Abstract

Trehalose (α-d-glucopyranosyl-(1 → 1)-α-d-glucopyranoside) is a non-reducing disaccharide composed of two glucose molecules linked by an α,α-1,1-glycosidic bond. It possesses physicochemical properties, which account for its biological roles in a variety of prokaryotic and eukaryotic organisms and invertebrates. Intensive studies of trehalose gradually uncovered its functions, and its applications in foods, cosmetics, and pharmaceuticals have increased every year. Currently, trehalose is industrially produced by the two-enzyme method, which was first developed in 1995 using maltooligosyltrehalose synthase (EC 5.4.99.15) and subsequently using maltooligosyltrehalose trehalohydrolase (EC 3.2.1.141), with starch as the substrate. This biotechnical method has lowered the price of trehalose and expanded its applications. However, when trehalose synthase (EC 5.4.99.16) was later discovered, this method for trehalose production using maltose as the substrate soon became a popular topic because of its simplicity and potential in industrial production. Since then, many trehalose synthases have been studied. This review summarizes the sources and characteristics of reported trehalose synthases, and the most recent advances on structural analysis of trehalose synthase, catalytic mechanism, molecular modification, and usage in industrial production processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Trehalose (α-d-glucopyranosyl-(1 → 1)-α-d-glucopyranoside) is a naturally occurring disaccharide composed of two glucose molecules with an α,α-1,1-glycosidic bond and was first isolated in 1832 from the ergot of rye (Teramoto et al. 2008). Since then, it was found to be present in bacteria, fungi, plants, and in many invertebrates, but it has not been found in mammals (Elbein et al. 2003). This is caused by (i) the absence of any trehalose synthesis genes and (ii) the significant amounts of trehalase (EC 3.2.1.28) in the human small intestine that specifically hydrolyze trehalose into two glucose molecules (Argüelles 2014). The other two isomers of α,α-trehalose, namely α,β-trehalose and β,β-trehalose, have not been isolated from any living organisms, but they were found in koji extract and starch hydrolysates, respectively (Elbein et al. 2003). In general, when people talk about trehalose, they are referring to α,α-trehalose. In 2000, trehalose was designated as generally recognized as safe (GRAS) by the US Food and Drug Administration (FDA,GRN No. 000045) (Ohtake and Wang 2011).

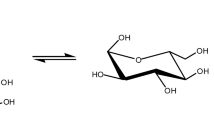

At first, trehalose was chemically synthesized via ethylene oxide addition reaction using 2,3,4,5-tetra-O-acetyl-d-glucose and 3,4,6-tri-O-acetyl-1,2-anhydro-d-glucose as the substrates, and later directly extracted form brewer’s yeast (Elbein et al. 2003). The price of trehalose remained as high as 700 US$ kg−1 until the development of a two-enzyme method. Here, maltooligosyltrehalose synthase (MTSase, EC 5.4.99.15) and maltooligosyltrehalose trehalohydrolase (MTHase, EC 3.2.1.141) were used in utilizing starch or maltodextrins as the substrate, which lowered the price to 5–6 US$ kg−1 in 1995 (Teramoto et al. 2008). MTSase converts α,α-1,4 bond to α,α-1,1 bond at the reducing end of the maltooligosaccharide, and MTHase releases trehalose by hydrolysis of the neighboring α,α-1,4 bond. Approximately 30,000 tons of trehalose is being produced every year utilizing this synthesis procedure (Song et al. 2016). Another well-known synthesis pathway is via trehalose-6-phosphate. Trehalose phosphate synthase (TPS, EC 2.4.1.15) catalyzes uridine diphosphate glucose with glucose-6-phosphate to produce trehalose-6-phosphate. Trehalose-6-phosphate phosphatase (TPP, EC 3.1.3.12) then converts trehalose-6-phosphate to trehalose. This pathway was known for its applications in bacteria or in plants for improved drought tolerance (Nuccio et al. 2015). Another trehalose synthase (TS, EC 5.4.99.16) pathway was found in some bacteria, e.g., Pimelobacter sp., which catalyzed a reversible interconversion of maltose and trehalose (Nishimoto et al. 1996). These three biosynthesis pathways are shown in Fig. 1.

Three biosynthesis pathways of trehalose production. The enzymes involved in the biosynthesis were as follows: a Trehalose phosphate synthase (TPS, EC 2.4.1.15) and trehalose-6-phosphate phosphatase (TPP, EC 3.1.3.12), b maltooligosyltrehalose synthase (MTSase,EC 5.4.99.15) and maltooligosyltrehalose trehalohydrolase (MTHase, EC 3.2.1.141), and c trehalose synthase (TS, EC 5.4.99.16). The glycosidic bonds were annotated in red

The MTSase/MTHase method has greatly lowered the price of trehalose and helped to expand the applications of trehalose. However, MTSase only acts on linear maltooligosaccharides with the degree of polymerization (DP) ≥ 3, and the branched starch, maltose, and maltotriose are left in the reaction mixture, which limits the efficiency of trehalose production. The one-enzyme method (TS pathway), on the other hand, attracted much attention from researchers who were eager to exploit an alternative and superior way to produce trehalose. Due to its simplicity, many studies have been performed with this method (Nishimoto et al. 1996; Kim et al. 2010; Wang et al. 2017). Reviews of trehalose production methods (Schiraldi et al. 2002), trehalose metabolism in bacteria (Ruhal et al. 2013) and plants (Lunn et al. 2014), and functions and applications of trehalose (Ohtake and Wang 2011) have been published, but there has been no specific review on trehalose synthase pathway. Our review focuses on the current status of trehalose biotechnological production via the trehalose synthase pathway, including characteristics of TSs from various organisms, catalytic mechanism, structural analysis, molecular modification, downstream purification, and its future prospects to be applied in the enzymatic manufacturing of trehalose.

