Abstract

Xylose is the second most abundant sugar derived from lignocellulose; it is considered less desirable than glucose for fermentation, and strategies that specifically increase xylose utilization in wild-type cells are goals for biofuel production. Xylose consumption, butanol production, and hydrogen production increased in both Clostridium beijerinckii and a novel solventogenic bacterium (strain DC-1) when anthraquinone-2,6,-disulfonate (AQDS) or riboflavin were used as redox mediators to transfer electrons to poorly crystalline Fe(OH)3 as an extracellular electron sink. Strain DC-1 was most closely related to Rhizobiales bacterium Mfc52 based on 95% 16S rRNA gene sequence similarity, which demonstrates that this response is not limited to a single genus of xylose-fermenting bacteria. Xylose utilization and butanol production were negligible in control incubations containing cells plus 3% (w/v) xylose alone during a 10-day batch fermentation, for both strains tested (n-butanol titers of 0.05 g L−1). Micromolar concentrations of AQDS and riboflavin were added as electron shuttling compounds with poorly crystalline Fe(OH)3 as an insoluble electron acceptor, and respective n-butanol titers increased to 6.35 and 7.46 g L−1. Increases in xylose consumption for the iron treatments were relatively high, from less than 0.49 g L−1 (xylose alone, no iron or electron shuttling molecules) to 25.98 and 29.15 g L−1 for the AQDS and riboflavin treatments, respectively. Hydrogen production was also 3.68 times greater for the AQDS treatment and 5.27 greater for the riboflavin treatment relative to controls. Strain DC-1 data were similar, again indicating that the effects are not specific to the genus Clostridium.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Butanol (n-butanol) is used as a chemical feedstock in several industrial sectors and has been suggested as a biofuel alternative to ethanol (Szwaja and Naber 2010; Cooney et al. 2009; Masum et al. 2014). Biologically synthesized butanol is attractive as a supplement for the world’s gasoline-powered transportation infrastructure due its favorable combustion properties and high energy content. However, substrate costs or poor utilization, low productivity, and low solvent titers continue to impede advancements of traditional industrial fermentations.

The current global market for n-butanol is estimated to be $10 billion, and it is projected to grow annually at a rate of 15.1% until 2021 (de Maria 2016). Butanol is considered an amendment to gasoline in lieu of ethanol or as a stand-alone liquid fuel for next-generation vehicles; the latter use is less likely given the current production (Harvey and Meylemans 2011). Although it is a low molecular mass alcohol, similar to ethanol, it has much higher energy content. Complete butanol combustion releases 29.2 MJ L−1 while ethanol releases 19.6 MJ L−1 (Lee et al. 2008). Butanol is stable and has good blending characteristics for use with traditional gasoline. It has become a significant target for alternative energy platforms in the USA and abroad. However, butanol derived from petroleum is undesirable due to uncertainty in the petroleum market and because petroleum-based fuels are regarded as less sustainable than operationally defined renewable fuels. Synthetic biological processes, such as acetone-butanol-ethanol (ABE) fermentations, are being investigated to supplement these approaches (Jiang et al. 2009; Atsumi et al. 2008; Connor and Liao 2009; Lee et al. 2012).

ABE fermentation is promising but does have several limitations, including, but not restricted to low solvent yields, poor substrate utilization, and low biomass conversion rates (Green 2011). These limitations have been addressed through genetic modifications and/or reactor engineering design alterations (Harris et al. 2001; Qureshi and Maddox 1988; Roffler et al. 1987). Both of these approaches have been successful, but these strategies are typically proprietary, and they often cannot be inserted into existing reactor infrastructure due to economic infeasibility. Emerging biofuel markets are seeking “drop-in” technologies that will work with current reactor designs with few modifications (Liang et al. 2002; Alkasrawi et al. 2003). In addition, genetically modified organisms (GMOs) are often viewed skeptically by the public, despite the strong progress made in the field.

Hemicellulose monomers such as xylose are desirable feedstocks for industrial ABE production since they do not compete directly with human food sources (Valentine et al. 2012). Xylose, a pentose sugar, comprises nearly 30% of all plant-derived biomass (Kumar et al. 2009). Many organisms cannot efficiently ferment xylose, or they lack the necessary machinery to transport and assimilate it into central metabolism (Gírio et al. 2010). This has made glucose the preferential sugar substrate; it is readily fermented by most industrial solvent-producing strains (El Kanouni et al. 1998).

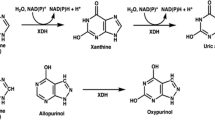

Certain members of the genus Clostridium rely either on xylose proton symporters or ATP-dependent xylose transport proteins to move the sugar molecules across the cell membrane (Servinsky et al. 2010). Xylose must be converted prior to glycolysis, with steps that require ATP hydrolysis and regeneration of NAD+ and NADP+ cofactors (Jeffries 1983). While glucose is usually 100% fermented by the cells of interest, xylose utilization in ABE fermentation can be 60% or less, and these xylose-amended cultures typically have acetate as a carbon co-substrate. Any strategies that increase xylose utilization will be beneficial to mixed sugar fermentations that rely on a variety of plant feedstocks (Xiao et al. 2012; Wu et al. 2016; Mes-Hartree and Saddler 1982).

