Abstract

Ethyl (R)-4-cyano-3-hydroxybutanoate (HN) is an important chiral synthon for side chain of the cholesterol-lowering drug atorvastatin (Lipitor), which is the hydroxymethylglutaryl CoA reductase inhibitor. HN is also used as a synthon in the production of l-carnitine and (R)-4-amino-3-hydroxybutanoic acid. It is necessary to have a clear understanding of the synthesis process of HN for its extensive use. This review gives an overview of different synthetic strategies of optically active HN, including chemical and enzymatic approaches. The emphasis is focused mainly on the synthetic routes using biocatalysts, such as halohydrin dehalogenase, nitrilase, carbonyl reductase, and lipase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

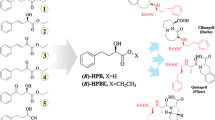

The majority of drugs are constituted by chiral molecules, and the two enantiomers may have significant differences in biological activities such as pharmacology, toxicology, pharmacokinetics, metabolism, etc. (Brooks et al. 2011; Hutt and O’Grady 1996; Nguyena et al. 2006). Therefore, chiral compounds have gained increasing attention in the pharmaceutical field (Patel 2006; Patel 2008). They are useful starting materials in the synthesis of drug substances. Chiral 4-substituted 3-hydroxybutyric acid derivatives, such as ethyl (S)-4-chloro-3-hydroxybutanoate ((S)-CHBE), ethyl (S)-4-bromo-3-hydroxybutyrate ((S)-BHBE), and ethyl (R)-4-cyano-3-hydroxybutanoate (HN), are commercially important building block in the pharmaceutical production (Davis et al. 2004, 2006; Patel 2009). HN is mainly used for the production of atorvastatin (Lipitor), which is a synthetic cholesterol-lowering agent (Fig. 1) (Brower et al. 1992; Roth 1987; Tao and Xu 2009). Atorvastatin selectively inhibits 3-hydroxy-3-methylglutaryl coenzyme A (HMG-CoA) reductase that catalyzes the conversion of HMG-CoA to mevalonate in the early and rate-limiting step of cholesterol biosynthesis (Barrios-Gonzalez and Miranda 2010; Roth 2002). HN is also a synthon in the production of l-carnitine and (R)-4-amino-3-hydroxybutanoic acid (GABOB) (Fig. 1) (Wang and Hollingsworth 1999). l-Carnitine is known as a very important quaternary ammonium compound in β-oxidation of fatty acids in mammals (Jung et al. 1993; Wang and Hollingsworth 1999), and GABOB is an anticonvulsant drug (Candela et al. 2000; Mete et al. 2003).

Because of its important use in the pharmaceutical industry, several different synthetic approaches have been developed for the synthesis of HN. The synthesis of single enantiomer can be executed by chemical or biocatalytic methods (Pantaleone 2005). Although a number of literatures have been published on the synthesis of (S)-CHBE (Kataoka et al. 2003; Kita et al. 1999; Ye et al. 2011) and (S)-BHBE (Asako et al. 2009), the review specifically focused on the HN synthesis that have not been reported so far. This paper gives information on the production of HN by various routes, and the advantages and disadvantages of each synthesis route are discussed.

Chemical synthesis of ethyl (R)-4-cyano-3-hydroxybutanoate

Chemical synthesis is a useful method for construction of complex chemical compounds from simple ones. By chemical synthesis, many substances important to daily life are obtained, such as shikimic acid (Jiang and Singh 1998), proanthocyanidins (He et al. 2008b), heterocyclic-sugar nucleoside analogues (Romeo et al. 2010), etc. To our knowledge, the first report on the synthesis of ethyl 4-cyano-3-hydroxybutanoate can be traced back to 1923 (Lespieau 1923). The product was obtained after hydrolysis, esterification, and cyanidation by using 4-chloro-3-hydroxybutyronitrile as substrate. However, the optical activity was not mentioned and the yield was low. Recently, many synthetic methods for R-enantiomer using different substrates as starting material have been developed (Kumar et al. 2005; Roh et al. 2003).

Synthesis of HN from (S)-epichlorohydrin

(S)-epichlorohydrin ((S)-ECH) is a valuable epoxide intermediate in organic synthesis (Liu et al. 2011c). It is very common to start with (S)-ECH for the preparation of optically active pharmaceuticals, such as Linezolid (Rajesh et al. 2011), (S)-timolol (Narina and Sudalai 2007), and (+)-yatakemycin (Okano et al. 2008). Hong and Jiang have reported a novel process for the preparation of HN from (S)-ECH, as shown in Fig. 2 (Hong and Jiang 2009; Jiang and Hong 2012). (S)-ECH was ring-opened with sodium cyanide to form (S)-4-chloro-3-hydroxybutyronitrile, which was then hydrolyzed and esterified to (S)-CHBE in the presence of alcohol and hydrochloric acid. (S)-CHBE was protected with hexamethyl disilazane, and further subjected to cyanidation. HN was obtained after deprotection with hydrochloric acid in the total yield of 57 %. The specific rotation of the product was calculated ([α] 25D = −32.4°, c 1.0, CHCl3), which is similar to that in previous report (Kumar et al. 2005). This route has been applied for HN production in Zhejiang Neo-Dankong Pharmaceutical Co. The raw material, (S)-ECH, can be prepared from the epoxide hydrolase-catalyzed kinetic resolutions of cheap racemic epichlorohydrin (Liu et al. 2011c). If the yield of HN can be improved, this conversion process has the broad application prospects in HN production.

Synthesis of HN from l-malic acid

Recently, an alternative process based on l-malic acid for the HN production has been reported (Lv et al. 2009). l-Malic acid was converted to (S)-malic acid diethyl ester via esterification, then asymmetric reduction with borane to form (3S)-3,4-dihydroxybutyric acid ethyl ester (Fig. 3). Subsequently, (3S)-3,4-dihydroxybutyric acid ethyl ester was bromized with hydrogen bromide, and cyanided with sodium cyanide in EtOH/H2O to give HN. As a result, the overall yield of the process is about 56.7 %. [α] 25D = −31.02° (c 1.0, CHCl3). Though l-malic acid is an inexpensive and easily obtained starting material, there are two significant drawbacks in the l-malic acid process that limit its industrial application: one is that the yield on the overall process is low; another is that, borane, the reducing agent in this process, is rather expensive and extremely dangerous (Guercio et al. 2009). The reduction reaction should be carried out under the protection of nitrogen, which increased production costs.

