Abstract

Microgravity and simulated microgravity (SMG) have quite significant effects on numerous microbial cellular processes. The effects of SMG on the production of recombinant proteins and transcription profiling in prokaryotic and eukaryotic expression host have been investigated. The present study showed that SMG significantly enhanced the specific productivities and activities of the reporter enzymes PGUS and AtXYN that were expressed in recombinant Pichia pastoris. Proteomic profiling revealed that 21 proteins were significantly up-regulated and 35 proteins were drastically down-regulated at the stationary phase, when the recombinant P. pastoris responded to SMG. Six strongly up-regulated genes, TPX, FBA, PGAM, ENO, SBA1, and AKR-E, involved in the oxidative stress response, methanol metabolism, glycolytic pathway, and protein folding, were selected to analyze their impacts on recombinant protein production by co-overexpression in the shaker flask fermentation. The co-overexpressed strains, particularly TPX, FBA, and PGAM, demonstrated promising results with approximately 2.46-fold, 1.58-fold, and 1.33-fold increases in the specific yields of PGUS compared to the control after 48 h of methanol induction, respectively. In the meantime, the corresponding PGUS specific activities were increased by 2.33-fold, 2.09-fold, and 1.32-fold, respectively. Thiol peroxidase (TPX), which is involved in the oxidative stress response, significantly influenced the transcriptional levels of the reporter gene PGUS. The present study provides valuable information for further exploration of the molecular mechanism of P. pastoris response to SMG and facilitates simulated microgravity for finding novel helper factors to rationally engineer the strains in normal fermentation by using proteomic studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the past several decades, Pichia pastoris has become an attractive eukaryotic host for the cost-efficient production of heterologous proteins due to the availability of the strong inducible and constitutive promoters and high cell density production protocols. Nevertheless, there is evidence of major bottlenecks to heterologous protein production (Thomas et al. 2013). It has been demonstrated that correct protein folding and secretion were highly interrelated with environmental stress factors. Scientists have investigated the impact of environmental perturbations, such as temperature, osmolality, and oxygen availability, on recombinant protein production by “omics” data mining and re-engineering yeast strains (Baumann et al. 2010). Dragosits et al. investigated the effects of temperature and osmolality on the transcriptome, proteome, and fluoxome of recombinant P. pastoris (Dragosits et al. 2009, 2010). Gasser et al. selected a range of significantly regulated genes based on the transcriptional profile under stress conditions and tested their Saccharomyces cerevisiae homologues for co-expression in a recombinant P. pastoris strain (Gasser et al. 2007). These studies demonstrated that the environmental stress on protein production conditions could provide important platforms to identify helper targets for cell engineering.

Simulated microgravity (SMG) is an exceptional environmental condition that can be modeled by special bioreactors in ground-based experiments. One such bioreactor is Rotary Cell Culture System (RCCS, Synthecon Inc., NASA), using High Aspect Ratio Vessel (HARV) to model the environment of microgravity on the ground. The RCCS randomizes the unidirectional gravitational force, minimizes turbulence of the fluid shear levels on the cell surface, and creates the net effect of “functional weightlessness” (Sheehan et al. 2007). The suspension culture system also provides efficient gas exchange, which is necessary for rapidly dividing cells, through a permeable membrane at the back of the HARV. The SMG and normal gravity (NG) control environment are created when the HARV is rotated horizontally (with the axis of the vessel perpendicular to the gravitational force) and vertically (with the axis of the vessel parallel to the gravitational force), respectively. In SMG, sedimentation, which leads to the different dispersion of nutrients and wastes within the vessel, is prevented. Previous studies showed the response of a variety of microorganisms to the reduced gravity in the form of variations in physiological characteristics and perturbations at the molecular levels (Nickerson et al. 2003, 2004). Furthermore, multiple research approaches reported microgravity effects in the fields of materials (Vailati et al. 2011) and space medico-engineering (Sanderson 2011).

Microbial glycoside hydrolases (GH) are industrial enzymes for biocatalysis and biotransformation of medicinal products. GH also occupies an important place in biomass utilization in biofuel applications. β-Glucuronidase from Penicillium purpurogenum Li-3 (PGUS) could directly biosynthesize glycyrrhetinic acid monoglucuronide (GAMG) from glycyrrhizin (GL) (Feng et al. 2006). GAMG is useful in the clinical treatment of inflammatory diseases; it is safer, more effective, and more absorbable than GL. In the xylan degradation process, endo-β-1, 4-xylanase plays an important role in efficient hydrolysis of this renewable source and abundant agricultural waste. It randomly cleaves the β-1, 4-glycosidic linkages of xylan into short xylo-oligosaccharides. Therefore, for sustainable and economical biotechnology processes, large amounts of hemicelluloses with low costs are highly desirable (Guo et al. 2013). P. pastoris has been considered as a good expression system for the heterologous production of the glycoside hydrolases due to its potential for higher protein productions and increasing specific activities that consequently reduced the cost. However, not all of the enzymes and biopharmaceutical proteins can be efficiently produced by P. pastoris. Developing new methodologies to improve industrial enzyme production has become a new research area.

In our latest published work, the beneficial impact of SMG on the secretion of the recombinant PGUS from P. pastoris in RCCS has been reported. The efficiency of PGUS secretion was enhanced up to 30 % under SMG. Comparative analysis of the transcriptomic data was performed to assess the behavior of P. pastoris in response to SMG (Qi et al. 2011a, b). The results indicated that the up-regulated genes of methanol metabolism, protein transportation, and secretion mainly contributed to enhanced production and secretion of the recombinant protein under SMG. However, a more detailed analysis of the mechanism of P. pastoris sensing microgravity and how the cells convert these mechanical signals into molecular responses to impact recombinant protein production needs to be further investigated. Conversely, little effective progress has been achieved regarding the utilization of reduced gravity effects in the fermentation industry. Therefore, it is imperative to unravel the global mechanism connecting protein production to environmental conditions and engineer the P. pastoris strain by introducing the new helper genes. In this study, for the first time, we examined the proteomic profiling of the SMG cultured recombinant P. pastoris and then identified potential helper genes by gene co-expression.