Biological functions of trehalose

Anhydrobiotic organisms are found to survive in almost complete dehydration state (e.g., 99% of water is removed). Trehalose accumulates endogenously in a variety of organisms such as brine shrimp and the resurrection plant such as selaginella during their dehydrating process, which is thought to play a protective role either as a water replacement molecule or as a vitrification agent in the dry state (Tapia et al. 2015; Williams et al. 2015). In plants, the disaccharide sucrose plays a similar role as trehalose, but most organisms prefer trehalose to sucrose because trehalose has a less tendency to form crystals (Elbein et al. 2003). In insects, trehalose serves as an energy and carbon reservoir for their growth and is consumed during flight in the hemolymph and thorax muscles (Wegener et al. 2010). Furthermore, trehalose is a stabilizer of membranes and proteins (Furuki et al. 2009). It also acts as a protectant against physiological stresses, including hypothermia (Chen and Haddad 2004), hyperthermia (Reina-Bueno et al. 2012), osmotic stress (Beblo-Vranesevic et al. 2017), and ethanol and oxidation (Bandara et al. 2009). In yeast, heat shock induces active expression of trehalose-6-P synthase, leading to the accumulation of trehalose that stabilizes enzymes and reduces the heat-induced formation of protein aggregates (Reina-Bueno et al. 2012). Exposure of S. cerevisiae to oxygen radicals increases the trehalose amount in cells, and it is suggested that trehalose acts as a free radical scavenger to prevent the amino acid damage (Bandara et al. 2009). In mycobacteria and corynebacteria, trehalose is the basic component of cell wall glycolipids. The cord factor, also known as trehalose-6,6′-dimycolate, is a toxic lipid in the cell wall of mycobacteria that has been identified as the main virulence factor of tuberculosis and is also responsible for the low permeability of the mycobacteria cell wall which lead to the drug resistance of these organisms (Caner et al. 2013; Elbein et al. 2003).

Physicochemical properties of trehalose

Important properties of trehalose are summarized in Table 1. Trehalose is a non-reducing disaccharide due to the linkage of two glucopyranose rings at the reducing end of the glycosyl residues. The pH stability of trehalose was tested in pH value of 3.5 to 10 at 100 °C for 24 h with a result of over 99% of trehalose remain unchanged (Ohtake and Wang 2011). This is due to the low energy (< 1 kcal/mol) of the α,α-1,1-glycosidic bond, which enables trehalose to be the most stable sugar in solutions. In addition, the transition glass temperature (Tg) of trehalose is higher than that of any other disaccharide at similar water content, which facilitates freeze-drying and spray drying processes (Zhang et al. 2017). Moreover, trehalose is superior to sucrose, a well-known and low-price disaccharide, in some aspects such as having a higher melting temperature, lower rate of hydrolysis, no acrylamide formation, lower sweetness, and lower calories (Gharsallaoui et al. 2008; Ohtake and Wang 2011). Therefore, due to its unique properties, trehalose is widely applied in food, cosmetic, and pharmaceutical industries (see below).

Applications of trehalose

In food industries, trehalose was used along with the food drying or frozen process to maintain the polyphenol content, the antioxidant activity, the aromatic volatiles (Kopjar et al. 2013), and the color (Umene et al. 2015) in fruits and vegetables (Neri et al. 2014). Some explanations for these phenomena have been proposed that trehalose is able (i) to form glass and lock the compounds, (ii) to replace the water and retain the hydrogen bonding, (iii) to increase the surface tension of the bulk solvent, (iv) to prevent phase separations in lipid bilayers, and (v) to keep membrane integrity (Loncaric et al. 2014). Other sugars such as sucrose and mannitol have a similar protective effect during freezing but are not as efficient as trehalose. This is due to their lower Tg (e.g., Tg, sucrose = 65–75 °C) in comparison with trehalose (Tg, trehalose = 110 °C), and they tend to hydrolyze during freezing (Ohtake and Wang 2011). Trehalose also served as an additive for food flavor enhancement (Ohtake and Wang 2011), prevention of starch aging (Liang et al. 2015), odor reduction, and extension of the shelf life by increasing its Tg (Yu et al. 2017a, b). In addition, no acrylamide was formed between trehalose and asparagine in food products because of the non-reducing property of trehalose. Furthermore, trehalose was lowly cariogenic with reduced caries scores in a rat experiment (Neta et al. 2000). Trehalose was also reported to mitigate insulin resistance, which leads to its value as a substitute of glucose or sucrose for diabetic patients and weight watchers (Arai et al. 2010).

In cosmetics, trehalose has been included in creams and lotions as moisture-retaining agent and storage stability enhancer and suppressor of the odor from active ingredients (Ohtake and Wang 2011). In particular, trehalose acted as a key ingredient in suppressing human body odor by stabilizing the unsaturated fatty acids from degradation (Schiraldi et al. 2002).

In pharmaceuticals, trehalose has had roles in the preservation of tissues and organs for transplantation (Ikeda et al. 2015) and cryopreservation of blood stem cells (Martinetti et al. 2017) and sperm (Olaciregui and Gil 2017), with increased cell viability. Trehalose was also reported to have a suppression effect on bone loss (Wada et al. 2014). In vivo studies showed trehalose was found to be effective in reducing peptide aggregation and increasing autophagy in animal models of neurodegenerative disorders including Alzheimer’s disease, Parkinson’s disease, and Huntington’s disease (Emanuele 2014). However, how trehalose helps reduce the aggregated peptides still remains unclear and needs to be further investigated (Portbury et al. 2017).

Biotechnological production of TS

Sources and characteristics of various TSs

Since the discovery of the TS pathway in bacteria metabolism (Elbein 1974; Paul et al. 2008), TSs have been purified from Pimelobacter sp. R48 (Nishimoto et al. 1996), Thermus aquaticus ATCC33923 (Nishimoto et al. 1997), Thermus caldophilus (Koh et al. 1998), Thermus thermophilus HB8 (Zdziebło and Synowiecki 2006), Pseudomonas sp. F1 (Ohguchi et al. 1997), and Mycobacterium smegmatis (Pan et al. 2004). Meanwhile, many TS genes have been cloned and heterologously expressed in Escherichia coli, as summarized in Table 2. The highest enzyme activities of TSs were reported from Thermus aquaticus with 135 U/mg (Nishimoto et al. 1997), and a novel TS gene retrieved from metagenomics with 134 U/mg activity on maltose (Jiang et al. 2013). TS does not only have transglucosidic activity but also have weak hydrolytic activity that hydrolyze trehalose and/or maltose into glucose. Therefore, the byproduct glucose was observed during the enzymatic reaction by most of the reported TSs. There was only one exception among all the reported TSs that no glucose was produced, which was the one from Pseudomonas stutzeri CJ 38 (Lee et al. 2005). TS from P. stutzeri catalyzed the reaction from maltose with a trehalose yield of 75% at 15 °C with no glucose detected after 19 h of reaction. When the reaction temperature was increased up to 35 °C, there was still no glucose observed in the reaction mixture.

