Abstract

Microbial production of ethanol might be a potential route to replace oil and chemical feedstocks. Bioethanol is by far the most common biofuel in use worldwide. Lignocellulosic biomass is the most promising renewable resource for fuel bioethanol production. Bioconversion of lignocellulosics to ethanol consists of four major unit operations: pretreatment, hydrolysis, fermentation, and product separation/distillation. Conventional bioethanol processes for lignocellulosics apply commercial fungal cellulase enzymes for biomass hydrolysis, followed by yeast fermentation of resulting glucose to ethanol. The fungus Neurospora crassa has been used extensively for genetic, biochemical, and molecular studies as a model organism. However, the strain's potential in biotechnological applications has not been widely investigated and discussed. The fungus N. crassa has the ability to synthesize and secrete all three enzyme types involved in cellulose hydrolysis as well as various enzymes for hemicellulose degradation. In addition, N. crassa has been reported to convert to ethanol hexose and pentose sugars, cellulose polymers, and agro-industrial residues. The combination of these characteristics makes N. crassa a promising alternative candidate for biotechnological production of ethanol from renewable resources. This review consists of an overview of the ethanol process from lignocellulosic biomass, followed by cellulases and hemicellulases production, ethanol fermentations of sugars and lignocellulosics, and industrial application potential of N. crassa.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the inevitable depletion of the world's energy supply, there has been an increasing worldwide interest in alternative sources of energy, such as biofuels (Lin and Tanaka 2006; Chandel et al. 2007; Agarwal 2008). Bioethanol is by far the most common biofuel in use worldwide (Koh and Ghazoul 2008; Sánchez and Cardona 2008). Moreover, biomass energy can play an important role in reducing greenhouse gas emissions. Ethanol production process only uses energy from renewable energy sources. Hence, no net carbon dioxide is added to the atmosphere, making ethanol an environmentally beneficial energy source (Lin and Tanaka 2006; Chandel et al. 2007). A variety of natural sources exist that can provide the required sugars for bioethanol production and can be classified based on their composition: (a) sucrose-containing feedstocks (e.g., sugar beet, sweet sorghum, and sugarcane), (b) starchy materials (such as wheat, corn, and barley), and (c) lignocellulosic biomass (e.g., wood, straw, and grasses; Sánchez and Cardona 2008; Balat et al. 2008; Tomás-Pejó et al. 2008).

Especially interesting are technologies for the production of second-generation biofuels. The term second generation means that, contrary to biofuels of the first generation (bioethanol from sugar or starch-containing plants), the raw materials are not used for the production of food products. These include mainly lignocellulosic raw materials such as energy plants, where the whole plant is processed, straw, wood, and various agricultural and wood processing waste products, such as organic waste (Festel 2008). During the last two decades, technology for ethanol production from non-food plant sources has been developed to the point at which large-scale industrial production will be a reality in the next few years (Lin and Tanaka 2006; Chandel et al. 2007; Wyman 2007).

The fungus Neurospora crassa has the ability to synthesize and secrete high levels of all main enzyme types involved in lignocellulosic biomass degradation. In addition, N. crassa has been reported to convert to ethanol various hexose and pentose sugars, cellulose polymers, and agro-industrial residues. The combination of these characteristics makes N. crassa a promising alternative candidate for biotechnological production of ethanol from lignocellulosic biomass. Previous reviews of N. crassa concerned only the strain's contributions to eukaryote genetics, biochemistry, molecular biology, or physiology (Perkins 1992; Maheshwari 1999; Perkins and Davis 2000; Davis and Perkins 2002; Prokisch et al. 2002; Borkovich et al. 2004; Kritsky et al. 2005; Catalanotto et al. 2006; Crosthwaite and Heintzen 2010; Rountree and Selker 2010; Riquelme et al. 2011; Baker et al. 2012). The aim of the present work is to review, for the first time, the literature demonstrating the biotechnological potential of N. crassa for ethanol production from renewable resources. This review consists of an overview of the ethanol process from lignocellulosic biomass, followed by reported cellulases and hemicellulases production and ethanol fermentations by N. crassa.

Overview of the ethanol production process

Structure of lignocellulosic biomass

Lignocellulosic materials are the most abundant biopolymers in the Earth. It is considered that lignocellulosic biomass comprises about 50 % of world biomass, about 180–200 million dry tons per year (Sánchez and Cardona 2008; Demain 2009). In general, prospective lignocellulosic materials for fuel ethanol production can be divided into six main groups: crop residues (cane bagasse, corn stover, wheat straw, rice straw, rice hulls, barley straw, sweet sorghum bagasse, olive stones, and pulp), hardwood (aspen and poplar), softwood (pine and spruce), cellulose wastes (newsprint, waste office paper, and recycled paper sludge), herbaceous biomass (alfalfa hay, switchgrass, reed canary grass, coastal bermudagrass, and Timothy grass), and municipal solid wastes (Lee et al. 2008; Sánchez and Cardona 2008; Demain 2009; Saxena et al. 2009).

