Abstract

Antimicrobial peptides (AMPs) are peptides exhibiting broad-spectrum antimicrobial activities and considered as potential therapeutic agents. LsGRP1C, a novel AMP derived from defense-related LsGRP1 protein of Lilium, was proven to inhibit kinds of bacteria and fungi via alteration of microbial membrane permeability and induction of fungal programmed cell death-like phenomena by in vitro assays using synthetic LsGRP1C. In this study, the prokaryotic production of LsGRP1C recombinant protein containing an N-terminal fusion partner of the yeast small ubiquitin-like modifier (SUMO) was achieved by using optimized Escherichia coli host and purification buffer system, which lead to a high yield of soluble SUMO-LsGRP1C fusion protein. In vitro assay revealed that E. coli-expressed SUMO-LsGRP1C exhibited even better antifungal activity as compared to synthetic LsGRP1C. Meanwhile, the ability of SUMO-LsGRP1C in conducting fungal membrane permeabilization and programmed cell death was verified by SYTOX Green staining and 4′,6-diamidino-2-phenylindole staining/terminal deoxynucleotidyl transferase dUTP nick-end labeling assays, respectively, indicating that E. coli-expressed SUMO-LsGRP1C shares identical modes of action with synthetic LsGRP1C. Herein, this E. coli expression system enables the effective and convenient production of antimicrobial LsGRP1C in a form of SUMO-fused recombinant protein.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Antimicrobial peptides (AMPs) are endogenous antibiotics acting as a primary defense barrier in living organisms to prevent the invasion of pathogenic microbes, belonging to the innate immunity system (Auvynet and Rosenstein 2009; Pelegrini et al. 2011). Because the development of antimicrobial resistance occurs frequently, natural AMPs with broad-spectrum activity and diverse modes of action are considered as a new and innovative alternatives to chemical antibiotics, having a promising future in drug development and agricultural application (Brandenburg et al. 2012; Montesinos 2007; Stotz et al. 2009). LsGRP1C, a novel antimicrobial peptide derived from the C-terminal region of defense-related LsGRP1 of Lilium, is naturally present in the extracellular space and the cell wall of leaf tissues, which exhibits in vitro inhibitory activity on types of fungal and bacterial species via the action modes of destroying microbial membrane and inducing fungal programmed cell death as applied in the form of synthetic peptide (Lin et al. 2014; Lin and Chen 2014). As LsGRP1C shares sequence homology with the C-terminal region of other plant glycine-rich proteins (GRPs) but not the characterized AMPs, a unique and un-understood role of LsGRP1 is implied, which may involve the plant innate immunity.

Successful expression and purification of biologically active protein products would greatly facilitate their functional study, structure analysis, and practical usage. Nowadays, prokaryotic systems (Escherichia coli and Bacillus subtilis), eukaryotic systems (yeast, insect cells, and mammalian cells) or in vitro system are available to express recombinant proteins, and E. coli system is most commonly used because of quick and easy molecular manipulation, and generally a low-cost of the culture materials (Khow and Suntrarachun 2012; Rosano and Ceccarelli 2014). In general, AMPs can be overproduced in E. coli in an inactive form of misfolded inclusion body by using solubility-decreasing fusion partners; however, to recover biologically active AMPs by solubilizing the inclusion bodies with chaotropic agents such as urea and guanidinium hydrochloride, and then refolding into the native conformations is a time-consuming and expensive task (Baneyx and Mujacic 2004; Yadav et al. 2016). The recent development of E. coli strains, expression vectors and fusion tags enormously help to reduce the limitations including codon bias, mRNA instability, toxicity, inclusion body formation, protein inactivity and lack of post-translational modification (Chou 2007; Dumon-Seignovert et al. 2004; Li 2009; Khow and Suntrarachun 2012). As known, a toxic-tolerant E. coli strain and a controller, which is capable of minimizing the background expression of AMP product, greatly improve the success rate and efficacy of AMP production (Dumon-Seignovert et al. 2004; Pan and Malcolm 2000; Studier 1991). Besides, a novel fusion partner, small ubiquitin-like modifier (SUMO), is proven capable of improving the folding and solubility of target proteins through the hydrophobic core and hydrophilic surface (Li 2009; Yadav et al. 2016). Several successful cases of AMP production in optimized E. coli strains suggest that the cooperation of SUMO fusion partner and a suitable E. coli strain meets the requirements of reducing lethal effect and enhancing solubility of biologically active AMP products (Chen et al. 2015; Gao et al. 2010; Li 2009; Tileva et al. 2016).

In this study, the LsGRP1C recombinant protein containing a solubility-increasing fusion partner SUMO was expressed in E. coli strains including commonly used E. coli BL21(DE3), toxic-tolerance E. coli C41(DE3), and E. coli C43(DE3) (Dumon-Seignovert et al. 2004) in the presence or absence of product background-reducing plasmid pLysS (Pan and Malcolm 2000; Studier 1991). Then the effect of SUMO fusion partner on achieving soluble LsGRP1C recombinant protein production was verified by examining the yield of products purified using the buffer system for recovering native protein or misfolded insoluble inclusion body. Finally, the antimicrobial activity and action modes of LsGRP1C recombinant protein were compared with the synthetic LsGRP1C peptide. The production system of antimicrobial LsGRP1C recombinant protein was therefore established and accordingly accelerated the functional study, structure analysis, and practical usage of LsGRP1C and other related plant GRPs.