Materials and methods

Strains cultured under SMG condition

The two recombinant P. pastoris strains P. pastoris-PGUS (pgus/pPIC9k GS115) expressing the β-glucuronidase (PGUS) derived from P. purpurogenum Li-3 (GenBank accession no. EU095019) and P. pastoris-AtXYN (atxyn/pPIC9k GS115) expressing the endo-β-1, 4-xylanase (AtXYN) derived from At. terreus Li-20 (GenBank accession No.JQ087496) were previously described (Qi et al. 2011a; Guo et al. 2013). The reporter genes were both ligated into pPIC9K and integrated into the AOX1 loci of the yeast genome. The production of the recombinant proteins was tightly regulated by the methanol inducible promoter AOX1. Conditions referred to as SMG were created by rotating the HARV in a horizontal direction perpendicular to the gravitational vector on rotating cell culture systems (RCCS-4H, 50 ml; Synthecon, USA). The NG control environment was created by vertical rotation. The rotation speed was kept at 15 rpm for efficient production of the recombinant protein. A single colony of recombinant P. pastoris was isolated from the YPD (1 % yeast extract, 2 % peptone, 2 % glucose, and 2 % agar) plate and inoculated with 200 ml of YPD medium in a 250-ml shaker flask at 28 °C, and 220 rpm for 24 h to OD600 = 13–16. The seed liquid cells were diluted (1:100) and re-suspended in 100 ml YPD medium (OD600 = 0.5–0.8). Then, aliquots of the YPD cultures were loaded into two sterile HARV vessels that were completely filled with 55 ml of medium for SMG and NG, respectively. Both HARV vessels were incubated at the speed of 15 rpm and 28 °C for 48 h. The cells were then harvested by centrifugation at 5,000 rpm for 5 min, washed twice with phosphate buffer (100 mM, pH 6.0), and re-suspended in 55 ml of BMMY medium (1 % yeast extract, 2 % peptone, 100 mM phosphate buffer saline, pH 6.0, 1.34 % YNB, 1.61 μM biotin, 1 % methanol). The BMMY medium was loaded into two HARV vessels for SMG and NG cultivation, respectively. All bubbles were removed to reduce shear using a sterile disposable syringe. Methanol was added every 12 h to a final concentration of 1 %. One milliliter of culture medium was sampled every 24 h, centrifuged at 5,000 rpm for 5 min at 4 °C, and the supernatant was analyzed for the specific productivities of reporter enzymes. The cultured processes were carried out in triplicate.

Cell density, protein production analysis, and enzyme assay

Cell density was tested periodically by measuring the OD600 using an ultraviolet spectrophotometer (Hitachi) and the dry cell weight was determined through the standard curve. The total crude protein concentration was determined using a BCA Protein Assay Kit (Applygen, China). Semi-quantitative determination of recombinant protein concentration was analyzed by SDS–PAGE and quantified by densitometric analysis with a ProExpress Imaging System (PerkinElmer, USA). TotalLab100 version 2006 software was used after the staining with Coomassie brilliant blue R250 (Qi et al. 2011a). Bovine serum albumin was used as an internal standard. The β-glucuronidase activities and the xylanase activities were assayed using HPLC (Shimadzu, Japan) and micro-plate reader (Biotek, USA), respectively. All the experiments from the biological samples were carried out in triplicate.

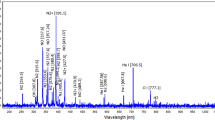

The β-glucuronidase activities were determined by the hydrolysis of GL (China). The assay mixture consisted of 100 μl of enzyme solution and 400 μl of 2 g/l GL (pH 5.0). After incubation at 55 °C for 30 min, the reaction was stopped by heating in boiling water for 5 min and then centrifuged at 10,000 rpm for 5 min. The supernatant was used for enzyme activity analysis using HPLC. The reaction mixture (10 μl) was subjected to reverse-phase HPLC with a C18 column (4.6 × 250 mm, 5 μm particle size; Kromasil, Sweden) at 40 °C. Separation was achieved with a mobile phase consisting of a mixture of methanol–0.6 % acetic acid in water (81:19 v/v) at 25 min. Elution was monitored with UV detection at 254 nm. The amount of GAMG could be read from the standard curve between the peak area and concentration of GAMG. One unit (U) of activity was defined as the amount of enzyme that released 1 μmol of biosynthesized GAMG in the reaction mixture per minute (Feng et al. 2006). The xylanase activities were assayed using birchwood xylan (Sigma, USA) as the substrate (Bailey et al. 1992). The amount of reducing sugars released was determined by the standard dinitrosalicylic acid method. One unit of xylanase activity was defined as the amount of enzyme producing 1 μmol of reducing sugar (xylose) from the substrate solution per minute under the assay conditions.