Synthesis of HN from maltodextrin

In 1999, Wang and Hollingsworth reported a process for HN production (Wang and Hollingsworth 1999). In that case, HN was prepared via bromization and cyanation processes by using (S)-3-hydroxy-γ-butyrolactone ((S)-HGB) as substrate. The yield was 84.5 %; [α] 25D = −31.3° (c 1.0, CHCl3). In later study, Kumar et al. developed a similar process by using maltodextrin as starting material to synthesize HN (Kumar et al. 2005). Reaction of maltodextrin with sodium hydroxide and cumene hydroperoxide provided 3,4-dihydroxybutyric acid (Fig. 4). Cyclization of the hydroxy acid, followed by addition of concentrated sulfuric acid, afforded (S)-HGB. (S)-HGB was transformed to HN by bromization and cyanation processes with the yield of 85 and 50 %, respectively. The specific rotation of HN was −32.5° (c 1.0, CHCl3). One of advantages of this process is that this method is simple, practical, and economical. There are no expensive and unstable reagents involved in the conversion reaction.

Synthesis of HN from (S)-3,4-epoxybutyric acid salt

There is another route to synthesis of HN by chemical method (Roh et al. 2003), using (S)-3,4-epoxybutyric acid salt as a starting material, which included cyanation and esterification (Fig. 5). (S)-3,4-Epoxybutyric acid salt, synthesized from (S)-3-hydroxy-γ-butyrolactone, was cyanided by 30 % of aqueous sodium cyanide solution. Then, the reaction mixture was acidified to pH 1 with concentrated sulfuric acid. Subsequently, the acidic solution was condensed, dissolved in ethanol, and filtered. The filtrate was refluxed for 5 h and neutralized with sodium carbonate. Then, the HN with the yield of over 90 % and optical purity of 99.8 % was obtained. The yield in this route is the highest one in chemical strategies in literatures.

Cyano-introducing reaction in the HN producing

In summary, chemical synthesis of HN is mainly based on a cyano-introducing reaction using an ethyl (S)-4-halo-3-hydroxybutanoate ((S)-HHBE) as substrate, such as (S)-CHBE (Hong and Jiang 2009) and (S)-BHBE (Kumar et al. 2005; Lv et al. 2009; Wang and Hollingsworth 1999), which is shown in Fig. 6. The difference between these routes is that (S)-HHBE was derived from various compounds. In addition to the synthesis methods discussed above, (S)-HHBE also can be easily synthesized by asymmetric reduction of ethyl 4-halo-3-oxobutanoate which was prepared via the diketene route using either chlorine or bromine (Fig. 7) (Hoff and Anthonsen 1999; Sundby et al. 2003).

Mitsuhashi et al. described a process for synthesis of HN from (S)-CHBE by a cyano-introducing reaction (Mitsuhashi et al. 1995). The cyano-introducing reaction happened in an aprotic polar solvent including dimethyl sulfoxide, dimethylformamide, water, ethanol, acetonitrile, and tetrahydrofuran; among them water is regarded as the most ideal solvent because it is cheap and it renders possible extraction with organic solvent (Matsuda et al. 1999).

It should be noted that the yield of this cyano-introducing reaction is greatly affected by the temperature. The yield was only 50 % when the reaction was performed at room temperature overnight (Kumar et al. 2005). When the reaction temperature was increased to 50 °C, the yield was raised to 84.5 % and the reaction time was decreased to 3 h (Wang and Hollingsworth 1999). As the temperature continued to raise, it would take over 2 h to complete the reaction, but the yield was decreased to 57.5 % (Mitsuhashi et al. 1995). These phenomena can be explained by the effects of temperature on the reaction rate and stability of HN. At room temperature, the reaction does not proceed at a reasonable rate because of the high activation energy. With increasing temperature, the substance molecules move faster, and the reaction rate is also increased greatly. Therefore, raising the reaction temperature is favorable to enhance the yield and shorten the reaction time. However, the yield was declined when the temperature was too high. It might be caused by the decomposition of HN because the product was unstable in polar solvent in thermal environment. We have studied the stability of aqueous solution of HN at different temperatures (Fig. 8) (not published data). The result showed that HN was more stable when the temperature was lower than 45 °C. The retention rate of HN was 92.7 % after incubation at 45 °C for 8 h, while that was 37.5 % when the temperature was increased to 60 °C. Therefore, the reaction rate and stability of HN must be balanced in the application of the process. The temperature must be maintained at appropriate point to keep a fast rate of reaction as well as to keep HN stable.

Thermal stability of ethyl (R)-4-cyano-3-hydroxybutanoate. The aqueous solution of HN (50 g/L) was incubated at different temperature for varying periods of time. The retention rate of HN was calculated using the following formula: Retention rate = C a / C i × 100 %, where C a is the concentration of HN after incubation and C i is the initial concentration of HN

The main disadvantage of this cyano-introducing reaction is the generation of by-products, including hydroxyacrylate, cyanoacrylate, 3-cyanobutyrolactone, 3-hydroxybutyrolactone, γ-crotonolactone, etc. (Matsuda et al. 1999). These compounds increased the difficulty of separation and purification of HN. To overcome this difficulty, a distillation process at 10 Torr with o-dichlorobenzene as solvent was constructed (Matsuda et al. 1999). The HN was purified to a concentration of 94.2 % by weight with a distillation yield of 96 % by this process.

Enzymatic synthesis of ethyl (R)-4-cyano-3-hydroxybutanoate

Chemical synthesis is a key tool for making useful substances, and made significant contributions to our lives. However, the chemical synthesis in industrial production also brings us a series of problems, especially the pollution of the environment (Garrett 1996). Therefore, green chemistry with environmentally friendly, clean, and atom economy features has received considerable attention in recent years (Anastas and Eghbali 2010). With the development of biotechnology, particularly in areas such as protein engineering (Bottcher and Bornscheuer 2010; Turner 2009), biocatalysis has fulfilled many key criteria of green chemistry which has 12 principles (Anastas and Eghbali 2010). Most of the chemical reactions can be catalyzed by enzymes (Findrik and Vasic-Racki 2009; Humble and Berglund 2011). The following sections are intended to provide a general knowledge about the applications of biocatalyst in the HN synthesis.