Materials and methods

Fungal species

Botrytis elliptica B061 (BCRC FU 30078) was cultured on V8 medium (20% V8 vegetable juice [Campbell Soup Company, Camden, New Jersey, USA], 0.3% CaCO3 and 1.5% agar) at 20 °C under near UV for 5–7 days and Alternaria brassicicola Ac1 (BCRC FU 30074) was cultured on potato dextrose agar (Difco Laboratories Inc., Detroit, Michigan, USA) at 25 °C for 7–10 days (Lin and Chen 2014). The conidia of B. elliptica and A. brassicicola were suspended in sterile water and adjusted to a final concentration of 2 × 105 conidia/mL.

Protein expression vector construction and transformation

LsGRP1C coding region was amplified from a plasmid containing LsGRP1 open reading frame sequences using primer K02 (5′-ATGCGCTGCTACAACGGTTGC-3′) and primer p170 (5′-CTATGGGTGTCCATAAGCAGGCTC-3′). The LsGRP1C amplicon was ligated into pET SUMO vector (Champion™ pET SUMO Protein Expression System, Invitrogen Corp., Carlsbad, California, USA) via TA-cloning method to generate pET SUMO-LsGRP1C recombinant vector capable of expressing LsGRP1C recombinant protein with an N-terminal portion consisting of a 6× histidine tag and a yeast SUMO protein SMT3, named as SUMO-LsGRP1C. The pET SUMO fragment added with a stop codon (TAG) at the end of SMT3-coding sequence was amplified from pET SUMO vector using a back-to-back primer pair of FW01 (5′-TAGGACAAGCTTAGGTATTTATTCGGCGC-3′) and FW02 (5′-ACCACCAAT CTGTTCTCTGTGAGC-3′). The amplicon was phosphorylated using T4 polynucleotide kinase (New England Biolabs Ltd., Hitchin, UK) and self-ligated to generate pET SUMO-CK recombinant vector capable of expressing SMT3 protein with an N-terminal 6× histidine tag, named as SUMO-CK protein.

Protein expression and purification

Vector pET SUMO-LsGRP1C was introduced into E. coli strains of BL21(DE3), C41(DE3), C43(DE3), C41(DE3)pLysS, and C43(DE3)pLysS separately by using the heat shock method. E. coli BL21(DE3) and the other four strains were purchased from Invitrogen Corp. and Lucigen Corp. (Middleton, Wisconsin, USA), respectively. The transformed E. coli was inoculated into 3 mL LB broth (1% tryptone, 0.5% yeast extract, 0.5% NaCl) with 50 mg/L kanamycin, cultured at 37 °C, 175 rpm for 12 h. Then the bacterial culture was subcultured to 300 mL LB broth with 50 mg/L kanamycin, incubated at 37 °C, 175 rpm until the OD600 reached 0.4–0.6, then added with 1 mM isopropyl β-D-1-thiogalactopyranoside (IPTG), and cultured at 37 °C, 175 rpm for another 4–6 h. The E. coli cells were collected by centrifugation at 3000×g for 10 min. For E. coli C41(DE3)pLysS and E. coli C43(DE3)pLysS, the culture medium was added with 34 mg/L chloramphenicol besides of 50 mg/L kanamycin.

To purify recombinant protein by using native purification buffer system, the E. coli cells were resuspended in native binding buffer (20 mM sodium phosphate, 0.5 M NaCl, 30 mM imidazole, pH 7.4) containing 1 mg/mL lysozyme (Sigma-Aldrich, St. Louis, Missouri, USA), incubated at 25 °C for 30 min, then sonicated at medium power 12 times with 10-s sonication and 20-s rest on ice using Sonicator S-4000 (Misonix Inc., Farmingdale, New York, USA). The supernatant was recovered by centrifugation at 13000×g for 10 min and incubated with Ni Sepharose 6 Fast Flow slurry (GE Healthcare, Piscataway, New Jersey, USA) at a rotational speed of 20 rpm, 25 °C for 1 h. The His-tagged protein binding on Ni Sepharose 6 Fast Flow slurry was recovered in polypropylene column (Qiagen, Hilden, Germany), washed with native binding buffer of fourfold volume of the slurry two times, and then eluted with native elution buffer (20 mM sodium phosphate, 0.5 M NaCl, 500 mM imidazole, pH 7.4). Denaturing purification buffer system including denaturing binding buffer (20 mM sodium phosphate, 0.5 M NaCl, 8 M urea, 30 mM imidazole, pH 7.4) and denaturing elution buffer (20 mM sodium phosphate, 0.5 M NaCl, 8 M urea, 500 mM imidazole, pH 7.4) was used to purify recombinant protein expressed in the form of misfolded insoluble inclusion body. The purified proteins were desalted by dialysis in sterile deionized water and the concentrations were determined by Bradford method using Bio-Rad Protein Assay Dye Reagent Concentrate (Biorad Laboratories, Inc., California, USA) and bovine serum albumin as a standard. The control protein SUMO-CK was expressed in the E. coli BL21(DE3) strain which was transformed with pET SUMO-CK, and then purified by using native purification buffer system as described above.

