1716. https://doi.org/10.1021/ef0600331

Zhang Y, Olias LG, Kongjan P, Angelidaki I (2011) Submersible microbial fuel cell for electricity production from sewage sludge. Water Sci Technol 64(1):50–55. https://doi.org/10.2166/wst.2011.678

Finkelstein DA, Tender LM, Zeikus JG (2006) Effect of electrode potential on electrode-reducing microbiota. Environ Sci Technol 40(22):6990–6995. https://doi.org/10.1021/es061146m

Gregoire KP, Glaven SM, Hervey J, Lin B, Tender LM (2014) Enrichment of a high-current density denitrifying microbial biocathode. J Electrochem Soc 161(13):H3049–H3057. https://doi.org/10.1149/2.0101413jes

Alatraktchi FAZA, Zhang Y, Noori JS, Angelidaki I (2012) Surface area expansion of electrodes with grass-like nanostructures and gold nanoparticles to enhance electricity generation in microbial fuel cells. Bioresour Technol 123:177–183. https://doi.org/10.1016/j.biortech.2012.07.048

Sharma T, Mohana Reddy AL, Chandra TS, Ramaprabhu S (2008) Development of carbon nanotubes and nanofluids based microbial fuel cell. Int J Hydrogen Energy 33(22):6749–6754. https://doi.org/10.1016/j.ijhydene.2008.05.112

Wang R, Yan M, Li H, Zhang L, Peng B, Sun J, Liu D, Liu S (2018) FeS2 nanoparticles decorated graphene as microbial-fuel-cell anode achieving high power density. Adv Mater 30(22):1–7. https://doi.org/10.1002/adma.201800618

Hernandez-Flores G, Solorza-Feria O, Ponce-Noyola MT (2013) Improvement of microbial fuel cell characteristics by inoculum enrichment and selection of anodic materials. J New Mater Electrochem Syst 129(18):121–129. https://doi.org/10.14447/jnmes.v18i3.357

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Thapa, B.S., T.S., C. Kluyvera georgiana MCC 3673: A Novel Electrogen Enriched in Microbial Fuel Cell Fed with Oilseed Cake. Curr Microbiol 76, 650–657 (2019). https://doi.org/10.1007/s00284-019-01673-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-019-01673-0