Abstract

Heart failure (HF) is a coronary disease that affects people worldwide and has a high mortality rate. N-terminal pro-brain natriuretic peptide (NT-proBNP) has been proven to be a useful and accurate biomarker for diagnosing systolic HF. Here, we report a strategy for the high-level production of recombinant (r)NT-proBNP in Escherichia coli. An Fh8 tag with six histidines was fused to the N terminus of NT-proBNP along with the recognition site of tobacco etch virus (TEV) protease; the 6HFh8-NT-proBNP fusion peptide was expressed in flask cultures of E. coli in almost completely soluble form. The peptide was purified by HisTrap affinity chromatography, and the N-terminal tag was cleaved by TEV protease. After a second round of HisTrap affinity chromatography to remove the TEV protease and N-terminal tag, rNT-proBNP was isolated with high purity (≥ 98%) by carboxymethyl cation exchange chromatography. The final yield of purified rNT-proBNP (97.5 mg/l of bacterial culture; 3.25 mg/g of wet cell) was 55-fold higher than that reported in previous studies (0.5–1.75 mg/l of bacterial culture). Furthermore, the high cell density E. coli fed-batch culture enabled high-level production of rNT-proBNP in the order of grams per liter. The purified rNT-proBNP was detected by enzyme-linked immunosorbent assay and chemiluminescence enzyme immunoassay using commercial monoclonal antibodies recognizing different epitopes, showing a linear dose-response relationship in the range of tested concentrations (slope = 3.58 and r2 = 0.995). These results demonstrate the efficiency of our process for mass producing (gram-to-liter level) rNT-proBNP with acceptable analytical performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Heart failure (HF) is a syndrome characterized by inefficient heart pumping, which is manifested as dyspnea, irregular heartbeat, rapid weight change, and chest pains (Jurgens et al. 2011). Millions of people worldwide—mostly elderly—experience HF each year, and only 50% have a life expectancy longer than 5 years (Ashrafian et al. 2007; Diez-Villanueva and Alfonso 2011; Natella et al. 2017). Early detection and treatment can help improve the prognosis of patients with suspected HF (Setoguchi et al. 2007).

Myocardial stretching leads to the production of prohormone brain natriuretic peptide (proBNP), a 108-amino acid (a.a.) peptide that is cleaved into the 76-a.a (Fig. 1). BNP and 32-a.a. N-terminal (NT)-proBNP are continuously released from the ventricles into blood (Hall 2005; Lippi and Sanchis-Gomar 2016). The half-life of NT-proBNP is six times longer than that of BNP (Weber and Hamm 2006), and the peptide is cleared from the body via the renal system and other mechanisms. BNP and NT-proBNP levels are elevated in patients with HF (Nishikimi et al. 2006; Omar and Guglin 2016), making them useful diagnostic biomarkers (Calzetta et al. 2016; Lippi and Sanchis-Gomar 2016; McKie and Burnett 2016; Zile et al. 2016).

The NT-proBNP immunoassay is one of the most widely used methods for diagnosing HF. The Elecsys NT-ProBNP test kit from Roche Diagnostics (Basel, Switzerland) has been commercially available since its approval by the US Food and Drug Administration in 2006, and similar products have recently been developed by other manufacturers. As a component of diagnostic kits, NT-proBNP has a longer shelf life than BNP (Ordonez-Llanos et al. 2008), as well as higher sensitivity for excluding dyspnea that is not caused by HF (Su et al. 2015), and can also aid with the diagnosis of pulmonary heart disease, anemia, myocardial disease, and heart valve disease. Several studies have reported a strong correlation between NT-proBNP level and rate of mortality from HF (Oremus et al. 2014; Zhang et al. 2013). The discourse for standardization of NT-proBNP was also recently published (Semenov and Feygina 2018), and efforts are underway to use NT-proBNP as a guide in patient prognosis (Latini and Masson 2013). Moreover, NT-proBNP is a convenient standard for native protein studies (Crimmins and Kao 2007). Thus, there is a growing interest in NT-proBNP peptide in both research settings and the pharmaceutical industry.

The limiting parameter in the production of NT-proBNP is cost; commercially produced NT-proBNP costs almost $1000 per 0.1 mg (MyBioSource, San Diego, CA, USA). Therefore, a lower-cost method for NT-proBNP production and purification is desired. In this study, we generated recombinant NT-proBNP (rNT-proBNP) harboring a Ser-Ser (SS) linker using Escherichia coli as host cells. Ion exchange chromatography was used for the three-step purification process. A previous study reported a low yield for purified NT-proBNP in the range of 0.75–1.5 mg/l bacterial culture (Ala-Kopsala et al. 2004; Soleh et al. 2014). Our method had a much higher yield and can thus serve as a reference for increasing the profitability of commercial rNT-proBNP production.

