Abstract

Chitin, present in crustacean shells, insects, and fungi, is the second most plentiful natural organic fiber after wood. To effectively use chitin in a cost-saving and environmentally friendly way in aquaculture, crustacean shells (e.g., shrimp-shell meal) are supplemented into aquafeed after degradation by chemical methods. Herein, we describe a chitinase from Aeromonas veronii B565, designated ChiB565, which potently degrades shrimp-shell chitin and resists proteolysis. We isolated recombinant ChiB565 of the expected molecular mass in large yield from Pichia pastoris. ChiB565 is optimally active at pH 5.0 and 50 °C and stable between pH 4.5 and 9.0 at 50 °C and below. Compared with the commercial chitinase C-6137, which cannot degrade shrimp-shell chitin, ChiB565 hydrolyzes shrimp-shell chitin in addition to colloidal chitin, powdered chitin, and β-1,3-1,4-glucan. The optimal enzyme concentration and reaction time for in vitro degradation of 0.1 g of powdered shrimp shell are 30 U of ChiB565 and 3 h, respectively. A synergistic protein-release effect occurred when ChiB565 and trypsin were incubated in vitro with shrimp shells. Tilapia were fed an experimental diet containing 5 % (w/w) shrimp bran and 16.2 U/kg ChiB565, which significantly improved growth and feed conversion compared with a control diet lacking ChiB565. Dietary ChiB565 enhanced nitrogen digestibility and downregulated intestinal IL-1β expression. The immunologically relevant protective effects of dietary ChiB565 were also observed for 2 to 3 days following exposure to pathogenic Aeromonas hydrophila.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chitin is a mucopolysaccharide that consists of N-acetyl-β-d-glucosamine (GlcNAc) linked by β-1,4-glycosidic bonds (Lindsay et al. 1984). It is the second most abundant carbohydrate in nature, and 10 billion tons are produced in aquatic environments annually (Cauchie 1997; Keyhani and Roseman 1999). Thus, how to effectively use this natural resource is an important scientific issue. The hydrolysis products of chitin, chito-oligosaccharides (COS), as feed additives improve the growth, survival, and immune response of the ovate pompano Trachinotus ovatus (Lin et al. 2012a) perhaps by stimulating host head kidney leukocytes to enhance superoxide anion production (Hoffman et al. 1997), by controlling pathogenic bacterial infections (Fernandes et al. 2008; Tokoro et al. 1989), and/or by stimulating growth of beneficial gut bacteria (Lee et al. 2002). Moreover, another hydrolysis product, GlcNAc, is more readily absorbed than is glucose in the digestive system of the dogfish (Scylliorhinus canicula) (Alliot 1967). Therefore, chitin is a potentially important prebiotic/carbohydrate source in aquafeed.

Despite its potential commercial benefits, chitin is the most underutilized biomass resource on earth (Tharanathan and Kittur 2003) owing to its complex cross-linked molecular structure. To solve this deficiency, chitin is mostly degraded by chemical methods before being added to fish diets as COS, GlcNAc, or chitosan (Lin et al. 2012a, b; Shiau and Yu 1999). However, the available chemical methods have several disadvantages, such as high cost, low yield, residual acidity, and serious environmental pollution (Harish and Tharanathan 2007). Thus, enzymatic methods that allow regioselective depolymerization of chitin under mild conditions are preferred (Se-Kwon and Niranjan 2005). Chitinase (EC 3.2.1.14), which cleaves the β-1,4-glycosidic bonds of chitin, is widely distributed in microorganisms (Felse and Panda 1999) and catalyzes the conversion of insoluble chitin into COS and GlcNAc. Although chitinases have been found in the stomach of the carnivorous cobia (Rachycentron canadum) (Fines and Holt 2010), their enzymatic activities are not high enough to efficiently process crustacean wastes. Moreover, endogenous chitinases have only been found in this seldom marine fish. Direct supplementation of aquafeed with exogenous chitinase has yet to be attempted but is an attractive proposal because it may improve the use of inoculating protein in the form of a dietary crustacean-shell chitin–protein complex (Cárdenas et al. 2004), could be easily incorporated into feed, and would lower production costs compared with extrinsic enzymatic digestion of chitin.

For the study reported herein, we identified the gene for a chitinase from Aeromonas veronii B565, expressed it, and characterized its protein product. This chitinase, denoted ChiB565, can potently digest insoluble chitin and is resistant to proteolysis.

Materials and methods

Strains, media, and chemicals

A. veronii B565 was originally isolated from aquaculture pond sediment. It was deposited in CGMCC (no. 4403) and its complete genomic sequence has been published (Li et al. 2011). A. veronii B565 and Escherichia coli DH5α (TaKaRa, Osaka, Japan) were cultured in Luria–Bertani medium (10 g of yeast extract, 10 g of tryptone, and 5 g of NaCl in 1 l of sterile water). Pichia pastoris GS115, the pPIC9 vector, and T4 DNA ligase were purchased from Invitrogen (Carlsbad, CA, USA). Aeromonas hydrophila NJ-1 (received from Dr. Jun Zhu, Nanjing Agricultural University), which was used to test tilapia resistance to a bacterial pathogen, was donated by Professor Yongjie Liu (Nanjing Agricultural University, Nanjing, China). Restriction endonucleases and LA Taq DNA polymerase were supplied by TaKaRa. Bovine serum albumin, GlcNAc, and p-nitrophenyl-N-acetyl-β-d-glucosaminide (pNP-GlcNAc) were purchased from Sigma-Aldrich (St. Louis, MO, USA). The oligosaccharide standards (GlcNAc)5, (GlcNAc)4, (GlcNAc)3, and (GlcNAc)2 were purchased from Toronto Research Chemicals (Toronto, Canada).

