Abstract

Levulinic acid was esterified with methanol, ethanol, and 1-butanol with the final goal to predict the maximum yield of these equilibrium-limited reactions as function of medium composition. In a first step, standard reaction data (standard Gibbs energy of reaction Δ R g 0) were determined from experimental formation properties. Unexpectedly, these Δ R g 0 values strongly deviated from data obtained with classical group contribution methods that are typically used if experimental standard data is not available. In a second step, reaction equilibrium concentrations obtained from esterification catalyzed by Novozym 435 at 323.15 K were measured, and the corresponding activity coefficients of the reacting agents were predicted with perturbed-chain statistical associating fluid theory (PC-SAFT). The so-obtained thermodynamic activities were used to determine Δ R g 0 at 323.15 K. These results could be used to cross-validate Δ R g 0 from experimental formation data. In a third step, reaction-equilibrium experiments showed that equilibrium position of the reactions under consideration depends strongly on the concentration of water and on the ratio of levulinic acid: alcohol in the initial reaction mixtures. The maximum yield of the esters was calculated using Δ R g 0 data from this work and activity coefficients of the reacting agents predicted with PC-SAFT for varying feed composition of the reaction mixtures. The use of the new Δ R g 0 data combined with PC-SAFT allowed good agreement to the measured yields, while predictions based on Δ R g 0 values obtained with group contribution methods showed high deviations to experimental yields.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The depletion of fossil resources and emerging environmental issues lead to massive efforts that are directed to identify attractive renewable energy and material resources. Within this context, biomass is recognized as resource for sustainable production of chemicals and fuels. (Alonso et al. 2010; Démolis et al. 2014; Weingarten et al. 2011; Zhang et al. 2012) Significant attention has therefore addressed renewable replacements for petroleum-based resources, because utilization of biomass represents a carbon-neutral and sustainable route for synthesis (Schwartz et al. 2014). Nevertheless, the practical conversion of biomass towards desired fuels and chemicals is still an enormous challenge for industry (Demma Carà et al. 2014; Kamm et al. 2000). Concepts are developed that integrate various production pathways in one process in order to overcome technical barriers and to become more competitive compared to classical fossil-based synthesis routes (Zhang 2008).

Various components obtained from biomass have been reported to have huge potential for serving as platform chemicals for chemical pathways and (bio-) transformations (Alonso et al. 2010; Kobayashi and Fukuoka 2013; Serrano-Ruiz et al. 2011). Levulinic acid (LA) belongs to this class of compounds. It has been reported as one of the most promising biomass-derived platform chemicals (Climent et al. 2014; Dautzenberg et al. 2011; Pileidis and Titirici 2016; Werpy and Petersen 2004; Wu et al. 2016). The bio-based synthesis of LA is discussed in literature extensively and will not be described here. In a published review from Pileidis and Titrici, synthesis of LA is discussed, including catalysis (homogeneous and heterogeneous catalysis) and the kind of starting material like for example furfural, 5-hydroxymethylfurfural, different sugars, lignocellulosic materials, and agricultural waste (Pileidis and Titirici 2016). LA contains a ketone group and a carboxylic acid group in its structure. These make LA to a very versatile building block for the synthesis of various chemicals, such as gamma-valerolactone, alkyl levulinates, 2-methyltetrahydrofuran, and acrylic acid (Bozell et al. 2000; Démolis et al. 2014; Isikgor and Becer 2015; Pileidis and Titirici 2016; Timokhin et al. 1999; Zhang et al. 2012).

Especially the alkyl levulinates have been recognized as very interesting LA derivatives due to their specific physicochemical properties and their range of applications (Leibig et al. 2011; Olson et al. 2001; Werpy and Petersen 2004; Zhang et al. 2012). The alkyl levulinates methyl-, ethyl-, and butyl levulinates are short-chain esters that are applicable in fields like flavorings and in fragrance industry (Bart et al. 1994; Lomba et al. 2013; Olson 2001). Besides, the esters of LA gained much interest as fuel additives. This is caused by the properties of the short-chain esters, such as non-toxicity, high lubricity, and flashpoint stability. (Christensen et al. 2011; Chung et al. 2015; Hayes 2009; Lomba et al. 2013) Further, these esters are discussed to be promising starting materials for various (bio-) chemical reactions. (Démolis et al. 2014; Olson 2001; Pileidis and Titirici 2016) Demolis et al. reviewed the synthesis and the application of alkyl esters (Démolis et al. 2014). In the literature, acid-catalyzed synthesis of esters starting from LA or furfuryl alcohol or carbohydrates in alcohols are suggested. Investigations showed that very different yields were obtained by using different reactants, and homogeneous and heterogeneous catalysis was studied and reviewed (Démolis et al. 2014; Pileidis and Titirici 2016).

In this work, the lipase-catalyzed esterification of LA in alcohol will be presented. Compared to chemical reaction routes, publications on enzyme-catalyzed synthesis are still scarce, although enzymatic synthesis provides several advantages in comparison to chemical esterification such as mild reaction conditions, lower energy requirement, and easier catalyst removal and reusability, cheapness, and good stability even in non-aqueous media (Lilly 1994; Petersson et al. 2005; Turner 1995). In this work, the enzyme Candida antarctica lipase B immobilized on acrylic resin (Novozym 435) was used. It was reported that this enzyme catalyzes the esterification of LA with ethanol (EtOH) or 1-butanol (1-BuOH).(Lee et al. 2010; Yadav and Borkar 2008) Lee et al. investigated the effect of several reaction conditions like enzyme amount, reaction time, temperature, and reactant ratio on the conversion of LA in solvent-free system (Lee et al. 2010). The dependence of conversion of enzyme amount suggests that not all of their data is equilibrium data. Besides conversion, Yadav et al. suggested a reaction mechanism and developed a kinetic model for the esterification of LA with 1-BuOH catalyzed by three different immobilized lipases in tetra-butyl methyl ether as solvent (Yadav and Borkar 2008). Although all these works let assume that a significant amount of work on kinetics of LA esterification exists in the literature, studies on thermochemistry and equilibrium thermodynamics of these reactions are still scarce. Bart et al. (Bart et al. 1994) have performed according experiments on esterification of LA with 1-BuOH catalyzed by sulphuric acid, and a kinetic model as well as equilibrium constants and reaction enthalpies were determined. However, these data neglect thermodynamic non-idealities due to deviations from ideal-mixture behavior by assuming activity coefficients of reacting agents to be one. Chung et al. used the kinetic model of Bart et al. in order to describe a reactive distillation system for the esterification of LA and 1-BuOH (Chung et al. 2015). This work is important and pioneering as it addresses purification concepts and unit operations for processes with LA esterification, which was accessed by thermodynamic modeling with NRTL (Chung et al. 2015).

