Abstract

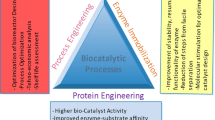

Industry has an increasing interest in the use of enzymes as environmentally friendly, highly efficient, and specific bio-catalysts. Enzymes have primarily evolved to function in aqueous environments at ambient temperature and pressure. These conditions however do not always correspond with industrial processes or applications, and only a small portion of all known enzymes are therefore suitable for industrial use. Protein engineering can sometimes be applied to convey more desirable properties to enzymes, such as increased stability, but is limited to the 20 naturally occurring amino acids or homologs thereof. Using post-production modification, which has the potential to combine desirable properties from the enzyme and the conjugated compounds, enzymes can be modified with both natural and synthetic molecules. This offers access to a myriad of possibilities for tuning the properties of enzymes. At this moment, however, the effects of post-production modification cannot yet be reliably predicted. The increasing number of applications will improve this so that the potential of this technology can be fully exploited. This review will focus on post-production modification of enzymes and its use and opportunities in industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymes are exceptional catalysts; they are capable of catalyzing a great variety of chemical transformations, and do so with high stereoselectivity, regioselectivity, and chemoselectivity, producing almost exclusively the desired product without unwanted side-products. As full conversion of reactants is not desired for every application, enzyme activity can be fine-tuned to fit the needs of the process. In addition, they function at ambient pressure and temperature, in contrast to most chemical syntheses. Better understanding of enzymes and improved production technologies has led to an increase in their application in industry (Iyer and Ananthanarayan 2008; Van den Berg et al. 2012). Enzymes are utilized in various industrial sectors such as the detergent, paper, food and pharmaceutical industry (Kirk et al. 2002). The demands of these industries with regard to enzyme performance, substrate specificity, stability, solubility, pharmacokinetic and pharmacodynamics properties are diverse and tuning of enzymes to fit the needs of a specific process is often desired. Protein engineering is often used to improve enzymes (Recktenwald et al. 1993), and while this is a powerful method, it is limited to the use of the 20 natural amino acids. Recently, it became possible to incorporate non-natural amino acids into enzymes (Kwon and Lim 2013; Schoffelen et al. 2008; Van Deventer et al. 2011), which can change the properties of the enzyme; however, this method is limited to incorporation of small, amino acid like groups. Furthermore, this approach often leads to a decrease in expression efficiency, which is undesirable for industrial applications. In nature, enzymes are often modified post-translational by addition of glycan chains (Spiro 2002), farnesyl groups (Novelli and D’Apice 2012), phosphate groups (Tarrant and Cole 2009), formyl groups (Baslé et al. 2010; Mader et al. 2013) or acetyl groups (Arif et al. 2010). These modifications can target enzymes to specific cellular compartments, activate or stabilize the protein. The engineering of post-translational modification (PTM) can be used to convey different properties on enzymes, like introduction of carbohydrate binding modules (CBM), glycosylation sequences or insertion of purification tags. As with protein engineering, modifications are limited to naturally occurring substances and processes; in addition, the modification of proteins during production can have a (negative) impact on the expression and purification efficiency. Alternatively, modification of enzymes can be done after expression and purification, i.e., post-production modification (PPM). In PPM, the enzyme can be modified with a selection of natural and synthetic substances with the goal to improve its properties to better suit the needs of the specific application. This review will focus on PPM and its use in industry. Crosslinking and immobilization strategies are often employed to increase stability, activity, and solvent tolerance of enzymes. These strategies have been extensively reviewed in other articles (Sheldon and van Pelt 2013; DiCosimo et al. 2013; Hanefeld et al. 2009; Franssen et al. 2013; Liese and Hilterhaus 2013), and will not be discussed here.

Modification methods

Chemical modification

Not all amino acids are equally suited to serve as an attachment point for modification. For this, the amino acids need to be situated on the surface of the enzyme, and contain a reactive group. Lysine, cysteine, glutamic acid, aspartic acid, serine, tyrosine, tryptophan residues can all be modified (Canalle et al. 2010), although not all are typically used. The majority of chemical modifications are performed using either lysine or cysteine (Hackenberger and Schwarzer 2008; Sletten and Bertozzi 2009; Davis 2003).

The ε-amine group of the lysine is reactive under physiological and alkaline conditions, and a wide variety of chemical methods are available for the modification of the lysine side chain (Fig. 1a) (Sletten and Bertozzi 2009). Different methods tend to be preferred for the attachment of different moieties to the enzymes. A more detailed discussion of specific methods can be found in the section commonly applied modification moieties. As multiple lysines are present on the surface of almost all enzymes, lysine modification can readily be applied to almost all proteins. Due to the presence of multiple lysines which can differ in reactivity towards the chemicals used, modification almost invariably results in differences in the modification degree and positions.

Like the ε-amine group of the lysine, the thiol headgroup of cysteine is also readily modified with a variety of methods (Fig. 1b) (Sletten and Bertozzi 2009; Hackenberger and Schwarzer 2008; Bernardes et al. 2008). In contrast to lysine, cysteine residues are mostly found in the interior of enzymes, and often bound to a second cysteine forming a sulfur bridge. They do offer the potential for site-selective modification, and can be introduced at a specific suitable position through protein engineering.

Glutamic and aspartic acid, which contain a carboxylic acid on their side chain, can be coupled to amine-containing molecules using peptide coupling strategies, usually using 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) as an activating agent.

Serine, tyrosine, and tryptophan are rarely used for enzyme modification. They are usually not present on the surface of enzymes, and require less standard coupling strategies (Sletten and Bertozzi 2009; McFarland et al. 2008; Romanini and Francis 2008; Tilley and Francis 2006; Canalle et al. 2010). Only a small portion of all enzymes can thus be modified this way.

In addition, the N-termini of proteins can be selectively modified, using the small pK a difference between the N-terminal α-amine group and the ε-amine groups of lysines (Dixon 1984; Witus et al. 2013).

Enzymatic modification

The vast majority of post-production modifications are currently carried out using chemical modification strategies. Enzymatic modification methods are emerging; they offer a biocompatible route to protein modification, typically with high site specificity and without the use of toxic chemicals or creation of toxic waste products. However, they usually cannot be applied directly to any protein, as they generally require specific recognition sequences or residues. Several enzyme classes have the ability to modify other enzymes in vivo, a review by Heck et al. (2013) provides an overview. One of the main industrial applications is protein crosslinking through oxidative enzymes, peptidases, and transglutaminase for food products (Heck et al. 2013). Here, we will limit the discussion to protein decorating enzymes, mainly through five enzyme types: transglutaminase, sortase A, protein farnesyltransferase (PFTase), endoglycosidase H (EndoH), and peptide-N-glycosidase F (PNGaseF).

Transglutaminase (Canalle et al. 2010) links a glutamyl to a primary amine-containing group like a lysyl (Lorand and Graham 2003) (Fig. 2a). It is mainly used in industry to “glue” pieces of meat or fish together, but it also has applications in dairy- and wheat-based products (Yokoyama et al. 2004). By forming crosslinks between the proteins, new structures can be obtained as well as coatings to preserve and stabilize food products. Transglutaminase can also be used to couple non-protein compounds containing a primary amine to a glutaminyl on an enzyme. This strategy has for example been used to couple polyethylene glycol (PEG) chains to several proteins (Fontana et al. 2008; Sato 2002) and trypsin to cyclodextrins (Villalonga et al. 2003).

Transglutaminase also has deamidation activity (Boros et al. 2006; Fleckenstein et al. 2002), which could be used to lower the stability of enzymes. Site-directed mutagenesis studies modifying the asparagine or glutamine residues have shown that deamidation usually lowers the (thermo)stability of enzymes (Chen et al. 1994; Ahern et al. 1987; Tomazic and Klibanov 1988). Enzymatic or chemical deamidation might therefore be expected to have similar effects on enzyme stability. This could be of use in the food industry, where enzymes typically have to be inactivated at relatively low temperatures. Care must be taken however, as along with a decrease in stability, often also a decrease in activity is observed (Ahern et al. 1987; Zale and Klibanov 1986; DeLuna et al. 2005). Chemical deamidation is relatively easy through acid or base hydrolysis. However, strong alkaline or acidic treatments can result in unwanted protein degradation. Alternatively, milder alkali or acid treatments can be used in combination with higher temperatures, although the elevated temperature could also result in protein degradation. Enzymatic deamidation would allow for mild reaction conditions. In addition to transglutaminase, which can deamidate proteins in absence of primary amines and at low pH, also peptidoglutaminase (Pgase) (Hamada 1994) and protein glutaminase (PG), which converts glutamine into glutamate (Miwa et al. 2010; Yie et al. 2006; Yamaguchi and Yokoe 2000), can be used for the deamidation of proteins.

