Abstract

An agar-degrading Thalassomonas bacterium, strain JAMB-A33, was isolated from the sediment off Noma Point, Japan, at a depth of 230 m. A novel α-agarase from the isolate was purified to homogeneity from cultures containing agar as a carbon source. The molecular mass of the purified enzyme, designated as agaraseA33, was 85 kDa on both SDS-PAGE and gel-filtration chromatography, suggesting that it is a monomer. The optimal pH and temperature for activity were about 8.5 and 45°C, respectively. The enzyme had a specific activity of 40.7 U/mg protein. The pattern of agarose hydrolysis showed that the enzyme is an endo-type α-agarase, and the final main product was agarotetraose. The enzyme degraded not only agarose but also agarohexaose, neoagarohexaose, and porphyran.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Agarose is a gelling component in the cell wall of marine red algae consisting of a linear chain of alternating 3-O-linked β-D-galactopyranose and 4-O-linked 3,6-anhydro-α-L-galactose units [2]. A number of agar-degrading enzymes have been purified from various genera and well characterized [1, 3, 4, 6–8, 11–14, 16, 18, 24], but almost all of the known agarases belong to the β-agarase group and hydrolyze only β-1,4 linkages between composite sugars in agarose. In contrast, α-agarases, which hydrolyze α-1,3 linkages, are poorly known. There is only one report of biochemical studies on an α-agarase purified from “Alteromonas agarlyticus GJ1B” (A. agarlytica DSM 12513) [14]. This enzyme hydrolyzed agarose to yield a series of agaro-oligosaccharides and showed α-galactosidase activity together with agarase activity. However, it was not capable of degrading agarohexaose, agarotetraose, and carrageenans. The other enzyme that hydrolyzes α-1,3 linkages of the same backbone is α-neoagaro-oligosaccharide hydrolase [17]. The enzyme does not degrade agarose, but cleaves α-1,3 linkages in neoagaro-oligosaccharides smaller than hexamers, yielding odd numbers of oligosaccharides and constitutive monosaccharides.

The agaro-oligosaccharides obtained upon breakdown of α-1,3 linkages of agarose have antioxidative and antitumorigenic properties that may be important in the medical and food industries [5]. Sulfated agaroses such as agaropectin and porphyran attract special attention because of their immunopotentiating, anticoagulant, and antioxidant activities [21–23]. Enzymatic processing of these marine polysaccharides is an essential step for rational development of new drugs.

We have isolated a number of agar-degrading microorganisms and characterized their β-agarases [12, 13]. In this report, we describe the isolation of a novel agar-degrading bacterium designated strain JAMB-A33 that was obtained from a sediment sample off Noma Point, Japan, at a depth of 230 m, and characterize the new α-agarase (agaraseA33) that it produced.

Materials and Methods

Isolation of an agarolytic bacterium and 16S rDNA analysis of the isolate

The procedure for the isolation of bacteria with agarolytic activity in sediment samples taken off Noma Point at a depth of 230 m followed the method described previously [13]. One of the bacteria exhibiting agarolytic activity was chosen and named strain JAMB-A33. The isolate was propagated on marine agar 2216 (Difco, Detroit, MI) or in marine broth 2216 (Difco) containing 0.1% agar at 30°C. 16S rDNA was amplified using eubacterial primers of 27f and 1525r, then the amplified 1.5 kb DNA fragment was sequenced by the method described previously [20] and used for the database search (http://www.ddbj.nig.ac.jp/) to find the species with the closest match.

