Abstract

Subway traffic is now being developed in China on a large scale and the planning subway stations are often located in dense district with tall building. The dewatering of confined aquifer may cause ground settlement, the cracking, deformation and tilting of the building, and even collapse. Combing with the dewatering project of environment protection of the pit of Yishan Road station of Shanghai subway No. 9, through the inversion of seepage parameters based on the field pumping test, the hydraulic barrier function of the underground continuous wall is simulated. The result indicates that with the reduction of the exposed length of the filter tube and the increase of that enclosed, the drawdown of the confined aquifer decreases. Especially with the increase of the enclosed length of the filter tube, the drawdown outside the pit can be controlled effectively. According to the result of the numerical simulation, the design of the continuous concrete wall of the pit for Shanghai Subway No. 9 is altered and the depth of the continuous concrete wall of the standing part and that in the end well are increased to 61 and 62 m, respectively. The monitored result of the equal drawdown pumping test indicates that the drawdown outside the pit with a distance of 1–6 m to the wall is less than 2 m; It means that there is nearly no influence on the environment around the pit during dewatering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The characteristics of seepage in the foundation pit with the hydraulic barrier such as the underground continuous wall have been discussed by Chinese scholars. According to the different position of the bottom of the underground continuous wall in aquifer, three types of seepage around the foundation pit were proposed by Wu et al. (2003): (1) the bottom of the underground continuous wall is located in the impermeable aquifer and the groundwater can be prevented from flowing into the pit; (2) the pit is built in the unconfined aquifer–aquitard–confined aquifer, and the bottom of the underground wall is located in the aquitard in which water can also be prevented effectively; and (3) the underground wall is located in the lower or middle part of the confined aquifer in which the majority of the confined aquifer between inside and outside of the pit is isolated. The properties of seepage of the above were also discussed by Wu. The seepage near the hydraulic barrier (pile foundation) was studied by Wang et al. (2001) with two-dimensional finite element method. According to the third type of seepage in the foundation pit presented by Wu, the seepage is closely related to the properties of the hydraulic barrier and the shape of the pit. For example, the shape of the pit may be square, circular, rectanglar or of other combined type, and the seepage should be considered as a three-dimensional flow, especially around the corner of the pit for its spatial characters of deformation and stress. It is inaccurate to use the two-dimensional finite element method to solve the above problem. Based on the two-dimensional finite element method, the seepage field and penetrating force at different stages of the pit construction were analyzed by Yu et al. (2002). But they discussed mainly the unconfined water, not the confined water. The seepage around the pit without the hydraulic barrier was studied by Zhang et al. (2002). The three-dimensional finite element method was adopted by Shi (2004) to discuss the influence of the successive wall depth and the discharge of the seepage field of the unconfined water. Therefore, it is necessary to study the hydraulic barrier function of the underground continuous wall during the dewatering of the confined water.

The subway traffic is now being developed in China on a large scale and the planning subway stations are often located in dense district with tall building. The dewatering of confined aquifer may cause ground settlement, the cracking, deformation and tilting of the buildings, and even its collapse. Therefore, it is important to protect the environment during dewatering. Based on the dewatering project of the pit of Yishan Road station of Shanghai subway No. 9, this paper presents the result of the field pumping test and discusses the function of the hydraulic barrier of the underground continuous wall. The conclusion provided in this paper can guide the protection of the environment for the similar dewatering project.

Description of the problem

The structure of the underground continuous concrete wall and the requirement of the environmental protection around the pit for Yishan Road station

Yishan Road station is located at Yishan Road with four storied island platform structure and the terminal station of Shanghai subway No. 9. It extends from the west (West Zhongshan Road) to the east (Kaixuan Road) with a total distance of 297.40 m. The width of its standard part is 21.2 m (Fig. 1). According to the primary design, the thickness of the underground continuous concrete wall is 1.2 m. The depth of the underground continuous wall is 48 m in the standard part and 51 m in the end well respectively.