In this work, the reaction equilibrium of the LA esterification with methanol, ethanol, and 1-butanol was investigated at 323.15 K. Novozym 435 was used as catalyst for the reactions. These reactions were studied under different reactant ratios and for different water concentrations in the initial reaction mixtures. In order to determine the thermodynamic equilibrium constant of the reactions, thermodynamic activities of the reacting agents were required. For this purpose, activity coefficients of the reacting agents were predicted by perturbed-chain statistical associating fluid theory (PC-SAFT) (Gross and Sadowski 2001; Gross and Sadowski 2002). In our previous work, PC-SAFT has been proved as successful model for the prediction of activity coefficients in multi-component reaction mixtures (Altuntepe et al. 2017a; Hoffmann et al. 2013; Riechert et al. 2015). In a final step, the obtained thermodynamic properties and equilibrium constants were used in order to predict conversions by iteratively solving the equations for reaction equilibrium.

Experiments and methods

Materials

Chemicals that have been used in this work are listed in Table S1. All chemicals were used as obtained without further purification. Lipase B from Candida antarctica was used as the immobilized form on acrylic resin (5 U mg−1, supplier information). The immobilized lipase, expressed in Aspergillus niger, was purchased from Sigma-Aldrich Chemie GmbH. In the following, the immobilized enzyme will be denoted as Novozym 435. Deionized water from the Millipore system (Merck KGaA) was used. All abbreviations and symbols are listed in Table 1.

Reaction equilibrium experiments and analysis

The reactions investigated in this work take place in the liquid phase, while the enzyme is present as heterogeneous catalyst. The reaction experiments were carried out in two types of set-ups. Equilibrium experiments were performed in double-jacket 10-mL glass vessels with a reaction medium of 5 mL and in 1.5-mL closable plastic vessels with a reaction medium of 1 mL volume. The reaction temperature in the 10-mL glass vessels was adjusted to 323.15 K and controlled by F 25 thermostat from Julabo (Seelbach, Germany) with an accuracy of ± 0.03 K. The temperature in the closable 1.5-mL plastic vessels was controlled in the ThermoMixer® comfort with a 1.5-mL thermoblock (Eppendorf, Hamburg, Germany). The glass vessels were stirred with a speed of 800 rpm, and the plastic vessels were mixed in the ThermoMixer® comfort (~ 1000 rpm). These stirring rates ensured homogeneous mixing and mass transfer to Novozym 435 without mechanical damage to immobilized enzymes and without affecting the obtained reaction equilibria.

The reaction mixtures were prepared gravimetrically using a XS205 DualRange balance from Mettler Toledo (Colubus, USA) with an accuracy of ± 10−4 g. Every initial reaction mixture was prepared twice, so that each experimental reaction equilibrium position was obtained by biological duplicates. First, defined mass of alcohol (MeOH, EtOH, or 1-BuOH) was filled in the vessels and then defined weights of LA and water were added. Different amounts of water were added to the initial reaction mixtures because it was one aim of this work to study the effect of water on reaction equilibrium and on initial enzyme activity. Besides LA, the reacting alcohol, water and enzyme, and additional chemicals have not been added to the mixtures, meaning that no additional solvent was present and the reacting alcohol served simultaneously as solvent. The glass vessels were sealed with caps containing a septum for sampling or substrate addition; 5-mL syringes were used for these purposes. The plastic vessels were sealed and have been opened only when the minimum time for equilibration of the reactions was reached. These times were determined as follows. Samples were taken after defined times of reactions (data not shown here) from the 10-mL glass vessels to study the time required for equilibration. This allowed sampling from 1.5-mL plastic vessels at reaction times where reaction equilibrium condition was ensured. The amount of Novozym 435 was adjusted in all vessels gravimetrically by setting the enzyme activity to about 125 U/g solution. This was a compromise between a minimum amount of enzyme required for reasonable reaction rates on the one hand and mechanical damage on the other hand due to the presence of more immobilized enzyme that lead to highly heterogeneous reaction mixtures where mechanical damage of Novozym 435 was observed. The similarity of results for the two types of vessels has been ensured by comparing equilibrium results for two equal set-ups in the two vessel types (10 and 1.5 mL). It can be stated here that parameters of the reaction set up like type of vessel, stirring speed, and amount of enzyme have been studied in detail and were found to not influence the thermodynamic reaction equilibrium. Thus, the conditions under study apparently did not cause enzyme inactivation or mass transport limitations.

Mole fractions of the reacting agents at equilibrium were analyzed using two different analytical methods. The mole fraction of water was determined using Karl-Fisher titration with a Metrohm 915 KF Ti-Touch (Metrohm, Herisau, Switzerland). Each sample was measured in triplicate and the results were averaged. To quantify alkyl levulinates, a gas chromatography system was used that consisted of an Agilent Technology 7890A GC equipped with an Agilent INNOWax column (30 m, 0.32 mm, 0.5 mm) and a flame ionization detector. All measurements were performed in triplicate, while calibration was performed separately for each ester system.