The applications of halohydrin dehalogenase in HN synthesis

The biocatalytic dehalogenation is a good example of a biocatalytic reaction. The enzyme involved in dehalogenation is halohydrin dehalogenase (HHDH, EC 4.5.X.X), which can degrade a halohydrin to its corresponding epoxide without the need of any cofactors for keeping its activity (Archelas and Furstoss 1997; van den Wijngaard et al. 1991; You et al. 2013b). HHDH also can catalyze the reverse reaction (epoxide ring opening) in the presence of nucleophiles such as cyanide-, azide-, and nitrite ions (Majerić Elenkov et al. 2006). Therefore, HHDH could be a potential candidate for the cyano-introducing reaction mentioned above in HN production (Fox et al. 2007; Majeric Elenkov et al. 2006). The catalytic process under HHDH can be divided into ring-closure and ring-opening. (S)-CHBE was firstly converted into ethyl (S)-3,4-epoxybutanoate by liberating of a chloride ion. Then, ethyl (S)-3,4-epoxybutanoate was converted into HN in the presence of nucleophile (CN−) (Fig. 9).

HHDH from Agrobacterium radiobacter has the most potential to catalyze the transformation between (S)-CHBE and HN (Janssen et al. 2006), which has been widely studied, and its nucleotide sequence, X-ray structure, and catalytic mechanism have been previously solved (de Jong et al. 2003, 2005; Tang et al. 2003; van Hylckama Vlieg et al. 2001). Unfortunately, the wild-type enzymes showed low activity and poor stability (Tang et al. 2002, 2005). It catalyzed the cyano-introducing reaction with a volumetric productivity of 0.006 g product per liter per hour per gram of catalyst, which was far from the industrial application demands (Fox et al. 2007). In the drive for enhanced synthetic efficiency, a multivariate protein optimization strategy based on protein sequence activity relationships was used to improve the catalytic properties of HHDH (Fox et al. 2007). A mutant enzyme with great advantage was obtained after 18 rounds of evolution. The volumetric productivity based on the mutant enzyme was increased ∼4,000-fold. The comparison of tertiary structure between mutant and wild-type enzymes by homology modeling showed that the substrate binding pocket was more open after mutagenesis (Fig. 10a, b), due to which (S)-CHBE could enter the active site easier. Moreover, the molecular docking results showed that the positions of (S)-CHBE in the two active sites are different (Fig. 10c, d). In the mutant HHDH, the distance from the hydroxyl of (S)-CHBE to Tyr145, which is the catalytic residue of the enzyme, is much closer. Therefore, Tyr145 is easier to abstract proton from the hydroxyl group. In addition, the wild-type enzyme was found to be susceptible to inactivation under oxidizing conditions (Tang et al. 2002). The main factor in this inactivation process is the oxidation of cysteine residues. By replacement of cysteine residues, two more stable mutant enzymes (C153S and C30A) were obtained which showed a similar activity as wild type (Tang et al. 2002). Recently, another two engineered variants, HheC2360 and HheC2656, with improved catalytic rates and temperature stability were obtained and characterized (Schallmey et al. 2013).

Surface representation of a wild-type HHDH and b mutant HHDH. The substrate binding pockets are indicated by arrows. Docking of (S)-CHBE into the active site of HHDH. c Wild type; d mutant. The structure of wild-type HHDH was obtained from PDB database (PDB code: 1PWX). The structure of mutant HHDH was generated by Build Homology Models (MODELER) in Discovery Studio (DS) 2.1 (Accelrys) using the structure of wild HHDH as a template. Molecular docking was also performed using the Dock Ligands Module (LibDock) in DS 2.1. All protein structure figures were prepared with PyMOL (www.pymol.org)

Ma et al. from Codexis had constructed an efficient, scalable, and enzyme-catalyzed process for synthesis of HN utilizing three enzymes including ketoreductase, glucose dehydrogenase, and HHDH (Ma et al. 2010). This process was divided into two steps. In the first step, a ketoreductase was used to asymmetric reduction of ethyl-4-chloroacetoacetate by using a NADP-dependent glucose dehydrogenase for cofactor regeneration. With 160 g/L of substrate and 0.9 g/L biocatalysts, the reaction was completed in 8 h and provided (S)-CHBE in 96 % recovered yield and >99.5 % e.e. In the second step, the HHDH was employed to catalyze the cyano-introducing reaction at neutral pH and ambient temperature. With 140 g/L of (S)-CHBE and 1.2 g/L biocatalysts, the reaction was completed in 5 h and provided HN in 92 % recovered yield and >99.5 % e.e. This new process has been scaled-up to 2,000 L reactors, indicated that it is a feasible route to synthesis of HN.

The applications of nitrilase in HN synthesis

Among the hydrolase family, nitrilase (EC 3.5.5.1) is one of the most important tools in organic synthesis, which is found in bacteria, fungi, and plants (Chen et al. 2009). Nitrilase can convert nitrile compounds to the corresponding carboxylic acid (Liu et al. 2011a, b). And they have a broad substrate range containing aliphatic nitriles, aromatic nitriles, and heterocyclic nitriles (Chen et al. 2008; Jin et al. 2011; Liu et al. 2011b; Shen et al. 2009; Xue et al. 2011). Due to its enantioselectivity, nitrilase has been employed in the synthesis of chiral compounds such as (R)-(−)-mandelic acid (Kaul et al. 2004), (S)-(+)-ibuprofen (Yamamoto et al. 1990), and (S)-naproxen (Kakeya et al. 1991). Another feature of nitrilase is regioselectivity, which leads to the asymmetric reduction of dinitriles. For example, the aliphatic nitrilase from Acidovorax facilis 72W could convert 2-methylglutaronitrile to 4-cyanopentanoic acid (Chauhan et al. 2003). Therefore, when the prochiral dinitriles is used as a substrate, one chiral center can be generated by the nitrilase-catalyzed asymmetric reduction. This process has been used to synthesize HN from 3-hydroxyglutaronitrile (Fig. 11).