Materials and methods

rNT-proBNP expression vector and host strain

E. coli was used as a host cell for efficient production of (r)NT-proBNP; Fh8 peptide (GenBank accession no. AF213970) from Fasciola hepatica parasite was used as a solubility enhancer and fusion tag (Fraga et al. 2010; Costa et al. 2013). A 6× histidine plus Fh8 tag (6HFh8) was fused to the N terminus of NT-proBNP via the S5N10 linker along with a tobacco etch virus (TEV) protease cleavage sequence (ENLYFQ/G) via a SS linker to generate 6HFh8-NT-proBNP (Genbank No. MK134377). The NT-proBNP coding region was digested from the synthesized vector (ATUM, Newark, CA, USA) with NdeI and XhoI restriction enzymes and inserted into the pKPM vector using T4 DNA ligase (Takara Bio, Otsu, Japan). The resultant plasmid pKPM-6HFh8-NT-proBNP was transformed into E. coli BL21 (DE3).

Production of rNT-proBNP in flask and 5-l fed-batch cultures

Flask cultivation was performed with the following auto-induction medium: 0.5 g/l glucose, 3 g/l glycerol, 2 g/l lactose, 0.15 g/l MgSO4·7H2O, 10 g/l yeast extract, 16 g/l tryptone, 3.3 g/l (NH4)2SO4, 1 ml/l trace elements, 6.8 g/l KH2PO4, and 7.1 g/l Na2HPO4·12H2O. Trace elements consisted of 0.5 g/l CoCl2·6H2O, 65 g/l FeSO4·7H2O, 3 g/l MnSO4·5H2O, 5 ml/l H2SO4 (95–98%), 0.08 g/l KI, 6 g/l CuSO4·5H2O, 20 g/l ZnCl2, 0.02 g/l H3BO3, 0.2 g/l Na2MoO4·2H2O, and 0.2 g biotin. The transformants were cultured overnight in test tubes in Luria-Bertani (LB) medium with kanamycin (50 μg/ml); 0.5 ml of the culture was transferred into 1-l baffled flasks containing 200 ml of auto-induction medium with 50 μg/ml kanamycin and incubated with shaking at 200 rpm for 12 h at 37 °C, 20 h at 30 °C, and 24 h at 25 °C.

Fed-batch fermentation was carried out in a 5-l bioreactor (CNS, Daejeon, Republic of Korea) in an initial volume of 2 l of medium composed of 15 g/l glucose, 1 g/l MgSO4·7H2O, 10 g/l yeast extract, 10 g/l casein peptone, 10 g/l (NH4)2SO4, 0.5 g/l NaCl, 3 g/l Na2HPO4·12H2O, 3 g/l KH2PO4, 1 ml/l trace elements, and 0.4 ml/l antifoam. Seed cultures were established by inoculating a single colony in 50-ml LB medium with 50 μg/ml kanamycin and culturing overnight at 37 °C and 200 rpm. The culture was transferred to 200-ml LB medium with 50 μg/ml kanamycin an incubated for 5 h at 37 °C and 200 rpm. The 2-l culture conditions were controlled as follows: initial mixing at 200 rpm; initial temperature of 37 °C; pH adjusted to 7.0 with NH4OH; dissolved oxygen maintained above 30%; airflow maintained at 1 vvm; and automatic agitation maintained below 900 rpm. All parameters were monitored and regulated by the bioreactor and glucose level was measured with a glucose analyzer (YSI 2700 Biochemistry Analyzer; Yellow Springs Instrument Co., Yellow Springs, OH, USA). When the glucose in the medium was completely exhausted, additional glucose was introduced into the culture at a feeding rate of 8 g/l/h for 2.5 h. After adjusting the temperature to 30 °C, the glucose feeding rate was decreased to 6 g/l/h, and 12 g/l lactose was added to induce the expression of rNT-proBNP followed by incubation for 24 h. Cells were harvested by centrifugation at 12,000 rpm and 4 °C for 20 min and stored − 70 °C until use.