It is found that, in general, there are two trehalose synthase genes existing in the same organism with one group ranging from 1600 to 1800 bp and the other one from 2800 to 3300 bp. In particular, P. stutzeri TS contains the nucleotides of 2067 bp, which does not belong to any of the two groups. The neighbor-joining phylogenetic trees of TSs from P. stutzeri and other organisms were constructed as shown in Fig. 2. The TS from P. stutzeri was far away from other TS homologs that indicates the low sequence similarity and its different origins. The amino acid sequence of TS from P. stutzeri CJ38 was then aligned with TSs from M. smegmatis, D. radiodurans R1, M. tuberculosis, T. terrenum, and T. thermophiles (Fig. S1). However, as no crystal structure of P. stutzeri TS was obtained, it still remains unknown why P. stutzeri TS does not produce a byproduct.

Neighbor-joining phylogenetic tree of amino acid sequences of reported trehalose synthases from various organisms. Accession number of each trehalose synthase was provided in the figure. The tree was constructed by iTOL v4 (http://itol.embl.de)

The values of conversion rate from enzymatic reactions with various TSs (in Table 2) imply that the substrate concentration did not have a suppression impact on the final trehalose yield. Some TSs from T. aquaticus (Nishimoto et al. 1997), T. curvata (Liang et al. 2013), P. torridus (Chen et al. 2006), P. stutzeri, and Pseudomonas sp. P8005 (Gao et al. 2013) were reported to have low activity on sucrose and catalyze the formation of trehalulose, which exhibited similar activity to isomaltulose synthase (EC 5.4.99.11). With regard to intramolecular transglucosylation, isomaltulose synthase has been studied in detail and could provide some insights into crystal structure analysis and molecular engineering of trehalose synthase (Mu et al. 2014). In conclusion, the low enzyme activity and instability of TS are still the main barriers for TS becoming the main force of industrial production of trehalose.

Temperature influence on trehalose yield

The theoretical equilibrium constant for the reversible interconversion by TS was 82% towards trehalose at 25 °C using thermodynamic parameters (Tewari and Goldberg 1991). The highest conversion rates of 80 and 92%, respectively, in favor of trehalose reported so far were with TS from T. thermophilus at 30 °C after 48 h and with D. radiodurans at 5 °C after 48 h (Wang et al. 2007). As reported, TS from D. radiodurans is a cold-active enzyme with the optimal temperature at 15 °C and retained 90% of its enzyme activity at 5 °C, which explained for its high product yield of 92% at 5 °C with barely no glucose observed. Other reported conversion rates towards trehalose were approximately 60–74% (Table 2). There was one phenomenon observed that the yield of trehalose decreased, and glucose increased at higher temperature. The possible mechanism lies behind is the increased flexibility of the protein structure in higher temperature, making the catalytic pocket more accessible to water molecules that attack the split glucose before the formation of the α,α-1,1- or α,α-1,4-glycosidic bond (Koh et al. 2003). In general, the decreased reaction temperature will achieve more trehalose product and less byproduct during the reaction. However, it will also extend the reaction time and require more energy to reach the equilibrium, which should be taken into account when considering the total production cost. In addition, there is no Maillard reaction for trehalose with amino acids as its non-reducing characteristic. Thus, higher reaction temperature with faster reaction rate, less possibility of bacterial contamination, and a compromised product yield is feasible for trehalose industrial production with a thermostable enzyme.

The effects of various metal ions on TS activity

Metal ions are crucial to the biological function and structure integrity of many enzymes (Barondeau and Getzoff 2004). Thus, the effects of various metal ions on TS activity were examined, and generally the addition of Ca2+ or Mg2+ increased most of the activity of the TSs by 10–15% (Chen et al. 2006; Zhu et al. 2010). The experimental results were in accordance with the structure findings that two metal ion-binding sites, Ca2+ and Mg2+, were found in TS structures from M. smegmatis and D. radiodurans (Caner et al. 2013; Wang et al. 2014). A very recent report of TS structure from T. terrenum claimed to discover two more metal ion-binding sites, which may explain for its good thermal stability of 80% activity retained after 30 min incubation at 70 °C (Wang et al. 2017). However, more experiments should be carried out to prove its structure importance.

Structural analysis and molecular modification

Catalytic mechanism of TS

Zhang et al. (2011) demonstrated a two-step, double displacement mechanism of TS from M. smegmatis (MsTS), which was consistent with other GH13 family members, e.g., isomaltulose synthase (EC 5.4.99.11) (Cheetham 1984; Xu et al. 2013). First, Asp230 in MsTS attacks the substrate on the anomeric center with a covalent β-glucosyl-enzyme intermediate, and a free glucose is formed inside the catalytic pocket. Second, the released glucose reorients within the active site as the 1-hydroxyl or 4-hydroxyl position for re-attack. The structure of MsTS revealed a narrow and enclosed active site pocket within which the intramolecular rearrangements occur (Caner et al. 2013). Structure analyses of TS from D. radiodurans (DrTS) confirmed a closed conformation between subdomain B and S7 by the induction of the substrate, which enhances the isomerization and reduces the water entry for hydrolysis (Wang et al. 2014). Kinetics research indicated the protein conformational changes were rate-limiting (Zhang et al. 2011).

Importance of C-terminal domain in TS for enzymatic catalysis

As mentioned above, TS is a member of the GH13 family, which is comprised of three domains: a catalytic (β/α)8 barrel, subdomain B, and a C-terminal domain shown in Fig. 3 (Caner et al. 2013). Domain C comprises a seven-stranded antiparallel β-sandwich from β13 to β19. The loop-rich subdomain 7 (S7, residues 315–361 in DrTS) and subdomain 8 (S8, residues 384–449 in DrTS) were reported to be unique to the TS structure (Wang et al. 2014). In DrTS, domain C and S8 contribute to the dimer formation, while domain B and S7 serve as a gateway for the opening and closing of the active site (Wang et al. 2014).