Sodium dodecyl sulfate-polyacrylamide gel electrophoresis and western blot analysis

E. coli cells or protein solutions were treated with 1× reducing sample buffers (3% SDS, 1.5% mercaptoethanol, 7.5% glycerol, 0.0125% Coomassie blue G-250, 37.5 mM Tris/HCl, pH 7.0) at 42 °C for 20–30 min. The supernatant of treated E. coli cells was collected as crude cell lysate. The crude cell lysate and other treated protein solutions were subjected to tricine-sodium dodecyl sulfate-polyacrylamide gel electrophoresis (Tricine-SDS-PAGE) (Schägger 2006) using a 4% stacking and 10% resolving gel and then transferred to 0.45 μm polyvinylidene fluoride membrane (PVDF membrane, Merck Millipore, Billerica, Massachusetts, USA) using Towbin transfer buffer (25 mM Tris, pH 8.3, 192 mM glycine, 20% methanol) at a constant output current of 400 mA for 120 min. The PVDF membrane with the transferred proteins was washed with distilled water for 5 min, blotted with 5% skim milk in phosphate-buffered saline (PBS) (137 mM NaCl, 2.7 mM KCl, 10 mM Na2HPO4, 2 mM KH2PO4, pH 7.4) for 1 h, hybridized with 6× His tag antibody in PBS containing 5% skim milk for 1 h, washed with PBST (0.05% Tween-20 in PBS) for 10 min, three times, hybridized with horseradish peroxidase-conjugated anti-Rabbit IgG in 5% skim milk-containing PBS for 1 h, and then washed with PBST for 10 min, three times. The signals of 6× His tag antibody-labeled proteins were generated using Immobilon Western HRP Substrate (Merck Millipore) and analyzed using the GeneGnome5 Chemiluminescent Western Imaging System (Syngene, Cambridge, England, UK). All antibodies were purchased from GeneTex Inc. (Irvine, California, USA).

Liquid chromatography-electrospray ionization-tandem mass spectrometry

Proteins were separated in a 10% separating gel by using Tricine-SDS-PAGE, treated with fixation solution (45% methyl alcohol and 10% acetic acid) for 30 min, and visualized by staining with Coomassie blue reagent (0.1% Coomassie Brilliant Blue R-250, 45% methyl alcohol, and 10% acetic acid) for 30 min. Protein bands were separately recovered from the gel, digested with trypsin, and assayed using liquid chromatography-electrospray ionization-tandem mass spectrometry (LC ESI-MS/MS) (Q Exactive; Thermo Fisher Scientific Inc., Hampton, New Hampshire, USA). The MS/MS data were analyzed to identify the proteins using the MASCOT search engine (Matrix Science, London).

Antimicrobial assay

The antimicrobial activity of SUMO-LsGRP1C was determined by measuring the inhibition rates of fungal spore germination. Fungal spore suspensions of 1 × 105 spores/mL were treated with SUMO-LsGRP1C at the culture temperature of treated fungal species for 16–20 h, and then spore germination was examined under a microscope. The germ tube greater than two times of the spore length was considered germinated. SUMO-CK protein and deionized water were used to replace SUMO-LsGRP1C as control treatments. Inhibition rate of fungal spore germination = [(Number of spores germinating in deionized water treatment − Number of spores germinating in protein treatment) ∕ Number of spores germinating in deionized water treatment] × 100%. All assays were performed in triplicate. Based on the results, the concentrations of proteins for 50% growth inhibition (IC50) of assayed fungi were determined.

SYTOX Green staining

Hyphae of B. elliptica B061 were treated with 4.5 or 9.0 μM SUMO-LsGRP1C at 20 °C for 2 h. Then the fungal cells were stained with 1 μg/mL SYTOX Green in the dark for 10 min before observation under the Leica DMIL florescent microscope equipped with a Chroma 41012 filter set (BP 460–500 nm, DM 505 nm, LP 510 nm). Sterile deionized water, 1% Triton X-100 and SUMO-CK (4.5 or 9.0 μM) were used instead of SUMO-LsGRP1C as negative, positive, and fusion partner controls, respectively.

Programmed cell death assay

Fungal nuclear DNA fragmentation was detected using terminal deoxynucleotidyl transferase-mediated dUTP-biotin nick-end labeling assay (TUNEL) with in situ Cell Death Detection Kit, Fluorescein (Roche, Mannheim, Germany). Hyphae of B. elliptica B061 was treated with SUMO-LsGRP1C or synthetic LsGRP1C (4.5 and 9.0 μM) at 20 °C for 24 h. The treated-fungal hyphae were fixed using 4% formaldehyde in PBS for 12 h, washed with PBS for 10 min, three times, digested with 10 mg/mL lysing enzymes from Trichoderma harzianum (Sigma-Aldrich Co., St. Louis, Missouri, USA) in PBS for 1 h, washed with PBS for 10 min, three times, soaked in permeabilization solution (0.1% Triton X-100 and 0.1% sodium citrate) on ice for 2 min, washed with PBS for 10 min, three times, and then soaked in 50 μl TUNEL solution. After incubation in the dark at 37 °C for 1 h, the fungal hyphae were treated with 1 μg/mL 4′,6′-diamidino-2-phenylindole (DAPI) in the dark for 10 min, and washed with PBS for 10 min, three times. The fungal hyphae were observed under a Leica DMR fluorescence microscope equipped with a Chroma Endow GFP filter set (a 450- to 490-nm band-pass excitation filter, a 495-nm dichroic mirror, and a 500- to 550-nm band-pass emission filter) for TUNEL-labeled signal and a Semrock DAPI-5060C filter set (a 352- to 402-nm band-pass excitation filter, a 409-nm dichroic mirror, and a 452- to 502-nm band-pass emission filter) for DAPI-stained signal. Sterile deionized water and SUMO-CK were used as negative and fusion partner controls, respectively.

