Abstract

Efficient utilization of xylose by bacteria is essential for production of fuels and chemicals from lignocellulosic biomass. In this study, Bacillus subtilis 168 was subjected to laboratory adaptive evolution, and a mutant E72, which could grow on xylose with a maximum specific growth rate of 0.445 h−1, was obtained. By whole-genome sequencing, 16 mutations were identified in strain E72. Through further analysis, three of them, which were in the coding regions of genes araR, sinR, and comP, were identified as the beneficial mutations. The reconstructed strain 168ARSRCP harboring these three mutations exhibited similar growth capacity on xylose to the evolved strain E72, and the average xylose consumption rate of this strain is 0.530 g/l/h, much higher than that of E72 (0.392 g/l/h). Furthermore, genes acoA and bdhA were deleted and the final strain could utilize xylose to produce acetoin at 71 % of the maximum theoretical yield. These results suggested that this strain could be used as a potential platform for production of fuels and chemicals from lignocellulosic biomass.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As an alternative to petrochemical production of fuels and chemicals, microbial fermentation of lignocellulosic biomass to produce valuable products is renewable and environmental friendly (Kim et al. 2013a). Glucose and xylose are the most abundant sugars in lignocellulosic biomass (Mosier et al. 2005). Efficient utilization of these sugars is essential for production of fuels and chemicals from lignocellulosic biomass such as wood waste and plants. However, although a few native microorganisms are able to utilize xylose (Kim et al. 2013b), most organisms cannot consume xylose as the sole carbon source (Utrilla et al. 2012).

There are two main pathways in nature for microbial utilization of xylose. The first pathway mainly exists in fungi, through which xylose is firstly reduced to xylitol by xylose reductase, and xylitol is then oxidized to xylulose by xylulose dehydrogenase. Xylulose is finally converted to xylulose-5-phosphate by xylulose kinase and enters into the pentose phosphate pathway (Kuhad et al. 2011). The second pathway is mainly from prokaryotes such as Escherichia coli. Through this pathway, xylose is directly catalyzed to generate xylulose by xylose isomerase, then xylulose is converted to xylulose-5-phosphate by xylulose kinase which is assimilated through the pentose phosphate pathway (Lawlis et al. 1984). Bacillus subtilis, the most characterized Gram-positive bacterium, which has been used for production of many valuable chemicals and enzymes (Liu et al. 2013; Shi et al. 2009), also possesses the second xylose assimilation pathway. It has been reported that genes xylA and xylB in B. subtilis encode xylose isomerase and xylulose kinase, respectively (Wilhelm and Hollenberg 1985). However, the wild-type B. subtilis is not able to utilize xylose as the sole carbon source due to the absence of specific xylose uptake system (Schmiedel and Hillen 1996). It was reported that the broad-substrate transporter AraE could import xylose into the cell, but it was synthesized only when arabinose was supplemented into the growth medium (Krispin and Allmansberger 1998). When araR gene encoding the transcriptional repressor AraR was insertionally inactivated, B. subtilis obtained the capacity to utilize xylose as the sole carbon source (Krispin and Allmansberger 1998). These results suggested that the repression of gene araE by protein AraR in B. subtilis was the reason for being incapable of utilizing xylose. Lately, the AraE expression cassette was constructed and integrated into the genome of B. subtilis 168 using the xylose-inducible xylA promoter, and the engineered strain could utilize xylose as the sole carbon source (Park et al. 2012). Similarly, araE was overexpressed on plasmid with strong promoter P43, which also allowed B. subtilis 168 to be able to grow with xylose as the sole carbon source (Chen et al. 2013). However, the consumption rate of xylose was still much slower as compared to that of glucose. Therefore, other strategies need to be carried out for gaining engineered B. subtilis capable of assimilating xylose more efficiently.

Adaptive laboratory evolution as a useful tool has been frequently used in strain development for production of fuels and chemicals (Portnoy et al. 2011). It can be used for expanding substrate utilization (Hua et al. 2007; Lee and Palsson 2010), improving fitness to changing environment (Cox et al. 2010; Ekberg et al. 2013; Lee et al. 2013; Zhang et al. 2012), and improving tolerance to harmful product (Fernández-Sandoval et al. 2012; Wang et al. 2011). With the rapid-developing genome-sequencing technologies, the genetic basis for the altered phenotype arising by adaptive evolution can be identified (Herring et al. 2006; Lee and Palsson 2010; Utrilla et al. 2012), and used as potential engineering targets for rational design. Until now, several Saccharomyces cerevisiae strains capable of fermenting xylose efficiently have been successfully obtained by adaptive laboratory evolution (Scalcinati et al. 2012; Shen et al. 2012; Sonderegger and Sauer 2003; Zhou et al. 2012). Pseudomonas putida was also subjected to laboratory evolution and a strain that could efficiently utilize xylose and arabinose was obtained (Meijnen et al. 2008).

In the present work, through adaptive laboratory evolution, we obtained a B. subtilis mutant capable of utilizing xylose efficiently. In addition, the underlying genetic basis for the gained phenotypic characteristics of the evolved mutant was determined by whole-genome sequencing and mutation analysis. Finally, three mutant genes, araR, sinR, and comP, were identified as the trait-conferring genes. Based on these results, a reconstructed strain 168ARSRCP harboring these mutations was developed. This strain could utilize xylose more rapidly than those previously reported (Park et al. 2012; Chen et al. 2013).

