Abstract

It is necessary to have a comprehensive understanding of the flow mechanisms within drip irrigation emitters to design emitters that have a high anti-clogging performance. The use of computational fluid dynamics (CFD) to research the flow characteristics is appropriate because the labyrinth flow path is narrow and its boundary is complex. In this paper, a CFD for numeric model was developed for numerical simulation of the velocity distribution and turbulence intensity distributions within labyrinth emitters. A two-dimensional digital particle-tracking velocimetry (2D-DPIV) visual display system of the full flow fields was also constructed using plain laser inducement fluorescence velocity measurement technology, custom-made fluorescent particles and a plane model of the emitters. The object lens of a microscope was fitted to a conventional charge coupled device (CCD) camera to overcome the contradiction problems between the image viewing area and resolution power within the flow path. The measured turbulence and velocity distribution characteristics within the labyrinth flow path were in good agreement with the calculated CFD results. This enabled the optimal emitter design patterns to be determined based on the hydraulic characteristics and clogging resistance in the labyrinth flow path.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Labyrinth emitters provide the highest performance of the non-compensating drip irrigation emitters. However, the flow paths are easily clogged by the pollutants in the water because the width and depth of the labyrinth is often small, ranging in size from 0.5 to 1.2 × 10−3 m. While the use of filters and system scouring reduces emitter clogging to some extent, the key design issue is to ensure a sound flow regime in the flow path (Adin et al. 1991; Dasberg et al. 1999; Li et al. 2006). To design emitters with high anti-clogging performance, it is necessary to have a comprehensive understanding of the flow regime within the flow path. Hence, the main requirement of the flow path designers is to conduct flow analyses to visualize the full-flow fields and supply effective theoretical guidance on optimal flow path design.

The labyrinth flow path in drip emitters is narrow and complex and conventional drip tubes or belts are not transparent. Hence, there are difficulties in taking conventional measurements of flow fields for evaluating prototype designs. An augmented model of the emitter flow path and Laser-Doppler velocimetry has been used to observe the internal flow movement (Zhang et al. 2007). However, this system focused on a single point, and the augmented model did not take into account the boundary layer similar to the prototype.

There are currently no published reports showing full-field measurement within the labyrinth flow paths. Inadequate design theory has led to a series of ad hoc design modifications involving experimental testing. Thus the period of design and development of new emitters is often lengthy and expensive. However, with the rapid development of computer technology, simulation technology for complex fluid flow has developed rapidly.

Computational fluid dynamics (CFD) has unique advantages for analyzing fluid flow. It provides the opportunity to combine numerical simulation with both experimental and theoretical research to better understand the fluid movement. CFD studies method possessed the function of internal movement prediction, numerical experiment and movement diagnosis, etc. It could help the designers to select the most rapid and economical approach to conveniently optimize the various alternatives, thus significantly reducing the need for physical experimental work. It could also help to achieve the optimal design, subject to various constraints, and is an indispensable component of modern emitter design theory (Wang et al. 2006).

CFD has been used to conduct exploratory research into the property of flow movement within the labyrinth flow path of drip irrigation emitter. Palau et al. (2004) simulated the relationship between pressure and discharge rates for an in-line emitter labyrinth with the commercially available CFD software, FLUENT. Li et al. (2005) also simulated the flow characteristics within three types of column labyrinth path emitters using FLUENT, enabling the velocity magnitude, vorticity magnitude, and the turbulence intensity distribution to be visualized. Wei et al. (2006) simulated the flow characteristics in triangular, rectangular, and trapezoidal labyrinth flow paths and Zhang et al. (2007) simulated the relationship between flow rate and pressure head, as well as the flow field distribution in the small arc labyrinth channels. However, there is some debate regarding the selection of an appropriate numerical model for simulating the flow characteristic in drip irrigation emitters. The discharge of the labyrinth path emitters is generally only about 0.2–8 L h−1 at pressures of 10–150 kPa, the cross-sectional area is about 0.6–1.0 × 10−6 m2, the cross-sectional average velocity \( {\left( {\overline{\upsilon } } \right)} \) is 0.1–1.0 m s−1, and the value of Reynolds number (Re, \( Re = \overline{\upsilon } R/\nu , \) ν is the moving viscous coefficient of fluid and R is the hydraulic diameter) is about 70–1,000. Hence, some scholars (Palau et al. 2004; Zhang et al. 2007) have used laminar models to conduct the CFD numerical simulation. However, the majority of the emitter discharge exponents are in the range of 0.50–0.65, which indicates that the internal flow is turbulent (Dasberg et al.1999). Hence, some scholars (Li et al. 2005; Wei et al. 2006; Zhang et al. 2007) have recently used a turbulent model for CFD research into emitters.