Proteomic analysis

Samples for proteomic analysis were harvested at the steady phase and mid-exponential growth phase of P. pastoris-PGUS in SMG and NG conditions. Continuous dilutions were performed after every 48 h of methanol induction to guarantee all the cells were maintained in the steady phase by monitoring the optical density. After four repeated processes, the culture medium was sampled and centrifuged at 8,000 rpm for 15 min at 4 °C, and then pellets were washed with PBS (100 mM, pH 7.0), frozen, and stored at −80 °C for further proteomic analysis. To obtain the cells in the mid-exponential phase, four repeated 12 h of methanol induction processes were carried out. Cell extraction was performed with the lysing buffer: 8 M urea, 65 mM DTT, 0.1 % Triton X-100, 100 mM NaCl, 50 mM Tris–HCl, 1 mM PMSF, 1 mM EGTA, and 1 mM EDTA (pH 7.4). The supernatant was kept to determine the protein content, and then precipitated by chloroform/methanol treatment, followed by re-dissolution in 0.2 ml buffer containing 8 M urea and 50 mM Tris–HCl (pH 8.2). The protein samples were treated with DTT at 37 °C for 2 h, followed by iodoacetamide (IAA) at room temperature in the dark for 40 min. Then, the solutions were diluted 8-fold using 50 mM Tris–HCl (pH 8.2) and subjected to trypsin digestion (trypsin/protein, 1:50, w/w) at 37 °C for 20 h. The tryptic digests were desalted with C18 solid-phase cartridges and lyophilized. Protein analysis technology was used by a 2D nano-LC–MS/MS system (Thermo, USA). The acquired MS/MS spectra were searched against the uniProt database (http://www.uniprot.org/) and the Pichia database (http://www.pichiagenome.org/) using the TurboSEQUEST (version 3.2) and XTandem software. The results were filtered using the SFOER software with optimized criteria, and the corresponding FDR was below 1 %. Proteins with a fold change >2, and a P value <0.05 for the t test of each of the two samples were assigned as differentially expressed.

Construction of engineered vectors for co-overexpression

Six host-specific regulated helper genes based on proteomic profiling data analysis were amplified from P. pastoris GS115 (Invitrogen, USA) genomic DNA. The list of the helper genes of interest and the corresponding primers of the restriction sites (EcoRI, XbaI, and KpnI) are given in Table S1. The helper genes were cloned into the vector pGAPZB (Invitrogen, USA), which confers resistance to zeocin in bacteria and in yeast. The verified plasmids containing the genes of interest were linearized with AvrII and transformed by a Gene PulserXcell™ Electroporation System (Bio-Rad, USA). The transformed DNA fragments were integrated into the GAP loci of the recombinant P. pastoris-PGUS and the recombinant P. pastoris-AtXYN genome. Large colonies of reconstructed yeast strains on zeocin (Invitrogen, USA, 50 μg/ml) YPD agar plates were picked after 2–3 days, and the genomic DNA was extracted and checked for correct integration by PCR with the pGAPZB primers. The copy numbers of obtained transformants were quantitatively determined by real-time quantitative PCR. Single clone was inoculated in 50 ml BMGY medium in a 250-ml baffled shaker flask at 28 °C and 170 rpm for nearly 24 h. The cells were then harvested and suspended in 50 ml BMMY medium. Methanol was added every 12 h to a final concentration of 1 % for the reporter proteins PGUS and AtXYN production. After 48–96 h of induction, the culture medium was sampled and centrifuged at 5,000 rpm for 5 min at 4 °C to determine the specific productivities of the reporter enzymes. Each engineered strain was cultured through triplicate independent experiments. The cell density, protein production analysis, and enzyme assay were calculated as triplicate. The strain having the empty pGAPZB vector was set as control.

RNA extraction and qRT-PCR analysis

Yeast cells were harvested during the exponential growth phase. Approximately 1 × 107 cells were used for the total RNA extraction using a Yeast RNA Kit (Omega, USA). Genomic DNA contamination was eliminated by DNaseI (TaKaRa, Japan). RNA concentration was quantified by measuring the absorbance at 260 nm using a NanoDrop 2000c (Thermo, USA). The readings of extracted RNA samples between 1.5 and 2 were selected as the template for the Transcript First Strand cDNA Synthesis Kit (Roche, Swiss) and library construction. Single-stranded cDNA was used as a template in the real-time PCR analysis. The reaction conditions had been established as recommended by SYBR Premix Ex Taq TM manual (TaKaRa, Japan). All real-time qPCR reaction assays were performed in biological replicates to allow for statistical confidence in differential gene expression. Triplicate samples of each template were run on LightCycler 480 real-time System (Roche, Swiss) using fast 96-well plates. The data was analyzed using LightCycler Software (v.1.5). The housekeeping gene GADPH was used as a reference gene. The data was normalized using GADPH as the endogenous control. The reaction without reverse transcriptase was used as the negative control. The genes TPX and GUS were used as target genes. The obtained relative mRNA levels indicated the relative comparisons of transcription levels between the target genes and reference genes. The mRNA levels of TPX and GUS in each strain were calculated and converted into relative ratios following the comparative CT method. (The data from the real-time PCR was converted to 2−△△iCT[△△CT = CT(target) − CT(ref)] where CT represented the threshold cycle.)

GenBank accession numbers

The GenBank accession number of PGUS gene is EU095019, and the GenBank accession number of AtXYN gene is JQ087496. The GenBank accession numbers of TPX, FBA, PGAM, ENO, SBA1, and AKR-E gene for co-overexpression were XM_002491758.1, XM_002489668.1, XM_002493014.1, XM_002492248.1, XM_002490110.1, and XM_002493818.1, respectively.

Results

Yields and activities of reporter enzymes in P. pastoris under SMG

Two recombinant P. pastoris strains, producing the β-glucuronidase (PGUS) and the endo-β-1, 4-xylanase (AtXYN), were grown in the HARVs (RCCS-4H) to access the effect of the simulated microgravity culture environment on the cell growth and recombinant protein production. Glucose and methanol were used in a two-phase feeding to produce heterologous proteins in P. pastoris.

