Abstract

The aim of this study is to summarize the current progress in the design of biocatalytic processes applicable for the production of optically pure mandelic acids and their analogues. These compounds are used as building blocks for pharmaceutical chemistry and as chiral resolving agents. Their enzymatic syntheses mainly employed nitrile hydrolysis with nitrilases, ester hydrolysis, ammonolysis or esterification with lipases or esterases, and ketone reduction or alcohol oxidation with dehydrogenases. Each of these methods will be characterized in terms of its product concentrations, enantioselectivities, and the types of catalysts used. This review will focus on the dynamic kinetic resolution of mandelonitrile and analogues by nitrilases resulting in the production of high concentrations of (R)-mandelic acid or (R)-2-chloromandelic acid with excellent e.e. Currently, there is no comparable process for (S)-mandelic acids. However, the coupling of the S-selective cyanation of benzaldehyde with the enantioretentive hydrolysis of (S)-mandelonitrile thus obtained is a promising strategy. The major product can be changed from (S)-acid to (S)-amide using nitrilase mutants. The competitiveness of the biocatalytic and chemical processes will be assessed. This review covers the literature published within 2003–2017.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The chemical synthesis of racemic mandelic acid (MA) is simple and inexpensive, consisting, e.g., of the cyanation of benzaldehyde (BA) followed by the hydrolysis of the mandelonitrile (MN) thus obtained. However, the separation of the racemic mixture or the direct synthesis of enantiopure (R)- or (S)-MA is challenging. A number of syntheses of fine and pharmaceutical chemicals require enantiopure MAs, which serve as building blocks for, e.g., semisynthetic antibiotics (penicillin, cephalosporin) and anticancer, antiobesity, or antithrombotic agents (Zhang et al. 2011; Zhang et al. 2012; Wang et al. 2015a). For instance, the methyl ester of (R)-2-ClMA is the chiral building block in some synthetic routes to the antithrombotic drug (S)-clopigogrel (Saeed et al. 2017). Optically pure MAs are also applied as chiral resolving agents in different ways, e.g., in the manufacture of enantioselective electrodes for the chiral recognition of 3,4-dihydroxyphenylalanine (DOPA; Yutthalekha et al. 2015).

Chemical or physico-chemical methods for the production of optically pure MAs are largely based on transition metal catalysis or diastereomeric crystallizations. The costs of chemicals used in these methods (complex metal catalysts or enantiopure resolving agents) make their upscaling difficult. These methods may also suffer from low yields, low enantioselectivities, or a need for harsh conditions, toxic chemicals, organic solvents, or protection/deprotection steps.

Biocatalysis is an attractive alternative for the synthesis of optically pure building blocks such as (R)- or (S)-MAs, providing a number of well-known benefits such as mild reaction conditions and high product yields and enantiopurities. The synthesis of optically pure MAs is possible with a variety of enzymes such as nitrilases (NLases), lipases, esterases, or dehydrogenases (Fig. 1). However, the majority of these syntheses have been only carried out at the laboratory scale. Their transfer to industrial scale has been rare, an example being the industrial use of NLase for the production of (R)-MA and its analogues by Mitsubishi Rayon or BASF (Kaul et al. 2007).

This study provides an overview of the various types of MA biocatalytic production processes and compares their benefits and drawbacks. The competitiveness of the biocatalytic and chemical syntheses will also be examined. The review will mainly cover the literature published within the last ca. 15 years. Some previous reviews addressing NLases in general summarized, in brief, also the use of these enzymes for MA production (Thuku et al. 2009; Martínková and Křen 2010; Gong et al. 2012; Martínková et al. 2017). MN hydrolysis by bacterial and fungal NLases was also compared by Veselá et al. (2015). However, no review has summarized and compared the different means of biocatalytic MA production or discussed their competitiveness with chemical and physico-chemical processes.

Hydrolysis of mandelonitrile with NLase

The first NLase able to recognize the stereochemistry of MN was found in Alcaligenes faecalis. This enzyme produced enantiomerically pure (R)-MA with high yields (91%), which were enabled by a rapid racemization of the starting material at pH 8.0. However, only a low substrate concentration (42 mM) was used (Yamamoto et al. 1991).

