Abstract

The study had the objective of examining the aspects involved in the cultivation of ectomycorrhizal fungi for the production of commercially sustainable inoculant to attend the demands of the seedling nursery industry. It focused on certain parameters, such as the oxygen consumption levels, during the cultivation of the ectomycorrhizal fungus Rhizopogon nigrescens CBMAI 1472, which was performed in a 5-L airlift bioreactor. The dynamic method was employed to determine the volumetric coefficient for the oxygen transfer (k L a) and the specific oxygen uptake rate (Q O2 ). The results indicate that specific growth rates (μ X ) and oxygen consumption decline rapidly with time, affected mainly by increases in biomass concentration (X). Increases in X are obtained primarily by increases in the size of pellets that are formed, altering, consequently, the cultivation dynamics. This is the result of natural increases in transferring resistance that are observed in these environments. Therefore, to avoid critical conditions that affect viability and the productivity of the process, particular settings are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Successful measures for a controlled mycorrhization of seedlings, intended mainly for the ever-demanding reforestation programs, are dependent primarily on a constant and uniform industrial supply of fungal inoculum. Studies on the effects of ectomycorrhizal (ECM) fungi on seedling development are plentiful. They aims are primarily at the fungi’s mechanisms of action, the benefits of the symbiotic partnership, and the physiology of both the plants and the associated fungi (Garbaye 1984; Le Tacon et al. 1987; Malajczuck et al. 1990; Kuek et al. 1992; Burgess et al. 1993; Giachini et al. 2004; Gandini et al. 2015). However, when it comes to the knowledge associated to the production of large volumes of fungal inoculum, there are still considerable gaps to be resolved. Not much is understood about the cultivation process of these microorganisms in an industrial scale. One of the main reasons for this lack of knowledge is the difficulty to grow these fungi in controlled culture conditions.

ECM fungi are generally slow growing (Pradella et al. 1991; Rossi et al. 2002, 2016), which may limit several applications, especially when traditional methods for cultivation are used. This is perhaps the reason that kept this sector from expanding. Nevertheless, studies have demonstrated that submerged cultivation of ECM fungi in airlift bioreactors is an excellent alternative for the production of large volumes of fungal biomass (Rossi 2006). Airlift bioreactors present fluid dynamics and shearing forces that affect fungal cells on a much lesser extent than stirred tank bioreactors (Chisti 1987). However, to improve the technology for fungal biomass production in airlift bioreactors, it is necessary that other parameters are tested and understood. Among them, the oxygen transfer rate, listed by many as one of the most limiting factors (Whitman 1923; Chisti 1989; Jin et al. 2001; Schmidell 2001; Krahe 2003; Garcia-Ochoa and Gomez 2009), especially due to the low oxygen solubility. If the bioreactor cannot supply the demands of an actively growing microbial population, critical levels of oxygen concentration can be reached in only a few seconds during a particular batch (Finn 1967), resulting in decreased yields and the possibility of growth failure. To keep a constant production, the rate in which oxygen is consumed must be equal to the rate it is supplied.

Oxygen transfer studies will help to determine the proper physical and biological conditions for the growth and development of ECM fungi. Therefore, the objective of this study was to evaluate the effects of consumption and transfer of oxygen during the cultivation of an ECM fungus in an airlift bioreactor to boost the technology for the production of large-scale, commercially feasible fungal inoculum.

Material and methods

Ectomycorrhizal fungal isolate

This study employed the ECM fungal isolate UFSC-Rh90, Rhizopogon nigrescens Coker & Couch, isolated from a managed Pinus taeda forest located in the state of Santa Catarina, Southern Brazil. The isolate is available from a publicly accessible culture collection (CBMAI WDCM823—Brazilian Collection of Microorganisms from the Environment and Industry, strain CBMAI 1472). During the study, the isolate was kept at 25 ± 1 °C on modified Merlin-Norkrans (MMN) solid medium (Marx 1969) with glucose as the sole source of carbon.

Culture media and inoculum production

Mycelial pellets from a previous bioreactor cultivation preserved under refrigeration (8 ± 2 °C) in a saline solution (0.85 % NaCl) for 3 days were utilized to prepare the inoculum. Inoculum viability was confirmed by the placement of 40 pellets in petri dishes containing MMN solid medium, incubated at 25 ± 1 °C for 48 h. To promote a suitable homogeneous mycelial suspension for the bioreactor, start-up, 50 g of biomass in the form of pellets (ca. 1.5 g dw) was fragmented in a blender (model LAR-15, Metvisa, Brazil) for 20 s at 3600 rpm in 300 mL of MMN liquid medium.