Evaluations of the fractal flow path of emitters have been identified as an effective approach to realizing the goal of simultaneously improving the hydraulic properties and clogging resistance in emitters (Li et al. 2007). In this paper, a CFD numerical simulation was used to analyze the fluid movement in labyrinth flow paths and a two dimensional digital particle image velocimetry (2D-DPIV) visual display system was developed to validate the veracity of the CFD method. Numerical experimental research was also conducted to identify the optimal designs for labyrinth flow paths.

Model construction and its solution

Construction of the theoretical model

The fluid in the emitter is water, as a result, it is assumed to be viscous, steady, and incompressible at room temperature under pressures of 10–150 kPa. The fluid gravity and the surface roughness of the channel wall are considered, while ignoring the surface tension. The mathematical–physical simulation model could be established with basic controlling equations and solution-determination conditions as follows (Murray 1970).

Continuum equation

Navier-Stokes equation system

Standard k-ε equation

where U denotes fluid velocity, \( U = u\ifmmode\expandafter\vec\else\expandafter\vec\fi{i} + v\ifmmode\expandafter\vec\else\expandafter\vec\fi{j} + w\ifmmode\expandafter\vec\else\expandafter\vec\fi{k} \) (m s−1), u, v, w denote the projected values on axes of x, y, and z, respectively; ρ (kg m−3) and μ (Pa s) denote the water density and dynamical viscidity coefficient, respectively; p (Pa) is the fluid pressure; f x f y f z are projected values of mass force (considering only gravity), f x = f y = 0, f x = −g; μ t denotes the viscidity coefficient of turbulent flow; G k and G b denote the average velocity gradient and the turbulent pulse kinetic energy caused by buoyancy, G b = 0; Y M denotes the kinetic energy dissipation ratio caused by the pulse dilation, Y M = 0; The constants in the model are: C 1ε = 1.44, C 2ε = 1.92, C μ = 0.09, σ k = 1.0, σ ε = 1.3.

Finding the solution

Geometric model and computational domain

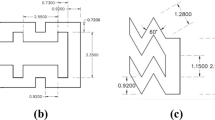

The emitter flow path consisted of the inlet, outlet and main body. The local water head loss was the main energy-dissipation pattern in the flow path of the emitter (Glaad et al. 1980), and about 98% of water head loss in dentation labyrinth flow path occurred at the dentation structure (Ozekici et al.1991). For the convenience of establishing the computational domain model (Fig. 1) and for the purpose of saving computational resources, the energy-dissipating unit of the plastic prototype of the emitter was simplified by neglecting the effects caused by the inlet and outlet. Table 1 shows the geometric parameters of the flow path.

Gridding

Grid selection is an important factor influencing the accuracy of the solution in numerical simulation methods (Zhang et al. 2007). In order to obtain high quality grids, each flow path unit was divided into five sections that were meshed with structured hexahedron grids. GAMBIT was used for gridding, and the length of the grid unit was 5 × 10−5 m. The finite volume method was solved using Eqs. (1)–(5).

Boundary conditions

To perform the CFD analysis, the pressure inlet condition was set at the emitter inlet boundary, while the pressure outlet condition was set along the external zone boundary. Except for the inlet and outlet of the flow path, the velocity vectors on the other boundaries were set to zero. The wall was assumed to behave under no-slip conditions, and a standard log-law wall function was used for the near-wall linear sub-layer.