Intensive innovations of this process enabled (R)-MA to be obtained from substrate concentrations as high as 1 and 2.9 M in batch and fed-batch modes, respectively (Ni et al. 2013; Wang et al. 2015a). This was partially due to replacing the wild-type organisms with recombinant Escherichia coli strains producing the NLases from Alcaligenes sp. or Burkholderia cenocepacia (Zhang et al. 2011; Wang et al. 2013a; Xue et al. 2013a; Wang et al. 2015a; Liu et al. 2014) and optimizing the process conditions. Primarily, the process was significantly improved by using biphasic organo-aqueous systems, in which the organic phase (toluene, ethyl acetate) served as the substrate reservoir (Zhang et al. 2011; Ni et al. 2013). This alleviated the negative effects of high substrate concentrations on the activity and enantioselectivity of the enzymes. Immobilization of the cells by entrapment in alginate (Zhang et al. 2011), optionally followed by cross-linking (Xue et al. 2013a), or attachment to magnetic nanoparticles (Ni et al. 2013), enabled the re-use of the catalysts, which resulted in high catalyst productivities of up to 156 g g−1 of dry cell weight (dcw) (Ni et al. 2013). In addition, the cultivation of the strain (Alcaligenes faecalis) was upscaled to 400 L (Xue et al. 2013a) and the biotransformation processes to 1–10 L (Xue et al. 2013a; Wang et al. 2015a).

NLases suitable for the hydrolysis of 2-ClMN were obtained either by database mining or by mutation of the MN-hydrolyzing NLase. The former strategy resulted in selecting Labrenzia aggregata NLase as the first-generation biocatalyst to produce 2-ClMA (e.e. 96.5%; Zhang et al. 2012). The latter consisted of constructing a variant of the NLase from B. cenocepacia (Wang et al. 2015b). This double mutant exhibited an increased activity and enantioselectivity for (R,S)-2-ClMN compared with the wild-type enzyme. Thus, (S)-2-ClMA (98.7%) was prepared from 0.5 M substrate with a catalyst productivity of 24 g g−1 of dcw (Wang et al. 2015b).

Some fungal NLases were also found to be promising for (R)-MA production. Among them, the NLases from Aspergillus niger (Table 1), Nectria haematococca, or Neurospora crassa exhibited the highest specific activities and enantioselectivities for (R)-MN (Kaplan et al. 2013; Veselá et al. 2015). In addition, fungal genomes contain many more genes encoding potential MN-hydrolyzing enzymes, as predicted by sequence alignments. In some NLases from Basidiomycota (Auricularia delicata) and Ascomycota (Aspergillus kawachii, Macrophomina phaseolina, Trichoderma virens), these activities were experimentally confirmed (Veselá et al. 2016).

Some other NLases acting on MN were found among the enzymes obtained by screening a metagenomic library including 137 characterized NLases (Robertson et al. 2004). The MN-hydrolyzing activity was detected in 48 enzymes, the majority of which being R-selective. There were only four S-selective enzymes and their degree of selectivity was low.

In fact, the production of (S)-MA by NLases seems to require engineered enzymes (Table 2). Such an enzyme was recently prepared from a bacterial NLase, which was moderately S-selective for MN (product e.e. 52.7%). The amino acid residues important for the degree of enantioselectivity (M113, R128) or even the enantioselectivity reversion (M113) were identified. In this way, NLase mutants were prepared, which gave (R)-MA or (S)-MA with ca. 90 and 91% e.e. (Sun et al. 2015). An alternative way of preparing (S)-MA employed a cascade of two enzymatic reactions—an S-selective cyanation of BA and an enantioretentive hydrolysis of (S)-MN (see below).

Coupling oxynitrilase and nitrile-hydrolyzing enzymes

Oxynitrilase enables MN to be synthesized enantioselectively from BA and HCN. The production of (S)-MA was accomplished by combining the strictly S-selective oxynitrilase from Manihot esculenta (cassava) and the moderately enantioselective NLase from Pseudomonas fluorescens. In contrast to the abovementioned R-selective NLases, the NLase from P. fluorescens formed significant amounts of mandelamide (MAA) as a by-product. The cascade process of BA to (S)-MA transformation was carried out using oxynitrilase and NLase co-expressed in Pichia pastoris (Rustler et al. 2008) or co-immobilized in cross-linked enzyme aggregates (CLEAs; Chmura et al. 2013). The tendency to form amide is a drawback in this process but it was circumvented by the addition of amidase, which was also co-immobilized in the CLEAs. Thus, (S)-MAA was converted into (S)-MA as the single product (Table 2). The reaction was carried out at pH 5.5 to suppress MN racemization.