Previous reports using glucose as the sole substrate suggest that electron mediators such as neutral red altered substrate utilization, solventogenesis, and most recently, hydrogen production (Park et al. 1999; Peguin and Soucaille 1995; Rao and Mutharasan 1987; Ye et al. 2012). Butanol production was increased in comparison to controls in pH-controlled, fed-batch anode (electrode) reactors amended with methyl viologen; the sole substrate was glucose in all cases (Peguin and Soucaille 1996). More recently, the redox potential of a fed-batch reactor was modified using a potentiostat to mimic “near oxic” conditions, and data indicated that solvent yield increased relative to controls (Shin et al. 2002). Influencing NAD+/NADH ratios was reported to increase production of certain fermentation end products (Meyer and Papoutsakis 1989; Singh et al. 2009). However, glucose was the sole substrate and the experiments did not directly address improving substrate utilization due to extracellular electron transfer. The data presented below were developed specifically to advance xylose as a comparable substrate to glucose, with wild-type solventogenic bacteria.

The following data demonstrate that Clostridium beijerinckii and non-Clostridia fermentative cells can utilize extracellular electron transfer molecules and ferric iron to alter the normal flow of carbon and electrons during xylose fermentation, thereby increasing both solventogenesis and xylose utilization in ABE-producing organisms. Both of these are desirable outcomes for eventual use in reactors with wild-type organisms used in biofuel production.

Methods

Culture maintenance

Clostridium beijerinckii strain NCIMB 8052 was re-vegetated from frozen spores to start each experiment. A 50-μL volume of the spore suspension was used to inoculate 10 mL of fresh tryptone-yeast-glucose (TYG) media, and this was incubated at 37 °C for 28 h. Fresh TYG media was inoculated with 3% (v/v) of a dormant culture of strain DC-1. This was incubated for 28 h at 37 °C. TYG medium consisted of 30 g L−1 tryptone, 20 g L−1 glucose, and 10 g L−1 yeast extract in nanopure water. TYG medium was prepared by dispensing 10 mL of media into anoxic Balch-type pressure tubes, and each was sparged with nitrogen for 10 min in the liquid phase, followed by a 1-min degassing of the headspace. Tubes were capped with blue butyl stoppers and sealed with aluminum crimps. The tubes were autoclaved for 15 min at 121 °C and cooled prior to inoculation.

Experimental conditions

Experiments using xylose as the fermentation feedstock were run in defined P2 medium, which consisted of 0.5 g L−1 KH2PO4, 0.5 g L−1 K2HPO4, 2.0 g L−1 (NH4)2SO4, 10 mL L−1 mineral mix (20 g MgSO4, 1 g MnSO4, 1 g NaCl, and 1 g FeSO4), and 10 mL L−1 vitamin mix (100 g p-aminobenzoic acid, 1 g biotin, and 10 g thiamine). P2 media for the batch fermentation containing Clostridium beijerinckii NCIMB 8052 was prepared in 160-mL serum bottles; the media was sparged with nitrogen for 15 min, and each headspace was degassed for 5 min. P2 media for DC-1 batch fermentation was prepared in anaerobic Balch tubes; the media was sparged with nitrogen for 10 min in the liquid phase, followed by a 1-min degassing of the headspace. Bottles and tubes were capped, crimped, and autoclaved at 121 °C for 20 min on a liquid cycle. Final liquid volumes at the onset of experimentation for Clostridium beijerinckii NCIMB 8052 and DC-1 were 100 and 10 mL, respectively. All experiments were conducted without off-gas release.

C. beijerinckii cells (6% v/v) were transferred from a culture grown on TYG for 28 h into P2 media containing 6 g L−1 xylose; this was incubated for an additional 28 h. A 6% (v/v) transfer of this culture was made to experimental 160-mL bottles. Strain DC-1 was transferred from a dormant culture to TYG media and allowed to incubate at 37 °C for 28 h. Following the 28-h incubation, 6% (v/v) of the culture grown on TYG was transferred to P2 media containing 6 g L−1 xylose, this incubated for 28 h at 37 °C. A 6% (v/v) transfer of this was made to experimental tubes, bringing the final volume to 10 mL at the start of each experiment.