Preparation of colloidal chitin

Colloidal chitin was prepared as described (Sandhya et al. 2004) with some modifications. Briefly, 5 g of powdered chitin (C-7071, Sigma-Aldrich) was dissolved in 400 ml of concentrated HCl, followed by gentle stirring of the mixture for 3 h (90-3 magnetic stirrer; Zhenrong Science Equipment Co. Ltd., Shanghai, China). After storage at 4 °C for 24 h, the mixture was added into 1 l of 50 % ethanol with constant mixing, followed by centrifugation at 10,000×g for 10 min at 4 °C. After removing the supernatant, the precipitate was repeatedly washed with distilled water until the pH of the final wash was 7.0. The final supernatant was discarded, and 500 ml of distilled water was added to form a 1 % (w/v) colloidal chitin solution, which was stored at 4 °C before use.

Construction of the ChiB565 expression plasmid

Genomic DNA was extracted from A. veronii B565 using TIANGEN DNA Isolation kit reagents (Beijing, China) and used as the template for PCR amplification of chiB565, which had been previously located in the A. veronii B565 genome (Li et al. 2011). A pair of primers (forward primer 5′-gtgTACGTACAGGCCGCTTATCCCGCCTATAAATC-3′ and reverse primer 5′-ggaGCGGCCGCATAGCTACAGGCAGACTTCCAGCTG-3′), incorporating SnabI and NotI restriction sites, respectively, were designed to allow amplification of the entire coding region of chiB565. The PCR program was 30 cycles of 94 °C for 30 s, 64 °C for 30 s, and 72 °C for 3 min. After purified with TIANGEN DNA purification kit reagents, the desired PCR product was digested with SnabI and NotI and ligated into a pPIC9 vector by T4 DNA ligase. This recombinant plasmid, pPIC9-chiB565, was transformed into E. coli DH5α by heat shock for 90 s at 42 °C, and the transformed cells were plated onto plates containing Luria–Bertani medium containing 50 mg ml–1 ampicillin and cultivated overnight at 37 °C. Recombinant plasmids were recovered from Escherichia coli cultures by alkaline lysis with E.Z.N.A. Plasmid Mini kit reagents (Omega Bio-Tek, Norcross, GA, USA), linearized with BglII, and transformed into P. pastoris GS115 competent cells by electroporation using a MicroPulser (Bio-Rad, Hercules, CA, USA). Recombinant P. pastoris cells were cultured on minimal dextrose plates at 30 °C for 2 days according to the Invitrogen Pichia protocols.

Selection of positive transformants

Transformants were selected for the ability to grow on histidine-deficient medium (RDB-agar plates) at 30 °C until colonies appeared (His + selection). Two hundred His + colonies were selected randomly. The integration of the expression cassette into the genome of the above stains was verified by PCR using the 5′ and 3′ AOX1 primers (5′-GGTTGAATGAAACCTTTTTGCC-3′ and 5′-CAACTAATTATTCGAAGGATCC-3′). Clones containing a gene of the expected size, as assessed with agarose gel electrophoresis, were incubated in 3 ml of buffered minimal glycerol medium (BMGY) (per liter, 10 g of yeast extract, 20 g of peptone, 13.4 g of yeast nitrogen base, 0.4 mg of biotin, and 10 ml of glycerol) at 30 °C in a gyratory shaker at 250×g for 2 days. Cells were harvested by centrifugation at 3,250×g at 4 °C for 10 min and cultured in 1 ml of buffered minimal methanol medium (BMMY) (per liter, 10 g of yeast extract, 20 g of peptone, 13.4 g of yeast nitrogen base, 0.4 mg of biotin, and 10 ml of methanol) for 2 days. The chitinase activity associated with the positive clones was determined by the assay described below.

Expression, purification, and identification of ChiB565

The positive clone with the greatest enzyme activity in the culture medium was grown in 200 ml of BMGY medium at 30 °C for 48 h. Cells were collected and transferred to a 1-l flask containing 100 ml of BMMY medium culturing for 24 h at 30 °C. The culture medium was recovered by centrifugation at 12,000×g for 10 min at 4 °C. Proteins were precipitated with 80 % (w/v) ammonium sulfate at 0 °C in an ice bath, and resuspended in 20 mM phosphate-citrate (pH 5.0). The crude enzyme was dialyzed against 20 mM phosphate-citrate (pH 5.0) overnight, and the retentate (10 ml) was loaded onto a Sephacryl S-100 HR FPLC column (Amersham Pharmacia Biotech, Uppsala, Sweden) that was pre-equilibrated with 20 mM phosphate–citrate (pH 5.0), 300 mM NaCl, which also served as the eluent. Protein purity was assessed by sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS–PAGE). Protein concentration was determined using Bio-Rad Protein Assay kit reagents with bovine serum albumin as the standard. To verify that ChiB565 had indeed been purified, its corresponding band was cut from the gel and identified using liquid chromatography-coupled electrospray ionization–tandem mass spectrometry at the State Key Laboratory of Biology of Biomembrane and Membrane Technology, Institute of Zoology, Chinese Academy of Science (Beijing, China).

Chitinase activity assay

Chitinase activity was measured by a colorimetric assay (Gomez et al. 2004). Each reaction contained 250 μl of the enzyme solution and 250 μl of 1 % (w/v) colloidal chitin in 20 mM phosphate–citrate (pH 5.0). Each reaction was incubated at 50 °C for 1 h before adding 2 ml of 3,5-dinitrosalicylic acid. Each mixture was immediately boiled for 5 min, cooled to room temperature, and centrifuged at 10,000×g for 1 min. The absorbance of reducing sugar was measured at 540 nm. One unit of chitinase activity was defined as the amount of enzyme that produced 1 μmol of GlcNAc per hour.

Measurement of substrate specificity

The substrate specificity of purified recombinant ChiB565 and the commercially available Streptomyces griseus chitinase C-6137 (Sigma-Aldrich) were determined by measuring their activities against colloidal chitin, carboxymethyl cellulose, β-1,3-1,4-glucan, powdered chitin, powdered chitosan, shrimp-shell chitin, glycol chitosan, and pNP-GlcNAc (all at 1 % w/v) after incubation in 20 mM phosphate-citrate (pH 5.0) at 50 °C for 60 min (each reaction was shaken gently by hand after 30 min of incubation). The amounts of reducing sugars produced were then measured by the 3,5-dinitrosalicylic acid method described above.