Theory

Based on the equilibrium mole fractions, the standard Gibbs energy of reaction Δ R g 0 can be expressed via the thermodynamic equilibrium constant K th of the reaction

Here, R is the universal gas constant. Eq. (1) and (4) show how the thermodynamic equilibrium constant K th is related to thermochemistry data of the reaction. K th of an esterification of a monocarboxylic acid can be expressed via the thermodynamic activities of the products over the reactants

The activity ɑ i is defined as the product of the mole fraction and the respective mole-fraction-based activity coefficient of reacting agent i. Therefore Eq. (2) can be written as

In Eqs. (2) and (3), esters studied in this work are methyl levulinate, ethyl levulinate, and butyl levulinate, and they belong to the alcohols MeOH, EtOH, and 1-BuOH, respectively. The mole fractions and thus K x values are equilibrium properties, and thus have to be accessed through reaction equilibrium experiments. Activity coefficients are accessible by thermodynamic modeling.

The standard Gibbs energy of reaction Δ R g 0 can be expressed via the thermodynamic properties of reacting species:

where ν i denotes the stoichiometric coefficient and \( {\Delta}^F{g}_{0i}^0 \) the standard Gibbs energy of formation of a pure reacting agent i. The latter is usually obtained by

where \( {\Delta}^F{h}_{0i}^0 \) is the standard enthalpy of formation and \( {\Delta}^F{s}_{0i}^0 \) the standard entropy of formation of the pure reacting agent i, and T is the absolute temperature in Kelvin. \( {\Delta}^F{s}_{0i}^0 \) can be calculated using the standard entropy of a pure reacting agent \( {s}_{0i}^0 \) and entropy of the elements \( {s}_{element}^0 \) (values see Table S9):

where elements refer to the elements that form the respective reacting agent i. The temperature dependencies of thermodynamic properties were described in this work with

where \( {c_p}_{0i}^0(T) \) is the temperature-dependent heat capacity of the pure component i.

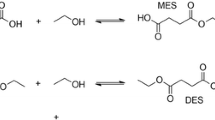

Thermochemical data on levulinic acid and alkyl levulinates required for calculation of the thermodynamic equilibrium constants of the LA esterification with alcohols are compiled in Tables S7–S10 (Fig. 1).

Scheme of the esterification of levulinic acid (LA) with alcohols (R = CH3 or CH2CH3 or (CH2)3CH3). Provenance and purity of compounds used in this study are lised in Table S1

PC-SAFT

PC-SAFT is based on the perturbation theory of Barker and Henderson (Barker and Henderson 1967) and calculates the residual Helmholtz energy a res of a system. The molecules are regarded as chains of hard spheres (hard chain), which represents the reference system and accounts for repulsive interactions. Perturbations due to attractive Helmholtz energy contributions in form of dispersive van der Waals attraction (dispersion) and hydrogen bonds (association) are added to a hard chain yielding

Within PC-SAFT, a component i is characterized by a set of pure-component parameters. It is described as a chain of \( {m}_i^{seg} \) segments with a specific segment diameter σ i . The chains interact via dispersion forces, which are accounted for by the dispersion-energy parameter \( \frac{u_i}{k_B} \), where k B is the Boltzmann constant. Association interactions are described by the two parameters association-energy parameter \( \frac{\varepsilon^{AiBi}}{k_B} \) and association-volume parameter κ AiBi, and a molecule is ascribed a certain number of associating sites N. This means that for an associating component, five parameters are required and for a non-associating component three parameters, respectively. These pure-component parameters are obtained by regression to vapor-pressure data and liquid-density data of pure components.

For the description of mixtures, mixing rules have to be applied. Lorentz-Berthelot combining rules were applied for the segment diameter σ ij and the dispersion-energy parameter u ij

Further, Wolbach-Sandler (Wolbach and Sandler 1998) mixing rules were applied to the association parameters:

As it can be observed, two binary parameters are present in these combining rules k ij and \( {k}_{ij}^{ws} \) which are binary interaction parameters between two components i and j. These parameters can be adjusted to binary phase equilibria like vapor-liquid, liquid-liquid, or solid-liquid equilibria. In general, binary interaction parameters can be expressed as temperature-dependent functions:

Once PC-SAFT pure-component parameters and binary parameters are available, activity coefficients can be obtained via fugacity coefficients φ i of a component i in mixture divided by the fugacity coefficient φ 0i of the pure component 0i:

The fugacity coefficient can be obtained as function of residual Helmholtz energy and derivations of a res with respect to mole fraction and number density.

Results

Pure-component PC-SAFT parameters

PC-SAFT parameters have to be known prior to predict K γ values that are required in Eq. (3). First, pure-component parameters of all components present in the reaction have to be estimated, except for Novozym 435 which is neglected in modeling due to the very low concentration in the reaction mixtures. PC-SAFT pure-component parameters for LA and the three corresponding alkyl levulinates were not available in the literature and were fitted in this work. The pure-component parameters for the alcohols MeOH, EtOH, and 1-BuOH and for water are available in literature and are summarized in Table S5. The pure-component parameters were adjusted in this work to experimental density and vapor pressure data of pure components using the following objective function:

The acid LA was treated as self-associating component; the levulinates were regarded as induced associating components. In the concept of induced association, it is assumed that the regarded molecule must not interact via self-association, but only via cross-association with other self-associating components. This means, five pure-component parameters were fitted for LA, and three for each alkyl levulinate. The so-determined PC-SAFT parameters are summarized in Table S5.

The comparison between experimental density data and PC-SAFT modeling results is illustrated in Fig. 2a, and a very good agreement can be observed. This statement is also valid for the pure-component vapor pressures, as shown in Fig. 2b.