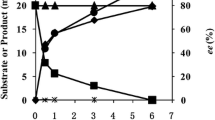

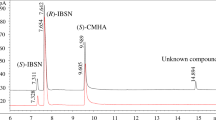

An analogous process was used to produce (S)-MAA but with a mutant of the NLase from P. fluorescens in the second step. This mutant with a deletion in the C-terminal region exhibited an increased ability to form amide. As a result, E. coli co-expressing the oxynitrilase and the NLase mutant produced (S)-MAA/(S)-MA in a 9:1 ratio. In contrast, a strain containing the wild-type NLase produced (S)-MAA/(S)-MA in a 3:4 ratio (Sosedov et al. 2009). Apart from deletions, various point mutations in NLases from P. fluorescens (Sosedov et al. 2010; Sosedov and Stolz 2014) and N. crassa (Petříčková et al. 2012) yielded enzyme variants producing MAA as the major product from MN.

Alternatively, an enzyme cascade consisting of nitrile hydratase (NHase) and amidase can be used to hydrolyze optically pure cyanohydrins such as 2-ClMN. This reaction was applied for the preparation of (R)-2-ClMA (e.e. > 99%) from (R)-2-ClMN, which was synthesized with an R-selective oxynitrilase. Whole cells of Rhodococcus erythropolis producing both NHase and amidase were used as the catalyst in the second step. However, this method was examined at ca. tenfold lower substrate concentrations than the hydrolysis of (R,S)-2-ClMN by R-selective NLase (Table 1). Nevertheless, the advantage of the cascade reaction is the possibility of obtaining the corresponding amide provided the reaction is stopped in its early stage or the purified NHase is used (Osprian et al. 2003; Rucká et al. 2014).

Reactions catalyzed with lipases and esterases

The great potential of lipases and esterases for enantioselective catalysis was also explored in the production of optically pure MAs. Thus, both (R)-MA and (S)-MA (Tables 1 and 2, respectively) were prepared via ester hydrolysis or esterification reactions. For instance, an immobilized lipase from Candida rugosa hydrolyzed (R,S)-MA methyl ester into R-MA with > 98% e.e. (Yilmaz 2012) and esterases from pseudomonades (Ju et al. 2010; Ma et al. 2013) or a recombinant lipase from Aspergillus fumigatus (Shangguan et al. 2012) hydrolyzed (R,S)-O-acetylMA and its chlorinated analogues into the corresponding S-MAs with ca. 92 to > 99% e.e. The chiral resolution of (R,S)-O-acetylMAs was also achieved through aminolysis with the Candida antarctica lipase, yielding the corresponding optically pure R-acids (Chen et al. 2016).

The majority of the above experiments were performed at low substrate concentrations except for the P. putida esterase studies, which used 100 mM substrates. Increasing the substrate concentration to 300 mM caused a reduction in product (S)-MA e.e. from > 99 to 96.5%. The reactions catalyzed by this enzyme enabled almost 50% yields to be obtained, which are the highest possible in this process type (kinetic resolution; Ma et al. 2013).

The esterification with vinyl acetate as a donor was performed on racemic MA. This reaction was used for the preparation of (R)-MA and (S)-O-acetylMA, the catalysts being lipases from either Burkholderia ambifaria (Yao et al. 2013) or Pseudomonas stutzeri (Cao et al. 2014). Excellent enantioselectivities were achieved at relatively low substrate concentrations of 30 mM with the former enzyme but at up to 180-mM substrate concentration with the latter.

Another method of direct MA resolution used a covalently immobilized lipase from, e.g., Pseudomonas sp. yielding almost optically pure (R)-MAA with ammonium ions as the acyl acceptor. In addition, the remaining substrate (optically pure (S)-MA) also exhibited high e.e. under optimized conditions (Yildirim and Tükel 2014).

Reactions catalyzed with dehydrogenases

Reactions catalyzed with mandelate dehydrogenase (MDH) were used to prepare (R)-MA (Table 1). The enzymes were employed either for the asymmetric reduction of the corresponding prochiral ketone (phenylglyoxylic acid, PGA) or for the enantioselective oxidation of (R,S)-MA. The benefit of the former process is the theoretical 100% yield. Different enzymes were used for each of these processes.

An NADH-dependent (R)-MDH found in Saccharomyces cerevisiae was used to produce (R)-MA from PGA. The catalyst was free cells (Xiao et al. 2005), or cells immobilized on chitosan (Li et al. 2007) or in alginate (Xiao et al. 2008). The immobilized catalysts were reusable six to ten times (Li et al. 2007; Xiao et al. 2008). High product e.e. were achieved, i.e., > 98%, from a 50 mM substrate (Xiao et al. 2008). A different form of the immobilized catalyst was also examined, consisting of the purified enzyme covalently bound to a magnetic carrier through epoxy bonds. This catalyst was reused nine times, retaining ca. half of its initial activity after the last use (Jiang et al. 2016).