Effects of pH and temperature on ChiB565 activity

Colloidal chitin was used as the substrate to characterize the pH and temperature properties of ChiB565. To determine its optimal pH, ChiB565 was incubated in buffers that had pH values between 3.0 and 12.0 at 37 °C for 60 min, with each reaction being shaken gently by hand at the 30-min point of the incubation. The buffers used were 100 mM phosphate–citrate (pH 3.0–6.0), 100 mM Tris–HCl (pH 6.0–9.0), and 100 mM glycine–NaOH (pH 9.0–12.0). To investigate the effect of pH on the stability of ChiB565, the enzyme was incubated in the aforementioned reaction buffers at 37 °C for 1 h in the absence of substrate with gentle shaking by hand at 0.5 h before measuring its residual activity under standard conditions (pH 5.0, 50 °C, 1 h).

The temperature optimum of ChiB565 was determined by incubating the enzyme in 20 mM phosphate–citrate (pH 5.0) for 1 h at temperatures ranging from 0 to 70 °C with gentle shaking by hand at 0.5 h. To determine the thermostability of ChiB565, the enzyme was pre-incubated in 20 mM phosphate–citrate (pH 6.0) for 1 h at temperatures between 0 and 70 °C without substrate and with gentle shaking by hand at 0.5 h, after which the residual activity was determined under standard conditions. All measurements were carried out in triplicate.

Effects of metal ions and proteases

The effects of metal ions and chemical reagents on ChiB565 activity were studied using Li+, Na+, K+, Ag+, Ca2+, Co2+, Ni2+, Cu2+, Mg2+, Mn2+, Zn2+, Pb2+, Cr3+, Fe3+, SDS, ethylenediaminetetraacetic acid, and β-mercaptoethanol each at 5 mM. Standard assay conditions served as the control. To determine the resistance of ChiB565 to proteolysis, residual chitinase activity was determined after incubating the enzyme in 100 mM phosphate–citrate containing pepsin (pH 2.0) or 100 mM Tris–HCl containing trypsin (pH 7.0), collagenase (pH 7.5), or subtilisin A (pH 7.5) for 30 or 60 min at 37 °C at a ratio of 1:10 (w/w) protease/ChiB565 without mixing.

Shrimp-shell degradation by ChiB565 in vitro

Cleaned and dried commercial-sized Penaeus vannamei Boone shrimp shells were ground to a fine powder, and the mean chitin content was found to be 26.8 % (w/w) (Black and Schwartz 1950). The optimal enzyme concentration for shrimp-shell degradation was determined by incubating 0 to 50 U of ChiB565 with 0.1 g of powdered shrimp shell for 6 h at 50 °C with gentle shaking by hand every 0.5 h. To determine the optimal reaction time, 0.1 g of powdered shrimp shell was incubated with ChiB565 at the predetermined optimal concentration and 50 °C for 0 to 6 h with gentle shaking by hand every 0.5 h. Reactions that lacked ChiB565 served as controls. The amounts of reducing sugar released were measured as described above. All measurements were carried out in triplicate.

To investigate the combined effect of trypsin and ChiB565, 0.2 g of powdered shrimp shell was incubated with 60 U of ChiB565 alone, 10 mg of trypsin alone, or 60 U of ChiB565 and 10 mg of trypsin for 3 h at 37 °C with gentle shaking by hand every 0.5 h. The amounts of reducing sugars released were determined, and the amount of tyrosine released was measured by Folin’s phenol method (Lowry et al. 1951). Commercial C-6137 chitinase served as the positive control.

In vitro hydrolysis of colloid chitin and powdered shrimp shell by ChiB565 assessed by HPLC

Flasks containing 3 ml of purified ChiB565 (50 U/ml) and 3 ml of 1 % (w/v) colloidal chitin or 0.3 g of powdered shrimp shell were incubated at 50 °C for 1–6 h (for colloidal chitin) or 3–12 h (for shrimp shells) with gentle shaking by hand every 0.5 h. One milliliter of a reaction mixture was subjected to HPLC (Waters 2695 system, Bristol, WI, USA) using a C18 column (4.6 mm × 250 mm). Elution was performed with 70 % (v/v) acetonitrile at a flow rate of 0.7 ml min–1, and the absorbance was monitored at A 215 with a Waters Lambda-Max model LC spectrophotometer. (GlcNAc)5, (GlcNAc)4, (GlcNAc)3, (GlcNAc)2, and GlcNAc served as standards.

Effects of dietary ChiB565 on tilapia growth

A 35-day feeding trial was conducted with the hybrid tilapia Oreochromis niloticus ♀ × Oreochromis aureus ♂ [purchased from the tilapia hatchery (Hainan, China)] in a circulating aquaculture system under the following conditions: water temperature 30 °C, pH 7.5, dissolved oxygen (DO) >5.0 mg O l–1, NH4 +–N <0.5 mg N l–1, and NO2–N <0.05 mg N l–1. Juvenile tilapias were transported from a tilapia hatchery (Hainan, China) to the Feed Research Institute, Chinese Academy of Agricultural Sciences. All fish were fed a basal diet of 44.6 % (w/w) defatted fish meal, 24 % (w/w) soybean meal, 24 % (w/w) wheat flour, 2 % (w/w) soybean oil, 2.2 % (w/w) Ca(H2PO4)2, 0.1 % (w/w) vitamin C–organic phosphate, 0.3 % (w/w) silicon-type choline chloride, 0.4 % (w/w) vitamin/mineral premix (NRC 2011), and 2.4 % (w/w) bentonite for at least 2 weeks to acclimate the fish to the experimental conditions. Three experimental diets were prepared: diet Control, 94.9 % (w/w) of the basal diet and 5 % (w/w) shrimp bran; diet T1, the control diet supplemented with 162 U kg–1 of ChiB565, which was determined to be a suitable dose according to the results of the in vitro assay described above and a preliminary in vivo dose-gradient feeding trial (data not shown); and diet T2, the control diet supplemented with 16.2 U kg–1 of ChiB565. Shrimp bran was supplied by Jiangsu Nanshan Feed Mills (Nantong, Jiangsu, China), and its mean chitin content was measured as ∼10.0 % of the dry matter. Each diet included 0.1 % (w/w) Y2O3 to determine the apparent digestibility of dry matter, nitrogen, and the energy content (Ward et al. 2005). Twelve fish in four replicate tanks (each of dimensions 0.6 × 0.3 × 0.3 m3) were fed one of the diets. The fish were fed to apparent satiation twice a day at 09:00 and 15:30. At the beginning and end of feeding period, the fish were batch weighed, and weight gain, feed conversion ratio, and survival rate were determined. Intact feces pellets were carefully collected from each tank by siphoning them off between 17:30 and 18:30 during the feeding period, stored at −20 °C, and lyophilized prior to determining the Y2O3, protein, and energy contents (AOAC 1995; Ward et al. 2005). The Y2O3, protein, and energy contents in the dry matter of each experimental diet were also determined (AOAC 1995; Ward et al. 2005). Apparent digestibility of the dry matter, protein, and energy content were calculated as:

where C 1 is the Y2O3 content (g kg–1 dry matter) in the diet, C 2 is the Y2O3 content in a fecal sample, N 1 is the protein content (g kg–1 dry matter) or energy content (MJ kg–1 dry matter) in the diet, and N 2 is the protein content or energy content in a fecal sample (Cho et al. 1982).

Intestinal cytokine gene expression as analyzed by real-time PCR

Expression of genes encoding Hsp70 and IL-1β in intestine samples was evaluated to examine the effects of dietary ChiB565 on stress tolerance and inflammation. At the end of the feeding period, three fish per tank were narcotized by MS-222 (purchased from Zibo Zichuanlonghu Chemical Co. Ltd., Shandong, China) and total RNA from the intestines of the three fish was isolated, with the RNA pooled according to the diet. RNA was extracted using TRIzon Reagent RNA kit reagents according to the manufacturer’s instructions (Promega, Madison, WI, USA) and then dissolved in RNase-free water to avoid amplification of genomic DNA. RT-PCR was performed using ReverTra Ace-α-RT-PCR kit reagents (TOYOBO, Shanghai, China) and primers specific for the genes encoding Hsp70 (F = TGCCTTTGTCCAGACCGTAG; R = GTGTCCAACGCTGTCATCAC) and IL-1β (F = TGCACTGTCACTGACAGCCAA; R = ATGTTCAGGTGCACTTTGCGG) (Liu et al., Fish Shellfish Immunol, under review) according to the manufacturer’s instructions. QPCR was performed with SYBR Green Premix Ex Taq TMII reagents (TaKaRa) in an iQ5 multicolor real-time PCR Detection system (Bio-Rad). The total volume of each PCR mixture was 20 μl and consisted of 10 μl of SYBR Green Premix Ex TaqII (2×), 1 μl of each primer, 2 μl of cDNA, and 6 μl of doubly distilled H2O. The reaction program was 95 °C for 3 min and then 40 cycles at 95 °C for 20 s, 55 °C for 20 s, and 72 °C for 20 s. All real-time PCRs were performed at least in triplicate. The relative quantification of the gene transcripts was calculated with β-actin as the reference gene using the 2−ΔΔCT method (Livak and Schmittgen 2001).

Assessment of dietary ChiB565 as a protectant against A. hydrophila NJ-1 infection

After removing fish for real-time PCR assessment, the tilapias in each tank were immersed in 108 CFU ml–1 of A. hydrophila NJ-1 without injuring their skin. During A. hydrophila exposure, the fish were not fed and held in one half the usual volume of water, which was aerated but not circulated. The accumulated fish mortality of each tank was recorded daily for 6 days.

Statistical analysis

Results are expressed as the mean ± SD. Statistical analysis was performed using one-way ANOVA with SPSS 17.0 (SPSS, Chicago, IL, USA). Significant differences were accepted at P <0.05.

Results

Expression, purification, and characterization of recombinant ChiB565

The gene fragment containing chiB565 and its flanking SnabI and NotI restriction sites was ligated into a pPIC9 vector to construct the plasmid, pPIC9-chiB565, which was then transformed into P. pastoris GS115 competent cells. The transformant with the greatest chitinase activity was cultured in a shaker flask at 30 °C for 48 h at which time ChiB565 expression was induced by the addition of methanol. The culture medium contained 112.9 U ml–1 chitinase activity 48 h later. ChiB565 (yield 93 %) was purified by ammonium sulfate precipitation and gel filtration chromatography.

To confirm the identity of the purified protein, the sequences of the following five ChiB565 peptides, deduced from the gene sequence, were identified by liquid chromatography–coupled electrospray ionization-tandem mass spectrometry: KVGEDTTAPWQVNWTPDAK, GLPAYLVSDIPWNKITHINYAFAAVDEQSHTIK, GDCSVNTAGINTLADSAVSWLWNEEK, and QTIPGGARIEFLVPTSTSDTITDQSGMGLKVVESGGNDNSEGIANEKDFHK.

Substrate specificity

The substrate specificities of ChiB565 against various substrates are shown in Table 1. Colloidal chitin and shrimp-shell chitin are the best substrates, and the enzyme is also active against powdered chitin and β-1,3-1,4-glucan.

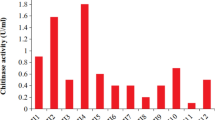

Environmental characterization of ChiB565 activity

ChiB565 retained at least 50 % of its activity between pH 4.5 and 9.0, and had an optimal pH of 5.0 (Fig. 1a). The enzyme was stable at pH 3.5–9.0, retaining more than 50 % of its activity between these values (Fig. 1b). ChiB565 also retained at least 50 % of its activity between 30 and 55 °C and had an optimal value of 50 °C (Fig. 1c). ChiB565 was very stable at/below 50 °C and maintained 95 % of its initial activity after a 2-h incubation at 50 °C (Fig. 1d).

The effects of metal ions, chemicals, and proteases on ChiB565 activity were also determined. In the presence of 5 mM Cu2+ or Mn2+, ChiB565 activity increased slightly, whereas the other metal ions tested inhibited or had no effect on the activity (Table 2). SDS strongly inhibited the activity (∼90 % decrease). ChiB565 was resistant to all neutral and acidic proteases tested, retaining more than 50 % of its activity after a 60-min incubation (Table 3).