In the P. pastoris system, the expression of foreign genes is usually driven by the outstanding promoter of the alcohol oxidase I (AOX1) gene, which encodes the first enzyme in the methanol utilization pathway. The AOX1 promoter is transcribed only in response to methanol and repressed by other carbon sources, such as glucose, fructose, or glycerol. However, P. pastoris grows slowly when using methanol as the sole source. Therefore, the general cultivation of methanol-inducible P. pastoris is by two-step fermentation conditions: (1) firstly, glucose, glycerol, or sorbitol is used as the main initial carbon source for increasing the cells concentration until it is exhausted or removed by washing with PBS buffer; (2) secondly, the inducer methanol is added for recombinant protein production. In this study, we used glucose instead of the traditional source of glycerol in the first stage. The interpretation was that the recombinant protein was not induced under SMG when glycerol was used. The catabolic repression from glycerol was not completely solved under SMG.

The recombinant P. pastoris was cultured in the first stage for 48 h, in which glucose was used as the sole carbon source. Then, the strains were harvested and methanol instead of glucose was used in the second stage for 72 h to induce the recombinant proteins continuously. The growth curves of P. pastoris strains in SMG were different from NG, showing shortened lag phase and prolonged exponential phase. After 48 h of methanol feeding, the strains reached the steady-state phase under SMG and NG. After methanol feeding for 12 h, the strains were at the mid-exponential growth phase under SMG and NG (Fig. 1). The physiological parameters of two recombinant strains are shown in Table 1. The recombinant protein concentration was analyzed by SDS–PAGE (Fig. S1) and semi-quantitative measuring methods. The AtXYN and PGUS yields were 0.31 ± 0.04 and 0.39 ± 0.05 mg/ml after methanol feeding of 48 h under SMG, which were about 2.81-fold and 2.43-fold increases in comparison to the NG control, respectively. Compared to the NG control, the SMG environment increased the specific productivities of both enzymes.

Proteomic analysis

In this study, we first examined the physiological changes of recombinant P. pastoris grown in SMG, and then we explored the proteomic profiling to identify the significant genes with changes in protein expression in response to modeled microgravity. According to a previous study, the efficiency of recombinant protein production at the steady-state phase, after methanol feeding for 48 h under SMG, was significantly higher than NG. The steady-state phase seemed to be a better time point to investigate microgravity effects on the heterologous protein production in P. pastoris. Furthermore, the cells at the mid-exponential growth phase of methanol feeding for 12 h was chosen as another time point. Of total proteins, 218 differentially expressed proteins in the steady stationary phase and 72 proteins in mid-exponential growth phase were identified (FDR < 1 %, RSD < 0.5) (Table S2, Table S3). Twenty-one proteins were significantly up-regulated (ratio fold change >2) and 35 proteins were drastically down-regulated (ratio fold change <0.5) at the stationary phase (S). In addition, seven proteins were up-regulated at the mid-exponential growth phase (L). It was observed that SMG affected the gene expression of P. pastoris (Fig. 2). These differentially expressed proteins were classified into four functional categories: (1) methanol metabolism and carbohydrate metabolic process, (2) cell redox homeostasis and oxidative stress, (3) translation and protein folding-related, and (4) other metabolism and uncharacterized protein (Table 2).

Schematic representing some significant differences of proteins in the recombinant P. pastoris-PGUS on the proteomic levels under SMG and NG cultivation during the steady phase and the mid-exponential growth phase. Italics indicate the lower abundance under SMG. Italics in shadows indicate the higher abundance under SMG. Upward arrows indicate the genes chosen for co-expression

The enzymes involved in the carbohydrate metabolic process, including FBA, PGAM, PEPCK, ICL1, and ENO, were identified to be strongly induced at the stationary phase and mid-exponential growth phase under SMG. However, the alcohol oxidases (AOX1, AOX2) that were the major source of methanol-oxidizing activity in P. pastoris showed decreased levels at the stationary phase. On the other hand, seven proteins including GLTA, CTA, PYK2, SFA1, ATP1, FDH, and DAK involved in methanol metabolism were down-regulated at the stationary phase under SMG. At the expression levels, all of the six identified proteins involved in the response to cell redox homeostasis and oxidative stress, including COX12, TPX, QCR, LIA1, AKR-E, and GLO1, were significantly up-regulated under SMG compared to the NG control.

Notably, co-chaperones AHA1 showed strongly increased abundances at the stationary phase, and SBA1 was significantly up-regulated at the mid-exponential growth phase. Co-chaperone SIS1 was down-regulated at the stationary phase. The components of protein folding and secretion machinery were also differentially regulated by SMG cultivation. ARF1 and PSME4 were up-regulated at the stationary phase, whereas SHP1 was down-regulated at the stationary phase. The expression levels of GLY1, MET17, YEF3, and elongation factor TUF1 involved in amino acid metabolism were decreased during SMG cultivation at the stationary phase. Translation initiation factor HYP2 and TAD1 were up-regulated at the mid-exponential growth phase and the stationary phase. The levels of ribosomal proteins RPL5, RPS7, RPS12, RPS21, and RPS29 were up-regulated at the mid-exponential growth phase. RPL8, RPL9, RPL11, RPL32, RPS4, RPS7, RPS10, RPS15, RPS17, RPS24, and RPS25 were down-regulated at the stationary phase. There were also other cellular mechanisms that seemed to be affected by SMG at the proteomic levels, like 6, 7-dimethyl-8-ribityllumazine synthase (RIB4) involved in riboflavin production and dihydrokaempferol 4-reductase (DFR) involved in flavonoid biosynthesis metabolism. The protein FPR1 involved in DNA mechanisms was up-regulated at the mid-exponential growth phase.