Robertson et al. discovered and characterized 137 unique nitrilases from environmental DNA libraries (Robertson et al. 2004). Among them, one (R)-specific nitrilase can catalyze the desymmetrization of 3-hydroxyglutaronitrile to provide (R)-4-cyano-3-hydroxybutyric acid on the gram scale. After reaction, HN was isolated in 98 % yield and 95 % e.e. (DeSantis et al. 2002). However, the enantiomeric excess was declined when the concentration of substrate was increased, which limited its large-scale application. Hence, DeSantis et al. (2003) employed a novel directed-evolution technique, the gene site saturation mutagenesis method, to improve the regioselectivity of nitrilase. Finally, they obtained the best mutant from 31,584 clones via a novel high-throughput screening by using the chiral 15N-(R)-3-hydroxyglutaronitrile as substrate. With 3 M concentration of substrate, the bioconversion was completed in 15 h and afforded (R)-4-cyano-3-hydroxybutyric acid in 96 % isolated yield and 98.5 % e.e. The volumetric productivity of the process is 619 g per liter per day.

Nevertheless, the disadvantage of this process is that the substrate 3-hydroxyglutaronitrile is difficult to synthesis in large-scale. Bergeron et al. have created a three-step process of HN production by using low-cost epichlorohydrin as starting material (Bergeron et al. 2006). The epichlorohydrin was cyanided by sodium cyanide to provide 3-hydroxyglutaronitrile. Then, the nitrilase-catalyzed biotransformation was performed at optimum conditions: 3 M concentration of 3-hydroxyglutaronitrile, 6 wt% of enzyme loading, pH 7.5, and 27 °C. After 16 h reaction, (R)-4-cyano-3-hydroxybutyric acid with 100 % conversion and 99 % e.e. was obtained. At last, the (R)-4-cyano-3-hydroxybutyric acid was esterified with ethanol, and crude HN was produced in 99 % yield and 98.7 % e.e. A similar catalytic process has been applied for a patent (Burk et al. 2011).

The applications of carbonyl reductase in HN synthesis

Carbonyl reductases (EC 1.1.1.184) belong to the short-chain dehydrogenases/reductases protein superfamily (Hoffmann and Maser 2007). They are widespread in nature and catalyze the reduction of many carbonyl compounds. The asymmetric reduction of prochiral ketones with carbonyl reductase is an effective approach that widely used in the synthesis of synthons for pharmaceuticals and fine chemicals (Zhu et al. 2005). In a typical application, (S)-CHBE was synthesized by carbonyl reductase using ethyl 4-chloro-3-oxobutanoate (COBE) as substrate (Kizaki et al. 2001; You et al. 2013a). A NADH-dependent carbonyl reductase from Streptomyces coelicolor has been cloned and expressed in Escherichia coli, and converted 600 g/L of COBE, which is the highest concentration of substrate in literatures, to (S)-CHBE in a yield of 93 % and an enantioselectivity of >99 % e.e. (Wang et al. 2011). Inspired by this formation process, scientists imagined a way to apply this to the production of HN, which is direct synthesis of HN from its β-ketoester precursor (Fig. 12).

He’s group recently reported the synthesis of HN from ethyl 4-cyano-3-oxobutanoate as starting material (He et al. 2008a). The whole cells of Bacillus pumilus Phe-C3 were used as biocatalyst. The substrate was consumed in a conversion of 100 % after 24 h reaction, and the product was obtained with 83.1 % isolated yield and 97 % e.e. The reuse batches of the cells of B. pumilus Phe-C3 were also investigated. The cells retained more than 80 % of the initial activity after six reaction cycles, indicated that the cells were relatively stable under the reaction conditions. Whole-cell reduction system has the advantages over the enzyme purification and cofactor regeneration. However, the substrate concentration was too low to meet the requirements for effective industrial processing. Though they later optimized the conditions for cell growth and biotransformation, cells tolerated the highest concentration of ethyl 4-cyano-3-oxobutanoate which still only 20 mM (Jin and Zhang 2012). Wakita has also patented the same bioconversion process, where several recombinant carbonyl reductases were used (Wakita 2004). In this process, the concentration of substrate was increased to 135 mM. Ethyl 4-bromo-3-oxobutanoate was used as raw material to synthesize ethyl 4-cyano-3-oxobutanoate with a yield of 56.8 %, which limited the applications of this process.

However, coenzyme regeneration in the carbonyl reduction is another key factor to consider. Because of the high price of coenzyme, the addition of a large amount of coenzyme is impossible in industrial scale. The effectiveness of whole-cell reduction system is very low. So, it is necessary to create an efficient and economical coenzyme regeneration system for the carbonyl reduction process (Leonida 2001). Generally, a coenzyme regeneration system was consisted of one enzyme and two substrates or two enzymes and two substrates. For example, the alcohol dehydrogenase from Leifsonia can produce (R)-form chiral alcohols from ketones using 2-propanol as an auxiliary substrate for the regeneration of cofactor (Inoue et al. 2006). The carbonyl reductase from Candida magnoliae and the glucose dehydrogenase from Bacillus megaterium were used to catalyze the asymmetric reduction of COBE to (S)-CHBE (Kizaki et al. 2001). In this process, glucose was used as a hydrogen donor for the cofactor regeneration. In addition, lactate dehydrogenase, glutamate dehydrogenase, and NADH oxidase were also used in the cofactor regeneration system (Lunzer et al. 1998; Presecki and Vasic-Racki 2009).

The applications of lipase in HN synthesis

Lipase (triacylglycerol acylhydrolase, EC 3.1.1.3) is an enzyme that catalyzes the hydrolysis, ammonolysis, and esterification reactions between esters and corresponding acids and alcohols. It has been widely used in various industrial applications including detergent, food, pharmaceutical, agrochemical, textile, and paper industries (Hasan et al. 2006; Houde et al. 2004; Liu et al. 2012a). Chiral resolution is an important tool in the production of optically active compounds from their racemic compounds. Based on the stereoselectivity, lipase has been successfully used as a catalyst for the chiral resolution of racemic compounds (Bhushan et al. 2011). Racemic ethyl 4-cyano-3-hydroxybutyrate can be separated into enantiomers by stereospecific hydrolysis using lipase (Fig. 13 route A). The docking analysis of crystal structure of Candida antarctica lipase B (PDB code: 1TCA) (Uppenberg et al. 1994), (S)- and (R)-ethyl 4-cyano-3-hydroxybutyrate in the active site showed that the distance between Ser105 and carbonyl of ethyl (S)-4-cyano-3-hydroxybutyrate was 2.5 Å, and the carbonyl of ethyl (R)-4-cyano-3-hydroxybutyrate was far from Ser105 (Fig. 14). According to the catalytic mechanism of lipase-catalyzed ester hydrolysis (Bornscheuer and Kazlauskas 1999), the nucleophilic attack of the serine residue on the carbonyl was the first step which cannot hydrolyze ethyl (R)-4-cyano-3-hydroxybutyrate.