In vitro degradation of shrimp-shell chitin by ChiB565

The optimal ChiB565 concentration for shrimp-shell (crude chitin content 26.8 % of the dry matter) degradation was 30 U when 0.1 g of powdered shrimp shell was used as the substrate; 10 U ChiB565 digested 0.055 g of powdered shrimp shell (55.0 % of the maximum) under the same conditions (Fig. 2a). After 3 h, release of reducing sugars was constant when 30 U ChiB565 and 0.1 g shrimp shell was used (Fig. 2b).

Given the aforementioned data, if 5 % (w/w) shrimp bran (with a chitin content of ∼10.0 % of the dry matter) is included in the diet, ∼5,040 and 1,680 U kg–1 of ChiB565 would be required to digest 100 % and 55.0 % of the chitin during a 3-h in vitro incubation period, respectively. Given these numbers, preliminary feeding trials that included 0, 160, 320, 640, 1,280, or 2,560 U kg–1 were conducted. However, only the 160 U kg–1 dose increased the weight gain of the tilapia and improved the feed conversion, and 160 U kg–1 (calculated as 162 U kg–1 in diet T1) was selected as a suitable dose in the formal feeding trial. At larger doses, these parameters decreased in relation to the amount of ChiB565 included in the diet (P > 0.05; data not shown). Given that we also expected ChiB565 to continue degrading the shrimp-shell chitin within the tilapia intestine, we used a dose of 16.0 U kg–1 (calculated as 16.2 U kg–1 in diet T2) as a reference.

ChiB565 released 134.2 g ml–1 GlcNAc from shrimp shell at 37 °C (Table 4). A significantly greater amount of tyrosine was released (P < 0.05) when shrimp shell was hydrolyzed in the presence of ChiB565 and trypsin rather than in the presence of only one of the enzymes, which indicated a synergistic effect for ChiB565 and trypsin. However, commercially available C-6137 did not degrade shrimp shell or act synergistically with trypsin (Table 4).

In vitro ChiB565 hydrolysis products

The major colloidal chitin products found after action by ChiB565 were (GlcNAc)4, (GlcNAc)3, and (GlcNAc)2. A small amount of (GlcNAc)5 was also found (Fig. 3a–c). When the reaction time was increased from 1 to 3 h, the amount of GlcNAc increased, with the amounts of (GlcNAc)5 and (GlcNAc)2 decreasing to barely detectable levels. The products found after a 6-h incubation were mainly GlcNAc, (GlcNAc)3, and (GlcNAc)4, which suggests that ChiB565 has endo- and exo-type activities. The ChiB565 hydrolysis products of shrimp-shell chitin were the same as those found for colloidal chitin hydrolysis, but the product compositions were dissimilar (Fig. 3d–f). For a 6-h incubation, theoretically, at least 11.2 % of the shrimp-shell chitin should be released as COS [mainly as (GlcNAc)4; Fig. 3e]; therefore, at least 0.50 g COS kg–1 feed should be available to the tilapia in their intestine (predicted emptying time ∼6 h; Shiau et al. 1988). After a 12-h incubation, a smaller amount of COS was found, but no (GlcNAc)2 was detected (Fig. 3f).

In vitro hydrolysis products of colloidal chitin at 1 h (a), 3 h (b), and 6 h (c) and shrimp-shell chitin at 3 h (d), 6 h (e), and 12 h (f) after incubation with ChiB565 at 50 °C. The mixture was analyzed with HPLC (Waters 2695 system, Bristol, WI, USA) equipped with a C18 column (4.6 mm × 250 mm). Elution was performed with 70 % (v/v) acetonitrile at a flow rate of 0.7 ml min–1, and the absorbance was monitored at A 215. Standards 1–5 are GlcNAc, (GlcNAc)2, (GlcNAc)3, (GlcNAc)4, and (GlcNAc)5, respectively

Effects of dietary ChiB565 on tilapia growth and feed utilization

Dietary ChiB565 at a dose of 16.2 U kg–1, but not at 162 U kg–1, had positive effects (P < 0.05) on fish weight gain and feed utilization compared with the control diet (Table 5). ChiB565 at 16.2 U kg–1 obviously improved (P < 0.05) protein digestibility, but ChiB565 at 162 U kg–1 significantly decreased it (P < 0.05). Other parameters, i.e., apparent digestibility of dry matter and energy content, were not significantly different for the fish fed the different diets (P < 0.05).

Intestinal cytokine gene expression as assessed by real-time PCR

Compared with the control mRNA-expression study, a small decrease in cytokine gene expression was found when tilapia were fed a ChiB565 dose of 16.2 U kg–1 (P > 0.05), whereas tilapias fed with a dose of ChiB565 162 U kg–1 had significantly greater expression levels of intestinal Hsp70 (P < 0.05; Fig. 4a). The intestinal IL-1β mRNA expression levels were significantly downregulated when the fish were dosed with 16.2 or 162 U kg–1 ChiB565 (P < 0.05; Fig. 4b).

RT-PCR analysis of stress tolerance index HSP70 (a) and cytokine gene IL-1β (b) expression in the intestines of tilapia. The densitometric quantification of these gene expression levels was normalized by β-actin and expressed as the percentage of the respective control. Each value represents mean ± SD of independent RT-PCR reaction of three replicates. Columns sharing the same symbol have no significant difference (P ≥ 0.05). Diet Cont., 94.9 % (w/w) of the basal diet and 5 % (w/w) shrimp bran; diet T1, the control diet supplemented with 162 U kg–1 of ChiB565; diet T2, the control diet supplemented with 16.2 U kg–1 of ChiB565

Immunoprotective effect of dietary ChiB565 against the bacterial pathogen A. hydrophila

No significant difference was seen for the survival rate of the group fed the diet containing 162 U kg–1 ChiB565 and challenged for 6 days with A. hydrophila and the control group (P > 0.05; Fig. 5). However, the survival rate when the fish were fed the diet containing 16.2 U kg–1 ChiB565 was greater than that of the control fish, with a significant difference detected during days 2–4 (P < 0.05).