Liquid densities a and vapor pressure b of LA and alkyl levulinates. Symbols are experimental data (circles LA, squares MLA, triangles ELA, stars BLA), and lines show PC-SAFT calculations using parameters from Table S5. Experimental data of LA, ELA, and BLA retrieved from (Lomba et al. 2011) and of MLA from (Lomba et al. 2013)

Binary PC-SAFT parameters

Besides pure-component parameters, binary parameters were adjusted prior to modeling multi-component reaction mixtures. For that purpose, phase equilibria of binary mixtures were used to determine binary interaction parameters k ij (and additional \( {k}_{ij}^{ws} \) for some binary mixtures) required in Eqs. (11) and (12). For one neat esterification mixture consisting of four reacting agents (LA, alcohol, water, alkyl levulinate), six binary pairs exist. This yields 16 binary pairs since three esterification mixtures were considered in this work. Experimental data for liquid-liquid equilibria (LLE) and vapor-liquid equilibria (VLE) of binary mixtures were used to adjust the binary interaction parameters. Table S6 summarizes all binary mixtures investigated in this work. Phase-equilibrium data of these binary systems were partly available in literature. However, data for some binary mixtures were not available in the literature. The strategy then was either to predict the phase equilibria of those mixtures with UNIFAC (like the approach Chung et al. (Chung et al. 2015) use, especially binary mixtures containing either MeOH or methyl levulinate), or to measure them in this work, or to use LLE data of ternary systems stemming from literature as shown in Fig. S1. The binary parameters that were adjusted in this work to the respective phase-equilibrium data, and the deviation between PC-SAFT modeling results and data sources in terms of ARD, are further listed in Table S6. To illustrate the accuracy of PC-SAFT modeling results, Fig. 3 compares the experimental VLE data of the system 1-BuOH/BLA and the experimental LLE data of the system H2O/BLA (measured in this work) with the PC-SAFT modeling. The binary mixtures H2O/EtOH and H2O/1-BuOH have been modeled in previous works and the corresponding binary interaction parameters k ij were inherited from literature (Altuntepe et al. 2017b).

a Experimental liquid-liquid equilibrium of the mixture water/BLA at atmospheric pressure. b Experimental vapor-liquid equilibrium of the mixture 1-BuOH/BLA at 0.02 bar determined in this work, with uncertainty u(x) = 0.0252 and u(T) = (0.15 + 0.002 (T − 273.15)) K. Lines are PC-SAFT calculations performed with the parameters summarized in Tables S5 and S6

LA esterification reaction: thermodynamic standard data at 323.15 K

In order to obtain reliable and consistent standard data, standard molar enthalpy and standard molar Gibbs energy of the LA esterification reaction have been derived from three different methods: from the reaction equilibrium data measured in this work (see Tables S2–S4), from thermochemical properties of the LA esterification reaction participants, as well as by assessment of the thermodynamic values by using a group contribution method (GCM) developed by Domalski and Hearing (Domalski and Hearing 1993). Admittedly, comparison of thermodynamic results has to be performed at any common temperature. While the reaction equilibrium measurements were carried out in this work at 323.15 K, it was necessary to use this temperature for the thermodynamic analysis and all required thermodynamic properties (see Table 2) were adjusted to 323.15 K. The adjustment was performed using heat capacities estimated by the well-established procedure by Ruzicka and Domalski (Rüžička and Domalski 1993). Thermodynamic properties of water and alcohols (MeOH, EtOH, and 1-BuOH) used in this work were taken from the literature (see Tables S7 and S8). Thermodynamic properties of LA were taken from our previous work (Verevkin and Emel’yanenko 2012). Thermodynamic data for the methyl levulinate (MLA), ethyl levulinate (ELA), and butyl levulinate (BLA) have been measured in our recent work (Emel’yanenko et al., personal communication). Compilation of the thermodynamic properties at 323.15 K used in this work is given in Table 2.

The group contribution methods are commonly useful tools for a first estimate of formation properties, but these values are often inaccurate. As it can be seen in Table 2, the thermodynamic properties of LA esters estimated by GCM are significantly different from the experimental data. As a consequence, the equilibrium constants derived from the GCM data are at least twice overestimated in comparison to the reliable data measured in this work. For example, the standard Gibbs energy of the LA esterification reaction with MeOH is Δ R g 0 = −13.85 kJ mol−1 and was calculated from the GCM results given in Table 2. The thermodynamic equilibrium constant K th = 173.2 was derived from the GCM estimates. The standard Gibbs energy of the same reaction Δ R g 0 = −11.79 kJ mol−1 (see Table 2) and the corresponding value K th = 80.5 clearly demonstrates the failing of the GCM to predict equilibrium constants accurately.

Considering Table 2, it can be stated that Δ R g 0 from GCM and from the experimental thermochemistry data are only in qualitative agreement. Both methods consistently predict Δ R g 0 values in the order Δ R g 0 (MeOH) < Δ R g 0 (EtOH) < Δ R g 0 (BuOH). Gibbs energies of reaction Δ R g 0 estimated with GCM are very similar for the reactions under consideration, but they are significantly more negative than Δ R g 0 values derived from our thermodynamic study based on measurements from (Emel’yanenko et al., personal communication).

