Abstract

Today, methane (CH4), nitrous oxide (N2O), and carbon dioxide (CO2) emissions represent approximately 98 % of the total greenhouse gas (GHG) inventory worldwide, and their share is expected to increase significantly in this twenty-first century. CO2 represents the most important GHG with approximately 77 % of the total GHG emissions (considering its global warming potential) worldwide, while CH4 and N2O are emitted to a lesser extent (14 and 8 %, respectively) but exhibit global warming potentials 23 and 298 times higher than that of CO2, respectively. Most members of the United Nations, based on the urgent need to maintain the global average temperature 2 °C above preindustrial levels, have committed themselves to significantly reduce their GHG emissions. In this context, an active abatement of these emissions will help to achieve these target emission cuts without compromising industrial growth. Nowadays, there are sufficient empirical evidence to support that biological technologies can become, if properly tailored, a low-cost and environmentally friendly alternative to physical/chemical methods for the abatement of GHGs. This study constitutes a state-of-the-art review of the microbiology (biochemistry, kinetics, and waste-to-value processes) and bioreactor technology of CH4, N2O, and CO2 abatement. The potential and limitations of biological GHG degradation processes are critically discussed, and the current knowledge gaps and technology niches in the field are identified.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, CH4, N2O, and CO2 emissions represent approximately 98 % of the total greenhouse gas (GHG) inventory worldwide, and their share is expected to increase in this twenty-first century based on their industrial and organic-based nature and the forthcoming scenario of increasing world population (European Environment Agency 2011; Environmental Protection Agency 2011). CH4, with a global warming potential 23 times higher than that of CO2 and an atmospheric concentration increasing at 0.2–1 % year−1, is mainly emitted from organic waste treatment activities such as landfilling, composting, and wastewater treatment (95 million tons CO2 equivalent in the European Union [EU]) and livestock farming (166 million tons CO2 equivalent in the EU) (European Environment Agency 2011). CH4 represents approximately 14 % of the total GHG emissions worldwide (Intergovernmental Panel on Climate Change 2007). Emissions from compost piles or animal houses typically contain 0–200 mg CH4 m−3, while these concentrations can increase up to 20–100 g CH4 m−3 in old landfills (Nikiema et al. 2007). On the other hand, N2O is not only a major GHG with a global warming potential 298 times higher than that of CO2 but it is also the most important O3-depleting substance emitted in the twenty-first century, with yearly atmospheric concentration increases of 0.3 % (Ravishankara et al. 2009). In the EU-27, N2O is mainly emitted in waste treatment activities (10 million tons CO2 equivalent), nitric and adipic acid production (27 million tons CO2 equivalent), and livestock farming (21 million tons CO2 equivalent) (European Environment Agency 2011). N2O contributes to 8 % of the GHG emissions worldwide (Intergovernmental Panel on Climate Change 2007). Concentrations ranging from 10 to 2,000 mg N2O m−3 are common in the emissions of these activities (Xu et al. 2004; Kampschreur et al. 2008). Even in tanks with novel microbial nitrogen removal processes such as nitritation/anaerobic ammonium oxidation (anammox), significant amounts of N2O have been recorded during wastewater treatment (Kampschreur et al. 2008). Finally, CO2 represents the most important GHG with approximately 77 % of the total GHG emissions worldwide and an annual atmospheric concentration increase of 0.5 % over the last decade (Intergovernmental Panel on Climate Change 2007). CO2 is mainly produced in electricity and heat production processes (1,400 million tons), transport (960 million tons), industrial and fuel manufacturing (700 million tons), and other sectors (e.g., commercial, residential, or agricultural; with 670 million tons). Typical CO2 concentrations in combustion gases range from approximately 90 to 270 g m−3 (European Environment Agency 2011).

Most members of the United Nations, based on the urgent need to maintain the global average temperature 2 °C above preindustrial levels, have committed themselves to significantly reduce their GHG emissions (Intergovernmental Panel on Climate Change 2007). In this context, an active abatement of these emissions will help to achieve these target emission cuts without compromising industrial growth. Besides, the development of cost-efficient GHG abatement methods might be of paramount importance in the near future since recent monitoring campaigns in waste treatment facilities, for instance, have shown that the CH4 and N2O emissions reported might be underestimated by one order of magnitude (Foley et al. 2010; Ahn et al. 2010). As a matter of fact, most international GHG inventories have based their estimations on Intergovernmental Panel on Climate Change emission factors, and there is increasing evidence that some of these factors, for instance, those applied to waste treatment activities, might lack a scientific basis or be based on studies under very specific and non-extrapolable conditions (Foley et al. 2010; Ahn et al. 2010). In addition, the gradual application of the EU Landfill Directive 1999/31 (enforcing a reduction in the organic matter content of the solid waste to be disposed) will result in emissions with lower CH4 concentrations, which will significantly limit the implementation of conventional energy recovery-based treatment technologies and will require the application of cost-efficient abatement methods for diluted CH4 streams.

However, despite the environmental relevance of CH4, N2O, and CO2 emissions, the development of cost-efficient and environmentally friendly GHG treatment technologies (especially of those intended for the treatment of emissions containing low GHG concentrations) has been scarce. Today, physical/chemical treatment methods for CH4 abatement such as activated carbon adsorption or incineration are either inefficient or costly at the low concentrations typically found in emissions from waste treatment and animal farming and possess a high CO2 footprint as a result of their intensive energy usage (Melse and Van der Werf 2005). On the other hand, conventional NO x treatment technologies such as selective catalytic reduction or selective noncatalytic reduction present prohibitive operating costs (and large environmental impacts) when treating large air flow rates containing low concentrations of NO x as a result of their intensive energy use (Skalska et al. 2010). Similarly, CO2 sequestration through physical/chemical methods, such as gas scrubbing with alkaline or amine solutions or direct injection into subsurface natural reservoirs (storage), entails prohibitive costs and secondary environmental pollution (Herzog 2001; Kumar et al. 2011). In this regard, biotechnologies can become, if properly tailored, a low-cost and environmentally friendly alternative to physical/chemical methods for the abatement of CH4, N2O, and CO2. Biotechnologies, which are based on the biocatalytic action of specialized bacteria, microalgae, or fungi, have been consistently proven as robust and efficient abatement methods for the treatment of industrial volatile organic compounds and malodors, exhibiting lower operating costs and environmental impacts than their physical/chemical counterparts (Estrada et al. 2011, 2012b). This study constitutes a state-of-the-art review of the microbiology (biochemistry, kinetics, and waste-to-value processes) and bioreactor technology of CH4, N2O, and CO2 abatement. The potential and limitations of biological GHG degradation processes are critically discussed, and the current knowledge gaps and technological research niches in the field are identified.

Biological CH4 removal

Microbiology of CH4 removal

Methanotrophs are methylotrophic bacteria able to utilize CH4 as the sole carbon and energy source, although several yeast genera such as Sporobolomyces and Rhodotorula or even the green microalgae Chlorella have been reported as methane oxidizers (Enebo 1967; Wolf and Hanson 1979). Most methanotrophs oxidize CH4 in the presence of O2, although some strains can couple the oxidation of CH4 to the reduction of sulfate, nitrate, nitrite, manganese, or iron (Beal et al. 2009; Knittel and Boetius 2009; Ettwig et al. 2010). Methanotrophs are ubiquitous in the environment and commonly found in tundra and wetlands, freshwater and eutrophic lakes, marine sediments and water columns, sewage sludge, rice paddies, agricultural soils and peat bogs, preferentially in the interface between aerobic and anaerobic areas with substantial fluxes of CH4 (Bowman 2006; Hanson and Hanson 1996). Three types of methanotrophs are distinguished: type I methanotrophs are characterized by uniform intracytoplasmic membranes throughout the cell as bundles of vesicular disks, membrane fatty acids with 14–16 carbons, and the use of the ribulose monophosphate pathway (RuMP) for formaldehyde assimilation. These methanotrophs belong to the Gammaproteobacteria class and include genera such as Methylomonas, Methylobacter, Methylomicrobium, and Methylococcus (Bratina et al. 1992). Encapsulated bacteria of the Clonothrix and Crenothrix genera within the Methylococcaceae family have been also recently identified as type I methanotrophs (Op den Camp et al. 2009). Type II methanotrophs are found within the Alphaproteobacteria class (Methylosinus and Methylocystis genera) and are characterized by intracytoplasmic membranes along the peripheral part of the cell, fatty acids with 18 carbons, and the use of the serine pathway for formaldehyde assimilation (Patt and Hanson 1978; Scott et al. 1981; Hanson and Hanson 1996). Type X methanotrophs contain membrane fatty acids with 16 carbons, use the RuMP pathway, posses a ribulose-1,5-bisphosphate carboxylase, grow at higher temperatures than types I and II, and belong mainly to the Methylococcus genera (Davies and Whittenbury 1970; Hanson and Hanson 1996). Despite the fact that most methanotrophs are included in the Gammaproteobacteria and Alphaproteobacteria classes, some of them belong to the NC10 phylum (nitrite-respiring methanotrophs), Verrucomicrobia, and Euryarchaeota (Hanson and Hanson 1996; Hou et al. 2008; Op den Camp et al. 2009; Ettwig et al. 2010; Semrau 2011).