Survival rates (%) of tilapia challenged by Aeromonas hydrophila NJ-1 for 6 days after fed diets supplemented with two different levels of dietary ChiB565 for 35 days. Each data represents the mean of four replicates, and the data sharing the same symbol have no significant difference (P ≥ 0.05). Diet Cont., 94.9 % (w/w) of the basal diet and 5 % (w/w) shrimp bran; diet T1, the control diet supplemented with 162 U kg–1 of ChiB565; diet T2, the control diet supplemented with 16.2 U kg–1 of ChiB565

Discussion

Chitinolytic microorganisms produce two types of enzymes that can degrade chitin: (exo and endo) chitinases and β-N-acetylglucosaminidases (Orikoshi et al. 2005). Exochitinase activity processively starts at the non-reducing ends of chitin chains with successive diacetylchitobiose units released (Felse and Panda 2000). Conversely, chitinases with endochitinase activity randomly and internally cleave chitin chains (Robbins et al. 1988). Most microbial chitinases are endochitinases (Bhattacharya et al. 2007). For the present study, using HPLC as the analytic tool, we found that ChiB565 has endo- and exochitinase activities (defined as GlcNAc released). To our knowledge, this is the first report of a microbial chitinase with both types of activities. We also found that the P. pastoris expression system, which has been used to produce large amounts of other recombinant proteins (Baumgartner et al. 2002; McGrew et al. 1997), provided substantial amounts of ChiB565. This expression system has several other advantages including its easy manipulation and the direct secretion of a recombinant protein into the culture medium (Sue et al. 2005). The yield and specific activity of ChiB565 expressed in P. pastoris were 203 mg l–1 and 554 U mg–1 with colloidal chitin as the substrate, respectively, which are values greater than those found for most other microbial chitinases (Fan et al. 2007; Goodrick et al. 2001; Perez-Martinez et al. 2007). For commercial purposes, the chiB565 expression level might be further improved by optimizing its codon usage, adjusting its G + C content, and/or adding a high-performance signal peptide sequence.

In addition to its high expression levels in P. pastoris, ChiB565 had several favorable properties as a potential feed enzyme for warm-water aquaculture. First, compared with the commercially available chitinases that cannot degrade shrimp-shell chitin, ChiB565 substrate specificity is broad and includes colloidal chitin, shrimp-shell chitin, powdered chitin, and β-1,3-1,4-glucan. The chitin-binding domains in ChiB565 allow the enzyme to degrade insoluble chitin (Vaaje-Kolstad et al. 2010; Wu et al. 2001). Second, the pH and temperature ranges for ChiB565 activity (≥50 % of the maximum activity between pH 4.5 and 9.0, and 30 and 55 °C) are similar to the physicochemical conditions found for the environments of warm-water fish. Third, ChiB565 produced in P. pastoris is stable at temperatures ≤50 °C, temperatures that are substantially higher than those found for the thermostability of ChiB565 expressed in E. coli (data not shown). This difference may reflect positive contributions to the activity brought about by a post-translational modification(s) of ChiB565 produced in the yeast system (Kern et al. 1992; Shental-Bechor and Levy 2008). Fourth, ChiB565 is resistant to proteolysis, and its activity is not affected by many metal ions, at least at the 5 mM concentration we tested. The metal ions found in shrimp shells are mainly Ca2+, Mn2+, Fe2+, Cu2+, Zn2+, As2+, and Ba2+ (Synowiecki and Al-Khateeb 2010), and we showed that ChiB565 activity was not affected by these metal ions. Fifth, ChiB565 partially/completely degraded shrimp-shell chitin (mainly) into (GlcNAc)4 within 6 h. In general, ingestion of COS at an appropriate dose improves the growth of farmed fish as well as their immunological state and disease resistance (Li et al. 2007; Lin et al. 2012a, b). The final and perhaps most important observation is the synergistic increase found for protein digestion (as tyrosine release) when shrimp shell was subjected to ChiB565 and trypsin digestion in vitro. Thus, ChiB565 may have potential as a feed additive because of its ability to hydrolyze a natural chitin (shrimp chitin) both within the fish intestine.

The results of the feeding and bacterial pathogen challenge tests support our expectation that ChiB565 would be an effective dietary supplement. A possible in vivo synergism for ChiB565 and tilapia endogenous protease(s) may be related to the significantly improved protein digestibility found when 16.2 U kg–1 ChiB565 was included in the diet. More protein from the chitin–protein complexes in the dietary shrimp bran (consisting of chitin, mineral salts, and protein; Synowiecki and Al-Khateeb 2010) used in our experiments may have been released in the tilapia intestine by ChiB565, and this protein might then be digested by endogenous tilapia proteases. In addition, the expected in vivo hydrolysis products of shrimp-shell chitin released by 16.2 U/kg ChiB565 should be mainly (GlcNAc)4, according to our in vitro study and the time required to empty the tilapia intestine (∼6 h; Shiau et al. 1988). The ingestion of COS by the fish should have probiotic effects, reflected as a significant downregulation of intestinal IL-1β expression. Dietary COS at a dose of 0.125 g kg–1 improved the growth of koi (Cyprinus carpio) as well as its immunoresponses, e.g., phagocyte respiratory burst activity, total phagocytic activity, serum lysozyme and superoxide dismutase activities, and protection against intraperitoneal injection of A. veronii (Lin et al. 2012b). Dietary supplementation with COS at 0.2 g kg–1 improved the growth performance and non-specific immunity function of rainbow trout (Oncorhynchus mykiss) (Liu et al. 2012; Luo et al. 2009). Dietary COS between 4 and 6 g kg–1 fed to T. ovatus stimulated its growth, feed conversion, phagocyte respiratory burst activity, phagocytic capacity, serum lysozyme and superoxide dismutase activities, and protective efficiency against Vibrio harveyi (Lin et al. 2012a). We anticipated that the ChiB565 dose of 162 U kg–1 would produce probiotic effects in tilapia, and this expectation was partially confirmed by the downregulation of intestinal IL-1β expression. However, the upregulation of gut Hsp70 expression and reduction in protein digestibility indicated that certain ChiB565 hydrolysis products had negative effects that counterbalanced the observed probiotic effects produced by COS in the tilapia intestine. Shiau and Yu (1999) reported that dietary chitosan supplementation depresses tilapia growth regardless of supplementation level. In addition, more fluid accumulated after an Aeromonas eucrenophila culture supernatant was passed through rabbit intestinal ideal loops and was closely related to the amount of microbial chitinase present (Singh and Sanyal 1999). Coated ChiB565, present in feed, might alleviate this detrimental effect if it eliminates or shortens the time that free ChiB565 interacts with the gastrointestinal mucosa. Although we expect that at least 0.50 g COS kg–1 feed should be produced within the tilapia intestine, the fact that both the 16.2 and 162 U kg–1 doses are much smaller than the predicted optimal dose of 5,040 U kg–1 in vitro suggests that further study will be required to determine the amount of COS produced by dietary ChiB565 within the tilapia gastrointestinal tract.