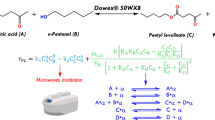

Equilibrium concentrations for the reactions under investigation were measured in a first step at different reaction conditions in order to have a broad data basis. The initial mole fractions of water and LA were varied in the different batches. After reaction equilibrium was reached, samples were taken and analyzed. The measured equilibrium mole fractions were used to calculate K x (Eq. (3)). The range of K x values was rather small due to the high excess of alcohol in the reaction mixtures. The results on K x values are listed in Tables S2–S4. In order to obtain K γ (Eq. (3)), the activity coefficients were predicted by PC-SAFT (see Tables S2–S4). It has turned out that K x values ranged from 0.1 to 2 and the corresponding K γ values ranged from 45 to 103 for the different reaction conditions of LA esterification with MeOH. With EtOH (1-BuOH), K x ranges between 0.4 and 0.8 (0.1 and 2) and K γ between 12 and 15 (2 and 8) for the different reaction conditions. For each different reaction, all K x values were multiplied with predicted K γ values, resulting in an averaged K th value for the individual reactions. At 323.15 K, the so-obtained K th values were found to be 36 ± 28 for LA esterification with MeOH, 8.9 ± 5.4 for LA esterification with EtOH, and 5.1 ± 2.8 for LA esterification with 1-BuOH, respectively. The given range of confidence is caused by experimental uncertainty of K x as well as the fact that many K x values were used to derive K th values (see Fig. 4).

Thermodynamic equilibrium constants of LA esterifications at 323.15 K for the MeOH-, EtOH-, and 1-BuOH esterification. Black: determination via reaction equilibrium experiments with PC-SAFT calculations, gray: determination via experimental thermochemical data from (Emel’yanenko et al., personal communication), and white: estimation via group contribution method of Domalski and Hearing (Domalski and Hearing 1993)

Water influence on reaction equilibrium

One of the aims of this work was to apply thermodynamics to understand the role of water for LA esterification. Water is a key component in enzyme-catalyzed esterifications because it affects both enzyme kinetics and reaction equilibrium. In previous works, it was shown that a slice amount of water in organic reaction medium has a positive effect on Lipase activity (see for example (Altuntepe et al. 2017a)). Nevertheless, more water in the feed composition will shift the reaction equilibrium of any esterification to the reactant side. Thus, the initial water content was varied in different reaction batches in order to quantify the effect of water on reaction equilibrium.

Three different reaction mixtures were prepared that contained the same initial LA concentration but three different initial water mole fractions. The equilibrium compositions were measured, and K x and LA conversion were calculated from that data. The results for LA esterification with EtOH are summarized in Fig. 5.

a Experimental and predicted equilibrium conversion of LA in dependence of the initial water mole fraction in the reaction mixture. Solid line: PC-SAFT prediction with K th from experimental thermochemistry data and dashed line: PC-SAFT prediction with K th from GCM. b Experimental apparent equilibrium constant K x (gray squares—left axis) and K γ (black squares—right axis) in dependence of the initial water mole fraction in the reaction mixture. Lines: PC-SAFT prediction of K x using K th from experimental thermochemistry data (solid line) or from GCM (dashed line)

From the experimental data in Fig. 5a, it gets obvious that the conversion of LA decreases with increasing initial water mole fraction. This is due to the shift of the reaction equilibrium to the reactant side with increasing amount of water in the reaction mixture.

Influence of LA concentration on reaction equilibrium

Next, the effect of LA concentration in the initial reaction mixtures on reaction equilibrium was investigated. For this, experiments were performed for LA esterifications with MeOH, EtOH, and 1-BuOH (data shown in Tables S2–S4) at rather low LA concentrations. It can be observed from the data that only slightly varying LA content in the reaction feeds does not have an influence on K x and on LA conversion. Thus, experiments were performed also for significantly higher LA contents in the reaction mixtures of LA esterification with 1-BuOH. The initial mole-fraction ratio of 1-BuOH to LA was set to 1:3, 1:1, or to 3:1. The results are summarized in Table 3. Please note that a small amount of water was added to each initial reaction mixture.

The experimental results show an unexpected behavior. While excess of 1-BuOH over LA (3:1) strongly shifts the reaction equilibrium to the product side (higher K x ) compared to equimolar reaction mixtures (1:1), the opposite was found for excess of LA over 1-BuOH (3:1). This can be observed in Fig. 6a for the K x values and in Fig. 6b for conversion of LA and 1-BuOH in dependence of ratio of 1-BuOH over LA in the initial reaction mixtures. It can be observed that conversion of LA increases with increasing 1-BuOH content, whereas 1-BuOH conversion slightly decreases (see Fig. 6b). This behavior can only be explained by molecular interactions, expressed in activity coefficients.

a Experimental apparent equilibrium constant K x (gray squares) and ratio of reacting agents' activity coefficients K γ (black squares—right axis) in dependence of the initial 1-BuOH/LA ratio. b LA conversion (black circles) and 1-BuOH conversion (gray squares) in dependence of the initial 1-BuOH/LA ratio

Predicting LA conversion

The main focus of this work has been to predict LA conversions, X LA , at equilibrium (maximum conversion) depending on the different initial reaction conditions and to compare these predictions with experimental data. Esterification of LA with 1-BuOH is chosen to demonstrate the procedure in the following. A strategy was developed to predict equilibrium compositions of reaction mixtures yielding \( {K}_x^{pred} \) values by minimizing the following objective function at constant temperature

In Eq. (17), the thermodynamic equilibrium constant K th has to be known. This value was inherited from the data presented in Fig. 4 using either thermochemical experimental data or GCM results. The activity coefficients of the reacting agents were predicted with PC-SAFT using the parameters in Tables S5 and S6 to quantify \( {K}_{\gamma}^{PC- SAFT} \). Equation (17) is a function of the extent of reaction λ that relates the input initial composition of the reacting agents (index 0) with the equilibrium mole fractions of the reacting agents based on the stoichiometry of the reaction:

Eqs. (17)–(21) yield λ at equilibrium and thus predicted equilibrium compositions that need experimental validation. These experimental data were taken from Fig. 5 and in Table 3. The equilibrium data were measured for different mole fractions of LA and water in the initial reaction mixtures.

