Abstract

Recent studies have shown that free nitrous acid (FNA) is biocidal to a broad range of microorganisms. Microorganisms residing in anaerobic sewer biofilms were found to be inactivated after a short (6–24 h) exposure to FNA. In this study, we investigate the inactivation kinetics of anaerobic sewer biofilms grown in real wastewater. Microbial viability of biofilms was determined using LIVE/DEAD staining. A two-fraction kinetic model was developed to simulate the inactivation of mixed culture in biofilms. The kinetic parameters were estimated by using Bayesian statistics. Model simulation found that a fraction (85 %) of the biofilm community was highly sensitive to FNA with a high inactivation rate, and a fraction (15 %) was tolerant to FNA and persisted after FNA treatment. This different susceptibility to FNA treatment was likely due to the diverse microbial community and biofilm protection. The fact that nearly 85 % microbes were inactivated confirmed that FNA is a strong biocide to mixed-culture biofilms. It was found that the inactivation rate constant was not affected by pH levels. The kinetic model was successfully used to optimize FNA dosage for sulfide control in sewer biofilms. Also, results suggest that a high FNA concentration is preferred than long exposure time to reduce the total chemical consumption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wastewater biofilms typically comprise diverse microbial populations embedded in a matrix of extracellular polymeric substances (EPS), which constitute a protected mode of microbial growth, allowing microorganisms to survive in hostile or adverse living environments (Simoes et al. 2010). Some biofilms such as those in biofilm reactors for wastewater treatment are beneficial while others have deleterious effects. For example, anaerobic biofilms in sewer systems (Hvitved-Jacobsen 2002) are notorious due to the production of hydrogen sulfide, which induces corrosion of concrete pipes, metal installation and equipment, in addition to causing odor and health problems (Rempel et al. 2006; US EPA 1991). In addition, anaerobic wastewater biofilms in sewers also produce a significant amount of methane (Foley et al. 2009; Guisasola et al. 2008; Guisasola et al. 2009), which is a potent greenhouse gas, with a heat-retaining potential 21 times that of carbon dioxide (IPCC 2006).

To overcome the major problems associated with wastewater biofilms, i.e., sulfide and methane generation, biocides are used to deactivate microorganisms, thus extinguish the corresponding activities. Nitrite causes specific inhibition to dissimilatory sulfate reduction (Greene et al. 2006) and therefore an exposure of sewer biofilms to a high-level of nitrite over an extended period of time (weeks) caused a gradual decrease of the sulfate-reducing bacteria (SRB) population and hence the loss of biofilm activity (Jiang et al. 2010; Mohanakrishnan et al. 2008).

Jiang et al. (2011b) further found that simultaneous addition of nitrite and acid deactivated sewer biofilm activity with an exposure time of 6–24 h. It was revealed that free nitrous acid (FNA or HNO2) formed from nitrite at acidic conditions (pH < 6) has a strong biocidal effect on anaerobic sewer biofilms, with the viable microbial cells in biofilms decreased from approximately 80 % prior to FNA dosage to 5–15 % after the biofilm was exposed to FNA at 0.2–0.3 mg HNO2–N/L for 6–24 h. Hydrogen peroxide, in combination with FNA, was found to enhance the microbial inactivation by 1-log (Jiang and Yuan 2013), in comparison with FNA dosing alone. FNA was identified as the primary inactivation agent and H2O2 enhanced its efficiency.

The strong biocidal effect of FNA on sewer biofilms implies that the simultaneous dosage of nitrite and acid could achieve rapid inactivation of SRB and methanogenic archaea in sewer biofilms, making it possible to achieve sulfide and methane control through intermittent FNA dosing (Jiang et al. 2011a). In designing the intermittent dosing, it is essential to determine the inactivation kinetics of wastewater biofilms by using FNA. Important dosing parameters, i.e., dosing concentration, exposure time, and dosing interval, can be estimated and optimized only with proper inactivation kinetic parameters.