The experiment in which glucose was used as the fermentation substrate was prepared as described previously (Baer et al. 1987). This media recipe contained supplementary acetate in the form of ammonium acetate. The fermentation broth was prepared under anoxic conditions in Balch tubes, and the final glucose concentration was 6% (w/v). An additional replicate was prepared in 160-mL serum bottles for pH monitoring throughout the fermentation. Prior to autoclaving, bottles were sparged and degassed with nitrogen, capped with blue butyl stoppers, and crimped. Final liquid volume at the onset of experimentation was 100 mL.

Stock solutions of 20 mM AQDS (Sigma, 98%), 20 mM riboflavin (Sigma, 98 + %), and 1 M poorly crystalline Fe(III) oxy(hydroxide) (poorly crystalline Fe(OH)3; also referred to as “FeGel” on figure axes) were prepared in nanopure H2O, sparged for 15 min in the liquid phase, and degassed for 5 min in the headspace with nitrogen which was passed over a heated copper column to remove trace oxygen (Lovley and Phillips 1986). The bottles were then sealed with blue butyl stoppers and crimped with aluminum caps. AQDS and riboflavin stocks were autoclaved at 121 °C for 20 min on a liquid cycle, and upon cooling, they were transferred to respective experimental bottles at a previously optimized final concentration of 500 μM prior to inoculation (Table S1). Chemical structures of the oxidized versus reduced forms are illustrated in Fig. S1.

Stock solutions of 600 g L−1 D-(+)-xylose (Alfa Aesar; 98 + %) and 600 g L−1 glucose (anhydrous; Fisher Chemical) were prepared in nanopure H2O, and they were degassed following the same procedures as listed above. Anoxic sugar stock solutions were filter sterilized into experimental triplicates using sterile 0.2-μm filters (Pall Supor Membrane) prior to starting the experiments.

Samples were collected periodically over a 240-h period. For each experimental analysis, 0.3 mL was withdrawn from experimental triplicates using sterile, anoxic syringes, and samples were filtered through 0.2-μm filters into autosampler vials with 250-μL glass inserts (Lab Supply Distributors). Screw top PFTE caps were used to seal the vials, and the samples were stored at 4 °C until GC and HPLC analyses. For the 100-mL batch fermentations, an additional 3 mL of culture broth was removed from experimental bottles at each time point, and these samples were dispensed into clean 15-mL screw top conical tubes for pH analysis. The pH was analyzed immediately after sample withdrawal. Headspace H2 was analyzed following liquid sampling. Headspace gas (0.5 mL) was withdrawn from each sample and analyzed as described below.

Analytical techniques

Solvents were analyzed using a Shimadzu 2014 gas chromatograph with a flame ionization detector (GC-FID) equipped with an autosampler and an Agilent DB-FFAP column (30 m × 0.250 mm; 0.25-μm film thickness), using helium as the carrier gas at a constant pressure of 125 kPa. Injector and detector temperatures were 200 and 250 °C, respectively. Liquid injections (1 μL) were used for sample analysis, followed by a methanol wash step and two nanopure H2O rinse steps prior to each successive injection. The temperature program included a 40 °C initial dwell for 4 min, followed by a temperature ramp at a rate of 50 °C min−1 until the column oven reached 220 °C. The column was held at this temperature for 4 min until cool down.

Xylose, glucose, and organic acids were analyzed using a Dionex high-performance liquid chromatograph (HPLC) equipped with a Bio-Rad HP-aminex column. The mobile phase consisted of 5 mM degassed H2SO4, and the flow rate was 0.6 mL min−1. Temperatures of the column oven and the RI detector were 60 and 50 °C, respectively. Organic acids were quantified using a UV-Visible wavelength detector set at 210 nm. Xylose and glucose were quantified using a Shodex RI-101 refractive index detector.

Headspace hydrogen was analyzed using a Shimadzu GC-8A equipped with an internal thermal conductivity detector (TCD) and a 100/120 Carbosieve SII column (10′ length × 1/8″ outer diameter). Nitrogen was the carrier gas at a constant pressure of 400 kPa. The TCD voltage was set at 60 V; the column temperature was set at 50 °C, and the injector and detector temperatures were both set at 150 °C. A Vici gas-tight syringe was used to deliver a 0.5-mL injection volume for each sample analyzed.

The pH was measured with a Thermo Scientific OrionStar A111 pH meter equipped with an Orion 9107BNMD probe. The meter was calibrated prior to each use with a reference standard buffer kit.

Biomass was quantified by measuring the total dry weight of cells. Aluminum weigh boats were baked overnight at 100 °C and were cooled in a desiccation chamber. Weigh boats containing cells were baked overnight at 100 °C and subsequently weighed after cooling to determine the total dry weight. Residual xylose was quantified and subtracted from the total weight, thus providing a more accurate biomass reading.