Docking of (S)- and (R)-ethyl 4-cyano-3-hydroxybutyrate into the active site of CALB. The structure of CALB was obtained from PDB database (PDB code: 1TCA). Molecular docking was performed using the Dock Ligands Module (LibDock) in DS 2.1. All protein structure figures were prepared with PyMOL (www.pymol.org)

Recently, Hwang and Chung (2009) has constructed a process for preparing optically active β-hydroxybutyl ester by stereospecific hydrolysis of racemic β-hydroxybutyl ester using lipase or lipase-producing microorganisms. Racemic ethyl 4-cyano-3-hydroxybutyrate was used as substrate and the commercial lipase (Novozyme 435) was used as a biocatalyst. HN was obtained with 99 % e.e. after reaction for 3 h. One disadvantage of this process is that only 50 % of a desired enantiomer is obtained.

There is another way to produce HN using lipase as biocatalyst, in which the prochiral diethyl 3-hydroxyglutarate was used as substrate and asymmetric hydrolyzed or ammonolyzed by lipase (Novozyme 435) (Fig. 13 route B). The ammonolysis reaction gave 98 % e.e. and 95 % yield. The products were converted into HN using chlorosulfonylisocyanate or 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (Moen et al. 2004). However, the high cost of catalysts in the last step limited the application of this method.

Concluding remarks

Ethyl (R)-4-cyano-3-hydroxybutanoate is an important building block in the pharmaceutical production. This review concentrated on the methods for the synthesis of HN, including chemical synthesis and enzymatic synthesis, and attempted to outline an economical, environmentally friendly, scalable, reliable, efficient process of HN production. Currently, HN is mainly produced by the chemical synthesis. The cyano-introducing reaction in chemical synthesis is a simple, practical, and economical process. The highest yield of HN in such reaction was over 90 %. But the separation and purification of HN from variety of by-products is very difficult, which prompted researchers to find a more appropriate method. Enzymatic synthesis is considered as a useful alternative compared with traditional chemical ways. Halohydrin dehalogenase, nitrilase, carbonyl reductase, and lipase are involved in the enzymatic synthesis of HN. The key point of enzymatic synthesis is a high catalytic activity of these enzymes at high substrate concentrations, broad pH, and temperature variations. With the development of genetic engineering and protein engineering technologies, such as direct evolution, the enzyme performances have been greatly improved. Using of these technologies, the halohydrin dehalogenase-catalyzed process and nitrilase-catalyzed process have achieved in large scale. These synthetic approaches have provided valuable lessons not only for the production of HN but also for the synthesis of numerous structurally related chemicals.

References

Anastas P, Eghbali N (2010) Green chemistry: principles and practice. Chem Soc Rev 39:301–312

Archelas A, Furstoss R (1997) Synthesis of enantiopure epoxides through biocatalytic approaches. Annu Rev Microbiol 51:491–525

Asako H, Shimizu M, Itoh N (2009) Biocatalytic production of (S)-4-bromo-3-hydroxybutyrate and structurally related chemicals and their applications. Appl Microbiol Biotechnol 84:397–405

Barrios-Gonzalez J, Miranda RU (2010) Biotechnological production and applications of statins. Appl Microbiol Biotechnol 85:869–883

Bergeron S, Chaplin DA, Edwards JH, Ellis BSW, Hill CL, Holt-Tiffin K, Knight JR, Mahoney T, Osborne AP, Ruecroft G (2006) Nitrilase-catalysed desymmetrisation of 3-hydroxyglutaronitrile: preparation of a statin side-chain intermediate. Org Process Res Dev 10:661–665

Bhushan I, Kumar A, Modi G, Jamwal S (2011) Chiral resolution of differently substituted racemic acetyl-1-phenyl ethanol using lipase from Bacillus subtilis. J Chem Technol Biotechnol 86:315–318

Bornscheuer UT, Kazlauskas RJ (1999) Hydrolases in organic synthesis—region- and stereoselective biotransformations. Wiley, Weinheim

Bottcher D, Bornscheuer UT (2010) Protein engineering of microbial enzymes. Curr Opin Microbiol 13:274–282

Brooks WH, Guida WC, Daniel KG (2011) The significance of chirality in drug design and development. Curr Top Med Chem 11:760–770

Brower PL, Butler DE, Deering CF, Le TV, Millar A, Nanninga TN, Roth BD (1992) The synthesis of (4r-Cis)-1,1-dimethylethyl 6-cyanomethyl-2,2-dimethyl-1,3-dioxane-4-acetate, a key intermediate for the preparation of Ci-981, a highly potent, tissue selective inhibitor of Hmg-Coa reductase. Tetrahedron Lett 33:2279–2282

Burk MJ, DeSantis G, Morgan G, Zhu ZL (2011) Process for making (R)-ethyl 4-cyano-3 hydroxybutyric acid, US 7932064B2

Candela M, Ruiz A, Feo FJ (2000) Validation of an analysis method for 4-amino-3-hydroxybutyric acid by reversed-phase liquid chromatography. J Chromatogr A 890:273–280

Chauhan S, Wu S, Blumerman S, Fallon RD, Gavagan JE, DiCosimo R, Payne MS (2003) Purification, cloning, sequencing and over-expression in Escherichia coli of a regioselective aliphatic nitrilase from Acidovorax facilis 72W. Appl Microbiol Biotechnol 61:118–122

Chen J, Zheng YG, Shen YC (2008) Biotransformation of p-methoxyphenylacetonitrile into p-methoxyphenylacetic acid by resting cells of Bacillus subtilis. Biotechnol Appl Biochem 50:147–153

Chen J, Zheng RC, Zheng YG, Shen YC (2009) Microbial transformation of nitriles to high-value acids or amides. Adv Biochem Eng Biotechnol 113:33–77

Davis SC, Grate JH, Gray DR, Gruber JM, Huisman GW, Ma SK, Newman LM, Sheldon R, Wang LA (2004) Enzymatic processes for the production of 4-substituted 3-hydroxybutyric acid derivatives. WO2004015132A2