While transglutaminase is quite aspecific, Sortase A mediates the ligation between an acceptor molecule containing a LPXTG motif and a donor molecule containing an N-terminal oligoglycin motif (Wu and Guo 2012; Spirig et al. 2011). The glycine and all amino acids on the C-terminal side of the LPXTG motif are replaced by the substrate molecule (Fig. 2b). The substrate molecule preferably contains multiple glycines, although conjugation with a single glycine tagged substrate molecule (Proft 2010) or aminomethylene groups have also been reported (Samantaray et al. 2008) albeit with reduced efficiency. The LPXTG motif can be introduced using protein engineering, or chemical synthesis, both requiring an extra modification step before ligation to the substrate. It has been shown that a large number of different chemical entities, like carbohydrates (Samantaray et al. 2008), small organic molecules (Maximilian et al. 2007), lipids (Antos et al. 2008), and synthetic polymers (Popp et al. 2011) can serve as substrates, as long as they contain C-terminal glycines or aminomethylene groups. When incorporating both a LPXTG motif and an oligoglycine sequence in the same enzyme, it is possible to circularize the enzyme (Antos et al. 2009), which can have a stabilizing effect on the enzyme, due to reduced N or C-terminal protease reactivity and a decreased flexibility of the enzyme. Sortase A can also transfer the LPXTG motif from the donor molecule to the ε-amino group of substrate molecules, thereby forming branched oligomers (Dasgupta et al. 2011). While a peptidase like Sortase A depends on a specific target sequence and is able to recognize this at various positions in a protein, other protease dependent methods are developed to specifically target the free amine at the N-terminus. To this end, IgA-Protease was employed to specifically modify IgA’s through controlled reversed proteolysis in water (Lewinska et al. 2004).

In a similar fashion, PFTase can be used to introduce a farnesyl group in proteins (Rashidian et al. 2012). PFTase catalyzes the reaction of a farnesyl group to a cysteine, when that cysteine is followed by two aliphatic amino acids and M, S, Q, A, or C, a so-called CAAX box. If this sequence is not present in the enzyme it can be introduced at the C-terminus, where the AAX sequence can be removed by treating the enzyme with carboxypeptidase after the farnesylation (Fig. 2c). By using farnesyl groups that contain a specific functional group, the farnesyl group can serve as a handle to site-specifically attach other moieties such as fluorescent labels or PEG.

Eukaryotes, as well as some industrially less relevant prokaryotes, are able to glycosylate enzymes (Messner 2004). This can serve diverse functions before as well as after expression of the enzyme (reviewed in Varki 1993). One of the functions of glycosylation is stabilization of the enzyme; consequently, many (secreted) enzymes are glycosylated. While for many applications increased stability and activity are desired, this is not true for all applications. For instance in food applications, where heat inactivation of enzymes at low temperatures is sometimes necessary to prevent ingestion of active enzymes, or incomplete conversion of the substrate is needed in order to obtain the desired food properties.

While deglycosylation can be achieved by removal of the glycosylation sequences from the encoding DNA sequence, this is not always the preferred method, as the glycan chains might have a significant function during protein expression. EndoH and PNGaseF are two enzymes that can remove the glycan chains from glycoproteins (Koide and Muramatsu 1974; Lee et al. 1986), although they have a different mode of action; i.e., EndoH cleaves the bond between two N-acetylglucosamine units linked to an asparagine, leaving only one unit linked to the amino acid, while PNGaseF breaks the bond between most types of glycosyl units and asparagine, and deamidates the remaining asparagine to an aspartic acid. As the functions of carbohydrate chains on proteins are diverse, deglycosylation can result either in drastic property changes of the enzyme or in no change at all (Ritter et al. 2013). The effects are thus difficult to predict, depending on the glycosylation site (Chen et al. 1994) and highly enzyme specific.

Deglycosylation of human liver α-l-fucosidase by PNGaseF did not result in changes in the catalytic properties of the enzyme, but did lead to decreased activity at acid pH, and to decreased thermostability (Piesecki and Alhadeff 1992).

Heterologous expression of enzymes can lead to differences in glycosylation pattern and the extent of glycosylation. This can influence the performance of enzymes, as demonstrated for Cel7A, a cellulase, which showed significantly increased N-glycosylation upon heterologous expression. This contributed to a decreased enzymatic activity, which could be partially restored by PNGaseF deglycosylation (Jeoh et al. 2008).

Commonly applied modification moieties

PEGylation

One of the most frequently applied post-production modification is PEGylation. The covalent attachment of polyethylene glycol (PEG) molecules to the surface of proteins can convey among other attributes, increased solubility in organic solvents (Koops et al. 1999; Quintanilla-Guerrero et al. 2008; Mabrouk 1997), thermostability (López-Cruz et al. 2006; He et al. 2000; Zhang et al. 2001), increased pharmacokinetic and pharmacodynamics properties (Milton Harris and Chess 2003).

PEG is a synthetic polymer for which a wide range of molecular masses are commercially available. It is very hygroscopic and binds two to three water molecules per monomer unit in aqueous solutions. In combination with a very flexible polymer backbone, this leads to high hydrodynamic volumes of PEG in aqueous solvents. Since it is a synthetic polymer, it is inherently polydisperse, with polydispersity values ranging from 1.01 for low MW polymers to 1.2 for high molecular weight polymers (Veronese 2001). For protein conjugation purposes, mostly the monomethoxylated variant of PEG (mPEG) is used, of which only the hydroxyl end can be functionalized. This prevents crosslinking of proteins, which could occur using PEG diol. Unfortunately, up to 10 % PEG diol can be present in mPEG (Dust et al. 1990). This can be removed by creating carboxymethyl functionalized PEG (CM-PEG) (Fig. 3), subsequently the mono and di-substituted variants can be separated using ion-exchange chromatography.

PEGylation methods

A variety of modification methods has been developed for coupling of ε-amino groups of lysine and the α-amino group of the N-terminus with PEG chains. To couple PEG to amino groups on the protein, it is necessary to activate the PEG molecule. A range of activating agents can be used for this (Fig. 4) (Milton Harris and Chess 2003; Roberts et al. 2002), each with their own advantages and disadvantages (Milton Harris and Chess 2003; Adamczak and Krishna 2004; Zhang et al. 2009; Bianchi et al. 1993; Canalle et al. 2010; Veronese and Pasut 2005).

Methods of PEG coupling to primary amines on proteins. a PEG trichlorophenyl carbonate; b PEG p-nitrophenylcarbonate; c PEG benzotriazole carbonate; d PEG carbonylimidazole; e PEG succinimidyl carbonate; f PEG succinimidyl ester; g PEG dichlorotriazine; h PEG2 chlorotriazine; i PEG succinate succinimidyl diester; j PEG tresylate; k PEG epoxide; l PEG propanal

If the positive charge on lysine is important for biological functionality, then alkylating PEGs can be used (Fig. 4j–l), preserving the positive charge. PEG-aldehyde can react with amino groups on the protein to form a Schiff base, which after cyanoborohydride reduction gives a permanent linkage. Unfortunately, this reaction is slow, up to a day can be necessary to functionalize enzymes, which is a disadvantage for more labile enzymes. In addition, cyanoborohydride is toxic. In pharmaceutical or food applications this is highly undesirable, but for biocatalysis applications this can be acceptable. Alternatively, tresyl chloride (Heiss 1995; Khan et al. 1992) can be used (Fig. 4j); although this often results in ill-defined reaction products (Roberts et al. 2002). A more frequently used activating agent is trichlorotriazine (Abuchowski et al. 1977a; b). The activated PEG (Fig. 4g) can react with several amino acid reactive groups, displacing one of the chlorides. Reactions with the remaining less reactive chloride can lead to the formation of cross-linked products. To overcome this problem, Matsushima et al. (1980) developed a trichlorotriazine functionalized with two PEG molecules (Fig. 4h), thus creating a branched PEG moiety. The only remaining chloride has a lower reactivity, thus resulting in a more selective modification of lysines and cysteines. Coupling with trichlorotriazine is fast and easy, it gives stable products, but the reaction intermediate is also toxic.

Acylated PEGs result in the removal of the positive charge of lysines (Fig. 4a–i). To this end, PEGs can be activated as hydroxysuccidimidyl esters (OSu), chloroformates (Veronese et al. 1985), or pentafluorophenyl esters (Abello et al. 2008). The reaction conditions are generally mild. Variants with higher stability against hydrolysis are propionic or butanoic acid derivatives (Fig. 5) (Harris and Kozlowski 1997). The higher stability is the result of the increased distance between the active ester and PEG by the alkane spacer.

Due to the prevalence of lysines in proteins, reaction with PEG usually results in a high degree of modification, but also in heterogeneous products with varying number of PEG chains attached to proteins at different positions. While for biocatalysis applications a high degree of modification is often important, for pharmaceutical applications, reproducibility is highly important and therefore the formation of isomers due to the modification of different lysines is undesirable. Modification techniques that are more site-selective have been developed (González and Vaillard 2013; Veronese and Pasut 2005). By lowering the pH during reaction of PEG with the protein, the more reactive α-amino group of the N-terminus can be preferentially targeted (Gaudriault and Vincent 1992; Kinstler et al. 2002; Hu and Sebald 2011). Thiol groups can also be targeted, using vinylsulfones, maleimides, and iodoacetamides. Since the latter two can also react with lysines, the reaction conditions have to be optimized to prevent this.

Alternatively, enzymatic PEGylation can be applied to introduce site-selective modifications. Transglutaminase catalyzes the acyl transfer between the carboxamide group of glutamine and the amino group of activated PEG-modules. Even more sophisticated single, targeted PEGylation is being explored by engineering Escherichia coli to efficiently produce proteins with add-on site-specific glycan (GalNAc) residue(s). PPM can target the glycan as site for PEGylation using sialyltransferase enzyme (Wright 2013).

Quantification of number of PEG molecules bound

Determining the amount of PEG bound to proteins is not trivial, as PEG is non-fluorescent, does not react easily and has different hydrodynamic properties from proteins making size exclusion difficult to quantify. Usually, the amount of bound PEG is derived from the decrease of free and detectable amine groups on the surface of proteins. This method is not completely reliable, as it is based on colorimetric or fluorimetric assays, which have an intrinsic variability. Additionally, the protein concentration needs to be separately determined.