Traditionally, microbial inactivation kinetics was modeled with a first-order kinetic model by Chick and Watson (Chick 1908; Watson 1908). This model was mainly developed for the inactivation of pure culture microbes in suspended form. The Chick–Watson model has been used widely for modeling the inactivation of different microorganisms, including Cryptosporidium parvum oocysts and Nitrosomonas europaea in water (Ruffell et al. 2000; Sivaganesan et al. 2003; Wahman et al. 2009). However, it lacks the flexibility to account for the complexity of wastewater biofilms, which contain mixed-culture populations.

For the inactivation of biofilm microbes, biofilm matrix might provide a protective mechanism against the applied biocide. Nonsensitive microbes might also survive the biocidal action in a mixed-culture biofilms. Both the biological heterogeneity (difference of microbial resistance to biocides, such as persisting phenotypes (Brown and Gilbert 1993)) and physical heterogeneity (different biofilm layers, protected biofilm niches or pockets) need to be considered in the inactivation kinetics of biofilms. To our knowledge, no report has addressed the inactivation kinetics of mixed-culture biofilms by biocides.

In this study, biofilms grew in laboratory reactors fed with real wastewater were exposed to FNA at different concentrations and pH levels for various time to determine the extent of inactivation. A biofilm inactivation kinetic model, including a term accounting for nonsensitive or protected fraction, was proposed to analyze the inactivation data. For different levels of pH, the two kinetic parameters, i.e., the inactivation rate constant and the fraction of persisting microorganisms, were analyzed using Bayesian statistics. The variability of these kinetic parameters was identified and its impact on applications discussed. The FNA dosage of an intermittent dosing strategy developed previously was then optimized using the estimated kinetic parameters.

Material and methods

Anaerobic biofilm development

A biofilm reactor, made of Perspex™, was set up to grow biofilms with real wastewater under anaerobic conditions. The reactor had a volume of 0.75 L, with a diameter of 80 mm and a height of 149 mm (Fig. 1). Plastic carriers (Anox Kaldnes, Norway) of 1 cm diameter were clustered on four stainless-steel rods inside each reactor to provide additional surfaces for biofilm growth and to allow sampling of intact biofilms. The total volume of the carriers used for each reactor was about 15 mL (2 % of the reactor volume). The total biofilm area in each reactor, including both the reactor wall and carrier surfaces, was approximately 0.05 m2. The area to volume ratio (A/V) was therefore 70.9 m2/m3.

Domestic wastewater, collected weekly from a wet well in Brisbane, Australia, and stored in a cold room at 4 °C, was used as the feed to the reactor. The sewage typically contained sulfide at concentrations of <3 mg-S/L, sulfate at concentrations between 10 and 25 mg S/L, and volatile fatty acid at 50–120 mg COD/L. Nitrate was present at negligible levels, below the detection limit of the analysis method used, i.e., 0.03 mg N/L.

Sewage was fed to the reactor through a peristaltic pump (Masterflex 7520–47) once every 6 h. Every feed pumping event lasted for 2 min, delivering one reactor volume of sewage into the reactor. Mixing (250 rpm) was provided continuously with a magnetic stirrer (Heidolph MR3000) to produce a moderate shear force at the inner surface of the reactor wall, calculated to be 1.7 Pa, and also to avoid solids settling at the bottom.

A ultraviolet–visible (UV–vis) spectrometer (Messtechnik GmbH, Austria) was used for online measurement of dissolved sulfide (Sutherland-Stacey et al. 2008). pH was measured with a TPS miniChem-pH controller (version 2.1.1).

Biofilm inactivation tests

The inactivation kinetics of wastewater biofilms from anaerobic reactors was assessed by doing batch exposure tests followed with viability determination. To investigate the impacts of FNA concentration, pH, and exposure time on the inactivation kinetics, different levels of these factors were employed in a total of 44 batch exposure tests (Table 1). FNA concentration varied from 0.01 to 0.31 mg N/L, with pH varying at 6, 6.5, and 7, exposure time ranging 6, 12, and 24 h. The ranges of pH, FNA concentration and exposure time are chosen around the effective level previously reported for the control of sulfate reducing and methanogenic activities in anaerobic sewer biofilms (Jiang et al. 2010).