Davis SC, Grate JH, Gray DR, Gruber JM, Huisman GW, Ma SK, Newman LM, Sheldon R, Wang LA (2006) Enzymatic processes for the production of 4-substituted 3-hydroxybutyric acid derivatives and vicinal cyano, hydroxy substituted carboxylic acid esters. WO 2004015132A2

de Jong RM, Tiesinga JJW, Rozeboom HJ, Kalk KH, Tang L, Janssen DB, Dijkstra BW (2003) Structure and mechanism of a bacterial haloalcohol dehalogenase: a new variation of the short-chain dehydrogenase/reductase fold without an NAD(P)H binding site. Embo J 22:4933–4944

de Jong RM, Tiesinga JJW, Villa A, Tang LX, Janssen DB, Dijkstra BW (2005) Structural basis for the enantioselectivity of an epoxide ring opening reaction catalyzed by halo alcohol dehalogenase HheC. J Am Chem Soc 127:13338–13343

DeSantis G, Zhu ZL, Greenberg WA, Wong KV, Chaplin J, Hanson SR, Farwell B, Nicholson LW, Rand CL, Weiner DP, Robertson DE, Burk MJ (2002) An enzyme library approach to biocatalysis: development of nitrilases for enantioselective production of carboxylic acid derivatives. J Am Chem Soc 124:9024–9025

DeSantis G, Wong K, Farwell B, Chatman K, Zhu ZL, Tomlinson G, Huang HJ, Tan XQ, Bibbs L, Chen P, Kretz K, Burk MJ (2003) Creation of a productive, highly enantioselective nitrilase through gene site saturation mutagenesis (GSSM). J Am Chem Soc 125:11476–11477

Findrik Z, Vasic-Racki D (2009) Overview on reactions with multi-enzyme systems. Chem Biochem Eng Q 23:545–553

Fox RJ, Davis SC, Mundorff EC, Newman LM, Gavrilovic V, Ma SK, Chung LM, Ching C, Tam S, Muley S, Grate J, Gruber J, Whitman JC, Sheldon RA, Huisman GW (2007) Improving catalytic function by ProSAR-driven enzyme evolution. Nat Biotechnol 25:338–344

Garrett RL (1996) Pollution prevention, green chemistry, and the design of safer chemicals. In: Devito SC, Garrett RL (eds) Designing safer chemicals green chemistry for pollution prevention, vol 640. American Chemical Society, Washington, pp 2–15

Guercio G, Manzo AM, Goodyear M, Bacchi S, Curti S, Provera S (2009) Synthesis of the NK1 receptor antagonist GW597599. Part 2: development of a scalable route to a key chirally pure arylpiperazine. Org Process Res Dev 13:489–493

Hasan F, Shah AA, Hameed A (2006) Industrial applications of microbial lipases. Enzym Microb Technol 39:235–251

He CM, Chang DL, Zhang J (2008a) Asymmetric reduction of substituted α- and β-ketoesters by Bacillus pumilus Phe-C3. Tetrahedron-Asymmetry 19:1347–1351

He F, Pan QH, Shi Y, Duan CQ (2008b) Chemical synthesis of proanthocyanidins in vitro and their reactions in aging wines. Molecules 13:3007–3032

Hoff BH, Anthonsen T (1999) Lipase-catalyzed resolution of esters of 4-chloro-3-hydroxybutanoic acid: effects of the alkoxy group and solvent on the enantiomeric ratio. Tetrahedron-Asymmetry 10:1401–1412

Hoffmann F, Maser E (2007) Carbonyl reductases and pluripotent hydroxysteroid dehydrogenases of the shortchain dehydrogenase/reductase superfamily. Drug Metab Rev 39:87–144

Hong HB, Jiang CJ (2009) Preparation of ethyl (R)-(−)-4-cyano-3-hydroxybutyrate. Chin J Pharm 40:486–487

Houde A, Kademi A, Leblanc D (2004) Lipases and their industrial applications—an overview. Appl Biochem Biotechnol 118:155–170

Humble MS, Berglund P (2011) Biocatalytic promiscuity. Eur J Org Chem 2011:3391–3401

Hutt AJ, O’Grady J (1996) Drug chirality: a consideration of the significance of the stereochemistry of antimicrobial agents. J Antimicrob Chemother 37:7–32

Hwang SO, Chung SH (2009) Method of making optically active ester derivatives and their acids from racemic esters. US7485452B2

Inoue K, Makino Y, Dairi T, Itoh N (2006) Gene cloning and expression of Leifsonia alcohol dehydrogenase (LSADH) involved in asymmetric hydrogen-transfer bioreduction to produce (R)-form chiral alcohols. Biosci Biotechnol Biochem 70:418–426

Janssen DB, Majeric-Elenkov M, Hasnaoui G, Hauer B, Lutje Spelberg JH (2006) Enantioselective formation and ring-opening of epoxides catalysed by halohydrin dehalogenases. Biochem Soc Trans 34:291–295

Jiang CJ, Hong HB (2012) A new practical synthesis of ethyl (R)-(−)-4-cyano-3-hydroxybutyrate from (S)-3-chloro-1,2-propanediol. Lett Org Chem 9:520–521

Jiang SD, Singh G (1998) Chemical synthesis of shikimic acid and its analogues. Tetrahedron 54:4697–4753

Jin J, Zhang J (2012) Enzymatic synthesis of both enantiomers of ethyl 4-cyano-3-hydroxybutanoate. Adv Mater Res 343–344:448–452

Jin LQ, Li YF, Liu ZQ, Zheng YG, Shen YC (2011) Characterization of a newly isolated strain Rhodococcus erythropolis ZJB-09149 transforming 2-chloro-3-cyanopyridine to 2-chloronicotinic acid. New Biotechnol 28:610–615

Jung H, Jung K, Kleber HP (1993) Synthesis of L-carnitine by microorganisms and isolated enzymes. Adv Biochem Eng Biotechnol 50:21–44

Kakeya H, Sakai N, Sugai T, Ohta H (1991) Microbial hydrolysis as a potent method for the preparation of optically-active nitriles, amides and carboxylic-acids. Tetrahedron Lett 32:1343–1346

Kataoka M, Kita K, Wada M, Yasohara Y, Hasegawa J, Shimizu S (2003) Novel bioreduction system for the production of chiral alcohols. Appl Microbiol Biotechnol 62:437–445

Kaul P, Banerjee A, Mayilraj S, Banerjee UC (2004) Screening for enantioselective nitrilases: kinetic resolution of racemic mandelonitrile to (R)-(−)-mandelic acid by new bacterial isolates. Tetrahedron-Asymmetry 15:207–211

