Absract

The growth rates and pyrene degradation rates of Pseudomonas sp. LP1 and Pseudomonas aeruginosa LP5 were increased in corn steep liquor (CSL) supplemented. On pyrene alone the highest specific growth rate of LP1 was 0.018 h−1, while on CSL-supplemented pyrene MSM, the value was 0.026 h−1. For LP5 the highest growth rate on CSL-supplemented pyrene-MSM was 0.034 h−1. Conversely, on pyrene alone the highest rate was 0.024 h−1. CSL led to marked reduction in residual pyrene. In the case of Pseudomonas sp. LP1 values of residual pyrene were 58.54 and 45.47%, respectively, for the unsupplemented and supplemented broth cultures, showing a difference of 13.09%. For LP5 the corresponding values were 64.01 and 26.96%, respectively, showing a difference of 37.05%. The rate of pyrene utilization by LP1 were 0.08 and 0.11 mg l−1 h−1 on unsupplemented and supplemented media, respectively. The corresponding values for LP5 were 0.07 and 0.015 mg l−1 h−1, respectively. These results suggest that CSL, a cheap and readily available waste product, could be very useful in the bioremediation of environments contaminated with pyrene.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pyrene is a peri-condensed four-ring polycyclic aromatic hydrocarbon (PAH). It is a high molecular weight (HMW) PAH. PAHs are hydrophobic compounds and their persistence within ecosystems is due in part to their low water solubility. This is because PAHs are composed of fused rings whose biochemical persistence arises from dense clouds of π-electrons on both sides of the ring structures, making them resistant to nucleophilic attack [18].

Hydrocarbons generally are weak sources of nutrients such as nitrogen and phosphorus which are essential building blocks of structural macromolecules like proteins and nucleic acids as well as enzymes and coenzymes. These nutrients are therefore highly limiting in petroleum polluted environments [22]. Consequently, the growth of hydrocarbon-degrading bacteria and hydrocarbon degradation can be enhanced by fertilization with inorganic nutrients. This has proven effective in bioremediation treatment on several petroleum-contaminated sites [13, 29].

It has been demonstrated that the addition of nitrogen to either continuously mixed slurry or field-wet soil incubations increased the rate and extent of mineralization of pyrene [19]. In static microcosm it was also discovered that nitrogen amendment decreased the lag period before significant pyrene mineralization occurred.

The demand for micro- and macronutrients including growth factors depend on the species or strain. While a pyrene degrader, Mycobacterium PYR-1 [16] had requirement for growth factor and Mycobacterium CH1 [10] had no such growth factor requirements. Vitamin solution, yeast extract, peptone, and yeast extracts are presently some of the growth supplements in use [16, 17, 20]. However, in spite of stimulation of hydrocarbon degradation by nutrient amendments, there have been some failures and conflicting reports are available in literature. Non-effect of inorganic nutrient sources on PAHs biodegradation has been demonstrated previously [7, 17]. Seklemova et al. [30] found that added nutrients had no effect on the decontamination of polluted forest soils. Similarly, Chaineau et al. [8] reported inhibition of aromatic fractions of crude oil at high nutrient levels. Some of the nutrients, depending on the source and concentration, may have direct toxic impact on indigenous microorganisms or may not be bioavailable. The use of cheap alternative sources such as corn steep liquor (CSL) might help circumvent these problems.

Corn steep liquor is a liquid mixture consisting entirely of the water soluble components of corn steeped in water. It has been shown to be very rich in nutrients required by most microorganisms [1, 14]. Its composition depends on the corn variety, steeping condition and age of the corn kernel [27]. CSL is used in the production of vitamins, peptides, antibiotics, and several other industrial fermentation products [2]. In the western world, it is primarily used as a nutrient for ruminant animals [24]. In Nigeria, however, it is essentially a waste stream product of domestic or cottage industry production of ogi (corn meal slurry). Only a small amount of this is used in medicinal preparation of concoctions and decoctions. A number of workers, however, have tried to explore its high nutritive value in improvement of media for culture and biotechnology. Omidiji et al. [28] produced α-amylase in corn steep liquor soya bean meal medium by a strain of Bacillus stearothermophilus. No study has focused on the possible enhancement of pyrene biodegradation in medium fortified with CSL. Since the goal of any bioremediation protocol is the destruction of the pollutant using cheap available nutrient sources, encouraging results from such study would present CSL as a powerful bioremediation tool for cleanup of PAH-contaminated matrices.