For bioreactor cultivation, we used a variation of the PGK medium (Rossi and Oliveira 2011), containing the following (g/L): glucose 14.0, soy peptone 3.0, malt extract 1.5, NH4NO3 1.0, KH2PO4 0.264, K2HPO4 0.628, MgSO4·7H2O 0.33, CuSO4·5H2O 0.0021, MnCl2·4H2O 0.0006, ZnSO4·7H2O 0.0005, and FeSO4·7H2O 0.0004, with a C/N (g/g) of approximately 16. The initial pH was adjusted to 5.8 with an equimolar solution of citric acid and 0.15 mol/L sodium citrate prior to sterilization. Additionally, we added 0.25 mL/L of polypropylene glycol to reduce foaming.

Bioreactor specifications and cultivation conditions

We used a 5-L stainless steel airlift bioreactor (Rossi et al. 2016) with external circulation (A d/A r = 0.11 and H/D = 12.5; nomenclature in Table 1), fitted with an InPro6000 polarographic probe (98 % of the response in 45 to 90 s) and a 4100e transmitter for the dissolved oxygen (DO) readings (Mettler-Toledo AG, Greifensee, Switzerland). The bioreactor was sterilized (121 °C and 30 min) using direct steam created by a 25-L autoclave connected to the bioreactor through a derivation of the air outlet.

Under a laminar flow, 350 mL of mycelial suspension was inoculated into a Mariotte flask containing 4.7 L of culture medium previously sterilized at 121 °C for 30 min. Afterwards, 5 L of the inoculated medium was aseptically transferred to the bioreactor using a sterilized connection. The bioreactor was then set for operation at 25 ± 1 °C in flow rates of 0.2 and 0.52 vvm, determined with a gas bubble meter tube. The injected air was purified with the aid of a PTFE filtering hydrophobic membrane (Millipore Corporation, Billerica, USA), with pores of 0.22 μm in diameter. The cultivation was conducted until the final declining phases of growth were reached.

Samples of approximately 40 mL were collected in different time intervals, more spaced in the beginning of the cultivation when the biomass concentration was lower. The samples were subsequently filtered in no. 1 filter paper (Whatman, Madison, UK), and the resulting biomass was air dried at 75 ± 1 °C until constant weight. The filtered biomass pH was determined conventionally and the residual glucose concentration determined by spectrophotometry set at 505 nm, utilizing the GOD-POD method (colorimetric enzymatic kit; Biodiagnostica, Pinhais, Brazil).

Oxygen transfer and microbial respiration

Even though there are several resistances to the transport of oxygen in microbial processes, the most important one is the mass transfer that takes place in the gas-liquid interface (Chisti 1989). The most employed theorization for the equation that estimates the oxygen transfer considers the existence of two stagnated films in equilibrium between the gas-liquid interface, as originally described by Whitman (1923). In synthesis, the resistance imposed by the gaseous film is insignificant compared to what happens in the liquid film. Therefore, in the transient state, the oxygen transfer rate is given by the following equation:

where C = oxygen concentration in the liquid phase (mg O2/L) and C S = oxygen concentration in equilibrium with the gas phase. The k L a (1/t) serves as a volumetric coefficient for the oxygen transfer since it is impossible to measure the surface area of all existing interfaces between the liquid and the formed bubbles. Although ordinary, the equation allows for the comprehension of all possible forms to control the dissolved oxygen levels in the culture medium (Schmidell 2001). In order to deal with the oxygen consumption as a function of microbial respiration, the specific oxygen uptake rate is defined as

where dO 2 /dt = oxygen uptake rate (mg O2/L/h) and X = biomass concentration (mg/L). The term Q O2 represents the biological component of the system, and it depends on the microorganism, the composition of the medium, and the cultivation conditions (pH, temperature, etc.). Its determination is done together with the determination of k L a.

Determination of k L a and Q O2

During the cultivation, the fungus simultaneously consumes oxygen as the bioreactor transfers oxygen from the gas to the liquid phase. Considering a complete mixing in the riser, where air is injected, and a plug flow regime in the downcomer, where the gas phase is not taken into account (Rossi et al. 2016), the equation obtained through an oxygen balance in the liquid (supplementary Fig. S1a) is

in which

The cultivation kinetics is presented in Eq. (3), where X varies with time and Q O2 varies with the specific growth rate (μ X). Since there is no gas phase in the downcomer for this airlift bioreactor design, its volume, which represents ca. 7 % of the bioreactor’s functional capacity, does not contribute to the oxygen transfer. Therefore, the right-sided denominator component of the equation represents this loss, due to the smaller volume available for oxygen transfer. The value is constant for a particular operation flow and, to simplify, will be identified as “z.”

