Abstract

While production of biofuels from renewable resources is currently receiving increased attention globally, concerns on availability and sustainability of cheap substrates for their production are growing as well. Lignocellulose-derived sugars (LDS) remain underutilized and merit consideration as a key feedstock. Among other obstacles such as low yield and low solvent titer, mitigation of stresses stemming from lignocellulose-derived microbial inhibitory compounds (LDMICs) that severely impair cell growth and solvent production is a major area of research interest. In addition to attempts at developing LDMIC-tolerant strains via metabolic engineering to enhance utilization of LDS, unconventional approaches that elicit different metabolic perturbations in microorganisms to relieve solvent- and LDMIC-mediated stresses have been explored to increase solvent production from LDS. In this review, the impacts of metabolic perturbations including medium supplementation with glycerol; furfural and 5-hydroxymethyl furfural; allopurinol, an inhibitor of xanthine dehydrogenase; calcium (Ca2+) and zinc (Zn2+) ions); and artificial electron carriers, methyl viologen and neutral red, on butanol production are discussed. Although these approaches have brought about considerable increases in butanol production, both from LDS and defined glucose-based media, the modes of action for most of these perturbations have yet to be fully characterized. Better understanding of these mechanisms would likely inform development of LDMIC-tolerant, butanol-overproducing strains, as well as possible combinatorial application of these approaches for enhanced butanol production. Hence, delineating the underlying mechanisms of these perturbations deserves further attention.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

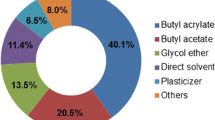

Bioproduction of butanol is currently receiving intensive research attention both in academia and industry. This is driven largely by the physicochemical properties of butanol, including higher energy content, reduced corrosiveness, higher octane rating, and a lower heat of vaporization (Knoshaug and Zhang 2009; Ranjan and Moholkar 2012) among other properties, when compared to ethanol. These properties make butanol a promising next-generation biofuel capable of replacing gasoline without the need to alter the current automobile engine technology (Cheng et al. 2012; Visioli et al. 2014). In addition to its huge potential as a transport fuel, butanol has multifarious industrial applications as a base chemical with an estimated global annual demand of 10–12 billion pounds worth US$7–8.4 billion, and the demand is expected to increase by 3 % annually (Kirschner 2006; Li et al. 2014). Toward achieving higher butanol concentrations and yields sufficient to warrant re-commercialization of bioproduction of butanol, researchers are employing a range of tools such as metabolic engineering and induction of metabolic perturbations in butanol-producing microorganisms to increase substrate utilization, cell growth, and productivity. Metabolic perturbations largely involve incorporation of substrate-based and non-substrate-based supplements to the fermentation medium, aimed at reinforcing metabolic flux towards product (butanol) formation, or to increase tolerance to microbial inhibitory compounds in the fermentation medium that impair cell growth and product formation.

Current trend seeks to produce butanol from renewable lignocellulosic biomass with a view to reducing the overall cost of production (Ezeji et al. 2010; Visioli et al. 2014). Lignocellulosic biomass (LB) has emerged as readily available and cheap source of fermentable sugars for the production of fuels and chemicals by microbial fermentation. However, use of lignocellulose-derived sugars (LDS) as a substrate for butanol production poses formidable challenges to commercial-scale production of butanol, mainly as a result of generation of lignocellulose-derived microbial inhibitory compounds (LDMICs) during pretreatment of LB to release LDS (Palmqvist and Hähn-Hägerdal 2000). High concentrations of LDMICs generated during LB pretreatment drain fermenting microorganisms of ATP and NAD(P)H, thereby distorting redox balance, with the attendant production of acids in solventogenic Clostridium species. Solventogenic Clostridium species resort to acid production to counter the ATP-draining effect of LDMICs (Ujor et al. 2014) because acid production serves as a means of ATP generation (Grupe and Gottschalk 1992). These activities ultimately cause cell death and premature termination of the fermentation due to the combined toxicity of acids and LDMICs (Grupe and Gottschalk 1992; Almeida et al. 2008; Ask et al. 2013; Ujor et al. 2014).

Developing affordable technologies to circumvent the inherent hurdles posed by the generation of LDMICs to acetone-butanol-ethanol (ABE) fermentation is vigorously pursued globally. The use of metabolic engineering to enhance bioproduction of butanol has made significant progress over the past decade. The results of such studies have been reviewed extensively elsewhere (Nielsen et al. 2009; Lütke-Eversloh and Bahl 2011; Jang et al. 2012). Furthermore, process design aimed at increasing butanol production has been well reviewed by other authors (Ezeji et al. 2007a; Jin et al. 2011). In addition to the complex metabolic cues that regulate butanol production by solventogenic Clostridium species, the inhibitory effects of LDMICs on microbial growth have necessitated the use of unconventional methods to ameliorate these negative effects and increase conversion of LDS to butanol. In this review, we highlight these unconventional methods, particularly those that employed metabolic perturbations for increasing butanol production from pure glucose and LDS.

Furan-mediated increase in ABE production

Among other compounds, the furans, furfural and 5-hydroxymethyl furfural (HMF) are key LDMICs that exert severe inhibitions on solventogenic Clostridium species during ABE fermentation of LDS (Ezeji et al. 2007b; Zhang et al. 2012; Zhang and Ezeji 2013; Ujor et al. 2014, 2015). Interestingly, at sublethal concentrations (≤2 g/L), furfural and HMF exert stimulatory effects on solventogenic Clostridium species, culminating in increased fermentation and butanol production. With Clostridium beijerinckii BA101, Ezeji et al. (2007b) reported up to 19 % increase in ABE concentration following addition of 0.5–1.0 g/L furfural or HMF to the fermentation medium. Further, increasing furfural/HMF concentration to 2 g/L led to 11 % increase in ABE production. With Clostridium acetobutylicum ATCC 824, the presence of either furfural or HMF (2 g/L) did not dampen ABE production, as both treated and untreated cultures (control) produced similar amounts of butanol and ABE, respectively (Zhang et al. 2012). However, in the same study, the presence of 2 g/L furfural or HMF did enhance the growth of C. acetobutylicum ATCC 824 by up to 25 %. Ezeji et al. (2007b) also observed up to 13 % increase in cell growth when C. beijerinckii BA101 cultures were supplemented with furfural or HMF (≤2 g/L).