Materials and Methods

Microorganisms and Culture Conditions

Isolation and characterization of the organisms used in this study, Pseudomonas sp. LP1 and P. aeruginosa LP5 has been described elsewhere [24]. The isolates were maintained in glycerol nutrient broth (1:1) at −20°C. Colonies growing on Luria–Bertani agar with very low percentage of PAH (0.005%) were harvested with sterile inoculating loop, pooled and transferred to screw-capped bottles containing 5 ml of physiological saline (0.9% NaCl). Enough culture was transferred to achieve an OD600 of approximately 1.5.

The organisms were grown in mineral salts medium (MSM) previously described by Kästner et al. [20]. The pH of the medium was adjusted to 7.2. Trace elements solution (1 ml/l) described by Bauchop and Elsden [3] was sterilized separately and added aseptically to the medium. Unless otherwise stated, incubation was performed at room temperature (29 ± 2.0°C).

Preparation of Corn Steep Liquor

Corn steep liquor was prepared using a method modified from Omodiji et al. [28] by soaking 500 g of well-washed healthy maize grains in 1 l of water for 48 h, grinding in a well-washed blender and allowing this to stand further at room temperature. After another 48 h, the suspension was mixed thoroughly and strained in a domestic sieve. The liquor obtained was made up to 1 l with more water and allowed to sediment for 2 h. The resultant supernatant was decanted and used in degradation studies.

Determination of Physico-Chemical Parameters of Corn Steep Liquor

The ash content, total organic carbon, total nitrogen content, and available phosphorous were determined as described previously [4, 6, 9] using solid residues (0.98 g) obtained after drying of 100 ml of sample in the oven at 80°C. The Black–Wakley method was used for the determination of total organic carbon (TOC). The carbohydrate content was estimated according to the method of Spiro [31] using 1 ml of the wet sample. The protein content was determined from diluted sample using the method of Bradford [5].

Growth on Pyrene Corn Steep Liquor Supplemented Medium

Replicate flasks (three at each time point) of 20 ml MSM containing 100 ppm of pyrene and 1.5% corn steep liquor were inoculated with LP1 and LP5 incubated. Total viable counts (TVC) and residual pyrene were determined at 3-day interval for 21 days. Total viable counts were determined after plating out aliquots of appropriate dilutions onto nutrient agar and incubating in the dark for 24 h at room temperature (29 ± 2°C). Inoculated flasks without CSL fortification, inoculated flasks with pyrene only and flasks amended with both pyrene and CSL but inoculated with heat attenuated cells all served as controls. The entire content of each flask was sacrificed to minimize error at each time point.

Analytical Method

Residual pyrene was extracted by liquid–liquid extraction using hexane as solvent. After two extraction cycles, the solvent was vented off in a preheated oven overnight and the pyrene residue was reconstituted in 2 ml acetone. Control flasks were handled similarly.

Hexane extract (1.0 μl) were analyzed with Hewlett Packard 5890 Series II gas chromatograph equipped with flame ionization detector (FID) and 30 m long HP-5 column (internal diameter, 0.25 mm; film thickness, 0.25 μm) as described recently [26].

Results and Discussion

Table 1 shows the nutritive composition of the corn steep liquor used in this study. The total dry weight solid was 0.98%. Of this, 12.09% was ash, 42.87% total organic carbon, nitrogen 0.15%, and protein 0.94%. The available phosphorus was 0.004 mg/l and carbohydrate was 8 mg/l.

Higher growth rates were observed when the pyrene MSM was fortified with CSL. Pseudomonas sp. LP1 showed similar pattern of growth on CSL alone and CSL-supplemented pyrene up till day 15 (Fig. 1). In both cases the highest population densities were attained on day 6, viz., 3.4 × 108 and 4.2 × 108 cfu/ml, respectively. Population densities dropped in both cases between days 6 and 9, and then rose to peak on day 12 before dropping on day 15 to 1.26 × 108 and 1.52 × 108 cfu/ml, respectively. Between days 15 and 21, there was no noticeable increase in the population density in CSL culture but the CSL amended pyrene medium showed marked increase in population density to 3.25 × 108 cfu/ml. On pyrene alone the highest specific growth rate of LP1 was 0.018 h−1 (t = 15–21 days), while on CSL-supplemented pyrene MSM, the value was 0.026 h−1 (t = 0–6 days). On CSL MSM alone growth rate was also highest in the first 6 days.