Purification of rNT-proBNP

Cells were resuspended in binding buffer (1× phosphate-buffered saline [PBS], 150 mM NaCl) and disrupted by sonication on ice at 10% amplitude, with pulse on for 3 s/pulse off for 5 s for a total of 30 min. Debris was removed by centrifugation at 12,000 rpm and 4 °C for 20 min and passed through a 0.45-μm filter. Protein expression and purification were evaluated by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE). All purifications were performed on an ÄKTAprime plus chromatography system (GE Healthcare, Little Chalfont, UK). The 6HFh8-NT-proBNP fusion peptide was purified in two steps using a HisTrap FF and HiTrap carboxymethyl (CM) column (GE Healthcare). The filtered 6HFh8-NT-proBNP sample (2 g/100 ml) was applied at a flow rate of 1 ml/min to the 5-ml HisTrap FF column that was pre-equilibrated with binding buffer (1× PBS, 150 mM NaCl) at a flow rate of 1 ml/min. The washing and elution steps were performed using the same buffer but with 10 and 500 mM imidazole, respectively, at a flow rate of 3 ml/min. The pooled eluents were dialyzed against 20 mM sodium phosphate buffer (pH 6.0). The dialyzed sample was applied to a 1-ml HiTrap CM column that was pre-equilibrated with 20 mM sodium phosphate buffer (pH 6.0) at a flow rate of 1 ml/min. Elution was performed using the same buffer containing 200 mM and 1 M NaCl. The eluents were stored at 4 °C until they were used in the activity assay.

The first purification of rNT-proBNP peptide was performed in the same manner as that of 6HFh8-NT-proBNP fusion peptide using a HisTrap FF column. After adding 15% (w/w) TEV protease with 6H (prepared in house), the mixture was incubated at 37 °C for 1 h and then dialyzed against binding buffer (1× PBS, 150 mM NaCl). The second purification was performed using a HisTrap column pre-equilibrated with the same binding buffer. The dialyzed sample was eluted using binding buffer containing 5 and 500 mM imidazole. The unbound fraction and fraction eluted with 5 mM imidazole were pooled and then dialyzed overnight at 4 °C against 20 mM sodium phosphate buffer (pH 6.0) containing 150 mM NaCl followed by dialysis against binding buffer (20 mM sodium phosphate [pH 6.0]) for 4 h. The dialyzed sample was applied to a 1-ml HiTrap CM column that was pre-equilibrated with binding buffer (20 mM sodium phosphate [pH 6.0]). Elution was performed using a linear gradient of binding buffer with 1 M NaCl over 10 column volumes. Eluents were stored at 4 °C until they were used in the activity assay.

Enzyme-linked immunosorbent assay

To evaluate the antigenicity of expressed rNT-proBNP, we used three commercial antibodies against a.a. residues 13–27 (ab13124 and ab14712; Abcam, Cambridge, UK) and 63–76 (ab13123; Abcam) of human NT-proBNP. A 96-well plate was coated overnight at 4 °C with 100 μl of carbonate coating buffer (50 mM NaHCO3/Na2CO3) containing 1 μg/ml each of 6HFh8-NT-proBNP fusion peptide, rNT-proBNP, and commercial NT-proBNP (HyTest, Turku, Finland). After removing the coating solution by washing twice with 200 μl PBS containing 0.05% Triton X-100, 200 μl PBS with 1% casein was used for blocking at 37 °C for 2 h. A 200-μl volume of blocking buffer containing the three antibodies was added to each well, followed by incubation at 37 °C for 1 h. For immunodetection, 100 μl of 3,3′,5,5′-tetramethylbenzidine was added to each well for 15–30 min; the reaction was terminated by adding 100 μl of 1 N H2SO4, and the absorbance was measured at 450 nm.

Evaluation of analytical performance of rNT-proBNP as a calibrant

The suitability of rNT-proBNP as a calibrant was evaluated using serial dilutions of the protein to generate a standard curve by plotting the concentration detected using PATHFASTTM Cardiac Biomarker Analyzer (LSI Medience Corporation, Kreischa, Germany) against anti-NT-proBNP antibody binding using Sigma Plot software (SPSS Inc., Chicago, IL, USA).

Evaluation of rNT-proBNP purity by high-performance liquid chromatography

The purity of rNT-proBNP was evaluated by high-performance liquid chromatography (HPLC) (1200 Series; Agilent Technologies, Santa Clara, CA, USA) with an ultraviolet diode array detector adjusted to a wavelength of 214 nm and two columns for size-exclusion chromatography (SEC) (AdvanceBio SEC 130 Å, 7.8 × 300 mm, 2.7 μm; Agilent Technologies) and C18 reverse-phase chromatography (C18 RP; Zorbax Eclipse XDB 80 Å C18, 4.6 × 150 mm, 5 μm; Agilent Technologies). For SEC-HPLC, the column was maintained at 25 °C; flow rate was 0.2 μl/min; sample volume was 0.25 μl; run time for each sample was 40 min; and PBS was used as a mobile phase. For the C18 RP-HPLC, the column was maintained at 37 °C; flow rate was 0.5 μl/min; sample volume was 20 μl; run time for each sample was 25 min; and the mobile phases were 5% buffer B (0.1% of trifluoroacetic acid [TFA] in acetonitrile) and buffer A (0.1% of TFA in distilled water). Protein separation was carried out with a gradient of 5–50% buffer B for 18 min.