Kinetic modeling

A modified Gompertz equation (Eq. 1) was used to fit the cumulative metabolite production curve to obtain the metabolite production rate R Metabolite for butanol (Lin and Lay 2004; Mu et al. 2006, 2007; Zwietering et al. 1990; Zhang et al. 2013). Specific production rate (in units of grams Butanol L−1 h−1) were calculated by normalizing the R Butanol by the volume of the medium in the batch experiments. The same equation was also used to fit the substrate utilization, plotted as substrate utilized versus time. Substrate utilization rates are expressed as gram per liter per hour. λ i is in units of hours.

Electron flux analysis

Electron flow modeling and the metabolic stoichiometric equations used in this model were adapted from previously described metabolic flux analyses, where it was assumed that (1) no intracellular intermediates accumulate during fermentation and (2) NADH remained balanced throughout the fermentation (Du et al. 2015; Ye et al. 2011; Lee et al. 2009). Xylose consumption and metabolite production data were used to calculate the total number of electrons liberated based on oxidation half reactions for each. Complete xylose oxidation was assumed to yield 20 electrons per mol fermented; biomass, butanol, ethanol, acetone, hydrogen, acetate, and butyrate productions were assumed to consume 28, 24, 12, 16, 2, 8, 20 electron equivalents per mol, respectively. The following assumptions were made on a per mol basis:

-

1.67 mol pyruvate is generated per mol xylose from glycolysis

-

Electron consumption from electron mediator reduction is negligible

-

Ferric iron (poorly crystalline Fe(OH)3) reduction consumes 1 meq electrons per mM Fe3+ reduced to Fe2+ based on a generalized stoichiometric iron reduction equation (Eq. 2):

Results

Electron shuttle-enhanced xylose utilization and solventogenesis in C. beijerinckii NCIMB 8052

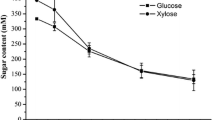

Ten-day, static batch fermentations demonstrated that electron shuttling to ferric iron increased xylose consumption and butanol production with 3% xylose as the sole fermentable substrate. Acetate was not supplemented in any experiment (i.e., true “xylose-alone” conditions). Xylose consumption (from a 30 g L−1 input) was limited in the controls containing cells plus xylose alone (0.49 g L−1), along with the incubation containing poorly crystalline Fe(OH)3 alone (3.76 g L−1; Table 1) though xylose consumption and butanol production in the poorly crystalline Fe(OH)3 alone incubations were higher than xylose only controls. However, cells amended with riboflavin or AQDS plus poorly crystalline Fe(OH)3 consumed 29.15 and 25.98 g L−1 xylose, respectively. In the absence of poorly crystalline Fe(OH)3, xylose consumption was minimal for fermentations amended with either AQDS (0.51 g L−1) or riboflavin alone (1.43 g L−1; Fig. S2).

Butanol production in controls containing xylose alone (0.05 g L−1; Fig. 1) or poorly crystalline Fe(OH)3 plus xylose (0.26 g L−1; Table 1) was relatively limited after 10 days of incubation. Cells amended with poorly crystalline Fe(OH)3 plus AQDS or riboflavin produced butanol at much higher concentrations (Fig. 1); the respective butanol titers for AQDS and riboflavin amended batches were 6.34 and 7.45 g L−1. The rates of butanol production were also significantly higher (P < 0.05; Table S3) in the electron shuttle-amended incubations (Table 1).

The solubility of the specific electron sink influenced xylose consumption and butanol production in ABE fermentations. Soluble iron in the form of Fe3+ citrate was also utilized as an electron sink in fermentations containing 3% xylose to which AQDS or riboflavin was not added. After 10 days of growth, respective xylose consumption and butanol production levels were 21.88 and 6.01 g L−1 (Fig. 1), which are similar to those with AQDS plus insoluble poorly crystalline Fe(OH)3 and riboflavin plus poorly crystalline Fe(OH)3. Citrate alone was not fermented (Fig. S3). However, xylose fermentations amended with 20 mM citrate produced 4.1 times less butanol than the Fe3+ citrate-amended triplicate (Fig. S3).

The increase in solvent production in the shuttle-amended experimental data was fitted using a modified Gompertz equation as previously reported (Lin and Lay 2004; Mu et al. 2006, 2007; Zwietering et al. 1990; Zhang et al. 2013). Xylose consumption rates for the treatments containing poorly crystalline Fe(OH)3 supplemented with AQDS and riboflavin were 104 times and 148 times greater than those for the control and 6.7 times and 9.6 times greater than those for the treatment amended with poorly crystalline Fe(OH)3 plus xylose, respectively (Table 1; Fig. S4). The Gompertz function was unable to fit the data generated for butanol productivity in the batch that was amended with cells plus 3% xylose (alone) due to the low levels of butanol production in the controls (see inset within Fig. 1).

Acetone concentration was lower than butanol in all fermentations containing shuttles plus poorly crystalline Fe(OH)3. Acetone was not detected in controls containing cells plus xylose alone, and minimal acetone (0.02 g L−1) was generated in the 20 mM poorly crystalline Fe(OH)3 experimental treatment (Fig. S5). Acetone titers of 0.49 and 1.2 g L−1 were quantified in fermentations amended with AQDS and riboflavin, respectively.