In a study with C. beijerinckii P260, supplementation of the fermentation medium (60 g/L glucose) with wheat straw hydrolysate containing <1 g/L of each of furfural and HMF was found to increase ABE concentration and productivity by ~17 and 100 %, respectively, when compared to the glucose control with no wheat straw hydrolysate (Qureshi et al. 2012). The authors observed that when 0.5 g/L furfural was added to fermentations with glucose (60 g/L), ABE productivity increased by ~4-fold, while addition of 0.5 g/L HMF engendered a 2-fold increase in ABE productivity. Also, increasing furfural or HMF concentrations to 1 g/L and combination of both inhibitors (0.5 g/L each of furfural and HMF) elicited considerable increases in ABE productivity (Qureshi et al. 2012).

The stimulatory effects of furfural and HMF on cell growth and ABE production at sublethal concentrations (≤2 g/L) have been attributed to enhanced NAD+ regeneration, which accelerates the oxidative step (glyceraldehyde-3-phosphate → 1,3-bisphosphoglycerate) of the glycolytic pathway and ultimately increases glycolysis (Zhang et al. 2012). Both NADH and NADPH are important cofactors in the transformation of furfural and HMF to their less toxic alcohols (furfuryl alcohol and HMF alcohol, respectively) by a variety of enzymes including aldo/keto reductases, alcohol dehydrogenases, and short-chain dehydrogenase/reductases (Almeida et al. 2008; Ask et al. 2013; Zhang et al. 2015). Similarly, NAD(P)H plays a crucial role in the transition from acidogenesis to solventogenesis (ABE production; Grupe and Gottschalk 1992). Consequently, high furan concentrations lead to the depletion of NAD(P)H, as fermenting cells attempt to detoxify the furans to their less toxic alcohols (Almeida et al. 2008; Ask et al. 2013; Ujor et al. 2014). This thereby triggers redox imbalance leading to inability to transition from acid production to solvent production, and consequently cell death, due to the combined toxicity of acids and undetoxified furfural/HMF (Ujor et al. 2014). Conversely, at concentrations ≤2 g/L, furfural and HMF are more rapidly detoxified with concomitant generation of NAD+, which is likely reduced via the glycolytic pathway (Fig. 1; Zhang et al. 2012). This would amplify flux through the glycolytic pathway, thus replenishing NADH, which ensures complete detoxification of furfural and/or HMF, with attendant increase in cell growth (for some species/strains). Subsequently, intracellular repletion of NADPH coupled with increased cell concentration (for some species/strains) promotes solventogenesis.

Key NADH and NAD+-generating and utilizing steps during furfural/HMF transformation and ABE biosynthesis. Similar to butanol and ethanol biosynthesis reactions, transformation of furfural and HMF to their less toxic alcohols uses NADH, while glycolysis upstream of the ABE pathway generates NADH. Increased flux through the glycolytic pathway appears a rational mechanism for regenerating NADH, hence accounting for increased growth and ABE production in most cultures challenged with ≤2 g/L furfural/HMF

The question that remains to be answered is whether the stimulatory effects of ≤2 g/L is as a result of enhanced activity of the glycolytic enzyme [glyceraldehyde-3-phosphate dehydrogenase (GAPDH), which regenerates NADH from NAD+ in the glycolytic pathway], or due to increased expression of furfural detoxifying enzymes in the presence of 2 g/L furfural (Zhang and Ezeji, 2013). No study has been conducted to specifically address either scenario, although there are indications that increased glycolytic flux may be responsible. However, in all cases where solventogenic Clostridium species were challenged with ≤2 g/L furfural/HMF, there was no significant increase in overall glucose consumption, despite increases in cell growth by C. acetobutylicum (Zhang et al. 2012) and C. beijerinckii BA101 (Ezeji et al. 2007b), while C. beijerinckii P260 exhibited a slight reduction in cell growth (Qureshi et al. 2012), possibly due to butanol toxicity. Hence, different strains/species may exhibit subtle differences in the mechanisms responsible for enhanced solvent accumulation upon furan supplementation.

Roles of calcium (Ca2+) and zinc (Zn2+) ions in ABE production

While the involvement of Fe2+, Mg2+, and Mn2+ in ABE production has been established over the years (Bahl et al. 1986; Peguin and Soucaille 1995), Ca2+ and Zn2+ have emerged of late as key players in the modulation of growth and ABE production in solventogenic Clostridium species. It has to be noted though that CaCO3 has long been used as a supplement during ABE fermentation, although largely as a buffer (Marchal et al. 1985; Ren et al. 2010). El Kanouni et al. (1998) were the first to report that the presence of CaCO3 in the fermentation medium relieves carbon catabolite repression, thereby allowing concomitant utilization of xylose and glucose by C. acetobutylicum. The study suggested that observed effect transcended the buffering capacity of CaCO3 and speculated that enhanced butanol tolerance occurred possibly through stabilization of membrane proteins by Ca2+. Further, addition of the nonbuffering CaCl2 to the fermentation medium produced a similar result as CaCO3 (concomitant utilization of glucose and xylose) in C. acetobutylicum and elicited increased ABE production in cultures of C. beijerinckii NCIMB 8052 (Han et al. 2013). By incorporating CaCO3 (4 g/L) in the fermentation medium, Richmond et al. (2011) also observed marked increases in growth and ABE production by C. acetobutylicum ATCC 824 and C. beijerinckii P260.

In light of these findings, Han et al. (2013) conducted an extensive comparison of CaCO3 to other buffering carbonates [Na2CO3, K2CO3, (NH4)2CO3, NaHCO3, NH4HCO3], and their results showed ~25 % higher ABE production in CaCO3-supplemented cultures relative to cultures supplemented with the other carbonates. Global proteomic analysis of CaCO3-treated cells of C. beijerinckii NCIMB 8052 showed dramatic increases in the levels of heat shock proteins, carbohydrate catabolic enzymes, and proteins involved in DNA synthesis, transcription, and repair, among other functions, relative to the untreated cells (Han et al. 2013). Thus, CaCO3-mediated increase in cell growth elicits increased expression of DNA and protein chaperones to mitigate potential increases in DNA mutations and protein misfolding due to rapid cell growth, which consequently relieves butanol toxicity (Fig. 2), as protein and DNA chaperones are known to increase butanol tolerance (Tomas et al. 2004).