SDS-PAGE might also be used, but this method is limited to low MW conjugates, as PEG hampers gel penetration, which together with the polydisperse nature of PEG leads to smearing of the bands, hindering quantification. Mass spectrometry, mostly MALDI or ESI-TOF can also be used for analysis (Gioacchini et al. 1997), because the product can be separated based on mass. In combination with endoproteinase digestion, this can also reveal the locations of the modifications, provided the different isoforms have been separated prior to analysis. In the absence of an internal standard, these methods are not quantitative however, and the percentage of modified/unmodified can thus not be determined. The most quantitative method involves introducing a norleucine spacer between PEG and protein (Sartore et al. 1991). After separating the protein from unreacted PEG, hydrolysis of the protein-PEG conjugate and subsequent determination of the norleucine content gives the average modification degree. As this method increases the costs of the procedure, it might be more applicable on labscale rather than on industrial scale.

Applications

In biocatalysis, PEGylation of enzymes is applied to enhance solubility and stability in organic solvents, increase thermal and pH stability, and improve activity.

Increased solubility of enzymes in organic solvents has several benefits. It enables enzymatic reactions with hydrophobic substrates and/or products, that would not be (or poorly) soluble under aqueous conditions. The reduced presence of water can shift the equilibrium to favor synthesis over hydrolysis reactions, thus enabling the synthesis of polymers. This has been successfully applied to peptide synthesis by chymotrypsin (Rolland-Fulcrand et al. 1994). Similarly, side reactions for which water is needed can be reduced, and an enzymatic catalysis step can more easily be incorporated in a chemical synthesis pathway. The absence of water also eliminates microbial growth (Grant et al. 2004). The amphiphilic nature of PEG makes enzymes more soluble in organic solvents upon PEGylation (Kwon et al. 1999; Iyer and Ananthanarayan 2008; Polizzi et al. 2007; Koops et al. 1999; Pina et al. 1989; Quintanilla-Guerrero et al. 2008; Takahashi et al. 1984; Matsushima et al. 1984). Since PEG is very hygroscopic, it also provides the enzymes with a surrounding water layer and protects the enzymes from stripping of their water layer by polar organic solvents. It has been shown that water bound to enzymes is essential for their activity (Zaks and Klibanov 1988).

In addition to aiding solubilization of enzymes in organic solvents, PEG has also been shown to increase solubility of subtilisin and lipases from Candida rugosa in ionic solvents (Moniruzzaman et al. 2010).

The increased solubility of enzymes in organic solvents is a general effect of PEGylation. Other effects, like enhanced or decreased enzymatic activity, are to a large extent unpredictable. It is therefore necessary to optimize the degree of modification and length of the PEG chains for each enzyme and application (Gaertner and Puigserver 1992; Zhang et al. 2009). To retain or even enhance activity, it is important that amino acids essential for enzyme activity or stability are not modified with PEG. Residues with such an essential role are often linked via hydrogen or ion bonds with other residues, which decrease their reactivity and the likelihood of PEG functionalization. This mechanism however, does not always prevent functionalization of essential lysines or other residues, and thus contributes to the diverse effects of PEGylation on enzymatic activity. PEGylation of residues near the active site can limit binding of substrate, thereby reducing activity.

Thermostability is often desirable because it increases the operational stability of an enzyme at a defined temperature. It also enables the performance of reactions at higher temperatures, increasing reaction speed. As a rule of thumb, a two-fold increase in reaction rate is expected with a 10 °C increase in temperature (van’t Hoff’s rule). In addition, a higher thermostability increases the lifetime of the enzyme, when compared to less thermostable enzymes stored or used at the same temperature. PEGylation has been shown to increase thermal stability in among others: subtilisin (Yang et al. 1996), horseradish peroxidase (Garcia et al. 1998), trypsin (Zhang et al. 1999; Gaertner and Puigserver 1992), lipases (Basri et al. 1995; Hernáiz et al. 1999), penicillin G acylase (Kazan and Erarslan 1997), cellulase (Zhang et al. 2009), peroxidase (Quintanilla-Guerrero et al. 2008).

The stability increase by PEGylation is likely caused by either decreased charge repulsion on the surface, due to modification of the lysines or by the amphiphilic nature of PEG (Quintanilla-Guerrero et al. 2008). The hydrophilic regions of bound PEG connect with the hydrophilic parts of the protein surface, resulting in an organized shield of water molecules, while the hydrophobic part of PEG is bound to the hydrophobic parts on the protein surface, producing a shell-like structure, increasing the rigidity of the protein and decreasing the unfolding rate of the active site.

A second theory is that the increased thermal stability is caused by steric hindrance of the PEG chain, resulting in reduced autolysis and an increase in the number of hydrogen bonds, resulting in decreased thermal denaturation (Zhang et al. 2001; He et al. 2000). In general, a higher degree of modification with PEG seems to result in a higher thermal stability (Hernáiz et al. 1999; Zhang et al. 2009). Also the molecular weight of the PEG is important, however the optimum usually is with PEG molecules that neither have a very low molecular weight nor a very high molecular weight, but the exact optimum is dependent on the specific enzyme.

PEGylation is successfully used in the pharmaceutical industry, and several commercial therapeutical proteins are on the market (Table 1). Various excellent reviews have covered this in depth (Milton Harris and Chess 2003; Veronese and Pasut 2005; Pasut and Veronese 2012; Knop et al. 2010; Kling 2013; Veronese and Mero 2008), thus we will only provide a short overview here.

Similarly as for non-pharmaceutical applications, PEGylation of therapeutic proteins will often improve the pH stability and thermostability of the proteins. More important for pharmaceutical application is the positive influence of PEGylation on the pharmacokinetic and pharmacodynamic properties of the therapeutic proteins. Due to the increased size of PEGylated proteins, the renal clearance of especially smaller therapeutic proteins is lowered (Milton Harris and Chess 2003; Pasut and Veronese 2012). The amphiphilic nature of PEG can increase water-solubility of the proteins, and protein aggregation is lowered due to repulsion between PEGylated surfaces (Basu et al. 2006; Hinds et al. 2000). The half-life of the proteins is improved and immunogenicity is reduced (Pasut and Veronese 2009; Caliceti and Veronese 2003), leading to decreases in adverse side effects and uptake by cells of the immune system (Knop et al. 2010). Although the in vivo activity of PEGylated proteins is often decreased, this is balanced by the positive effects, resulting in an improved clinical effect (Milton Harris and Chess 2003).

Although PEG is considered non-toxic, there are concerns that with an increasing amount of PEGylated drugs, side effects might become noticeable, like accumulation in the body, degradation under stress, and interaction with the immune system (Knop et al. 2010; Caliceti and Veronese 2003; Schellekens et al. 2013; Garay et al. 2012). For pharmaceutical products, reproducibility and low batch-to-batch variation are extremely important. The so-called first generation PEGylation techniques based on modification of lysines with relatively low molecular weight linear mPEG have many drawbacks, such as mixtures of isomers, unstable linkages, sometimes toxic coupling reagents, small hydrodynamic radii, incomplete shielding of the protein immunogenic sites, and potential crosslinking of proteins due to the use of diol contaminated mPEG (Milton Harris and Chess 2003; Pasut and Veronese 2012; Kozlowski and Milton Harris 2001). Second-generation PEGylation techniques (Milton Harris and Chess 2003; Roberts et al. 2002) like site-specific coupling to a cysteine residue—introduced on the surface of the protein by engineering—is one of the solutions to isomeric mixtures. Branched PEGs improve shielding and results in a higher hydrodynamic volume as compared with linear PEG of the same molecular weight.

Glycoconjugation

It is estimated that about 50 % of all enzymes are glycosylated in nature (Apweiler et al. 1999) suggesting this can be beneficial. Glycosylation plays a role in targeting of enzymes, and influences activity, solubility and stability (Varki 1993; Shental-Bechor and Levy 2008; Dwek 1996). Glycoconjugation, the non-enzymatic modification of enzymes with natural or synthetic (poly)saccharides is different from glycosylation in some aspects. N-glycosylation only occurs at specific consensus sequences and the many different types of glycosylation often result in complex glycosylation patterns, which can serve as targeting signals. Each glycan chain attached to enzymes and proteins during post-translational modification in the cell is coupled to only one amino acid residue on the protein, while modification with polysaccharides often results in multipoint attachment of the chain to the protein.

Glycoconjugation of enzymes is often used to increase stability of enzymes (Mislovicová et al. 2006; Gonera et al. 2004; Villalonga et al. 1999; 2000; 2003; Rajalakshmi and Sundaram 1995), most notably thermal stability (Gonera et al. 2004; De La Casa et al. 2002; Venkatesh et al. 2005). This was clearly illustrated by the heterologous expression of different Pseudomonas aeruginosa elastase variants in Pichia pastoris. Removing one or more of the three glycosylation sites leads not only to a significant reduction in expression, but also to decreased stability for the hydrolytic (at 70 °C) as well as the synthetic (at 50 % v/v organic solvent) reactions (Han et al. 2014). There are several mechanisms through which glycoconjugation could improve stability. The addition of glycan chains to the surface of the enzyme increases the overall rigidity of the enzyme, thereby preventing unfolding. Intramolecular crosslinks caused by multipoint attachment of glycans have a similar effect, preventing unfolding by impairing the conformational freedom of the enzyme (Venkatesh et al. 2005). Electrostatic repulsion between the polyanionic glycans can prevent aggregation of the enzymes, which often plays an important role in thermal inactivation (Moskvichyov et al. 1986). Furthermore, salt bridges between the enzyme and the glycan can contribute to maintaining the active conformation (Perutz 1978).