The volumetric coefficient for oxygen transfer (k L a) and the specific oxygen uptake rate (Q O2 ) were determined by the dynamic method (Schmidell 2001; Garcia-Ochoa and Gomez 2009) utilizing the signal from the probe immersed in the culture medium. For that purpose, in a particular moment during cultivation, aeration was interrupted to discontinue the oxygen transfer. As illustrated in the schematics (supplementary Fig. S1b), the concentration of dissolved oxygen in the initial phase (C 0 ) starts to decline, being the signal of the probe continuously recorded. When a certain value of C 01 is obtained, aeration is reestablished in the normal conditions and the increases in dissolved oxygen concentration recorded until the original C 0 value is again reached. This procedure took only a few minutes to be completed. It is important that the concentration do not reach critical values, since that would affect the metabolism of the fungus. In this short period, we assume that there were no increases in X and that Q O2 stayed constant. For the period without aeration, the Eq. (3) results in

Considering that Q O2 is constant, Eq. (4) can be integrated resulting in

Equation (5) foresees a linear variation with time during the period when aeration is interrupted, producing the value of Q O2 via the angular coefficient Q O2 X. The value of X was determined during the development of the assay. Since in an airlift bioreactor stopping aeration also stops stirring, special consideration was made to treat the data, as described previously (Rossi et al. 2015).

The values obtained to determine the dissolved oxygen concentration increments, related to the second portion presented in supplementary Fig. S1b, were also used to define k L a. Considering a steady state just prior to the interruption in aeration and applying Eq. (3) integrally, we obtain

In this way, a linear response is obtained by computing C = f(t), according to Eq. (6), from which the angular coefficient gives the value of k L a.

k L a and Q O2 taking into account the probe’s response delay

For the same reasons discussed by Rossi et al. (2015), it may be necessary to correct the values of k L a and Q O2 . The only difference is that now, the correction needs to be made during the cultivation. Referring back to Eq. (5) and making t 0 = 0 (time zero for the interruption in aeration), and adding the value of C in the probe’s signal equation (C p ) (Rossi et al. 2015), the following expression is obtained:

which, after integration, gives

where C 0 = C p0 = concentration of O2 prior to the interruption in aeration, corresponding to the probe’s signal and k P = the constant delay of probe response. By adjusting Eq. (8) according to the experimental values (C p = f(t)), we get the correct value of Q O2 . Likewise, for the correction of k L a, we go back to Eq. (3), remove the consumption term, and by integration from an instant t 2 (delay) with C 02, dissolved oxygen concentration get

The substitution of C (Eq. (9)) in the probe’s signal (C p ) equation and the integration of the resulting expression give

where C pO2 = probe’s signal at instant t 2 = 0 and C O2 = real concentration of O2 at instant t 2 = 0. The correct value of k L a was obtained by adjusting Eq. (10) to the experimental data.

Critical concentration of oxygen for microbial respiration

The respiration rate of a cell, and consequently its growth, is progressively limited when the dissolved oxygen concentration is set below a certain value, known as the critical level (C crit ). For this study, the C crit was determined by interrupting aeration in a particular moment during cultivation and recording the probe’s oxygen reading reduction (supplementary Fig. S1b). During this short period during which the assay was developed, the biomass is considered constant. Correspondingly, as long as oxygen is available, the oxygen uptake rate is also constant. In the exact moment the oxygen concentration line drops, the respiration rate starts to reduce, indicating the critical value.

Specific growth rate

With increases in cellular concentration during simple batches, instantaneous growth rate, which is related to cellular concentration, is more accurate. Therefore, cell-specific growth rate (μ X ) profiles, defined by Eq. (11), were obtained with the geometrical calculations from the derivatives (Leduy and Zajic 1973), utilizing Microsoft Excel 12.0 (Microsoft Corporation, Redmond, WA).

Results

Critical oxygen concentration

Figure 1 shows the results of an assay to determine the critical oxygen concentration during the cultivation of fungal species R. nigrescens CBMAI 1472 in a bioreactor with an airflow rate of 0.2 vvm. The reestablishment of aeration was done approximately 9 min after its interruption. However, as specified in Fig. 1, critical levels of oxygen were reached even when high relative DO concentrations were observed; once half way through the interruption period, there was a reduction in oxygen consumption. There was an abrupt drop in the concentration of oxygen with the reestablishment of aeration, with a posterior increase and stabilization after 10 min following interruption. Table 2 shows the variables taken into account for this assay.