Purification of agarase from JAMB-A33

Strain JAMB-A33 was propagated in 2 L of marine broth 2216 containing 0.1% agar with shaking at 75 rpm in a rotary shaker for 72 h at 30°C. The following procedures were carried out at temperatures below 4°C. The centrifugal pellet of the culture was suspended in 10 mM Tris-HCl, pH 7.5, and sonicated by an ultrasonic disrupter (UD-201; Tomy, Tokyo, Japan). The resulting suspension was mixed with Hydroxyapatite (Seikagaku Kogyo, Tokyo, Japan) to trap the agarolytic enzyme. After being mixed for 30 min, the suspension was filtered using a bottle-top nitrocellulose filter (0.45 μm pore size). After confirming that no agarolytic activity was present in the filtrate, the resin was resuspended in 400 mL of 0.1 M sodium phosphate, pH 7.0, and filtered as described above. The filtrate obtained was applied to a DEAE-Toyopearl 650M column (2.5 × 15 cm; Tosoh, Tokyo, Japan), and eluted by a linear gradient of NaCl (0–0.5 M) in 10 mM Tris-HCl, pH 7.5. The active fractions were pooled and applied to a hydroxyapatite column (2.5 × 15 cm; Seikagaku Kogyo), and the proteins eluted by a linear gradient of sodium phosphate buffer (5–100 mM, pH 7.5). The active fractions were pooled and further purified by re-chromatography using a DEAE-Toyopearl 650M column as described above. The active fractions were pooled and concentrated to 10 mL by ultrafiltration. The concentrate was further purified by a gel filtration column (Hiprep 26/60 Sephacryl S-200 HR; Amersham Bioscience, Piscataway, NJ) pre-equilibrated with 20 mM Tris-HCl, pH 7.5, containing 0.15 M NaCl. The active fractions were pooled, concentrated to 1 mL, and the concentrate was used as the final preparation of purified enzyme throughout the experiments. The purified enzyme was designated as agaraseA33.

Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) of the purified enzyme was performed essentially as described by Laemmli [9]. Activity staining was carried out essentially as described previously [13]. The molecular mass of the enzyme was estimated by SDS-PAGE and by gel filtration on Hiprep 26/60 Sephacryl S-200 HR (Amersham Bioscience) with Precision-plus dual standards and a high-molecular-mass protein kit (Amersham Bioscience) as molecular mass standards, respectively.

For determination of internal amino acid sequences, agaraseA33 was digested with lysyl endopeptidase (Wako Pure Chemical, Kyoto, Japan) and blotted on a polyvinylidene difluoride membrane (Applied Biosystems, Foster City, CA) that had been wetted with methanol. The N-terminal amino acid sequence of the peptides was determined directly using a protein sequencer (Procise; Applied Biosystems).

Enzyme assay

A suitably diluted solution of enzyme preparation was incubated at 45°C in 50 mM N-tris(hydroxymethyl)methyl-3-aminopropanesulfonic acid-NaOH buffer (TAPS, pH 8.5), containing 5 mM CaCl2 (standard conditions) and 0.2% agar (Nacalai Tesque, Kyoto Japan). The enzyme assay and kinetic analysis followed the methods described previously [13]. One unit (U) of enzymatic activity was defined as the amount of protein that produced 1 μmol of reducing sugar as D-galactose (Sigma Chemical, St. Louis, MO) per minute under the assay conditions.

Preparation of the oligosaccharides

Enzymatic hydrolysis of agarose (Bio-Rad, Hercules, CA) with agaraseA33 was carried out under standard conditions at 40°C for 24 h. To obtain neoagarobiose, neoagarohexaose (Dextra Laboratories, Reading, UK) was hydrolyzed with β-agarase from “Pseudomonas atlantica” [10] in the manufacturer’s buffer (BioWhittaker Molecular Applications, Rockland, ME) at 40°C for 24 h. For preparation of a series of agaro-oligosaccharides, agarose was partially hydrolyzed by 0.05 M HCl at 85°C for 30 min, followed by the addition of NaOH to stop the hydrolysis and adjust the pH of the hydrolysate to neutral. Each reaction mixture was desalted using ion-exchange resins from Amberlite (Organo, Tokyo, Japan) and Diaion (Mitsubishi Chemical, Tokyo, Japan). The desalted solution was freeze-dried and dissolved in 15% acetonitrile. The sample was fractionated on a series of four gel filtration columns: two Superdex peptide 10/300 columns (10 × 300 mm; Amersham Bioscience), an Ultrahydrogel DP 120Å column (7.8 × 300 mm, Waters, Milford, MA), and a Asahipak GS220 G7 column (6.7 × 500 mm; Asahi Kasei, Tokyo, Japan), using an LC-10Avp with CLASS-VP HPLC system (Shimadzu, Kyoto, Japan) equipped with a refractive index detector (RID-10A; Shimadzu). Each fraction of oligosaccharides was pooled and freeze-dried. The samples were dissolved in 50% acetonitrile and applied to a Glyco-PakN column (7.8 × 300 mm, Waters) for further purification. After elution by 73% acetonitrile, each of the oligosaccharide fractions was freeze-dried. The degrees of polymerization of the oligosaccharides were calibrated on the gel filtration columns using the HPLC system and commercially available neoagaro-oligosaccharides (neoagarohexaose and neoagarotetraose; Dextra Laboratories) and D-galactose as standards.