Methods of glycoconjugation

The two most frequently used strategies to couple a polysaccharide to an enzyme are reductive alkylation and coupling using carbodiimides (Fig. 6). In reductive alkylation, the polysaccharide is first oxidized using NaIO4; this requires the presence of two adjacent hydroxyl groups. The amino groups on the enzyme can then react with the formed aldehydes, resulting in Schiff base formation. Reduction of the Schiff base gives a stable amino linkage between the enzyme and the polysaccharide. Reduction is commonly carried out with NaBH4 (Villalonga et al. 2000; Villalonga et al. 1999; De La Casa et al. 2002) or NaCNBH4 (Mislovicová et al. 2006; Sundaram and Venkatesh 1998). Sodium borohydride is a stronger reducing agent than NaCNBH4. When added during the coupling reaction, it will therefore reduce the oxidized hydroxyl groups, leading to a decrease in the modification degree. For this reason, it is usually added after the coupling reaction. NaCNBH4 is a milder reducing agent and can be added during the coupling reaction, however, due to the cyanide group, it is toxic. Siddiqui and Cavicchioli (2005), have successfully used borane-pyridine complex, a mild non-toxic reducing agent as an alternative to the borohydrides.

Another commonly employed strategy is the use of a carbodiimide to couple a carboxy group and a primary amine group. Some polysaccharides, like carboxymethylcellulose (CMC) contain carboxyl groups, which can be coupled to lysines on the enzymes (Matos et al. 2012). Alternatively, polysaccharides can be functionalized with NH2 groups (Hernández et al. 2006; Fernández et al. 2005).

Chemoenzymatic coupling methods have also been developed; transglutaminase can be used to couple polysaccharides functionalized with a diamine, thus resembling a lysine side chain, to glutamine residues on the surface of enzymes (Villalonga et al. 2003). A different method consists of two steps: in the first step, the enzyme is functionalized with sucrose molecules that have been activated with cyanogen bromide; in the second step the glycosidic chain is enzymatically lengthened using fructosyltransferase from A. niger (Longo and Combes 1995; Longo and Combes 1997).

Applications

Proteases are important enzymes in diverse industries, such as the pharmaceutical, detergent, and food. Several glycoconjugation strategies have been described to improve the properties of trypsin. For use in the detergent industry, increased stability of trypsin in the presence of detergents is desirable. Trypsin was modified with CMC (Villalonga et al. 2000), which resulted in a high degree of intramolecular cross linking and increased stability, extended pH range and higher affinity for the substrate. Modification with cyclodextrins also resulted in increased stability, and also in a higher specific activity as well as a lower K m (Fernández et al. 2002).

As modified cyclodextrins are expensive, which limit their industrial applicability, less expensive dextrans for conjugation with trypsin were explored (Hernández et al. 2006). The dextrans were monoactivated, thereby preventing crosslinking. Thermal stability was improved, as well as the autolytic resistance to degradation. Since autolytic degradation is the main inactivation mechanism for proteolytic enzymes, this leads to increased operational stability.

Other enzymes that have been stabilized using glycoconjugation include Penicillin G acylase (PGA) (Mislovicová et al. 2006; Masárová et al. 2001), α-amylase (Villalonga et al. 1999; Srimathi and Jayaraman 2005) and glucose oxidase (Matos et al. 2012). PGA is used for the production of 6-aminopenicillanic acid (6-APA), an important building block in the production of semi-synthetic penicillins. Upon modification with different dextrans, the stability and thermostability were improved slightly, which could lead to reducing the frequency of redosing in the factory (Mislovicová et al. 2006).

CALB, the cold-adapted Candida antartica lipase B, was reacted with dextran, ficoll and inulin (Siddiqui and Cavicchioli 2005). Modification with dextran resulted in an increase in thermal stability from 18 to 168 min at 70 °C, and a 65 % higher specific activity. In general, a higher thermal stability is related to a higher specific activity, indicating that activity does not necessarily have to be sacrificed to obtain better thermo stability.

Modification with polysialic acid (PSA) can have similar effects as modification with PEG (Gregoriadis et al. 2005). PSA is even less immunogenic than PEG, as there are no known receptors for PSA in the body (Gregoriadis et al. 1993; Crocker and Varki 2001). In contrast to PEG, which is either excreted or stored in the body (Caliceti and Veronese 2003), PSA is biodegradable, with non-toxic degradation products. Polysialation has been shown to increase blood circulation times and stability for asparaginase (Fernandes and Gregoriadis 1997; Fernandes and Gregoriadis 2001), superoxide dismutase (Wu et al. 2010), insulin (Jain et al. 2003), and an antibody fragment (Constantinou et al. 2008).

Modification with other polymers

In addition to PEG, other synthetic polymers have been used to modify enzymes. POA-MAA is a copolymer of polyoxyalylene and maleic anhydride. The ratio of propylene oxide to ethylene oxide (the monomer of PEG) determines the hydrophobicity of the polymer, which can thus be varied. The enzyme is coupled to the copolymer via reaction with the maleic anhydride monomers. POA-MAA has been used for the modification of cellulases, used for the saccharification of cellulose, an important step in the production of bioethanol. During saccharification, a large portion of the cellulases has been shown to adsorb to the substrate, which is presumed to have a negative impact on final conversion rates. Cellulases modified with different variants of POA-MAA showed lower activity, but also less adsorption to the substrate, such that the overall glucose yield was increased compared to native cellulase. The more hydrophilic POA-MAA gave the best increase in glucose yield (Park et al. 2002; Park and Kajiuchi 1995). POA-MAA has also been used in the modification of laccase (Shin-Ya et al. 2005), an enzyme with a broad range of industrial applications, including the removal of phenolic compounds in wastewater, whitening of paper pulp and dehazing of beer (Xu 2005). Modification with POA-MAA resulted in an increased thermal stability and increased activity.

Modification using small molecules

Modification with small molecules does not significantly increase the size of the enzyme or form a physical shield from the environment, like PEGylation or glycosylation can. Modification with small molecules are typically applied to neutralize or invert charges on the enzyme surface, adding more bulky headgroups on amino acids or a crosslink in the case of bi-functional reagents. Like PEGylation and glycosylation, modification with small molecules can have varying effects, depending on the nature of the small molecule, the modification degree, and the enzyme used. Thermostabilization is the most common objective for modification using small molecules.

Modification methods

Various methods are used to introduce small molecules on the surface of proteins, such as reaction with anhydrides, succinimates or acids. Modification with anhydrides is a relatively simple process where the anhydride is added stepwise to the enzyme at a slight alkaline pH. During the reaction, acid is released from the anhydride, and the pH is kept constant by addition of a suitable amount of a base like NaOH (Miland et al. 1996; Khajeh et al. 2001).

Applications

Functionalization with a monocarboxylic anhydride like citraconic anhydride will replace the positive charge of lysine with one negative charge, while functionalization with dicarboxylic anhydrides like trimellitic anhydride result in the replacement by two negative charges (Fig. 7). By varying the anhydride, one can tune the charge of the modified enzyme.

Modification of horseradish peroxidase (HRP) with both mono- and dicarboxylic anhydrides showed that while below 65 °C both types of anhydrides provided thermostabilization, above 65 °C only modification with mono carboxylic anhydrides resulted in significant thermostabilization (Hassani 2012a). This might be explained by a balance between stabilization through hydrophilization of the surface, which is most effectively achieved by the use of dicarboxylic acids, and destabilization due to an increase in electrostatic repulsion. It appears that at lower temperatures the stabilizing effect of a hydrophilization is most important, where at higher temperatures the charge repulsion becomes more important. This effect was even more pronounced when HRP was modified with pyromellitic dianhydride, replacing the positive charge of the modified lysine groups with three negative charges from the carboxylic acid groups of the dianhydride (Hassani 2012b). Below T m (50–65 °C), the thermostability of the modified HRP was increased, while it decreased above T m (70–80 °C), confirming the balance between stabilizing and destabilizing interactions as hypothesized above. This dual behavior could be useful in food applications, where often it is required to inactivate the enzyme in the final product, but good stability during processing is beneficial.

Modification of HRP with phthalic anhydride resulted in an increased stability in aqueous buffer (Liu et al. 2002) and organic solvents (Song et al. 2005). In addition, the thermal stability in aqueous solutions at 50 °C was increased 10-fold, and thermal stability in tetrahydrofuran (THF), acetonitrile (ACN) and methanol at 30 and 60 °C was also increased. Modification of HRP using different bis-succinimides yielded 6–23-fold increase in thermal stability at 75 °C in aqueous buffer, while modification with bis-imidates hardly increased thermal stability (Ryan et al. 1994). In contrast to modification with bis-succinimides, modification with bis-imidates does not result in the neutralization of the positive charge of lysine, as it does not introduce a negative charge. Similarly, modification with acetic anhydride does not result in addition of a negative charge.