The detailed analysis of proteomic data mining could provide a library of potential helper genes for the improvement of yeast P. pastoris. Focusing on up-regulated genes, which have potential functions in the carbohydrate metabolic process, secretion machinery, and stress regulation, six potentially superior up-regulated genes (TPX, FBA, PGAM, ENO, SBA1, and AKR-E) were selected for further analysis of effects on the recombinant protein production by co-overexpression methods.

The effects of co-overexpressing helper genes on recombinant PGUS production in P. pastoris

The strains harboring a single copy of the helper genes were screened for testing protein expression changes. The strains were obtained via integration of the GAP loci of a single copy of the helper genes. The helper genes were expressed under the control of a constitutive promoter of GAP in vivo and to detect their functions on the production and secretion of reporter enzymes which were expressed using the methanol-inducible promoter AOX. The PGUS secretion capacities of verified clones were performed in methanol batch cultivation using baffled shaker flasks. The strains overexpressing TPX, FBA, and PGAM genes demonstrated improved recombinant protein production after 48 h of methanol induction. Approximately 2.46-fold, 1.58-fold, and 1.33-fold increases in the PGUS specific yields were achieved compared to the control without co-overexpressing genes. However, the clones of co-overexpressing AKR-E and ENO showed the disadvantageous rather than beneficial effects. Overexpressing the molecular chaperone SBA1 significantly increased the PGUS up to 0.25-fold (Fig. 3a). The protein production capacities of positively impacted genes were measured by SDS–PAGE stained by Coomassie brilliant blue R250 and semi-quantitative determination (Fig. 3b). TPX, FBA, and PGAM enhanced PGUS specific activities to about 2.33-fold (49.16 U/mg), 2.09-fold (44.14 U/mg), and 1.32-fold (27.93 U/mg) compared to the control (21.09 U/mg) (Fig. 4). Overall, the TPX overexpressing mutant clone seemed to favor PGUS secretion more significantly than other target genes.

The PGUS specific yields of the strains co-expressing different target genes. a The protein concentration of PGUS after 48 h of methanol induction. The yield ratios were relative to the control strain without co-expressing any target genes (value = 1). Data are represented as means ± standard deviation (SD), two-sided paired t test, P < 0.05 (∗). b Coomassie-stained SDS–PAGE (12 %) examination of the effective helper genes on the PGUS production (CK the control strain)

Time courses of the PGUS specific activities of the strains co-expressing the effective helper genes. Methanol concentration was maintained at 1 % at 12-h intervals. The every group of samples was compared with control strain without co-expressing any helper genes. Data are represented as means ± standard deviation (SD), two-sided paired t test, P < 0.05 (∗)

Transcriptional effects on the PGUS specific yields by different TPX gene copies

To further understand the TPX gene dosage effects on recombinant protein production, four recombinant P. pastoris clones Tpx-1, Tpx-2, Tpx-3, and Tpx-4 harboring disparate copies of TPX gene were cultured after methanol induction for 48 h in baffled shaker flasks (Fig. 5a). Compared to the control (strain without overexpressing helper gene cultured in normal fermentation condition), the strain (Tpx-1, two copies) showed the highest PGUS specific activity, while the strain (Tpx-4, 10 copies) exhibited the lowest PGUS specific activity (Fig. 5b). The higher transcriptional levels of the helper gene could not increase the specific protein yields. Notably, the transcriptional levels of the reporter gene PGUS seemed to be inhibited in the strains co-expressing the helper gene. In order to better evaluate the transcriptional effects, the strains without overexpression of the helper gene were cultured under SMG and NG environments as another two controls, respectively. The transcriptional level of TPX under SMG was much higher than NG, and the reporter gene PGUS under SMG was also higher than NG. The transcriptional level of the reporter gene PGUS in baffled shaker flasks control was higher than SMG control. However, the PGUS specific yields showed no significant difference under the two culture conditions.

Transcriptional effects on the PGUS specific activities by co-expressing different TPX gene copies. All the strains were harvested and their mRNA levels were tested by qRT-PCR after 48 h of methanol induction. a Comparison of the relative transcriptional levels of PGUS and TPX. b The PGUS specific activities of the strains harboring different TPX gene copies. (Tpx-1, Tpx-2, Tpx-3, and Tpx-4—four recombinant P. pastoris strains harboring 2, 4, 8, and 10 copies of TPX gene, respectively; CK-SF the control strain cultured in a baffled shaker flask; CK-SMG the control strain cultured under SMG; CK-NG the control strain cultured under NG. Methanol concentration was maintained around 1 % at 12-h intervals. Results are expressed relative to mean for the every control group samples for each gene. Data are represented as means ± standard deviation (SD). Paired comparing Tpx-1, -2, -3, -4 and CK-SF, two-sided paired t test, P < 0.01 (∗∗)

Verification of TPX transcription effects on reporter enzyme AtXYN production

Another reporter enzyme endo-β-1, 4-xylanase (AtXYN) was chosen to evaluate the potential benefit of the helper gene TPX in order to preclude a reporter protein-specific effect. PGAPZB-TPX plasmid was transformed into the P. pastoris-AtXYN strain. Eight verified clones co-overexpressing TPX were randomly chosen and cultured in baffled shaker flasks. After 48 h of methanol feeding, the xylanase specific activities were detected (Fig. 6). Only two TPX mutants (clone #1, clone #3) seemed to favor AtXYN specific activities, while the other five mutants showed a slight increase or negative impacts on AtXYN specific activities. The relative transcriptional levels of TPX were determined by qRT-PCR for the differentially AtXYN expressed clones. However, the differences of TPX mRNA levels were no quite significant (data not shown).