Influence of temperature on K th

All reaction equilibrium measurements in this work have been performed only at 323.15 K. However, all required thermodynamic standard data for predicting conversions are temperature dependent. Modeling temperature dependence of K th values requires enthalpy data and heat capacities. For alkyl levulinates, LA, and alcohols, the latter were calculated with the method of Ruzicka and Domalski (Rüžička and Domalski 1993). For water, all required temperature-dependent thermodynamic properties were taken from Chase (Chase 1998). All these data were used to determine Δ R g 0 with Eq. (4) at 298.15 K. Standard thermodynamic relations (Eqs. (5)–(8)) were then applied to calculate the temperature dependence of Δ R g 0, and thus the respective K th . So-obtained K th values are illustrated in Fig. 7 and compared with K th at 323.15 K (inherited from the data presented in Fig. 4) with the respective confidence range.

Summary of the K th values in dependence of the reaction temperature. Squares are results from reaction equilibrium determinations with PC-SAFT calculations of activity coefficients. Black: MeOH esterification, dark gray: EtOH esterification, and bright gray: 1-BuOH esterification. Lines: a K th via GCM (b) K th via experimental formation properties

Figure 7 illustrates once again that K th values from GCM significantly overestimate K th values from thermochemical data on alkyl levulinates (Emel’yanenko et al., personal communication) as well as from experimental reaction equilibrium data measured in this work that were combined with PC-SAFT predicted \( {K}_{\gamma}^{PC- SAFT} \) values. Nevertheless, the obtained results are remarkable considering the fact that many different independent methods and data (experimental thermochemical properties, heat capacity estimations, reaction equilibrium measurements, and activity coefficient predictions) were used to consistently predict reaction equilibria of enzyme-catalyzed LA esterification.

Discussion

Standard data of LA esterification

The obvious deviation that is described in Table 2 is discussed by comparing the shown Δ R g 0 data with Δ R g 0 values from reaction equilibrium experiments and activity coefficients. This is possible because the activity-based equilibrium constant is related to Δ R g 0 by Eq. (1). As activity is defined by concentration times activity coefficients, experiments and thermodynamic modeling were performed.

The fact that the activity coefficients are strongly non-unity shows that K x strongly depends on concentration, and the reaction mixtures for LA esterification in MeOH are strongly non-ideal, caused by molecular interactions. This supports findings from other works that observed that esterification mixtures strongly deviate from ideality (see (Altuntepe et al. 2017a; Grob and Hasse 2005; Riechert et al. 2015)). Considering K γ values, it can be stated that the non-ideality of the reaction mixtures decreases (K γ values get closer to one) from MeOH to 1-BuOH. This is a reasonable observation as LA is a C5 acid, and mixtures of LA with small molecules (such as MeOH) usually demonstrate significant deviation from ideal-mixture behavior.

The K th values of the LA esterification reactions with alcohols obtained from K γ and K x were further compared with equilibrium constants estimated by GCM and with those obtained by experimental formation data in Fig. 4. It can be observed from Fig. 4 that K th calculated from reaction equilibrium data measured in this work and activity coefficients predicted by PC-SAFT is in very good agreement with the K th values derived from experimental thermochemical data on LA and its esters measured in our recent work by combustion calorimetry and transpiration method (Emel’yanenko et al., personal communication). In contrast, the K th values estimated with the GCM significantly deviate from the both experimental determinations. Thus, it can be stated that K th from reaction equilibrium data and activity coefficient predictions are cross-validated with experimental formation properties, and that the use of GCMs should be avoided if other data are available.

Water influence on LA conversion

In Fig. 5b, an unexpected dependence of K x values on water content is observed. It is expected that K x decreases with the shift of the equilibrium to the reactant side, which is obviously contrary to the experimental results. The reason for the fact that K x increases with increasing mole fraction of water in the feed is the excess of EtOH in the reaction mixture compared to a relatively low water content, which obviously compensates the effect of water. Further, higher x H2O values cause decreased LA conversion and increased K x because of the definition in Eq. (3). This effect is dominating at low water mole fractions, while K x might indeed decrease with increasing x H2O for higher initial water content. To summarize, it can be stated that a decrease in LA conversion does not necessarily cause a decreased K x and vice versa. Similar behaviors were observed also for LA esterification with MeOH and with 1-BuOH (see Tables S2–S4).

The formalism presented in Eqs. (17)–(21) were further used to predict LA conversion. Comparing experimental LA conversions with the predictions using K th from experimental thermochemical formation, data are in very good agreement with experimental results. In contrast, the predicted LA conversions with K th estimated from GCM significantly overestimated the experimental LA conversions. Nevertheless, the qualitative dependence of the water content on LA conversion is described correctly with Eqs. (17)–(21) using K th from GCM. The deviations are caused by too high K th value, which therefore results in LA mole fractions that were then significantly too low. These results point out to the importance of accurate and consistent K th values, and they explain the errors obtained by using inconsistent K th values.

Influence of ratio 1-BuOH:LA on LA conversion

Next to the water influence on reaction equilibrium, the influence of the ratio 1-BuOH:LA in the initial reaction mixtures was predicted. Since K th is only a function of temperature, the product of K x and K γ has to be constant in order to fulfill Eq. (17). As it could be observed from Fig. 6, K x values increased upon increasing initial 1-BuOH:LA ratio. Thus, K γ is expected to decrease upon increasing initial 1-BuOH:LA ratio. As it can be seen in Fig. 6, this was exactly obtained with activity coefficients of the reacting agents predicted with PC-SAFT. That is, the concentration dependence of LA conversion that has been observed experimentally can be explained with activity coefficients of the reacting agents, or in other words, with the molecular interactions which are strongly non-ideal in esterification mixtures. The summarized prediction results are listed in Table 3 and compared to experimental LA conversion data in dependence of the initial mole-fraction ratio 1-BuOH/LA.