For each batch test, wastewater stored in the 4 °C cold room was heated to 20 °C and was adjusted to the specified pH with 1 M hydrochloric acid. The pre-conditioned wastewater was filled into single-use sterile bottles (Sarstedt Australia). FNA was generated by adding a pre-determined amount of nitrite to the acidic wastewater. The FNA concentration was calculated as FNA = NO2 − − N/(K a × 10pH), where K a is the ionization constant of the nitrous acid (Anthonisen et al. 1976). FNA decomposition is expected to be negligible at the nitrite concentrations and pH levels applied (Jiang and Yuan 2013).

A plastic carrier with attached biofilm was transferred from the biofilm reactors into each bottle. The bottle was then capped and kept anaerobic with caution to avoid air bubbles. During the exposure period, gentle mixing was provided by an orbital shaker at 60 rpm. At the end of each test, the biofilm on the carrier was sampled for LIVE/DEAD staining. Accuracy of LIVE/DEAD staining in determining the viability of sewer biofilms was checked by using autoclaved biofilms (121 °C, 15 min) as a control sample. The level of variation was found to be 0.5 %, which might be caused by background fluorescence in the biofilm samples. This level of accuracy is acceptable for the purpose of this study.

The viability of bacterial cells in biofilms was determined using the LIVE/DEAD® BacLightTM bacterial viability kits (Molecular Probes, L-7012). Biofilm was dispersed in filtered (0.22 μm) sewage and 125 μL of the biofilm suspension was stained with 50 μL of SYTO-9 and PI mixture solution for 15 min in a dark place at a room temperature (20 °C), allowing the staining reactions to complete. Twenty photographs of randomly chosen areas of the stained biofilm samples were photographed using a confocal laser scanning microscope (Zeiss LSM 510 META), equipped with a Krypton–Argon laser (488 nm) and two He–Ne lasers (543 and 633 nm). Quantification of live and dead cells was done by determining the relative abundance of green and red pixels by using DAIME 1.3.1.

Biofilm characterization

Once the biofilm reactor reached steady state, the biofilm was characterized by measuring its depth and biomass as described by Mohanakrishnan et al. (2008). Sulfide and methane production rates in the biofilm reactor were monitored by conducting batch tests regularly (every 1–2 weeks) (Jiang et al. 2011b). After feeding the reactor with fresh sewage, wastewater samples were taken at time interval of 15–30 min. Dissolved inorganic sulfur (sulfide, sulfite, thiosulfate, and sulfate) and dissolved methane were analyzed using methods described by Jiang et al. (2011b). Sulfide and methane production rates were then determined by linear regression of the sulfide and methane concentration, respectively.

Microbial morphology of the biofilms was studied using scanning electron microscope (SEM). To prepare biofilm samples for electron microscopy, one carrier with biofilm was fixed with 3 % glutaraldehyde (w/w) using the method described by Jiang et al. (2009). Fixed samples were frozen in liquid nitrogen and small particles showing inner structure were fractured, thawed in 100 % ethanol. These particles were mounted using carbon tab on stainless-steel stubs and sputter coated with platinum. Mounted samples were examined using JEOL 6400F to obtain SEM images.

Inactivation kinetic model and parameter estimation

Traditionally, the kinetics of microbial inactivation has been analyzed using a well-known first-order model proposed by Chick (1908) and Watson (1908).

where N 0 and N are viable microbes prior to and after the biocide treatment, respectively; C is the biocide concentration and t is exposure time. k represents the inactivation rate constant for the microbes. This is named as the one-fraction model (1F-model) because it does not differentiate the microbes in a mixed-culture biofilm.