N-terminal sequencing and matrix-assisted laser desorption/ionization time-of-flight mass spectrometry

N-terminal sequencing of purified rNT-proBNP fixed to a polyvinylidene difluoride membrane was performed with a Procise ABI 492 protein sequencer (Applied Biosystems, Foster City, CA, USA). For matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF MS), purified rNT-proBNP was dried and resuspended in 4-μl distilled water with 0.2% TFA. After adding the sinapinic acid matrix solution to the sample followed by gentle vortexing, 2 μl of the mixture was air-dried and the molecular weight was analyzed on an Ultraflex III mass spectrometer (Bruker Daltonics, Bremen, Germany) at eMASS (Seoul, Republic of Korea).

Results

Construction and expression of 6HFh8-NT-proBNP in E. coli

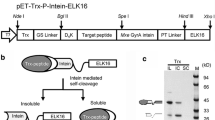

The a.a. sequence of the expressed region in the pKPM-6HFh8-NT-proBNP vector is shown in Fig. 2 a and b. As described in the “Materials and methods” section, the gene encoding human NT-proBNP was fused to 6HFh8 tag to the N terminus to facilitate purification. Two additional a.a. residues (SS) with TEV protease cleavage sequence arrow to improve cleavage efficiency. The 6HFh8-NT-proBNP fusion peptide, which was codon-optimized for E. coli, was expressed under the control of the isopropyl β-d-1-thiogalactopyranoside-inducible T7 promoter. The soluble expression was observed at three different temperatures (25 °C, 30 °C, and 37 °C) in the flask cultivation (Fig. 2c). The rNT-proBNP fusion peptide was expressed in almost completely soluble form at all three temperatures, with the highest expression (> 24% of total cell protein) at 30 °C. The volumetric yield of 6HFh8-NT-proBNP was calculated to be 467 mg/l.

Expression of 6HFh8-NT-proBNP fusion peptide in flask cultures of recombinant E. coli. a 6HFh8-NT-proBNP fusion construct in the pET30+ expression vector. 6H, 6× histidine; T7p, T7 promoter; T7t, T7 terminator. b a.a. sequences of 6HFh8-NT-proBNP fusion peptide. c SDS-PAGE analysis of total (T), soluble (S), and insoluble (I) protein fractions of flask cultures of E. coli BL21 (DE3) expressing pKPM-6HFh8-NT-proBNP at 37 °C, 30 °C, and 25 °C. Arrow indicates the expressed Fh8-NT-proBNP fusion peptide. Lane M, molecular marker

Purification of rNT-proBNP

Figure 3a shows the simple flowchart of rNT-proBNP purification. E. coli BL21 (DE3)/pKPM-6HFh8-NT-proBNP cells were lysed and the supernatant was loaded onto a HisTrap column (Fig. 3b). When the bound protein was eluted with 500 mM imidazole, a prominent protein band of ~ 19.6 kDa corresponding to the rNT-proBNPs fusion peptide was observed (line B in Fig. 3c). The fusion partner 6HFh8 (11 kDa) was completely removed from the fusion protein by the cleavage reaction of TEV protease, so that the rNT-proBNP (8.7 kDa) was produced (lane A in Fig. 3c). The reactants were dialyzed against HisTrap binding buffer and were loaded on the HisTrap column to remove TEV protease and 6HFh8 (Fig. 3d). The unbound and eluted rNT-proBNP was dialyzed against 20 mM sodium phosphate buffer (pH 6.0); the dialyzed fraction was loaded onto the HiTrap CM column and rNT-proBNP was eluted with a linear gradient of 1 M NaCl (Fig. 3e). The yield and total amount of rNT-proBNP at each purification step are summarized in Table 1. Coomassie Brilliant Blue R250 staining following SDS-PAGE revealed that rNT-proBNP was purified to homogeneity (Fig. 4a). Furthermore, the purity of the purified rNT-proBNP was > 98% by SEC- and C18 RP-HPLC when the buffer peaks were removed (Fig. 4b, c). The molecular mass of rNT-proBNP was confirmed as 8684.99 Da by MALDI-TOF MS (Fig. 4d). The sequence GSSHPLGSPG—corresponding to the vector-derived N-terminal Gly-Ser-Ser tripeptide followed by the native peptide sequence—was confirmed by N-terminal sequencing. The 6HFh8-NT-proBNP fusion peptide was purified by HisTrap and HiTrap CM chromatography without TEV protease treatment (Fig. S1).