The positive effects of Ca2+ have also been reported for cultures grown in typically toxic LDS-based media. For instance, while hot-water-pretreated Miscanthus giganteus hydrolysate (15 % solid loading) did not support growth and ABE production in C. beijerinckii NCIMB 8052 at all due to the presence of LDMICs, addition of CaCO3 to the hydrolysate ameliorated the inhibitory effects of LDMICs on C. beijerinckii NCIMB 8052 with concomitant ABE production (Zhang and Ezeji 2014). Similarly, CaCO3 supplementation was reported to enhance the production of hydrogen, volatile fatty acids, and solvents by C. sporogenes BE01 in dilute acid-pretreated rice straw, by positively modulating electron transport (Gottumakkala et al. 2015). In a study with multiple strains, Li et al. (2013) reported enhanced growth, sugar utilization, and solvent production following CaCO3 supplementation of xylose liquor, a by-product of acid-mediated hydrolysis of corncobs.

The growth of solventogenic Clostridium species in LDMIC-containing media increases acid production (Ujor et al. 2014) to counteract inhibitor-mediated depletion of ATP (Almeida et al. 2008; Ask et al. 2013). Consequently, the buffering effect of CaCO3 helps to relieve acid-induced toxicity during fermentation of lignocellulosic biomass hydrolysate (LBH). However, the positive effect of CaCO3 in this regard cannot be solely ascribed to its buffering capacity. First, acid production (which generates ATP for growth) during ABE fermentation can only occur upon inception of cell growth. Second, growth is completely inhibited in non-CaCO3-supplemented cultures in LBHs. Therefore, it is plausible that another mechanism(s) beyond buffering, which perhaps includes Ca2+-mediated signaling contributes to the onset of C. beijerinckii growth, as well as tolerance to LDMICs and solvents during fermentation of LBHs. Whereas Ca2+ signaling is well defined in eukaryotes, the same cannot be said of prokaryotes, although some progress has been made. Identification of a dedicated Ca2+ receptor in prokaryotes akin to the eukaryotic calcium receptor (calmodulin) may help to understand in greater detail the roles of Ca2+ in the biology of solventogenic Clostridium species.

Zn2+ was not considered an important component of ABE fermentation medium prior to the work of Wu et al. (2013), who reported that medium supplementation with 0.001 g/L ZnSO4·7H2O engendered early initiation of solventogenesis with a modest increase (8 %) in ABE concentration, significant increases in productivity (77 %) and optical density (cell growth; ~24 %). Consequently, supplementation of the fermentation medium with ZnSO4·7H2O reduced the duration of ABE fermentation from 64 to 40 h, with a slight increase in final solvent concentration. Zn2+ has been reported to positively influence the expression of glycolytic enzymes (Wu et al. 2013) as well as exert a stabilizing effect on butanol dehydrogenase, the terminal enzyme of the butanol production pathway (Walter et al. 1992). Further, Zn2+ plays a key role in the regulation of intracellular metabolism via interactions with Zn-dependent DNA binding domains. Although further studies are required to unravel the specific mechanisms by which Zn2+ evokes an earlier initiation of solventogenesis, it appears Zn2+ upregulates diverse genes whose protein products are involved in sugar utilization and ABE production, thereby leading to a more rapid growth and early switch to solventogenesis, following swift accumulation of acids (Fig. 3).

Putative mechanism of Zn2+-induced increase in ABE productivity. a Rapid induction of ABE production in Zn2+-supplemented cultures. b Typical ABE accumulation in non-Zn2+-supplemented cultures. The presence of Zn2+ expedites fermentation, thereby leading to reduced fermentation time and hence, productivity

Supplementation of fermentation medium with glycerol enhances ABE production from LBH

The high cost of fermentative butanol production is largely ascribed to the cost of substrate. Attempts at overcoming this obstacle have identified LB as a veritable source of cheap sugars not only for butanol production but also for biological production of other biofuels and biochemicals (Palmqvist and Hähn-Hägerdal 2000). Depending on the type of plant biomass used, the amount (solid loading), and pretreatment conditions, the resulting concentrations of various LDMICs vary and may severely or completely inhibit the growth of solventogenic Clostridium species (Ezeji et al. 2007b; Zhang and Ezeji 2014). Even when inhibition of the growth of the fermenting microorganisms is not substantial, butanol production is often dramatically impaired despite the intrinsic capacity of these microorganisms to transform LDMICs to less toxic products during fermentation (Ezeji et al. 2007b; Zhang and Ezeji 2014).

Boosting intracellular supply of NAD(P)H and/or ATP represents a rational strategy for combating LDMIC-mediated inhibitions during fermentation of LBH. Whereas glycerol as a sole substrate or in combination with glucose may not significantly increase total ABE production, it does enhance butanol and ethanol production over acetone (Girbal et al. 1995). However, when fermentation is conducted in LDMIC-containing media, glycerol does exert a considerable positive impact on total ABE production and still favors butanol accumulation over acetone (Ujor et al. 2014). In a rather unconventional approach in which C. beijerinckii NCIMB 8052 was grown in furfural-replete cultures, Ujor et al. (2014) demonstrated that glycerol supplementation of a glucose-based medium resulted in 2.3-fold increase in both cell growth and ABE production.

To demonstrate the inherent capacity of C. beijerinckii to detoxify furfural to the less toxic furfuryl alcohol, 4–6 g/L furfural which normally inhibit cell growth when added to cultures at 0 h were pulse-fed into cultures of C. beijerinckii NCIMB 8052 at 10 h (when considerable cell density had been accumulated; Ujor et al., 2014). One set of fermentation was conducted in a medium containing only glucose, while another set contained a mixture of glucose and glycerol (glucose/glycerol molar ratio 1:2). With 4 g/L furfural, both sets of cultures exhibited similar growth, ABE and furfural detoxification profiles (Ujor et al. 2014). However, increasing furfural concentration to 5 and 6 g/L resulted in dramatic changes in the growth, ABE and furfural detoxification profiles in favor of glycerol-supplemented cultures over the un-supplemented culture controls (Ujor et al. 2014). The ability of glycerol to enhance solvent production in LDMIC-containing cultures was further accentuated by the work of Sabra et al. (2014), who showed that glycerol supplementation of LBH resulted in 2.6-fold increase in butanol production when compared to the unsupplemented LBH.