Results

Expression of recombinant LsGRP1C protein in different E. coli strains using pET SUMO vector system

The vector for recombinant LsGRP1C protein expression was constructed by cloning the coding sequence of LsGRP1C (101th–138th amino acids of LsGRP1, GenBank accession number AAL61539.1) into the TA-cloning site of pET SUMO vector, and confirmed by sequencing (Fig. 1a). Herein, pET SUMO-LsGRP1C recombinant vector with a cassette presumably encoding SUMO-LsGRP1C recombinant protein with an N-terminal portion consisting of a 6× histidine tag (HisG epitope) and a yeast SMT3 protein (SUMO) under the control of a bacteriophage T7 promoter and a T7 terminator was obtained.

Expression of LsGRP1C recombinant protein in different E. coli strains. a Schematic of SUMO-LsGRP1C expression vector. The coding sequence of LsGRP1C was cloned into pET SUMO vector. T7, T7 promoter; lacO, lac operator; RBS, ribosome binding site; ATG, start codon; HisG epitope, 6× His tag coding sequence; SUMO, coding sequence of small ubiquitin-like modifier (SUMO), Kanamycin, coding sequence of kanamycin resistance gene; pBR322 ori, replication origin; rop, ROP ORF; lacI, lacI ORF. b SUMO-LsGRP1C was separately expressed in five E. coli strains including BL21(DE3), C41(DE3), C43(DE3), C41(DE3)pLysS, and C43(DE3)pLysS. The total lysates of these bacterial cells were individually collected at 4 h post induction with 1 mM IPTG and analyzed by western blotting with His tag antibody. The positions of 15-, 20-, 25-, and 35-kDa marker proteins (SMOBiO PM2700) are indicated

To optimize the E. coli strain for recombinant LsGRP1C protein expression, pET SUMO-LsGRP1C recombinant vector was transformed to five E. coli strains including BL21(DE3), C41(DE3), C43(DE3), C41(DE3)pLysS, and C43(DE3)pLysS. Then the cells of transformed E. coli strains were separately collected at 4 h post induction of 1 mM IPTG, and SUMO-LsGRP1C within bacterial cells were detected by western blotting with His tag antibody (Fig. 1b). Among five assayed strains, His tag antibody-labeled signals of 18, 23, and 28 kDa were present in the crude cell lysates of IPTG-induced E. coli BL21(DE3), E. coli C41(DE3), and E. coli C43(DE3) and even in the crude cell lysate of uninduced E. coli BL21(DE3). In contrast, no His tag antibody-labeled signal was detected in the crude cell lysates of E. coli C41(DE3)pLysS and C43(DE3)pLysS transformants under IPTG-induced or uninduced conditions. Besides, the planktonic cell densities of E. coli BL21(DE3), E. coli C41(DE3), and E. coli C43(DE3) transformants were higher than those of E. coli C41(DE3)pLysS and E. coli C43(DE3)pLysS transformants, and the population differences were increased post IPTG induction (data not shown), suggesting that E. coli C41(DE3)pLysS and E. coli C43(DE3)pLysS were not the suitable hosts to express SUMO-LsGRP1C. Because the expected size of SUMO-LsGRP1C recombinant protein is about 17.9 kDa, coinciding with the 18-kDa signal, E. coli BL21(DE3), and E. coli C41(DE3) conducting higher level of 18-kDa signal were chosen for further evaluation of buffer systems suitable for SUMO-LsGRP1C purification.

Purification of recombinant LsGRP1C protein under native or denaturing conditions

Native and denaturing purification buffer systems were used to purify SUMO-LsGRP1C expressed in E. coli BL21(DE3) or E. coli C41(DE3), and the product yields were shown in Table 1. Among four combinations, purification of SUMO-LsGRP1C expressed in E. coli C41(DE3) using native purification buffer system resulted in a highest target protein yield of 12.011 mg/L; on the contrary, the E. coli C41(DE3)-expressed SUMO-LsGRP1C was seldom recovered using denaturing purification buffer system (0.524 mg/L). Besides, the yields of E. coli BL21(DE3)-expressed SUMO-LsGRP1C purified by using native and denaturing purification buffer systems were 5.852 and 3.897 mg/L, respectively; both were much lower than the yield from the combination of E. coli C41(DE3) expression host and native purification buffer system.

To verify the product size, the total cell lysates, flow-through fractions, washing fractions and elution fractions were separately collected during the processes of SUMO-LsGRP1C purification from E. coli BL21(DE3) and E. coli C41(DE3) harboring pET SUMO-LsGRP1C using native purification buffer system, and assayed by SDS-PAGE and western blotting with His tag antibody (Fig. 2). Three His tag antibody-labeled proteins of 18, 23, and 28 kDa were found in the total cell lysate and elution fraction from E. coli C41(DE3) harboring pET SUMO-LsGRP1C while only two His tag antibody-labeled proteins of 18 and 23 kDa presented in the total cell lysate and elution fraction from E. coli BL21(DE3) harboring pET SUMO-LsGRP1C. The 18-, 23-, and 28-kDa proteins purified from E. coli C41(DE3) using native purification buffer system were then separately assayed using LC ESI-MS/MS and Mascot search. The results indicated that the 18-, 23-, and 28-kDa proteins were identified as SUMO-LsGRP1C with significant protein scores of 4290, 3211, and 8010 in 90, 94, and 99% sequence coverage, respectively (Fig. 3). None of them were considered E. coli proteins because of the low Mascot scores (below 130). Besides, the SUMO-CK protein with an expected size of 13.42 kDa, was expressed in E. coli BL21(DE3) and purified by using native purification buffer system (Fig. S1). Thus, the optimized strategy for SUMO-LsGRP1C production is to be expressed in E. coli C41(DE3) host and then recovered by using native purification buffer system, and the product includes SUMO-LsGRP1C of 18, 23, and 28 kDa.