All methanotrophs use methane monooxygenases (MMOs) during the aerobic oxidation of CH4 to methanol, utilizing reducing equivalents for the split of the O2 bonds. Two forms of MMOs have been identified in methanotrophs: soluble and particulate. The soluble MMO form (sMMO) was first detected in the cytosol of methanotrophs II and X and recently identified in type I (Koh et al. 1993; Hanson and Hanson 1996). This monooxygenase has a broader range of substrates than other monooxygenases and it is composed of a hydroxylase, a reductase, and a regulatory protein (Lipscomb 1994; Hanson and Hanson 1996; Wallar and Lipscomb 2001). sMMOs are synthesized when levels of Cu2+ are below 0.86 μmol g−1 dry weight (dw) and contain iron as an important cofactor in the reaction center (Hanson and Hanson 1996; Nielsen et al. 1997; Choi et al. 2003). On the other hand, particulate or membrane-bound MMOs (pMMO) are constitutive in all aerobic methanotrophs at Cu2+ concentrations above 0.86 μmol g−1 dw, except in the genera Methyloferula and Methylocella (Dalton 1992; Semrau et al. 2010). pMMO is also composed of three polypeptides, which exhibit a lower specific activity compared to sMMO, but nowadays, little is known about its molecular properties (Basu et al. 2003; Choi et al. 2005). Soluble MMOs employ NADH + H+ as reducing agent to oxidize the CH4 present in the intracellular medium (which previously diffused from the extracellular aqueous medium) to CH3OH, while pMMO requires a cytochrome complex to oxidize the CH4 present in the cytoplasm. Then, the periplasmic enzyme methanol dehydrogenase catalyzes the conversion of methanol to formaldehyde (Fig. 1) (O’Connor 1981; Anthony 1982; Dalton 1992; Hanson and Hanson 1996; Glass and Orphan 2012). Formaldehyde is then either converted to formic acid by formaldehyde dehydrogenase or to biomass through the RuMP pathway in type I and X methanotrophs or through the serine pathway in type II methanotrophs (Hanson and Hanson 1996).

Methane oxidation pathways in type I and II methanotrophs. Continuous lines represent a unidirectional flow in the pathway, while dashed lines represent alternative pathways. sMMO soluble methane monooxygenase, pMMO particulate methane monooxygenase, MDH methanol dehydrogenase, FDH formate dehydrogenase, FalDH formaldehyde dehydrogenase, cyt red/ox cytochrome reduced/oxidized, STHM serine hydroxymethyltransferase, H6PS hexulose-6-phosphate synthase. Adapted from Hanson and Hanson (1996) and Semrau et al. (2010)

Finally, carbon dioxide is produced from formate in an oxidation step catalyzed by formate dehydrogenase with the production of the reducing equivalents required at the initial steps of CH4 oxidation (Hanson and Hanson 1996; Chistoserdova 2011; Glass and Orphan 2012). Moreover, type X methanotrophs can assimilate formaldehyde through the RuMP pathway while fixing CO2 using a ribulose-1,5-bisphosphate carboxylase (Whittenbury 1981). For a more extensive discussion of the biochemistry of aerobic CH4 oxidation, readers are referred to specialized reviews (Higgins et al. 1981; Hanson and Hanson 1996; Semrau et al. 2010).

In contrast to aerobic CH4 oxidation, the information available in the literature about anaerobic CH4 oxidation is scarce. Moreover, anaerobic methane-oxidizing archaea, which are responsible for 7–25 % of the total CH4 oxidation worldwide, can undertake this process in symbiosis with sulfate-reducing bacteria, using CH4 as an electron donor to convert sulfate into sulfite (Hanson 1980; Hoehler et al. 1995, Reeburgh 2007). On the other hand, aerobic CH4-oxidizing bacteria can grow concomitantly with denitrifying bacteria, consuming oxygen and producing electron donors for denitrification (Bédard and Knowles 1989; Thalasso et al. 1997). In addition, a recently discovered denitrifying methanotroph Methylomirabilis oxyfera, from the phylum NC10, is able to perform intra-aerobic CH4 oxidation utilizing the oxygen contained in nitric oxide (NO) (Wu et al. 2011).

Microbial CH4 oxidation is often described by both Monod and Michaelis–Menten models. However, the different experimental setups and models used for the estimation of the kinetic parameters often hinder the direct comparison of the data available in literature (Table 1). The Michaelis–Menten constant (K M) determines the rate of the overall enzymatic activity and ranges from 31.7 × 10−9 to 2.8 × 10−5 M, the lowest value highlighting the high affinity of some bacterial enzymes for CH4 oxidation (Scheutz et al. 2009). Similarly, the Monod constant (K S) defines the affinity of microorganisms for the substrates and, in the particular case of CH4, ranges typically from 1 × 10−6 to 4.74 × 10−4 M. pMMO-bearing bacteria have been reported to exhibit a higher affinity for CH4 (lower K S values) than sMMO-bearing microorganisms (Bédard and Knowles 1989). Moreover, the maximum CH4 oxidation rates (V max) are often reported in a wide variety of units, with values ranging from 0.02 to 0.6 g m−3 h−1, from 1.48 × 10−4 to 25.7 g m−2 h−1, from 2.88 × 10−6 to 0.50 g g−1 h−1, and from 3.2 × 10−15 to 1.44 × 10−12 g cell−1 h−1. Varied biomass yields ranging from 0.02 to 0.8 g biomass g CH4 −1 are also typically found in the literature (Arcangeli and Arvin 1999).

The rates of CH4 oxidation depend on parameters such as dissolved oxygen and CH4 concentrations, moisture content in the media, temperature, pH, type of nitrogen source, or copper levels. Hence, both types I and II methanotrophs exhibit their maximum oxidation rate at gas oxygen concentrations ranging from 1.5 to 10.5 % v/v (Whittenbury and Dalton 1981; Wilshusen et al. 2004). Furthermore, high CH4/O2 ratios stimulated the growth of type II methanotrophs (high K M), while low CH4/O2 ratios stimulated the growth of type I methanotrophs (low K M) (Bender and Conrad 1995; Amaral and Knowles 1995). These findings support the hypothesis that sMMOs are usually expressed at high CH4 concentrations and pMMO at low CH4 concentrations (Lontoh and Semrau 1998; Henckel et al. 2000). The optimum moisture content for methanotroph growth was shown to be packing media specific, which will be discussed later on in the reactor section. Methanotrophs are mesophilic microorganisms, although thermotolerant and thermophilic Methylothermus, Methylocaldum, Methylococcus, or Verrucomicrobia strains have been isolated from hot springs, with an optimal growth in the range of 42–65 °C (Bodrossy et al. 1999; Tsubota et al. 2005). Psychrophilic strains of Methylobacter, Methylosphaera, and Methylomonas have been isolated from tundra soils, Antarctic meromictic lakes, and deep igneous groundwater, exhibiting an optimal growth range of 3.5–15 °C (Omelchenko et al. 1993; Bowman et al. 1997; Kalyuzhnaya et al. 1999). Hence, maximum oxidation rates in composite soils occurred at 31 °C, while in most peat soils, the optimal temperature was 25 °C (Bédard and Knowles 1989; Whalen et al. 1990; Dunfield et al. 1993; Bender and Conrad 1995). On the other hand, low CH4 oxidation rates were recorded in samples from forest and landfill cover soils at 2–5 °C (Whalen and Reeburgh 1996; Christophersen et al. 2000). Species from the Methylocella and Methylocapsa genera or the Verrucomicrobia phylum exhibiting an optimum growth at pH 2–2.5 have been isolated from acidic environments, but most methanotrophs preferably live and oxidize CH4 at pH 7–7.65 (Bender and Conrad 1995; Dedysh et al. 1998, 2002; Pol et al. 2007; Dunfield et al. 2007). Oxidation rates by acidophilic methanotrophs have been found to be higher in samples from acidic peat soils (pH values of 4–5) compared to those from neutral soils (pH values of 6–8) (Born et al. 1990; Dunfield et al. 1993). Despite type II methanotrophs being able to express the enzyme nitrogenase at low O2 levels and perform N2 fixation, nitrate and ammonia are the preferred N sources (Quayle 1972). Type I methanotrophs are dominant in environments with low methane concentrations and high inorganic nitrogen levels, while type II methanotrophs are often predominant in scenarios with high CH4/N ratios (Amaral and Knowles 1995). Microbial stimulation or inhibition mediated by inorganic nitrogen sources such as ammonia or nitrate depend on the nitrogen and CH4 concentration, the pH, and the type of methanotroph. Hence, optimal growth and CH4 oxidation rates were recorded at 12–61 mM ammonia for some methanotrophic communities, while some studies revealed that concentrations of 4–10 mM could reduce CH4 oxidation by 30 % (Bender and Conrad 1995). Some in situ investigations suggest that high ammonia concentrations could inhibit CH4 oxidation either by toxicity or enzymatic competition, although such detrimental effects could be also due to a nitrite accumulation from ammonia oxidation (Bédard and Knowles 1989). In this context, ammonia fertilizers seem to be more hazardous to type II than to type I methanotrophs (Mohanty et al. 2006). Copper positively regulates the activity of pMMO/sMMO and controls the expression of their genes (Stanley et al. 1983; Dalton et al. 1984). However, Cu2+ concentrations have to be controlled in order to maintain copper homeostasis and prevent metal toxicity. The optimal growth of most methanotrophs is achieved at cooper concentrations lower than 4.3 mM (Bender and Conrad 1995), although a combination of high Cu levels and organic material can favor the rapid growth of type II methanotrophs (Graham et al. 1993). Besides, in Cu-limiting scenarios, some aerobic methanotrophs excrete a molecule called methanobactin able to bind cooper in the extracellular medium and actively transport it into the cell at concentrations as low as 0.7–1 μM (Kim et al. 2004; Balasubramanian et al. 2011).