Variation of dissolved oxygen concentration with time, as a function of microbial consumption during interruption and posterior reestablishment of aeration. An assay was performed with the fungal species Rhizopogon nigrescens CBMAI 1472, set at growing temperatures of 25 ± 1 °C and airflow rate of 0.2 vvm

Determination of k L a and Q O2

Figure 2a, b shows the results typically observed during the execution of a dynamic assay. These values were utilized to determine the specific uptake rate (Q O2 ) and the volumetric coefficient for the oxygen transfer (k L a) during cultivation. From these results, we can notice that in later developmental stages, where the DO concentration is generally lower and the demand is higher, the execution of the assay could bring the DO to critical levels. Figure 2b shows that upon the reestablishment of aeration, the DO concentration stabilizes in a higher level than prior to the beginning of the assay (as observed for the determination of C crit ), indicating a lower oxygen consumption compared to the levels prior to the interruption in aeration. This outcome indicates a harmful effect of the assay in the cell’s development.

The reduction in the DO levels was detected only hours after the beginning of the batch, being confused, therefore, with the effects of cultivation. The levels of DO were close to 40 % of saturation (3 mg O2/L), indicating that in the inner layers of the pellets, these values could be even lower. With the reestablishment of aeration, there was an abrupt decline in the DO concentration (hatched ellipse from Fig. 2a, b) due to the mixing of oxygen-poor medium from the bottom, where biomass has been depositing, with the rest of the medium from the upper part, reestablishing the system’s fluid dynamics. These experimental points, determined by the time of mixture (Rossi et al. 2015), were not taken into account when determining the k L a during these periods of instability.

k L a and Q O2 taking into account the probe’s response delay

Figure 3 shows the experimental values for the DO concentration during a dynamic assay in the fourth day of cultivation for the fungal species R. nigrescens CBMAI 1472 on an airflow rate of 0.52 vvm. It also shows, in the first section of the graph, the simulation of the theoretically estimated points (Eq. (5)) and the experimental points corrected from the response delay (Eq. (8)), utilizing the k p value obtained for static liquids (106/h; Rossi et al. 2015). Likewise, the second section of the graph also presents the simulation of the theoretically estimated points (Eq. (6)) and the experimental points, but this time corrected from the probe’s response delay (Eq. (10)), utilizing the k p value obtained for liquids under stirring (389/h; Rossi et al. 2015).

Data for the dynamic method obtained from a cultivation of the fungal species Rhizopogon nigrescens CBMAI 1472. The curve represents the theoretical values (Cteor); solid circles represent the experimental C p values; open squares represent the values of C p corrected for the delayed response time (C p corr). Shaded area represents the transient state caused by mixing

The first interval of the graph indicates that Eq. (8) did not adjust the experimental data properly. This effect is caused, probably, by the extremely low k p . Nonetheless, disregarding the initial points from the transient state, due to the existence of air bubbles in the initial moments after the interruption in aeration (not predicted in Eq. (8)), both the experimental data and the corrected data follow the theoretical values of C. Considering the time extent for the assay, the term 1/(k p e kp.t) from Eq. (8) is therefore disregarded, creating a curve parallel to the one represented by the theoretical points.

With the reestablishment of aeration (Fig. 3) after the transient state caused by mixing (between 1.8 and 2.4 min—shaded area), it is noticed that both the experimental (C p ) and the corrected data (C p corr) follow the theoretical values predicted in Eq. (6). For high values of C p corr, as is the case in stirred tank bioreactors, the difference between the real value of C and the value read by the probe (C p ) is higher, as already reported by Badino et al. (2000). Therefore, for this study, the transient time, defined by the time of mixture, varied from 50 to 60 s (Rossi et al. 2015), period in which the experimental data have to be unaccounted for the determination of k L a. During this period, the probe’s readings stabilize and follow the real values. Consequently, the values of Q O2 and k L a did not need adjustments due to the probe’s response delay. A similar result was obtained for the airflow rate of 0.2 vvm.

Oxygen transfer and consumption

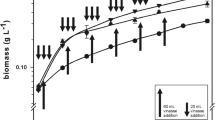

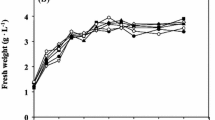

Figures 4, 5, and 6 present the results from the cultivation of the fungal species R. nigrescens CBMAI 1472, maintained under the aeration flow regimes of 0.2 and 0.52 vvm. As can be seen, a total consumption of glucose, properly converted into biomass, is initially detected, although happening in different stages. These results indicate that the values for the kinetic variables decline with the cultivation time, being more evident from about half the final cell concentration, where the values of μ X and Q O2 reduce more rapidly (Fig. 5).