Materials and methods

Strains, plasmids, and primers

The strains and plasmids used in this study are listed in Table 1. B. subtilis 168 was used as the wild type. Primers used for plasmid construction and genetic manipulation are listed in Table S1 in the Supplementary Material. For plasmid construction and strain construction, Luria–Bertani (LB) broth was used for culture, when necessary, supplemented with ampicillin (100 μg/ml), chloramphenicol (12 μg/ml for E. coli and 6 μg/ml for B. subtilis), and 5-fluorouracil (50 μg/ml). For solid culture, 1.5 % agar was added. All DNA manipulations were performed according to standard protocols. The two-step transformation method for B. subtilis was used in this work (Anagnostopoulos and Spizizen 1961). Plasmid pHP13 was used for the examination of the transformation efficiency.

Genetic methods

Construction of plasmid p9CU

For gene mutagenesis and deletion, gene upp was used as the counter selection marker (Fabret et al. 2002). A DNA fragment containing the pMB1 ori and chloramphenicol resistance gene was amplified from plasmid pHP13 using primers P1 and P2, and the gene upp from B. subtilis 168 encoding uracil phosphoribosyltransferase was amplified using primers P3 and P4. After digestion with the respective restriction enzymes (Table S1 in the Supplementary Material), the DNA fragment and upp gene were ligated to produce plasmid p9CU (Fig. S1 in the Supplementary Material).

Markerless gene deletion

The markerless gene deletion was performed as described previously (Fabret et al. 2002). Take gene sigD as an example. The upstream and downstream regions of gene sigD were amplified from the genome of B. subtilis 168 using primers PsigD1/PsigD2 and PsigD3/PsigD4, respectively, which were cloned into plasmid p9CU successively. The respective restriction enzymes used are listed in Table S1 in the Supplementary Material. The resulting plasmid pDsigD was then transformed into strain 168AR. The positive clone was selected on plates containing 6 μg/ml chloramphenicol and picked into a 15-ml test tube containing 4 ml LB medium. After culturing in liquid medium for about 6–8 h, appropriate amount of cells were spread on plates containing 50 μg/ml 5-fluorouracil. The single colonies on 5-fluorouracil plates were then transferred to LB plates and chloramphenicol plates correspondingly. Colonies that could grow well on LB plates but were not able to grow on chloramphenicol plate were chosen for further verification by PCR. The deletions of gene acoA and bdhA were similar to that of gene sigD, and the plasmids used for their deletions were pCU-acoAFB and pCU-bdhAFB (Fu et al. 2014) respectively.

Mutagenesis

A two-step double-crossover method was used to introduce the araR A184G mutation into strain 168Δupp (Chen et al. 2013). Mutated gene araR with A184G mutation was amplified from the genome DNA of strain E72 using primers ParaR1 and ParaR2, treated with T4 polynucleotide kinase, and cloned into SmaI-digested plasmid pUC18 to yield plasmid pUCaraR. A fragment containing chloramphenicol resistance gene cat and gene upp was amplified from plasmid p9CU using primers P3 and P5, treated with T4 polynucleotide kinase, and cloned into AfeI-digested plasmid pUCaraR to yield plasmid pMaraR. PCR fragment araR::upp-cat was then amplified with plasmid pMaraR as the template using primers ParaR1 and ParaR2 and transformed into strain 168Δupp. The positive clone was selected on chloramphenicol plate and designated as 168ΔuppΔaraR. PCR fragments amplified from the genome of strain E72 using primers ParaR3 and ParaR4 which harbored the A184G mutation was then transformed into strain 168ΔuppΔaraR. The positive clone was selected by growth on plates with 5-fluorouracil and designated as 168AR.

Introduction of other mutations was performed through a modified method based on single-crossover, which was similar to the process of gene sigD deletion. Taking gene sodA as an example, the mutated gene was amplified from the genome of strain E72 using primers PsodA1 and PsodA2 and cloned into SmaI-digested plasmid p9CU. The resulting plasmid p9CU-SA was then transformed into strain 168AR or 168ARSR. The method for selection of the positive clone using chloramphenicol and 5-fluorouracil was the same as mentioned above and the point mutation was verified by sequencing finally. The procedure for other mutations knock-in was the same as gene sodA.

Growth media and cultivation conditions

Flask fermentations under aerobic conditions were performed using M9 minimal medium supplemented with trace elements and 50 mg/l tryptophan (Harwood et al. 1990). Xylose or arabinose was added in the medium at a concentration of 9 g/l as the sole carbon resource. All cultures were incubated at 37 °C and 220 rpm. Unless otherwise specified, the volume of medium was 50 ml in a 500-ml shake flask. For flask culture, the strain was firstly streaked on LB agar plate from −80 °C glycerol stock. After incubation at 37 °C for about 12 h, a single colony was inoculated into a 15-ml test tube containing 4 ml of LB medium and incubated at 37 °C and 220 rpm for about 9 h. Subsequently, a 0.5-ml culture was transferred into a 500-ml flask containing 50 ml of M9 medium. During the mid-exponential phase, 1 % of the culture was transferred into fresh M9 medium in a 500-ml flask.

For fermentations under microaerobic conditions, the medium and culture conditions were the same as that of flask fermentations under aerobic conditions, except that 250-ml shake flasks containing 100-ml medium and 100 rpm were used (Wang et al. 2012).

Adaptive evolution

At the start of adaptive evolution, B. subtilis 168 was streaked on a LB plate and incubated at 37 °C. A single colony was selected and inoculated into a test tube containing 4 ml of LB medium. After incubation at 37 °C and 220 rpm for about 12 h, 0.5 ml culture was transferred into a 500-ml flask containing 50 ml of M9 minimal medium supplemented with 1 g/l glucose and 9 g/l xylose. The flask was incubated at 37 °C and 220 rpm in a rotary shaker. Adaptive evolution was performed through serial transfer into fresh M9 medium supplemented with 9 g/l xylose at mid-exponential phase. Glucose was added as carbon source only in the first culture. The volume of inoculum for each transfer was adjusted according to the changing growth rate. Serial transfers were terminated when no further improvement in the growth rate was observed.