Microbial CH4 oxidation can be coupled with the production of high added-value biotechnological products. Thus, some methanotrophs can utilize acetyl-CoA from the serine or RuMP pathways to form polyhydroxyalkanoates such as polyhydroxybutyrate (PHB), an important commodity in the bioplastic industry (Higgins et al. 1981; Lidstrom and Stirling 1990). PHB generation can be stimulated under N-, S-, or Mg-limiting conditions. For instance, N limitations supported the production of PHB at 39 % (w/w) in Methylobacterium organophilum in a bioreactor and even at 57 % (w/w) in serological glass bottles (Zúñiga et al. 2011). Exopolysaccharides at 62 % (w/w) can be also produced from CH4 oxidation using Methylocystis parvus (Hou et al. 1978; Chida et al. 1983). CH4-oxidizing bacteria, as well as algae, fungi, or yeasts, can be also used in single-cell protein production for human and animal consumption. For instance, Norferm Danmark A/S in Norway produces 8,000 tons protein year−1 (BioProtein) from Methylococcus capsulatus Bath (Winder 2004).

Reactors for biological CH4 oxidation

Several bioreactor configurations such as biofilters, biotrickling filters, airlifts, and stirred tanks have been used for CH4 abatement from air emissions (Fig. 2). Biotechnologies for CH4 abatement have been implemented in enclosed bioreactors where the polluted air (containing O2) is supplied by forced ventilation in either upflow or downflow mode and in open bioreactors where the CH4-bearing emission (e.g., landfill gas) is supplied upwards at the bottom of the system, while O2 diffuses from the air at the top of the bioreactor (Gebert et al. 2001; Gebert and Gröngröft 2006)

Enclosed laboratory-scale bioreactors are the most popular CH4 abatement systems reported in the literature likely due to the fact that operational parameters such as temperature and moisture content can be controlled. On the other hand, open bioreactors constitute the most implemented technology to treat real CH4 emissions from landfills at full scale. Unfortunately, forced air ventilation to provide the O2 needed by aerobic methanotrophs is not recommended when treating real landfill CH4 emissions to avoid explosion risks (CH4 concentration in landfill gas in the range of 30–70 % v/v) (Kallistova et al. 2005; Zamorano et al. 2007). Therefore, O2 supply in open passively vented biofilters strongly depends on climate conditions, and O2-limiting conditions are often encountered in these bioreactors (Humer and Lechner 1999; Gebert et al. 2001; Berger et al. 2005). In this regard, a three-dimensional numerical model has been recently developed, incorporating the effect of advection–diffusion gas flows, heat, and moisture on CH4 oxidation in open biofilters (Hettiarachchi et al. 2011). This innovative model allowed for the estimation of CH4 removal under several environmental conditions confirming that CH4 oxidation in open biofilters strongly depends on environmental factors.

Biofilters are by far the most common bioreactors used for CH4 removal although innovative multiphase systems operated in different bioreactor configurations have emerged in the last 5 years. Despite being relatively simple systems, biofilters constitute the most studied and implemented technology to date and can support high CH4 removal rates when parameters such as the O2 concentration or the moisture content are optimized. For instance, biofilter operation in landfills at O2 concentrations of 18–28 μM (1.7–2.6 % in the gas phase) resulted in maximum oxidation rates of 1.78 × 10−6 mol CH4 g−1 dw h−1 (Gebert et al. 2003). The optimum moisture content was shown to depend on water activity, which itself is often packing media specific, with maximum CH4 oxidation rates at a moisture content of 11 % (w/w) in composite soils, 10–20 % in landfill cover soils, and 20–35 % in other types of soils, while moisture contents of 5, 56, or 71 % in composite soils supported low oxidations rates (Whalen et al. 1990; Bender and Conrad 1995). The intensive research conducted on biofiltration over the last 20 years has resulted in important advances in packing material technology, evolving from a bed of simple materials such as compost, pine bark, or perlite to more sophisticated structured packings such as metallic or polymeric ring and foams or custom-made nutrients containing polymeric pellets. Besides, optimum environmental conditions, nutrient requirements, and potential inhibitors of CH4 oxidation in biofilters have been recently identified (Veillette et al. 2012). These breakthroughs in biofiltration technology have resulted in significant reductions in the EBRTs required to efficiently abate CH4 emissions. For instance, ECs of 1.2–25 g m−3 h−1 have been recorded in conventional biofilters operated at EBRTs of 10–360 h (Table 2) (du Plessis et al. 2003; Berger et al. 2005; Melse and Van der Werf 2005), while third generation enclosed biofilters operated at EBRTs of 0.3–20 h were able to reach ECs of 65–280 g m−3 h−1 (Gebert and Gröngröft 2006; Nikiema and Heitz 2009; Park et al. 2009). To the best of our knowledge, Park et al. (2009) reported the highest abatement performance in a biofilter treating CH4 with a maximum EC of 280 g m−3 h−1 (corresponding to an RE of 50 %) at an EBRT of 1.2 h. Girard et al. (2011) achieved an EC of 14.5 g m−3 h−1 in a biofilter operated at an EBRT of 0.07 h. Interestingly, a similar EC to that obtained by Park et al. (2009) would be expected if the ECs obtained by Girard et al. (2011) were multiplied by 17, which is the EBRT ratio between these reports.

Several bioreactor configurations and operation modes have been recently investigated in order to overcome the typical mass transfer limitations encountered in conventional biofilters as a result of the low water solubility of this GHG (Fig. 2). Rocha-Rios et al. (2009, 2011) studied the performance of the so-called two-phase partitioning bioreactors (TPPBs) for CH4 abatement, which are based on the addition of a nonaqueous phase (e.g., a liquid solvent or a solid polymer) with a high affinity for CH4, resulting in higher CH4 absorptions and driving forces for mass transfer (Quijano et al. 2009). Silicone oil, exhibiting 15 times higher affinity for CH4 than water is one of the most commonly used nonaqueous phases in TPPBs. In this context, a silicone oil-based TPPB implemented in a stirred tank reached a maximum EC of 106 g m−3 h−1 at an EBRT as short as 0.08 h (corresponding to 4.8 min) (Rocha-Rios et al. 2009). This important reduction in the EBRT dramatically decreased the size of the abatement unit and consequently the overall technology cost. In the quest for less energy-demanding systems than stirred tank reactors, TPPBs have been also implemented in airlift systems with a maximum EC of 22 g m−3 h−1 at an EBRT of 0.12 h. Nevertheless, a better performance was reported in a TPPB operated as a biotrickling filter, exhibiting a maximum EC of 51 g m−3 h−1 at an EBRT of 0.08 h (Rocha-Rios et al. 2009). Likewise, Avalos et al. (2012) recently reported that a biotrickling filter (without the nonaqueous phase) using stones as packing material and provided with a nonionic surfactant was able to reach a maximum EC of 21 g m−3 h−1 at EBRTs as short as 0.07 h (corresponding to 4.2 min). Although promising results have been obtained in TPPBs and single liquid-phase biotrickling filters, more research is still necessary to boost the overwhelming CH4 abatement potential of biotechnologies.

At this point, it is important to stress that little attention has been given to the microbiological aspects in bioreactors devoted to CH4 abatement (Scheutz et al. 2009). In some studies, the bioreactors were operated for months to stimulate the growth of the indigenous methanotrophic microorganisms present in the packing materials, which resulted in either very long start-up periods (du Plessis et al. 2003; Einola et al. 2008) or in a poor CH4 abatement performance (Berger et al. 2005). A more efficient performance and shorter start-up periods were recorded when the bioreactor was inoculated with methanotrophic biomass from the leachate (or directly with a portion of the packing material) of a CH4-treating biofilter (Nikiema and Heitz 2009; Avalos et al. 2012). The enrichment of methanotrophs from activated sludge of wastewater treatment plants is also another common strategy to produce acclimated inocula and to reduce process start-up periods (Rocha-Rios et al. 2009). On the other hand, Avalos et al. (2012) found that clogging issues were very different in a biotrickling filter packed with clay spheres, polypropylene spheres, and stones, despite using the same biomass and inoculation protocol, the reactor packed with stones being more susceptible to clogging and presenting stability problems. These recent studies, therefore, confirm that microbiology and reactor/packing material design are important research areas to be pursued due to their key role on bioreactor start-up and abatement performance.

Biological N2O removal

Microbiology of N2O removal

To date, research on N2O emission control has been mainly focused on minimizing and/or preventing N2O generation and its release to the atmosphere. Once N2O is formed, removal by in situ consumption might be also promoted before implementing end-of-pipe technologies (Desloover et al. 2012). The mitigation strategies developed to date were based on microbiological studies investigating the influence of process operational conditions on N2O production rates, especially in wastewater treatment plants and composting facilities (Kampschreur et al. 2009; Rassamee et al. 2011). In this context, the elucidation of the complex mechanisms governing the microbial production and consumption of N2O is crucial to develop cost-effective end-of-pipe biotechnologies for N2O abatement.