SUMO-LsGRP1C expressed in E. coli BL21(DE3) or E. coli C41(DE3) purified via Ni2+ column and native purification buffer system. The total cell lysate, flow-through fraction, washing fraction, and elution fraction were collected from different steps and assayed by SDS-PAGE (upper panel) and western blotting with His tag antibody (lower panel). The positions of 15-, 20-, 25-, and 35-kDa marker proteins (SMOBiO PM2700) are indicated

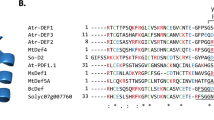

Identification of E. coli-expressed SUMO-LsGRP1C by LC ESI-MS/MS. SUMO-LsGRP1C of 18, 23, and 28 kDa expressed in E. coli C41(DE3) and purified via Ni2+ column and native purification buffer system had 90, 96, and 99% sequence coverage (underlined region) in the amino acid sequence of SUMO-LsGRP1C. The LsGRP1C region in the amino acid sequence of SUMO-LsGRP1C is italicized

E. coli-expressed LsGRP1C fusion exhibited better antifungal activity as compared with synthetic LsGRP1C

In vitro antifungal assay was performed by comparing the inhibition effects of SUMO-LsGRP1C and synthetic LsGRP1C on spore germination. The result revealed that the IC50 of SUMO-LsGRP1C on spore germination of A. brassicicola and B. elliptica were 102.12 and 98.70 μg/mL, i. e., 5.72 and 5.56 μM, respectively (Table 2). Meanwhile, the IC50 of synthetic LsGRP1C on spore germination of A. brassicicola and B. elliptica were 54.80 and 80.24 μg/mL, i. e., 12.64 and 18.49 μM, respectively. Besides, SUMO-CK, the fusion partner control of SUMO-LsGRP1C did not affect the spore germination of two assayed fungal species in all treated concentrations. According to the IC50 in molar concentration, E. coli-expressed SUMO-LsGRP1C which contains a non-antifungal N-terminal fusion partner exhibits better antifungal activity at least twofold higher than synthetic LsGRP1C.

E. coli-expressed LsGRP1C fusion and synthetic LsGRP1C have identical action modes

As synthetic LsGRP1C is capable destroying microbial membrane integrity and inducing programmed cell death-like phenomena of chromatin condensation and reactive oxygen species accumulation (Lin and Chen 2014), the effects of E. coli-expressed SUMO-LsGRP1C on fungal membrane and cell destiny were investigated. To verify the influence of SUMO-LsGRP1C on microbial membranes, SYTOX Green, a green-fluorescent nucleic acid stain impermeable to normal cells but penetrating damaged cell membrane and staining the nucleic acid was used. The result showed that the pretreatment of 4.5 and 9.0 μM SUMO-LsGRP1C caused severe membrane permeabilization of B. elliptica whereas the pretreatment of SUMO-CK protein in the same molar concentrations caused sparse fungal membrane damage (Fig. 4). Meanwhile, the pretreatments of sterile deionized water (H2O), a negative control, did not result in fungal membrane permeabilization at all; the pretreatments of 1% Triton X-100, a detergent used as a positive control to destroy membrane integrity, led to numerous SYTOX Green-labeled nuclei in B. elliptica cells. Besides, the brightness of SYTOX Green-labeled nuclei triggered by SUMO-LsGRP1C was superior to that caused by Triton X-100, indicating the nuclear DNAs of SUMO-LsGRP1C-treated fungal cells possibly became more condensed. Thus, the ability of SUMO-LsGRP1C to alter microbial membrane integrity would come from the LsGRP1C region mainly without excluding the possibility of partly involving the action of N-terminal SUMO fusion partner.

Fungal membrane permeabilization caused by SUMO-LsGRP1C. The hyphae of B. elliptica were treated with SUMO-LsGRP1C for 2 h, and then assayed by SYTOX Green staining. Sterile deionized water (H2O), 1% Triton X-100 and SUMO-CK protein were used instead of SUMO-LsGRP1C as negative, positive, and fusion partner control, respectively. Bar = 100 μm

To demonstrate the effect of SUMO-LsGRP1C on inducing fungal programmed cell death, two typical phenomena of programmed cell death, i. e., nuclear chromatin condensation and chromosome DNA fragmentation, were detected post SUMO-LsGRP1C treatment by using DAPI staining and TUNEL assay, respectively. The highly condensed chromatin with bright blue fluorescence and nuclear DNA fragmentation with green fluorescence presented in B. elliptica cells treated with E. coli-expressed SUMO-LsGRP1C and synthetic LsGRP1C but not those treated with SUMO-CK or sterile deionized water (H2O) (Fig. 5), revealing the induction ability of SUMO-LsGRP1C and synthetic LsGRP1C in fungal programmed cell death. Therefore, SUMO-LsGRP1C is presumably endowed with the ability to induce fungal programmed cell death through the LsGRP1C region.