Whole-genome sequencing

Whole-genome sequencing was performed on the Illumina HiSeq2000 platform at Novogene (Novogene, Beijing, China) using B. subtilis 168 as the reference strain.

Analytical methods

Growth was monitored by measuring cell density at 600 nm (TU-1901, Persee, Beijing, China), and the cell dry weight (CDW) was calculated according to the following: 1 OD600 = 0.325 g CDW/l. Samples from flask cultures were centrifuged at 13,000 rpm for 10 min, and the supernatant was stored at −20 °C for future analysis. Glucose was determined using a SBA sensor machine (Institute of Microbiology, Shandong, China). Xylose and fermentation products were determined by using HPLC (HP1100, Agilent Technologies, Palo Alto, CA, USA) equipped with a ion exclusion Aminex HPX 87-H column (Bio-Rad, Richmond, CA, USA) and 5 mM H2SO4 (0.4 ml/min) was used as the mobile phase at 65 °C. Xylose, glucose, and 2,3-butanediol were detected by a refractive index (RI) detector (Agilent, HP1047A), and acetoin was detected by an UV absorbance detector (Agilent, G1315D).

Real-time quantitative PCR

Unless otherwise specified, samples from cultures in M9 xylose minimal medium in 500-ml flasks at 37 °C and 220 rpm were collected during the mid-exponential growth phase and RNA was extracted using RNAprep Pure Cell/Bacteria Kit (Tiangen, Beijing, China) according to the manufacturer’s protocol. After quantified by an ultra-micro ultraviolet spectrophotometer (Biodropsis BD-2000, Beijing Oriental Science & Technology Development Company), 500 ng total RNA was used for cDNA synthesis with FastQuant RT Kit (with gDNase) (Tiangen, Beijing, China). The cDNA was then quantified and directly used for real-time quantitative PCR (RT-qPCR). RT-qPCR was performed in a Light CyclerH 480 II (Roche, Basel, Switzerland) with Real Master Mix (SYBR Green) (Tiangen, Beijing, China) using 16s rRNA gene rrnA-16S as the internal control. The primers designed for RT-qPCR are also listed in Table S1 in the Supplementary Material. The RT-qPCR was operated using the following conditions: 95 °C for 1 min, 40 cycles at 95 °C for 5 s, 55 °C for 10 s, and 72 °C for 15 s. The relative quantitative method (2−ΔΔCT) (Livak and Schmittgen 2001) was adopted for estimating the changes of gene expression levels between different strains.

Strains submission and nucleotide sequence data deposition

B. subtilis 168 used as the beginning strain for adaptive evolution in this work and the evoluted strain B. subtilis E72 were submitted to China General Microbiological Culture Collection Center, and the accession numbers were CGMCC 1.12939 and CGMCC 1.12938, respectively. Genome sequences of these strains were deposited in the NCBI GenBank under the following accession numbers: JNCM00000000 (http://www.ncbi.nlm.nih.gov/nuccore/JNCM00000000) (B. subtilis 168 used as the beginning strain for adaptive evolution in this work) and JNCN00000000 (http://www.ncbi.nlm.nih.gov/nuccore/JNCN00000000) (B. subtilis E72).

Results

Adaptive evolution

B. subtilis 168 can utilize many kinds of carbon sources including glucose, sucrose, arabinose, glycerol, cellobiose, and so on. However, this strain is not able to grow on xylose as the sole carbon source due to the lack of xylose transporter AraE, whose expression is repressed by AraR and induced by arabinose (Mota et al. 1999). Even though AraE was overexpressed, the utilization of xylose is still unsatisfied (Chen et al. 2013). Therefore, adaptive evolution of B. subtilis 168 was performed using serial transfer method, with the aim to acquire a mutant capable of utilizing xylose efficiently.

In order to obtain a larger bacterial population, 1 g/l glucose was initially supplemented into M9 minimal medium containing 9 g/l xylose to allow the growth of B. subtilis 168. As expected, the growth ceased after glucose was exhausted wherein the OD600 of the culture was about 1. After several days of incubation, the OD600 of the culture reached 2, and 1 % of the culture was transferred into fresh M9 medium supplemented with 9 g/l xylose. In the fresh M9 xylose medium without glucose, the culture could grow slowly with xylose as the sole carbon source. In order to further improve the growth rate, serial transfers were continued in M9 xylose medium. After 72 transfers, the culture exhibited a high and stable specific growth rate. Then, a mutant was isolated and designated as E72. Strain E72 could grow in M9 minimal medium with xylose as the sole carbon source at a specific growth rate of 0.445 h−1. In addition, the color of the culture at the late stage of the fermentation changed to red.

Moreover, when cultured in M9 minimal medium with arabinose as the sole carbon source, the specific growth rate of E72 (0.429 h−1) was also much higher than that of the wild type (0.317 h−1). This result suggested that through adaptive evolution not only xylose utilization was improved, but also arabinose utilization.

The growth of E72 in LB-rich medium was also examined, and no considerable changes were observed as compared to the wild type, except that formation of flocs at the early stage and faster cell sedimentation at the later stage were exhibited by the culture of E72. The changed phenotype of cell sedimentation of E72 could be attributed to the altered motility. Therefore, the motility was explored for E72 and the wild type on M9 semisolid minimal medium supplemented with 9 g/l glucose. As depicted in Fig. S2 in the Supplementary Material, the motility of E72 was almost completely lost.