N2O may be biologically produced by both nitrification and denitrification processes (Fig. 3). Nitrification is a sequential and predominantly autotrophic process where NH3 is first oxidized to NO2 − by ammonia-oxidizing bacteria and then further oxidized to NO3 − by nitrite-oxidizing bacteria. Conventional denitrification involves NO3 − reduction by heterotrophic denitrifiers to N2 through a stepwise reduction sequence involving NO2 −, NO, and N2O. Thus, the main routes for N2O production are hydroxylamine oxidation, nitrifier denitrification, and heterotrophic denitrification (Kampschreur et al. 2009; Desloover et al. 2012; Wunderlin et al. 2012) (Fig. 3).

Overview of the main metabolic routes involved in N2O production and biodegradation in bacterial cultures. The enzymes responsible of each individual reaction are ammonia monooxygenase (AMO), hydroxylamine oxidoreductase (HAO), nitrite oxidoreductase (NXR), nitrate reductase (NAR), nitrite reductase (NIR), nitric oxide reductase (NOR), and nitrous oxide reductase (NOS). Adapted from Wrage et al. (2001), Desloover et al. (2012), and Glass and Orphan (2012)

Hydroxylamine (NH2OH) is an intermediate in the nitritation step (oxidation of NH3 to NO2 −). The oxidation of NH3 to NH2OH is catalyzed by an ammonia monooxygenase (Wood 1986; Wrage et al. 2001), while the oxidation of NH2OH to NO2 − is catalyzed by a hydroxylamine oxidoreductase (Hooper and Terry 1979). N2O production occurs via chemical decomposition of NH2OH in a process called chemodenitrification or through NO2 − reduction with electron donors such as organic (e.g., amines) or inorganic (e.g., Fe2+ and Cu2+) compounds (Wunderlin et al. 2012). During nitrifier denitrification, NH3 is partially oxidized to NO2 − and then further reduced to NO, N2O, and N2 in a process carried out by a very specific group of microorganisms (Wrage et al. 2001). Since nitrifier denitrification involves both nitritation and denitrification steps, N2O may thus be produced in both processes (Colliver and Stephenson 2000). Finally, N2O production during heterotrophic denitrification is caused by an interruption in the last reduction step before reaching the most reduced compound (N2). Thus, imbalances in the production and consumption of the enzyme nitrous oxide reductase (NOS), which catalyzes N2O reduction to N2, have been pointed out as the main responsible of N2O accumulation (Wunderlin et al. 2012; Glass and Orphan 2012). In brief, suboptimal conditions for nitrification and denitrification are intrinsically related to N2O emissions. For instance, when nitrification occurs under oxygen-limiting conditions, ammonia-oxidizing bacteria use NO2 − as the terminal electron acceptor instead of O2, leading to higher N2O emissions (Colliver and Stephenson 2000; Wunderlin et al. 2012). Indeed, emissions of N2O have been also recorded in anammox tanks, although these emissions could not be directly attributed to the anaerobic oxidation of ammonium (Kampschreur et al. 2008). Likewise, the enzyme NOS catalyzing N2O reduction during heterotrophic denitrification is the most sensitive to O2, causing incomplete denitrification and N2O accumulation at high O2 concentrations (Tallec et al. 2008; Uggetti et al. 2012). High NO2 − concentrations can also induce an enhanced reduction of this compound to N2O during nitrification and lower denitrification rates, resulting in an accumulation of NO and N2O (Kampschreur et al. 2009).

Based on the fact that the aerobic oxidation of N2O, to the best of our knowledge, has not been reported yet, any biotechnology devoted to N2O removal must focus on reducing N2O to N2 by favoring the activity of the enzyme (NOS). In this context, the enzyme NOS is known to require Cu in larger quantities than other enzymes, and the reduction of N2O is thus feasible when Cu is present above a certain threshold concentration (Glass and Orphan 2012). Granger and Ward (2003) observed a low NOS activity in denitrifiers grown at 0.3 nM of total dissolved Cu and a complete consumption of N2O when Cu was increased up to 10 nM. Environments rich in sulfides might support low N2O reduction rates since sulfide scavenging and metal precipitation may reduce Cu bioavailability. Very few studies have investigated the potential of microorganisms for N2O reduction, and the few studies available focused on O2-free emissions, conditions which are far from those present in most real N2O emissions. For instance, Apel and Turick (1992) assessed the ability of nine bacterial species to reduce N2O to N2 under anaerobic conditions (headspace filled with N2O and He) in organic synthetic media. Seven species were able to successfully consume N2O, with Pseudomonas denitrificans and Paracoccus denitrificans exhibiting the best N2O biodegradation performance. The optimum temperature for those two species was in the range of 30–35 °C, and maximum N2O removal rates of 0.017 and 0.015 mM mg−1 dw h−1 were obtained for Pseudomonas denitrificans (initial N2O concentration of 0.9 mM) and Paracoccus denitrificans (initial N2O concentration of 1.6 mM), respectively. Miyahara et al. (2010) reported that Pseudomonas stutzeri TR2 was able to aerobically denitrify with a low production of N2O, suggesting that bioaugmentation with this strain could reduce N2O emissions from aerobic wastewater treatment systems due to its improved denitrification ability in the presence of oxygen. P. stutzeri TR2 grew at a rate of 0.32 h−1, comparable to the specific growth rates of anaerobic denitrifiers, and was classified by the authors as an expert anaerobic denitrifier.

Bioreactors for N2O abatement

The implementation of N2O control strategies is likely to become mandatory in the coming years due to the elevated contribution of this GHG to global warming and ozone depletion. To date, only physical/chemical technologies such as thermal decomposition (Löffler et al. 2002), selective catalytic reduction (Muramatsu et al. 1997; Satsuma et al. 2000), or adsorption (Golden et al. 2004) have been used for the removal of N2O from off-gases. The application of these abatement methods usually involves the consumption of expensive and/or hazardous chemicals, generation of secondary pollution, and high operating costs when treating high flow rates at the typical low N2O concentrations. Conversely, biotechnologies offer a more environmentally friendly and cost-effective platform for the removal of N2O based on their lower energy requirement, absence of hazardous chemicals or catalyst, and innocuous nature of their final end products (N2 and biomass) (Devinny et al. 1999; Boswell 2001).

Although the number of studies on the application of biological reactors for the removal of N2O is scarce, their potential has been demonstrated. For instance, Desloover et al. (2011) recently assessed the performance of a bioelectrochemical system with a cation exchange membrane separating the biological anodic and cathodic compartments. In this system, the electrons originated in the anode from sodium acetate biodegradation were supplied to the denitrifying bacteria present in the biocathode and promoted the reduction of N2O to N2 according to the equation: N2O + 2e − + 2H+ → N2 + H2O (E 0 = +1.36 V). N2O removal rates up to 1 kgN2O Nm−3 net cathodic compartment day−1 were achieved, with a cathodic coulombic efficiency of ≈100 %. However, although this technology constitutes a promising alternative due to its cost efficiency, challenges regarding its scale-up and sensitivity to aerobic environments still need to be solved (Desloover et al. 2011). Conventional biotechnologies for off-gas treatment such as biofiltration, biotrickling filtration, or bioscrubbing have been rarely applied for N2O abatement, with most of the studies reported for NO removal based on autotrophic nitrification and heterotrophic denitrification (Shanmugasundram et al. 1993; Nascimento et al. 2000; Chou and Lin 2000; Woertz et al. 2001). For instance, Utami et al. (2012) evaluated the performance of a biofilter packed with a cow manure-based compost batchwise for 9 h at different operating conditions, with the highest N2O REs (61 %) obtained at an EBRT of 58 min and a moisture content of 50 %. Likewise, Hood (2011) recorded N2O REs ranging from 14 to 17 % in a biofilter packed with compost and woodchips (30/70 %) at an EBRT of 7.6 s and N2O inlet concentrations of 0.68–1.24 mg m−3. Lower N2O removal efficiencies (0.7 %) were supported by a biofilter packed with pine nuggets and lava rock operated at an EBRT of 5 s, a relative humidity of 90 %, and inlet N2O concentrations of 428 ± 22.2 ppbv (Akdeniz et al. 2011). The low performance recorded in these biofilters was probably due to the lack of a specific microbial community acclimated to N2O biodegradation under aerobic conditions, since these systems were not specifically designed for the abatement of N2O. Besides, the presence of hydrogen sulfide in some of these air emissions might had promoted the precipitation of metals such as copper, whose presence is mandatory for the synthesis of the enzyme NOS and the correct functioning of N2O-degrading communities. In brief, the high sensitivity of the biological N2O reduction step towards the presence of O2, which is inherent in most N2O emissions, and the lack of economic or legislative incentive for its removal to date have hindered the development of high performance biological N2O abatement technologies (Desloover et al. 2012). Nevertheless, the few studies addressing the biological removal of N2O have shown promising results but require further process optimization.