Kita K, Kataoka M, Shimizu S (1999) Diversity of 4-chloroacetoacetate ethyl ester-reducing enzymes in yeasts and their application to chiral alcohol synthesis. J Biosci Bioeng 88:591–598

Kizaki N, Yasohara Y, Hasegawa J, Wada M, Kataoka M, Shimizu S (2001) Synthesis of optically pure ethyl (S)-4-chloro-3-hydroxybutanoate by Escherichia coli transformant cells coexpressing the carbonyl reductase and glucose dehydrogenase genes. Appl Microbiol Biotechnol 55:590–595

Kumar P, Deshmukh AN, Upadhyay RK, Gurjar MK (2005) A simple and practical approach to enantiomerically pure (S)-3-hydroxy-gamma-butyrolactone: synthesis of (R)-4-cyano-3-hydroxybutyric acid ethyl ester. Tetrahedron-Asymmetry 16:2717–2721

Leonida MD (2001) Redox enzymes used in chiral syntheses coupled to coenzyme regeneration. Curr Med Chem 8:345–369

Lespieau R (1923) Nitriles β-oxyglutarique, β-bromoglutarique et gultaconique. Bull Soc Chim Fr 33:725–733

Liu ZQ, Dong LZ, Cheng F, Xue YP, Wang YS, Ding JN, Zheng YG, Shen YC (2011a) Gene cloning, expression, and characterization of a nitrilase from Alcaligenes faecalis ZJUTB10. J Agric Food Chem 59:11560–11570

Liu ZQ, Li FF, Cheng F, Zhang T, You ZY, Xu JM, Xue YP, Zheng YG, Shen YC (2011b) A novel synthesis of iminodiacetic acid: biocatalysis by whole Alcaligenes faecalis ZJB-09133 cells from iminodiacetonitrile. Biotechnol Prog 27:698–705

Liu ZQ, Zhang LP, Cheng F, Ruan LT, Hu ZC, Zheng YG, Shen YC (2011c) Characterization of a newly synthesized epoxide hydrolase and its application in racemic resolution of (R, S)-epichlorohydrin. Catal Commun 16:133–139

Liu ZQ, Zheng XB, Zhang SP, Zheng YG (2012a) Cloning, expression and characterization of a lipase gene from the Candida antarctica ZJB09193 and its application in biosynthesis of vitamin A esters. Microbiol Res 167:452–460

Liu ZQ, Zhou M, Zhang XH, Xu JM, Xue YP, Zheng YG (2012b) Biosynthesis of iminodiacetic acid from iminodiacetonitrile by immobilized recombinant Escherichia coli harboring nitrilase. J Mol Microbiol Biotechnol 22:35–47

Lunzer R, Ortner I, Haltrich D, Kulbe KD, Nidetzky B (1998) Enzymatic regeneration of NAD in enantioselective oxidation of secondary alcohols: glutamate dehydrogenase versus NADH dehydrogenase. Biocatal Biotransform 16:333–349

Lv SX, Guo YH, Wang YP, Wang XJ, Xiang WS (2009) A novel synthesis of (R)-4-cyano-3-hydroxybutyric acid ethyl ester. Chin J Org Chem 29:1997–1999

Ma SK, Gruber J, Davis C, Newman L, Gray D, Wang A, Grate J, Huisman GW, Sheldon RA (2010) A green-by-design biocatalytic process for atorvastatin intermediate. Green Chem 12:81–86

Majerić Elenkov M, Hauer B, Janssen DB (2006) Enantioselective ring opening of epoxides with cyanide catalysed by halohydrin dehalogenases: a new approach to non-racemic β-hydroxy nitriles. Adv Synth Catal 348:579–585

Majeric Elenkov M, Tang L, Hauer B, Janssen DB (2006) Sequential kinetic resolution catalyzed by halohydrin dehalogenase. Org Lett 8:4227–4229

Matsuda H, Shibata T, Hashimoto H, Kitai M (1999) Method for producing (R)-4-cyano-3-hydroxybutyric acid lower alkyl ester. US5908953

Mete E, Maras A, Secen H (2003) A short synthesis of 4-amino-3-hydroxybutyric acid (GABOB) via allyl cyanide. Russ Chem B+ 52:1879–1881

Mitsuhashi S, Sakurai K, Kumobayashi H (1995) T-butyl (R)-(−)-4-cyano-3-hydroxybutyrate and process for preparing the same. US5430171

Moen AR, Hoff BH, Hansen LK, Anthonsen T, Jacobsen EE (2004) Absolute configurations of monoesters produced by enzyme catalyzed hydrolysis of diethyl 3-hydroxyglutarate. Tetrahedron-Asymmetry 15:1551–1554

Narina SV, Sudalai A (2007) Enantioselective synthesis of (S)-timolol via kinetic resolution of terminal epoxides and dihydroxylation of allylamines. Tetrahedron 63:3026–3030

Nguyena LA, Hua H, Chuong P-H (2006) Chiral drugs: an overview. Int J Biomed Sci 2:85–100

Okano K, Tokuyama H, Fukuyama T (2008) Total synthesis of (+)-yatakemycin. Chem-Asian J 3:296–309

Pantaleone DP (2005) Biotransformations: green processes for the synthesis of chiral fine chemicals. In: Ager DJ (ed) Handbook of chiral chemicals. CRC, New York, pp 359–403

Patel RN (2006) Biocatalysis: synthesis of chiral intermediates for drugs. Curr Opin Drug Discov Dev 9:741–764

Patel RN (2008) Synthesis of chiral pharmaceutical intermediates by biocatalysis. Coord Chem Rev 252:659–701

Patel JM (2009) Biocatalytic synthesis of atorvastatin intermediates. J Mol Catal B Enzym 61:123–128

Presecki AV, Vasic-Racki D (2009) Mathematical modelling of the dehydrogenase catalyzed hexanol oxidation with coenzyme regeneration by NADH oxidase. Process Biochem 44:54–61

Rajesh T, Madhusudhan G, Mukkanti K, Narayana Rao SP, Kishore Babu K (2011) A new and concise synthetic route to enantiopure Linezolid from (S)-epichlorohydrin. Der Pharma Chem 3:168–175