To develop the kinetic model for biofilm inactivation, the 1F-model was employed as the base model and was tested using the measured inactivation data. Inactivation parameters, estimated using the procedure described below, were employed to calculate model fitted values for each inactivation test. The correlation between measured data and fitted value was used to amend the model to produce more appropriate inactivation kinetic models.

Kinetic parameters were estimated using Bayesian statistics. Bayesian statistics represents major advances in simulation-based computational methods, collectively known as Markov chain Monte Carlo (MCMC) methods (Link and Barker 2010). Specific software like WinBUGS has been developed to fit sophisticated Bayesian models and to conduct inference using Gibbs sampling (http://www.mrc-bsu.cam.ac.uk/bugs/). Traditionally, parameters of the proposed biofilm inactivation kinetic model can be determined using linear or nonlinear regression methods of least-square and maximum likelihood. However, Bayesian approach provides a more accurate way to model the parameters and would give more exact confidence bounds for parameters, especially in the case of data sets with limited sample sizes. There are a few reports about the application of Bayesian statistics in the analysis of microbial inactivation kinetics (Sivaganesan and Sivaganesan 2005; Wahman et al. 2009).

The Bayesian approach to statistical modelling is based on the premise that the uncertainty about unknown parameters in a model is described by a probability distribution. According to Bayesian’s theorem, the posterior distribution of model parameters is proportional to the product of above priors and likelihood defined by the experimental data. To obtain the posterior distribution, a Bayesian model using MCMC method was implemented in WinBUGS to estimate parameters, including their credible intervals. The joint highest-posterior-density (HPD) region of a parameter pair was determined using the posterior distributions to provide a clearer picture of the parameter estimates and associated confidence. A total of 5,000 samplings from the posterior distribution were generated from WinBUGS. From these MCMC-generated posterior distributions, HPD regions were calculated as a two-dimensional kernel density on a square grid. The HPD contour was then generated by normalizing the plot and calculating the bivariate region corresponding to the specified probability level (i.e., 95 %).

Results

Characteristics of anaerobic wastewater biofilm

The anaerobic wastewater biofilms attached to the reactor wall or plastic carriers looked like a dark green-brownish slime layer, with a depth between 500 to 1,000 μm. The measured biomass (as volatile solids) of the biofilm in the whole reactor was 108.3 ± 0.3 g/m2. It was found that sulfide and methane were produced simultaneously in the biofilm reactor fed with real sewage. The sulfate-reducing and methanogenic activity in the biofilm reactor was measured to be 5.6 ± 0.3 mg S L−1 h−1 and 43.5 ± 1.5 mg COD L−1 h−1, respectively. These biological rates were similar to previously reported values in sewer reactors (Guisasola et al. 2008; Jiang et al. 2011a; Jiang et al. 2011b). Also, these rates indicate the reactors reached steady state at the commencement of inactivation tests.

Figure 2a, b shows SEM images of biofilm cells with different morphologies, in the outer layers and biofilm bottom, i.e., interface of biofilm and substratum (plastic carrier). The biofilm outer layer was cocci-dominated, while the bottom layer was dominated by long filaments, and rod-shaped bacteria. This clearly indicates that the wastewater biofilm is a mixed-culture microbial community. The biofilm was previously analyzed using dsr-DGGE and sequencing, showing a diversified population comprised of a number of heterotrophic Gram-positive bacteria and Gram-negative Proteobacteria including Desulfovibrio, which was the only genus of SRB detected using 16S rRNA-based DGGE, indicating that members of this genus were abundant (Mohanakrishnan et al. 2009).

Inactivation kinetic model development

Figure 3 shows two confocal microscope images obtained on the unexposed biofilm and the FNA-treated biofilm. The viable microbes were determined as the percentage of areas in green to the total area of both green and red, which were 90.8 and 15.8 % for the control and inactivated biofilms, respectively.