Biological CO2 removal

Microbiology of CO2 removal

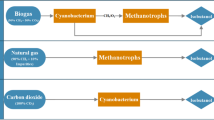

Biological CO2 fixation is carried out via photosynthesis by all terrestrial plants, although microorganisms such as microalgae and cyanobacteria can do it at higher rates and with 10–50 times better efficiency (Costa et al. 2000). Among microalgae, Chlorophyta (including genera such as Chlamydomonas, Chlorella, Dunaliella, Haematococcus, Botryococcus, or Scenedesmus), Euglenophyta (Euglena), Bacillariophyta (Nitzschia), Rhodophyta (Porphyridium), and Eustigmatophyta (Nannochloropsis) rank among the most investigated for biological CO2 fixation (Richmond 2004; Madigan et al. 2006; Barsanti and Gualtieri 2006). Despite constituting a phylum of bacteria rather distant taxonomically, cyanobacteria or blue–green algae are frequently considered as microalgae because of their ability to carry out photosynthesis. Cyanobacteria group includes genera such as Nostoc, Oscillatoria, Synechococcus, Synechocystis, Spirulina, Arthrospira, Anabaena, or Pediastrum. Both types of photosynthetic microorganisms, from now on referred to as microalgae, are ubiquitous in terrestrial and aquatic environments and can survive in extreme environments such as geysers and hot water springs, desert soils, and Antarctic locations (Madigan et al. 2006; Kumar et al. 2011).

Microalgae use light as the sole source of energy and CO2 as the sole carbon source during photosynthesis. Nevertheless, some species such as Chlorella vulgaris, Dunaliella salina, Euglena gracilis, and Tetraselmis tetrathele also exhibit a concomitant heterotrophic metabolism capable of utilizing from simple organic substrates like acetate, glucose, glutamate, lactate, or amino acids (Gladue and Maxey 1994, Ogbonna and Tanaka 1998) to complex aromatics such as cresols or naphthalene (Semple et al. 1999). Microalgae photosynthesis involves a redox process considered as oxygenic when H2O acts as the electron donor:

At least 8 mol of photons is required to obtain a mole of CH2O, with 218 KJ energy mol−1 photons (Ho et al. 2011). CO2 assimilation during microalgal photosynthesis involves two stages: light reactions where H2O oxidation to O2 results in the production of ATP and NADPH and dark reactions where CO2 is reduced to organic compounds utilizing NADP+/NAD+ as the electron acceptor.

Light reactions are initiated with light harvesting by the antenna complexes of the thylakoid membranes (Staehelin 1986; Taiz and Zeiger 2002). The excitation energy is then conveyed to the reaction center, where pigments such as chlorophyll a absorb a few photons per second with a conversion efficiency of 25–27 % (Taiz and Zeiger 2002). These photons mediate the photolysis of H2O with the subsequent reduction of chlorophyll P680 from the photosystem II (PSII) (Iverson 2006), the electron transport continuing through quinones, cytochromes, and plastocyanin, finally reaching photosystem I (PSI) and reducing the P700 pigment (Hill and Bendall 1960; Cerveny et al. 2009). Simultaneously, protons are pumped from the thylakoid lumen in order to obtain ATP (Fig. 4).

Carbon and electron fluxes during photosynthesis in green microalgae (upper figure) and in cyanobacteria (lower figure). The ATP and NADPH produced during the electron transport in the light reactions are used later on for CO2 reduction in the Calvin cycle. The term “electron transporters” include several components such as quinones, the cytochrome system, or plastocyanin. R RuBisCo, P phosphoribulokinase, CA carbonic anhydrase, PSII photosystem II, PSI photosystem I

Dark reactions, also known as Calvin cycle, imply CO2 fixation and, consequently, the use of the NAD(P)H and ATP obtained in the light reactions (Calvin 1989; Taiz and Zeiger 2002; Nelson and Cox 2005). The Calvin cycle includes three basic stages: carboxylation of the CO2 acceptor ribulose-1,5-bisphosphate to 3-phosphoglycerate by the enzyme ribulose bisphosphate carboxylase (RuBisCo), reduction of 3-phosphoglycerate to glyceraldehydes-3-phosphate utilizing the obtained ATP and NADPH, and regeneration of the CO2 acceptor through a phosphorylation mediated by the enzyme phosphoribulokinase (Fig. 4). Twelve NAD(P)H molecules and 18 ATP molecules are needed to produce a molecule of fructose-6-phosphate from 6 molecules of CO2 using the RuBisCo (Hall and Rao 1999; Taiz and Zeiger 2002, Madigan et al. 2006):

RuBisCo also exhibits an oxygenase activity and O2 can compete with CO2 as substrate, resulting in a process named photorespiration (Miziorko and Lorimer 1983; Edwards and Walker 2004). Photorespiration is favored at high O2/CO2 ratios, high temperatures, or high irradiations and can cause a decrease of up to 30–50 % in the photosynthetic efficiency (PE) of microalgae, with the subsequent reduction in CO2 assimilation (Zhu et al. 2008; Gioardano et al. 2005). The enzyme RuBisCo in microalgae exhibits a low affinity for CO2, since typical C3 plants present K M values in the range of 15–25 μM, green algae over 30 μM, and cyanobacteria up to 200 μM (Moroney and Somanchi 1999; Savir et al. 2010). Due to the low affinity of some microalgal species for CO2, most microalgae and cyanobacteria present specific organelles hosting key enzymes such as RuBisCo and inorganic carbon-concentrating mechanisms (CCMs) (Matsuda et al. 1998; Raven et al. 2008). CCMs consist of ATP-driven plasma membrane pumps induced by low levels of dissolved CO2. Inorganic carbon-accumulating pumps (CO2 and HCO3 −) increase the CO2 levels in the vicinity of RuBisCo and consequently reduce the extent of photorespiration, even at atmospheric CO2 levels (0.035 %) (Fig. 4) (Moroney and Somanchi 1999). By using these CCMs, microalgae can concentrate HCO3 − more than 20-folds over ambient CO2 levels and cyanobacteria more than 100-folds (Miller et al. 1990). The incorporation of CO2 into the Calvin cycle requires the conversion of HCO3 − to CO2 by a carbonic anhydrase, whose level of expression is also governed by CO2 concentrations (Price and Badger 1989; Price et al. 1992; Karlsson et al. 1998).

The rates of photosynthetic CO2 assimilation depend on factors such as the temperature, pH, light intensity, O2 and CO2 levels, or presence of inhibitory compounds. Optimal temperatures for microalgae growth and photosynthesis vary from 15 to 25 °C (Tamiya 1957). Despite higher temperatures inducing a reduced photosynthesis due to a decrease in the solubility of CO2, some microalgae species such as Chlorella have been reported to grow optimally in the range of 30–35 °C, which are typically encountered in outdoor cultivations (Pulz 2001). In this context, the isolation of thermophilic species is mandatory in order to implement microalgae-based CO2 capture methods in power plants, whose exhaust gas emissions are discharged at high temperatures. For instance, Synechococcus elongatus was able to fix CO2 at 60 % v/v and 52 °C at rates comparable to those recorded at 20 % v/v and 25 °C (Miyairi 1995). Likewise, thermophilic species of Chlorogloeopsis were able to fix CO2 at 50 °C (Ono and Cuello 2007). Microalgae and cyanobacteria preferentially grow at a neutral pH, although species like Spirulina platensis exhibit an optimum pH of 9 and Chlorococcum littorale a pH of 4 (Kodama et al. 1993; Hu et al. 1998). The effect of pH on microalgae growth is complex since it is difficult to dissociate the direct effects on microalgae growth from collateral effects such as the modification in the CO2/HCO3 −/CO3 2− and NH3/NH4 + equilibria or in phosphorus or heavy metal availability (Muñoz and Guieysse 2006). The photosynthetic activity increases linearly with increasing light intensities up to 400 μmol photon m−2 s−1, although some species such as Scenedesmus or Chlorella exhibit saturation thresholds of 100–200 μmol photon m−2 s−1 (≈5–10 % sunlight) (Hanagata et al. 1992; Muñoz and Guieysse 2006; Tredici 2009). In this context, S. platensis was able to withstand light energy fluxes of up to 8,000 μmol photon m−2 s−1 at a culture density of 8.4 ± 1.6 g L−1 under optimum mixing (Hu et al. 1996). Despite the fact that high light intensities can cause photoinhibition over PSII, microalgae strategies such as the reduction in the pigment content, PSII inactivation, or growth under heterotrophic or mixotrophic conditions can minimize its pernicious effects (Behrenfeld et al. 1998; Melis 1999; Ogbonna and Tanaka 2000; Carlsson et al. 2007). Indeed, genetic modifications of microalgae have emerged as a promising tool to reduce the size of the antenna complexes to minimum values of 37 chlorophyll molecules for PSII and 95 for PSI, which can increase photosynthetic efficiencies by 50 % (Nakajima and Ueda 1997; Mitra and Melis 2008; Eriksen 2008). Despite the high solar energy fluxes impinging on the earth surface, microalgae cultivation is often limited by light supply. Hence, considering the sole absorption of the photosynthetically active radiation from the total impinging solar radiation and the energy losses due to reflection, respiration, photosaturation, and photoinhibition, the maximum PE in microalgal culture often decreases from the expected 12.4 % to values of ≈5 % or even lower (Tredici 2009). Microalgae and cyanobacteria are able to efficiently grow at CO2 atmospheric levels (≈0.0387 % v/v) but are frequently cultivated at CO2 levels in the range of 5–15 % v/v in order to increase microalgal productivities (Kumar et al. 2010a). Microalgae tolerance to CO2 concentrations is species-dependent with optimum ranges of 2–15 % v/v for S. platensis and 15 % for Nannochloropsis salina (Doucha et al. 2005; Kumar et al. 2010b). Several strains of the thermophilic red alga Cyanidium caldarium were even capable of growing at CO2 levels of 100 % (Seckbach and Ikan 1972). On the other hand, high dissolved O2 concentrations (>35 mg L−1) in the cultivation broth favor photorespiration and O2 radical formation, with the subsequent decrease in microalgal productivity (Pulz 2001; Carvalho et al. 2006; Ho et al. 2011). Finally, heavy metals, NH3, or industrial gases such as SO x and NO x can inhibit microalgae growth. In the context of CO2 capture from flue gases, NO x is not as toxic as SO x towards microalgae and can be even used as nitrogen source. Thus, several Nannochloropsis species can grow at 100 ppmv of NO, while Dunaliella tertiolecta can withstand NO x concentrations of up to 1,000 ppmv (Yoshihara et al. 1996; Nagase et al. 1998). In contrast, high levels of SO x (>400 ppmv) severely reduce the cultivation pH and the photosynthetic rate (Packer 2009; Kumar et al. 2010b). In this regard, Tetraselmis species can grow in flue gases containing 14 % v/v CO2, 185 ppmv of SO x , and 125 ppmv of NO x (Matsumoto et al. 1995).