Purification of rNT-proBNP. a Schematic illustration of rNT-proBNP purification steps. b 6HFh8-NT-proBNP fusion peptide was isolated in the first HisTrap purification. The peptide was eluted with 500 mM imidazole in 1× PBS (150 mM NaCl). c Cleavage of 6HFh8 tag by TEV protease. d rNT-proBNP was isolated in the second HisTrap purification by TEV protease-mediated removal of 6HFh8 tag. Elution 1 (E1), 5 mM imidazole in 1× PBS (150 mM NaCl); elution 2 (E2), 500 mM imidazole in same buffer. rNT-proBNP was present in the unbound fraction and the eluate from step 1. e rNT-proBNP was isolated by HisTrap CM purification; elution was performed in a gradient of 1 M NaCl in 20 mM sodium phosphate (pH 6.0) with 10 column volumes. A, after TEV protease treatment; B, before TEV protease treatment; M, molecular marker; R, raw sample loaded onto the column; U, unbound protein sample; W, washing sample

Performance of rNT-proBNP as a calibrant

To evaluate the antigenicity of rNT-proBNP variants with or without 6HFh8, antigen-ELISA was performed using three antibodies recognizing the N and C termini, two detecting a.a. residues 13–27, and one directed against a.a. residues 63–76. All antibodies recognized both rNT-proBNP and the commercially available NT-proBNP (HyTest) but not rNT-proBNP with the 6HFh8 tag (Fig. 5a). The calibration curve in the suitability assay showed that the response was linearly proportional to rNT-proBNP concentration in the range of 19.6–5650 pg/ml (slope = 3.53, r2 = 0.995), but was not proportional to 6HFh8-NT-proBNP concentration (Fig. 5b, c).

Production of rNT-proBNP in 5-l fed-batch culture

For mass production of rNT-proBNP in a reactor, glucose-limited fed-batch cultivation mode was used to increase the volumetric yield of E. coli BL21 (DE3) harboring pKPM-6HFh8-NT-proBNP (Fig. 6). When the initial glucose was completely exhausted 4.5 h after inoculation, a highly concentrated glucose solution was continuously fed into the culture at a rate of 8 glucose/l/h (Fig. 6a). After 2 h of glucose feeding, lactose (12 g/l final concentration) was added to induce expression of rNT-proBNP, and the culture temperature was lowered to 30 °C, because this produced the highest level of rNT-proBNP in flask cultures. The lactose was hydrolyzed into glucose and galactose; the former was consumed while the latter accumulated in the culture medium due to the gal− genotype of E. coli BL21 (DE3). Glucose was continuously fed into the culture at a rate of 6 g/l/h after lactose induction and the concentration remained at zero during the entire fed-batch phase. Acetic acid formed during the batch phase was consumed in the period between glucose exhaustion and feeding initiation and was not present in significant amounts (maximum concentration < 0.5 g/l). Cells grew exponentially in the batch phase, with a specific growth rate (μ) of 0.74; on the other hand, μ remained below 0.02 in the fed-batch phase. A maximum optical density at 600 nm (OD600) of 106 was achieved at the end of fed-batch culture (2.2 l); it reached 206 g of wet cell (119 g/l). The 6HFh8-rNT-proBNP fusion peptide was expressed 2 h after lactose induction; the expression level was 32.6% of total cell protein and the volumetric yield of fusion protein was calculated to be about 4.7 g/l at the end of fed-batch culture. The protein was almost completely soluble and the expression level was higher than flask culture (Fig. 6b, c).

Glucose-limited fed-batch culture (5 l) of E. coli harboring pKMK-6HFh8-NT-proBNP. a Fed-batch culture profile. b Coomassie Brilliant Blue–stained SDS polyacrylamide gel of fed-batch culture samples. c Comparison of 6HFh8-NT-proBNP expression level from both flask and fed-batch cultures in a same gel. T, total protein; S, soluble fraction of protein; I, insoluble fraction of protein

Discussion

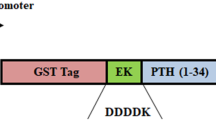

Prohormones of NPs in the circulation are important diagnostic tools for cardiac disease. In particular, the measurement of NT-proBNP concentration in the blood or plasma has been useful for HF diagnosis in clinical settings (Magnussen and Blankenberg 2018). NT-proBNP is commercially produced in recombinant E. coli for use as a biomarker and calibrant; however, there have been few detailed studies on its production and purification, and the reported yields are very low (Table 2). Soluble NT-proBNP has been expressed using a glutathione S-transferase (GST) fusion system owing to its tendency to aggregate in E. coli, with a purified yield of 0.1–0.5 mg/l of bacterial culture (Ala-Kopsala et al. 2004, 2005). Another study reported the production of 10 × His-tagged NT-proBNP in insoluble inclusion bodies; after refolding, the yield was 1.75 mg/l of bacterial culture (Soleh et al. 2014).