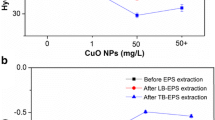

Figure 4 shows the measured viable percentages for all the inactivation tests listed in Table 1. The viability of wastewater biofilms decreased sharply with the increase of FNA concentration and exposure time. This trend gradually slowed down after C t reached above 1 mg N h L−1 and finally leveled off for C t above 3 mg N h L−1. It is clear that the microbial inactivation data obtained for the wastewater biofilm were nonlinear with respect to C t .

The first-order kinetic model, i.e., the 1F-model, could not fit well with the experimental data particularly when C t was above 1.5 mg N h L−1 (Fig. 4). This is likely because the 1F-model neglects the possible nonsensitivity to a biocide by some persisting phenotypes in a mixed-culture biofilm (Brown and Gilbert 1993). This negligence can be a serious pitfall when treating a much diversified microbial population. A biofilm inactivation kinetic model needs to consider the biological heterogeneity in mixed-culture biofilm, i.e., the difference of microbial resistance to biocides. Nonsensitive microbes might survive the biocidal action in a mixed culture biofilm, such as an anaerobic wastewater biofilm. This can be considered by including a parameter f r, the fraction of microbes that can persist for a high level of biocide, in a two-fraction kinetic model (2F-model), as shown below:

As shown in Fig. 4, the 2F-model could fit with the measured data with high accuracy including the high C t range that the 1F-model failed to predict. Good correlation existed between the measured data with 2F-model (Fig. 4b). The coefficients of determination were calculated to be 0.9049 and 0.9991 for 1F- and 2F-model, respectively.

Parameters of the two fraction model

The 2F-model was then employed to determine the key inactivation kinetic parameters, including inactivation rate constants and the two fractions. The 2F-model was implemented in WinBUGS software to estimate the model parameters and their 95 % credible bounds. An initial simulation of 2,000 iterations was performed as a burn-in before a further 5,000 iterations were used to estimate the model parameter posterior distributions. The convergence was found to be satisfactory for either uniform or normal distribution as the priors (Table 2). Information about the parameters prior to obtaining the experimental data is unknown. With no prior information assumed, a diffuse normal (with a mean of 0 and a variance of 10−6) or uniform distribution was used. For σ 2, a diffuse inverse-gamma (0.001, 0.001) prior distribution was used as reported before (Sivaganesan et al. 2003; Sivaganesan and Sivaganesan 2005).

Figure 5 shows the inactivation kinetic model parameters obtained and their 95 % confidence bounds. Inactivation rate constant k and persisting fraction f r were estimated to be 1.75 and 0.16, with 95 % confidence bounds (1.39, 2.15) and (0.1, 0.22), respectively (Fig. S1). The 95 % joint HPD regions were also determined, giving confidence regions of the estimated pair of parameters. In general, the uncertainties are limited, indicating reliable parameter estimation.

Effects of pH on inactivation kinetic parameters

The inactivation kinetic parameters were also estimated using experimental data at different levels of pH, i.e., 6, 6.5, and 7. Figure 6 and Table S1 summarize the estimated kinetic parameters using the same procedure described in “Inactivation kinetic model development.” It is clear that tests carried out at different pH levels led to statistically identical (P < 0.05) inactivation rate constant k, which is not related to the pH condition. The estimated f r values at pH = 7 than 6 and 6.5 also do not appear to be statistically different (P < 0.05), The f r value at pH 7.0 has a relatively higher level of uncertainty. This is likely because FNA concentration is very low at pH 7. Figure 4a indicates the tailing begins at C t above 2 mg N h L−1. Thus, the highest C t for tests with pH 7.0, which is 0.744 mg N h L−1, would not allow the accurate determination of f r.

Discussion

Kinetic parameters and implications

Comparisons of the model-fitted curves with the experimental data indicate that traditional microbial inactivation model is insufficient for describing the inactivation kinetics. Instead, 2F-model appears to be an appropriate kinetic model for simulating the biofilm inactivation data. It adequately depicts the sigmoidal curve with a long flat tail by accounting for the fraction of microbial population that persisted the FNA treatment.