Papain, a cysteine protease, was also modified with different acid anhydrides (Szabó et al. 2009). This stabilized the enzymes in aqueous protic ethanol and polar ACN, but not in aprotic THF. Papain modified with acetic or propionic anhydrides, which do not introduce a negative charge, showed a greater increase in activity and stability than when modified with citraconic, maleic or succinic acid anhydrides, which do introduce a negative charge. Papain could be used for the removal of proteinacous stains from clothing, which is usually achieved by the addition of serine proteases to detergents. Papain has a broad substrate range and a high thermal stability, but is not stable under alkaline conditions and in the presence of detergents. Modification of papain with succinic anhydride shifts the pH optimum to more alkaline pH and greatly improves activity of papain in detergents, enhancing the detergent compatible protease spectrum (Khaparde and Singhal 2001).

Reduction of the positive-to-negative charged sites in α-chymotrypsin by modification with acetic or succinic anhydrides resulted in an increase of activity and stability in the ionic solvent [BMIM][Cl]. The decreased amount of positive charges reduces anion binding which is thought to have a stabilizing effect (Nordwald and Kaar 2013).

Conclusions

Nature has provided us with a myriad of highly efficient and selective enzymes. Use of these catalysts instead of the more traditional chemical ones, leads to more environmentally friendly processes, new pharmaceutical products and could allow the synthesis of novel products that are very hard or even impossible to produce with other methods. However, at this moment, only a fraction of the enzymes available to us are used for industrial purposes. One of the main reasons for this is that industrial process conditions and requirements are very different from the conditions and requirements in the host organism for which the enzymes were evolved. There is therefore a need for methodologies to adapt enzymes to the demands of the industry. In principle, two strategies can be applied, the first is incorporating modifications at the level of protein synthesis. In vivo synthesis can be steered through protein engineering, a powerful tool but can only partly help, as it is restricted to changing the amino acid sequence or incorporation of amino acid homologs. In vitro synthesis with artificial amino acids or peptide segment condensation intrinsically offers more possibilities to adapt the enzymes to the requirements (Miyazawa et al. 2002), but predicting the outcome is still rather difficult.

As shown in this review, enzymes can be modified post-production with a wide variety of both natural and synthetic compounds. This has the potential to combine the strengths and benefits of synthetic and natural molecules with the exceptional qualities of enzymes. Conjugation of an enzyme with other molecules does however not automatically combine the strengths of the two compounds. More often than not, the desired outcome is not achieved. Molecules that provide increased stability to one enzyme can have a different effect on the properties of another enzyme. To complicate matters even further, the type of molecule, site and degree of modification, and in the case of polymers, the molecular weight and amount of branching of the polymer, all have a profound influence on the resulting properties of the enzyme. There are only a few general observations that can be made from all literature at hand (Table 2). For each reported modification that resulted in an improved property, there are likely many non-reported attempts that did not result in any change, or led to a decrease of functionality. From the successful attempts, glycoconjugation often appears to result in increased temperature stability. PEGylation also regularly has this effect, next to an increased tolerance for organic solvents. In the pharmaceutical industry, PEGylation is regularly applied because it tends to lead to improved pharmacokinetic and pharmacodynamics properties of pharmaceutical products.

Variability in enzyme properties after conjugation can also occur within one experiment, as modification is usually not site-selective, resulting in several isomers. Fortunately, new modification techniques are still being developed, and the emergence of more site-selective methods could improve upon this. Over the years, the developed modification techniques have become milder, more biocompatible, and more specific. This will help unlock the full potential of post-production modification of enzymes, and aid in the increased use of enzymes in industrial applications.

References

Abello N, Geurink PP, Van Der Toorn M, Van Oosterhout AJM, Lugtenburg J, Van Der Marel GA, Kerstjens HAM, Postma DS, Overkleeft HS, Bischoff R (2008) Poly(ethylene glycol)-based stable isotope labeling reagents for the quantitative analysis of low molecular weight metabolites by LC-MS. Anal Chem 80:9171–9180

Abuchowski A, McCoy JR, Palczuk NC, van Es T, Davis FF (1977a) Effect of covalent attachment of polyethylene glycol on immunogenicity and circulating life of bovine liver catalase. J Biol Chem 252:3582–3586

Abuchowski A, Van Es T, Palczuk NC, Davis FF (1977b) Alteration of immunological properties of bovine serum albumin by covalent attachment of polyethylene glycol. J Biol Chem 252:3578–3581

Adamczak M, Krishna SH (2004) Strategies for improving enzymes for efficient biocatalysis. Food Technol Biotechnol 42:251–264

Ahern TJ, Casal JI, Petsko GA, Klibanov AM (1987) Control of oligomeric enzyme thermostability by protein engineering. Proc Natl Acad Sci U S A 84:675–679

Antos JM, Miller GM, Grotenbreg GM, Ploegh HL (2008) Lipid modification of proteins through sortase-catalyzed transpeptidation. J Am Chem Soc 130:16338–16343

Antos JM, Popp MW, Ernst R, Chew G, Spooner E, Ploegh HL (2009) A straight path to circular proteins. J Biol Chem 284:16028–16036

Apweiler R, Hermjakob H, Sharon N (1999) On the frequency of protein glycosylation, as deduced from analysis of the SWISS-PROT database. Biochim Biophys Acta Gen Subj 1473:4–8

Arif M, Senapati P, Shandilya J, Kundu TK (2010) Protein lysine acetylation in cellular function and its role in cancer manifestation. Biochim Biophys Acta Gen Regul Mech 1799:702–716

Barbarić S, Mrša V, Ries B, Mildner P (1984) Role of the carbohydrate part of yeast acid phosphatase. Arch Biochem Biophys 234:567–575

Baslé E, Joubert N, Pucheault M (2010) Protein chemical modification on endogenous amino acids. Chem Biol 17:213–227

Basri M, Ampon K, Yunus WMZW, Razak CNA, Salleh AB (1995) Synthesis of fatty esters by polyethylene glycol-modified lipase. J Chem Technol Biotechnol 64:10–16

Basu A, Yang K, Wang M, Liu S, Chintala R, Palm T, Zhao H, Peng P, Wu D, Zhang Z, Hua J, Hsieh M, Zhou J, Petti G, Li X, Janjua A, Mendez M, Liu J, Longley C, Zhang Z, Mehlig M, Borowski V, Viswanathan M, Filpula D (2006) Structure-function engineering of interferon-ß-1b for improving stability, solubility, potency, immunogenicity, and pharmacokinetic properties by site-selective mono-PEGylation. Bioconjug Chem 17:618–630

Bernardes GJL, Chalker JM, Errey JC, Davis BG (2008) Facile conversion of cysteine and alkyl cysteines to dehydroalanine on protein surfaces: versatile and switchable access to functionalized proteins. J Am Chem Soc 130:5052–5053

Besson C, Favre-Bonvin G, O’Fagain C, Wallach J (1995) Chemical derivatives of Pseudomonas aeruginosa elastase showing increased stability. Enzyme Microb Technol 17:877–881

Bianchi D, Battistel E, Bosetti A, Cesit P, Fekete Z (1993) Effects of chemical modification on stereoselectivity of Pseudomonas cepacia lipase. Tetrahedron Asymmetr 4:777–782

Boros S, Åhrman E, Wunderink L, Kamps B, De Jong WW, Boelens WC, Emmanuelsson CS (2006) Site-specific transamidation and deamidation of the small heat-shock protein Hsp20 by tissue transglutaminase. Proteins 62:1044–1052

Caliceti P, Veronese FM (2003) Pharmacokinetic and biodistribution properties of poly(ethylene glycol)-protein conjugates. Adv Drug Deliv Rev 55:1261–1277

Canalle LA, Löwik DWPM, Van Hest JCM (2010) Polypeptide-polymer bioconjugates. Chem Soc Rev 39:329–353

Chen HM, Ford C, Reilly PJ (1994) Substitution of asparagine residues in Aspergillus awamori glucoamylase by site-directed mutagenesis to eliminate N-glycosylation and inactivation by deamidation. Biochem J 301:275–281

Constantinou A, Epenetos AA, Hreczuk-Hirst D, Jain S, Deonarain MP (2008) Modulation of antibody pharmacokinetics by chemical polysialylation. Bioconjug Chem 19:643–650

Crocker PR, Varki A (2001) Siglecs, sialic acids and innate immunity. Trends Immunol 22:337–342

Dasgupta S, Samantaray S, Sahal D, Roy RP (2011) Isopeptide ligation catalyzed by quintessential sortase A: mechanistic cues from cyclic and branched oligomers of indolicidin. J Biol Chem 286:23996–24006

Davis BG (2003) Chemical modification of biocatalysts. Curr Opin Biotechnol 14:379–386

De La Casa RM, Guisán JM, Sánchez-Montero JM, Sinisterra JV (2002) Modification of the activities of two different lipases from Candida rugosa with dextrans. Enzyme Microb Technol 30:30–40

DeLuna A, Quezada H, Gómez-Puyou A, González A (2005) Asparaginyl deamidation in two glutamate dehydrogenase isoenzymes from Saccharomyces cerevisiae. Biochem Biophys Res Commun 328:1083–1090

DiCosimo R, McAuliffe J, Poulose AJ, Bohlmann G (2013) Industrial use of immobilized enzymes. Chem Soc Rev 42:6437–6474

Dixon HBF (1984) N-terminal modification of proteins—a review. J Protein Chem 3:99–108

Dust JM, Fang ZH, Harris JM (1990) Proton NMR characterization of poly(ethylene glycols) and derivatives. Macromolecules 23:3742–3746

Dwek RA (1996) Glycobiology: toward understanding the function of sugars. Chem Rev 96:683–720