Illustration of the architecture of trehalose synthase from Mycobacterium smegmatis (MsTS, PDB ID: 3ZO9), Mycobacterium tuberculosis (MtTS, PDB ID: 4LXF), and Deinococcus radiodurans (DrTS, PDB ID: 4TVU). Chain A of MsTS, MtTS, and DrTS was shown with helix, sheet, and loop in cyan, red, and orange, respectively. The surfaces of domains A, B, and C from chain B of MsTS, MtTS, and DrTS were shown in green, yellow, and red, respectively. MtTS and DrTS were in dimer and MtTS was in tetrameric form in buffer. The Cl−, Mg2+, and Ca2+ were represented in green, red, and magenta, respectively

As TS from T. thermophilus ATCC 33923 (TtTS) showed exceptional stability which was stable from pH 5.5–9.5 and up to 80 °C for 60 min, in comparison to other thermophilic TSs from M. ruber and P. torridus (see in Table 2). The amino acid sequence of TtTS was aligned with its homologs (Fig. S1), which indicated a special C-terminus that is particularly larger than most other TSs (Wang et al. 2007). Given that the C-terminus (415 amino acid residues) is the key difference from other TSs, the functions of the C-terminal domain were studied by deletion from TtTS (Wang et al. 2007; Cho et al. 2017), and the fusion proteins of C-terminus with other TSs were constructed (e.g., cold-active DrTS (Wang et al. 2007) and TSs from P. putida, C. glutamicum, Streptomyces coelicolor, and Thermotoga maritime (Li et al. 2017)). The results showed that the C-terminal domain from TtTS plays a key role in maintaining the thermostability, reducing the byproduct glucose formation, and increasing TS activity.

Directed evolution of various TSs

Molecular modification technology has been widely applied to enzymes for obtaining improved enzyme activity and thermostability, in order to have a prospect for industrial production. Some important mutants of trehalose synthase and their activities were summarized in Table 3. Three variants of T. curvata TS on amino acid leucine (position 116) displayed the variation of enzyme activity on maltose and sucrose compared to the wild type and the E330A variant only exhibited the hydrolase activity indicating its importance for product formation (Jiang et al. 2013). Wang et al. (2014) also reported three variants R148A, I150A, and N253A of D. radiodurans TS with decreased isomerase activity as low as 11% and increased hydrolase activity up to 180% compared to the wild type. However, as the previously reported one-site mutants have not exhibited higher isomerase activity or enhanced thermostability, the double-site mutagenesis could be applied to TS when some reported double-site mutants of other enzymes have displayed exciting results. For example, the double-site Y68I/G109P variant of d-psicose 3-epimerase from Clostridium bolteae for d-psicose production displayed an increased value of halftime from 156 to 260 min and a decreased KM value of 17.9% (Zhang et al. 2016). Another example was the double-site G121A/T122L variant of inulin fructotransferase from Streptomyces davawensis, which exhibited a 4.5 °C increase of melting temperature (Tm) value and a 48.7% enhancement of enzyme activity (Yu et al. 2017a, b). To date, five crystal structures of TS have been analyzed, as summarized in Table 4. The relationship between structure and function of TS has been well studied (Koh et al. 2003; Pan et al. 2004; Caner et al. 2013; Wang et al. 2014; Wang et al. 2017); thus, site-directed mutagenesis could be designed based on the TS structure to improve the enzyme activity and thermostability of TS. However, there is currently no report of any variant with higher thermostability of trehalose synthase yet.

Bioproduction of trehalose

Immobilization of TS

Immobilization techniques were applied to offer improved stability, increased activity, improved separation, reusable enzyme, and consequently more efficient and low-cost production (Eş et al. 2015). Cho et al. (2006) reported an immobilization of TS from T. caldophilus GK24 using Eupergit C250L as the carrier. The immobilized TS exhibited an optimal temperature shift from 45 to 65 °C and increased stability with 90% activity retained after 16 days at 70 °C, whereas the wild type only had 13% of the original activity after 6 days. In addition, the continuous reaction achieved better trehalose yield than the batch process due to the elimination of glucose formed during the reaction, a strong inhibitor to TS activity (Zhu et al. 2010). Another immobilization of TS from D. geothermalis was performed on glutaraldehyde activated silanized magnetic ferrous-ferric oxide (Panek et al. 2013). The nanoparticle size of the sample with the enzyme was below 30 nm. It retained 82% of the initial activity after 12 repeated batches. The advantage of using magnetic nanoparticle was the simplicity of separation between immobilized TS and the reaction medium by an external magnetic field. The carrier-free immobilization method, cross-linked enzyme aggregates (CLEAs), was tested on TS from M. ruber using polyethyleneimine and polyethylene glycol as precipitants and glutaraldehyde as the cross-linking reagent resulting in improved thermal and pH stability (Zheng et al. 2014). With the development of immobilization techniques, new materials and new methods will enable increased enzyme recovery and stability to lower the production cost (e.g., protein residue-explicit covalent immobilization for stability enhancement system (PRECISE) that orients the protein covalent bond to gain the best substrate access to the activity pocket, which is worth attempting on trehalose synthase enzyme (Wu et al. 2015a)).

Whole-cell production of trehalose

Trehalose synthase is an intracellular enzyme that must be released by cell disruption before enzymatic applications. The whole cells, as biocatalysts in the medium, possess advantages over the free TS enzymatic production process in that they omit the enzyme purification and immobilization processes. As reported, E. coli was treated with permeation reagents such as toluene and EDTA (Ma et al. 2006), chloroform (Zheng et al. 2015), or colistin sulfate (Song et al. 2016) to increase the permeability of small molecules through the cell membrane, whereas the enzymes were retained in the cells, and nearly no enzyme activity loss occurred. An alternative method was to display enzymes on the surface of living cells with the advantage of easy access of the substrates to the enzyme, simple subsequent separation and purification, and increased activity and stability (Schüürmann et al. 2014). It was reported that the TS gene from P. torridus integrated onto the Yarrowia lipolytica cell surface, exhibiting improved thermal and pH stability compared to free TS and a final trehalose yield of 73% under optimal conditions (Li et al. 2016).