The stimulatory effect of glycerol on cell growth and ABE production in LDMIC-containing cultures can be traced largely to the biochemistry of glycerol catabolism (Fig. 4). While ATP is central to growth and overall cell functioning, detoxification of most LDMICs is NAD(P)H-dependent because LDMIC-transforming aldehyde and alcohol dehydrogenases are NAD(P)H-reliant. Relative to molar equivalent of glucose, glycerol utilization generates two additional moles of NADH (Lin 1976) and different authors have reported significant increases in both NADH and ATP in C. acetobutylicum during ABE fermentation of a glucose + glycerol medium (molar ratio, 1:2), in comparison with cultures grown on glucose alone with no glycerol supplementation (Girbal and Soucaille 1994; Vasconcelos et al. 1994; Girbal et al. 1995). Similarly, C. beijerinckii grown in a mixture of glucose and glycerol was found to exhibit higher intracellular NADH and NADPH levels than those grown solely on glucose (Ujor et al. 2014). Glycerol catabolism generates NADH directly (Fig. 4). Given that NAD+ is a precursor for NADP+ in a reaction catalyzed by ATP-NAD+ kinase (Moat and Foster 1987; Heuser et al. 2007), glycerol metabolism can indirectly generate NADPH, which likely explains intracellular increase in NADPH levels in glycerol-supplemented cultures (Ujor et al. 2014). The protein product of the gene, Cbei_1708, in C. beijerinckii NCIMB 8052 is annotated as an ATP-NAD+ kinase. Interestingly, glycerol supplementation has been shown to increase alcohol and aldehyde dehydrogenases activities in C. acetobutylicum, which play a central role in butanol biosynthesis and transformation of furfural and HMF to their less toxic alcohols (Girbal and Soucaille 1994; Vasconcelos et al. 1994; Girbal et al. 1995; Almeida et al. 2008; Zhang et al. 2015).

Influence of enhanced NADH-generating capacity of glycerol catabolism on furfural transformation and alcohol (butanol and ethanol) biosynthesis in furfural-challenged, glycerol-supplemented cultures, during ABE fermentation. DHAP dihydroxyacetone phosphate, AKR aldo/keto reductase, SDR short chain dehydrogenase/reductase, AD alcohol dehydrogenase

Taken together, the presence of glycerol in the growth medium increases intracellular supply of ATP and reducing equivalents [NAD(P)H] critical for growth and LDMIC detoxification by solventogenic Clostridium species, respectively. Increased intracellular NAD(P)H levels elicit a corresponding increase in NAD(P)H-dependent LDMIC-detoxifying alcohol and aldehyde dehydrogenases, which collectively amplify the intracellular arsenal that directly combats LDMICs. Ultimately, these activities (Fig. 4) result in rapid detoxification of LDMICs and transition from acid to solvent production as evidenced by reduced butyric and acetic acid levels in glycerol-supplemented LDMIC-containing cultures of C. beijerinckii and Clostridium pasteurianum (Ujor et al. 2014; Sabra et al. 2014). Further, increases in the levels of aldehyde and alcohol dehydrogenases, particularly butyraldehyde and butanol dehydrogenases, in glycerol-supplemented cultures (Girbal and Soucaille 1994; Girbal et al. 1995; Vasconcelos et al. 1994) may contribute to butanol production following LDMIC detoxification (Fig. 4). Ujor et al. (2014) reported a spike in glycerol/glucose utilization ratio with increasing furfural concentration (4–6 g/L) during fermentation of glycerol-supplemented glucose media, which suggests that the redox stresses caused by furfural enhanced glycerol utilization. Increase in glycerol metabolism generated a corresponding increase in intracellular NAD(P)H levels, which are disposed of (oxidized to NAD(P)+) by accelerated transformation of LDMICs to less inhibitory alcohols and enhanced biosynthesis butanol and ethanol (Fig. 4).

Despite the positive effects observed with glycerol, most solventogenic Clostridium species utilize glycerol poorly. Often, glycerol is utilized only when supplied as a co-substrate with glucose. Hence, large amounts of glycerol are left unutilized after fermentation, thereby constituting a major economic waste. Therefore, further studies are imperative to better delineate roadblocks to glycerol utilization by most solventogenic Clostridium species. Findings from such studies will forge a roadmap to genetic construction of efficient glycerol-utilizing strains. Such strains will not only allow efficient conversion of glycerol, which is currently accumulated in excess as a by-product of biodiesel production (Johnson and Taconi 2007) to butanol but also ensure robust conversion of LBH to butanol via glycerol supplementation.

Allopurinol supplementation: a new strategy for mitigating the toxicity of LDMICs during ABE fermentation

Allopurinol [4-hydroxypyrazolo-(3,4-D)-pyrimidine)] is an analog of hypoxanthine primarily used in the treatment of gout in humans (Rundles et al. 1963; Kelley et al. 1968). In vivo, allopurinol is metabolized to oxypurinol [4,6-dihydroxypyrazolo-(3,4-D)-pyrimidine], which competitively inhibits xanthine dehydrogenase (XDH; Rundles et al. 1963; Kelley et al. 1968). Oxypurinol inhibits XDH by binding tightly to the latter, and in so doing competitively excludes the natural substrates of XDH, xanthine, and hypoxanthine, from binding to this enzyme (XDH), hence drastically reducing uric acid formation (Kelley et al. 1968). Although allopurinol appears to be the least likely candidate for alleviating LDMIC toxicity, addition of allopurinol to furfural-challenged medium during ABE fermentation resulted in marked increase in butanol production with corresponding increase in cell growth (Ujor et al. 2015).