Profiles for the specific growth rate, specific oxygen uptake rate, biomass concentration, oxygen uptake rate, and volumetric coefficient for oxygen transfer in relation to time, during the cultivation of the fungal species Rhizopogon nigrescens CBMAI 1472 at 25 ± 1 °C, with airflow rates of 0.2 (a) and 0.52 vvm (b)

Since the viscosity of the medium is practically constant under the operational conditions (unpublished data), the small reduction in the values of k L a, in average 5.3 % (Table 3), are due, also, to the increase in biomass, which, in turn, favors the coalescence of air bubbles. This outcome is produced by the reduction in the volume available for such bubbles to be formed and by the biomass that is formed over the air supplier, altering, therefore, the pattern for the formation of the air bubbles. According to Jin et al. (2001), major variations for this term are observed in viscous liquids. The shortest time for cultivation, obtained with the maximum oxygen availability when the unit was operated under the airflow rate of 0.52 vvm, allowed for a 7.5 % higher conversion Y X/S (Fig. 6), certainly due to the smaller energy supply required for the maintenance of the cells.

Figure 7 shows some aspects of cultivation, highlighting the evolution noticed in the pellet size between the initial (a) and the final (b) phases. Differences observed in the pellet’s pigmentation, due likely to the increase in the metabolite concentrations, are underlined. Figure 7c depicts the foam formed during cultivation, and Fig. 7d shows the biomass adhered to the top of the bioreactor, one of the main difficulties encountered when growing filamentous fungi. Figure 8 shows pellets of biomass from different sizes sectioned at different cultivation times (4, 7, 9, and 11 days) and stained using triphenyl tetrazolium chloride (TTC). The image shows clear internal regions, illustrating loss of viability: The larger the pellet, the larger the non-viable region. With TTC, viable cells produce an intensely red coloration.

Images from a cultivation of the fungal species Rhizopogon nigrescens CBMAI 1472 in an airlift bioreactor set at airflow rates of 0.2 vvm. a Four and b 10 days after cultivation, seen through the central glass visor. Notice clear changes in color; c formation of foam, seen through the upper glass visor; d upper view of the bioreactor opened, after the removal of biomass, showing remains of biomass trapped to the body of the bioreactor

Viability assay using a vital dye (TTC) that shows viable hyphae intensely red. Biomass pellets of the fungal species Rhizopogon nigrescens CBMAI 1472 with diameters from 1.6 to 4 mm, measured previously transversal sectioning. From left to right pellets sampled at 4, 7, 9, and 11 days of cultivation, with an airflow rate of 0.2 vvm

Discussion

To the best of our knowledge, no studies have been reported in the literature about mass transfer during the cultivation of ECM fungi. Furthermore, few are those that present information on the growth rate of those microorganisms. Moreover, this type of study exemplifies a few particular difficulties. Among them are the slow growing feature, which is intrinsic to these fungi, and the cultivation time, which is measured in days, rather than in hours. One additional struggle is related to the type of bioreactor employed for fungal growth. Airlift bioreactors are only used in ca. 5 % of the bioprocesses known, indicating that more research is needed to intensify their application on a larger scale.

Rossi (2006) presented a stoichiometric evaluation related to fungal development, pointing for the fact that the gaseous balance method (Badino et al. 2000, 2001) cannot be employed in studies aiming to determine the values for oxygen transfer. He indicates that the difference in oxygen concentration between the entrance and the exit is close to the experimental error value, making it impossible to be used. Therefore, in this study, the oxygen transfer values were determined using the dynamic method taking into account the considerations and corrections proposed elsewhere (Rossi et al. 2015). One particular issue is the fact that the biomass cannot be kept in suspension throughout the development of the assay. Furthermore, for the oxygen mass balance in the liquid phase, the composition of the gaseous phase in the riser was considered constant, since only a small fraction of oxygen from the air that enters the bioreactor is transferred to the liquid (Chisti 1989). Additionally, for large and for tall airlift bioreactors, a special consideration must be made due to the existence of an axially variable C S as a function of the hydrostatic pressure variation.

Despite the studies pointing for the important effects following the introduction of ECM fungi, the technology available for the development of fungal inoculum is still insipient. Among the few studies that aimed on producing ECM inoculum, we can describe two developed in Brazil for species of Pisolithus. The first, carried out by Pradella et al. (1991), used a 3-L stirred tank bioreactor operated with an airflow rate of 0.27 vvm at 300 rpm. The system was set to operate in repetitive batches: The biomass obtained from the most productive phase was used to inoculate a second bioreactor, and from that a third, and so on. For that study, the best results showed a maximum cell concentration of 3.3 g/L and productivities of 0.15 g/L/day. In the second study, Rossi et al. (2002), using a 2.3-L airlift bioreactor with external circulation (prototype for the bioreactor used in the present study) operating at airflow rates of 0.34 vvm, obtained maximum cell concentration of 5.0 g/L and productivities of 0.48 g/L/day.