Whole-genome sequencing

In order to determine the genetic basis of the observed phenotype for E72, genomic DNA of E72 was extracted and sequenced by using the solexa sequencing system. In addition, the genome of B. subtilis 168 used as the starting strain in this study was also sequenced as a control. In comparison with the genome sequence of B. subtilis 168 from NCBI (NC_000964.3), a total of 79 putative mutations were identified in strain E72. However, when compared to the genome sequence of B. subtilis 168 used as the beginning strain for adaptive evolution in this work, 63 SNPs were found to be harbored in the wild type of our lab, and only 16 mutations was identified to be accumulated during the process of adaptive evolution. All of the 16 mutations (Table 2) were located in the coding regions and clustered in 11 genes, of which 7 were silent mutations, 5 were missense mutations, and 4 were frameshift mutations. The details of the mutations and the mutated genes were listed in Table 2.

Effect of araR mutation on xylose utilization

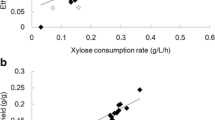

Among the 11 mutated genes in the evolved strain E72, gene araR, encoding the transcription repressor protein AraR, had a missense mutation at position 184 of the coding region. The expression of xylose transporter AraE is transcriptionally repressed by AraR, which causes the inability of the wild type to utilize xylose. Therefore, this mutation was very likely to be directly related to the growth phenotype of strain E72 in M9 xylose medium. In order to verify this hypothesis, the A184G mutation was introduced into strain 168Δupp to yield strain 168AR. As expected, strain 168AR was able to grow in M9 medium with xylose as the sole carbon source (Fig. 1). The specific growth rate of 168AR in M9 xylose medium was 0.278 h−1. However, in M9 medium with arabinose as the sole carbon source, the maximum specific rate (0.339 h−1) of strain 168AR was not significantly increased as compared to the wild type.

Because AraR was the repressor of gene araE and araABDLMNPQ-abfA operon, the araR A184G mutation was supposed to cause transcriptional change of gene araE and araABDLMNPQ-abfA operon. Moreover, whether the mutation could influence the transcription of the xylAB operon, which is involved in catabolism of xylose, was also of concern. Therefore, the transcriptional level of genes araE, araA, and xylA in strains 168AR and E72 and the wild type were explored (Fig. 2). The results showed that araE was upregulated about 20-fold and araA was upregulated about 100-fold in strains 168AR and E72, as compared to the wild type. These results confirmed the inactivation of protein AraR and the derepression of araE expression. However, no change in the transcriptional level of xylAB operon was observed. This indicated that xylAB expression was not influenced by the araR A184G mutation.

Relative transcriptional levels of araE, araA, and xylA for strains 168AR and E72 as compared to the wild type. Values were normalized to the transcriptional levels in the control strain 168. Samples were from cultures in LB medium due to the inability of 168 to grow in M9 xylose medium. The error bars represent the standard deviation calculated from triplicates

Identification of sinR mutation

To the best of our knowledge, except the araR missense mutation, all other mutations had no direct relationships with xylose metabolism. In order to clarify their functions and figure out the mutations resulting in the growth phenotype of the evolved mutant E72, seven nonsynonymous mutations in the coding regions were preferentially chosen and introduced into strain 168AR. The growth performance of the resulting strains in M9 xylose medium was examined (Table 3). The results showed that strain 168ARSR having both araR mutation and sinR mutation got an increase of the specific growth rate to 0.437 h−1, which was close to that of E72. A similar phenomenon was also observed in M9 arabinose medium, the specific growth rate of strain 168ARSR was increased to 0.440 h−1 with arabinose as the sole carbon source. However, the growth rate did not have obvious change in M9 xylose medium after introducing the other six mutations into strain 168AR. As shown in Table 3, accompanying with the improved maximum specific growth rate, the xylose consumption rate of strain 168ARSR was increased more than 80 % to 0.449 g/l/h, and cell yield was also increased more than 50 % to 0.352 g dry cell/g xylose, compared with those of the parental strain 168AR. In addition, about 1 g/l acetoin was produced from 9 g/l xylose by strain 168ARSR in flask culture aerobically, compared with below 0.1 g/l acetoin produced by the other strains.

To find out the reason for the improvement in growth rate by sinR mutation, the transcriptional level of genes involved in xylose utilization pathway and the rate-limiting steps of central carbon metabolism was also examined for strain 168ARSR and 168AR. As can be seen from Fig. 3, genes involved in xylose utilization pathway including araE and xylA was not upregulated and instead downregulated in strain 168ARSR. This suggested that the faster growth resulted from sinR mutation was not related to the xylose utilization pathway. Genes rpe, ywlF, tkt, and ywjH all belong to the pentose phosphate pathway and encode ribulose-phosphate 3-epimerase (Foulger and Errington 1998), ribose 5-phosphate isomerase (Shi et al. 2009), transketolase (Schiott et al. 1997), and transaldolase (Schurmann and Sprenger 2001), respectively. The results showed that the transcriptional levels of gens ywlF and tkt were almost unchanged and those of genes rpe and ywjH were slightly downregulated. In addition, genes involved in the glycolysis pathway (pfkA and pyk) and genes involved in the TCA cycle (citZ, icd, sucA) were all slightly downregulated. The transcriptional level of the anaplerotic enzyme pyruvate carboxylase (pycA) also had the same trend. The only exception was gene pdhA, whose expression was upregulated slightly in strain 168ARSR. These results suggested that these carbon metabolism pathways had not been affected significantly by the sinR mutation. The improved growth probably had no direct relations with the carbon metabolism, and the sinR mutation might be correlative to some other unknown factors affecting the growth of strain 168AR on xylose.

The mutation in gene sinR was also introduced to strain 168Δupp. And the resulting strain 168SR could not grow in M9 medium with xylose as the sole carbon source due to the absence of araR mutation.