Downstream purification of trehalose

The enzymatic process using trehalose synthase usually leads to a mixture of trehalose, maltose, and glucose. However, the separation and purification are hampered by their similarities in chemical structure and physicochemical properties. Thus, it is necessary to develop efficient and cost-saving processes for the purification of trehalose. Wu et al. (2013, 2015b) reported sequential enzymatic hydrolyses from maltose to glucose by glucoamylase and then glucose to gluconic acid by glucose oxidase to modify maltose and glucose in the mixture. A recent report showed a purification method using two-stage simulated moving bed chromatography (SMB) with a result of 97.6% purity of trehalose and 95.9% recovery yield (Song et al. 2016). In addition, it was reported that the residual maltose and glucose were fermented to ethanol by a Saccharomyces cerevisiae strain (Li et al. 2016).

Conclusions and future prospects

Trehalose is a functional sugar that is applied to food, cosmetic, and pharmaceutical applications (Ohtake and Wang 2011). However, the metabolism and physiological functions of trehalose in humans are still unclear and urgently need to be solved. The currently reported TSs could still not meet the criteria for the trehalose production due to their low enzyme activities and stabilities with regard to the total production cost. Thus, finding novel TS genes with superior properties of the corresponding enzymes from metagenomic DNA, that have been successfully applied to find for instance high-performance β-galactosidases (Erich et al. 2015; Rentschler et al. 2016), could be conducted in the future, as 99% of microorganisms in nature remain uncultured. Meanwhile, molecular engineering methods such as directed evolution and structure-based site-directed mutagenesis could also be performed to obtain an improved trehalose synthase for trehalose production. Finally, the food safety problem should be taken into account for industrial biotechnological production of trehalose.

References

Arai C, Arai N, Mizote A, Kohno K, Iwaki K, Hanaya T, Arai S, Ushio S, Fukuda S (2010) Trehalose prevents adipocyte hypertrophy and mitigates insulin resistance. Nutr Res 30(12):840–848. https://doi.org/10.1016/j.nutres.2010.10.009

Argüelles J-C (2014) Why can’t vertebrates synthesize trehalose? J Mol Evol 79(3–4):111–116. https://doi.org/10.1007/s00239-014-9645-9

Bandara A, Fraser S, Chambers PJ, Stanley GA (2009) Trehalose promotes the survival of Saccharomyces cerevisiae during lethal ethanol stress, but does not influence growth under sublethal ethanol stress. FEMS Yeast Res 9(8):1208–1216. https://doi.org/10.1111/j.1567-1364.2009.00569.x

Barondeau DP, Getzoff ED (2004) Structural insights into protein-metal ion partnerships. Curr Opin Struct Biol 14(6):765–774. https://doi.org/10.1016/j.sbi.2004.10.012

Beblo-Vranesevic K, Galinski EA, Rachel R, Huber H, Rettberg P (2017) Influence of osmotic stress on desiccation and irradiation tolerance of (hyper)-thermophilic microorganisms. Arch Microbiol 199(1):17–28. https://doi.org/10.1007/s00203-016-1269-6

Caner S, Nguyen N, Aguda A, Zhang R, Pan YT, Withers SG, Brayer GD (2013) The structure of the Mycobacterium smegmatis trehalose synthase reveals an unusual active site configuration and acarbose-binding mode. Glycobiology 23(9):1075–1083. https://doi.org/10.1093/glycob/cwt044

Cheetham PS (1984) The extraction and mechanism of a novel isomaltulose-synthesizing enzyme from Erwinia rhapontici. Biochem J 220(1):213–220. https://doi.org/10.1042/bj2200213

Chen Q, Haddad GG (2004) Role of trehalose phosphate synthase and trehalose during hypoxia: from flies to mammals. J Exp Biol 207(18):3125–3129. https://doi.org/10.1242/jeb.01133

Chen YS, Lee GC, Shaw JF (2006) Gene cloning, expression, and biochemical characterization of a recombinant trehalose synthase from Picrophilus torridus in Escherichia coli. J Agric Food Chem 54(19):7098–7104. https://doi.org/10.1021/jf060828q

Cho C-B, Park D-Y, Lee S-B (2017) Effect of C-terminal domain truncation of Thermus thermophilus trehalose synthase on its substrate specificity. Enzym Microb Technol 96:121–126. https://doi.org/10.1016/j.enzmictec.2016.10.006

Cho Y-J, Park O-J, Shin H-J (2006) Immobilization of thermostable trehalose synthase for the production of trehalose. Enzym Microb Technol 39(1):108–113. https://doi.org/10.1016/j.enzmictec.2005.10.004

Elbein AD (1974) The metabolism of α,α-trehalose. Adv Carbohydr Chem Biochem 30(C):227–256. https://doi.org/10.1016/S0065-2318(08)60266-8

Elbein AD, Pan YT, Pastuszak I, Carroll D (2003) New insights on trehalose: a multifunctional molecule. Glycobiology 13(4):17R–27R. https://doi.org/10.1093/glycob/cwg047

Emanuele E (2014) Can trehalose prevent neurodegeneration? Insights from experimental studies. Curr Drug Targets 15(5):551–557. https://doi.org/10.2174/1389450115666140225104705

Erich S, Kuschel B, Schwarz T, Ewert J, Böhmer N, Niehaus F, Eck J, Lutz-Wahl S, Stressler T, Fischer L (2015) Novel high-performance metagenome β-galactosidases for lactose hydrolysis in the dairy industry. J Biotechnol 210:27–37. https://doi.org/10.1016/j.jbiotec.2015.06.411

Eş I, Vieira JDG, Amaral AC (2015) Principles, techniques, and applications of biocatalyst immobilization for industrial application. Appl Microbiol Biotechnol 99(5):2065–2082. https://doi.org/10.1007/s00253-015-6390-y

Filipkowski P, Pietrow O, Panek A, Synowiecki J (2012) Properties of recombinant trehalose synthase from Deinococcus radiodurans expressed in Escherichia coli. Acta Biochim Pol 59(3):425–31

Furuki T, Oku K, Sakurai M (2009) Thermodynamic, hydration and structural characteristics of alpha, alpha-trehalose. Front Biosci 14:3523–3535. https://doi.org/10.2741/3468

Gao Y, Xi Y, Lu X-L, Zheng H, Hu B, Liu X-Y, Jiao B-H (2013) Cloning, expression and functional characterization of a novel trehalose synthase from marine Pseudomonas sp. P8005. World J Microbiol Biotechnol 29(11):2195–2206. https://doi.org/10.1007/s11274-013-1385-2