The environmental conditions around Yishan Road station are very complex, and it requires high level of environmental protection. The middle part of the south side of Yishan station is Shanghaiqijian Decoration Building with 17 storied concrete frame structure, which is 14 m away from the boundary of the enclosure protection of the pit; in the north of the station are Jianshijia Building and Jinyindao Material Hall, which are 13 m away from the pit. In its east, there are Mingzhu viaduct and the Yishan Road station of Mingzhu subway. The minimum distance is 7 m between the pile cap of Mingzhu viaduct and the pit while that between the Yishan Road station of Mingzhu subway and the pit is 23 m; the west of the station is Zhongshan viaduct with a minimum distance of 25 m between its center and the pit. All the buildings and roads have a strict requirement for settlement control which is mainly caused by dewatering of the confined aquifer.

The hydrogeological condition of the pit for Yishan Road station

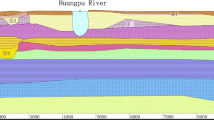

According to the geotechnical investigation report of Yishan Road station, the main types of groundwater in the pit are the unconfined water in the shallow clay aquifer, the sub-confined water in the shallow aquifer of silt soil and the confined water in the deep aquifer of silt and sandy soil (Fig. 2). The water table of the unconfined water is usually 0.3–1.5 m below the ground surface and its annual value is 0.5–0.7 m. The buried depth of water table of the sub-confined water (Layer ④2 and Layer ⑤2–2) and the deep confined water (Layer ⑦) are 3–6 and 4–12 m usually both being lower than that of the unconfined water. The groundwater table is influenced by many factors, such as season, climate, rainfall, tide etc. In an area where it is close to the river, the water table is mainly influenced by the tide, especially in an aquifer of silt and sandy soil. Based on the primary exploration and recharge test, the buried depth of the confined water table of Layer ⑦ is 5.86–8.64 m.

Table 1 shows the result of the indoor penetration test for aquifers ②, ③, ④1, ④2, ⑤1–1, ⑤1–2 and ⑤3. Aquifer ⑦ mainly consists of silt sand and it is impossible to obtain the sample for the indoor penetrating test, thus its permeability coefficient is obtained by the field pumping test.

Three-dimensional numerical simulation analysis on the dewatering of the pit for Yishan Road station

Field pumping test

According to the primary design, the depth of the underground continuous wall is 48 m. To obtain the permeability coefficient of aquifer ⑦, the field pumping test was carried out in September, 2005. The layout of three pumping wells is in a triangle as shown in Fig. 3. The space between them is 15 m. The depths of pumping wells are 61, 63 and 65 m while that of the filter tube in each well is from 53 to 60, 53–62 and 53–64 m (Fig. 4). Meanwhile, three observation wells are located in aquifer ⑦ with the same depth of 60 m. Observation well No.1 is located at the center of the three pumping wells and the distances to the center of the two observation wells are 15 and 30 m, respectively. For shallow aquifers, one observation well is located in aquifer ⑤2 with a depth of 42 m; two observation wells are located in aquifer ④2 with the same depth of 20 m.

The field pumping test includes the single-well pumping test and multiple-well pumping test. Three single-well pumping tests are carried out and each of them last 1,440 min; multiple-well pumping test began from 1 September 2005 and finished on 16 September 2005.

Numerical simulation analysis of three-dimensional for the parameter inversion of aquifer ⑦, based on the field pumping test

To obtain the hydrogeological parameters of aquifer ⑦ for the forward analysis, the three-dimensional numerical inverse simulation is carried out based on the result of the field pumping test. To ensure the consistency and rationality of the result of the numerical simulation, both the forward analysis model and inverse analysis model are used in the same discrete grids. The finite difference method (FDM) is adopted in the two models. According to the influence radius of many pit dewatering projects, the calculation range of the two models is defined as 1,000 × 1,000 m away from the pit (Fig. 5) and the whole calculation area is divided into 270,976 units. In the vertical direction, 150 m below the ground is considered in the two models on the basis of the geotechnical exploration. The initial head of each unit is obtained from the field observation result. The boundary condition of the two models is defined as a constant head boundary.