Finding a solution to the model

The coupling implicit algorithm with definite constants was used for the numerical calculation. The first-order conservative upwind difference scheme was used for pressure items. SIMPLEC was used for coupling between pressure and velocity (Fluent Inc. 2003). The convergence accuracy was chosen to be 1 × 10−4.

Construction of visual display system with 2D-DPIV

System integration and its key components

The 2D-DPIV system was used to display the internal flow within the emitter and consisted of both hardware and software components. The hardware included a dual-pulse LASER, CCD camera, synchronic controller, image-collection board, and a computer. The software required was used for image-collection, display, velocity calculation, and velocity field analysis.

Image collection and processing

The 2D-DPIV system of image collection and processing consisted of a frame straddle CCD, wave-filtering slice, image-collection board, and a computer. The digital camera was a Kodak MEGAPLUS II [resolving power of 1,600 × 1,200 (2M)]. The dimension of emitter flow paths is usually 0.5–1.2 × 10−3 m and dentation interval is usually within 3.0–5.0 × 10−3 m. The large viewing area associated with when using the conventional DPIV system for measurement, resulted in low image quality and test accuracy. In this application, the viewing area being (0.5 × 10−3) m × (0.5 × 10−3) m, the system could not display the flow movement characteristics around each dentation, hence the CCD camera was modified by installing a G10-2111 (Beijing Daheng Camera Company) microscope object lens (fourfold) to obtain an appropriate digital-image resolving power with a viewing area of (4 × 10−3) m × (4 × 10−3) m.

Laser light source

Laser emitters have been used as the light source in the DPIV measurement because they are high-energy monochrome sources with high stability, directional control and pulse control. The dual-pulse laser emitter used in this DPIV system was a t Q Nd; YAG (LABEST Company). The laser emitter had a work frequency of 10 Hz, wave length of 5.32 × 10−7 m, laser energy of 0.05 J, pulse width of (6–8) × 10−9 s, radiating angle of 0.6 mrads, super Gauss facula mode and a dual-pulse time interval of less than 1 × 10−6 s.

Analysis software

The system analysis software used was MicroVec Version 2.0 developed by Wei Yunjie. Tecplot 9.0 was used for displaying the whorl fields.

Tracing fluorescence particles of 2D-DPIV

An important factor in the operation of the DPIV system is the tracing particle. Tracing particles have been developed in some countries. However, during the process of manufacturing plain model, the existence of nick caused noise in the shooting images and reduced the accuracy of velocity measurement (Fig. 2). Hence this paper introduced plane laser inducement fluorescence technology and used wave-filtering slice to eliminate the noise beyond the fluorescence. Custom-made fluorescence particles that could be suspended in water with a micro-disturbance were constructed from polystyrene (density of 1.02 kg m−3), with an average diameter of (1–1.5) × 10−5 m. The particles produced an adequate dispersion response to the laser (fluorescence wave band of 6.20 × 10−7 m) and a wave-filtering slice was used to eliminate all noises in the plane model.

The concentration of the tracing particles affects the ability of the DPIV system to accurately identify the flows. High concentrations of the particles affected the velocity field and could cause 2-phase flow. However, low concentrations of tracing particles could affect the measurement accuracy. Preliminary experiments showed that 1–2% was an appropriate concentration of fluorescence particles for the DPIV system.

Characteristics of fluid flow in the fractal flow path of emitters

Characteristics of velocity distribution

A digital camera was used to obtain photos of the flow fields. The characteristic parameter distribution (e.g., velocity) on a profile was achieved by correlation analysis between the two adjacent frames of particle images. Figure 3 shows images of the particle flow fields in the flow path and Fig. 4 shows the resulting velocity distribution under 10, 50, 100 and 150 kPa. Some whorls were observed in the labyrinth flow path. However, the velocity distributions were similar under the four different pressure levels. The velocity distribution could be divided into regions experiencing mainstream velocity and secondary flow velocity regions. The mainstream swayed on both sides of the flow path. The mainstream continuously mixed into the secondary flow and energy exchange continuously occurred to dissipate the pressured energy. From this, it is concluded that the flow within the labyrinth flow paths were turbulent at these pressures and that there was no transition from laminar to turbulent flow within this pressure range. Hence, the turbulent model should be used in CFD numerical simulation for pressures, in the range of 10–150 kPa.