Fungal programmed cell death induced by SUMO-LsGRP1C and synthetic LsGRP1C. The hyphae of B. elliptica were treated with E. coli-expressed SUMO-LsGRP1C or synthetic LsGRP1C for 20 h. Chromatin condensation and nuclear DNA fragmentation of treated hyphae were assayed by DAPI staining and TUNEL assay. Sterile deionized water (H2O) and SUMO-CK protein were used instead of SUMO-LsGRP1C as negative and fusion partner control, respectively. Bar = 100 μm

Discussion

The poor yield and inactive inclusion body formation together with host cell death are the major problems of AMP production using E.coli system (Baneyx and Mujacic 2004; Chou 2007; Dumon-Seignovert et al. 2004). In this study, the production system of antimicrobial LsGRP1C in the form of SUMO-fused recombinant protein was established by optimizing the E. coil expression host and purification procedure. Although SUMO-LsGRP1C and synthetic LsGRP1C exhibited identical action modes on inhibiting fungi via inducing membrane permeabilization and programmed cell death, the stronger antifungal activity of SUMO-LsGRP1C suggested that the presence of SUMO fusion partner may enhance the lethal effect of LsGRP1C on fungal species. An interesting finding was that the sole treatment of SUMO-CK, the fusion partner control of SUMO-LsGRP1C, did not affect the spore germination or cause fungal programmed cell death, but slightly damaged the plasma membrane of B. elliptica. Since SUMO protein is known to improve the solubility of aggregation-prone target proteins through the peripheral hydrophilic and central hydrophobic core structure (Ding et al. 2005; Yadav et al. 2016), the membrane permeabilization ability of SUMO-CK is presumably resulted from the detergent-like solubilizing function of SUMO protein. On the other hand, as only very few studies by far referred that the recombinant proteins exhibit desired bioactivity before its SUMO fusion partner being removed (Ai et al. 2011; Chen et al. 2014; Shen et al. 2011), some further analysis is required to clarify whether the slight membrane damage caused by SUMO fusion partner is the key factor leading to more severe fungal cell death conducted by the antimicrobial LsGRP1C region of SUMO-LsGRP1C. After all, our system enables the high-yield, low-cost, and activity-enhanced production of antimicrobial LsGRP1C in the form of SUMO-fused recombinant protein, implying an alternative strategy for producing functional AMPs without removing SUMO fusion partner.

The pET SUMO plasmid used to express SUMO-LsGRP1C belongs to pET vector serials which uses the T7 promoter-driven system and allows high expression of target gene under the control of the T7 promoter in the presence of T7 RNA polymerase (T7RNAP); thereby the genetically engineered E. coli strains such as BL21(DE3) able to provide T7RNAP are the main hosts of pET vector serials (Studier and Moffatt 1986). Although numerous proteins have been successfully expressed to very high levels in E. coli-T7RNAP system, the difficulty of expressing toxic gene products is the biggest problem, owing to the background expression of T7RNAP (Studier 1991). Since using toxic-tolerance E. coli strains and/or co-expressing T7 lysozyme (T7Lys), a natural inhibitor to reduce T7RNAP production have been proven to improve the expression of toxic products including antimicrobial proteins, membrane proteins, globular proteins, and thermostable proteins in E. coli-T7RNAP system (Dumon-Seignovert et al. 2004; Miroux and Walker 1996; Sørensen et al. 2003; Studier 1991), the effect of applying toxic-tolerant E. coli C41(DE3) and E. coli C43(DE3), together with T7Lys-expression vector pLysS on SUMO-LsGRP1C production was evaluated. Although the highest SUMO-LsGRP1C expression level presented in E. coli BL21(DE3) (Fig. 1), the highest yield of soluble SUMO-LsGRP1C was recovered from E. coli C41(DE3) using native purification buffer system (Table 1). This result implied that most E. coli C41(DE3)-expressed SUMO-LsGRP1C was folded in native form whereas part of E. coli BL21(DE3)-expressed SUMO-LsGRP1C might form misfolded inclusion bodies which were unable to be purified using native purification buffer system and had to be recovered with the assistance of denaturing purification buffer system. Both E. coli C41(DE3) and E. coli C43(DE3) are natural mutants derived from E. coli BL21(DE3) with lower T7RNAP expression level because of the mutations in T7RNAP-groven lacUV5 promoter occurring in the DE3 region, and presumably rescues the bacterial cells from the toxicity caused by uncoupling the transcription and translation (Kwon et al. 2015; Schlegel et al. 2015; Wagner et al. 2008). As compared to that in E. coli BL21(DE3), SUMO-LsGRP1C had minimized basal expression in E. coli C41(DE3) that was very likely resulted from the weakened T7RNAP activity and accordingly conducted more soluble SUMO-LsGRP1C accumulation post IPTG induction. Because the mutations in lacUV5 promoter of E. coli C41(DE3) and E. coli C43(DE3) are identical, the different expression efficacy of SUMO-LsGRP1C in E. coli C41(DE3) and E. coli C43(DE3) may come from the strain-specific mutations which have not be functionally clarified (Kwon et al. 2015). On the other hand, the presence of T7Lys-encoding pLysS vector greatly reduced the expression of SUMO-LsGRP1C in both E. coli C41(DE3) and E. coli C43(DE3). T7Lys is a bacteriophage-infection-related bifunctional protein capable of cutting a bond in E. coli cell wall (Inouye et al. 1973) and selectively inhibiting T7RNAP by binding to it (Moffatt and Studier 1987); herein, expressing T7Lys may reduce E. coli fitness by affecting the cell wall integrity. Besides, the detergent-like SUMO fusion partner may also damage E. coli cells by affecting microbial membrane premeability. Accordingly, it is very possible that the E. coli with the weaken cell wall and plasma membrane triggered by T7Lys and SUMO fusion partner cannot overcome the stress from expressing antimicrobial LsGRP1C recombinant protein. This point of view is also supported by the lower planktonic cell density of E. coli C41(DE3)pLysS and E. coli C43(DE3)pLysS transformed with pET SUMO-LsGRP1C.