Glucose fermentation by C. beijerinckii NCIMB 8052

Ten-day batch fermentations using C. beijerinckii NCIMB 8052 with 6% glucose as the sole fermentable substrate were conducted to demonstrate that the wild-type cells used in these experiments functioned identically to strain 8052 reported in other studies, to negate the possibility that the xylose data were an artifact of a degenerate strain of C. beijerinckii NCIMB 8052. The fermentations were conducted using conditions identical to past reports and contained acetate-amended P2 media with 6% glucose (Bryant and Blaschek 1988). The fermentations ran longer than typical glucose-fed cultures, but this was likely due to smaller inoculum volumes and differences in how the batch cultures were incubated (static versus agitated). Despite the slightly longer incubation time, the resulting products were very similar to the reported data.

Butanol was produced in all treatments (Fig. 2), and the glucose-only controls had similar or identical solvent titers to previously reported studies (Formanek et al. 1997; Zhang and Ezeji 2013). Poorly crystalline Fe(OH)3, with or without electron shuttle amendments, increased butanol production in a manner similar to the xylose-fermenting cultures, but the variations amongst treatments were not as large (Fig. 2). This is consistent with previous data suggesting the extracellular electron transfer effect is minimal with glucose as the sole fermentable substrate, suggesting it is better as a strategy for targeting less efficient carbon molecules such as xylose (Ye et al. 2012).

Hydrogen production with xylose and glucose

Hydrogen concentrations increased in the presence of electron shuttles plus ferric iron (Figs. S6 and S7), while the control containing cells alone and 6% glucose was 1.7–1.9 times less than these treatments after 240 h (Fig. S8). These data are consistent with previous results suggesting that hydrogen production increased as a response to electron shuttling (Zhang et al. 2013; Ye et al. 2011).

Electron shuttling-enhanced xylose utilization and solventogenesis in strain DC-1

Strain DC-1 is a novel solventogenic culture that was isolated from crystalline cellulose-fed enrichments developed from woodland marsh sediment at Clemson University (in progress). The 16S rRNA gene sequence analysis indicated that DC-1 shares a 95% sequence similarity to Rhizomicrobium electricum Mfc52 (Rhizobiales bacterium Mfc52, AB365487.1), and all data indicate that this is a novel species or genus of solvent-generating eubacteria. Strain DC-1 is phylogenetically distinct from most ABE-producing organisms, but it possesses similar metabolic characteristics, including the ability to carry out ABE fermentation. Furthermore, the bacterium forms central endospores, and terminal inclusion bodies are visible in both sporulated and non-sporulated cells suggesting morphological differences between it and the other ABE-generating genera or species.

Using nearly identical fermentation conditions as for C. beijerinckii NCIMB 8052, strain DC-1 was tested to determine if electron shuttles plus ferric iron influenced xylose consumption and butanol production in a similar manner. The only difference was that strain DC-1 fermentations were performed in 10-mL Balch tubes, rather than 100-mL bottles. Cells incubated with 3% xylose alone produced little butanol (0.11 g L−1) relative to cells incubated with poorly crystalline Fe(OH)3 (7.58 g L−1) or AQDS or riboflavin (both approximately 8 g L−1) (Fig. 3; Table 2). Xylose consumption for the 3% xylose-alone control and the 20 mM poorly crystalline Fe(OH)3-amended incubations were 3.07 g L−1 and 8.41 g L−1 (Fig. 4), respectively. In comparison, the poorly crystalline Fe(OH)3-amended treatments that contained AQDS or riboflavin had respective xylose consumption values of 29.2 g L−1 and 29.6 g L−1 (Fig. 4). Kinetic data for xylose consumption and butanol production by treatment, quantified using the modified Gompertz equation, are listed in Table 2.

Xylose consumption after 10 days of fermentation using C. beijerinckii NCIMB 8052 or strain DC-1. The inset indicates xylose consumption with the electron shuttles AQDS or riboflavin, without poorly crystalline Fe(OH)3. Results are the means of triplicate incubations; bars indicate one standard deviation

Electron distribution analysis

Approximately 69–81% of all end product electron equivalents (including those consumed from acidogenic pathways used for the formation of butanol) liberated from pyruvate were consumed by the butanol pathway, and only 10–11% of the reducing equivalents contributed to the acidogenic pathways in the shuttle-amended treatments and the treatment amended with ferric citrate (Table S2). The combined acetate and butyrate pathways accounted for the largest end product electron distribution (32%) in the cells plus xylose control.