The velocity in the mainstream was high, while the velocity in the secondary flow region was low (Fig. 4). The regions of low velocity included A, B, C and D (Fig. 4a). Small particles tend to subside in regions of low velocity and may eventually block the emitters. Hence, while designing the rational flow paths, the design should eliminate regions of low velocity by creating smooth arc connections in these regions. This will also enhance the self-cleaning capacity by optimization of the flow path boundaries. With increasing pressure, the region of low velocity gradually diminished and the velocity adjacent to the boundary increased. Hence, the optimal arc radius will be different for emitters designed to operate at different pressures.

Figure 5 shows the CFD analysis of velocity distribution under different pressures. Comparison of Fig. 4 and Fig. 5 suggests that the CFD calculated results are in good agreement with the physical testing, confirming the appropriateness of using CFD analysis to evaluate emitter performance in the 10–150 kPa pressure range.

Characteristics of turbulence intensity distribution

The turbulence intensity is one physical variable describing the turbulence strength of the flow and it can be used as one of the indices for describing the energy dissipation properties of emitters. By experimental research, Murray (1970) showed that the reduction in particle sedimentation rate increased with respect to increasing flow turbulence intensity. This indicated that the pollutant carrying capacity of turbulent flow increased with turbulence intensity. Hence, the turbulence intensity could be used as one of the indices for describing the clogging resistance of emitters.

Figure 6 shows the turbulence intensity distributions in conventional labyrinth flow path and fractal flow path under the pressure of 100 kPa. The figure also indicates that the turbulence intensity in the fractal flow path was higher than that in the labyrinth path. The turbulence intensity along the whole mainstream was similar, which could explain why the index of flow regime in the fractal flow path was smaller than that in the conventional flow path. Figure 6a, b indicates that the turbulence intensity in the unit length of two labyrinth flow paths increases along the flow direction (Li et al. 2005). The turbulence intensity in the whole flow path displayed a cyclical repetition from weak to strong but the straight-line portion of the flow path weakened the turbulence intensity. Hence to increase the turbulence intensity, the length of straight line in the flow path should be reduced. Where there are more energy dissipation nodes in the fractal flow path, the turbulence intensity along the whole path is maintained at a relatively high level.

Optimal designs for fractal flow path

There were some low velocity regions in the flow path (Fig. 4). Because energy was dissipated in the low velocity regions, pollutants could be deposited causing path clogging (Shi et al. 1995). Based on the requirement for emitters to enhance clogging resistance, the flow path should be designed in order to avoid or limit the existence of low velocity regions.

Numerical experimental design

Velocity in region D (Fig. 4) was relatively high, where the arc connection had a radius of 0.5 W (W denotes the path width). The same arc connection treatment was applied in regions A and C where the secondary flow area was similar. Refer to Table 2 for details, and Fig. 7 shows the gridding.

Effect on hydraulic characteristics of different designs

Table 3 shows the numerically simulated free discharges of the prototype and optimized emitters modeled under different pressures. The results indicate that the discharge of various optimized models were all smaller than that of the prototype emitter with a discrepancy of less than 10.0%. There was no significant difference in the free discharges of the optimized emitters with various arc treatments. This also reflected that the reduction in cross-section could increase the friction-resistance and enhance the hydraulic characteristics of the flow path.

Table 3 shows the results of the indices of flow regime (x) and the discharge coefficient (K d) by the regression equation q = K d h x (q is the free discharge and h is the work pressure). The results indicate that the indices of flow regime for various optimized emitters were all smaller than that of the prototype emitter with a discrepancy of less than 6.0%. This also shows that the optimization treatment had little effect on the hydraulic characteristics of the flow path. Hence, the clogging resistance property should be considered in optimal design of emitter flow paths and the self-cleaning capacity could be enhanced by increasing the velocity of flow near the boundary wall of the path.