In furfural-challenged cultures of C. beijerinckii, supplementation of the fermentation medium with allopurinol (1 mM) enhances the rate of furfural detoxification, growth, and ABE production (Ujor et al. 2015). However, the presence of allopurinol in the fermentation medium did not increase NAD(P)H levels. On the contrary, allopurinol supplementation did in fact mitigate the negative effects of nalidixic acid (a DNA-damaging antibiotic) on growth and butanol production by C. beijerinckii. Furfural compromises the cellular integrity of fermenting microbial cells, which includes DNA damage (Zdzienicka et al. 1978). It is deducible that allopurinol-mediated mitigation of furfural toxicity is as a result of purine salvage. XDH inhibition leads to the accumulation of purines, xanthine, and hypoxanthine, both of which are precursors of deoxyribonucleotides, the monomers for DNA replication and repair (Kolberg et al. 2004). Thus, it is reasonable that the excess hypoxanthine and xanthine resulting from XDH inhibition by allopurinol is reutilized via the purine salvage pathway for DNA replication and repair (Christiansen et al. 1997; Xi et al. 2000; Ujor et al. 2015). This assumption is supported by the finding that genes encoding both hypoxanthine and xanthine phosphoribosyltransferases (HPRT and XPRT), both of which are key purine salvage enzymes, were upregulated in C. beijerinckii grown in fermentation medium supplemented with allopurinol during furfural challenge (Ujor et al. 2015). In the same study, both inosine (precursor of hypoxanthine) and xanthine were also found to produce modest increases in butanol production in furfural-challenged cultures.

In a similar study, the ability of Escherichia coli to tolerate furfural increased following over-expression of thyA, which encodes thymidylate synthase, an essential enzyme in de novo biosynthesis of deoxythymidine monophosphate (dTMP). Further, addition of the pyrimidine and pyrimidine precursor, thymine and thymidine, as well as combination of tetrahydrofolate and serine to the fermentation medium also enhanced furfural tolerance in E. coli (Zheng et al. 2012). These findings, therefore, suggest that increased supply of purine and pyrimidine deoxyribonucleotides during exposure to furfural stress enhances furfural tolerance owing to increased repair of furfural-mediated DNA damage (Zheng et al. 2012; Ujor, et al. 2015). In solventogenic Clostridium species, enhanced recovery from furfural stress, particularly DNA damage, ultimately streamlines the progression of cell growth to ensure transition from the acidogenic to the solventogenic growth phases. As demonstrated in E. coli (by overexpression of thyA), overexpression of HPRT and XPRT as well as other purine and/or pyrimidine salvage enzymes represents a rational approach for combating furfural toxicity and perhaps, toxicities stemming from other LDMICs in solventogenic Clostridium species.

Increase in butanol production by redox modulations that inhibit/limit hydrogen production

During ABE fermentation, acidogenesis is accompanied by a high level of hydrogen production, which reduces upon transition to the solventogenic phase (Girbal et al. 1995; Hönicke et al. 2012; Du et al. 2015). Hydrogen production is reduced during solventogenesis because the biosynthesis of butanol and ethanol is NAD(P)H-dependent; hence, both pathways compete with hydrogen biosynthesis for reducing equivalents (Girbal and Souicaille 1998; Lütke-Eversloh and Bahl 2011; Hönicke et al. 2012). Therefore, drastic reduction of or complete inhibition of hydrogen biosynthesis frees up extra reducing equivalents, which results in increased accumulation of NAD(P)H and early initiation of solventogenesis and consequently, higher butanol and ethanol titers (Girbal et al. 1995; Girbal and Souicaille 1998; Lütke-Eversloh and Bahl 2011; Hönicke et al. 2012; Du et al. 2015).

One approach for achieving increased generation of NAD(P)H is by the use of metabolic engineering tools to construct mutant strains in which electron flow and carbon flux are modulated to favor generation of NAD(P)H for butanol biosynthesis (Lütke-Eversloh and Bahl 2011; Du et al. 2015). Another approach which has been classically employed to achieve the same objective is the use of different metabolic perturbations that lead to reduced hydrogen production such as inhibition of hydrogenase activity by increasing hydrogen partial pressure (Yerushalmi and Volesky 1985), reversible inhibition of hydrogenase by carbon monoxide sparging (Meyer et al. 1986), iron limitation (Peguin and Soucaille 1995), and supply of artificial electron carriers such as methyl viologen (MV) and neutral red (NR; Girbal et al. 1995; Peguin and Soucaille 1995; Hönicke et al. 2012; Du et al. 2015). These perturbations alter conventional flow of electrons and carbon flux during fermentation to increase NAD(P)H generation, thereby enhancing butanol and ethanol biosynthesis at the expense of hydrogen production (Hönicke et al. 2012; Du et al. 2015).

For the purpose of this review, culture supplementation with the artificial electron carriers, MV and NR (particularly MV, which has been studied more extensively), will be discussed further in relation to increased butanol production. A considerable body of evidence in the literature suggests that both MV and NR share similar mechanisms of action, which involves siphoning electrons from ferredoxin, the orthodox carrier of electrons for hydrogen production (Girbal et al. 1995; Hönicke et al. 2012; Du et al. 2015). During acidogenesis, hydrogenase steals electrons from reduced ferredoxin (FdH2) for hydrogen production while pyruvate/ferredoxin oxidoreductase (PFdOR) regenerates FdH2 during oxidative decarboxylation of pyruvate to acetyl-CoA, a key intermediate in acid and solvent biosynthesis (Girbal et al. 1995; Hönicke et al. 2012; Du et al. 2015). In the solventogenic phase, however, re-oxidation of ferredoxin is carried out by ferredoxin/NAD(P)+ reductase (FNR) and in so doing, generates ample reducing equivalents [NAD(P)H] for butanol biosynthesis (Girbal and Soucaille 1998; Hönicke et al. 2012; Du et al. 2015).

Supplementation of the culture with MV and NR has been shown to exert little or no effect on hydrogenase activity and mRNA levels (Girbal et al. 1995; Hönicke et al. 2012). On the contrary, FNR activity and mRNA levels increase dramatically in response to MV or NR supplementation (Girbal et al. 1995; Hönicke et al. 2012). Indeed, FNR has a higher affinity for MV than ferredoxin as substrate (with a low K m value for MV), while hydrogenase has a high K m value for MV (MV is a poor substrate for hydrogenase; Demuez et al. 2007). Hönicke et al. (2012) reported that while culture supplementation with MV barely affects hydrogenase mRNA levels, the expression of ferredoxin-encoding genes reduced considerably. Whereas these findings reveal a complex web of underlying genetic events in MV-treated cells, some of which might be as a result of cascade effect, interesting deductions can be drawn. For instance, contrary to the notion that reduced hydrogen production in MV- and NR-supplemented cultures was likely as a result of depressed hydrogenase activity or expression, enzymatic and microarray analyses suggest otherwise (Girbal et al. 1995; Hönicke et al. 2012). Therefore, the mechanism(s) by which artificial electron carriers such as MV and NR exert their effects on product formation could be attributed to reduced ferredoxin and increased FNR expression (Fig. 5).