The ability of C. vulgaris, Botryococcus braunii, C. littorale, Scenedesmus sp., Chlamydomonas reinhardtii, and Spirulina sp. for CO2 capture was recently assessed based on their high CO2 fixation rates and ability to yield high added-value products (de Morais and Costa 2007a, b, c; Packer 2009; Ota et al. 2009; Chen et al. 2010; Yoo et al. 2010). Moreover, typical maximum specific growth rates (μ max) of microalgae under photosynthetic, heterotrophic, and mixotrophic conditions are 0.110, 0.098, and 0.198 h−1 for C. vulgaris and 0.061, 0.040, and 0.048 h−1 for Scenedesmus acutus, respectively (Ogawa and Aiba 1981).

Microalgae CO2 capture can also be coupled with the production of high added-value biotechnological products, which would significantly improve the process economy. Thus, health-promoting molecules from Chlorella species (Richmond 1990; Gouveia et al. 1996), β-carotenes from D. salina (Metting 1996; Ben-Amotz 1999), pharmaceuticals and phycobiliproteins from S. platensis (Spolaore et al. 2006; Raja et al. 2008), ketocarotenoid astaxanthins from Haematococcus pluvialis (Lee and Ding 1994; Spolaore et al. 2006), carotenes or cosmetics from Arthrospira (Richmond 1986; Viskari and Colyer 2003; Spolaore et al. 2006), and eicosapentaenoic acid from Nannochloropsis species (Boussiba et al. 1987; Chisti 2007; Chen et al. 2010) rank among the most common high added-value products marketed nowadays and can significantly contribute to the economic viability of microalgae-based CO2 capture technologies.

Photobioreactors for CO2 abatement

Photobioreactors (PBRs) are considered “direct” CO2 capture methods where a CO2-rich off-gas is directly pumped into the cultivation medium of the bioreactor in contrast to higher plant biomass systems based on CO2 diffusion (Benemann 1997). The first approach to an engineered microalgae cultivation system dates back to the World War II, when Germany looked for innovative protein sources to replace animal proteins during shortage periods (Carvalho et al. 2006). The concept was further developed during the 1950s and 1960s, but the focus shifted from protein production towards bioenergy production during the first energy crisis in the early 1970s (Chaumont 1993). Today, algal mass cultivation for bioenergy production is still perceived as economically nonsustainable by itself based on the high microalgae production costs (in the range of 4–70 € kg−1 microalgae depending on the PBR scale) and the relatively low cost of the energy obtained from them (Norsker et al. 2011; Acién et al. 2012a). Hence, the integration of microalgal CO2 capture with the production of high added-value products or wastewater treatment is nowadays regarded as the only alternative to make the process economically viable (Morweiser et al. 2010; Wang et al. 2008). In this context, recent studies have also shown the possibility of recycling the culture medium after biomass harvesting and a suitable sterilization in the mass production of microalgae to minimize nutrient losses (González López et al. 2013).

The most important parameters in PBR design and operation are light distribution and CO2 supply, the latter becoming even more relevant when the main goal of the system is CO2 capture (Morweiser et al. 2010). Scale-up of PBRs is particularly difficult due to the self-shading of cells, which causes the nonhomogeneous distribution of light, and increased mixing rates are sometimes not applicable due to the sensitivity of some photosynthetic strains to shear stress (García Camacho et al. 2011). Apart from the parameters mentioned in the “Microbiology of CO2 removal” section, the control of sterile conditions, mixing, and removal of O2 (by high turbulence or stripping with inert gases) is also of paramount relevance during PBR design and operation (Pulz 2001). Moreover, PBR design can be also tailored in order to increase the illuminated area-to-volume ratio, reduce the light path, and increase the frequency of the light–dark cycles, with the subsequent increase in microalgae productivity and CO2 removal rates (Pulz 2001; Richmond 2004). In this context, the shorter the light path is, the higher the frequency of the light–dark cycles and the photosynthetic rates. These frequencies also depend on the optimal cell density (OCD) in the cultivation broth due to the increased mutual shading at increasing microalgae concentrations (Richmond 2004; Tredici 2009). Since the OCD and light path are inversely correlated, PBRs with narrow light path (i.e., 1–2 cm) and high irradiances can support high-density cultures (Zou et al. 2000). The combination of both environmental and operational parameters, together with the selection of the optimum microbial strain, determines the CO2 capture potential, which can be estimated from microalgae productivities by applying the stoichiometric CO2 requirement factor for microalgae growth of 1.85 g CO2 g−1 biomass (Table 3) (Carvalho et al. 2006; Posten 2009). The main PBR configurations will be discussed following the traditional classification into open and enclosed systems.

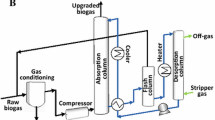

Open photobioreactors

Open ponds are the simplest and cheapest technology for microalgae cultivation and can be classified into natural water bodies (lakes, lagoons, or ponds) or artificial ponds (Singh and Sharma 2012). Of them, raceway ponds, also named as high rate algal ponds (HRAP), are the most applied configuration due to their higher microalgal productivities (compared to other open alternatives) at a reasonable energy cost (200 MJ ha−1 day−1 or 0.03–0.2 W m−3 for mixing) (Tredici 2009). In these HRAPs, the microalgae broth is continuously recirculated around a closed loop channel using a rotating paddlewheel (the most cost-effective mixing mode), while CO2 (or air) can be injected at different locations of the PBR via CO2 diffusion pumps or external CO2 bubble columns (Fig. 5a) (Xu et al. 2009; Muñoz et al. 2012). The main advantages of HRAPs are their simplicity of construction and operation and their lower investment (in the range of 2.3–20 € m−2) and operating costs compared to enclosed PBRs (Lundquist et al. 2010; Craggs et al. 2012). However, open configurations present critical disadvantages inherent to their design such as a high vulnerability to external contamination with undesired wild microalgae species or predators, a poor light utilization as a result of the low light–dark frequencies supported by the hydrodynamics of the ponds, a high water footprint by evaporation (up to 40 L m−2 day−1 in desertic climates) (Massey University 2011, large land requirements, and low CO2 transfer efficiencies as a result of the technical limitations for CO2 supply (Xu et al. 2009). Overall, open ponds support lower biomass productivities than enclosed PBRs (Table 3) and, therefore, a lower potential for CO2 capture (Ugwu et al. 2008). Nevertheless, despite the previously mentioned limitations, open ponds still hold a promising potential for CO2 capture in particular applications such as biogas upgrading (the process of enriching biogas in CH4 by removing CO2 and H2S). For instance, Muñoz et al. (2012) achieved removal efficiencies of 90 % for CO2 and 100 % for H2S in a HRAP coupled with an independent bubble absorption column (60 cm depth) where the microalgae broth was continuously recycled. Likewise, Mandeno et al. (2005) achieved reductions in the CO2 content of biogas from 40 to 50 % by sparging the biogas into a HRAP in a countercurrent pit to improve CO2 mass transfer (Mandeno et al. 2005). Despite presenting a lower potential for CO2 fixation (up to 0.20 g CO2 L−1 day−1) than their enclosed counterparts, HRAPs are the PBRs with the highest ratio of CO2 fixed/CO2 emitted (≈90.6 kg CO2 fixed kg−1 CO2 emitted, considering an energy consumption of 0.02 kWh kg−1 CO2 assimilated and the average EU-27 specific CO2 emission factor of 0.46 tonnes CO2 emitted MWh−1) (Covenant of Mayors 2012).