Effect on clogging resistance characteristics by different optimization treatments

Changing the structure of the flow path is one approach to enhancing the clogging resistance of the flow path. From the perspective of the flow path, there are two main reasons for clogging. One reason is that the flow path is narrow and large suspended particles cannot pass easily. The other reason is that the low-flow velocity causes some suspended particles to deposit and reduce the cross-section of the flow. The latter phenomenon is not apparent initially but the effect worsens over time. Tong et al. (1998) showed that the number of suspended particles deposited in the low velocity region increased gradually. However, increasing the velocity near the boundary wall of flow path could prevent or alleviate clogging in the path.

Figure 8 shows the numerical experiment results of the velocity distribution in the typical unit of the flow path with treatments 1–9 at 100 kPa. These data show that the secondary flow developed in regions A and C with treatments 1–9 operating at 100 kPa. Howver, the velocity near the boundary wall increased as the arc radius was reduced. For region B, secondary flow was difficult to develop and the velocity of secondary flows under various treatments were not significantly different. Hence, in this region the secondary flow should be eliminated. Treatment 6 was selected as the best combination of the arc radii and Fig. 9 shows the velocity in the typical unit length of the path.

Discussion

Direct particle imaging

This paper has reported on the development of a full-field non-disturbance test for evaluating the flow path of emitters. However, some problems with the system should be noted:

-

(1)

The experiment applied the plane model of labyrinth flow path of cylindrical emitters and ignored the roughness of the model and the circumfluent issues. From the geometric perspective, there is some roughness on the path wall except for specially processed fine surfaces. In engineering practice, the roughness of the solid surface is usually 1.0–25.0 × 10−6 m. For single-phase flow, considering the path wall as geometrically smooth surface does not cause irrational results in practice. However for 2-phase flow, the particle dimension and path surface roughness are on the same scale. In this case, if the path wall is considered as geometrically smooth, then the vertical velocity of the particle would approach zero resulting in an inappropriate increase in collisions between path wall and the particles. The DPIV test showed that relatively large errors occur where the particle concentration is high and there are differences in manufacturing workmanship between the plane model and the plastic model. In addition, the boundary of labyrinth flow path and the collision mechanism between particles and path wall are both complex. Hence there is a need to conduct prototype research using plastic emitters.

-

(2)

This work has shown the presence of two-dimensional flow within the labyrinth path of emitters. However, the properties of flow, adjacent to the path wall and the possible existence of secondary flow on the cross-section needs further research.

CFD analysis

Using CFD for analyzing the flow fields of irrigation emitters is a relatively new research application and the stable-status theory and the macro-dimension model are all approximating approaches. Hence, there are three types of problems for this area of research:

-

(1)

Stable-status treatment. Treating the flow in the path as a continuous stable-status flow cannot describe the response of drips from the emitter outlet to the flow process. Under high pressure, the stable-status treatment could be appropriate but large errors may occur under low pressures when a non-stable status treatment should be implemented.

-

(2)

Boundary wall treatment. Using a boundary wall function to treat the flow near the boundary wall can cause errors because the boundary wall function is applicable only for parallel walls within a certain range. The complex structure of emitters, complex bending of the flow and different thickness of boundary layers can all produce errors.

-

(3)

Single-phase flow. This research on clogging resistance was based on the assumption that the flow was single-phase. Further research should focus on using multi-phase flow assumptions for analyzing the flow locus of microorganisms, viscous particles and suspended sands. The critical non-depositing velocity of the particles as well as the interactive effect between particle concentration, particle sizes and the flow should be further studied.

Conclusions

This paper used CFD analysis and direct particle imaging to study the flow charateristics in labyrinth flow paths. Custom-made fluorescence particles were developed and used with DPIV measurement technology to measure the flow fields of emitters and conduct two-dimensional non-disturbance tests within the flow path of emitters. An object lens-modified microscope fitted to a conventional CCD camera was used to display the flow fields and successfully solved the contradiction between viewing region and imaging resolving power within the critical scale of the flow path. Based on this research, the following findings can be made:

-

(1)

Velocity distribution differences were used to divide the flow into mainstream and secondary flows. The mainstream continuously mixed into the secondary flow and energy exchange continuously occurred in the flow path. The mainstream flow was turbulent at pressures between 10 and 150 kPa and there was no transition process from laminar to turbulent flow observed with increasing pressure. Hence, the turbulent model could be used for CFD numerical simulation in this pressure range. The simulated velocity distribution for the central cross-section of the emitter flow path was similar to the measured velocity distribution by the 2D-DPIV test. Hence, the established numerical simulation model for flow in the labyrinth flow path relatively described the flow process accurately.