Increased NADPH generation and reduced hydrogen biosynthesis due to culture supplementation with methyl viologen (MV) or neutral red (NR). a Cells supplemented with MV or NR in which hydrogenase (Hyd) expression/activity does not change significantly while ferredoxin/NAD(P)+ reductase (FNR) is significantly upregulated, and ferredoxin (FdH2) is downregulated. The abundant ferredoxin/NAD(P)+ reductase binds to the equally abundant MV/NR, leading to enhanced NADPH generation at the expense of hydrogen biosynthesis. b In cells un-supplemented with MV/NR, hydrogenase and ferredoxin are more abundant than ferredoxin/NAD(P)+ reductase. Hence, there is more interaction between hydrogenase and ferredoxin resulting in relatively higher hydrogen production than NADPH generation. MVH reduced methyl viologen, NRH reduced neutral red, Hyd no change in hydrogenase expression, FdH2 downregulation of ferredoxin, FNR upregulation of FNR

Hydrogenase prefers FdH2 over reduced MV as substrate, thus, reduced levels of FdH2 in MV-supplemented cultures leads to decrease in hydrogen production due to diminished interaction between hydrogenase and FdH2, a key prerequisite for hydrogen biosynthesis. Further, concomitant increase in the level of FNR, which prefers MV as substrate ultimately translates to increased interaction between FNR and MV, and consequently enhanced NAD(P)H generation (Fig. 5). Since the intracellular levels of FdH2 is low following MV supplementation, MV becomes the prevalent electron carrier, and thereby rendering the hydrogenase-catalyzed hydrogen production unfavorable while enhancing NAD(P)H generation owing to increased MV–FNR interaction. The resulting increase in NAD(P)H generation supplies ample reducing power for butanol and ethanol biosynthesis.

Concluding remarks

Ever since the genomes of two major solventogenic Clostridium species—C. acetobutylicum 824 and C. beijerinckii NCIMB 8052—were sequenced, these bacteria have been the focus of significant analyses and adaptive engineering toward increasing solvent production (particularly butanol) during ABE fermentation (Ezeji et al. 2010). In parallel, substrate cost has been widely recognized as a factor that exerts a significant influence on the cost of biological production of butanol, thus necessitating the use of alternative substrates such as LDS. Although considerable advances have been made on both fronts, low solvent productivity and inefficient utilization of LDS by solventogenic Clostridium species constitute a major stumbling block to the commercialization of bio-butanol production. Consequently, three broad research efforts are currently under vigorous pursuit. First is the use of transcriptomic and proteomic tools to better understand the negative effects of solvents on the metabolism of solventogenic Clostridium species as well as development of appropriate technologies to mitigate solvent toxicity during fermentation (Tomas et al. 2004; Hönicke et al. 2012; Han et al. 2013; Ni et al. 2013). Second, isolation of new cellulases and use of site-directed mutagenesis geared toward enhancing the catalytic efficiency of cellulases, and thereby enhancing LB deconstruction to LDS. Third, knockdown/deletion of catabolite control protein A (CcpA), the master effector of catabolite repression in solventogenic Clostridium species (Ren et al. 2010), to override the intrinsic order of sugar utilization, and thus enhance efficient utilization of mixed sugars (e.g., LDS). However, little attention is given to LDMICs and their effects on solventogenic Clostridium species during fermentation. Indeed, these inhibitors have contributed considerably to recent failures reported during cellulosic ethanol scale-up and commercialization. We are certain that without addressing the inhibitory effects of butanol and LDMICs on solventogenic Clostridium species during ABE fermentation, it will be difficult to achieve butanol concentrations and yields sufficient to warrant re-commercialization of biological butanol production. We reason that information obtained with “omics” and downstream processing technologies could be used to elicit metabolic perturbations in fermenting microorganisms to serve as a paradigm for solvent production improvement studies that judiciously exploit the intrinsic capacity of these microorganisms to adapt to stressful conditions such as high concentrations of butanol and LDMICs.

To achieve optimum performance with regards to butanol yield and productivity, unraveling the dynamics of the molecular interplays that underlie MV- or NR-induced increases in butanol production seems an untapped area in the quest to better understand the molecular physiology of these microorganisms during ABE fermentation. For example, knockout or knockdown of ferredoxin-, hydrogenase-, and/or FNR-encoding genes in select solventogenic Clostridium species, with and without MV or NR supplementation, may provide further insights into how these artificial electron carriers enhance butanol production. Data emanating from such studies may form the basis for engineering a butanol-overproducing strain, which excludes the economic burden of MV or NR supplementation. Additionally, as demonstrated in E. coli (by overexpression of thyA), overexpression of HPRT and XPRT as well as other purine and/or pyrimidine salvage enzymes in solventogenic Clostridium species may be a rational approach for combating inhibitions stemming from LDMICs in LBHs and consequently, enhance LDS utilization for butanol production. Further, evaluating the combined effect of Ca2+ and Zn2+ may prove instructive for enhanced ABE productivity, particularly from LDS with a view to improving the economics of LDS-based ABE fermentation. Unraveling the specific mechanisms underlying Zn2+-mediated increase in solvent productivity will likely contribute to rational design of a butanol overproducing strain when combined with knowledge of Ca2+-induced increase in ABE productivity, cell growth, and solvent tolerance.