The number of electron equivalents consumed by the control incubations in the hydrogen pathway was 2–3.5 times greater than that in the iron and shuttle-amended batch incubations, indicating that overall electron flow was shunted away from the hydrogenase pathway towards the longer chain alcohols and ketones within these treatments. Calculated ATP generation was consistent throughout the control and the experimental incubations, with respect to the amount of xylose consumed (Fig. 1).

Solvent yields

Total butanol yields for treatments containing the terminal electron acceptor poorly crystalline Fe(OH)3 and amended AQDS were 2.4 and 6.5 times greater than those for controls containing xylose alone for C. beijerinckii NCIMB 8052 and strain DC-1, respectively (Tables 1 and 2). Treatments amended with poorly crystalline Fe(OH)3 and riboflavin had butanol yields of 2.6 and 6.75 times higher than that of the cells plus xylose control for C. beijerinckii and strain DC-1 (Tables 1 and 2). In comparison, strain BA101, a butanol hyperproducing mutant of C. beijerinckii NCIMB 8052, had only 1.2 times higher butanol yield than the wild type when xylose was used as the fermentation substrate (Qureshi et al. 2008).

Discussion

Electron shuttling was the primary driver in substantially increasing both productivities and yields from xylose, making batch fermentation kinetics more favorable, notably in that these cultures were incubated without supplemental acetate (to increase butanol yield). These levels of xylose consumption have thus far only been reported for genetically modified Clostridium strains, where the xylose utilization genes had been altered to increase uptake and metabolism; to the best of our knowledge, this is the first report of nearly 100% xylose utilization in wild-type C. beijerinckii NCIMB 8052 with concomitant increases in butanol production (Li et al. 2013; Xiao et al. 2011). Results were identical using a xylose-fermenting novel strain most closely related to members of the Rhizobiales, indicating the physiological response is not limited to a specific order of microorganisms, but rather influences the xylose fermentation pathway irrespective of taxonomic affiliation.

Experiments with glucose were conducted with acetate added to the growth medium, which is the standard culturing condition for this strain (Bryant and Blaschek 1988). Glucose-grown cultures utilized nearly 100% of the added glucose on a consistent basis, although extracellular electron transfer did slightly increase butanol production. Previous studies have indicated that acetate influenced ABE fermentations by inducing expression of the sol operon or acting as a direct substrate for acetoacetyl-CoA, thus increasing solvent production (Chen and Blaschek 1999). However, acetate was withheld from all xylose fermentation experiments in an effort to simplify the culture conditions and isolate the effects of Fe3+ plus electron shuttles, by eliminating another carbon/electron donating molecule from the reactions.

Engineering processes to provide the highest metabolite yield are paramount in industrial fermentation design. Ideal processes have the highest stoichiometric ratios of metabolite produced-to-substrate consumed. As mentioned previously, the fermentations in this study were not performed in the presence of exogenous acetate, a supplementary carbon source which increases ABE fermentation efficiency. Furthermore, supplementation of this value-added product would contribute to an overall decrease in the ratio of carbon transformed into butanol, thus rendering the process economically infeasible if performed on the scale required to meet current alternative energy demands. These data demonstrate a strategy for specifically targeting xylose uptake and utilization in biofuel-producing wild-type cells, which can be easily retrofitted to existing fermentation systems without needing to modify reactor infrastructure. Any technologies that increase xylose fermentation make pre-treated lignocellulose more feasible as a feedstock.

References

Alkasrawi M, Eriksson T, Börjesson J, Wingren A, Galbe M, Tjerneld F, Zacchi G (2003) The effect of Tween-20 on simultaneous saccharification and fermentation of softwood to ethanol. Enzym Microb Technol 33:71–78

Atsumi S, Cann AF, Connor MR, Shen CR, Smith KM, Brynildsen MP, Liao JC (2008) Metabolic engineering of Escherichia coli for 1-butanol production. Metab Eng 10:305–311

Baer SH, Blaschek HP, Smith TL (1987) Effect of butanol challenge and temperature on lipid composition and membrane fluidity of butanol-tolerant Clostridium acetobutylicum. Appl Environ Microbiol 53:2854–2861

Bryant DL, Blaschek HP (1988) Buffering as a means for increasing growth and butanol production by Clostridium acetobutylicum. J Ind Microbiol Biotechnol 3:49–55

Chen CK, Blaschek HP (1999) Effect of acetate on molecular and physiological aspects of Clostridium beijerinckii NCIMB 8052 solvent production and strain degeneration. Appl Environ Microbiol 65:499–505

Connor MR, Liao JC (2009) Microbial production of advanced transportation fuels in non-natural hosts. Curr Opin Biotechnol 20:307–315

Cooney C, Wallner T, McConnell S, Gillen JC, Abell C, Miers SA, Naber JD (2009) Effects of blending gasoline with ethanol and butanol on engine efficiency and emissions using a direct-injection, spark-ignition engine. In: ASME 2009 Internal Combustion Engine Division Spring Technical Conference ASME 157-165

de Maria P (ed) (2016) Industrial biorenewables: a practical viewpoint, 1st edn. John Wiley & Sons, Inc., Hoboken