After the three-dimensional FDM simulation, the permeability coefficient of Layer ⑦ which is obtained from the field pumping test is modified by fitting the calculated value and observation value (Table 2).

Analysis on the hydraulic barrier function of underground continuous concrete wall

Primary design for the dewatering of the pit

Yishan Road subway station includes four pits and Pit No. Z3 has the nearest distance to the pile cap of Mingzhu viaduct which is the object to be studied in this section. Based on the calculation result against piping, six pumping wells (Y3-1, Y3-2, Y3-3, Y3-4, Y3-5 and Y3-6) are applied to discharge the confined water. Their depths are 60 m while the depths of their filter tube are from 53 to 60 m. Meanwhile, two observation wells Y3 and G3-1 are placed to obtain the confined water table during dewatering (Fig. 6).

Forward analysis for the hydraulic barrier function of the underground continuous wall on the basis of FDM method

According to primary design, the buried depth of the underground successive wall in the standard part of Pit No. Z3 is 48 m and that in the end well part is 51 m. The elevations of the filter tube of the pumping well are −55.34 to −48.34 m. The elevation of the bottom of underground continuous wall is −43.34 m in the standard part and −46.34 m in the end well. The entire filter tube is exposed to the confined aquifer completely in the primary design. The result of FDM simulation analysis shows that outside Pit No. Z3, the maximum drawdown is 13.04 m at 5 m away from the pit, which cannot meet the requirement of the environmental protection and may cause differential settlement and other serious environmental problems.

To meet the requirement of environmental protection, the increase of the buried depth of the underground continuous wall is a feasible and efficient way. In the FDM simulation analysis presented in this paper, the buried depth of the successive wall increases gradually from 53 (elevation being −48.28 m) to 62 m (elevation being −57.28 m) with a step of 1 m each time. Meanwhile, the maximum drawdown at every observation point with a distance of 5, 10, 20 and 40 m away from the underground continuous wall is recorded to calibrate the simulation result (Fig. 7). With the reduction of the exposed length of the filter tube and the increase of the depth of the continuous wall, the drawdown of the confined aquifer outside the pit decreases (Figs. 8, 9). Especially when the enclosed length of the filter tube is increased to 2 m, the maximum drawdown outside Pit No. Z3 at a distance of 5 m is reduced to 1 m and it will not cause settlement around the pit.

The reason for the reduction of drawdown outside the pit by increasing the depth of underground continuous concrete wall is as follows: (1) when the bottom of the continuous wall is located at the lower-middle or middle part of the confined aquifer, the groundwater will flow to the bottom of the underground continuous wall first and then flow into the filter tube, which will cause the increase of seepage distance and the decrease of the drawdown outside the pit on the basis of the constant hydraulic gradient; (2) the soft soil in Shanghai is anisotropic in permeability and its vertical penetrating coefficient is usually less than its horizontal penetrating coefficient. When the horizontal flow line of groundwater is changed to the vertical, less quantity of water is needed to meet the same drawdown requirement in the pit under the constant hydraulic gradient and it will reduce the disturbance of the groundwater.

Linear relationship between the exposed length of the filter tube and the drawdown of the confined water outside the pit is obtained by regression analysis. Table 3 shows the formulas between the drawdown and the exposed–enclosed length of the filter tube and it can be adopted for the evaluation of the hydraulic barrier function of the underground continuous wall.

Verification and application of three-dimensional numerical simulation results

According to the above analysis, the buried depth of underground continuous wall in the standard part and in the end well of Pit No. Z3 were increased to 61 m and to 62 m at the end of 2005. After the underground wall was built in April, 2007, the result of the pumping test based on the equal drawdown condition indicates that when the drawdown in the pit achieves its requirement, the drawdown of the observation well G3-1 (1 m away from the pit boundary), Y3 (6 m away from the pit boundary), and Y4-5 (10 m away from the pit boundary) (Fig. 6) are less than 2 m (Fig. 10). The result proves that the increase of the depth of the underground continuous concrete wall can reduce the drawdown outside the pit and it will help us to achieve the goal of environmental protection during dewatering. It also proved that the predicted value of three-dimensional FDM model has a good agreement with the monitored value.