Identification of comP mutation

Strain 168ARSR obtained the similar maximum specific growth rate as strain E72 though introducing the sinR mutation. However, the growth capability of strain 168ARSR was still not as good as strain E72, which could be seen from the maximum biomass density (Fig. 1). In order to verify the effects of the remaining six mutations on growth performance in combination with the sinR and araR mutations and further improve the growth capability to the level of strain E72, they were introduced into strain 168ARSR individually. The growth of the mutants in M9 xylose medium was explored and depicted in Table 4. No improvement in the maximum specific growth rate was observed for all the mutants compared to the parental strain 168ARSR. Only the mutant 168ARSRCP harboring the comP mutation exhibited an improved growth capability which was very similar to strain E72. The mutation of gene comP could improve the growth capability in M9 xylose medium through extending the exponential phase of the culture. As shown in Fig. 1, the exponential phase of strain 168ARSR terminated at the OD600 value below 3 after which the growth rate gradually slowed down. However, the growth rate remained unchanged for strain 168ARSRCP until the biomass reached an OD600 value of about 5, resulting in the different biomass density. The effect of this mutation in gene comP can also be shown in strain 168ARCP, which reached a much higher maximum cell density than other strains containing two mutations (Table 3). Accompanying with the higher maximum cell density, the xylose consumption rate of strain 168ARSRCP was increased to 0.530 g/l/h, improved about 18 % as compared with that of strain 168ARSR.

Strain 168CP was also constructed, which only harbors the point mutation in gene comP. As expected, it could not grow in the M9 medium with xylose as the sole carbon source.

Strain 168ARSRCP harboring three mutations had acquired the same growth capacity as strain E72. In addition, it could be seen from Fig. 1 that the lag phase of strain 168ARSRCP was much shorter than that of strain E72. This suggested that all of the important mutations in the evolved strain E72 had been identified.

Production of acetoin from xylose under microaerobic conditions

Acetoin is a widely used flavor compound and platform compound in many industries. Therefore, the performance of acetoin production from xylose for our strain 168ARSRCP was explored under microaerobic conditions. As shown in Fig. 4, about 21 g/l xylose was consumed in 96 h and 5 g/l acetoin was produced by strain 168ARSRCP. 2,3-Butanediol was also produced as a by-product. Although 2,3-butanediol was ultimately converted to acetoin, the yield of acetoin was reduced and the fermentation period was prolonged. Therefore, genes bdhA encoding 2,3-butanediol dehydrogenase was deleted in strain 168ARSRCP. In addition, gene acoA encoding acetoin dehydrogenase was also deleted to avoid the degradation of acetoin. As expected, 2,3-butanediol was no longer accumulated by the resulting strain 168ARSRCPΔacoAΔbdhA, and 7.6 g/l acetoin was produced from about 21 g/l xylose at 71 % of the maximum theoretical yield.

Discussion

In this study, we aimed to construct a B. subtilis strain which was capable to utilize xylose efficiently. Through simple and straight pathway manipulation, the purpose could not always be achieved due to the complexity and nonlinearity of the biological metabolic network. However, evolutionary engineering can acquire desired phenotypes by the fitness of bacterium itself to the changing environments. Schmiedel and Hillen (1996) have already reported that large colonies of B. subtilis harboring mutations could be obtained on minimal plates with xylose as the sole carbon source in a few days. Similarly, strains that could grow on xylose were also obtained in a few days in our work. Through serial transfers, an individual with better growth was enriched, which gradually improved the growth rate. At the same time, other phenotypes were obtained accompanying the phenotype of growth as a result of the adaptive evolution. For instance, the color of culture and the motility were altered for the evolved strain E72 in comparison with the wild type. This indicated that evolutionary engineering could induce unknown effects on other characteristics of the bacteria in addition to the desired phenotypes.

There were three important mutations were identified in the evolved mutant. The first mutation in the gene araR enabled B. subtilis to grow on xylose by derepressing the xylose transporter. The second one was in the gene sinR and its effect on improving the growth rate on xylose was confirmed. And the third mutation in the gene comP extended the exponential phase. The final reconstructed strain 168ARSRCP harboring these mutations could consume 9 g/l xylose in 18 h in flask culture, while strains JY123 (Park et al. 2012) and BSUL11 (Chen et al. 2013), developed both though replacing the promoter of the gene araE, could consume only 5.4 g/l xylose in 24 h and 10 g/l xylose in 32 h, respectively.

However, there was no direct connection between the regulator SinR and xylose metabolism. Protein SinR is a pleiotropic regulator in B. subtilis which regulates many genes evolved in competence for genetic transformation, sporulation, protease production, motility, and so on (Gaur et al. 1991; Hamoen et al. 2003; Mandic-Mulec et al. 1995; Sekiguchi et al. 1988). The motility test of strain 168ARSR on the semisolid medium (Fig. S2 in the Supplementary Material) suggested that the bacterial motility was seriously damaged. This was in accordance with the phenomenon reported previously that the motility would be damaged by the inactivation of gene sinR (Márquez-Magaña et al. 1994). Therefore, the proteins SinR of strain 168ARSR were believed to be inactivated due to this mutation, and the loss of motility of strain E72 was also the result of the mutation in gene sinR. But the specific growth rate of 168ARSD, the motility master sigma factor SigD deletion strain, had only a minor increase to 0.33 h−1 compared with the parental strain 168AR. This result suggested that the damage of motility was not the reason for the faster growth rate which resulted from the mutation of gene sinR. Gene comP, involved in the formation of competence for genetic transformation of B. subtilis (Piazza et al. 1999), also had no direct connection with xylose metabolism. And protein ComP was also believed to be inactivated by the mutation, because a five-fold decrease in the efficiency of chemical transformation was observed in strain 168ARSRCP compared with strain 168ARSR (Fig. S3 in the Supplementary Material). Moreover, because of the comP mutation, the color of the culture of strain 168ARSRCP at the later stage of fermentation changed to red, which probably resulted from the red pigment production (Tang et al. 2006) by this strain. The same color phenotype of strain E72 was believed to be also resulted from the mutation of comP. The reasons for the improved growth resulted from the mutations of sinR and comP are still unknown and need further research which is underway in our lab.