Besides the increase in biomass concentration and the subsequent rise in DO consumption, presented earlier, the enlargement and sturdiness of the fungal pellets, as a function of time of cultivation (Rossi et al. 2002), also imposes additional limitations to the transfer of oxygen all the way to the interior of the compressed, agglomerated hyphae. These observations were fundamental for the interpretation of the kinetics of the process. These conditions limit the cultivation of such organisms for longer periods. As suggested previously (Rossi 2006), the maximum concentration of carbon in the culture medium in batch cultivation should be around 16 g/L. This value can vary slightly as a function of the morphology of each fungal isolate. Therefore, considering an acceptable biological quality, the largest practical cellular concentration that can be obtained for ECM fungi cultivated in submerged medium is 7.0 g/L.

According to Rossi (2006), the maintenance of the fungal viability is one of the critical issues while developing a microbial-based inoculant. Cell fragmentation is a necessary step of the process, and independently of time of fragmentation (unpublished data), substances released by fragmented hyphae become toxic, which causes a fast and irreversible cell viability loss. This effect is so significant that the addition of activated charcoal is fundamental during the biomass production and inoculum manufacturing. Although short periods of fragmentation (e.g., 10 s in blender) do not solve the viability problem, well-fragmented biomass is essential for the growing kinetics of ECM fungi, especially when considering that the formation of the pellets deteriorates the mass transferring conditions. This is particularly important since critical oxygen levels are observed in the inner portion of the pellets, resulting in productivity cutbacks. Independent of the microorganism, the amount of biomass that composes the inoculum directly affects the time of cultivation, but not the specific growth rate. Furthermore, for ECM fungi, it also impacts the size of the pellets, which, as previously discussed, affects the conditions for mass transfer and, therefore, specific growth rate (see Table 3).

By looking at Q O2 = f(t) (Fig. 5), we can notice the difficulties for the interpretation of the data, since some variables, such as pH, metabolite increment, and fluid dynamics, the latter two can be clearly noticed by changes in color (Fig. 7), flux pattern variation as a function of pellet size, etc., are simultaneously involved. For the cultivation under 0.2 vvm, the values of Q O2 remain practically constant until the sixth/seventh day of cultivation, starting to decrease from about that moment. This reduction can be associated with the increase in the pellets’ size, and the reduction of DO, which, from this point, reaches values under 70 % of saturation (7.5 mg O2/L in saturation) (Rossi et al. 2015). Furthermore, it can also be associated with the pH values that seem to become limiting below 4.5, since both cultivations showed a more noticeable reduction when this pH value was reached. Surprisingly, for the airflow rate of 0.52 vvm, this behavior was observed even for very similar values of DO, even though noticed only between the third and the fourth days of cultivation (Figs. 4 and 5).

The constant variation for the specific oxygen uptake rate, together with the specific growth rate, indicates an undefined exponential phase for the study. The consumption of oxygen increased throughout the cultivation, even when Q O2 decreased, indicating a progressive increase in the cellular concentration (X). For this reason, in order to maintain the cultivation under non-limiting conditions, we must project the transfer system to attend the highest value of Q O2 X (Schmidell 2001). For a better comparison, Table 3 shows the values of different terms obtained in the two separate cultivation settings. An interesting coherence is seen between the duplication of the specific growth rate and the duplication of the specific oxygen uptake rate, corroborating the data obtained in the special conditions necessary for their determination (Rossi et al. 2015). In this analysis, the time of cultivation was practically reduced in half, duplicating, therefore, productivity. The largest variation in the k L a value for the cultivation under the smaller airflow rate could be justified by the losses noticed in the fluid dynamic quality. This is a function of the biomass that was trapped to the body of the bioreactor (Fig. 7). This adherence was more pronounced in cultivations done in longer time spans.

Due to the limitations in the supply of oxygen, the stationary state observed during the assay, where the biomass concentration does not vary, was established at a higher DO level than that detected in the beginning of the experiment (Fig. 2). The reduction in the respiratory metabolism is an indicative that the critical point was reached. However, it is not possible to infer in which oxygen concentration that happened. Due to the biomass sedimentation, the initial reduction in the respiration rate can be mistaken with the reduction in the biomass concentration in the zone where the probe is mounted. The time elapsed for the determination of C p after the interruption in aeration, defined elsewhere (Rossi et al. 2015), was 2 min, while the assay to determine C crit took over 8 min to be completed.