The rate constant is reported to be 0.1–0.24 L mg−1 h−1 for the inactivation of N. europaea by monochloramine (Wahman et al. 2009). In comparison, the inactivation rate constant obtained in this study (1.75 L mg−1 h−1) is much higher. This suggests microbes are highly intolerant to FNA, confirming that FNA is a strong biocidal agent for anaerobic wastewater biofilm (Jiang et al. 2011b). Our recent study showed that FNA likely undergoes decomposition, forming many biocidal intermediate compounds like NO, NO2, N2O3, N2O4, and ONOO−/ONOOH, which contribute to the overall biocidal action (Jiang and Yuan 2013).

It is noted that a significant tailing was found for the inactivation data, which is accounted for as a persistent fraction (f r) in the 2F inactivation model. The persistence observed is likely because of the resisting species and/or limited penetration of FNA in a thick sewer biofilm. Nitrite may not fully penetrate into biofilms due to its potential consumption by viable cells (Jiang and Yuan 2013). Also, FNA and its reactive intermediates produced by self-decomposition could react with lipids, proteins and DNA in the microbes (Klug et al. 2009; Yoon et al. 2006). Thus, consumption of FNA for inactivation further reduced its penetration especially at the beginning of the exposure to FNA. To improve the inactivation rate, a higher FNA concentration (thus deeper penetration of the biocidal agents) is required considering the large depth of wastewater biofilms. Consequently, exposure time can be reduced with higher FNA concentrations.

Application in the optimization of FNA dosage

Kinetic parameters of inactivation models provide the tools to compare the impact of different inactivation methods on the reduction of microbial populations. They are also useful for the development and design of biofilm control strategies to prevent harmful microbial activities. This paper for the first time developed a 2F-model for the inactivation of mixed-culture biofilms. The kinetic parameters obtained could be used in the design of chemical dosing strategy to control adverse biofilm activities.

Previously, an intermittent dosing strategy, composed of short periods (hours) of FNA dosing and long intervals (days) of recovery, was developed for the control of sulfide production by sewer biofilms (Jiang et al. 2011a). In the study, one single dosage of FNA at 0.26 mg N/L for 12 h was shown to suppress the sulfide production. Because of the slow recovery of sulfide production activity, a subsequent dosage was only required after 5 days to achieve an overall 80 % control efficiency (average sulfide level in the recovery period was 80 % below the baseline level). To achieve a certain level (e.g., 80 %) control of the biofilm activity, the higher the dosages, the longer the recovery time and the less frequent the dosages. Thus, one important aspect of such a dosing strategy design is to determine the optimal dosage that achieves a certain level of biofilm activity control with the lowest chemical consumption.

After being inactivated by FNA, sulfate reducing bacteria regrow in sewer biofilms because FNA is washed away with the sewage flow. This biofilm regrowth could be simulated using the Gompertz growth model \( r={r}_0+\left(1-{r}_0\right){e}^{\left(-{e}^{-a\left(t-{t}_0\right)}\right)} \). r is the sulfate reduction rate; r 0 is the persisting sulfate reducing activity after FNA dosage; α is the relative recovery rate at time t 0 (in days); t 0 is the time when recovery rate is at maximum. For sulfate-reducing bacteria, the parameters α and t 0 were determined to be 0.1 d-1 and 10 days, respectively (Jiang et al. 2010).

To optimize the FNA dosage for an intermittent dosing strategy, the 2F inactivation model with estimated parameters was employed to calculate the residual viability at the end of FNA treatment (r 0). This was then used to establish the recovery curves using the Gompertz growth model. Figure 7a shows examples of calculated recovery curves with three dosing conditions with C t being 1, 2, and 4 mg N h L−1, respectively. In all these cases, re-application of FNA was initiated when recovery reached 40 %. The curves clearly show that a more frequent dosing is needed for a lower C t value, and therefore there should be an optimal C t value that would lead to minimum chemical consumption for the same level of sulfide control.