Gharsallaoui A, Rogé B, Mathlouthi M (2008) Water-disaccharides interactions in saturated solution and the crystallisation conditions. Food Chem 106(4):1329–1339. https://doi.org/10.1016/j.foodchem.2006.12.068

Ikeda M, Bando T, Yamada T, Sato M, Menjyu T, Aoyama A, Sato T, Chen F, Sonobe M, Omasa M, Date H (2015) Clinical application of ET-Kyoto solution for lung transplantation. Surg Today 45(4):439–443. https://doi.org/10.1007/s00595-014-0918-0

Jiang L, Lin M, Zhang Y, Li Y, Xu X, Li S, He Huang H (2013) Identification and characterization of a novel trehalose synthase gene derived from saline-alkali soil metagenomes. PLoS One 8(10):e77437. https://doi.org/10.1371/journal.pone.0077437

Kim TK, Jang JH, Cho HY, Lee HS, Kim YW (2010) Gene cloning and characterization of a trehalose synthase from Corynebacterium glutamicum ATCC13032. Food Sci Biotechnol 19(2):565–569. https://doi.org/10.1007/s10068-010-0079-x

Koh S, Kim J, Shin HJ, Lee D, Bae J, Kim D, Lee DS (2003) Mechanistic study of the intramolecular conversion of maltose to trehalose by Thermus caldophilus GK24 trehalose synthase. Carbohydr Res 338(12):1339–1343. https://doi.org/10.1016/S0008-6215(03)00172-1

Koh S, Shin HJ, Kim JS, Lee DS, Lee SY (1998) Trehalose synthesis from maltose by a thermostable trehalose synthase from Thermus caldophilus. Biotechnol Lett 20(8):757–761. https://doi.org/10.1023/A:1005342921339

Kopjar M, Hribar J, Simcic M, Zlatić E, Pozrl T, Pilizota V (2013) Effect of trehalose addition on volatiles responsible for strawberry aroma. Nat Prod Commun 8(12):1767–1770. https://doi.org/10.1073/pnas.0703993104

Lee JH, Lee KH, Kim CG, Lee SY, Kim GJ, Park YH, Chung SO (2005) Cloning and expression of a trehalose synthase from Pseudomonas stutzeri CJ38 in Escherichia coli for the production of trehalose. Appl Microbiol Biotechnol 68(2):213–219. https://doi.org/10.1007/s00253-004-1862-5

Li N, Wang H, Li L, Cheng H, Liu D, Cheng H, Deng Z (2016) Integrated approach to producing high-purity trehalose from maltose by the yeast Yarrowia lipolytica displaying trehalose synthase (TreS) on the cell surface. J Agric Food Chem 64(31):6179–6187. https://doi.org/10.1021/acs.jafc.6b02175

Li Y, Sun X, Feng Y, Yuan Q (2015) Cloning, expression and activity optimization of trehalose synthase from Thermus thermophilus HB27. Chem Eng Sci 135:323–329. https://doi.org/10.1016/j.ces.2015.02.034

Li Y, Wang Z, Feng Y, Yuan Q (2017) Improving trehalose synthase activity by adding the C-terminal domain of trehalose synthase from Thermus thermophilus. Bioresour Technol 245(Pt B):1749–1756. https://doi.org/10.1016/j.biortech.2017.05.189

Liang J, Huang R, Huang Y, Wang X, Du L, Wei Y (2013) Cloning, expression, properties, and functional amino acid residues of new trehalose synthase from Thermomonospora curvata DSM 43183. J Mol Catal B Enzym 90:26–32. https://doi.org/10.1016/j.molcatb.2013.01.014

Liang J, Wang S, Ludescher RD (2015) Effect of additives on physicochemical properties in amorphous starch matrices. Food Chem 171:298–305. https://doi.org/10.1016/j.foodchem.2014.09.010

Loncaric A, Dugalic K, Mihaljevic I, Jakobek L, Pilizota V (2014) Effects of sugar addition on total polyphenol content and antioxidant activity of frozen and freeze-dried apple purée. J Agric Food Chem 62(7):1674–1682. https://doi.org/10.1021/jf405003u

Lunn JE, Delorge I, Figueroa CM, Van Dijck P, Stitt M (2014) Trehalose metabolism in plants. Plant J 79(4):544–567. https://doi.org/10.1111/tpj.12509

Ma Y, Xue L, Sun DW (2006) Characteristics of trehalose synthase from permeablized Pseudomonas putida cells and its application in converting maltose into trehalose. J Food Eng 77(2):342–347. https://doi.org/10.1016/j.jfoodeng.2005.06.042

Martinetti D, Colarossi C, Buccheri S, Denti G, Memeo L, Vicari L (2017) Effect of trehalose on cryopreservation of pure peripheral blood stem cells. Biomedical Reports 6(3):314–318. https://doi.org/10.3892/br.2017.859

Mu W, Li W, Wang X, Zhang T, Jiang B (2014) Current studies on sucrose isomerase and biological isomaltulose production using sucrose isomerase. Appl Microbiol Biotechnol 98(15):6569–6582. https://doi.org/10.1007/s00253-014-5816-2

Neri L, Hernando I, Pérez-Munuera I, Sacchetti G, Mastrocola D, Pittia P (2014) Mechanical properties and microstructure of frozen carrots during storage as affected by blanching in water and sugar solutions. Food Chem 144:65–73. https://doi.org/10.1016/j.foodchem.2013.07.123

Neta T, Takada K, Hirasawa M (2000) Low-cariogenicity of trehalose as a substrate. J Dent 28(8):571–576. https://doi.org/10.1016/S0300-5712(00)00038-5

Nishimoto T, Nakada T, Chaen H, Fukuda S, Sugimoto T, Kurimoto M, Tsujisaka Y (1997) Action of a thermostable trehalose synthase from Thermus aquaticus on sucrose. Biosci Biotechnol Biochem 61(5):898–899. https://doi.org/10.1271/bbb.61.898

Nishimoto T, Nakano M, Nakada T, Chaen H, Fukuda S, Sugimoto T, Kurimoto M, Tsujisaka Y (1996) Purification and properties of a novel enzyme, trehalose synthase, from Pimelobacter sp. R48. Biosci Biotechnol Biochem 60(4):640–644. https://doi.org/10.1271/bbb.60.640