It can be observed from Table 3 that the experimental LA conversion increases with increasing excess of 1-BuOH in the initial reaction mixtures from 0.10 (ratio 1:3) to 0.19 (ratio 1:1) to 0.79 (ratio 3:1). These experimental results predicted with the formalism in Eqs. (17)–(21) were qualitatively correct using activity coefficients from PC-SAFT and K th value obtained either from GCM or from thermochemistry. However, distinct quantitative differences between results obtained with K th from GCM or from thermochemistry in Eq. (17) can be observed. K th from GCM (K th = 60.3) significantly overestimated LA conversion. This is due to the comparably high K th value. In contrast, using activity coefficients from PC-SAFT and K th of 2.6 from thermochemistry allow predicting LA conversions that are in very good agreement to the experimental data.

As summary, it can be stated that reaction equilibria and maximum LA conversion as function of different reaction conditions could be predicted with the formalism presented in this work. This formalism requires the thermodynamic equilibrium constant K th , accessible from a group contribution method for Gibbs energy of formation, experimentally determined formation properties, and reaction equilibrium measurements accompanied by activity coefficient predictions using PC-SAFT. The K th values obtained from the experimental methods were found to be in good agreement but significant disagreement was observed for the K th values estimated from Gibbs energy of formation obtained with group contribution method. Further, the experimental K th values were used in order to determine the reaction coordinate and thus, finally to determine LA conversion. Activity coefficients required for the thermodynamic interpretation of the equilibrium studies have been predicted by PC-SAFT. Required model parameters were either available from literature or determined in this work from reaction-independent phase-equilibrium data. Modeling revealed that for the investigated reaction mixtures activity coefficients significantly deviated from unity caused by strong molecular interactions. This caused increasing LA conversion data upon increasing 1-BuOH excess and upon decreasing the water content in the initial reaction mixtures. Accounting for these strong non-ideal behaviors by predicting the activity coefficients with PC-SAFT allowed predicting LA conversion in very good agreement with the experimental observations. For this, experimental K th values from experimental formation properties were used. In contrast, distinct deviations to the experimental LA conversions were observed if K th values were used that have been estimated by group contribution method.

To conclude, bringing thermodynamic modeling with PC-SAFT together with experimental thermochemistry data enabled precise prediction of equilibrium compositions and thus K x and LA equilibrium conversions. The initial feed compositions, thermodynamic equilibrium constant, and activity coefficients are required for that. Note, that the modeling with PC-SAFT was parametrized to reaction-independent phase-equilibrium data.

References

Alonso DM, Bond JQ, Dumesic JA (2010) Catalytic conversion of biomass to biofuels. Green Chem 12(9):1493–1513

Altuntepe E, Greinert T, Hartmann F, Sadowski G, Held C (2017a) Thermodynamics of enzyme-catalyzed esterifications: I. Succinic acid esterification with ethanol. Appl Microbiol Biotechnol 101:5973–5984

Altuntepe E, Reinhardt A, Brinkmann J, Briesemann T, Sadowski G, Held C (2017b) Phase behavior of binary mixtures containing succinic acid or its esters. J Chem Eng Data 62:1983–1993

Barker JA, Henderson D (1967) Perturbation theory and equation of state for fluids: the square-well potential. J Chem Phys 47(8):2856–2861

Bart H, Reidetschläger J, Schatka K, Lehmann A (1994) Kinetics of esterification of succinic anhydride with methanol by homogeneous catalysis. In J Chem Kinet 26(10):1013–1021

Bozell JJ, Moens L, Elliott D, Wang Y, Neuenscwander G, Fitzpatrick S, Bilski R, Jarnefeld J (2000) Production of levulinic acid and use as a platform chemical for derived products. Resour Conserv Recy 28(3):227–239

Chase MW (1998) NIST-JANAF thermochemical tables, 4 edn. American Chemical Society; American Institute of Physics for the National Institute of Standards and Technology, [Washington, D.C.], Woodbury, N.Y

Christensen E, Williams A, Paul S, Burton S, McCormick RL (2011) Properties and performance of levulinate esters as diesel blend components. Energy Fuel 25(11):5422–5428

Chung Y-H, Peng T-H, Lee H-Y, Chen C-L, Chien I-L (2015) Design and control of reactive distillation system for esterification of levulinic acid and n-butanol. Ind Eng Chem Res 54(13):3341–3354

Climent MJ, Corma A, Iborra S (2014) Conversion of biomass platform molecules into fuel additives and liquid hydrocarbon fuels. Green Chem 16(2):516–547

Dautzenberg G, Gerhardt M, Kamm B (2011) Bio based fuels and fuel additives from lignocellulose feedstock via the production of levulinic acid and furfural. Holzforschung 65(4):439–451

Demma Carà P, Ciriminna R, Shiju N, Rothenberg G, Pagliaro M (2014) Enhanced heterogeneous catalytic conversion of furfuryl alcohol into butyl levulinate. ChemSusChem 7(3):835–840

Démolis A, Essayem N, Rataboul F (2014) Synthesis and applications of alkyl levulinates. ACS Sustain Chem Eng 2(6):1338–1352

Domalski ES, Hearing ED (1993) Estimation of the thermodynamic properties of C-H-N-O-S-halogen compounds at 298.15 K. J Phys Chem Ref Data 22(4):805–1159

Grob S, Hasse H (2005) Thermodynamics of phase and chemical equilibrium in a strongly nonideal esterification system. J Chem Eng Data 50(1):92–101

Gross J, Sadowski G (2001) Perturbed-chain SAFT: an equation of state based on a perturbation theory for chain molecules. Ind Eng Chem Res 40(4):1244–1260

Gross J, Sadowski G (2002) Application of the perturbed-chain SAFT equation of state to associating systems. Ind Eng Chem Res 41(22):5510–5515

Hayes DJ (2009) An examination of biorefining processes, catalysts and challenges. Catal Today 145(1):138–151