Optimization of the chemical dosage. a Examples of intermittent dosing use different dosages and intervals. b Relationship between chemical consumption and FNA dosage. Optimal dosing is shown as a crossed symbol. Field trial chemical consumptions are shown in line-filled circles (24-h dosing) and fully filled circles (8-h dosing)

With the inactivation model and the Gompertz growth model, the dependency of chemical consumption on C t value, for a given sulfide control requirement, could be determined. Figure 7b shows the curve of chemical consumption (for a sulfide control efficiency of 80 %) at different FNA dosage. The most cost-effective dosage is thus determined as 1.4 mg N h L−1 for the 80 % control efficiency. Recently, two field trials of the intermittent FNA dosing strategy were carried out in real sewers using FNA at 0.26 mg N/L for 24 h followed by two trials with 8 h dosing, achieving 80 % control of sulfide (Jiang et al. 2013). Chemical consumptions for the four trials are very close to the model predictions. This confirmed the model accuracy and the extrapolation from lab results to the full-scale data.

It is interesting that the 24-h trials (line-filled circles) are slightly above the theoretical curve while the 8-h trials (filled circles) are slightly below. This was likely due to consecutive dosing weakening the sewer biofilm, which became more susceptible to the subsequent FNA dosage. Overall, the proposed optimization approach could be used as guidance in choosing FNA dosage.

References

Anthonisen AC, Loehr RC, Prakasam TBS, Srinath EG (1976) Inhibition of nitrification by ammonia and nitrous acid. J Water Pollut Control Fed 48(5):835–852

Brown MRW, Gilbert P (1993) Sensitivity of biofilms to antimicrobial agents. J Appl Bacteriol 74:S87–S97

Chick H (1908) An investigation of the laws of disinfection. J Hyg 8:92–158

Foley J, Yuan Z, Lant P (2009) Dissolved methane in rising main sewer systems: field measurements and simple model development for estimating greenhouse gas emissions. Water Sci Technol 60(11):2963–2971

Greene EA, Brunelle V, Jenneman GE, Voordouw G (2006) Synergistic inhibition of microbial sulfide production by combinations of the metabolic inhibitor nitrite and biocides. Appl Environ Microbiol 72(12):7897–7901

Guisasola A, de Haas D, Keller J, Yuan Z (2008) Methane formation in sewer systems. Water Res 42(6–7):1421–1430

Guisasola A, Sharma KR, Keller J, Yuan ZQ (2009) Development of a model for assessing methane formation in rising main sewers. Water Res 43(11):2874–2884. doi:10.1016/j.watres.2009.03.040

Hvitved-Jacobsen T (2002) Sewer processes: microbial and chemical process engineering of sewer networks. CRC Press, Boca Raton

IPCC (2006) 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme. In: Eggleston HS, Buendia L, Miwa K, Ngara T, Tanabe K (eds) 2006 IPCC Guidelines for National Greenhouse Gas Inventories. IGES, Japan

Jiang G, Yuan Z (2013) Synergistic inactivation of anaerobic wastewater biofilm by free nitrous acid and hydrogen peroxide. J Hazard Mater 250–251:91–98

Jiang G, Sharma KR, Guisasola A, Keller J, Yuan Z (2009) Sulfur transformation in rising main sewers receiving nitrate dosage. Water Res 43(17):4430–4440

Jiang G, Gutierrez O, Sharma KR, Yuan Z (2010) Effects of nitrite concentration and exposure time on sulfide and methane production in sewer systems. Water Res 44(14):4241–4251

Jiang G, Gutierrez O, Sharma KR, Keller J, Yuan Z (2011a) Optimization of intermittent, simultaneous dosage of nitrite and hydrochloric acid to control sulfide and methane production in sewers. Water Res 45(18):6163–6172