Nuccio ML, Wu J, Mowers R, Zhou H-P, Meghji M, Primavesi LF, Paul MJ, Chen X, Gao Y, Haque E, Basu SS, Lagrimini LM (2015) Expression of trehalose-6-phosphate phosphatase in maize ears improves yield in well-watered and drought conditions. Nat Biotechnol 33(8):862–869. https://doi.org/10.1038/nbt.3277

Ohguchi M, Kubota N, Wada T, Yoshinaga K, Uritani M, Yagisawa M, Ohishi K, Yamagishi M, Ohta T, Ishikawa K (1997) Purification and properties of trehalose-synthesizing enzyme from Pseudomonas sp. F1. J Ferment Bioeng 84(4):358–360. https://doi.org/10.1016/S0922-338X(97)89260-4

Ohtake S, Wang YJ (2011) Trehalose: current use and future applications. J Pharm Sci 100(6):2020–2053. https://doi.org/10.1002/jps.22458

Olaciregui M, Gil L (2017) Freeze-dried spermatozoa: a future tool? Reprod Domest Anim 52:248–254. https://doi.org/10.1111/rda.12838

Pan YT, Edavana VK, Jourdian WJ, Edmondson R, Carroll JD, Pastuszak I, Elbein AD (2004) Trehalose synthase of Mycobacterium smegmatis: purification, cloning, expression, and properties of the enzyme. Eur J Biochem 271(21):4259–4269. https://doi.org/10.1111/j.1432-1033.2004.04365.x

Panek A, Pietrow O, Synowiecki J, Filipkowski P (2013) Immobilization on magnetic nanoparticles of the recombinant trehalose synthase from Deinococcus geothermalis. Food Bioprod Process 91(4):632–637. https://doi.org/10.1016/j.fbp.2013.04.007

Paul MJ, Primavesi LF, Jhurreea D, Zhang Y (2008) Trehalose metabolism and signaling. Annu Rev Plant Biol 59(1):417–441. https://doi.org/10.1146/annurev.arplant.59.032607.092945

Portbury SD, Hare DJ, Sgambelloni C, Perronnes K, Portbury AJ, Finkelstein DI, Adlard PA (2017) Trehalose improves cognition in the transgenic Tg2576 mouse model of Alzheimer’s disease. J Alzheimers Dis 60(2):549–560. https://doi.org/10.3233/JAD-170322

Reina-Bueno M, Argandoña M, Nieto JJ, Hidalgo-García A, Iglesias-Guerra F, Delgado MJ, Vargas C (2012) Role of trehalose in heat and desiccation tolerance in the soil bacterium Rhizobium etli. BMC Microbiol 12(1):207. https://doi.org/10.1186/1471-2180-12-207

Rentschler E, Schwarz T, Stressler T, Fischer L (2016) Development and validation of a screening system for a β-galactosidase with increased specific activity produced by directed evolution. Eur Food Res Technol 242(12):2129–2138. https://doi.org/10.1007/s00217-016-2709-x

Roy R, Usha V, Kermani A, Scott DJ, Hyde EI, Besra GS, Alderwick LJ, Fütterer K (2013) Synthesis of α-glucan in mycobacteria involves a hetero-octameric complex of trehalose synthase TreS and Maltokinase Pep2. ACS Chem Biol 8(10):2245–2255. https://doi.org/10.1021/cb400508k

Ruhal R, Kataria R, Choudhury B (2013) Trends in bacterial trehalose metabolism and significant nodes of metabolic pathway in the direction of trehalose accumulation. Microb Biotechnol 6(5):493–502. https://doi.org/10.1111/1751-7915.12029

Schiraldi C, Di Lernia I, De Rosa M (2002) Trehalose production: exploiting novel approaches. Trends Biotechnol 20(10):420–425. https://doi.org/10.1016/S0167-7799(02)02041-3

Schüürmann J, Quehl P, Festel G, Jose J (2014) Bacterial whole-cell biocatalysts by surface display of enzymes: toward industrial application. Appl Microbiol Biotechnol 98(19):8031–8046. https://doi.org/10.1007/s00253-014-5897-y

Song X, Tang S, Jiang L, Zhu L, Huang H (2016) Integrated biocatalytic process for trehalose production and separation from maltose. Ind Eng Chem Res 55(40):10566–10575. https://doi.org/10.1021/acs.iecr.6b02276

Tapia H, Young L, Fox D, Bertozzi CR, Koshland D (2015) Increasing intracellular trehalose is sufficient to confer desiccation tolerance to Saccharomyces cerevisiae. Proc Natl Acad Sci 112(19):6122–6127. https://doi.org/10.1073/pnas.1506415112

Teramoto N, Sachinvala ND, Shibata M (2008) Trehalose and trehalose-based polymers for environmentally benign, biocompatible and bioactive materials. Molecules 13(8):1773–1816. https://doi.org/10.3390/molecules13081773

Tewari YB, Goldberg RN (1991) Thermodynamics of hydrolysis of disaccharides. Lactulose, α-d-melibiose, palatinose, d-trehalose, d-turanose and 3-o-β-d -galactopyranosyl-d-arabinose. Biophys Chem 40(1):59–67. https://doi.org/10.1016/0301-4622(91)85029-P

Umene S, Hayashi M, Kato K, Masunaga H (2015) Physical properties of root crops treated with novel softening technology capable of retaining the shape, color, and nutritional value of foods. Dysphagia 30(2):105–113. https://doi.org/10.1007/s00455-014-9581-2

Wada S, Ohba S, Someno T, Hatano M, Nomoto A (2014) Structure and biological properties of lentztrehalose: a novel trehalose analog. J Antibiot 67(4):319–322. https://doi.org/10.1038/ja.2013.143

Wang J, Ren X, Wang R, Su J, Wang F (2017) Structural characteristics and function of a new kind of thermostable trehalose synthase from Thermobaculum terrenum. J Agric Food Chem 65(35):7726–7735. https://doi.org/10.1021/acs.jafc.7b02732

Wang JH, Tsai MY, Chen JJ, Lee GC, Shaw JF (2007) Role of the C-terminal domain of Thermus thermophilus trehalose synthase in the thermophilicity, thermostability, and efficient production of trehalose. J Agric Food Chem 55(9):3435–3443. https://doi.org/10.1021/jf070181p