Conclusions

Many planning subway stations in Shanghai are often located in dense district with tall buildings. The dewatering of the confined aquifer during the pit construction of the subway station may cause ground settlement, the cracking, deformation and tilting of the buildings, and even collapse. It is important and essential to protect environment during the dewatering of the foundation pit project.

A case study on Yishan Road subway station is presented in this paper. According to the result of the field pumping test, the three-dimensional model is applied to obtain the inverse permeability coefficient of Layer ⑦ by the method of FDM and that is the basis of the forward analysis for the hydraulic barrier function of the underground continuous concrete wall.

This paper presents the forward analysis for the hydraulic barrier function of the underground continuous concrete wall on the basis of inversion parameters. With the increase in the depth of the continuous wall, the exposed length of the filter tube as well as the drawdown outside the pit decreases. Especially when the enclosed length of the filter tube increased to 2 m, the maximum drawdown outside the pit is less than 1 m. In that case, dewatering will not affect the environment around Pit No. Z3.

The exposed length of the filter tube has a good linear relation with the drawdown outside the pit. Based on regression analysis, the formulas of the relationship between the drawdown outside the pit and the exposed length of the filter tube can be obtained and it is useful for analyzing the hydraulic barrier function of the underground continuous wall.

According to the result of the three-dimensional numerical simulation analysis, the depth of the underground continuous wall of the pit for Yishan Road subway station is increased. The field equal drawdown test indicates the drawdown outside the pit, such as G3-1 (1 m away from the underground wall), Y3 (6 m away from the underground wall) and Y4-5 (10 m away from the underground wall) are less than 2 m. The result proved that with the increase of depth of the underground continuous concrete wall, the drawdown outside the pit decreases and it will achieve the goal of the environmental protection successfully.

Generalizing the geological information and determining the hydrogeology parameters properly are very important in creating numerical model of dewatering project. Based on the field geological information and the numerical simulation analysis of three-dimensional for the parameter inversion of aquifer ⑦, three-dimensional FDM numerical model is applied to analyze the dewatering of pit No. Z3 of Yishan road station. The equal drawdown test indicates that the predicted value of the three-dimensional FDM model has a good agreement with the monitored value and it can guide similar project.

References

Shi Y (2004) The 3-D finite element analysis for unsteady seepage in excavation engineering. Thesis submitted to Tianjin University for the Degree of Master of Engineering in Science

Wu LG et al (2003) Design and construction of dewatering engineering and theory of pit seepage. China Communication Press, Beijing

Wang GG, Yan P, Gong XN, Wang CH (2001) Research on the seepage field of excavation with waterproof structure. Ind Constr 31(4):43–45

Yu HL, Lu JF, Li SD (2002) Study on seepage field characteristics of foundation pit excavation. J Zhejiang Univ China (Science Edition) 29(5):595–600

Zhang JX, Li L, Zhang BS (2002) 3D calculation and analysis of seepage in pit dewatering. Geotech Eng Field 5(5):50–51

Acknowledgments

This work presented in this paper was supported by the research grant (No. 50579097) from National Natural Science Foundation of Ya Longjiang hydropower of China, the research grant (No. 062012004) from Scientific Climbing Plan of Shanghai Science Committee of China and the research grant (No. 2006CB403200) from National Basic Research Program of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Hu, L., Wu, L. et al. Hydraulic barrier function of the underground continuous concrete wall in the pit of subway station and its optimization. Environ Geol 57, 447–453 (2009). https://doi.org/10.1007/s00254-008-1315-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00254-008-1315-z