13C-NMR spectroscopy of the product of agarose hydrolysis

The main product of agarose hydrolysis with agaraseA33 was purified and dried as described above, then dissolved in DMSO-d6. The sample was analyzed by 13C-NMR at 25°C on a Varian Unity Inova 500 system (Palo Alto, CA, USA) operating at 125.7 MHz, essentially as described by Rochas et al. [15]. The spectrum was recorded using a 1.4 s delay, a 45° pulse, an acquisition time of 1.1 s, a scan number of 27,104, and a 30 kHz sweep width.

Analysis of the pattern of agarose hydrolysis and substrate specificity

Enzymatic hydrolyses of agarose, agarohexaose, agarotetraose, neoagarohexaose, and neoagarotetraose were carried out under standard conditions using 1.0% of each substrate at 40°C for up to 24 h. Aliquots of the reaction mixtures were analyzed by thin-layer chromatography (TLC) using a solvent system composed of chloroform–methanol–acetic acid (3:3:1, vol/vol), as previously described [13]. Calibration of the degree of the polymerization and quantification of reaction products were carried out by gel filtration chromatography using the high-performance liquid chromatography (HPLC) system as described above. To examine the substrate specificity of the enzyme, porphyran was prepared from Porphyra yezoencis, according to the method of Takahashi et al. [19]. p-Nitrophenyl α, β-galactopyranoside and ι-,κ-, and λ-carrageenans were purchased from Sigma Chemical and used as substrates under standard conditions.

Nucleotide sequence accession number

The 16S rDNA nucleotide sequence data of strain JAMB-A33 has been submitted to the DDBJ, EMBL, and GenBank databases under accession number AB162002.

Results and Discussion

16S rDNA sequence analysis of the isolate

To determine the phylogenetic position of the agar-degrading bacterium JAMB-A33, the 1.5 kb fragment of 16S rDNA was amplified by polymerase chain reaction (PCR). The 1469 bp length of the sequence was determined and used for comparative sequence analysis against known 16S rDNA sequences. The 16S rDNA sequence of the isolate showed a relationship (95%) to each of Thalassomonas viridans or T. ganghwensis within the γ-Proteobacteria. The phylogenetic tree suggested that the isolate may be a new species in the genus Thalassomonas (Fig. 1). Further taxonomic analyses are in progress.

Production of agaraseA33

The production of agarase by strain JAMB-A33 was monitored for 4 days. The growth rate of the isolate was independent of the presence of agar and inhibited strongly by galactose in the medium. The agarase activity was detected only in the presence of agar and reached a maximum after 72 h of cultivation.