Identification of the TPX effects on AtXYN expression. Eight individual clones co-expressing TPX were used for a small-scale screening in baffled shaker flasks. The AtXYN specific activities were calculated after 48 h of methanol induction (U/mg). The specific activities were relative to the control strain without co-expressing any target genes (value = 1). Data are represented as means ± standard deviation (SD). There were no significant differences of the samples compared with the control strain (P < 0.05)

Discussion

As a unique environment, microgravity and simulated microgravity have significant effects on numerous microbial cellular processes. Changes in cellular functions include cell clumping, shortened lag phase and prolonged exponential phase in the gene expression, and protein folding to alter the productivities of the secondary metabolites in bacteria (Escherichia coli, Pseudomonas aeruginosa) and yeast (S. cerevisiae) (Benoit et al. 2006; Baker et al. 2004; Crabbé et al. 2011; Sheehan et al. 2007). Only a few studies have shown that microgravity can impact the heterologous proteins production, such as enhanced expression of the recombinant β-glucuronidase in E. coli, and β-galactosidase and glycodelin in human cells (Xiang et al. 2010; Stephen 2007). In contrast, some other studies indicated that SMG could not always promote protein expression (Boyle et al. 1995). In the present study, our results showed that SMG could facilitate the specific productivities of β-glucuronidase and endo-β-1, 4-xylanase. We hypothesized that the important reason for the enhancement of protein expression was the genomic response of yeast to microgravity. Our previous study revealed differentially regulated genes of the recombinant P. pastoris-PGUS under SMG by next-generation sequencing (NGS) technologies (Qi et al. 2011b). We summarized four categories of significantly changed genes. Most of the positive genes were related to methanol metabolism and protein transportation and were up-regulated in both the exponential and stationary phase. The capabilities of recombinant protein production were not just relative to the multiple metabolic processes but also subject to specific environmental disturbances and different protein properties (size, number of disulfide bonds and glycan). The low-shear fluid environment of SMG may alter the genes transcription, which modulates cell growth and correct protein folding.

Using the 2D nano-LC–MS/MS approach and sequence similarity search strategy, we first assessed and quantified the global protein expression patterns in the recombinant P. pastoris-PGUS cultured under SMG condition. The proteins involved in the glycolytic pathway showed higher expression levels under SMG, which indicated that SMG could increase the recombinant protein yields. Interestingly, the proteomic levels of alcohol oxidases were down-regulated at the stationary phase. However, the transcriptional levels of alcohol oxidase were 3.6-fold up-regulated at the logarithmic phase and 1.4-fold up-regulated at the stationary phase in our previous study (Qi et al. 2011b). The discrepant results were also found in some proteins involved in methanol metabolism according to the present proteomic profiling data. Our previous study suggested that the significant transcriptional changes of the methanol metabolism genes would cause faster oxygen and methanol uptake, which promotes transcription of the recombinant gene. Apparently, the proteomic research findings could not support the hypothesis. There must be other reasons responsible for the enhanced protein expression of P. pastoris in a SMG environment.

In the methanol fed-batch phase, the cells were exposed to dual oxidative stress resulting from methanol degradation and recombinant protein production. Previous studies described that the protein folding process was also related to oxidative stress (Malhotra et al. 2008; Vanz et al. 2012). The proteins involved in oxidative stress had a higher abundance under SMG according to the proteomic data, implying that microgravity increased the oxidative stress response in the cell processing. The transcriptome profiling data was in accordance with the proteomic data. The transcriptional levels of thiol peroxidase, which exhibited a major role in weakening the oxidative stress, were 1.69-fold up-regulated at the logarithmic phase and 1.93-fold up-regulated at the stationary phase. The proteomic level of thiol peroxidase was highly up-regulated to 2.59-fold at the stationary phase. The chaperones with higher transcriptional and proteomic levels indicated that the SMG environmental stresses could easily provoke overload of the endoplasmic reticulum (ER) folding machine, resulting in the aggregations of unprocessed proteins and consequently the onset of the unfolded protein response. The high abundance of ribosome-associated proteins indicated that the changes on the cellular protein synthesis machinery contributed to the enhanced production of the recombinant protein under SMG.

A systematic approach for finding novel targets could facilitate the subsequent rational strain engineering strategies. We compared the proteomic data and selected six significantly regulated genes and tested their functions in recombinant protein production. Thiol peroxidases were involved in transferring oxidative signals and regulating transcription by direct oxidation of numerous cellular proteins. Fructose 1, 6-bisphosphate aldolase, an important enzyme for cofactor regeneration, catalyzed the formation of fructose 1, 6-bisphosphate from dihydroxyacetone and glyceradehyde-3-phosphate and replenished the xylulose-5-phosphate to the downstream reactions of the methanol metabolism. In methylotrophic yeasts, the first step in the metabolism of methanol was the oxidation of formaldehyde by the alcohol oxidase, which generated high level of H2O2 and caused the oxidative stress response (Fomenko et al. 2011). The refolding of unfolded or misfolded proteins in the ER had a chain of oxidative folding processes. Improving the transcription of two helper genes could significantly enhance the heterologous PGUS production. Research showed that overexpressing helper genes supporting folding and secretion like PDI and HAC1 turned out to be valuable strategies to improve recombinant protein production (Guerfal et al. 2010). Thus, SBA1, an up-regulated co-chaperone, was selected. However, the secretion of the heterologous PGUS was slightly improved by SBA1. In addition, AKR-E was selected in order to determine whether other genes involved in the oxidative response would get the similar improvement like TPX. However, the result did not support the hypothesis. The relation of oxidative response and protein production were still not fully understood even though the whole genome sequence of the organism had been available. Apparently, the supporting factor TPX seemed to play a positive role to raise the correct protein yields at the initial period of the fermentation process.