Laboratory evolution is a powerful tool for optimization of the phenotype and performance of bacterial strains. However, side effects and undesired phenotypes will likely be produced by adaptive evolution, some of which are harmless with regard to the phenotype concerned, whereas some are not. The process of genome sequencing-based strain reconstruction can obtain strains with better performance than the evolved strains through exclusion of the harmful mutations and retention of the beneficial mutations. In this study, the evolved strain E72 could utilize xylose efficiently, however, a long lag phase was observed in xylose minimal medium for this strain. In contrast, the reconstructed strain 168ARSRCP not only could assimilate xylose rapidly similar to strain E72, but also had a shorter lag phase than E72. In addition, the efficiency of transformation of E72 was extremely low (10 cfu/μg of DNA) and as a result it was difficult to manipulate this strain genetically in the future. As compared to E72, the efficiency of transformation of strain 168ARSRCP was much higher (240 cfu/μg of DNA), which was sufficient for further general DNA manipulation. It proves that the effect of combination of evolutionary engineering, whole-genome sequencing, and inverse metabolic engineering will be more powerful than the traditional employment of evolutionary engineering or metabolic engineering alone. As supplementation and extension of the traditional engineering methods, these combined technologies will be very useful for strain optimization.

References

Anagnostopoulos C, Spizizen J (1961) Requirements for transformation in Bacillus subtilis. J Bacteriol 81(5):741–746

Barbe V, Cruveiller S, Kunst F, Lenoble P, Meurice G, Sekowska A, Vallenet D, Wang T, Moszer I, Medigue C, Danchin A (2009) From a consortium sequence to a unified sequence: the Bacillus subtilis 168 reference genome a decade later. Microbiol (UK) 155:1758–1775. doi:10.1099/mic.0.027839-0

Butcher RA, Schroeder FC, Fischbach MA, Straightt PD, Kolter R, Walsh CT, Clardy J (2007) The identification of bacillaene, the product of the PksX megacomplex in Bacillus subtilis. Proc Natl Acad Sci U S A 104(5):1506–1509. doi:10.1073/pnas.0610503104

Chen T, Liu WX, Fu J, Zhang B, Tang YJ (2013) Engineering Bacillus subtilis for acetoin production from glucose and xylose mixtures. J Biotechnol 168(4):499–505. doi:10.1016/j.jbiotec.2013.09.020

Chillappagari S, Miethke M, Trip H, Kuipers OP, Marahiel MA (2009) Copper acquisition is mediated by YcnJ and regulated by YcnK and CsoR in Bacillus subtilis. J Bacteriol 191(7):2362–2370. doi:10.1128/JB.01616-08

Cox J, Schubert AM, Travisano M, Putonti C (2010) Adaptive evolution and inherent tolerance to extreme thermal environments. BMC Evol Biol 10(75):1471–2148. doi:10.1186/1471-2148-10-75

Craig JE, Ford MJ, Blaydon DC, Sonenshein AL (1997) A null mutation in the Bacillus subtilis aconitase gene causes a block in Spo0A-phosphate-dependent gene expression. J Bacteriol 179(23):7351–7359

Ekberg J, Rautio J, Mattinen L, Vidgren V, Londesborough J, Gibson BR (2013) Adaptive evolution of the lager brewing yeast Saccharomyces pastorianus for improved growth under hyperosmotic conditions and its influence on fermentation performance. FEMS Yeast Res 13(3):335–349. doi:10.1111/1567-1364.12038

Fabret C, Ehrlich SD, Noirot P (2002) A new mutation delivery system for genome-scale approaches in Bacillus subtilis. Mol Microbiol 46(1):25–36. doi:10.1046/j.1365-2958.2002.03140.x

Fernández-Sandoval MT, Huerta-Beristain G, Trujillo-Martinez B, Bustos P, González V, Bolivar F, Gosset G, Martinez A (2012) Laboratory metabolic evolution improves acetate tolerance and growth on acetate of ethanologenic Escherichia coli under non-aerated conditions in glucose-mineral medium. Appl Microbiol Biotechnol 96(5):1291–1300. doi:10.1007/s00253-012-4177-y

Foulger D, Errington J (1998) A 28 kbp segment from the spoVM region of the Bacillus subtilis 168 genome. Microbiology 144(Pt 3):801–805

Fu J, Wang Z, Chen T, Liu W, Shi T, Wang G, Tang Y-J, Zhao X (2014) NADH plays the vital role for chiral pure D-(−)-2,3-butanediol production in Bacillus subtilis under limited oxygen conditions. Biotechnol Bioeng. doi:10.1002/bit.25265

Gaur NK, Oppenheim J, Smith I (1991) The Bacillus subtilis sin gene, a regulator of alternate developmental processes, codes for a DNA-binding protein. J Bacteriol 173(2):678–686

Haima P, Bron S, Venema G (1987) The effect of restriction on shotgun cloning and plasmid stability in Bacillus subtilis Marburg. Mol Gen Genet 209(2):335–342. doi:10.1007/BF00329663

Hamoen LW, Venema G, Kuipers OP (2003) Controlling competence in Bacillus subtilis: shared use of regulators. Microbiology 149(Pt 1):9–17. doi:10.1099/mic.0.26003-0