The substrate specificity of the (R)-MDH from Rhodotorula was changed by site-directed mutagenesis: the activity for 2-ClMA was significantly improved in the Ala89His mutant, which was designed using the crystal structure of the enzyme. It was concluded that a new interaction between the imidazolyl group of His and the chlorine atom of the substrate was established through a specific halogen bond, as His was able to form this bond in contrast to Ala. In addition, the catalytic mechanism was also supported by an interaction between the protein and the NAD+ cofactor in the mutant enzyme (Guo et al. 2016).

A different, FMN-dependent MDH, which was S-selective, was recombinantly produced in E. coli. The enzymes of this type originate from bacteria (Alcaligenes, Pseudomonas) or fungi (Aspergillus). The partially purified enzyme, optionally immobilized on cross-linked chitosan, was applied to oxidize (R,S)-MA into PGA (Wang et al. 2013b; Wang et al. 2014). Stopping the reaction at ca. 50% conversion enabled R-MA to be obtained with > 99% e.e. from low substrate concentrations (10 mM; Wang et al. 2013b). A similar process enabled (R)-MA and a number of its substituted derivatives to be obtained with ca. 50% conversion and excellent e.e. from 30 mM substrates (Xue et al. 2013b).

The disadvantage of using isolated dehydrogenases is the necessity to regenerate the cofactors. In the transformation of (S)-MA, FMN was regenerated by oxidation of FMNH2 with ferricyanide (Wang et al. 2014), which, in turn, could be re-oxidized by a laccase (Wang et al. 2013b).

A different type of the aldo-keto dehydrogenase (diol dehydrogenase) was used to catalyze an R-selective oxidation of (R,S)-phenyl-1,2-ethanediol. The enzyme from Brevibacterium lutescens was used in the form of alginate-immobilized whole cells. This catalyst was reusable at least 16 times. As a result, a high catalyst productivity of ca. 28 g of (R)-MA g−1 of dcw was achieved, which is probably the highest in the production of (R)-MA with dehydrogenases (He et al. 2013).

Chemical and physico-chemical processes and their comparison with biocatalytic procedures

Some of the chemical and biocatalytic syntheses of optically pure MAs are based on common reactions such as the cyanation of BA followed by hydrolysis, or the PGA reduction. The chemical catalysts are transition metal complexes containing chiral ligands.

For instance, the synthesis of (R)-MAs employed a cyanation-hydrolysis cascade. The first step consisted of a stereoselective cyanation of ortho-substituted BA derivatives such as 2-ClBA with trimethylsilylcyanide and transition metal catalysts such as vanadium or titanium complexes of chiral tetradentate (salen) ligands. In the second step, the cyanohydrin silyl ether thus obtained was hydrolyzed with HCl. In this way, (R)-2-ClMN silyl ether was prepared in the first step with an e.e. of 76%, and this optical purity was maintained in the final product (R)-2-ClMA (Blacker and Houson, 2002).

A different strategy for the synthesis of optically pure MAs resided in the asymmetric reduction of PGA using stereoselective catalysts consisting of the iridium complexes of spiro pyridine–aminophosphine (spiroPAP) ligands. The reaction, which proceeded at a room temperature and under high hydrogen pressure, afforded (S)-MA and its analogues at up to 93 and 88–98% e.e., respectively (Yan et al. 2014).

The chemical syntheses exhibit certain disadvantages compared with their biocatalytic counterparts. Thus, the enantioselectivities of the aforementioned chemical reactions largely fell somewhat behind those of the best biocatalytic processes. The synthesis of the chiral catalysts is labor-demanding and their price may be prohibitive for large-scale use. Reduction with metal catalysts requires high hydrogen pressure and the corresponding equipment (autoclaves). In contrast, the capacity to accept a wide range of structurally similar substrates is an undisputable advantage of the metal catalysts.

A radically different approach to the synthesis of enantiopure products was demonstrated with the use of a chiral 3-D matrix as the reaction environment and exemplified in the synthesis of optically pure MAs (Yutthalekha et al. 2016). The chiral imprinted matrix was similar to that used for the chiral recognition of d- and l-DOPA (Yutthalekha et al. 2015). It consisted of mesoporous platinum deposited around liquid crystals of Brij 56 (polyoxyethylene (10) cetyl ether) and imprinted with optically pure MAs. The ability of the matrix to affect the enantioselectivity of the reaction was shown for the electrochemical reduction of PGA into optically enriched (R)- or (S)-MA depending on the imprinting molecule ((R)- or (S)-MA, respectively). Although the e.e. obtained were low (≤ 19.05%), this new principle is certainly worthy of further investigation.