SUMO-LsGRP1C fusion proteins of 18, 23, and 28 kDa were obtained in this study, and none of them was found to be cross-linked to or covalently bond with E. coli proteins according to the LC ESI-MS/MS result, suggesting that they might generate from some protein modifications and/or crosslinking with itself. As the native LsGRP1 in Lilium presents three variants of 14, 16, and 23 kDa and the accumulation of 23-kDa LsGRP1 is highly recommended to be associated with the occurrence of induced disease resistance (Lin and Chen 2014), the C-terminal of LsGRP1 playing a key role of LsGRP1 variant formation and defense enhancement is implied.

The production system of bioactive LsGRP1C in the form of SUMO-fused recombinant protein was established in this study by optimizing the E. coil expression host and purification buffer system. The antimicrobial activity and action modes of this LsGRP1C recombinant protein not only highlight its application potential, but also suggest an effective and convenient strategy enable soluble AMP production functioning in a form without removing SUMO fusion partner. In addition, the features and functions of LsGRP1C recombinant protein implicate the biochemical and defensive traits of native LsGRP1 related to the induced disease resistance in Lilium.

Change history

22 November 2017

The published online version contains editing mistake in Table 2. See below for the corrected Table.

References

Ai H, Shen Y, Min C, Pang S, Zhang J, Zhang S, Zhao Z (2011) Molecular structure, expression and bioactivity characterization of TNF13B (BAFF) gene in mefugu, Takifugu obscurus. Fish Shellfish Immunol 30(6):1265–1274. https://doi.org/10.1016/j.fsi.2011.03.020

Auvynet C, Rosenstein Y (2009) Multifunctional host defense peptides: antimicrobial peptides, the small yet big players in innate and adaptive immunity. FEBS J 276(22):6497–6508. https://doi.org/10.1111/j.1742-4658.2009.07360.x

Baneyx F, Mujacic M (2004) Recombinant protein folding and misfolding in Escherichia coli. Nat Biotechnol 22(11):1399–1408. https://doi.org/10.1038/nbt1029

Brandenburg LO, Merres J, Albrecht LJ, Varoga D, Pufe T (2012) Antimicrobial peptides: multifunctional drugs for different applications. Polymers 4(1):539–560. https://doi.org/10.3390/polym4010539

Chen C, Liu M, Wu J, Yang X, Hu X, Pu J, Long G, Xie Y, Jiang H, Yuan Y, Liao F (2014) Microplate-based method to screen inhibitors of isozymes of cyclic nucleotide phosphodiesterase fused to SUMO. J Enzym Inhib Med Chem 29(6):836–839. https://doi.org/10.3109/14756366.2013.858145

Chen X, Shi J, Chen R, Wen Y, Shi Y, Zhu Z, Guo S, Li L (2015) Molecular chaperones (TrxA, SUMO, Intein, and GST) mediating expression, purification, and antimicrobial activity assays of plectasin in Escherichia coli. Biotechnol Appl Biochem 62(5):606–614. https://doi.org/10.1002/bab.1303/

Chou CP (2007) Engineering cell physiology to enhance recombinant protein production in Escherichia coli. Appl Microbiol Biotechnol 76(3):521–532. https://doi.org/10.1007/s00253-007-1039-0

Ding H, Xu Y, Chen Q, Dai H, Tang Y, Wu J, Shi Y (2005) Solution structure of human SUMO-3 C47S and its binding surface for Ubc9. Biochemistry 4(8):2790–2799. https://doi.org/10.1021/bi0477586

Dumon-Seignovert L, Cariot G, Vuillard L (2004) The toxicity of recombinant proteins in Escherichia coli: a comparison of overexpression in BL21(DE3), C41(DE3), and C43(DE3). Protein Expr Purif 37(1):203–206. https://doi.org/10.1016/j.pep.2004.04.025

Gao X, Chen W, Guo C, Qian C, Liu G, Ge F, Huang Y, Kitazato K, Wang Y, Xiong S (2010) Soluble cytoplasmic expression, rapid purification, and characterization of cyanovirin-N as a His-SUMO fusion. Appl Microbiol Biotechnol 85(4):1051–1060. https://doi.org/10.1007/s00253-009-2078-5

Inouye M, Arnheim N, Sternglanz R (1973) Bacteriophage T7 lysozyme is an N-acetylmuramyl-L-alanine amidase. J Biol Chem 248(20):7247–7252

Khow O, Suntrarachun S (2012) Strategies for production of active eukaryotic proteins in bacterial expression system. Asian Pac J Trop Biomed 2(2):159–162. https://doi.org/10.1016/S2221-1691(11)60213-X

Kwon SK, Kim SK, Lee DH, Kim JF (2015) Comparative genomics and experimental evolution of Escherichia coli BL21(DE3) strains reveal the landscape of toxicity escape from membrane protein overproduction. Sci Rep 5:16076. https://doi.org/10.1038/srep16076