Robertson DE, Chaplin JA, DeSantis G, Podar M, Madden M, Chi E, Richardson T, Milan A, Miller M, Weiner DP, Wong K, McQuaid J, Farwell B, Preston LA, Tan XQ, Snead MA, Keller M, Mathur E, Kretz PL, Burk MJ, Short JM (2004) Exploring nitrilase sequence space for enantioselective catalysis. Appl Environ Microbiol 70:2429–2436

Roh KR, Yu HS, Kim KI, Lee WJ, Hwang DI (2003) Process for preparing (R)-4-cyano-3-hydroxybutyric acid ester. US6586616B1

Romeo G, Chiacchio U, Corsaro A, Merino P (2010) Chemical synthesis of heterocyclic-sugar nucleoside analogues. Chem Rev 110:3337–3370

Roth BD. (1987) Trans-6-[2-(3- or 4-carboxamido-substituted pyrrol-1-yl) alkyl]-4-hydroxypyran-2-one inhibitors of cholesterol synthsis, US4681893

Roth BD (2002) The discovery and development of atorvastatin, a potent novel hypolipidemic agent. Prog Med Chem 40:1–22

Schallmey M, Floor RJ, Hauer B, Breuer M, Jekel PA, Wijma HJ, Dijkstra BW, Janssen DB (2013) Biocatalytic and structural properties of a highly engineered halohydrin dehalogenase. ChemBioChem 14:870–881

Shen M, Zheng YG, Liu ZQ, Shen YC (2009) Production of acrylic acid from acrylonitrile by immobilization of Arthrobacter nitroguajacolicus ZJUTB06-99. J Microbiol Biotechnol 19:582–587

Sundby E, De Zotti M, Anthonsen T (2003) The enantioselectivity of reduction of ethyl 4-halo-3-oxobutanoate catalyzed by Geotrichum candidum depends on the cofactor. J Mol Catal B Enzym 21:63–66

Tang LX, van Hylckama JET, Spelberg JHL, Fraaije MW, Janssen DB (2002) Improved stability of halohydrin dehalogenase from Agrobacterium radiobacter AD1 by replacement of cysteine residues. Enzym Microb Technol 30:251–258

Tang LX, Spelberg JHL, Fraaije MW, Janssen DB (2003) Kinetic mechanism and enantioselectivity of halohydrin dehalogenase from Agrobacterium radiobacter. Biochemistry 42:5378–5386

Tang LX, Pazmino DET, Fraaije MW, de Jong RM, Dijkstra BW, Janssen DB (2005) Improved catalytic properties of halohydrin dehalogenase by modification of the halide-binding site. Biochemistry 44:6609–6618

Tao J, Xu JH (2009) Biocatalysis in development of green pharmaceutical processes. Curr Opin Chem Biol 13:43–50

Turner NJ (2009) Directed evolution drives the next generation of biocatalysts. Nat Chem Biol 5:568–574

Uppenberg J, Hansen MT, Patkar S, Jones TA (1994) The sequence, crystal structure determination and refinement of two crystal forms of lipase B from Candida antarctica. Structure 2:293–308

van den Wijngaard AJ, Reuvekamp PT, Janssen DB (1991) Purification and characterization of haloalcohol dehalogenase from Arthrobacter sp. strain AD2. J Bacteriol 173:124–129

van Hylckama Vlieg JE, Tang L, Lutje Spelberg JH, Smilda T, Poelarends GJ, Bosma T, van Merode AE, Fraaije MW, Janssen DB (2001) Halohydrin dehalogenases are structurally and mechanistically related to short-chain dehydrogenases/reductases. J Bacteriol 183:5058–5066

Wakita R (2004) Method for producing 4-cyano-3-oxobutanoate and 4-cyano-3-hydroxybutanoate. US6781009B2

Wang GJ, Hollingsworth RI (1999) Synthetic routes to L-carnitine and L-gamma-amino-beta-hydroxybutyric acid from (S)-3-hydroxybutyrolactone by functional group priority switching. Tetrahedron-Asymmetry 10:1895–1901

Wang LJ, Li CX, Ni Y, Zhang J, Liu X, Xu JH (2011) Highly efficient synthesis of chiral alcohols with a novel NADH-dependent reductase from Streptomyces coelicolor. Bioresour Technol 102:7023–7028

Xue YP, Xu SZ, Liu ZQ, Zheng YG, Shen YC (2011) Enantioselective biocatalytic hydrolysis of (R,S)-mandelonitrile for production of (R)-(−)-mandelic acid by a newly isolated mutant strain. J Ind Microbiol Biotechnol 38:337–345

Yamamoto K, Ueno Y, Otsubo K, Kawakami K, Komatsu KI (1990) Production of S-(+)-Ibuprofen from a nitrile compound by Acinetobacter sp strain-Ak226. Appl Environ Microbiol 56:3125–3129

Ye Q, Ouyang P, Ying H (2011) A review-biosynthesis of optically pure ethyl (S)-4-chloro-3-hydroxybutanoate ester: recent advances and future perspectives. Appl Microbiol Biotechnol 89:513–522

You ZY, Liu ZQ, Zheng YG (2013a) Characterization of a newly synthesized carbonyl reductase and construction of a biocatalytic process for the synthesis of ethyl (S)-4-chloro-3-hydroxybutanoate with high space-time yield. Appl Microbiol Biotechnol. doi:10.1007/s00253-013-5042-3

You ZY, Liu ZQ, Zheng YG (2013b) Properties and biotechnological applications of halohydrin dehalogenases: current state and future perspectives. Appl Microbiol Biotechnol 97:9–21

Zhu DM, Mukherjee C, Hua L (2005) ‘Green’ synthesis of important pharmaceutical building blocks: enzymatic access to enantiomerically pure alpha-chloroalcohols. Tetrahedron-Asymmetry 16:3275–3278

Acknowledgments

The authors gratefully acknowledge the financial supports of the National High Technology Research and Development Program of China (863 Program) (No. 2011AA02A210075), the Major Basic Research Development Program of China (973 Project) (2011CB710804), and Natural Science Foundation of Zhejiang Province (No. Z4090612, Y4110409 and No. R3110155).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

You, ZY., Liu, ZQ. & Zheng, YG. Chemical and enzymatic approaches to the synthesis of optically pure ethyl (R)-4-cyano-3-hydroxybutanoate. Appl Microbiol Biotechnol 98, 11–21 (2014). https://doi.org/10.1007/s00253-013-5357-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5357-0