Another option for optically pure MA preparation is the diastereomeric crystallization, exemplified by the resolution of chiral MA (Pham et al. 2009). The principle of this method is the interaction of (R,S)-MA with an optically pure compound followed by crystallizing one of the two diastereomers thus formed. The correctness of this principle was demonstrated with various resolving agents, although the e.e. of the diastereomeric products was generally low. The highest selectivity for (S)-MA (e.e. 52.3%) was obtained with l-Phe as a compound structurally similar to (S)-MA. Subsequently, the product e.e. was increased to 85% through the optimization of the MA/l-Phe ratio. Performance of this method with high MA concentrations (up to 2.171 M) is advantageous, but the consumption of large amounts of the resolving agent (such as 0.36 M) is a drawback. In addition, the product is a diastereomeric mixture consisting of MA and Phe at a ca. 1:1 ratio. However, this physico-chemical method can compete with the chemically or enzymatically catalyzed reactions through its simplicity and robustness.

Conclusions and prospects

The review of the optically pure MA production processes suggests that the biocatalytic procedures are strong competitors of the chemical or physico-chemical ones. The preparation of the biocatalysts is possible under environmentally benign conditions, and the biocatalysts can be used in various forms enabling repeated use. The heterologous production of NLases has been improved, enabling the preparation of these enzymes (both prokaryotic and eukaryotic) in E. coli with high yields and at up to hundred-liter scale. The biocatalytic reactions require no extreme conditions and no special precautions except for standard measures connected with handling the nitriles. The use of organic solvents in these processes is low, as is their waste production. On the other hand, the chiral metal catalysts exhibit advantages such as robustness and a lower susceptibility to the substrate variations compared to the enzymes.

The industrial implementation of the biocatalytic processes designed at the lab scale requires further optimization of the catalyst performance and the process. The improved knowledge of enzyme crystal structures will strengthen the role of rational enzyme design and engineering. These studies have high potential to bring biocatalysis to a prominent position among processes for the industrial production of chiral building blocks such as MAs.

References

Blacker AJ, Houson IN (2002) Preparation of mandelic acid derivatives. Patent WO2002066410A1 (29. 8. 2002)

Cao Y, Wu SS, Li JH, Wu B, He BF (2014) Highly efficient resolution of mandelic acid using lipase from Pseudomonas stutzeri LC2-8 and a molecular modeling approach to rationalize its enantioselectivity. J Mol Catal B-Enzym 99:108–113. https://doi.org/10.1016/j.molcatb.2013.10.026

Chen S, Liu FY, Zhan K, Huang HS, Wang HN, Zhou JY, Zhang J, Gong YW, Zhang DL, Chen YP, Lin C, Wang B (2016) An efficient enzymatic aminolysis for kinetic resolution of aromatic α-hydroxyl acid in non-aqueous media. Tetrahedron Lett 57(48):5312–5314. https://doi.org/10.1016/j.tetlet.2016.10.054

Chmura A, Rustler S, Paravidino M, van Rantwijk F, Stolz A, Sheldon RA (2013) The combi-CLEA approach: enzymatic cascade synthesis of enantiomerically pure (S)-mandelic acid. Tetrahedron-Asymmetry 24(19):1225–1232. https://doi.org/10.1016/j.tetasy.2013.08.013

Gong JS, Li H, Lu ZM, Shi JS, Xu ZH (2012) Recent progress in the application of nitrilase in the biocatalytic synthesis of pharmaceutical intermediates. Prog Chem 27(4):448–458. https://doi.org/10.7536/PC141113

Guo F, Ye LD, Li AP, Yan XH, Yang CC, Yu HW (2016) Insight into the role of halogen bond in the activity of D-mandelate dehydrogenase toward halogenated substrates. Tetrahedron Lett 57(18):1944–1948. https://doi.org/10.1016/j.tetlet.2016.03.001

He YC, Ma CL, Zhang X, Li L, Xu JH, Wu MX (2013) Highly enantioselective oxidation of racemic phenyl-1,2-ethanediol to optically pure (R)-(−)-mandelic acid by a newly isolated Brevibacterium lutescens CCZU12-1. Appl Microbiol Biotechnol 97(16):7185–7194. https://doi.org/10.1007/s00253-013-4989-4

Jiang XP, Lu TT, Liu CH, Ling XM, Zhuang MY, Zhang JX, Zhang YW (2016) Immobilization of dehydrogenase onto epoxy-functionalized nanoparticles for synthesis of (R)-mandelic acid. Int J Biol Macromol 88:9–17. https://doi.org/10.1016/j.ijbiomac.2016.03.031