Purification of agaraseA33

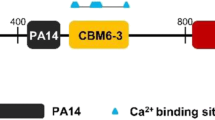

The purified enzyme had a specific activity of 40.7 U/mg. The molecular mass of the enzyme was determined to be 85 kDa by gel filtration chromatography. The SDS-PAGE of the purified enzyme gave a single band with an apparent mass of 85 kDa (Fig. 2), consistent with the result of the gel filtration chromatography. Consequently, the enzyme is suggested to be a monomeric protein, unlike the α-agarase from “A. agarlyticus GJ1B” which is a multimeric protein consisting of a 180 kDa unit with agarase activity and one or two 90 kDa units of unidentified function. The N-terminal sequence of the purified agaraseA33 could not be determined for some reason. Thus, we treated agaraseA33 with lysyl endopeptidase and determined a part of the amino acid sequence of the enzyme. A stretch of the amino acid sequence was determined to be Leu-Leu-Thr-Glu-Gly-Asn-Ile-Asn-Phe-Asp, and a BLAST search analysis (http://www.ncbi.nlm.nih.gov/) revealed that the sequence showed 80% similarity to the amino acid sequences corresponding to amino acids 1255–1264 (Ile-Leu-Thr-Glu-Asp-Asn-Ile-Asn-Phe-Asp) of the α-agarase from “A. agarlyticus GJ1B” [14].

SDS-PAGE and activity staining of purified agaraseA33. (a) SDS-PAGE of the purified enzyme (0.5 μg protein) on 7.5% polyacrylamide gel. The proteins were stained with Coomassie brilliant blue (CBB) (lane P). Protein mass markers (in kDa) are indicated on the left (lane M). (b) Activity staining of the purified enzyme.

Biochemical properties of the enzyme

The pH optim- um for activity of the enzyme was examined in various buffers. The buffers used were 50 mM 2-morpholin- oethanesulfonic acid-NaOH buffers (MES), pH 5.5–7.0; 3-morpholinopropanesulfonic acid-NaOH buffers (MO- PS), pH 6.5–7.5; TAPS, pH 7.5–9.0; N-cyclohexyl-2-aminoethanesulfonic acid-NaOH buffers (CHES), pH 8.5–10.0; and N-cyclohexyl-3-aminopropanesulfonic acid-NaOH buffers (CAPS), pH 9.5–11.0. AgaraseA33 showed activity at a wide range of pH (4.5–9.5) with an optimum at pH 8.5, more alkaline than the optimal pH of 7.2 for the reported α-agarase [14]. To determine pH stability, the enzyme was incubated at 25°C for 30 min in these buffers. The residual activity was measured under standard assay conditions. The enzyme was very stable in a broad range of pH (6–11), retaining more than 80% of the original activity. The optimal temperature for the activity of the enzyme was 45°C in 50 mM TAPS, pH 8.5, containing 5 mM CaCl2. The enzyme was stable up to 40°C during 30 min incubation in the same buffer. The enzyme showed low activity (>15%) in the absence of CaCl2 compared with the standard assay conditions (taken as 100%). When calcium ion was supplied as either nitrate or acetate salt at 1–100 mM, the same activity was observed either in Tris-acetate or in TAPS, pH 8.5, as in the standard assay conditions. The other metal salts abundant in seawater—NaCl, KCl, and MgCl2—did not significantly affect expression of the full enzyme activity. These results suggested that the enzyme requires Ca2+ ion for full activity.

Analysis of hydrolysis products and substrate specificity

After complete hydrolysis of agarose, the major product was purified and analyzed by 13C-NMR spectrometry. The spectrum of the product contained a signal at 203.9 ppm, indicating the presence of aldehydic residues, and the peak profile in the range of 60-110 ppm was in agreement with that reported for agarotetraose [15]. Six signals were assigned to the carbons (C-1, 90.77; C-2, 73.38; C-3, 83.15; C-4, 85.49; C-5, 76.43; C-6, 73.76 ppm) of the 3,6-anhydro-α-L-galactose residue (hydrated aldehydic form) at the reducing end, according to Rochas et al. [15]. These results confirmed that agaraseA33 cleaved α-1,3 linkages in agarose, and that the major product of agarose hydrolysis was agarotetraose. The products of agarose hydrolysis are suggested to exist as a mixture of the aldehyde and hydrated forms at equilibrium in aqueous solutions [14].