References

Almeida JRM, Röder A, Modig T, Laadan B, Lidén G, Gorwa-Grauslund MF (2008) NADH- vs NADPH-coupled reduction of 5-hydroxymethyl furfural (HMF) and its implications on product distribution in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 78:939–945

Ask M, Bettiga M, Mapelli V, Olsson L (2013) The influence of HMF and furfural on the redox-balance and energy-state of xylose and energy-state of xylose-utilizing Saccharomyces cerevisiae. Biotechnol Biofuels 6:22–34

Bahl H, Gottwald M, Kuhn A, Rale V, Andersch W, Gottschalk G (1986) Nutritional factors affecting the ratio of solvents produced by Clostridium acetobutylicum. Appl Environ Microbiol 52:169–172

Cheng CL, Che PY, Chen BY, Lee WJ, Lin CY, Chang JS (2012) Biobutanol production from agricultural waste by an acclimated mixed bacterial microflora. Appl Energy 100:3–9

Christiansen LC, Schou S, Nygaard P, Saxlid HH (1997) Xanthine metabolism in Bacillus subtilis: characterization of the xpt-pbutX operon and evidence of purine- and nitrogen-controlled expression of genes involved in xanthine salvage catabolism. J Bacteriol 179:2540–2550

Demuez M, Cournac L, Guerrini O, Soucaille P, Girbal L (2007) Complete activity profile of Clostridium acetobutylicum [FeFe]-hydrogenase and kinetic parameters for endogenous redox partners. FEMS Microbiol Lett 275:113–121

Du Y, Jiang W, Yu M, Tang I-C, Yangl S-T (2015) Metabolic engineering of Clostridium tyrobutylicum ∆ack – adhE2 for enhanced n-butanol production from glucose: effects of methyl viologen on NADH availability, flux distribution, and fermentation kinetics. Biotechnol Bioeng 112:795–715

El Kanouni A, Zerdani I, Zaafa SM, Znassni M, Loufti M, Boudouma M (1998) The improvement of glucose/xylose fermentation by Clostridium acetobutylicum using calcium carbonate. World J Microbiol Biotechnol 14:431–435

Ezeji TC, Milne C, Price ND, Blaschek HP (2010) Achievements and perspectives to overcome the poor solvent resistance in acetone and butanol producing microorganisms. Appl Microbiol Biotechnol 85:1697–1712

Ezeji TC, Qureshi N, Blaschek HP (2007a) Bioproduction of butanol from biomass: from genes to bioreactors. Curr Opin Biotechnol 18:220–227

Ezeji TC, Qureshi N, Blaschek HP (2007b) Butanol production from agricultural residues: impact of degradation products on Clostridium beijerinckii growth and butanol fermentation. Biotechnol Bioeng 97:1460–1469

Girbal L, Croux C, Vasconcelos I, Soucaille P (1995) Regulation of metabolic shifts in Clostridium acetobutylicum ATCC 824. FEMS Microbiol Rev 17:287–297

Girbal L, Soucaille P (1994) Regulation of Clostridium acetobutylicum metabolism as revealed by mixed-substrate steady-state continuous cultures: role of NADH/NAD ratio and ATP pool. J Bacteriol 176:6433–6438

Girbal L, Soucaille P (1998) Regulation of solvent production in Clostridium acetobutylicum. Trends Biotechnol 16:1–16

Gottumukkala LD, Sukumaran RK, Mohan SV, Valappil SK, Sarkarb O, Pandeya A (2015) Rice straw hydrolysate to fuel and volatile fatty acid conversion by Clostridium sporogenes BE01: bio-electrochemical analysis of the electron transport mediators involved. Green Chem 17:3047–3058

Grupe H, Gottschalk G (1992) Physiological events in Clostridium acetobutylicum during the shift from acidogenesis to solventogenesis in continuous culture and presentation of a model for shift induction. Appl Environ Microbiol 58:3896–3902

Han B, Ujor V, Lai LB, Gopalan V, Ezeji TC (2013) Use of proteomic analysis to elucidate the role of calcium in acetone-butanol-ethanol fermentation by Clostridium beijerinckii NCIMB 8052. Apple Environ Microbiol 79:282–293

Heuser F, Schroer K, Lutz S, Bringer-meyer S, Sahm H (2007) Enhancement of the NAD(P)H pool in Escherichia coli for biotransformation. Eng Life Sci 7:343–353

Hönicke D, Janssen H, Grimmler C, Ehrenreich A, Lütke-Eversloh T (2012) Global transcriptional changes of Clostridium acetobutylicum cultures with increased butanol:acetone ratios. New Biotechnol 29:485–493

Jang YS, Lee J, Malaviya A, Seung do Y, Cho JH, Lee SY (2012) Butanol production from renewable biomass: rediscovery of metabolic pathways and metabolic engineering. Biotechnol J 7:186–198

Jin C, Yao M, Liu H, Lee CF, Ji J (2011) Progress in the production and application of n-butanol as a biofuel. Renew Sust Energ Rev 15:4080–4106

Johnson DT, Taconi KA (2007) The glycerin glut: options for the value-added conversion of crude glycerol resulting from biodiesel production. Environ Prog 126:338–348

Kelley WN, Rosenbloom FM, Miller J, Seegmiller JE (1968) An enzymatic basis for variations in response to allopurinol. New Engl J Med 278:287–293

Kirschner M (2006) n-Butanol. Chem Mark Report 269:42

Knoshaug EP, Zhang M (2009) Butanol tolerance in a selection of microorganisms. Appl Biochem Biotechnol 153:13–20

Kolberg M, Strand KR, Graff P, Anderson KK (2004) Structure, function and mechanism of ribonucleotide reductases. Biochim Biophys Acta 1699:1–34

Li T, Yan Y, He J (2014) Reducing cofactors contribute to the increase of butanol production by wild-type Clostridium sp. Strain BOH3. Bioresour Technol 155(220):228

Li Z, Xiao H, Jiang W, Jiang Y, Yang S (2013) Improvement of solvent production from xylose mother liquor by engineering xylose metabolic pathway in Clostridium acetobutylicum EA 2018. Appl Biochem Biotechnol 171:555–568

Lin ECC (1976) Glycerol dissimilation and its regulation in bacteria. Ann Rev Microbiol 30:535–578

Lütke-Eversloh T, Bahl H (2011) Metabolic engineering of Clostridium acetobutylicum: recent advances to improve butanol production. Curr Opin Biotechnol 22:634–347

Marchal R, Blanchet D, Vandecasteele J (1985) Industrial optimization of acetone-butanol fermentation: a study of the utilization of Jerusalem artichokes. Appl Microbiol Biotechnol 23:92–98

Meyer CL, Roos JW, Papoutsakis ET (1986) Carbon monoxide gassing leads to alcohol production and butyrate uptake without acetone formation in continuous cultures of Clostridium acetobutylicum. Appl Microbiol Biotechnol 24:159–167