Hanahan D (1985) Techniques for transformation of E. coli. In: Glover DM (ed) DNA cloning: a practical approach, vol 1. IRL, Oxford, pp 109–135

Harwood CR, Cutting SM, Chambert R (1990) Molecular biological methods for Bacillus. Wiley, Chichester

Herring CD, Raghunathan A, Honisch C, Patel T, Applebee MK, Joyce AR, Albert TJ, Blattner FR, van den Boom D, Cantor CR, Palsson BO (2006) Comparative genome sequencing of Escherichia coli allows observation of bacterial evolution on a laboratory timescale. Nat Genet 38(12):1406–1412. doi:10.1038/ng1906

Hua Q, Joyce AR, Palsson BØ, Fong SS (2007) Metabolic characterization of Escherichia coli strains adapted to growth on lactate. Appl Environ Microbiol 73(14):4639–4647. doi:10.1128/aem.00527-07

Inaoka T, Matsumura Y, Tsuchido T (1999) SodA and manganese are essential for resistance to oxidative stress in growing and sporulating cells of Bacillus subtilis. J Bacteriol 181(6):1939–1943

Kim OC, Suwannarangsee S, Oh DB, Kim S, Seo JW, Kim CH, Kang HA, Kim JY, Kwon O (2013a) Transcriptome analysis of xylose metabolism in the thermotolerant methylotrophic yeast Hansenula polymorpha. Bioprocess Biosyst Eng 36(10):1509–1518. doi:10.1007/s00449-013-0909-3

Kim SR, Park Y-C, Jin Y-S, Seo J-H (2013b) Strain engineering of Saccharomyces cerevisiae for enhanced xylose metabolism. Biotechnol Adv 31(6):851–861. doi:10.1016/j.biotechadv.2013.03.004

Krispin O, Allmansberger R (1998) The Bacillus subtilis AraE protein displays a broad substrate specificity for several different sugars. J Bacteriol 180(12):3250–3252

Kuhad RC, Gupta R, Khasa YP, Singh A, Zhang YHP (2011) Bioethanol production from pentose sugars: current status and future prospects. Renew Sust Energ Rev 15(9):4950–4962. doi:10.1016/j.rser.2011.07.058

Lawlis VB, Dennis MS, Chen EY, Smith DH, Henner DJ (1984) Cloning and sequencing of the xylose isomerase and xylulose kinase genes of Escherichia coli. Appl Environ Microbiol 47(1):15–21

Lazarevic V, Soldo B, Medico N, Pooley H, Bron S, Karamata D (2005) Bacillus subtilis α-phosphoglucomutase is required for normal cell morphology and biofilm formation. Appl Environ Microbiol 71(1):39–45. doi:10.1128/AEM.71.1.39-45.2005

Lee D-H, Palsson BØ (2010) Adaptive evolution of Escherichia coli K-12 MG1655 during growth on a nonnative carbon source, L-1,2-propanediol. Appl Environ Microbiol 76(13):4158–4168. doi:10.1128/aem.00373-10

Lee J-Y, Seo J, Kim E-S, Lee H-S, Kim P (2013) Adaptive evolution of Corynebacterium glutamicum resistant to oxidative stress and its global gene expression profiling. Biotechnol Lett 35(5):709–717. doi:10.1007/s10529-012-1135-9

Liu Y, Liu L, Shin H-D, Chen RR, Li J, Du G, Chen J (2013) Pathway engineering of Bacillus subtilis for microbial production of N-acetylglucosamine. Metab Eng 19:107–115. doi:10.1016/j.ymben.2013.07.002

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2-ΔΔCT Method. Methods 25(4):402–408. doi:10.1006/meth.2001.1262

Mandic-Mulec I, Doukhan L, Smith I (1995) The Bacillus subtilis SinR protein is a repressor of the key sporulation gene spo0A. J Bacteriol 177(16):4619–4627

Márquez-Magaña LM, Mirel DB, Chamberlin MJ (1994) Regulation of sigma D expression and activity by spo0, abrB, and sin gene products in Bacillus subtilis. J Bacteriol 176(8):2435–2438

Meijnen J-P, de Winde JH, Ruijssenaars HJ (2008) Engineering Pseudomonas putida S12 for efficient utilization of D-xylose and L-arabinose. Appl Environ Microbiol 74(16):5031–5037. doi:10.1128/aem.00924-08

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96(6):673–686. doi:10.1016/j.biortech.2004.06.025

Mota LJ, Tavares P, Sa-Nogueira I (1999) Mode of action of AraR, the key regulator of L-arabinose metabolism in Bacillus subtilis. Mol Microbiol 33(3):476–489. doi:10.1046/j.1365-2958.1999.01484.x

Paik SH, Chakicherla A, Hansen JN (1998) Identification and characterization of the structural and transporter genes for, and the chemical and biological properties of, sublancin 168, a novel lantibiotic produced by Bacillus subtilis 168. J Biol Chem 273:23134–23142. doi:10.1074/jbc.273.36.23134

Park YC, Jun SY, Seo JH (2012) Construction and characterization of recombinant Bacillus subtilis JY123 able to transport xylose efficiently. J Biotechnol 161(4):402–406. doi:10.1016/j.jbiotec.2012.07.192

Piazza F, Tortosa P, Dubnau D (1999) Mutational analysis and membrane topology of ComP, a quorum-sensing histidine kinase of Bacillus subtilis controlling competence development. J Bacteriol 181(15):4540–4548

Portnoy VA, Bezdan D, Zengler K (2011) Adaptive laboratory evolution—harnessing the power of biology for metabolic engineering. Curr Opin Biotechnol 22(4):590–594. doi:10.1016/j.copbio.2011.03.007