TLC was used to monitor the hydrolysis patterns (Fig. 3). In the initial stage, agaraseA33 hydrolyzed agarose to generate a series of agaro-oligosaccharides. The percentage of oligosaccharides larger than tetramers decreased, and a predominant tetramer was produced with concomitant production of hexamers and dimers. This hydrolysis pattern indicates that agaraseA33 is an endo-α-agarase. Reaction products after 24 h of incubation were quantified by gel filtration chromatography. The proportion of the products was calculated from area ratios on the chromatogram to be 9% agarohexaose, 77% agarotetraose, 9% agarobiose, and 5% other products. AgaraseA33 did not hydrolyze tetramers, whereas it did hydrolyze hexamers. The products of agarohexaose hydrolysis were calibrated to be tetramers and dimers on gel filtration chromatography, whereas neoagarohexaose hydrolysis produced two kinds of trimer detected at slightly different retention times on the gel filtration chromatogram. These results showed that agaraseA33 hydrolyzes α-1,3 linkages in agarose, agaro-oligosaccharides, and neoagaro-oligosaccharides comprising six sugars. The K m value for agar was 4.9 mg/mL. The catalytic efficiency (kcat/K m ) for agar was 36.3 mL/mg/sec. The α-agarase from “A. agarlyticus GJ1B” does not degrade partially methylated and sulfated agarose [14]. In contrast, agaraseA33 efficiently hydrolyzed porphyran extracted from Porphyra yezoensis, which is a highly sulfated agarose, showing 95% activity compared with agarose hydrolysis activity (taken as 100%) under the standard assay condition. Similar to other known agarases, agaraseA33 did not degrade ι-,κ-, and λ-carrageenans, which are also sulfated polysaccharides with similar backbones. These results suggested that agaraseA33 recognizes the difference in configurations of 4-linked sugars between agarose including porphyran (L-configuration) and carrageenans (D-configuration). In contrast to the reported α-agarase [14], agaraseA33 did not hydrolyze glycosidic linkages in either p-nitrophenyl α- or β-galactopyranoside.

Thin-layer chromatography (TLC) of the products of hydrolysis, by agaraseA33, of agarose and oligosaccharides with the same backbone as agarose. The reactions were carried out at 40°C at pH 8.5 in 50 mM TAPS with 0.04 U/ml enzyme and 1.0% substrates. Aliquots from the reaction mixtures were sampled and analyzed by TLC. The substrates used were as follows: agarose (lanes 1–8), agarohexaose (lane 13), agarotetraose (lane 14), neoagarohexaose (lane 15), neoagarotetraose (lane 16). Incubation times for hydrolysis were as follows: 0 h (lane 1), 0.5 h (lane 2), 1 h (lane 3), 2 h (lane 4), 3 h (lane 5), 6 h (lane 6), 12 h (lane 7), 24 h (lanes 8 and 13–16). Lanes 9 and 17, agaro-oligosaccharides obtained by acid hydrolysis of agarose; lanes 10 and 18, galactose; lane 11, 3,6-anhydrogalactose; lane 12, neoagaro-oligosaccharides including neoagarobiose, neoagarotetraose, and neoagarohexaose.

In conclusion, agaraseA33 is a novel α-agarase from a newly isolated Thalassomonas sp. It specifically cleaves α-1,3 linkages in polysaccharides and oligosaccharides with the same backbone as agarose. The enzyme has industrial importance with respect to oligosaccharide production from agar and porphyran. The nucleotide sequence encoding for this enzyme is under investigation and will be published soon. Together with these results, the enzymatic properties of this enzyme will contribute to understanding of the mechanism of the hydrolysis of α-1,3 linkages in agarose.