Du Y, Jiang W, Yu M, Tang I, Yang ST (2015) Metabolic process engineering of Clostridium tyrobutyricum Δack–adhE2 for enhanced n-butanol production from glucose: effects of methyl viologen on NADH availability, flux distribution, and fermentation kinetics. Biotechnol Bioeng 112:705–715

El Kanouni A, Zerdani I, Zaafa S, Znassni M, Loutfi M, Boudouma M (1998) The improvement of glucose/xylose fermentation by Clostridium acetobutylicum using calcium carbonate. World J Microbiol Biotechnol 14:431–435

Formanek J, Mackie R, Blaschek HP (1997) Enhanced butanol production by Clostridium beijerinckii BA101 grown in semidefined P2 medium containing 6 percent maltodextrin or glucose. Appl Environ Microbiol 63:2306–2310

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Łukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101:4775–4800

Green EM (2011) Fermentative production of butanol—the industrial perspective. Curr Opin Biotechnol 22:337–343

Harris LM, Blank L, Desai RP, Welker NE, Papoutsakis ET (2001) Fermentation characterization and flux analysis of recombinant strains of Clostridium acetobutylicum with an inactivated solR gene. J Ind Microbiol Biotechnol 27:322–328

Harvey BG, Meylemans HA (2011) The role of butanol in the development of sustainable fuel technologies. J Chem Technol Biotechnol 86:2–9

Jeffries TW (1983) Utilization of xylose by bacteria, yeasts, and fungi. Springer Berlin, Heidelberg, pp 1–32

Jiang Y, Xu C, Dong F, Yang Y, Jiang W, Yang S (2009) Disruption of the acetoacetate decarboxylase gene in solvent-producing Clostridium acetobutylicum increases the butanol ratio. Metab Eng 11:284–291

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Lee SY, Park JH, Jang SH, Nielsen LK, Kim J, Jung KS (2008) Fermentative butanol production by Clostridia. Biotechnol Bioeng 101:209–228

Lee HS, Krajmalinik-Brown R, Zhang H, Rittmann BE (2009) An electron-flow model can predict complex redox reactions in mixed-culture fermentative BioH2: microbial ecology evidence. Biotechnol Bioeng 104:687–697

Lee J, Jang YS, Choi SJ, Im JA, Song H, Cho JH, Lee SY (2012) Metabolic engineering of Clostridium acetobutylicum ATCC 824 for isopropanol-butanol-ethanol fermentation. Appl Environ Microbiol 78:1416–1423

Li Z, Xiao H, Jiang W, Jiang Y, Yang S (2013) Improvement of solvent production from xylose mother liquor by engineering the xylose metabolic pathway in Clostridium acetobutylicum EA 2018. Biotechnol Appl Biochem 171:555–568

Liang TM, Cheng SS, Wu KL (2002) Behavioral study on hydrogen fermentation reactor installed with silicone rubber membrane. Int J Hydrog Energy 27:1157–1165

Lin CY, Lay CH (2004) Effects of carbonate and phosphate concentrations on hydrogen production using anaerobic sewage sludge microflora. Int J Hydrog Energy 29:275–281

Lovley DR, Phillips EJ (1986) Organic matter mineralization with reduction of ferric iron in anaerobic sediments. Appl Environ Microbiol 51:683–689

Masum BM, Kalam MA, Masjuki HH, Palash SM, Fattah IR (2014) Performance and emission analysis of a multi cylinder gasoline engine operating at different alcohol–gasoline blends. RSC Adv 4:27898–27904

Mes-Hartree M, Saddler JN (1982) Butanol production of Clostridium acetobutylicum grown on sugars found in hemicellulose hydrolysates. Biotechnol Lett 4:247–252

Meyer CL, Papoutsakis ET (1989) Increased levels of ATP and NADH are associated with increased solvent production in continuous cultures of Clostridium acetobutylicum. Appl Microbiol Biotechnol 30:450–459

Mu Y, Zheng XJ, Yu HQ, Zhu RF (2006) Biological hydrogen production by anaerobic sludge at various temperatures. Int J Hydrog Energy 31:780–785

Mu Y, Yu HQ, Wang G (2007) A kinetic approach to anaerobic hydrogen-producing process. Water Res 41:1152–1160

Park DH, Laivenieks M, Guettler MV, Jain MK, Zeikus JG (1999) Microbial utilization of electrically reduced neutral red as the sole electron donor for growth and metabolite production. Appl Environ Microbiol 65:2912–2917

Peguin S, Soucaille P (1995) Modulation of carbon and electron flow in Clostridium acetobutylicum by iron limitation and methyl viologen addition. Appl Environ Microbiol 61:403–405