Ju X, Yu HL, Pan J, Wei DZ, Xu JH (2010) Bioproduction of chiral mandelate by enantioselective deacylation of α-acetoxyphenylacetic acid using whole cells of newly isolated Pseudomonas sp. ECU1011. Appl Microbiol Biotechnol 86(1):83–91. https://doi.org/10.1007/s00253-009-2286-z

Kaplan O, Veselá AB, Petříčková A, Pasquarelli F, Pičmanová M, Rinágelová A, Bhalla TC, Pátek M, Martínková L (2013) A comparative study of nitrilases identified by genome mining. Mol Biotechnol 54(3):996–1003. https://doi.org/10.1007/s12033-013-9656-6

Kaul P, Banerjee A, Banerjee UC, Nitrile hydrolases in: Polaina J, Mac Cabe AP (Eds.): Industrial enzymes: structure, function and applications. Springer Dordrecht 2007, pp. 531–547

Li GY, Huang KL, Jiang YR, Ding P (2007) Production of (R)-mandelic acid by immobilized cells of Saccharomyces cerevisiae on chitosan carrier. Process Biochem 42(10):1465–1469. https://doi.org/10.1016/j.procbio.2007.06.015

Liu ZQ, Zhang XH, Xue YP, Xu M, Zheng YG (2014) Improvement of Alcaligenes faecalis nitrilase by gene site saturation mutagenesis and its application in stereospecific biosynthesis of (R)-(–)-mandelic acid. J Agric Food Chem 62(20):4685–4694. https://doi.org/10.1021/jf405683f

Ma BD, Yu HL, Pan J, Liu JY, Ju X, Xu JH (2013) A thermostable and organic-solvent tolerant esterase from Pseudomonas putida ECU1011: catalytic properties and performance in kinetic resolution of alpha-hydroxy acids. Bioresour Technol 133:354–360. https://doi.org/10.1016/j.biortech.2013.01.089

Martínková L, Křen V (2010) Biotransformations with nitrilases. Curr Opin Chem Biol 14(2):130–137. https://doi.org/10.1016/j.cbpa.2009.11.018

Martínková L, Rucká L, Nešvera J, Pátek M (2017) Recent advances and challenges in the heterologous production of microbial nitrilases for biocatalytic applications. World J Microbiol Biotechnol 33(1):8. https://doi.org/10.1007/s11274-016-2173-6

Ni K, Wang H, Zhao L, Zhang M, Zhang S, Ren Y, Wei D (2013) Efficient production of (R)-(–)-mandelic acid in biphasic system by immobilized recombinant E. coli. J Biotechnol 167(4):433–440. https://doi.org/10.1016/j.jbiotec.2013.07.024

Osprian I, Fechter MH, Griengl H (2003) Biocatalytic hydrolysis of cyanohydrins: an efficient approach to enantiopure α-hydroxy carboxylic acids. J Mol Catal B-Enzym 24-25:89–98. https://doi.org/10.1016/S1381-1177(03)00113-9

Petříčková A, Sosedov O, Baum S, Stolz A, Martínková L (2012) Influence of point mutations near the active site on the catalytic properties of fungal arylacetonitrilases from Aspergillus niger and Neurospora crassa. J Mol Catal B-Enzym 77:74–80. https://doi.org/10.1016/j.molcatb.2012.01.005

Pham XH, Kim JM, Chang SM, Kim IH, Kim WS (2009) Enantioseparation of D/L-mandelic acid with L-phenylalanine in diastereomeric crystallization. J Mol Catal B-Enzym 60(1–2):87–92. https://doi.org/10.1016/j.molcatb.2008.12.023

Robertson DE, Chaplin JA, DeSantis G, Podar M, Madden M, Chi E, Richardson T, Milan A, Miller M, Weiner DP, Wong K, McQuaid J, Farwell B, Preston LA, Tan X, Snead MA, Keller M, Mathur E, Kretz PL, Burk MJ, Short JM (2004) Exploring nitrilase sequence space for enantioselective catalysis. Appl Environ Microbiol 70(4):2429–2436. https://doi.org/10.1128/AEM.70.4.2429-2436.2004

Rucká L, Volkova O, Pavlík A, Kaplan O, Kracík M, Nešvera J, Martínková L, Pátek M (2014) Expression control of nitrile hydratase and amidase genes in Rhodococcus erythropolis and substrate specificities of the enzymes. Antonie Van Leeuwenhoek 105(6):1179–1190. https://doi.org/10.1007/s10482-014-0179-3

Rustler S, Motejadded H, Altenbuchner J, Stolz A (2008) Simultaneous expression of an arylacetonitrilase from Pseudomonas fluorescens and a (S)-oxynitrilase from Manihot esculenta in Pichia pastoris for the synthesis of (S)-mandelic acid. Appl Microbiol Biotechnol 80(1):87–97. https://doi.org/10.1007/s00253-008-1531-1