To the best of our knowledge, very few reports have considered microbial chitinase to be a potential feed supplement that would improve fish growth and induce host immunity against pathogens. For the study reported herein, we show that ChiB565 can be used in aquaculture for the purpose of degrading natural chitin. The addition of shrimp-shell processing wastes (e.g., shrimp bran), with exogenous ChiB565 for its degradation, into fish diets should decrease feed costs and reduce the negative environmental impact of chitin wastes.

References

Alliot E (1967) Absorption intestinale de 1'N-acetyl-glucosamine chez la petite rousette (Scylliorhinus canicula). Comptes Rendus des Seances de la Societe de Biologie et deses Filiales 161:2544–2546

AOAC (1995) Official Methods of Analysis of AOAC International. Vol. 1. Agriculture Chemicals; Contaminants, Drugs, 16th edn. AOAC International, Arlington

Baumgartner P, Raemaekers RJ, Durieux A, Gatehouse A, Davies H, Taylor M (2002) Large-scale production, purification, and characterization of recombinant Phaseolus vulgaris phytohemagglutinin E-form expressed in the methylotrophic yeast Pichia pastoris. Protein Expres Purif 26:394–405

Bhattacharya D, Nagpure A, Gupta RK (2007) Bacterial chitinases: properties and potential. Crit Rev Biotechnol 27:21–28

Black MM, Schwartz HM (1950) The estimation of chitin and chitin nitrogen in crawfish waste and derived products. Analyst 75:185–189

Cárdenas G, Cabrera G, Taboada E, Miranda SP (2004) Chitin characterization by SEM, FTIR, XRD, and 13C cross polarization/mass angle spinning NMR. J Appl Polym Sci 93:1876–1885

Cauchie HM (1997) An attempt to estimate crustacean chitin production in the hydrosphere. In: Domard, A, Roberts, GAF, Varum, KM (eds) Advances in chitin science. Andre, Lyon, pp. 32–38

Cho CY, Slinger SJ, Bayley HS (1982) Bioenergetics of salmonid fishes: energy intake, expenditure and productivity. Comp Biochem Physiol 73B:24–41

Fan Y, Zhang Y, Yang X, Pei X, Guo S, Pei Y (2007) Expression of a Beauveria bassiana chitinase (Bbchit1) in Escherichia coli and Pichia pastoris. Protein Expres Purif 56:93–99

Felse PA, Panda T (1999) Regulation and cloning of microbial chitinase genes. Appl Microbiol Biotechnol 51:141–151

Felse PA, Panda T (2000) Production of microbial chitinases—a revisit. Bioproc Biosystems Eng 23:127–134

Fernandes JC, Tavaria FK, Soares JC, Ramos OS, João Monteiro M, Pintado ME, Xavier FM (2008) Antimicrobial effects of chitosans and chitooligosaccharides, upon Staphylococcus aureus and Escherichia coli, in food model systems. Food Microbiol 25:922–928

Fines BC, Holt GJ (2010) Chitinase and apparent digestibility of chitin in the digestive tract of juvenile cobia, Rachycentron canadum. Aquaculture 303:34–39

Gomez RM, Rojas AL, Rojas ANG, Cruz CR (2004) Colloidal chitin stained with Remazol Brilliant Blue R, a useful substrate to select chitinolytic microorganisms and to evaluate chitinases. J Mol Med 56:213–219

Goodrick JC, Xu M, Finnegan R, Schilling BM, Schiavi S, Hoppe H, Wan NC (2001) High-level expression and stabilization of recombinant human chitinase produced in a continuous constitutive Pichia pastoris expression system. Biotechnol Bioeng 74:492–497

Harish PKV, Tharanathan RN (2007) Chitin/chitosan: modifications and their unlimited application potential—an overview. Trends Food Sci Tech 18:117–131

Hoffman J, Johansen A, Steiro K, Gildberg A, Stenberg E, Bøgwald J (1997) Chitooligosaccharides stimulate Atlantic salmon, Salmo salar L., head kidney leukocytes to enhanced superoxide anion production in vitro. Comp Biochem Physiol 118:105–115

Kern G, Schülke N, Schmid FX, Jaenicke R (1992) Stability, quaternary structure, and folding of internal, external, and core-glycosylated invertase from yeast. Protein Sci 1:120–131

Keyhani NO, Roseman S (1999) Physiological aspects of chitin catabolism in marine bacteria. Acta Biochim Biophys Sin 1473:108–122

Lee HW, Park YS, Jung JS, Shin WS (2002) Chitosan oligosaccharides, dp 2–8, have prebiotic effect on the Bifidobacterium bifidum and Lactobacillus sp. Anaerobe 8:319–324

Li XJ, Piao XS, Kim SW, Liu P, Wang L, Shen YB, Jung SC, Lee HS (2007) Effects of chito-oligosaccharide supplementation on performance, nutrient digestibility, and serum composition in broiler chickens. Poult Sci 86:1107–1114