We employed three strategies to improve recombinant protein yield in this study: fusion of a small epitope tag for soluble expression; complete removal of the fused tag from rNT-proBNP to facilitate purification; and preparation of high-density E. coli cell cultures. Various solubility-enhancing fusion partners exist, including GST (211 a.a.) and maltose-binding protein (396 a.a.). In general, these two fusion partners are good for giving the solubility, but those are the negative effect on the final yield of purified protein because of its large size than the target protein (Hammarström et al. 2006; Costa et al. 2013). In the previous study, GST enhanced the solubility of NT-proBNP, but the final yield was very low (Ala-Kopsala et al. 2004, 2005). Also, the insoluble expression of 6× histidine–fused NT-proBNP indicated that 6× histidine tag did not effect on the solubility in the case of NT-proBNP (Soleh et al. 2014). Therefore, we hypothesized that the small-sized (69 a.a.) Fh8 molecule which has similar size with NT-proBNP is suitable for the solubilization and high-yield production. The fusion peptide was almost completely soluble at various temperatures (Fig. 2c) as we expected, consistent with previous reports that the Fh8 tag enhances protein solubility (Costa et al. 2013; Fraga et al. 2010). Moreover, the expression level was increased to > 24% of the total cell protein in shake-flask cultures, and the final yield was also increased almost 55 times. These result indicated that using of suitable fusion partner is important for the increase of expression level, the promotion of purification efficacy, and the improvement of production yield.

In the second strategy, the Fh8 tag was removed from the fusion peptide by proteolytic cleavage using TEV protease, which recognizes the ENLYFQ/G/S sequence, with some additional residues (Adams et al. 2005). Although a.a. residues other than proline at the seventh position of the recognition sequence lead to complete or partial proteolysis, proline at this site is not processed (Renicke et al. 2013). For complete removal of the Fh8 tag, we inserted two additional a.a. residues (SS) into the C terminus of the recognition site (ENLYFQ/G) of TEV protease, since proline was the second residue from the N terminus of NT-proBNP. This allowed full separation of the Fh8 tag from rNT-proBNP (Fig. 3c). Further purification by immobilized metal affinity and ion exchange chromatography yielded rNT-proBNP with a high degree of purity (≥ 98%) and a volumetric yield of 97.5 mg/l of bacterial culture (the specific yield of 3.25 mg/g of wet cell), which is 55 times higher than that reported in previous studies (Figs. 3 and 4 and Table 1) (Costa et al. 2013). The purified rNT-proBNP was analyzed by MALDI-TOF MS, which revealed the molecular mass as ~ 8.7 kDa and showed that GSS residues remained in the N terminus. Antigen-ELISA using commercial antibodies recognizing the N and C termini of the protein showed that these residues did not affect immunodetection, whereas the relatively large 6HFh8 fusion tag was a hindrance. The standard curve generated from various concentrations of 6HFh8-NT-proBNP and rNT-proBNP showed linearity in the range of concentrations tested. These results indicate that the rNT-proBNP produced in this study is suitable as a calibrant for the diagnosis of HF.

The third strategy used to increase recombinant protein yield was to prepare 5-l high-density fed-batch cultures. Glucose as a carbon source enhances recombinant protein synthesis and prevents catabolite repression. We therefore continuously fed an appropriate amount of glucose (6–8 g/l/h) into the culture when the initial substrate was completely exhausted. Controlled glucose feeding along with good aeration prevented accumulation of by-products such as acetic acid and lactate, resulting in high cell densities (OD600 = 106) at the end of the culture period. Lactose as an inducer was consumed within 6 h of addition and was hydrolyzed into glucose and galactose. Since E. coli BL21 (DE3) cannot metabolize galactose, about 5 g/l galactose accumulated in the culture medium. Galactose is an inducer of the lac operon (Barkley et al. 1975), and concentrations above 1.2–2.6 mM can cause high-level protein expression in fed-batch cultures (Xu et al. 2012). Thus, residual galactose allows expression of rNT-proBNP fusion peptides until the end of the culture period following lactose consumption. The expression level of 6HFh8-rNT-proBNP was higher in fed-batch as compared with batch shake-flask cultures (32.6% vs. 24% of total cell protein; Fig. 6c); furthermore, the volumetric yield of fusion protein was tenfold higher (4.7 g vs. 467 mg/l). These results demonstrated that the rNT-proBNP was successfully expressed by the fed-batch fermentation and it had a potential for the industrial scale production of rNT-proBNP.