Saeed A, Shahzad D, Faisal M, Larik FA, El-Seedi HR, Channar PA (2017) Developments in the synthesis of the antiplatelet and antithrombotic drug (S)-clopidogrel. Chirality 29(11):684–707. https://doi.org/10.1002/chir.22742

Shangguan JJ, Fan LQ, Ju X, Zhu QQ, Wang FJ, Zhao J, Xu JH (2012) Expression and characterization of a novel enantioselective lipase from Aspergillus fumigatus. Appl Biochem Biotechnol 168(7):1820–1833. https://doi.org/10.1007/s12010-012-9899-x

Sosedov O, Matzer K, Bürger S, Kiziak C, Baum S, Altenbuchner J, Chmura A, van Rantwijk F, Stolz A (2009) Construction of recombinant Escherichia coli catalysts which simultaneously express an (S)-oxynitrilase and different nitrilase variants for the synthesis of (S)-mandelic acid and (S)-mandelic amide from benzaldehyde and cyanide. Adv Synth Catal 351(10):1531–1538. https://doi.org/10.1002/adsc.200900087

Sosedov O, Baum S, Bürger S, Matzer K, Kiziak C, Stolz A (2010) Construction and application of variants of the Pseudomonas fluorescens EBC191 arylacetonitrilase for increased production of acids or amides. Appl Environ Microbiol 76(11):3668–3674. https://doi.org/10.1128/AEM.00341-10

Sosedov O, Stolz A (2014) Random mutagenesis of the arylacetonitrilase from Pseudomonas fluorescens EBC191 and identification of variants, which form increased amounts of mandeloamide from mandelonitrile. Appl Microbiol Biotechnol 98(4):1595–1607. https://doi.org/10.1007/s00253-013-4968-9

Sun HH, Wang HL, Gao WY, Chen LF, Wu K, Wei DZ (2015) Directed evolution of nitrilase PpL19 from Pseudomonas psychrotolerans L19 and identification of enantiocomplementary mutants toward mandelonitrile. Biochem Biophys Res Commun 468(4):820–825. https://doi.org/10.1016/j.bbrc.2015.11.038

Thuku RN, Brady D, Benedik MJ, Sewell BT (2009) Microbial nitrilases: versatile, spiral forming, industrial enzymes. J Appl Microbiol 106(3):703–727. https://doi.org/10.1111/j.1365-2672.2008.03941.x

Veselá AB, Křenková A, Martínková L (2015) Exploring the potential of fungal arylacetonitrilases in mandelic acid synthesis. Mol Biotechnol 57(5):466–474. https://doi.org/10.1007/s12033-015-9840-y

Veselá AB, Rucká L, Kaplan O, Pelantová H, Nešvera J, Pátek M, Martínková L (2016) Bringing nitrilase sequences from databases to life: the search for novel substrate specificities with a focus on dinitriles. Appl Microbiol Biotechnol 100(5):2193–2202. https://doi.org/10.1007/s00253-015-7023-1

Wang HL, Sun HH, Wei DZ (2013a) Discovery and characterization of a highly efficient enantioselective mandelonitrile hydrolase from Burkholderia cenocepacia J2315 by phylogeny-based enzymatic substrate specificity prediction. BMC Biotechnol 13:14. https://doi.org/10.1186/1472-6750-13-14

Wang P, Yang JF, Jiang L, Feng J, Yang CL, Li DL (2013b) A bi-enzymatic system for efficient enantioselective bioconversion of racemic mandelic acid. J Mol Catal B-Enzym 94:47–50. https://doi.org/10.1016/j.molcatb.2013.05.009

Wang HL, Fan HY, Sun HH, Zhao L, Wei DZ (2015a) Process development for the production of (R)-(−)-mandelic acid by recombinant Escherichia coli cells harboring nitrilase from Burkholderia cenocepacia J2315. Org Process Res Dev 19(12):2012–2016. https://doi.org/10.1021/acs.oprd.5b00269

Wang HL, Gao WY, Sun HH, Chen LF, Zhang L, Wang XD, Wei DZ (2015b) Protein engineering of a nitrilase from Burkholderia cenocepacia J2315 for efficient and enantioselective production of (R)-o-chloromandelic acid. Appl Environ Microbiol 81(24):8469–8477. https://doi.org/10.1128/AEM.02688-15

Wang P, Li DL Yang JF, Jiang L, Feng J, Yang CL, Shi RF (2014) Immobilization of (S)-mandelate dehydrogenase and its catalytic performance on stereoselective transformation of mandelic acid. J Taiwan Inst Chem Eng 45(3):744–748. https://doi.org/10.1016/j.jtice.2013.09.016