Literature Cited

J Allouch M Jam W Helbert T Barbeyron B Kloareg B Henrissat et al. (2003) ArticleTitleThe three-dimensional structures of two β-agarases J Biol Chem 278 47171–47180 Occurrence Handle10.1074/jbc.M308313200 Occurrence Handle1:CAS:528:DC%2BD3sXovFKktLY%3D Occurrence Handle12970344

M Duckworth W Yaphe (1971) ArticleTitleStructure of agar. I. Fractionation of a complex mixture of polysaccharides Carbohydr Res 1 189–197 Occurrence Handle10.1016/S0008-6215(00)86113-3

JC Ha GT Kim SK Kim TK Oh JH Yu IS Kong (1997) ArticleTitleβ-agarase from Pseudomonas sp. W7: Purification of the recombinant enzyme from Escherichia coli and the effects of salt on its activity Biotechnol Appl Biochem 26 1–6 Occurrence Handle1:CAS:528:DyaK2sXlsVGkurY%3D Occurrence Handle9261996

A Hosoda M Sakai S Kanazawa (2003) ArticleTitleIsolation and characterization of agar-degrading Paenibacillus spp. associated with the rhizosphere of spinach Biosci Biotechnol Biochem 67 1048–1055 Occurrence Handle10.1271/bbb.67.1048 Occurrence Handle1:CAS:528:DC%2BD3sXktlygtbs%3D Occurrence Handle12834282

I Kato (2000) ArticleTitleAntioxidative and antitumorigenic properties of agaro-oligosaccharide Bio Industry 17 13–19 Occurrence Handle1:CAS:528:DC%2BD3cXntFyktLc%3D

K Kendall J Cullum (1984) ArticleTitleCloning and expression of an extracellular-agarase from Streptomyces coelicolor A3(2) in Streptomyces lividans 66 Gene 29 315–321 Occurrence Handle10.1016/0378-1119(84)90060-X Occurrence Handle1:CAS:528:DyaL2MXhtlGj Occurrence Handle6489757

BJ Kim HJ Kim SH Ha SH Hwang DS Byun TH Lee et al. (1999) ArticleTitlePurification and characterization of β-agarase from marine bacterium Bacillus cereus ASK202 Biotechnol Lett 21 1011–1015 Occurrence Handle10.1023/A:1005604618242 Occurrence Handle1:CAS:528:DyaK1MXotFSitbs%3D

YH Kim YS Kim JR Lee EK Lee JH Seu (1993) ArticleTitleEnzymatic characteristics of an extracellular agarase of Cytophaga sp. KY-1 and molecular cloning of the agarase gene J Microbiol Biotechnol 3 31–38 Occurrence Handle1:CAS:528:DyaK2cXmslCqtrg%3D

UK Laemmli (1970) ArticleTitleCleavage of structural proteins during the assembly of the head of bacteriophage T4 Nature 227 680–685 Occurrence Handle1:CAS:528:DC%2BD3MXlsFags7s%3D Occurrence Handle5432063

LM Morrice MW McLean WF Long FB Williamson (1983) ArticleTitleβ-agarases I and II from Pseudomonas atlantica. Substrate specificities Eur J Biochem 137 149–154 Occurrence Handle10.1111/j.1432-1033.1983.tb07808.x Occurrence Handle1:CAS:528:DyaL2cXmtl2qug%3D%3D Occurrence Handle6653550

T Naganuma DA Coury M Poline-Fuller A Gibor K Horikoshi (1993) ArticleTitleCharacterization of agarolytic Microscilla isolates and their extracellular agarases Syst Appl Microbiol 16 183–190 Occurrence Handle1:CAS:528:DyaK2cXhsFyhtLk%3D

Y Ohta Y Hatada Y Nogi Z Li HM Zhang S Ito et al. (2004a) ArticleTitleThermostable β-agarase from a deep-sea Microbulbifer isolate J Appl Glycosci 51 203–210

Y Ohta Y Hatada Y Nogi M Miyazaki Z Li M Akita et al. (2004b) ArticleTitleEnzymatic properties and nucleotide and amino acid sequences of a thermostable β-agarase from a novel species of deep-sea Microbulbifer Appl Microbiol Biotechnol 64 505–514 Occurrence Handle10.1007/s00253-004-1573-y Occurrence Handle1:CAS:528:DC%2BD2cXjtFyis7o%3D