Several cases showed that increased copy numbers of a helper gene can affect normal metabolism in P. pastoris (Zhu et al. 2011). To understand the regulation mechanism of a helper gene, the transcriptional levels were investigated in this study. Clones harboring the low copy numbers of the helper gene TPX had positive effects on the specific PGUS yields. Improvement of target protein production was normally thought to be due to the increasing level of transcription. However, co-expression of the helper gene could also compete with the target gene for transcription. Baumann et al. reported that the reporter gene mRNA levels among the recombinant protein production improved strains of overexpressing helper genes were similar to the reference strain (Baumann et al. 2011). In our research, the transcriptional level of PGUS was decreased when the helper gene TPX was overexpressed. Inversely, the PGUS specific activities were increased. The helper gene here seemed to facilitate the enhancement of the ability of the protein to fold correctly and be secreted but not help the transcriptional regulation. To validate the discrepant results, we also have investigated the PGUS secretion of TPX overexpressing strains (Tpx-1, 2, 3, 4 and CK-SF) by Coomassie brilliant stained SDS–PAGE. The results showed that the PGUS productions in TPX overexpressing strains were enhanced (data not shown).

Poorly folded proteins in the ER generally involve a chain of oxidative folding processes. Thiol peroxidases were reported as global regulators of gene expression for providing an antioxidant defense by reducing hydroperoxides. Therefore, overexpression of TPX might efficiently counteract oxidative stress arising from heterologous protein production. We compared the transcription levels of genes involved in folding stress and oxidative stress and in the low copy of the TPX gene strain (Tpx-1) and the control strain without co-expressing the TPX gene (CK-SF) by real-time PCR after 24 h of methanol induction. The relative transcription level of GLR1 (glutathione reductase, responsible for converting oxidized glutathione to reduced glutathione) was up-regulated by 10 % in Tpx-1, indicating that the strain of co-expression was undergoing oxidative stress owing to the folding of TPX. The relative transcription level of PDI1 (disulfide isomerase, a chaperone that catalyzes the formation of disulfide bonds) was increased by 15 % in Tpx-1, indicating the process of correct folding of PGUS (data not shown). The results indicated that the strain overexpressing TPX was undergoing oxidative stress owing to the process of recombinant proteins correctly folding.

Alteration of the expression levels of the helper gene seemed to impact the protein production process. There were significant differences in specific yields among clonal variations of AtXYN, whereas transcriptional levels of TPX gene were similar. The transcriptional levels of AtXYN in the improved clones were also decreased when TPX was overexpressed (data not shown). This result suggested that other factors may be involved in the clonal variation. These conflicting results indicated that the ways of controlling helper gene expression levels to get stable improved protein expression needed further and deeper investigation.

Therefore, additional studies should further deeply analyze the omic data and investigate the potential synergetic actions of the individual helper factors in the future. Studies concerning the influence of the microgravity environment on microbial cells may receive much attention, and such information could provide insights into the ways that microgravity affects the yeast cells. Utilizing the microgravity effect to find novel targets related with protein production would be a new and more robust tool for subsequent strain improvement in normal fermentation.

Reference

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23(3):257–270. doi:10.1016/0168-1656(92)90074-J

Baker PW, Meyer ML, Leff LG (2004) Escherichia coli growth under modeled reduced gravity. Microgravity Sci Technol 15(4):39–44

Baumann K, Carnicer M, Dragosits M, Graf AB, Stadlmann J, Jouhten P, Maaheimo H, Gasser B, Albiol J, Mattanovich D, Ferrer P (2010) A multi-level study of recombinant Pichia pastoris in different oxygen conditions. BMC Syst Biol 4:141. doi:10.1186/1752-0509-4-141

Baumann K, Adelantado N, Lang C, Mattanovich D, Ferrer P (2011) Protein trafficking, ergosterol biosynthesis and membrane physics impact recombinant protein secretion in Pichia pastoris. Microb Cell Factories 10:93. doi:10.1186/1475-2859-10-93

Benoit MR, Li W, Stodieck LS, Lam KS, Winther CL, Roane TM, Klaus DM (2006) Microbial antibiotic production aboard the international space station. Appl Microbiol Biotechnol 70(4):403–411. doi:10.1007/s00253-005-0098-3

Boyle D, Montelone B, Cornejo A, Takemoto L (1995) Effects of microgravity upon growth, morphology, and expression of recombinant protein in E. coli. Cosm Res 34:609

Crabbé A, Schurr M, Monsieurs P, Morici L, Schurr J, Wilson JW, Ott CM, Tsaprailis G, Pierson DL, Stefanyshyn-Piper H, Nickerson CA (2011) Transcriptional and proteomic responses of Pseudomonas aeruginosa PAO1 to spaceflight conditions involve Hfq regulation and reveal a role for oxygen. Appl Environ Microbiol 77(4):1221–1230. doi:10.1128/AEM. 01582-10

Dragosits M, Stadlmann J, Albiol J, Baumann K, Maurer M, Gasser B, Sauer M, Altmann F, Ferrer P, Mattanovich D (2009) The effect of temperature on the proteome of recombinant Pichia pastoris. J Proteome Res 8(3):1380–1392. doi:10.1021/pr8007623

Dragosits M, Stadlmann J, Graf A, Gasser B, Maurer M, Sauer M, Kreil D, Altmann F, Mattanovich D (2010) The response to unfolded protein is involved in osmotolerance of Pichia pastoris. BMC Genomics 11:207. doi:10.1186/1471-2164-11-207