Li Y, Liu Y, Zhou Z, Huang H, Ren Y, Zhang Y, Li G, Zhou Z, Wang L (2011) Complete genome sequence of Aeromonas veronii strain B565. J Bacteriol 193:3389–3390

Lin S, Mao S, Guan Y, Lin X, Luo L (2012a) Dietary administration of chitooligosaccharides to enhance growth, innate immune response and disease resistance of Trachinotus ovatus. Fish Shellfish Immunol 32:909–913

Lin S, Mao S, Guan Y, Luo L, Pan Y (2012b) Effects of dietary chitosan oligosaccharides and Bacillus coagulans on the growth, innate immunity and resistance of koi (Cyprinus carpio koi). Aquaculture 342:36–41

Lindsay GJH, Walton MJ, Adron JW, Fletcher TC, Cho CY, Cowey CB (1984) The growth of rainbow trout (Salmo gairdneri) given diets containing chitin and its relationship to chitinolytic enzymes and chitin digestibility. Aquaculture 37:315–334

Liu H, Sun M, Wang H, Wan W, Wang J (2012) Effects of chito-oligosaccharides on growth performance, serum biochemical indices and non-specific immunity function of rainbow trout (Oncorhynchus mykiss). Chin J Animal Nutr 479–486

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2–ΔΔCT method. Methods 25: 402e8

Lowry OH, Rose NJ, Lewis FA, Randall RJ (1951) Protein measurement with Folin phenol reagent. J Biol Chem 193:265–275

Luo L, Cai XF, He X, Xue M, Wu XF, Cao HN (2009) Immune response, stress resistance and bacterial challenge in juvenile rainbow trouts Oncorhynchus mykiss fed diets containing chitosan-oligosaccharides. Curr Zool 55:416–422

McGrew JT, Leiske D, Dell B, Klinke R, Krasts D, Wee SF, Abbott N, Armitage R, Harrington K (1997) Expression of trimeric CD40 ligand in Pichia pastoris: use of a rapid method to detect high-level expressing transformants. Gene 187:93–200

National Research Council 2011. Nutrient requirements of fish and shrimp. The National Academies Press, Washington, D.C., pp. 327–328

Orikoshi H, Nakayama S, Miyamoto K, Hanato C, Yasuda M, Inamori U, Tsujibo H (2005) Roles of four chitinases (ChiA, ChiB, ChiC, and ChiD) in the chitin degradation system of marine bacterium Alteromonas sp. strain O-7. Appl Environ Microbiol 71:1811–1815

Perez-Martinez AS, Leon-Rodriguez AD, Harris LJ, Herrera-Estrella A, Barba de la Rosa AP (2007) Overexpression, purification and characterization of the Trichoderma atroviride endochitinase, Ech42, in Pichia pastoris. Protein Expr Purif 55:183–188

Robbins PW, Albright C, Benflield B (1988) Cloning and expression of a Streptomyces plicatus chitinase in Escherichia coli. J Biol Chem 263:443–447

Sandhya C, Adapa LK, Nampoothiri KM, Binod P, Szakacs G, Pandey A (2004) Extracellular chitinase production by Trichoderma harzianum in submerged fermentation. J Basic Microbiol 44:49–58

Se-Kwon K, Niranjan R (2005) Enzymatic production and biological activities of chitosan oligosaccharides (COS): a review. Carbohydr Polymer 62:357–368

Shental-Bechor D, Levy Y (2008) Effect of glycosylation on protein folding: a close look at thermodynamic stabilization. Proc Natl Acad Sci USA 105:8256–8261

Shiau SY, Yu YP (1999) Dietary supplementation of chitin and chitosan depresses growth in tilapia, Oreochromis niloticus × O. aureus. Aquaculture 179:1–4

Shiau SY, Yu HL, Hwa S, Chen SY, Hsu SI (1988) The influence of carboxymethylcellulose on growth, digestion, gastric emptying time and body composition of tilapia. Aquaculture 70:345–354

Singh DV, Sanyal SC (1999) Virulence patterns of Aeromonas eucrenophila isolated from water and infected fish. J Diarrhoeal Dis Res 17:37–42

Sue MP, Mariana LF, Brian M, Linda MH (2005) Heterologous protein production using the Pichia pastoris expression system. Yeast 22:249–270

Synowiecki J, Al-Khateeb NA (2010) Production, properties, and some new applications of chitin and its derivatives. Crit Rev Food Sci 43:145–171

Tharanathan RN, Kittur FS (2003) Chitin—the undisputed biomolecule of great potential. Crit Rev Food Sci 43:61–87

Tokoro A, Kobayashi M, Tatewaki N, Suzuki K, Okawa Y, Mikami T (1989) Protective effect of N-acetyl chitohexaose on Listeria monocytogenes infection in mice. Microbiol Immunol 33:357–367

Vaaje-Kolstad G, Bjørge W, Horn SJ, Liu Z, Zhai H, Sørlie M, Eijsink VGH (2010) An oxidative enzyme boosting the enzymatic conversion of recalcitrant polysaccharides. Science 330:219–222

Ward DA, Cater CG, Townsend AT (2005) The use of yttrium oxide and the effect of faecal collection timing for determining the apparent digestibility of minerals and trace elements in Atlantic salmon (Salmo salar L.) feeds. Aquacult Nutr 11:49–59

Wu M, Chuang Y, Chen J, Chen C, Chang M (2001) Identification and characterization of the three chitin-binding domains within the multidomain chitinase Chi92 from Aeromonas hydrophila JP101. Appl Environ Microbiol 67:5100–5106

Acknowledgments

The present study was supported by the “Twelfth Five-Year” National Science and technology project in rural areas (2013BAD10B01-2) the special funds for Technology Development and Research for Research Institutes (2011EG134221) and the National Science and Technology Support Program Project of China (2012BAD25B02).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhou, Z., Liu, Y. et al. High-yield production of a chitinase from Aeromonas veronii B565 as a potential feed supplement for warm-water aquaculture. Appl Microbiol Biotechnol 98, 1651–1662 (2014). https://doi.org/10.1007/s00253-013-5023-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5023-6