P Potin C Richard C Rochas B Kloareg (1993) ArticleTitlePurification and characterization of the α-agarase from Alteromonas agarlyticus (Cataldi) comb nov., strain GJ1B. Eur J Biochem 214 599–607

C Rochas P Potin B Kloareg (1994) ArticleTitleNMR spectroscopic investigation of agarose oligomers produced by an α-agarase Carbohydr Res 253 69–77 Occurrence Handle10.1016/0008-6215(94)80056-1 Occurrence Handle1:CAS:528:DyaK2cXivF2isLs%3D Occurrence Handle8156559

DC Schroeder MA Jaffer VE Coyne (2003) ArticleTitleInvestigation of the role of a β (1–4) agarase produced by Pseudoalteromonas gracilis B9 in eliciting disease symptoms in the red alga Gracilaria gracilis Microbiology 149 2919–2929 Occurrence Handle10.1099/mic.0.26513-0 Occurrence Handle1:CAS:528:DC%2BD3sXosVGqurk%3D Occurrence Handle14523124

Y Sugano H Kodama I Terada Y Yamazaki M Noma (1994) ArticleTitlePurification and characterization of a novel enzyme, α-neoagarooligosaccharide hydrolase (α-NAOS hydrolase), from a marine bacterium, Vibrio sp. strain JT0107 J Bacteriol 176 6812–6818 Occurrence Handle1:STN:280:ByqD2M%2FisVM%3D Occurrence Handle7961439

Y Sugano I Terada M Noma T Matsumoto (1993) ArticleTitlePurification and characterization of a new agarase from a marine bacterium, Vibrio sp. strain JT0107 Appl Environ Microbiol 59 1549– 1554

K Takahashi Y Hirano S Araki M Hattori (2000) ArticleTitleEmulsifying ability of porphyran prepared from dried nori, Porphyra yezoensis, a red alga J Agric Food Chem 48 2721–2725 Occurrence Handle10.1021/jf990990b Occurrence Handle1:CAS:528:DC%2BD3cXjvVOls7w%3D Occurrence Handle10898612

WG Weisburg SM Barns DA Pelletier DJ Lane (1991) ArticleTitle16S ribosomal DNA amplification for phylogenetic study J Bacteriol 173 697–703 Occurrence Handle1987160

WP Winter J Yodh (1983) ArticleTitleInteraction of human hemoglobin and its variants with agar Science 221 175–178 Occurrence Handle1:CAS:528:DyaL3sXks1OjtLo%3D Occurrence Handle6190229

Y Yoshizawa A Ametani J Tsunehiro K Nomura M Itoh F Fukui et al. (1995) ArticleTitleMacrophage stimulation activity of the polysaccharide fraction from a marine alga (Porphyra yezoensis): structure–function relationships and improved solubility Biosci Biotechnol Biochem 59 1933–1937 Occurrence Handle1:CAS:528:DyaK2MXptVKitrY%3D Occurrence Handle8534986

Q Zhang N Li X Liu Z Zhao Z Li Z Xu (2004) ArticleTitleThe structure of a sulfated galactan from Porphyra haitanensis and its in vivo antioxidant activity Carbohydr Res 339 105–111 Occurrence Handle10.1016/j.carres.2003.09.015 Occurrence Handle1:CAS:528:DC%2BD3sXpsVKrs7o%3D Occurrence Handle14659676

Z Zhong A Toukdarian D Helinski V Knauf S Sykes JE Wilkinson et al. (2001) ArticleTitleSequence analysis of a 101-kilobase plasmid required for agar degradation by a Microscilla isolate Appl Environ Microbiol 67 5771–5779

Acknowledgments

We are grateful to Dr. Y. Sakano of Tokyo University of Agriculture and Technology for stimulating discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ohta, Y., Hatada, Y., Miyazaki, M. et al. Purification and Characterization of a Novel α-Agarase from a Thalassomonas sp.. Curr Microbiol 50, 212–216 (2005). https://doi.org/10.1007/s00284-004-4435-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-004-4435-z