Scalcinati G, Otero JM, Van Vleet JRH, Jeffries TW, Olsson L, Nielsen J (2012) Evolutionary engineering of Saccharomyces cerevisiae for efficient aerobic xylose consumption. FEMS Yeast Res 12(5):582–597. doi:10.1111/j.1567-1364.2012.00808.x

Schiott T, von Wachenfeldt C, Hederstedt L (1997) Identification and characterization of the ccdA gene, required for cytochrome c synthesis in Bacillus subtilis. J Bacteriol 197(6):1962–1973

Schmiedel D, Hillen W (1996) A Bacillus subtilis 168 mutant with increased xylose uptake can utilize xylose as sole carbon source. FEMS Microbiol Lett 135(2–3):175–178. doi:10.1016/0378-1097(95)00445-9

Schurmann M, Sprenger GA (2001) Fructose-6-phosphate aldolase is a novel class I aldolase from Escherichia coli and is related to a novel group of bacterial transaldolases. J Biol Chem 276(14):11055–11061. doi:10.1074/jbc.M008061200

Sekiguchi J, Ezaki B, Kodama K, Akamatsu T (1988) Molecular cloning of a gene affecting the autolysin level and flagellation in Bacillus subtilis. J Gen Microbiol 134(6):1611–1621

Shen Y, Chen X, Peng B, Chen L, Hou J, Bao X (2012) An efficient xylose-fermenting recombinant Saccharomyces cerevisiae strain obtained through adaptive evolution and its global transcription profile. Appl Microbiol Biotechnol 96(4):1079–1091. doi:10.1007/s00253-012-4418-0

Shi S, Chen T, Zhang Z, Chen X, Zhao X (2009) Transcriptome analysis guided metabolic engineering of Bacillus subtilis for riboflavin production. Metab Eng 11(4–5):243–252. doi:10.1016/j.ymben.2009.05.002

Sonderegger M, Sauer U (2003) Evolutionary engineering of Saccharomyces cerevisiae for anaerobic growth on xylose. Appl Environ Microbiol 69(4):1990–1998. doi:10.1128/aem.69.4.1990-1998.2003

Steller S, Vollenbroich D, Leenders F, Stein T, Conrad B, Hofemeister J, Jacques P, Thonart P, Vater J (1999) Structural and functional organization of the fengycin synthetase multienzyme system from Bacillus subtilis b213 and A1/3. Chem Biol 6(1):31–41. doi:10.1016/S1074-5521(99)80018-0

Tang MR, Sternberg D, Behr RK, Sloma A, Berka RM (2006) Use of transcriptional profiling and bioinformatics to solve production problems: eliminating red pigment production in a Bacillus subtilis strain producing hyaluronic acid. Ind Biotechnol 2(1):66–74. doi:10.1089/ind.2006.2.66

Utrilla J, Licona-Cassani C, Marcellin E, Gosset G, Nielsen LK, Martinez A (2012) Engineering and adaptive evolution of Escherichia coli for D-lactate fermentation reveals GatC as a xylose transporter. Metab Eng 14(5):469–476. doi:10.1016/j.ymben.2012.07.007

Wang Y, Manow R, Finan C, Wang J, Garza E, Zhou S (2011) Adaptive evolution of nontransgenic Escherichia coli KC01 for improved ethanol tolerance and homoethanol fermentation from xylose. J Ind Microbiol Biotechnol 38(9):1371–1377. doi:10.1007/s10295-010-0920-5

Wang M, Fu J, Zhang X, Chen T (2012) Metabolic engineering of Bacillus subtilis for enhanced production of acetoin. Biotechnol Lett 34(10):1877–1885. doi:10.1007/s10529-012-0981-9

Wilhelm M, Hollenberg CP (1985) Nucleotide sequence of the Bacillus subtilis xylose isomerase gene: extensive homology between the Bacillus and Escherichia coli enzyme. Nucleic Acids Res 13(15):5717–5722

Yanisch-Perron C, Vieira J, Messing J (1985) Improved M13 phage cloning vectors and host strains: nucleotide sequences of the M13mp18 and pUC19 vectors. Gene 33(1):103–119. doi:10.1016/0378-1119(85)90120-9

Zhang J, Wu C, Du G, Chen J (2012) Enhanced acid tolerance in Lactobacillus casei by adaptive evolution and compared stress response during acid stress. Biotechnol Bioprocess Eng 17(2):283–289. doi:10.1007/s12257-011-0346-6

Zhou H, Cheng J-S, Wang BL, Fink GR, Stephanopoulos G (2012) Xylose isomerase overexpression along with engineering of the pentose phosphate pathway and evolutionary engineering enable rapid xylose utilization and ethanol production by Saccharomyces cerevisiae. Metab Eng 14(6):611–622. doi:10.1016/j.ymben.2012.07.011

Acknowledgments

This work was supported by National 973 Project [2011CBA00804, 2012CB725203]; National Natural Science Foundation of China [NSFC-21176182, NSFC-21206112, NSFC-21390201]; Natural Science Foundation of Tianjin (No. 12JCYBJC12900); the Research Fund for the Doctoral Program of Higher Education (20100032120014); the Independent Innovation of Tianjin University (No. 2010XJ-0049).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 564 kb)

Rights and permissions

About this article

Cite this article

Zhang, B., Li, N., Wang, Z. et al. Inverse metabolic engineering of Bacillus subtilis for xylose utilization based on adaptive evolution and whole-genome sequencing. Appl Microbiol Biotechnol 99, 885–896 (2015). https://doi.org/10.1007/s00253-014-6131-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6131-7