Jiang G, Gutierrez O, Yuan Z (2011b) The strong biocidal effect of free nitrous acid on anaerobic sewer biofilms. Water Res 45(12):3735–3743

Jiang G, Keating A, Corrie S, O’halloran K, Nguyen L, Yuan Z (2013) Dosing free nitrous acid for sulfide control in sewers: Results of field trials in Australia. Water Res 47(13):4331–4339

Klug WS, Cummings MR, Ward SM, Spencer C, Palladino MA (2009) Concepts of genetics, 9th edn. Pearson Benjamin Cummings, San Francisco

Link WA, Barker RJ (2010) Bayesian Inference with ecological applications. Academic, New York

Mohanakrishnan J, Gutierrez O, Meyer RL, Yuan Z (2008) Nitrite effectively inhibits sulfide and methane production in a laboratory scale sewer reactor. Water Res 42(14):3961–3971

Mohanakrishnan J, Gutierrez O, Sharma KR, Guisasola A, Werner U, Meyer RL, Keller J, Yuan Z (2009) Impact of nitrate addition on biofilm properties and activities in rising main sewers. Water Res 43(17):4225–4237

Rempel CL, Evitts RW, Nemati M (2006) Dynamics of corrosion rates associated with nitrite or nitrate mediated control of souring under biological conditions simulating an oil reservoir. J Ind Microbiol Biotechnol 33(10):878–886

Ruffell KM, Rennecker JL, Marinas BJ (2000) Inactivation of Cryptosporidium parvum oocysts with chlorine dioxide. Water Res 34(3):868–876

Simoes M, Simoes LC, Vieira MJ (2010) A review of current and emergent biofilm control strategies. LWT-Food Sci Technol 43(4):573–583

Sivaganesan M, Sivaganesan S (2005) Effect of lot variability on ultraviolet radiation inactivation kinetics of Cryptosporidium parvum oocysts. Environ Sci Technol 39(11):4166–4171

Sivaganesan M, Rice EW, Marinas BJ (2003) A Bayesian method of estimating kinetic parameters for the inactivation of Cryptosporidium parvum oocysts with chlorine dioxide and ozone. Water Res 37(18):4533–4543

Sutherland-Stacey L, Corrie S, Neethling A, Johnson I, Gutierrez O, Dexter R, Yuan Z, Keller J, Hamilton G (2008) Continuous measurement of dissolved sulfide in sewer systems. Water Sci Technol 57(3):375–381

USEPA (1991) Hydrogen sulphide corrosion in wastewater collection and treatment system. Technical Report

Wahman DG, Wulfeck-Kleier KA, Pressman JG (2009) Monochloramine disinfection kinetics of Nitrosomonas europaea by propidium monoazide quantitative PCR and live/dead baclight methods. Appl Environ Microbiol 75(17):5555–5562

Watson HE (1908) A note on the variation of the rate of disinfection with change in the concentration of the disinfectant. J Hyg 8:536

Yoon SS, Coakley R, Lau GW, Lymar SV, Gaston B, Karabulut AC, Hennigan RF, Hwang S-H, Buettner G, Schurr MJ, Mortensen JE, Burns JL, Speert D, Boucher RC, Hassett DJ (2006) Anaerobic killing of mucoid Pseudomonas aeruginosa by acidified nitrite derivatives under cystic fibrosis airway conditions. J Clin Invest 116(2):436–446

Acknowledgments

The authors acknowledge the financial support provided by the Australian Research Council and many members of the Australian water industry through LP0882016 the Sewer Corrosion and Odor Research Project (www.score.org.au). Guangming Jiang is especially grateful to the research fund by the New Staff Start-up Grant from The University of Queensland.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 248 kb)

Rights and permissions

About this article

Cite this article

Jiang, G., Yuan, Z. Inactivation kinetics of anaerobic wastewater biofilms by free nitrous acid. Appl Microbiol Biotechnol 98, 1367–1376 (2014). https://doi.org/10.1007/s00253-013-5031-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5031-6