Xiao MT, Huang YY, Shi XA, Guo YH (2005) Bioreduction of phenylglyoxylic acid to R-(–)-mandelic acid by Saccharomyces cerevisiae FD11b. Enzym Microb Technol 37(6):589–596. https://doi.org/10.1016/j.enzmictec.2005.02.018

Xiao MT, Huang YY, Ye J, Guo YH (2008) Study on the kinetic characteristics of the asymmetric production of R-(–)-mandelic acid with immobilized Saccharomyces cerevisiae FD11b. Biochem Eng J 39(2):311–318. https://doi.org/10.1016/j.bej.2007.10.002

Xue YP, Xu M, Chen HS, Liu ZQ, Wang YJ, Zheng YG (2013a) A novel integrated bioprocess for efficient production of (R)-(–)-mandelic acid with immobilized Alcaligenes faecalis ZJUTB10. Org Process Res Dev 17(2):213–220. https://doi.org/10.1021/op3001993

Xue YP, Tian FF, Ruan LT, Liu ZQ, Zheng YG, Shen YC (2013b) Concurrent obtaining of aromatic (R)-2-hydroxyacids and aromatic 2-ketoacids by asymmetric oxidation with a newly isolated Pseudomonas aeruginosa ZJB1125. J Biotechnol 167(3):271–278. https://doi.org/10.1016/j.jbiotec.2013.06.015

Yamamoto K, Oishi K, Fujimatsu I, Komatsu KI (1991) Production of R-(–)-mandelic acid from mandelonitrile by Alcaligenes faecalis ATCC 8750. Appl Environ Microbiol 57(10):3028–3032

Yan PC, Xie JH, Zhang XD, Chen K, Li YQ, Zhou QL, Che DQ (2014) Direct asymmetric hydrogenation of α-keto acids by using the highly efficient chiral spiro iridium catalysts. Chem Commun 50(100):15987–15990. https://doi.org/10.1039/c4cc07643e

Yao CJ, Cao Y, Wu SS, Li S, He BF (2013) An organic solvent and thermally stable lipase from Burkholderia ambifaria YCJ01: purification, characteristics and application for chiral resolution of mandelic acid. J Mol Catal B-Enzym 85-86:105–110. https://doi.org/10.1016/j.molcatb.2012.08.016

Yildirim D, Tükel SS (2014) Asymmetric ammonolysis of (R/S)-mandelic acid by immobilized lipases via direct amidation of mandelic acid in biphasic media. Biocatal Biotransform 32(5–6):251–258. https://doi.org/10.3109/10242422.2014.971120

Yilmaz E (2012) Enantioselective enzymatic hydrolysis of racemic drugs by encapsulation in sol-gel magnetic sporopollenin. Bioprocess Biosyst Eng 35(4):493–502. https://doi.org/10.1007/s00449-011-0622-z

Yutthalekha T, Warakulwit C, Limtrakul J, Kuhn A (2015) Enantioselective recognition of DOPA by mesoporous platinum imprinted with mandelic acid. Electroanalysis 27(9):2209–2213. https://doi.org/10.1002/elan.201500145

Yutthalekha T, Wattanakit C, Lapeyre V, Nokbin S, Warakulwit C, Limtrakul J, Kuhn A (2016) Asymmetric synthesis using chiral-encoded metal. Nat Commun 7:12678. https://doi.org/10.1038/ncomms12678

Zhang ZJ, Pan JA, Liu JF, Xu JH, He YC, Liu YY (2011) Significant enhancement of (R)-mandelic acid production by relieving substrate inhibition of recombinant nitrilase in toluene–water biphasic system. J Biotechnol 152(1–2):24–29. https://doi.org/10.1016/j.jbiotec.2011.01.013

Zhang CS, Zhang ZJ, Li CX, Yu HL, Zheng GW, Xu JH (2012) Efficient production of (R)-o-chloromandelic acid by deracemization of o-chloromandelonitrile with a new nitrilase mined from Labrenzia aggregata. Appl Microbiol Biotechnol 5(1):91–99. https://doi.org/10.1007/s00253-012-3993-4

Acknowledgements

The financial support by the Czech Science Foundation (project 18-00184S) and Czech Ministry of Education (LTC17009) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Martínková, L., Křen, V. Biocatalytic production of mandelic acid and analogues: a review and comparison with chemical processes. Appl Microbiol Biotechnol 102, 3893–3900 (2018). https://doi.org/10.1007/s00253-018-8894-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-8894-8