Hoffmann P, Voges M, Held C, Sadowski G (2013) The role of activity coefficients in bioreaction equilibria: thermodynamics of methyl ferulate hydrolysis. Biophys Chem 173:21–30

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6(25):4497–4559

Kamm B, Gruber PR, Kamm M (2000) Biorefineries—industrial processes and products Ullman’s encyclopedia of industrial chemistry. Wiley-VCH Verlag GmbH & Co. KGaA

Kobayashi H, Fukuoka A (2013) Synthesis and utilisation of sugar compounds derived from lignocellulosic biomass. Green Chem 15(7):1740–1763

Lee A, Chaibakhsh N, Rahman MBA, Basri M, Tejo BA (2010) Optimized enzymatic synthesis of levulinate ester in solvent-free system. Ind Crop Prod 32(3):246–251

Leibig C, Mullen B, Mullen T, Rieth L, Badarinarayana V (2011) Cellulosic-derived levulinic ketal esters: a new building block renewable and sustainable polymers. ACS Symposium Series, vol 1063. American Chemical Society, pp 111–116

Lilly MD (1994) Eighth PV Danckwerts memorial lecture presented at Glaziers’ Hall, London, UK 13 May 1993: Advances in biotransformation processes. Chem Eng Sci 49(2):151–159

Lomba L, Giner B, Bandrés I, Lafuente C, Pino MR (2011) Physicochemical properties of green solvents derived from biomass. Green Chem 13(8):2062–2070

Lomba L, Lafuente C, García-Mardones M, Gascón I, Giner B (2013) Thermophysical study of methyl levulinate. J Chem Thermodyn 65:34–41

Olson ES (2001) Conversion of lignocellulosic material to chemicals and fuels. National Energy Technology Lab., Pittsburgh, PA (US); National Energy Technology Lab., Morgantown, WV (US)

Olson ES, Kjelden MR, Schlag AJ, Sharma RK (2001) Levulinate esters from biomass wastes chemicals and materials from renewable resources. ACS symposium series, vol 784. American Chemical Society, pp 51–63

Petersson AEV, Gustafsson LM, Nordblad M, Borjesson P, Mattiasson B, Adlercreutz P (2005) Wax esters produced by solvent-free energy-efficient enzymatic synthesis and their applicability as wood coatings. Green Chem 7(12):837–843

Pileidis FD, Titirici MM (2016) Levulinic acid biorefineries: new challenges for efficient utilization of biomass. ChemSusChem 9(6):562–582

Riechert O, Husham M, Sadowski G, Zeiner T (2015) Solvent effects on esterification equilibria. AIChE J 61(9):3000–3011

Rüžička Jr V, Domalski ES (1993) Estimation of the heat capacities of organic liquids as a function of temperature using group additivity. J Phys Chem Ref Data 22(3)

Schwartz TJ, O’Neill BJ, Shanks BH, Dumesic JA (2014) Bridging the chemical and biological catalysis gap: challenges and outlooks for producing sustainable chemicals. ACS Catal 4(6):2060–2069

Serrano-Ruiz JC, Luque R, Sepulveda-Escribano A (2011) Transformations of biomass-derived platform molecules: from high added-value chemicals to fuelsvia aqueous-phase processing. Chem Soc Rev 40(11):5266–5281

Timokhin BV, Baransky VA, Eliseeva GD (1999) Levulinic acid in organic synthesis. Russ Chem Rev 68(1):73–84

Turner MK (1995) Biocatalysis in organic chemistry (part II): present and future. Trends Biotechnol 13(7):253–258

Verevkin SP, Emel’yanenko VN (2012) Renewable platform-chemicals and materials: thermochemical study of levulinic acid. J Chem Thermodyn 46:94–98

Weingarten R, Tompsett GA, Conner WC, Huber GW (2011) Design of solid acid catalysts for aqueous-phase dehydration of carbohydrates: the role of Lewis and Brønsted acid sites. J Catal 279(1):174–182

Werpy T, Petersen G (2004) Top value added chemicals from biomass: volume I—results of screening for potential candidates from sugars and synthesis gas.; National Renewable Energy Lab., Golden, CO (US), p medium: ED; size: 76 pp. pages

Wolbach JP, Sandler SI (1998) Using molecular orbital calculations to describe the phase behavior of cross-associating mixtures. Ind Eng Chem Res 37(8):2917–2928

Wu K, Wu Y, Chen Y, Chen H, Wang J, Yang M (2016) Heterogeneous catalytic conversion of biobased chemicals into liquid fuels in the aqueous phase. ChemSusChem 9(12):1355–1385

Yadav GD, Borkar IV (2008) Kinetic modeling of immobilized lipase catalysis in synthesis of n-butyl levulinate. Ind Eng Chem Res 47(10):3358–3363

Zhang Y-HP (2008) Reviving the carbohydrate economy via multi-product lignocellulose biorefineries. J Ind Microbiol Biotechnol 35(5):367–375

Zhang J, Wu S, Li B, Zhang H (2012) Advances in the catalytic production of valuable levulinic acid derivatives. ChemCatChem 4(9):1230–1237

Acknowledgements

This work was supported by the German Science Foundation (Leibniz award to G. Sadowski). The authors moreover acknowledge support by the Cluster of Excellence RESOLV (EXC 1069) funded by the Deutsche Forschungsgemeinschaft (DFG). This work was also partly supported by the Government of Russian Federation (decree №220 of 9 April 2009), agreement №14.Z50.31.0038.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(PDF 595 kb).

Rights and permissions

About this article

Cite this article

Altuntepe, E., Emel’yanenko, V.N., Forster-Rotgers, M. et al. Thermodynamics of enzyme-catalyzed esterifications: II. Levulinic acid esterification with short-chain alcohols. Appl Microbiol Biotechnol 101, 7509–7521 (2017). https://doi.org/10.1007/s00253-017-8481-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8481-4