Feng SJ, Li C, Xu XL, Wang XY (2006) Screening strains for directed biosynthesis of β-D-mono-glucuronide-glycyrrhizin and kinetics of enzyme production. J Mol Catal B Enzyme 43:63–67. doi:10.1016/j.molcatb

Fomenko DE, Koc A, Agisheva N, Jacobsen M, Kaya A, Malinouski M, Rutherford JC, Siu KL, Jin DY, Winge DR, Gladyshev VN (2011) Thiol peroxidases mediate specific genome-wide regulation of gene expression in response to hydrogen peroxide. Proc Natl Acad Sci U S A 108(7):2729–2734. doi:10.1073/pnas.1010721108

Gasser B, Sauer M, Maurer M, Stadlmayr G, Mattanovich D (2007) Transcriptomics-based identification of novel factors enhancing heterologous protein secretion in yeasts. Appl Environ Microbiol 73:6499–6507

Guerfal M, Ryckaert S, Jacobs PP, Ameloot P, Van Craenenbroeck K, Derycke R, Callewaert N (2010) The HAC1 gene from Pichia pastoris: characterization and effect of its overexpression on the production of secreted, surface displayed and membrane proteins. Microb Cell Factories 9:49. doi:10.1186/1475-2859-9-49

Guo X, Zhang R, Li Z, Dai D, Li C, Zhou X (2013) A novel pathway construction in Candida tropicalis for direct xylitol conversion from corncob xylan. Bioresour Technol 128:547–552. doi:10.1016/j.biortech

Malhotra JD, Miao H, Zhang K, Wolfson A, Pennathur S, Pipe SW, Kaufman RJ (2008) Antioxidants reduce endoplasmic reticulum stress and improve protein secretion. Proc Natl Acad Sci U S A 105(47):18525–18530. doi:10.1073/pnas.0809677105

Nickerson CA, Ott CM, Wilson JW, Ramamurthy R, LeBlanc CL, Höner zu Bentrup K, Hammond T, Pierson DL (2003) Low-shear modeled microgravity: a global environmental regulatory signal affecting bacterial gene expression, physiology, and pathogenesis. J Microbiol Methods 54(1):1–11. doi:10.1016/S0167-7012(03)00018-6

Nickerson CA, Ott CM, Wilson JW, Ramamurthy R, Pierson DL (2004) Microbial responses to microgravity and other low-shear environments. Microbiol Mol Biol Rev 68(2):345–361. doi:10.1128/MMBR. 68.2.345-361

Qi F, Kaleem I, Lv B, Guo XX, Li C (2011a) Enhancement of recombinant β-glucuronidase production under low-shear modeled microgravity in Pichia pastoris. J Chem Technol Biotechnol 86(4):505–511. doi:10.1002/jctb.2541

Qi F, Wang C, Liu Y, Kaleem I, Li Q, Li C (2011b) Transcriptional profiling of protein expression related genes of Pichia pastoris under simulated microgravity. PLoS One 6(11):e26613. doi:10.1371/journal.pone.0026613

Sanderson K (2011) Commercial space flight: scientists in space. Nature 476(7361):477–478

Sheehan KB, McInnerney K, Purevdorj-Gage B, Altenburg SD, Hyman LE (2007) Yeast genomic expression patterns in response to low-shear modeled microgravity. BMC Genomics 8:3. doi:10.1186/1471-2164-8-3

Stephen N (2007) Rotary bioreactor for recombinant protein production. Cell Technol Cell Products 3:567–569

Thomas V, Franz S, Anton G (2013) New opportunities by synthetic biology for biopharmaceutical production in Pichia pastoris. Curr Opin Biotechnol 24(6):1094–1101. doi:10.1016/j.copbio.2013.02.024

Vailati A, Cerbino R, Mazzoni S, Takacs CJ, Cannell DS, Giglio M (2011) Fractal fronts of diffusion in microgravity. Nat Commun 2:290. doi:10.1038/ncomms1290

Vanz AL, Lünsdorf H, Adnan A, Nimtz M, Gurramkonda C, Khanna N, Rinas U (2012) Physiological response of Pichia pastoris GS115 to methanol-induced high level production of the Hepatitis B surface antigen: catabolic adaptation, stress responses, and autophagic processes. Microb Cell Factories 11:103. doi:10.1186/1475-2859-11-103

Xiang L, Qi F, Dai DZ, Li C, Jiang YD (2010) Simulated microgravity affects growth of Escherichia coli and recombinant β-glucuronidase production. Appl Biochem Biotechnol 162(3):654–661. doi:10.1007/s12010-009-8836-0

Zhu T, Guo M, Zhuang Y, Chu J, Zhang S (2011) Understanding the effect of foreign gene dosage on the physiology of Pichia pastoris by transcriptional analysis of key genes. Appl Microbiol Biotechnol 89(4):1127–1135. doi:10.1007/s00253-010-2944-1

Acknowledgments

This work was financially supported by the National High Technology Research and Development Program of China (863 Program) (No. 2012AA02A704), the Major State Basic Research Development Program of China (973 Program) (No. 2013CB733900), and the Natural Science Foundation of Beijing (No. 2112035).

Conflict of interest

The authors declare that no competing financial interests exist.

Author information

Authors and Affiliations

Corresponding author

Additional information

Jie Huangfu and Feng Qi contributed equally to this study

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 862 kb)

Rights and permissions

About this article

Cite this article

Huangfu, J., Qi, F., Liu, H. et al. Novel helper factors influencing recombinant protein production in Pichia pastoris based on proteomic analysis under simulated microgravity. Appl Microbiol Biotechnol 99, 653–665 (2015). https://doi.org/10.1007/s00253-014-6175-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6175-8