One possible solution for the determination of C crit would be to take a volume from the cultivation and reproduce the assay using a magnetic stirring system fitted with atmosphere and temperature controls. Nevertheless, an increase in pellet size and density was detected during cultivation, aggravating the conditions for mass transfer (see Fig. 5). This phenomenon requires a higher dissolved oxygen concentration to compensate for the ever-increasing transport resistances, making C crit variable, and, therefore, uncertain. This condition is expected for any submerged cultivation of ECM, pellet-forming fungi.

Considering a critical oxygen concentration of 50 % saturation value for fungal development at 0.52 vvm, if interruption in aeration occurs, oxygen limitation to the hyphae located in the pellet’s surface in the final moments during cultivation would be seen in less than 80 s following the event. This effect is even more pronounced in the core of the pellet (see Fig. 8). Because of the higher transferring resistances, oxygen limitation in the core of the pellet may happen even at higher levels of DO. During cultivation, biomass increases are generally a function of pellet size: The bigger the pellet, the larger the biomass. This, in turn, reduces the relation between area and volume and therefore the contact with the stirred liquid, which, consequently, increases mass transfer resistance. To better illustrate this situation, consider the example of a cultivation set at a flow rate of 0.2 vvm, where the average oxygen consumption, in relation to the amount that enters the bioreactor, is 0.28 % only. This extremely low amount is a characteristic of pneumatic reactors, in which airflows are big and the coefficients of oxygen transfer (k L a) are small, being the opposite of what is seen in stirred tank bioreactors.

The reduction of k L a contributes to a drop in the DO levels. This reduction, associated with the increase in consumption caused by biomass increases, brings the DO to limiting levels, reflecting the continuous drop of Q O2 , which is more accentuated from half way through the cultivation process and, consequently, affects the specific growth rate (μ X ). These results confirm that oxygen is one of the main limiting factors affecting the growth of fungi in submersed cultivation. The two airflow rates employed in this study were established to understand these questions. However, assuming critical DO concentrations in the order of 50 % saturation, this value can be settled as the control set point so that the airflow may be automatically increased as a function of increased demand, while maintaining the concentration above the critical level.

Considering average conditions, the airlift bioreactor utilized in this study can operate at airflow rates of up to 1.4 vvm, creating k L a values in the order of 80/h, which is 30 % higher than the observed for cultivations set at 0.52 vvm. Acceptable operational conditions for this type of bioreactor occur when low aerosol formation is seen in the gas separator. Furthermore, in bioreactors operating with internal pressure of 1.2 atm, ca. 0.19 above the normal cultivation settings described earlier, it is possible to increase the oxygen availability to the fungi in more than 18 %. Even though it is difficult to determine the Q O2 under such conditions since there is a large oxygen loss upon depressurization, altering the consumption measurements, this is the most simple way to supply more oxygen and, therefore, assure oxygen concentrations above critical. Although, in batch cultivations, it is normal that the conditions deteriorate with time, such as the nutrient depletion and metabolite accumulation, the process can be projected in a way as to allow for maximum yield and biological quality, which are dependent on the amount of available oxygen.

Our results indicate that successful inoculant production for ECM fungi can be done in airlift bioreactors utilizing at least 0.5 g/L of a well-fragmented fungal biomass as initial inoculum. The results further indicate that more diluted media will result in smaller pellets, amplifying the mass transfer area. Considering the oxygen transfer coefficients obtained in this study, large-scale productions must anticipate airflow rates that generate k L a values above 55/h to avoid insufficient oxygen concentration for the development of the fungal cell. Likewise, maintaining the pH into a frame acceptable to the fungi is important. For the values of k L a typical of recirculating pneumatic bioreactors, the real values for the dissolved oxygen concentration can be obtained directly from the probes, considering that they are reliable.

References

Badino AC, Facciotti MCR, Schmidell W (2000) Improving kLa determination in fungal fermentation, taking into account electrode response time. J Chem Technol Biotechnol 75(6):469–474

Badino AC, Facciotti MCR, Schmidell W (2001) Volumetric oxygen transfer coefficients (kLa) in batch cultivations involving non-Newtonian broths. Biochem Eng J 8(2):111–119

Burgess TI, Malajczuck N, Grove TS (1993) The ability of 16 ectomycorrhizal fungi to increase growth and phosphorus uptake of Eucalyptus globulus Labill. and E. diversicolor F. Muell. Plant Soil 153(2):155–164

Chisti MY (1987) Airlifts reactors: characteristics, applications and design considerations. Chem Eng Comm 60:195–242

Chisti MY (1989) Airlift bioreactors. Elsevier Applied Sciences, London

Finn RK (1967) Agitation and aeration. In: Blakebrough N (ed) Biochemical and biological engineering science. Academic Press, London, pp. 69–99