Moat GA, Foster JW (1987) Biosynthesis and salvage pathways of pyridine nucleotides. In: DDO A, Poulson R (eds) Pyridine nucleotide coenzymes part A. John Wiley & Sons, Inc, New York

Ni Y, Song L, Qian X, Sun Z (2013) Proteomic analysis of Pseudomonas putida reveals an organic solvent tolerance-related gene mmsB. PLoS One 8(2):e55858

Nielsen DR, Leonard E, Yoon SH, Tseng HC, Yuan C, Prather KL (2009) Engineering alternative butanol production platforms in heterologous bacteria. Metab Eng 11:262–273

Palmqvist E, Hähn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysate. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Peguin S, Soucaille P (1995) Modulation of carbon and electron flow in Clostridium acetobutylicum by iron limitation and methyl viologen addition. Appl Environ Microbiol 61:403–405

Qureshi N, Bowmana MJ, Sahaa BC, Hectora R, Berhowb MA, Cottaa MA (2012) Effect of cellulosic sugar degradation products (furfural and hydroxymethyl furfural) on acetone–butanol–ethanol (ABE) fermentation using Clostridium beijerinckii P260. Food Bioprod Bioprocess 90:533–540

Ranjan A, Moholkar VS (2012) Biobutanol: science, engineering, and economics. Int J Energ Res 36:277–323

Ren C, Gu Y, Hu S, Wu Y, Wang P, Yang Y, Yang C, Yang S, Jiang W (2010) Identification and inactivation of a leitropic regulator CcpA to eliminate glucose repression of xylose utilization in Clostridium acetobutylicum. Metab Eng 12:446–454

Richmond C, Han B, Ezeji TC (2011) Stimulatory Effects of Calcium Carbonate on Butanol Production by Solventogenic Clostridium Species 5:18–28

Rundles RW, Wyngaarden JB, Hitchings GH, Ellion GB, Silberman HR (1963) Effects of xanthine oxidase inhibitor on thiopurine metabolism, hyperuricemia and gout. Tr Am Phys 76:126–140

Sabra W, Groeger C, Sharma PN, Zeng A-P (2014) Improved n-butanol production by non-acetone producing Clostridium pasteurianum DSMZ 525 in mixed substrate fermentation. Appl Microbiol Biotechnol 98:4267–4276

Tomas CA, Beamish J, Papousakis ET (2004) Transcriptional analysis of butanol stress tolerance in Clostridium acetobutylicum. J Bacteriol 186:2006–2018

Ujor V, Agu CV, Gopalan V, Ezeji TC (2014) Glycerol supplementation enhances furfural detoxification by Clostridium beijerinckii during butanol fermentation. Appl Microbiol Biotechnol 98:6511–6521

Ujor V, Agu CV, Gopalan V, Ezeji TC (2015) Allopurinol-mediated lignocellulose-derived microbial inhibitor tolerance by Clostridium beijerinckii during acetone–butanol–ethanol (ABE) fermentation. Appl Microbiol Biotechnol 99:3729–3740

Vasconcelos I, Girbal L, Soucaille P (1994) Regulation of carbon and electron flow in Clostridium acetobutylicum grown in chemostat culture at neutral pH on mixture of glucose and glycerol. J Bacteriol 176:1443–1450

Visioli LJ, Enzweiler H, Kuhn RC, Schwaab M, Mazutti MA (2014) Recent advances in butanol production. Sustainable Chem Processes 2:15

Walter KA, Bennett G, Papoutsakis ET (1992) Molecualr characterization of two Clostridium acetobutylicum ATCC 824 butanol dehydrogenase isozyme genes. J Bacteriol 174:7149–7158

Wu Y-D, Xue C, Chen L-J, Bai F-W (2013) Effect of zinc supplementation on acetone-butanol-ethanol fermentation by Clostridium acetobutylicum. J Biotechnol 165:18–21

Xi H, Schneider BL, Reitzer L (2000) Purine catabolism in Escherichia coli and function of xanthine dehydrogenase in purine salvage. J Bacteriol 182:5332–5341

Yerushalmi L, Volesky B (1985) Importance of agitation in acetone butanol fermentation. Biotechnol Bioeng 27:1297–1305

Zdzienicka M, Tudek B, Zielenska M, Szymczyk T (1978) Mutagenic activity of furfural in salmonella typhimurium TA100. Mutat Res 58:205–209

Zhang Y, Ujor V, Wick M, Ezeji TC (2015) Identification, purification and characterization of furfural transforming enzymes from Clostridium beijerinckii NCIMB 8052. Anaerobe 33:124–131

Zhang Y, Han B, Ezeji TC (2012) Biotransformation of furfural and 5-hydroxymethyl furfural by Clostridium acetobutylicum ATCC 824 during butanol fermentation. New Biotechnol 29:345–351

Zhang Y, Ezeji TC (2013) Transcriptional analysis of Clostridium beijerinckii NCIMB 8052 to elucidate the role of furfural stress during acetone butanol fermentation. Biotechnol Biofuels 6:66–82

Zhang Y, Ezeji TC (2014) Elucidating and alleviating the impacts of lignocellulose-derived microbial inhibitors on Clostridium beijerinckii during fermentation of miscanthus giganteus to butanol. J Ind Microbiol Biotechnol 41:1505–1516

Zheng H, Wang X, Yomano LP, Shangmugan KT, Ingram LO (2012) Increase in furfural tolerance in ethanologenic Escherichia coli LY180 by plasmid-based expression of thyA. Appl Environ Microbiol 78:4346–4352

Acknowledgments

Salaries and research support were provided in part by State funds appropriated to the Ohio State University, Ohio Agricultural Research and Development Center (OARDC), and the Hatch grant (project no. OHO01333). This research was also supported in part by grants to T.C.E. from the US Department of Transportation (grant DTOS59-07-G-00052) and the Northeast Sun Grant Initiative award/agreement no. 52110-9615.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Ujor, V., Okonkwo, C. & Ezeji, T.C. Unorthodox methods for enhancing solvent production in solventogenic Clostridium species. Appl Microbiol Biotechnol 100, 1089–1099 (2016). https://doi.org/10.1007/s00253-015-7166-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-7166-0