Growth curve of Pseudomonas sp. strain LP1 on pyrene (filled circle), pyrene and corn steep liquor (filled square) and corn steep liquor (1%) alone (filled triangle). Data are means of replicate determinations (n = 3); error bars represent the standard deviation; error bars on control (filled circle) are not visible because of close proximity of triplicate values

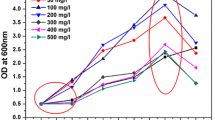

Pseudomonas aeruginosa LP5 grew on CSL and CSL-supplemented pyrene medium with an exponential growth pattern. On CSL alone the organism also grew without a lag phase and stationary phase was attained in 9 days at population density of 5.7 × 108 cfu/ml. The highest growth rate of 0.044 h−1 was recorded in the first 3 days of incubation but subsequently the rate fell below 0.020 h−1. But on CSL-supplemented pyrene, after an initial lag phase of 3 days (72 h) growth continued at exponential rate up till day 15 when it reached 1.07 × 109 cfu/ml (Fig. 2). However, the highest growth rate was attained between days 3 and 6 (0.034 h−1). Conversely, on pyrene alone, the highest rate was 0.024 h−1, attained within 15 days after an initial 6-day lag phase.

The effect of supplementation of pyrene medium with CSL on amount of residual pyrene in the cultures as determined by gas chromatography after 21 day of incubation with organisms is shown in Table 2. Fortification with CSL resulted in marked reduction in residual pyrene. In the case of strain LP1, values of residual pyrene were 58.54 and 45.47%, respectively, for the unsupplemented and supplemented broth cultures, showing a difference of 13.09%. For LP5 the corresponding values were 64.01 and 26.96%, respectively, showing a difference of 37.05%. The rate of pyrene utilization by LP1 was 0.11 and 0.08 mg l−1 h−1 (Table 2).

Growth curve of Pseudomonas aeruginosa LP5 on pyrene (filled circle), pyrene and corn steep liquor (filled square) and corn steep liquor (1%) alone (filled triangle). Data are means of replicate determinations (n = 3); error bars represent the standard deviation; error bars on control (filled circle) are not visible because of close proximity of triplicate values

In media amended with or without CSL, respectively, the corresponding values for LP5 were 0.015 and 0.07 mg l−1 h−1.

Microorganisms generally require mineral (inorganic) nutrients sources for growth. If any of the required nutrients is lacking or becomes limiting, particularly the macromineral elements, pollutant degradation reaction may be slow even though carbon and energy sources required for growth are available [15, 23, 32]. Higher growth rates were observed when the pyrene mineral medium was supplemented with CSL. This may not be unconnected with the fact that CSL is a rich source of nutrient, particularly organic nitrogen, essential minerals, and co-factors [11], which may have helped in boosting initial biomass. This was reflected in the similarity in patterns of growth exhibited on CSL alone and CSL-supplemented pyrene medium particularly by LP1 in the early period of incubation. Furthermore, it is a well-established fact that growth rate is often not dependent on a single substrate in a multi-substrate system [21]. The effect on CSL was further reflected in the fact that in both isolates, upsurges in growth were observed in CSL-supplemented pyrene medium at the same time as stationary phase was attained on CSL alone. The differences observed in the effect on CSL supplementation on LP1 and LP5 could be a function of differential utilization of the nutrient supplements. Biochemical analysis recently conducted on the two organisms showed LP5 to be positive for urea utilization, malonate, and lipid hydrolysis [25]. Furthermore, LP5 produced pyoverdin on nutrient agar. The biochemical versatility of LP5 may thus mean a more resourceful utilization of the additional nutrient provided in CSL by this organism than LP1. For instance corn steep liquor is a source of lipid, which can be readily utilized by LP5 but not LP1.

The higher degradation of pyrene in the presence of CSL could be attributed to enhanced hydrocarbon utilization as certain minimum biomass is required to establish degradation. The additional energy and carbon source provided by CSL must have played a major role in this regard. Fava et al. [12] similarly observed faster and more complete removal of PAHs in soya lecithin (SL) amended bioreactors.

References

Akinrele LA (1970) Fermentation studies on maize during the preparation of a traditional African starch cake food. J Sci Food Agric 21:619–625

Atlas RM (1995) Principles of microbiology. Mosby, St. Louis, p 808

Bauchop T, Elsden SR (1960) The growth of microorganisms in relation to their energy. J Gen Microbiol 23:457–459

Black CA (1965) Methods of soil analysis. No. 9, Part 2. American Society of Agronomy, Madison, Wisconsin

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Bray RH, Kurtz LT (1945) Determination of total organic and available forms of phosphorus in soils. Soil Sci 59:39–45

Carmichael LM, Pfaender FK (1997) The effects of inorganic and organic supplements on the microbial degradation of phenanthrene and pyrene in soils. Biodegradation 8:1–13

Chaineau CH, Rougeux G, Yepremian C et al (2005) Effects of nutrient concentration on the biodegradation of crude oil and associated microbial populations in the soil. Soil Biol Biochem 37:1490–1497