Fernandes AI, Gregoriadis G (1997) Polysialylated asparaginase: preparation, activity and pharmacokinetics. Biochim Biophys Acta Protein Struct Mol 1341:26–34

Fernandes AI, Gregoriadis G (2001) The effect of polysialylation on the immunogenicity and antigenicity of asparaginase: implication in its pharmacokinetics. Int J Pharm 217:215–224

Fernández M, Fragoso A, Cao R, Baños M, Villalonga R (2002) Chemical conjugation of trypsin with monoamine derivatives of cyclodextrins: catalytic and stability properties. Enzyme Microb Technol 31:543–548

Fernández M, Fragoso A, Cao R, Villalonga R (2005) Stabilization of α-chymotrypsin by chemical modification with monoamine cyclodextrin. Process Biochem 40:2091–2094

Fleckenstein B, Molberg Ø, Qiao S, Schmid DG, Von Mülbe FD, Elgstøen K, Jung G, Sollid LM (2002) Gliadin T cell epitope selection by tissue transglutaminase in celiac disease. Role of enzyme specificity and pH influence on the transamidation versus deamidation reactions. J Biol Chem 277:34109–34116

Fontana A, Spolaore B, Mero A, Veronese FM (2008) Site-specific modification and PEGylation of pharmaceutical proteins mediated by transglutaminase. Adv Drug Deliv Rev 60:13–28

Franssen MCR, Steunenberg P, Scott EL, Zuilhof H, Sanders JPM (2013) Immobilised enzymes in biorenewables production. Chem Soc Rev 42:6491–6533

Fukal L, Marek M, Kás J (1983) Proteolytic activity and immunoreactivity of chemically modified Papain. Z Lebensm Unters Forsch 176:430–433

Gaertner HF, Puigserver AJ (1992) Increased activity and stability of poly(ethylene glycol)-modified trypsin. Enzyme Microb Technol 14:150–155

Garay RP, El-Gewely R, Armstrong JK, Garratty G, Richette P (2012) Antibodies against polyethylene glycol in healthy subjects and in patients treated with PEG-conjugated agents. Expert Opin Drug Del 9:1319–1323

Garcia D, Ortéga F, Marty J (1998) Kinetics of thermal inactivation of horseradish peroxidase: stabilizing effect of methoxypoly(ethylene glycol). Biotechnol Appl Biochem 27:49–54

Gaudriault G, Vincent J (1992) Selective labeling of α- or ε-amino groups in peptides by the Bolton-Hunter reagent. Peptides 13:1187–1192

Gioacchini AM, Carrea G, Secundo F, Baraldini M, Roda A (1997) Electrospray mass spectrometric analysis of poly(ethylene glycol)-protein conjugates. Rapid Commun Mass Spectrom 11:1219–1222

Gonera A, Mischnick P, Ukeda H (2004) The application of O-aminopropyl amylose for the stabilization of horseradish peroxidase via addition and cross-linking. Enzyme Microb Technol 34:248–254

González M, Vaillard SE (2013) Evolution of reactive mPEG polymers for the conjugation of peptides and proteins. Curr Org Chem 17:975–998

Grant WD, Danson MJ, Scott DJ, Halling PJ, Engberts JBFN, Ho MW, Berendsen HJC (2004) Life at low water activity. Phil Trans R Soc B 359:1249–1267

Gregoriadis G, McCormack B, Wang Z, Lifely R (1993) Polysialic acids: potential in drug delivery. FEBS Lett 315:271–276

Gregoriadis G, Jain S, Papaioannou I, Laing P (2005) Improving the therapeutic efficacy of peptides and proteins: a role for polysialic acids. Int J Pharm 300:125–130

Hackenberger CPR, Schwarzer D (2008) Chemoselective ligation and modification strategies for peptides and proteins. Angew Chem Int Ed 47:10030–10074

Hamada JS (1994) Deamidation of food proteins to improve functionality. Crit Rev Food Sci Nutr 34:283–292

Han M, Wang X, Ding H, Jin M, Yu L, Wang J, Yu X (2014) The role of N-glycosylation sites in the activity, stability, and expression of the recombinant elastase expressed by Pichia pastoris. Enzyme Microb Technol 54:32–37

Hanefeld U, Gardossi L, Magner E (2009) Understanding enzyme immobilisation. Chem Soc Rev 38:453–468

Harris JM, Kozlowski A (1997) Poly(ethylene glycol) and related polymers monosubstituted with propionic or butanoic acids and functional derivatives thereof for biotechnical applications. US 08/642,231

Hassani L (2012a) Chemical modification of Horseradish peroxidase with carboxylic anhydrides: effect of negative charge and hydrophilicity of the modifiers on thermal stability. J Mol Catal B 80:15–19

Hassani L (2012b) The Effect of chemical modification with pyromellitic anhydride on structure, function, and thermal stability of horseradish peroxidase. Appl Biochem Biotechnol 167:489–497

Hassani L, Ranjbar B, Khajeh K, Naderi-Manesh H, Naderi-Manesh M, Sadeghi M (2006) Horseradish peroxidase thermostabilization: the combinatorial effects of the surface modification and the polyols. Enzyme Microb Technol 38:118–125

He Z, Zhang Z, He M (2000) Kinetic study of thermal inactivation for native and methoxypolyethylene glycol modified trypsin. Process Biochem 35:1235–1240

Heck T, Faccio G, Richter M, Thöny-Meyer L (2013) Enzyme-catalyzed protein crosslinking. Appl Microbiol Biotechnol 97:461–475

Heiss L (1995) Polyethylene glycol monomethyl ether-modified pig liver esterase: preparation, characterization and catalysis of enantioselective hydrolysis in water and acylation in organic solvents. Tetrahedron Lett 36:3833–3836

Hernáiz MJ, Sánchez-Montero JM, Sinisterra JV (1999) Modification of purified lipases from Candida rugosa with polyethylene glycol: a systematic study. Enzyme Microb Technol 24:181–190

Hernández K, Fernández L, Gómez L, Villalonga R (2006) Glycosidation of trypsin with end-group activated dextran. Process Biochem 41:1155–1159

Hinds K, Koh JJ, Joss L, Liu F, Baudyš M, Kim SW (2000) Synthesis and characterization of poly(ethylene glycol)-insulin conjugates. Bioconjug Chem 11:195–201

Hu J, Sebald W (2011) N-terminal specificity of PEGylation of human bone morphogenetic protein-2 at acidic pH. Int J Pharm 413:140–146

Iyer PV, Ananthanarayan L (2008) Enzyme stability and stabilization—Aqueous and non-aqueous environment. Process Biochem 43:1019–1032

Jain S, Hreczuk-Hirst DH, McCormack B, Mital M, Epenetos A, Laing P, Gregoriadis G (2003) Polysialylated insulin: synthesis, characterization and biological activity in vivo. Biochim Biophys Acta Gen Subj 1622:42–49

Jeoh T, Michener W, Himmel ME, Decker SR, Adney WS (2008) Implications of cellobiohydrolase glycosylation for use in biomass conversion. Biotechnol Biofuels 1:1–13

Kajiuchi T, Park J (1992) Characteristics of cellulase modified with a copolymer of polyethylene glycol derivative and maleic acid anhydride. J Chem Eng Jpn 25:202–206

Kazan D, Erarslan A (1997) Stabilization of Escherichia coli penicillin G acylase by polyethylene glycols against thermal inactivation. Appl Biochem Biotechnol 62:1–13

Khajeh K, Naderi-Manesh H, Ranjbar B, Moosavi-Movahedi AA, Nemat-Gorgani M (2001) Chemical modification of lysine residues in Bacillus α-amylases: effect on activity and stability. Enzyme Microb Technol 28:543–549

Khan SA, Halling PJ, Bosley JA, Clark AH, Peilow AD, Pelan EG, Rowlands DW (1992) Polyethylene glycol-modified subtilisin forms microparticulate suspensions in organic solvents. Enzyme Microb Technol 14:96–100

Khaparde SS, Singhal RS (2001) Chemically modified papain for applications in detergent formulations. Bioresour Technol 78:1–4

Kinstler O, Molineux G, Treuheit M, Ladd D, Gegg C (2002) Mono-N-terminal poly(ethylene glycol)–protein conjugates. Adv Drug Deliv Rev 54:477–485

Kirk O, Borchert TV, Fuglsang CC (2002) Industrial enzyme applications. Curr Opin Biotechnol 13:345–351

Kling J (2013) Pegylation of biologics. Bioprocess Int 11:34–43

Knop K, Hoogenboom R, Fischer D, Schubert US (2010) Poly(ethylene glycol) in drug delivery: pros and cons as well as potential alternatives. Angew Chem Int Ed 49:6288–6308

Koide N, Muramatsu T (1974) Endo ß N acetylglucosaminidase acting on carbohydrate moieties of glycoproteins. Purification and properties of the enzyme from Diplococcus pneumoniae. J Biol Chem 249:4897–4904

Koops BC, Verheij HM, Slotboom AJ, Egmond MR (1999) Effect of chemical modification on the activity of lipases in organic solvents. Enzyme Microb Technol 25:622–631

Kotormán M, Cseri A, Laczkó I, Simon LM (2009) Stabilization of α-chymotrypsin in aqueous organic solvents by chemical modification with organic acid anhydrides. J Mol Catal B 59:153–157

Kozlowski A, Milton Harris J (2001) Improvements in protein PEGylation: pegylated interferons for treatment of hepatitis C. J Control Release 72:217–224