Li Y (2009) Carrier proteins for fusion expression of antimicrobial peptides in Escherichia coli. Biotechnol Appl Biochem 54(1):1–9. https://doi.org/10.1042/BA20090087

Lin CH, Chang MW, Chen CY (2014) A potent antimicrobial peptide derived from the protein LsGRP1 of Lilium. Phytopathology 104(4):340–346. https://doi.org/10.1094/PHYTO-09-13-0252-R

Lin CH, Chen CY (2014) Characterization of the dual subcellular localization of Lilium LsGRP1, a plant class II glycine-rich protein. Phytopathology 104(10):1012–1020. https://doi.org/10.1094/PHYTO-01-14-0020-R

Miroux B, Walker JE (1996) Over-production of proteins in Escherichia coli: mutant hosts that allow synthesis of some membrane proteins and globular proteins at high levels. J Mol Biol 260(3):289–298. https://doi.org/10.1006/jmbi.1996.0399

Moffatt BA, Studier FW (1987) T7 lysozyme inhibits transcription by T7 RNA polymerase. Cell 49(2):221–227. https://doi.org/10.1016/0092-8674(87)90563-0

Montesinos E (2007) Antimicrobial peptides and plant disease control. FEMS Microbiol Lett 270(1):1–11. https://doi.org/10.1111/j.1574-6968.2007.00683.x

Pan SH, Malcolm BA (2000) Reduced background expression and improved plasmid stability with pET vectors in BL21(DE3). BioTechniques 29(6):1234–1238

Pelegrini BP, del Sarto RP, Silva ON, Franco OL, Grosside-Sa MF (2011) Antibacterial peptides from plants: what they are and how they probably work. Biochem Res Int 2011:250349. https://doi.org/10.1155/2011/250349

Rosano GL, Ceccarelli EA (2014) Recombinant protein expression in Escherichia coli: advances and challenges. Front Microbiol 5:172. https://doi.org/10.3389/fmicb.2014.00172

Schägger H (2006) Tricine-SDS-PAGE. Nat Protoc 1(1):16–22. https://doi.org/10.1038/nprot.2006.4

Schlegel S, Genevaux P, de Gier JW (2015) De-convoluting the genetic adaptations of E. coli C41(DE3) in real time reveals how alleviating protein production stress improves yields. Cell Rep 10:1758–1766. https://doi.org/10.1016/j.celrep.2015.02.029

Shen Y, Wang S, Ai H, Min C, Chen Y, Zhang S (2011) Molecular structure, bioinformatics analysis, expression and bioactivity of BAFF (TNF13B) in dog (Canis familiaris). Vet Immunol Immunopathol 142(1–2):133–139. https://doi.org/10.1016/j.vetimm.2011.04.014

Sørensen HP, Sperling-Petersen HU, Mortensen KK (2003) Production of recombinant thermostable proteins expressed in Escherichia coli: completion of protein synthesis is the bottleneck. J Chromatogr B 786(1–2):207–214. https://doi.org/10.1016/S1570-0232(02)00689-X

Stotz HU, Thomson JG, Wang Y (2009) Plant defensins: defense, development and application. Plant Signal Behav 4(11):1010–1012

Studier FW (1991) Use of bacteriophage T7 lysozyme to improve an inducible T7 expression system. J Mol Biol 219(1):37–44. https://doi.org/10.1016/0022-2836(91)90855-Z

Studier FW, Moffatt BA (1986) Use of bacteriophage T7 RNA polymerase to direct selective high-level expression of cloned genes. J Mol Biol 189(1):113–130. https://doi.org/10.1016/0022-2836(86)90385-2

Tileva M, Krachmarova E, Ivanov I, Maskos K, Nacheva G (2016) Production of aggregation prone human interferon gamma and its mutant in highly soluble and biologically active form by SUMO fusion technology. Protein Expr Purif 117:26–34. https://doi.org/10.1016/j.pep.2015.09.022

Wagner S, Klepsch MM, Schlegel S, Appel A, Draheim R, Tarry M, Högbom M, van Wijk KJ, Slotboom DJ, Persson JO, de Gier JW (2008) Tuning Escherichia coli for membrane protein overexpression. Proc Natl Acad Sci U S A 105(38):14371–14376. https://doi.org/10.1073/pnas.0804090105

Yadav DK, Yadav N, Yadav S, Haque S, Tuteja N (2016) An insight into fusion technology aiding efficient recombinant protein production for functional proteomics. Arch Biochem Biophys 612:57–77. https://doi.org/10.1016/j.abb.2016.10.012

Acknowledgments

This study was financially supported by the Council of Agriculture and the Ministry of Science and Technology, Taiwan, Republic of China.

Funding

This study was funded by the Council of Agriculture (grant number 100AS-9.2.2-BQ-B3) and the Ministry of Science and Technology (grant number MOST100-2321-B-002-034-MY3), Taiwan, Republic of China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

A correction to this article is available online at https://doi.org/10.1007/s00253-017-8630-9.

Electronic supplementary material

ESM 1

(PDF 387 kb)

Rights and permissions

About this article

Cite this article

Lin, CH., Pan, YC., Liu, FW. et al. Prokaryotic expression and action mechanism of antimicrobial LsGRP1C recombinant protein containing a fusion partner of small ubiquitin-like modifier. Appl Microbiol Biotechnol 101, 8129–8138 (2017). https://doi.org/10.1007/s00253-017-8530-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8530-z