Enclosed bioreactors

Enclosed PBRs are more efficient at maintaining axenic microalgae cultures, allow for a better control over the process variables (temperature, pH, and CO2 concentration), and minimize both CO2 and water losses (Singh and Sharma 2012). In order to improve light penetration and minimize photoinhibition effect, enclosed PBRs present high illuminated area-to-volume ratios (30–70 m−1 in enclosed systems vs 3–10 m−1 in HRAPs). In enclosed PBRs, CO2 is supplied at high concentrations (even pure CO2 is directly supplied) by means of high-performance diffusion systems at certain locations of the PBR or directly injected in the recirculating cultivation broth to avoid inorganic carbon limitations since most PBRs are always designed considering light supply as the limiting parameter for microalgae growth (Carvalho et al. 2006). Finally, the cultivation broth must be mixed with minimum energy requirements to prevent microalgae settling and facilitate the access of microalgae cells to the photic zone of the culture, while avoiding cell damage by excessive shear stress (Carvalho et al. 2006; Posten 2009). Enclosed PBRs are classified into three major categories, depending on their configuration:

-

1.

Vertical tubular reactors consists of a vertical pipe made of transparent materials such as polyethylene or glass and where a CO2-enriched gas is sparged into fine bubbles at the bottom of the column for CO2 supply and culture mixing (Kumar et al. 2011). Typical area-to-volume ratios in these systems are in the range of 10 to 30 m−1 (Sánchez Mirón et al. 1999). If the liquid flow is essentially random, the vertical PBR is a bubble column (Fig. 5b). On the other hand, if a concentric tube is installed inside the vertical column (namely, riser) and the CO2-enriched gas is sparged inside the riser creating a recirculating flow pattern (upwards in the riser and downwards in the downcomer), the PBRs are named airlift PBRs (Fig. 5c).

Vertical tubular PBRs are compact and low-cost alternatives in terms of investment cost, and some PBRs include dome or annular configurations in order to minimize the dark zones, since the low illuminated surface area is their main drawback (Morweiser et al. 2010). The energy input required ranges from 50 to 70 W m−3 (Béchet et al. 2012). Vertical tubular PBRs provide an average potential for CO2 capture higher than open ponds, but lower than that of their horizontal counterparts. A recent study reported a maximum CO2 fixation rate of 0.97 g L−1 day−1 in a 3-L bubble column PBR using the microalga Scenedesmus obtusiusculus (Toledo-Cervantes et al. 2013), while CO2 capture rates of up to5.4 g L−1 day−1 were recorded for Aphanothece microscopica Nägeli in the same type of PBR (Jacob-Lopes et al. 2009). The high variability of these results confirms the high impact of the strain and the operational conditions on the PBR potential. Furthermore, estimated CO2 capture rates of up to 1.45 g CO2 L−1 day−1 have been achieved in column PBRs operated with the cyanobacteria Anabaena (González López et al. 2009) (Table 3). At these CO2 fixation rates in vertical tubular PBRs, the ratio of kilograms of CO2 fixed to kilograms of CO2 emitted can be estimated to be 1.9 (Covenant of Mayors 2012).

-

2.

Flat-plate PBRs are similar to the vertical tubular PBRs described previously but are designed to minimize the light path and to provide a homogeneous light penetration. Flat prisms between 3 and 10 cm deep with a surface area of ≈1–2 m2 made of a transparent material are employed, which provide the high illuminated area-to-volume ratios (20–40 m−1) needed to achieve high photosynthetic efficiencies and, therefore, high CO2 removal rates (Fig. 5d) (Tredici and Zittelli 1998; Barbosa et al. 2005). Gas sparging at the bottom is employed for both pneumatic mixing and CO2 supply, with energy consumptions similar to those of vertical tubular configurations, although alternative agitation methods consisting of panel rotation have been implemented (Kumar et al. 2011). Flat-plate PBRs are mainly illuminated on one side and can be arranged in optimal angles facing solar irradiation to maximize microalgae growth (Xu et al. 2009). Recently, new configurations such as alveolar and V-shaped panels have been implemented, resulting in increased microalgae productivities (Carvalho et al. 2006). On the other hand, flat-plate PBRs require high land areas and supporting structures when many replicate units are installed in full-scale applications (Ugwu et al. 2008). The productivities and, therefore, the CO2 capture rates in flat-plate PBRs are similar to those recorded in vertical tubular reactors (≈1 g CO2 L−1 day−1) but 10 times higher than that in HRAPs (Posten 2009; Morita et al. 2000) (Table 3). Besides, flat-plate PBRs possess ratios of 1.46 kg CO2 fixed kg−1 CO2 emitted (Covenant of Mayors 2012).

-

3.

Horizontal tubular PBRs consist of a set of horizontal transparent tubes arranged in parallel, closed loop, coiled around a hollow cylinder, or α-shape, acting as light collector (Carvalho et al. 2006; Merchuk et al. 2007; Kumar et al. 2011). They are usually equipped with a centrifugal pump or an airlift system to provide adequate flow and mixing, with the airlift systems being employed for the cultivation of shear-sensitive microalgae (Fig. 5e). Gas exchange takes place in the tubes or in especially dedicated CO2 absorption units. The high illuminated area-to-volume ratios (45–70 m−1) result in high biomass productivities (Tredici and Zittelli 1998). The large pH, CO2, and O2 gradients in long tubes and fouling have been pointed out as the major causes of process failures in industrial-scale facilities, while the need to maintain adequate liquid velocities in the tubes implies high energy consumption (≥100 W m−3). Strategies such as water spraying over the tubes, installation of heat exchangers, tube overlapping, and immersion of the tubes inside a pool are the most cost-effective alternatives for temperature control in outdoor facilities (Ugwu et al. 2008; Kumar et al. 2011; Singh and Sharma 2012). Horizontal tubular PBRs support the highest biomass productivities and, thus, CO2 capture potential, with average values higher than 2 g CO2 L−1 day−1 (Acién Fernández et al. 2001; Morita et al. 2002; Hall et al. 2003), although capture values higher than 4.5 g CO2 L−1 day−1 have been occasionally achieved in a tubular airlift bioreactor (Sobczuk et al. 2000). CO2 capture rates of ≈1 g CO2 L−1 day−1 have been recently recorded outdoors in a 220-L external loop airlift PBR with Anabaena sp. ATCC 33047 (Sánchez Fernández et al. 2012). Finally, ratios of up to 4.1 kg CO2 fixed kg−1 CO2 emitted for these PBRs have been recorded, which represent the best results so far reported among enclosed PBRs (Covenant of Mayors 2012).

Despite CO2 solubility in water being relatively high compared to that of O2, CH4, or N2 (Henry’s law constant of 3.4 × 10−2 mol L−1 atm−1), its cost-efficient supply to the microalgae broth still constitutes a large-scale technical challenge, affecting the pH and mixing in the system. Three main CO2 supply systems have been implemented in the PBR configurations previously described: independent gas exchangers, direct gas injection to the cultivation broth, and membrane-based transfer. Among them, membrane transfer deserves special attention when CO2 capture is the primary objective of the PBR since mass transfer in membrane units is no longer affected by the boundary layer between the gas and the aqueous phase, but a gas-permeable membrane allows CO2 diffusion from the gas and O2 desorption from the microalgal cultivation medium. This approach allows for reduced operating costs, since CO2 absorption is decoupled from culture mixing, which represents a degree of freedom for process optimization (Morweiser et al. 2010). Theoretically, membrane transfer avoids CO2 losses to the atmosphere and allows for an accurate control of the transfer rates. The use of hollow fiber membranes allows for operation at low pressure drops since no water column pressure has to be overcome by the CO2-laden emission. On the other hand, porous membranes provide high transfer areas but require high pressures to force the CO2 through the membrane (especially in highly salty media), the latter implying thicker membranes and high-performance materials (Carvalho et al. 2006). A recent study reported CO2 removal efficiencies of 85 % at a CO2 concentration of 2 % in a hollow fiber membrane PBR (Kumar et al. 2010a). Finally, another recently proposed strategy to efficiently capture CO2 from flue gases consists of absorbing the CO2 in an aqueous solution, which is further purified by microalgae in a PBR. Alkaline sodium carbonate and bicarbonate solutions have been proposed as suitable solutions that can be biologically regenerated as an alternative to methyl ethyl amine, diethyl amine, or NaOH, which are used as chemical absorbents and must be regenerated by heating in highly energy-demanding processes (González López et al. 2012).

Limitations in the biological treatment of GHGs and future research needs

Despite the promising potential of biotechnologies for the abatement of CH4, N2O, and CO2 emissions, their cost-efficient application is often limited by the poor mass transport of CH4, and in a lower extent of N2O and CO2, from the gas to the aqueous phase due to the low aqueous solubility of these GHGs (dimensionless Henry’s law constants, H, H CH4 = 30, H N2O = 2, and H CO2 = 1.2). Thus, these high H values result in low concentration gradients (low driving forces) for GHG mass transport from the gas to the aqueous phase containing or surrounding the microbial communities and, therefore, in a reduced GHG biodegradation performance (Muñoz et al. 2007). In the particular case of CH4 and N2O, this low mass transport entails process operation at high EBRTs, which significantly increases both the investment and operating costs of conventional biotechnologies. In PBRs, this limited mass transport restricts the implementation of a direct bubbling of the CO2-laden streams in HRAPs and increases the volume of external CO2 transfer units or in situ pumps. In this context, the development of innovative high-performance mass transfer approaches is mandatory. However, unlike the classical approach of improving mass transport by increasing the energy input to the bioreactor, the high-performance transport should be based on increased GHG concentration gradients (e.g., absence of aqueous phase, high cell hydrophobicity, high pH, or presence of a nonaqueous organic phase) and larger gas–cell interfacial areas.