Kwon I, Lim SI (2013) Non-natural amino acids for protein engineering and new protein chemistries. Macromol Chem Phys 214:1295–1301

Kwon OH, Imanishi Y, Ito Y (1999) Catalytic activity and conformation of chemically modified subtilisin Carlsberg in organic media. Biotechnol Bioeng 66:265–270

Lee K, Gesundheit N, Chen H, Weintraub BD (1986) Enzymatic deglycosylation of thyroid-stimulating hormone with peptide N-glycosidase F and endo-ß-N-acetylglucosaminidase F. Biochem Biophys Res Commun 138:230–237

Lewinska M, Seitz C, Skerra A, Schmidtchen FP (2004) A novel method for the N-terminal modification of native proteins. Bioconjug Chem 15:231–234

Liese A, Hilterhaus L (2013) Evaluation of immobilized enzymes for industrial applications. Chem Soc Rev 42:6236–6249

Liu J, Wang M (2007) Improvement of activity and stability of chloroperoxidase by chemical modification. BMC Biotechnol 7:23

Liu J, Song H, Weng L, Ji L (2002) Increased thermostability and phenol removal efficiency by chemical modified horseradish peroxidase. J Mol Catal B 18:225–232

Longo MA, Combes D (1995) A novel chemoenzymatic glycosylation strategy: application to lysozyme modification. FEBS Lett 375:63–66

Longo MA, Combes D (1997) Influence of surface hydrophilic/hydrophobic balance on enzyme properties. J Biotechnol 58:21–32

López-Cruz JI, Viniegra-González G, Hernández-Arana A (2006) Thermostability of native and pegylated Myceliophthora thermophila laccase in aqueous and mixed solvents. Bioconjug Chem 17:1093–1098

Lorand L, Graham RM (2003) Transglutaminases: crosslinking enzymes with pleiotropic functions. Nat Rev Mol Cell Biol 4:140–156

Mabrouk PA (1997) The use of poly(ethylene glycol)-enzymes in nonaqueous enzymology. In: Harris JM, Zalipky S (eds) Poly(ethylene glycol) chemistry and biological applications. ACS, Washington, DC, pp 118–133

Mader D, Liebeke M, Winstel V, Methling K, Leibig M, Götz F, Lalk M, Peschel A (2013) Role of N-terminal protein formylation in central metabolic processes in Staphylococcus aureus. BMC Microbiol 13:1–9

Masárová J, Mislovicová D, Gemeiner P, Michalková E (2001) Stability enhancement of Escherichia coli penicillin G acylase by glycosylation with yeast mannan. Biotechnol Appl Biochem 34:127–133

Matos M, Simpson BK, Ramírez HL, Cao R, Torres-Labandeira JJ, Hernández K (2012) Stabilization of glucose oxidase with cyclodextrin-branched carboxymethylcellulose. Biotecnol Apl 29:29–34

Matsushima A, Nishimura H, Ashihara Y, Yokota Y, Inada Y (1980) Modification of E.coli asparaginase with 2,4-bis(O-methoxypolyethylene glycol)-6-chloro-S-triazine(activated PEG2); Disappearance of binding ability towards anti-serum and retention of enzymic activity. Chem Lett 9:773–776

Matsushima A, Okada M, Inada Y (1984) Chymotrypsin modified with polyethylene glycol catalyzes peptide synthesis reaction in benzene. FEBS Lett 178:275–277

Maximilian WP, John MA, Gijsbert MG, Spooner E, Hidde LP (2007) Sortagging: a versatile method for protein labeling. Nat Chem Biol 3:707–708

McFarland JM, Joshi NS, Francis MB (2008) Characterization of a three-component coupling reaction on proteins by isotopic labeling and nuclear magnetic resonance spectroscopy. J Am Chem Soc 130:7639–7644

Messner P (2004) Prokaryotic glycoproteins: unexplored but important. J Bacteriol 186:2517–2519

Miland E, Smyth MR, Fágáin CÓ (1996) Increased thermal and solvent tolerance of acetylated horseradish peroxidase. Enzyme Microb Technol 19:63–67

Milton Harris J, Chess RB (2003) Effect of pegylation on pharmaceuticals. Nat Rev Drug Discov 2:214–221

Mislovicová D, Masárová J, Bucko M, Gemeiner P (2006) Stability of penicillin G acylase modified with various polysaccharides. Enzyme Microb Technol 39:579–585

Miwa N, Yokoyama K, Wakabayashi H, Nio N (2010) Effect of deamidation by protein-glutaminase on physicochemical and functional properties of skim milk. Int Dairy J 20:393–399

Miyazawa T, Ensatsu E, Hiramatsu M, Yanagihara R, Yamada T (2002) α-chymotrypsin-catalysed segment condensations via the kinetically controlled approach using carbamoylmethyl esters as acyl donors in organic media. J Chem Soc Perkin Trans 1 396–401

Moniruzzaman M, Kamiya N, Goto M (2010) Activation and stabilization of enzymes in ionic liquids. Org Biomol Chem 8:2887–2899

Moskvichyov BV, Komarov EV, Ivanova GP (1986) Study of trypsin thermodenaturation process. Enzyme Microb Technol 8:498–502

Nordwald EM, Kaar JL (2013) Stabilization of enzymes in ionic liquids via modification of enzyme charge. Biotechnol Bioeng 110:2352–2360

Novelli G, D’Apice M (2012) Protein farnesylation and disease. J Inherit Metab Dis 35:917–926

Park JW, Kajiuchi T (1995) Development of effective modified cellulase for cellulose hydrolysis process. Biotechnol Bioeng 45:366–373

Park J, Park K (2001) Improvement of the physical properties of reprocessed paper by using biological treatment with modified cellulase. Bioresour Technol 79:91–94

Park J, Park K, Song H, Shin H (2002) Saccharification and adsorption characteristics of modified cellulases with hydrophilic/hydrophobic copolymers. J Biotechnol 93:203–208

Pasut G, Veronese FM (2009) Pegylation for improving the effectiveness of therapeutic biomolecules. Drugs Today 45:687–695

Pasut G, Veronese FM (2012) State of the art in PEGylation: the great versatility achieved after forty years of research. J Control Release 161:461–472

Perutz MF (1978) Electrostatic effects in proteins. Science 201:1187–1191

Piesecki S, Alhadeff JA (1992) The effect of carbohydrate removal on the properties of human liver α-l-fucosidase. Biochim Biophys Acta Protein Struct Mol 1119:194–200

Pina C, Clark D, Blanch H (1989) The activity of PEG-modified chymotrypsin in aqueous and organic media. Biotechnol Tech 3:333–338

Poh S, Abdul Majid F (2011) Thermal stability of free bromelain and bromelain-polyphenol complex in pineapple juice. Int Food Res J 18:1051–1060

Polizzi KM, Bommarius AS, Broering JM, Chaparro-Riggers JF (2007) Stability of biocatalysts. Curr Opin Chem Biol 11:220–225

Popp MW, Dougan SK, Chuang T, Spooner E, Ploegh HL (2011) Sortase-catalyzed transformations that improve the properties of cytokines. Proc Natl Acad Sci U S A 108:3169–3174

Proft T (2010) Sortase-mediated protein ligation: an emerging biotechnology tool for protein modification and immobilisation. Biotechnol Lett 32:1–10

Qian G, Ma J, Zhou J, He B (1997) Chemical modification of E. coli L-asparaginase with poly(N-vinylpyrrolidone-co-maleic anhydride). React Funct Polym 32:117–121

Quintanilla-Guerrero F, Duarte-Vázquez MA, Tinoco R, Gómez-Suárez M, García-Almendárez BE, Vazquez-Duhalt R, Regalado C (2008) Chemical modification of turnip peroxidase with methoxypolyethylene glycol enhances activity and stability for phenol removal using the immobilized enzyme. J Agric Food Chem 56:8058–8065

Rajalakshmi N, Sundaram PVS (1995) Stability of native and covalently modified papain. Protein Eng 8:1039–1047

Rashidian M, Song JM, Pricer RE, Distefano MD (2012) Chemoenzymatic reversible immobilization and labeling of proteins without prior purification. J Am Chem Soc 134:8455–8467

Recktenwald A, Schomburg D, Schmid RD (1993) Protein engineering and design method and the industrial relevance. J Biotechnol 28:1–23

Ritter DW, Roberts JR, McShane MJ (2013) Glycosylation site-targeted PEGylation of glucose oxidase retains native enzymatic activity. Enzyme Microb Technol 52:279–285

Roberts MJ, Bentley MD, Harris JM (2002) Chemistry for peptide and protein PEGylation. Adv Drug Deliv Rev 54:459–476

Rolland-Fulcrand V, May N, Viallefont P, Lazaro R (1994) Enzymatic peptide synthesis by new supported biocatalysts. Amino Acids 6:311–314

Romanini DW, Francis MB (2008) Attachment of peptide building blocks to proteins through tyrosine bioconjugation. Bioconjug Chem 19:153–157

Ryan O, Smyth MR, Fágáin CÓ (1994) Thermostabilized chemical derivatives of horseradish peroxidase. Enzyme Microb Technol 16:501–505

Samantaray S, Marathe U, Dasgupta S, Nandicoori VK, Roy RP (2008) Peptide-sugar ligation catalyzed by transpeptidase sortase:a facile approach to neoglycoconjugate synthesis. J Am Chem Soc 130:2132–2133

Sangeetha K, Abraham TE (2006) Chemical modification of papain for use in alkaline medium. J Mol Catal B 38:171–177