In this study, we cloned and expressed rNT-proBNP in E. coli and purified a protein that was almost completely soluble due to the fused Fh8 tag. Calibrant suitability testing showed that the purified rNT-proBNP was bound by antibody to a degree similar to commercially available forms of the protein. Furthermore, high cell density was achieved in E. coli fed-batch cultures, which can lower production cost and increase gram-to-liter yield. These results demonstrate that rNT-proBNP can be rapidly, cheaply, and efficiently produced on an industrial scale for the diagnosis of HF and other applications.

References

Adams MJ, Antoniw JF, Beaudoin F (2005) Overview and analysis of the polyprotein cleavage sites in the family Potyviridae. Mol Plant Pathol 6:471–487. https://doi.org/10.1111/j.1364-3703.2005.00296.x

Ala-Kopsala M, Magga J, Peuhkurinen K, Leipälä J, Ruskoaho H, Leppäluoto J, Vuolteenaho O (2004) Molecular heterogeneity has a major impact on the measurement of circulating N-terminal fragments of A- and B-type natriuretic peptides. Clin Chem 50:1576–1588. https://doi.org/10.1373/clinchem.2004.032490

Ala-Kopsala M, Ruskoaho H, Leppäluoto J, Seres L, Skoumal R, Toth M, Horkay F, Vuolteenaho O (2005) Single assay for amino-terminal fragments of cardiac A- and B-type natriuretic peptides. Clin Chem 51:708–718. https://doi.org/10.1373/clinchem.2004.039891

Ashrafian H, Frenneaux MP, Opie LH (2007) Metabolic mechanisms in heart failure. Circulation 116:434–448. https://doi.org/10.1161/CIRCULATIONAHA.107.702795

Barkley MD, Riggs AD, Jobe A, Burgeois S (1975) Interaction of effecting ligands with lac repressor and repressor-operator complex. Biochemistry 14:1700–1712. https://doi.org/10.1021/bi00679a024

Calzetta L, Orlandi A, Page C, Rogliani P, Rinaldi B, Rosano G, Cazzola M, Matera MG (2016) Brain natriuretic peptide: much more than a biomarker. Int J Cardiol 221:1031–1038. https://doi.org/10.1016/j.ijcard.2016.07.109

Costa SJ, Almeida A, Castro A, Domingues L, Besir H (2013) The novel Fh8 and H fusion partners for soluble protein expression in Escherichia coli: a comparison with the traditional gene fusion technology. Appl Microbiol Biotechnol 97:6779–6791. https://doi.org/10.1007/s00253-012-4559-1

Crimmins DL, Kao JLF (2007) The human cardiac hormone fragment N-terminal pro B-type natriuretic peptide is an intrinsically unstructured protein. Arch Biochem Biophys 461:242–246. https://doi.org/10.1016/j.abb.2007.02.024

Diez-Villanueva P, Alfonso F (2011) Heart failure in the elderly. Clin Geriatr 19:21–28. https://doi.org/10.11909/j.issn.1671-5411.2016.02.009

Fraga H, Faria TQ, Pinto F, Almeida A, Brito RMM, Damas AM (2010) FH8 – a small EF-hand protein from Fasciola hepatica. FEBS J 277:5072–5085. https://doi.org/10.1111/j.1742-4658.2010.07912.x

Hall C (2005) NT-ProBNP: the mechanism behind the marker. J Card Fail 11:S81–S83. https://doi.org/10.1016/j.cardfail.2005.04.019

Hammarström M, Woestenenk EA, Hellgren N, Härd T, Berglund H (2006) Effect of N-terminal solubility enhancing fusion proteins on yield of purified target protein. J Struct Funct Genom 7:1–14. https://doi.org/10.1007/s10969-005-9003-7

Jurgens CY, Moser DK, Armola R, Carlson B, Sethares K, Riegel B (2011) Symptom clusters of heart failure. Res Nurs Health 32:551–560. https://doi.org/10.1002/nur.20343.Symptom

Latini R, Masson S (2013) NT-PROBNP : a guide to improve the management of patients with heart failure. Int Fed Clin Chem Lab Med 24:1–7

Lippi G, Sanchis-Gomar F (2016) Monitoring B-type natriuretic peptide in patients undergoing therapy with neprilysin inhibitors. An emerging challenge? Int J Cardiol 219:111–114. https://doi.org/10.1016/j.ijcard.2016.06.019

Magnussen C, Blankenberg S (2018) Biomarkers for heart failure: small molecules with high clinical relevance. J Intern Med 283:530–543. https://doi.org/10.1111/joim.12756

McKie PM, Burnett JC (2016) NT-proBNP: the gold standard biomarker in heart failure. J Am Coll Cardiol 68:2437–2439. https://doi.org/10.1016/j.jacc.2016.10.001