Gandini AMM, Grazziotti PH, Rossi MJ, Grazziotti DCFS, Gandini EMM, Silva E de B, Ragonezi C (2015) Growth and nutrition of eucalypt rooted cuttings promoted by ectomycorrhizal fungi in commercial nurseries. Rev Bras Ciência do Solo 39:1554–1565

Garbaye J (1984) Competitivité des champignons ectomycorhiziens: prèmiers résultats et application à la sélection de souches pour la mycorhization contrôlée du hêtre et du chêne rouvre dans le nord-est de la France. Rev For Fr 1:33–43

Garcia-Ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27(2):153–176

Giachini AJ, Souza LA, Oliveira VL (2004) Species richness and seasonal abundance of ectomycorrhizal fungi in plantations of Eucalyptus dunnii and Pinus taeda in southern Brazil. Mycorrhiza 14:375–381

Jin B, Yu Q, Yan XQ, van Leeuwen JH (2001) Characterization and improvement of oxygen transfer in pilot plant external air-lift bioreactor for mycelial biomass production. World J Microbiol Biotechnol 17(3):265–272

Krahe M (2003) Biochemical Engineering. In: Ullmann’s Encycl Ind Chem. Wiley-VCH Verlag GmbH & Co, Weinheim

Kuek C, Tommerup IC, Malajczuck N (1992) Hydrogel bead inocula for the production of ectomycorrhizal eucalyptus for plantations. Mycol Res 96(4):273–277

Le Tacon F, Garbaye J, Carr G (1987) The use of mycorrhizas in temperate and tropical forests. Symbiosis 3:179–206

Leduy A, Zajic JE (1973) A geometrical approach for differentiation of an experimental function at a point: applied to growth and product formation. Biotechnol Bioeng 15:805–810

Malajczuck N, Lapeyrie F, Garbaye J (1990) Infectivity of pine and eucalypt isolates of Pisolithus tinctorius on roots of Eucalyptus urophylla in vitro. New Phytol 114(4):627–631

Marx DH (1969) The influence of ectotrophic mycorrhizal fungi on the resistance of pine roots to pathogenic fungi and soil bacteria. Phytopatol 59:153–163

Pradella JGD, Zuccolo M, Lopes SAR, Oliveira MS (1991) Pisolithus tinctorius vegetative mycelia production: effects of nitrogen sources and cultivation in stirred tank fermenter. Rev Microbiol 22(1):7–11

Rossi MJ (2006) Tecnologia para produção de inoculantes de fungos ectomicorrízicos utilizando cultivo submerso em biorreator airlift. Thesis, Universidade Federal de Santa Catarina. http://www2.enq.ufsc.br/teses/d035.pdf

Rossi MJ, Oliveira VL (2011) Growth of the ectomycorrhizal fungus Pisolithus microcarpus in different nutritional conditions. Braz J Microbiol 42(2):624–632

Rossi MJ, Souza JAR, Oliveira VL (2002) Inoculum production of the ectomycorrhizal fungus Pisolithus microcarpus in an airlift bioreactor. Appl Microbiol Biotechnol 59(2):175–181

Rossi MJ, Cardoso Cortez DH, Giachini AJ, Oliveira VL, Furigo A Jr (2015) Evaluation of different pre-setting conditions in airlift bioreactor to determine the respiratory kinetics of fungi. J Adv Biotechnol 5:625–633

Rossi MJ, Nascimento FX, Giachini AJ, Oliveira VL, Furigo A Jr (2016) Airlift bioreactor fluid-dynamic characterization for the cultivation of shear stress sensitive microorganisms. J Adv Biotechnol 5:640–651

Schmidell W (2001) Agitação e aeração em biorreatores. In: Schmidell W, Lima UA, Aquarone E, Borzani E (eds) Biotecnologia Industrial Vol II: Engenharia Bioquímica. Edgard Blücher Ltda, São Paulo, pp. 277–331

Whitman WG (1923) The two-film theory of gas absorption. Chem Metall Eng 29:146–148

Acknowledgments

The authors gratefully acknowledge the Brazilian “Conselho Nacional de Ciência e Tecnologia (CNPq)” and the “Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina (FAPESC)” for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 194 kb)

Rights and permissions

About this article

Cite this article

Rossi, M.J., Nascimento, F.X., Giachini, A.J. et al. Transfer and consumption of oxygen during the cultivation of the ectomycorrhizal fungus Rhizopogon nigrescens in an airlift bioreactor. Appl Microbiol Biotechnol 101, 1013–1024 (2017). https://doi.org/10.1007/s00253-016-7854-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-7854-4