Wang YL, Chow SY, Lin YT, Hsieh YC, Lee GC, Liaw SH (2014) Structures of trehalose synthase from Deinococcus radiodurans reveal that a closed conformation is involved in catalysis of the intramolecular isomerization. Acta Crystallogr Sect D Biol Crystallogr 70(12):3144–3154. https://doi.org/10.1107/S1399004714022500

Wegener G, Macho C, Schlöder P, Kamp G, Ando O (2010) Long-term effects of the trehalase inhibitor trehazolin on trehalase activity in locust flight muscle. J Exp Biol 213(22):3852–3857. https://doi.org/10.1242/jeb.042028

Wei Y-T, Zhu Q-X, Luo Z-F, Lu F-S, Chen F-Z, Wang Q-Y, Huang K, Meng J-Z, Wang R, Huang R-B (2004) Cloning, expression and identification of a new trehalose synthase gene from Thermobifida fusca genome. Acta Biochim Biophys Sin Shanghai 36(7):477–484. https://doi.org/10.1093/abbs/36.7.477

Williams B, Njaci I, Moghaddam L, Long H, Dickman MB, Zhang X, Mundree S (2015) Trehalose accumulation triggers autophagy during plant desiccation. PLoS Genet 11(12):e1005705. https://doi.org/10.1371/journal.pgen.1005705

Wu JCY, Hutchings CH, Lindsay MJ, Werner CJ, Bundy BC (2015a) Enhanced enzyme stability through site-directed covalent immobilization. J Biotechnol 193:83–90. https://doi.org/10.1016/j.jbiotec.2014.10.039

Wu T-T, Ko C-C, Chang S-W, Lin S-C, Shaw J-F (2015b) Selective oxidation of glucose for facilitated trehalose purification. Process Biochem 50(6):928–934. https://doi.org/10.1016/j.procbio.2015.03.006

Wu T-T, Lin S-C, Shaw J-F (2013) Enzymatic processes for the purification of trehalose. Biotechnol Prog 29(1):83–90. https://doi.org/10.1002/btpr.1669

Wu XL, Ding HB, Yue M, Qiao Y (2009) Gene cloning, expression, and characterization of a novel trehalose synthase from Arthrobacter aurescens. Appl Microbiol Biotechnol 83(3):477–482. https://doi.org/10.1007/s00253-009-1863-5

Xu Z, Li S, Li J, Li Y, Feng X, Wang R, Xu H, Zhou J (2013) The structural basis of Erwinia rhapontici isomaltulose synthase. PLoS One 8(9):e74788. https://doi.org/10.1371/journal.pone.0074788

Yan J, Qiao Y, Hu J, Ding H (2013) Cloning, expression and characterization of a trehalose synthase gene from Rhodococcus opacus. Protein J 32(3):223–229. https://doi.org/10.1007/s10930-013-9476-3

Yu H, Yang S, Yuan C, Hu Q, Li Y, Chen S, Hu Y (2017a) Application of biopolymers for improving the glass transition temperature of hairtail fish meat. J Sci Food Agric. https://doi.org/10.1002/jsfa.8611

Yu S, Zhang Y, Zhu Y, Zhang T, Jiang B, Mu W (2017b) Improving the catalytic behavior of DFA I-forming inulin fructotransferase from Streptomyces davawensis with site-directed mutagenesis. J Agric Food Chem 65(34):7579–7587. https://doi.org/10.1021/acs.jafc.7b02897

Yue M, Wu XL, Gong WN, Ding HB (2009) Molecular cloning and expression of a novel trehalose synthase gene from Enterobacter hormaechei. Microb Cell Factories 8(1):34. https://doi.org/10.1186/1475-2859-8-34

Zdziebło A, Synowiecki J (2006) Production of trehalose by intramolecular transglucosylation of maltose catalysed by a new enzyme from Thermus thermophilus HB-8. Food Chem 96(1):8–13. https://doi.org/10.1016/j.foodchem.2005.01.048

Zheng J, Chen Y, Yang L, Li M, Zhang J (2014) Preparation of cross-linked enzyme aggregates of trehalose synthase via co-aggregation with polyethyleneimine. Appl Biochem Biotechnol 174(6):2067–2078. https://doi.org/10.1007/s12010-014-1104-y

Zhang M, Oldenhof H, Sydykov B, Bigalk J, Sieme H, Wolkers WF (2017) Freeze-drying of mammalian cells using trehalose: preservation of DNA integrity. Sci Rep 7(1):6198. https://doi.org/10.1038/s41598-017-06542-z

Zhang R, Pan YT, He S, Lam M, Brayer GD, Elbein AD, Withers SG (2011) Mechanistic analysis of trehalose synthase from Mycobacterium smegmatis. J Biol Chem 286(41):35601–35609. https://doi.org/10.1074/jbc.M111.280362

Zhang W, Jia M, Yu S, Zhang T, Zhou L, Jiang B, Mu W (2016) Improving the thermostability and catalytic efficiency of the D-psicose 3-epimerase from Clostridium bolteae ATCC BAA-613 using site-directed mutagenesis. J Agric Food Chem 64(17):3386–3393. https://doi.org/10.1021/acs.jafc.6b01058

Zhu Y, Wei D, Zhang J, Wang Y, Xu H, Xing L, Li M (2010) Overexpression and characterization of a thermostable trehalose synthase from Meiothermus ruber. Extremophiles 14(1):1–8. https://doi.org/10.1007/s00792-009-0281-z

Zheng Z, Xu Y, Sun Y, Mei W, Ouyang J (2015) Biocatalytic production of trehalose from maltose by using whole cells of permeabilized recombinant Escherichia coli. PLoS One 10(10):e0140477. https://doi.org/10.1371/journal.pone.0140477

Funding

This work was funded by the 863 Project of China (No. 2013AA102102) and the National Natural Science Foundation of China (No. 31371788).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 163 kb).

Rights and permissions

About this article

Cite this article

Cai, X., Seitl, I., Mu, W. et al. Biotechnical production of trehalose through the trehalose synthase pathway: current status and future prospects. Appl Microbiol Biotechnol 102, 2965–2976 (2018). https://doi.org/10.1007/s00253-018-8814-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-8814-y