Chopra SL, Kanwar JS (1998) Analytical agricultural chemistry. MacMillian Press, London

Churchill SA, Harper JP, Churchill PF (1999) Isolation and characterization of a Mycobacterium species capable of degrading three- and four-ring aromatic and aliphatic hydrocarbons. Appl Environ Microbiol 65:549–552

CRA (2006) Assessment plan for corn steep liquor, CAS #6607-94-1. The Corn, Refiners Association, Keller and Heckman, Washington, DC 14 pp

Fava F, Berselli S, Conte P, Piccolo A et al (2004) Effects of humic acid substances and soya lecithin on the aerobic bioremediation of soil historically contaminated by polycyclic aromatic hydrocarbons (PAHs). Biotechnol Bioeng 88:214–223

Fedorak PM, DWS (1981) Degradation of aromatics and saturates in crude oil by soil enrichments. Water Air Soil Poll 16:367–375

Foda MS, Sadem SA, Hegazi SM et al (1973) Biochemical studies for utilization of corn steep liquor in production of proteins. J Sci Food Agric 24:17–22

Giordani G, Donnelly A, Azzoni R (1998) The uptake of inorganic phosphate by Z. noltii in the Basin d’ Arcachon, In: Proceedings (Handbook) of summer conference of the society for applied microbiology, University of Lancaster, UK, pp 22–23

Heitkamp MA, Franklin W, Cerniglia CE (1988) Microbial metabolism of polycyclic aromatic hydrocarbons: isolation and characterisation of a pyrene-degrading bacterium. Appl Environ Microbiol 54:2549–2555

Jimenez IY, Bartha R (1996) Solvent-augmented mineralization of pyrene by a Mycobacterium sp. Appl Environ Microbiol 62:2311–2316

Johnsen AR, Wick LY, Harms H (2005) Principles of microbial PAH-degradation in soil. Environ Poll 133:71–84

Jones MD, Singleton DR, Carstensen DP et al (2008) Effect of incubation conditions on the enrichment of pyrene-degrading bacteria identified by stable-isotope probing in an aged, PAH-contaminated soil. Microb Ecol 56:341–349

Kastner M, Breuer-Jammali M, Mahro B (1994) Enumeration and characterisation of the soil microflora from hydrocarbon-contaminated soil sites able to mineralise polycylic aromatic hydrocarbons. Appl Microbiol Biotechnol 41:267–273

Kovarova-Kovar K, Egli T (1998) Growth kinetics of suspended microbial cells: from single-substrate controlled growth to mixed substrate kinetics. Microbiol Mol Biol Rev 62:646–666

Leahy JG, Colwell RR (1990) Microbial degradation of hydrocarbons in the environment. Microbiol Rev 54:305–315

Lehtola M, Miettinen I, Vartianen T, et al. (1998) Purification of drinking water phosphorus and bacterial growth. In: Proceedings (Handbook) of summer conference of the society for applied microbiology, University of Lancaster, UK), pp 16–17

Liggett WR, Koffler H (1948) Steep liquor in microbiology. Bacteriol Rev 12(4):297–311

Obayori O (2008) Degradation of some petroleum hydrocarbon pollutants by microorganisms from contaminated tropical soils. PHD Thesis, University of Lagos, Lagos, Nigeria

Obayori OS, Ilori MO, Adebusoye SA, Oyetibo GO, Amund OO (2008) Pyrene-degradation potentials of Pseudomonas species isolated from polluted tropical soils. World J Microbiol Biotechnol 24:2639–2646

Okafor N (1987) Industrial microbiology. University of Ife Press, Ile-Ife, p 413

Omidiji O, Amund OO, Braimoh A et al (1997) Production of α-amylase in a corn steep liquor-soya bean meal medium by a strain of Bacillus staerothermophilus. Microbios 90:155–162

Roling WFM, Milner MG, Jones DM et al (2002) Robust hydrocarbon degradation and dynamics of bacterial communities during nutrient-enhanced oil spill bioremediation. Appl Environ Microbiol 68:5537–5548

Seklemova E, Pavlova A, Kovacheva K (2001) Biostimulation-based bioremediation diesel fuel: field demonstration. Biodegradation 12:311–316

Spiro TG (1966) Analysis of sugars found in glycoproteins. Methods Enzymol 8:7–9

Vidali M (2001) Bioremediation: an overview. Pure Appl Chem 73:1163–1172

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Obayori, O.S., Adebusoye, S.A., Ilori, M.O. et al. Effects of Corn Steep Liquor on Growth Rate and Pyrene Degradation by Pseudomonas strains. Curr Microbiol 60, 407–411 (2010). https://doi.org/10.1007/s00284-009-9557-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-009-9557-x