Sartore L, Caliceti P, Schiavon O, Monfardini C, Veronese FM (1991) Accurate evaluation method of the polymer content in Monomethoxy(polyethylene glycol) modified proteins based on Amino acid analysis. Appl Biochem Biotechnol 31:213–222

Sato H (2002) Enzymatic procedure for site-specific pegylation of proteins. Adv Drug Deliv Rev 54:487–504

Schellekens H, Hennink WE, Brinks V (2013) The immunogenicity of polyethylene glycol: facts and fiction. Pharm Res 30:1729–1734

Schoffelen S, Lambermon MHL, Van Eldijk MB, Van Hest JCM (2008) Site-specific modification of Candida antarctica lipase B via residue-specific incorporation of a non-canonical amino acid. Bioconjug Chem 19:1127–1131

Sheldon RA, van Pelt S (2013) Enzyme immobilisation in biocatalysis: why, what and how. Chem Soc Rev 42:6223–6235

Shental-Bechor D, Levy Y (2008) Effect of glycosylation on protein folding: a close look at thermodynamic stabilization. Proc Natl Acad Sci U S A 105:8256–8261

Shin-Ya Y, Aye HN, Hong K, Kajiuchi T (2005) Efficacy of amphiphile-modified laccase in enzymatic oxidation and removal of phenolics in aqueous solution. Enzyme Microb Technol 36:147–152

Siddiqui KS, Cavicchioli R (2005) Improved thermal stability and activity in the cold-adapted lipase B from Candida antarctica following chemical modification with oxidized polysaccharides. Extremophiles 9:471–476

Sletten EM, Bertozzi CR (2009) Bioorthogonal chemistry: fishing for selectivity in a sea of functionality. Angew Chem Int Ed 48:6974–6998

Song H, Yao J, Liu J, Zhou S, Xiong Y, Ji L (2005) Effects of phthalic anhydride modification on horseradish peroxidase stability and structure. Enzyme Microb Technol 36:605–611

Spirig T, Weiner EM, Clubb RT (2011) Sortase enzymes in Gram-positive bacteria. Mol Microbiol 82:1044–1059

Spiro RG (2002) Protein glycosylation: nature, distribution, enzymatic formation, and disease implications of glycopeptide bonds. Glycobiology 12:43R–56R

Srimathi S, Jayaraman G (2005) Effect of glycosylation on the catalytic and conformational stability of homologous α-amylases. Protein J 24:79–88

Sundaram PV, Venkatesh R (1998) Retardation of thermal and urea induced inactivation of α-chymotrypsin by modification with carbohydrate polymers. Protein Eng 11:699–705

Szabó A, Kotormán M, Laczkó I, Simon LM (2009) Improved stability and catalytic activity of chemically modified papain in aqueous organic solvents. Process Biochem 44:199–204

Takahashi K, Nishimura H, Yoshimoto T, Saito Y, Inada Y (1984) A chemical modification to make horseradish peroxidase soluble and active in benzene. Biochem Biophys Res Commun 121:261–265

Tarrant MK, Cole PA (2009) The chemical biology of protein phosphorylation. Annu Rev Biochem 78:797–825

Tilley SD, Francis MB (2006) Tyrosine-selective protein alkylation using π-allylpalladium complexes. J Am Chem Soc 128:1080–1081

Tomazic SJ, Klibanov AM (1988) Mechanisms of irreversible thermal inactivation of Bacillus α-amylases. J Biol Chem 263:3086–3091

Ugarova NN, Rozhkova GD, Berezin IV (1979) Chemical modification of the ε-amino groups of lysine residues in horseradish peroxidase and its effect on the catalytic properties and thermostability of the enzyme. Biochim Biophys Acta Enzymol 570:31–42

Van den Berg M, Schooneveld M, Vlasie M, Roos A, Smith D (2012) Fungal genes and their respective enzymes in industrial food, bio-based and pharma applications. In: Gupta VK, Ayyachamy M (eds) Biotechnology of fungal genes. Science, New Hampshire, pp 189–221

Van Deventer JA, Fisk JD, Tirrell DA (2011) Homoisoleucine: a translationally active leucine surrogate of expanded hydrophobic surface area. ChemBioChem 12:700–702

Varki A (1993) Biological roles of oligosaccharides: all of the theories are correct. Glycobiology 3:97–130

Venkatesh R, Srimathi S, Yamuna A, Jayaraman G (2005) Enhanced catalytic and conformational stability of Atlantic cod trypsin upon neoglycosylation. Biochim Biophys Acta Gen Subj 1722:113–115

Veronese FM (2001) Peptide and protein PEGylation: a review of problems and solutions. Biomaterials 22:405–417

Veronese FM, Mero A (2008) The impact of PEGylation on biological therapies. BioDrugs 22:315–329

Veronese FM, Pasut G (2005) PEGylation, successful approach to drug delivery. Drug Discov Today 10:1451–1458

Veronese FM, Largajolli R, Boccu E (1985) Surface modifications of proteins. Activation of monomethoxy-polyethylene glycols by phenylchloroformates and modification of ribonuclease and superoxide dismutase. Appl Biochem Biotechnol 11:141–152

Villalonga R, Gómez L, Ramírez HL, Villalonga ML (1999) Stabilization of α-amylase by chemical modification with carboxymethylcellulose. J Chem Technol Biotechnol 74:635–638

Villalonga R, Villalonga ML, Gómez L (2000) Preparation and functional properties of trypsin modified by carboxymethylcellulose. J Mol Catal B Enzym 10:483–490

Villalonga R, Fernández M, Fragoso A, Cao R, Mariniello L, Porta R (2003) Thermal stabilization of trypsin by enzymic modification with β-cyclodextrin derivatives. Biotechnol Appl Biochem 38:53–59

Witus LS, Netirojjanakul C, Palla KS, Muehl EM, Weng C, Iavarone AT, Francis MB (2013) Site-specific protein transamination using N-methylpyridinium-4- carboxaldehyde. J Am Chem Soc 135:17223–17229

Wright PC (2013) Improving biopharmaceutical production in microbial systems: Engineering GlycoPEGylation in E.coli. BBSRC Sustainable Bioenergy Centre BB/K011200/1

Wu Z, Guo Z (2012) Sortase-mediated transpeptidation for site-specific modification of peptides, glycopeptides, and proteins. J Carbohydr Chem 31:48–66

Wu JR, Lin Y, Zheng ZY, Lin CC, Zhan XB, Shen YQ (2010) Improvement of the CuZn-superoxide dismutase enzyme activity and stability as a therapeutic agent by modification with polysialic acids. Biotechnol Lett 32:1939–1945

Xiong Y, Gao J, Zheng J, Deng N (2011) Effects of succinic anhydride modification on laccase stability and phenolics removal efficiency. Chin J Catal 32:1584–1591

Xu F (2005) Applications of oxidoreductases: recent progress. Ind Biotechnol 1:38–50

Xue Y, Li S, Zhang H, Nie H, Zhu L, Branford-White CJ (2009) Enzyme design by chemical modification of papain lysine. 3rd International Conference on Bioinformatics and Biomedical Engineering, iCBBE 2009

Xue Y, Wu C, Branford-White CJ, Ning X, Nie H, Zhu L (2010) Chemical modification of stem bromelain with anhydride groups to enhance its stability and catalytic activity. J Mol Catal B 63:188–193

Yamaguchi S, Yokoe M (2000) A novel protein-deamidating enzyme from Chryseobacterium proteolyticum sp. nov., a newly isolated bacterium from soil. Appl Environ Microbiol 66:3337–3343

Yang Z, Domach M, Auger R, Yang FX, Russell AJ (1996) Polyethylene glycol-induced stabilization of subtilisin. Enzyme Microb Technol 18:82–89

Yie HY, Yamaguchi S, Matsumura Y (2006) Effects of enzymatic deamidation by protein-glutaminase on structure and functional properties of wheat gluten. J Agric Food Chem 54:6034–6040

Yokoyama K, Nio N, Kikuchi Y (2004) Properties and applications of microbial transglutaminase. Appl Microbiol Biotechnol 64:447–454

Zaks A, Klibanov AM (1988) The effect of water on enzyme action in organic media. J Biol Chem 263:8017–8021

Zale SE, Klibanov AM (1986) Why does ribonuclease irreversibly inactivate at high temperatures? Biochemistry (NY) 25:5432–5444

Zhang Z, He Z, Guan G (1999) Thermal stability and thermodynamic analysis of native and methoxypolyethylene glycol modified trypsin. Biotechnol Tech 13:781–786

Zhang Z, He Z, He M (2001) Stabilization mechanism of MPEG modified trypsin based on thermal inactivation kinetic analysis and molecular modeling computation. J Mol Catal B 14:85–94

Zhang Y, Liang J, Fu E, Li B (2007) Effect of modified enzymatic catalysis on the extraction of diosgenin from Dioscorea zingiberensis C.H. Wright. Chem Eng Technol 30:1488–1494

Zhang Y, Tang L, An X, Fu E, Ma C (2009) Modification of cellulase and its application to extraction of diosgenin from Dioscorea zingiberensis C.H. Wright. Biochem Eng J 47:80–86

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Minten, I.J., Abello, N., Schooneveld-Bergmans, M.E.F. et al. Post-production modification of industrial enzymes. Appl Microbiol Biotechnol 98, 6215–6231 (2014). https://doi.org/10.1007/s00253-014-5799-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5799-z