Natella P-A, Le Corvoisier P, Paillaud E, Renaud B, Mahé I, Bergmann J-F, Perchet H, Mottier D, Montagne O, Bastuji-Garin S (2017) Long-term mortality in older patients discharged after acute decompensated heart failure: a prospective cohort study. BMC Geriatr 17:34. https://doi.org/10.1186/s12877-017-0419-2

Nishikimi T, Maeda N, Matsuoka H (2006) The role of natriuretic peptides in cardioprotection. Cardiovasc Res 69:318–328. https://doi.org/10.1016/j.cardiores.2005.10.001

Omar HR, Guglin M (2016) Extremely elevated BNP in acute heart failure: patient characteristics and outcomes. Int J Cardiol 218:120–125. https://doi.org/10.1016/j.ijcard.2016.05.038

Ordonez-Llanos J, Collinson PO, Christenson RH (2008) Amino-terminal pro-B-type natriuretic peptide: analytic considerations. Am J Cardiol 101:9–15. https://doi.org/10.1016/j.amjcard.2007.11.013

Oremus M, McKelvie R, Don-Wauchope A, Santaguida PL, Ali U, Balion C, Hill S, Booth R, Brown JA, Bustamam A, Sohel N, Raina P (2014) A systematic review of BNP and NT-proBNP in the management of heart failure: overview and methods. Heart Fail Rev 19:413–419. https://doi.org/10.1007/s10741-014-9440-0

Renicke C, Spadaccini R, Taxis C (2013) A tobacco etch virus protease with increased substrate tolerance at the P1' position. PLoS One 8:1–12. https://doi.org/10.1371/journal.pone.0067915

Semenov AG, Feygina EE (2018) Advances in clinical chemistry. In: Makowski G (ed) Standardization of BNP and NT-proBNP immunoassays in light of the diverse and complex nature of circulating BNP-related peptides. Academic press, Cambridge, pp 1–30

Setoguchi S, Stevenson LW, Schneeweiss S (2007) Repeated hospitalizations predict mortality in the community population with heart failure. Am Heart J 154:260–266. https://doi.org/10.1016/j.ahj.2007.01.041

Soleh MT, Foo JYY, Bailey UM, Tan NY, Wan Y, Cooper-White J, Schulz BL, Punyadeera C (2014) A rapid and cost-effective method of producing recombinant proBNP and NT-proBNP variants in Escherichia coli for immunoassay of heart failure. Biotechnol Lett 36:133–140. https://doi.org/10.1007/s10529-013-1341-0

Su Q, Liu H, Zhang X, Dang W, Liu R, Zhao X, Yuan X, Qin Y, Zhang J, Chen C, Xia Y (2015) Diagnostic values of NT-proBNP in acute dyspnea among elderly patients. Int J Clin Exp Pathol 8:13471–13476

Weber M, Hamm C (2006) Role of B-type natriuretic peptide (BNP) and NT-PROBNP in clinical routine. Heart 92:843–849. https://doi.org/10.1136/hrt.2005.071233

Xu J, Banerjee A, Pan SH, Li ZJ (2012) Galactose can be an inducer for production of therapeutic proteins by auto-induction using E. coli BL21 strains. Protein Expr Purif 83:30–36. https://doi.org/10.1016/j.pep.2012.02.014

Zhang X, Wang W, Yu Y, Wang Q, Yang Y (2013) BNP and NT-proBNP assays for heart-failure diagnosis in patients with cerebral infarction. Lab Med 44:46–50. https://doi.org/10.1309/LMPEAZF6UYU8FG4H

Zile MR, Claggett BL, Prescott MF, McMurray JJV, Packer M, Rouleau JL, Swedberg K, Desai AS, Gong J, Shi VC, Solomon SD (2016) Prognostic implications of changes in N-terminal pro-B-type natriuretic peptide in patients with heart failure. J Am Coll Cardiol 68:2425–2436. https://doi.org/10.1016/j.jacc.2016.09.931

Funding

This project was funded by a grant from the KRIBB Research Initiative Program and by the Advanced Biomass R&D Center (ABC) of the Global Frontier Project funded by the Ministry of Science, ICT, and Future Planning (ABC-2015M3A6A2074238).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 123 kb)

Rights and permissions

About this article

Cite this article

Kim, Y.S., Karisa, N., Jeon, W.Y. et al. High-level production of N-terminal pro-brain natriuretic peptide, as a calibrant of heart failure diagnosis, in Escherichia coli. Appl Microbiol Biotechnol 103, 4779–4788 (2019). https://doi.org/10.1007/s00253-019-09826-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-019-09826-8