Peguin S, Soucaille P (1996) Modulation of metabolism of Clostridium acetobutylicum grown in chemostat culture in a three-electrode potentiostatic system with methyl viologen as electron carrier. Biotechnol Bioeng 51:342–348

Qureshi N, Maddox IS (1988) Reactor design for the ABE fermentation using cells of Clostridium acetobutylicum immobilized by adsorption onto bonechar. Biotechnol Bioprocess Eng 3:69–72

Qureshi N, Ezeji TC, Ebener J, Dien BS, Cotta MA, Blaschek HP (2008) Butanol production by Clostridium beijerinckii. Part I: use of acid and enzyme hydrolyzed corn fiber. Bioresour Technol 99:5915–5922

Rao G, Mutharasan R (1987) Altered electron flow in continuous cultures of Clostridium acetobutylicum induced by viologen dyes. Appl Environ Microbiol 53:1232–1235

Roffler S, Blanch HW, Wilke CR (1987) Extractive fermentation of acetone and butanol: process design and economic evaluation. Biotechnol Prog 3:131–140

Servinsky MD, Kiel JT, Dupuy NF, Sund CJ (2010) Transcriptional analysis of differential carbohydrate utilization by Clostridium acetobutylicum. Microbiology 156:3478–3491

Shin H, Zeikus J, Jain M (2002) Electrically enhanced ethanol fermentation by Clostridium thermocellum and Saccharomyces cerevisiae. Appl Microbiol Biotechnol 58:476–481

Singh A, Lynch MD, Gill RT (2009) Genes restoring redox balance in fermentation-deficient E. coli NZN111. Metab Eng 11:347–354

Szwaja S, Naber JD (2010) Combustion of n-butanol in a spark-ignition IC engine. Fuel 89:1573–1582

Valentine J, Clifton-Brown J, Hastings A, Robson P, Allison G, Smith P (2012) Food vs. fuel: the use of land for lignocellulosic ‘next generation’energy crops that minimize competition with primary food production. Glob Change Biol Bioenergy 4:1–19

Wu YD, Xue C, Chen LJ, Bai FW (2016) Impact of zinc supplementation on the improved fructose/xylose utilization and butanol production during acetone–butanol–ethanol fermentation. J Biosci Bioeng 121:66–72

Xiao H, Gu Y, Ning Y, Yang Y, Mitchell WJ, Jiang W, Yang S (2011) Confirmation and elimination of xylose metabolism bottlenecks in glucose phosphoenolpyruvate-dependent phosphotransferase system-deficient Clostridium acetobutylicum for simultaneous utilization of glucose, xylose, and arabinose. Appl Environ Microbiol 77:7886–7895

Xiao H, Li Z, Jiang Y, Yang Y, Jiang W, Gu Y, Yang S (2012) Metabolic engineering of D-xylose pathway in Clostridium beijerinckii to optimize solvent production from xylose mother liquid. Metab Eng 14:569–578

Ye X, Morgenroth E, Zhang X, Finneran KT (2011) Anthrahydroquinone-2,6,-disulfonate (AH2QDS) increases hydrogen molar yield and xylose utilization in growing cultures of Clostridium beijerinckii. Appl Microbiol Biotechnol 92:855–864

Ye X, Zhang X, Morgenroth E, Finneran KT (2012) Anthrahydroquinone-2,6-disulfonate increases the rate of hydrogen production during Clostridium beijerinckii fermentation with glucose, xylose, and cellobiose. Int J Hydrog Energy 37:11701–11709

Zhang Y, Ezeji TC (2013) Transcriptional analysis of Clostridium beijerinckii NCIMB 8052 to elucidate role of furfural stress during acetone butanol ethanol fermentation. Biotechnol Biofuels 6:66

Zhang X, Ye X, Guo B, Finneran KT, Zilles JL, Morgenroth E (2013) Lignocellulosic hydrolysates and extracellular electron shuttles for H2 production using co-culture fermentation with Clostridium beijerinckii and Geobacter metallireducens. Bioresour Technol 147:89–95

Zwietering MH, Jongenburger I, Rombouts FM, Van't Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56:1875–1881

Acknowledgements

We thank Dr. Hans Blaschek of the University of Illinois for C. beijerinckii strain NCIMB 8052. We also thank two anonymous reviewers for the suggestions on improving the electron balance analyses and the data presentation.

Funding

This work was partially funded by the National Science Foundation (grant number 0756054).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors declare no conflict(s) of interest. This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic Supplementary Information

ESM 1

(PDF 2439 kb)

Rights and permissions

About this article

Cite this article

Popovic, J., Ye, X., Haluska, A. et al. Ferric iron and extracellular electron shuttling increase xylose utilization and butanol production during fermentation with multiple solventogenic bacteria. Appl Microbiol Biotechnol 101, 8053–8061 (2017). https://doi.org/10.1007/s00253-017-8533-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8533-9