Under mass transfer-limiting conditions, the poor knowledge of the GHG biodegradation kinetics at the trace level concentrations (almost equal to micrograms per liter) typically present in the aqueous phase when treating real emissions has also limited the correct design of bioreactors for GHG abatement (Estrada et al. 2012a). For instance, for typical emissions containing 10–200 mg m−3 of CH4 and 50–1,000 mg m−3 of N2O, microorganisms would be exposed to maximum aqueous concentrations ranging from 0.3 to 7 μg CH4 L−1 and from 25 to 500 μg N2O L−1, respectively (Shimizu et al. 2000; Kampschreur et al. 2008; Girard et al. 2011; Gustavsson and la Cour Jansen 2011). In this context, it must be stressed that microbial characteristics and, in particular, microbial affinity for the target pollutant quantified as K M and K S play a key role on the performance of biotechnologies treating poorly soluble gaseous pollutants (Hernández et al. 2010; Rocha-Rios et al. 2011). Despite the empirical evidence for the fact that microorganisms can mineralize pollutants down to the picograms per liter level, the number of studies evaluating pollutant biodegradation at the micrograms per liter to nanograms per liter level is unfortunately scarce (Roch and Alexander 1997). Besides, the few kinetic studies reported for methanotrophs were carried out using a methodology based on the estimation of the aqueous CH4 concentration by CH4 headspace analyses in closed systems inoculated at high biomass concentrations and under gentle agitation, conditions which do not ensure the absence of mass transfer limitations and, therefore, the validity of the experimental data (Yoon et al. 2009). As a matter of fact, while mechanistic model predictions using the available kinetic data for methanotrophs show that CH4 biodegradation would not be feasible at atmospheric concentrations (1.8 ppmv), there are empirical evidence of CH4 removal from 1.8 to 0.1 ppmv (Whalen et al. 1990). Likewise, in the particular case of N2O-degrading bacteria or photosynthetic microorganisms, the number of studies conducted to date is scarce. In light of the current limitations of microbiology, novel methodologies for the accurate determination of microbial GHG biodegradation kinetics at trace level concentrations must be developed. The quantification of microbial growth and the measurement of the GHG concentrations at the micrograms per liter level, in both the aqueous phase and the biofilm, constitute key analytical challenges.

The biological abatement of N2O is also limited by the poor understanding of the microbiology governing N2O biodegradation under aerobic conditions. The few existing studies on biological NO x treatment (mainly NO and NO2) were based on heterotrophic denitrification using O2-free synthetic emissions (conditions which are far from those typically found in real N2O-laden emissions) and autotrophic nitrification and, in most cases, were mass transfer limited (Flanagan et al. 2002). In addition, several authors have concluded that the implementation of nitrogen oxide removal based on denitrification might be limited by the need for low O2 concentrations and the use of an exogenous carbon source (Kalkowski and Conrad 1991; Sakurai and Sakurai 1997). In this regard, aerobic denitrification might constitute the cornerstone for the development of cost-efficient N2O abatement processes. Thus, despite the controversy that has surrounded aerobic denitrification for years, there are nowadays consistent research findings to support the constitutive nature of some NO3 −, NO2 −, and N2O reductases in bacteria such as P. stutzeri or Thiosphaera pantotropha (Robertson et al. 1995). As a matter of fact, N2O reduction coupled to the oxidation of an electron donor (e.g., acetate) has been reported even at O2 concentrations twice that of air saturation (Miyahara et al. 2010). However, apart from this proof of concept carried out in test tubes, aerobic denitrification has never been evaluated in a continuous bioreactor configuration, which constitutes a technological challenge in terms of electron donor supply and competition with obligate aerobic heterotrophs.

Finally, microalgae-based CO2 capture is also limited by the low PE achieved in conventional PBRs (2–5 %) during outdoors cultivation (which significantly increases both investment and operation costs) and also by the perishable nature of microalgal biomass, which does not allow for the long-term storage of CO2 (Acién Fernández et al. 2012b). In this context, the development of both innovative PBRs capable of minimizing the detrimental effects of photorespiration, photoinhibition, photosaturation, and temperature on PE and of low-cost microalgae harvesting technologies is crucial. Today, CO2 capture using microalgae-based processes still exhibit high operating costs, despite being lower than those of their physical/chemical counterparts. In a recent literature review published by Acién Fernández et al. (2012b), the cost of CO2 capture in a 100-ha facility of HRAP was estimated at 0.23 € kg−1CO2 by using wastewater as free nutrient source and flue gases as free CO2 source. Microalgae harvesting constitutes a significant part of the overall operating costs and is often carried out by centrifugation, filtration, coagulation–flocculation, flotation, or gravity sedimentation (Packer 2009). Full-scale algal mass production plants are often constructed with centrifugation or filtration units, despite not being recommended for small species like Chlorella or Scenedesmus (Molina Grima et al. 2003). In this context, Acién Fernández et al. (2012b) estimated the energy requirements associated to microalgae harvesting by flocculation–sedimentation followed by centrifugation in 0.1 kWh m−3. In brief, most of the CO2 mitigation of microalgae-based processes will actually come from the production of bioenergy from the biomass produced (with the subsequent reduction in fossil fuel consumption) and from the energy-efficient carbon and nutrients removal during wastewater treatment in PBRs (Muñoz and Guieysse 2006; Kumar et al. 2010b; Acién Fernández et al. 2012b).

Conclusions

To date, biotechnologies for GHG abatement have shown promising results in terms of elimination capacity and environmental impact. The prohibitive treatment costs and the CO2 footprint of physical/chemical techniques, especially when dealing with large volumes of air with low GHG concentration, certainly encourage the development and application of high-performance biological methods to mitigate this global environmental problem. Despite the fact that some technical and microbiological limitations must still be overcome, the potential of biological techniques for GHG abatement has been consistently demonstrated, high removal efficiencies being so far reached mainly for CH4 and CO2 and in a lower extent for N2O. In this context, the understanding of the microbiology underlying GHG biodegradation was identified as one of the most important knowledge gaps requiring further research. In addition, the development of innovative bioreactor configurations to improve both GHG mass transfer from the gas phase to the microorganisms and light supply (in the case of CO2 abatement processes) constitutes a key research niche. Finally, the feasibility of coupling GHG biodegradation with the production of high added-value products such as PHB, single-cell protein, pharmaceuticals, or biofuels can impact positively on the overall cost-effectiveness of biological treatment processes.

References

Acién Fernández FG, Fernández Sevilla JM, Sánchez Pérez JA, Molina Grima E, Chisti Y (2001) Airlift-driven external-loop tubular photobioreactors for outdoor production of microalgae: assessment of design and performance. Chem Eng Sci 56:2721–2732. doi:10.1016/S0009-2509(00)00521-2

Acién FG, Fernández JM, Magán JJ, Molina E (2012) Production cost of a real microalgae production plant and strategies to reduce it. Biotechnol Adv 30:1344–1353. doi:10.1016/j.biotechadv.2012.02.005

Acién Fernández FG, González-López CV, Fernández Sevilla JM, Molina Grima E (2012) Conversion of CO2 into biomass by microalgae: how realistic a contribution may it be to significant CO2 removal? Appl Microbiol Biotechnol 96:577–586. doi:10.1007/s00253-012-4362-z

Ahn JH, Kim S, Park H, Rahm B, Pagilla K, Chandran K (2010) N2O emissions from activated sludge processes, 2008–2009: results of a national monitoring survey in the United States. Environ Sci Technol 44:4505–4511. doi:10.1021/es903845y

Akdeniz N, Janni KA, Salnikov IA (2011) Biofilter performance of pine nuggets and lava rock as media. Biores Technol 102:4974–4980. doi:10.1016/j.biortech.2011.01.058

Amaral JA, Knowles R (1995) Growth of methanotrophs in methane and oxygen counter gradients. FEMS Microbiol Lett 126:215–220. doi:10.1111/j.1574-6968.1995.tb07421.x

Anthony C (1982) The biochemistry of methylotrophs. Academic, New York

Apel WA, Turick CE (1992) The use of denitrifying bacteria for the removal of nitrogen oxides from combustion gases. Fuel 72:1715–1718. doi:10.1016/0016-2361(93)90360-E

Arcangeli JP, Arvin E (1999) Modeling the growth of a methanotrophic biofilm: estimation of parameters and viability. Biodegrad 10:177–191

Avalos A, Jones PJ, Heitz M (2012) Methane treatment in biotrickling filters packed with inert materials in presence of a non-ionic surfactant. J Chem Technol Biotechnol 87:848–853. doi:10.1002/jctb.3811

Balasubramanian R, Kenney GE, Rosenzweig AC (2011) Dual pathways for copper uptake by methanotrophic bacteria. J Biol Chem 286:37313–37319. doi:10.1074/jbc.M111.284984

Barbosa MJ, Zijffers JW, Nisworo A, Vaes W, van Schoonhoven J, Wijffels RH (2005) Optimization of biomass, vitamins, and carotenoid yield on light energy in a flat-panel reactor using the A-stat technique. Biotechnol Bioeng 89:233–242. doi:10.1002/bit.20346

Barsanti L, Gualtieri P (2006) Algae: anatomy, biochemistry and biotechnology. CRC, Boca Raton