-

(2)

Designing of rational flow paths should involve eliminating the regions of low velocity by creating smooth arc connections in these regions and enhancing the self-cleaning capacity by optimization of flow path boundaries. Evaluations of nine optimization treatments for labyrinth flow paths had little effect on the hydraulic characteristics of the flow path. Hence, the clogging resistance property should be given consideration in optimal design of flow path of emitter and the self-cleaning capacity should be enhanced by increasing the velocity of flow near the boundary wall of the path. This work suggests that the value of 0.5 W arc radius should be used in regions A and C, while the value of 1.0 W arc radius should be used in region B.

References

Adin A, Sacks M (1991) Drip-clogging factors in wastewater irrigation. J Irrig Drain Div ASCE 117(6):813–826

Dasberg S, Or D (1999) Drip irrigation. Spinger, Heidelberg

Fluent Inc (2003) FLUENT User’s Guide. Fluent Inc

Glaad YK, Klous LZ (1980) Hydraulic and mechanical properties of Drippers. In: Proceedings of the second international drip irrigation congress. 7–14 July

Li GY, Wang JD, Alam M, Zhao YF (2006) Influence of geometrical parameters of labyrinth flow path of drip emitters on hydraulic and anti-clogging performance. Trans ASABE 49(3):637–643

Li YK, Yang PL, Ren SM, Wang Y. (2005) Analyzing and modeling flow regime in labyrinth path drip irrigation column emitter with CFD. J Hydrodyn Ser A 20(6):736–743 (in Chinese)

Li YK, Yang PL, Ren SM, Guan XY. (2007) Effects of fractal flow path designing and its parameters of emitter hydraulic performace. Chin J Mech Eng 43(7):109–114. (in Chinese)

Murray SP (1970) Settling velocities and vertical diffusion of particles in turbulence water. J Geophys Res 75(9):73–84

Ozekici B, Ronald S (1991) Analysis of pressure losses in tortuous-path emitters. ASAE, pp 112–115

Palau SG, Arviza VJ, Bralts VF. (2004) Hydraulic flow behavior through an in-line emitter labyrinth using CFD techniques. In: 2004 ASAE/CSAE Annual international meeting. Fairmont Chateau Laurier, the Westin, Government Centre Ottawa, ON, Canada

Shi XL, Zhang MZ (1995) Chemical water quality treatment for emitter clogging. Water Sav Irri (2):39–42 (in Chinese)

Tong ZY, Wang CL (1998) The physical–chemical mechanism for solid particles to form and grow in water body of dripping irrigation. Water Sav Irri (5):31–33 (in Chinese)

Wang FJ, Wang WE (2006) Development and issues of CFD analysis researches on flow path of emitters. Trans CSAE 22(7):188–192 (in Chinese)

Wei QS, Shi YS, Dong WC, Lu G, Huang SH (2006) Study on hydraulic performance of drip emitters by computational fluid dynamics. Agric Water Manage 84(1–2):130–136

Zhang J, Zhao WH, Wei ZY, Tang YP, Lu BH (2007) Numerical and experimental study on hydraulic performance of emitters with arc labyrinth channels. Comp Electron Agric 56:120–129

Acknowledgments

We are grateful for financial support from the National Natural Science Fund of China (NSFC) (No. 50379053, No.50609029) and support by the Program for Changjiang Scholars and Innovative Research Team in University (PCSIRT) (No.IRT0657) and the Initiating Research Fund from China Agricultural University (No.2005065).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by S. Raine.

Rights and permissions

About this article

Cite this article

Li, Y., Yang, P., Xu, T. et al. CFD and digital particle tracking to assess flow characteristics in the labyrinth flow path of a drip irrigation emitter. Irrig Sci 26, 427–438 (2008). https://doi.org/10.1007/s00271-008-0108-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-008-0108-1