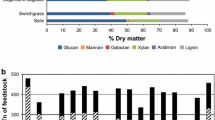

Numerous studies for developing large-scale production of ethanol from lignocellulosics have been carried out in the world. However, the main limiting factor is the higher degree of complexity inherent to the processing of this feedstock (Sánchez and Cardona 2008). This is related to the nature and composition of lignocellulosic biomass. The main components of the biomass are cellulose, hemicellulose, and lignin (Balat et al. 2008; Kumar et al. 2008; Taherzadeh and Karimi 2008). Cellulose is a linear homopolysaccharide composed of β-d-glucopyranose units, linked by β-(1 → 4)-glycosidic bonds. Cellulose fibers provide wood's strength. Cellobiose is the smallest repetitive unit of cellulose and can be converted into glucose residues. Hemicelluloses are heterogeneous polymers built up by pentoses (d-xylose and d-arabinose), hexoses (d-mannose, d-glucose, and d-galactose), and sugar acids. Hemicelluloses in hardwood contain mainly xylans, while in softwood, glucomannans are most common. Lignin is a highly branched, substituted, mononuclear aromatic polymer in the cell walls of certain biomass, especially woody species, and is often bound to adjacent cellulose fibers to form a lignocellulosic complex. Lignin is the most recalcitrant component of the plant cell wall, and the higher the proportion of lignin, the higher the resistance to chemical and enzymatic degradation.

Bioconversion of lignocellulosics to ethanol

The bioconversion of lignocellulosics to ethanol consists of four major unit operations: pretreatment, hydrolysis, fermentation, and product separation/distillation (Fig. 1) (Wyman et al. 2005; Hahn-Hägerdal et al. 2006; Chandel et al. 2007; Balat et al. 2008; Sánchez and Cardona 2008; Taherzadeh and Karimi 2008; Margeot et al. 2009). The first step in the conversion of biomass to ethanol is pretreatment. The pretreatment aims to increase pore size and reduce cellulose crystallinity. In acid-catalyzed pretreatment, the hemicellulose layer is hydrolyzed, whereas in alkali-catalyzed pretreatment, mainly, a part of the lignin is removed, and hemicellulose has to be hydrolyzed by the use of hemicellulases. Hence, pretreatment is necessary to expose the cellulose fibers to the enzymes or to at least make the cellulose more accessible to the enzymes. This should be done with a minimum formation of compounds which inhibit the fermenting microorganisms (Olofsson et al. 2008).

General process scheme for ethanol production from lignocellulosic biomass, including process integration options (adapted and modified from Cardona and Sánchez 2007)

The aim of the enzymatic hydrolysis is to depolymerize cellulose fibers and other oligo- and polysaccharides (e.g., from hemicellulose) released during pretreatment step (Olofsson et al. 2008; Margeot et al. 2009). Therefore, the hemicellulose and cellulose polymers are hydrolyzed to release monomeric sugars. The sugars from the pretreatment and enzymatic hydrolysis steps are fermented by bacteria, yeast, or filamentous fungi. Contrary to sucrose- and starch-based ethanol production, lignocellulose-based production is a mixed-sugar fermentation in the presence of inhibiting compounds—low molecular weight organic acids, furan derivatives, and phenolics and inorganic compounds—released and formed during pretreatment and/or hydrolysis of the raw material (Hahn-Hägerdal et al. 2006).

After final purification (by distillation and molecular sieves or other separation techniques), the ethanol is ready to be used as a fuel. A part of the lignin, the principal solid part of the biomass remaining, can be burnt to provide heat and electricity for the process, whereas the rest is retained as a valuable co-product (Wyman et al. 2005; Hahn-Hägerdal et al. 2006).

Process integration

Bioconversion can be performed either in separate enzyme hydrolysis and fermentation steps, or in a combined step (Fig. 1). The classic configuration employed for fermenting biomass hydrolyzates involves a sequential process where the hydrolysis of cellulose (saccharification) and the fermentation are carried out in different units, known as separate hydrolysis and fermentation (SHF) (Sánchez and Cardona 2008). One of the main features of the SHF process is that each step can be performed at its optimal operating conditions (reaction time, temperature, pH, enzyme dosage, and substrate load). The disadvantage is that cellulolytic enzymes are end-product inhibited so that the rate of hydrolysis is progressively reduced when glucose and cellobiose accumulate (Hahn-Hägerdal et al. 2006).

The most important process improvement made for the enzymatic hydrolysis of biomass is the introduction of simultaneous saccharification and fermentation (SSF) (Chandel et al. 2007). The SSF process appears more attractive than the SHF, as higher ethanol yields can be obtained and less energetic consumption is required (Sánchez and Cardona 2008). In this case, the enzymes and microorganisms are added to the same process unit allowing that the glucose formed during the enzymatic hydrolysis of cellulose be immediately consumed by the microbial cells converting it into ethanol. Thus, the inhibition effect caused by the sugars over the enzymes is neutralized. However, the need of employing more dilute media to reach suitable rheological properties will lead to low final product concentrations. In addition, this process operates at non-optimal conditions for hydrolysis and requires higher enzyme dosage, which positively influences on substrate conversion, but negatively on process costs.

An alternative technology for lignocellulosic biomass bioconversion has been proposed, known as consolidated bioprocessing (CBP) or direct microbial conversion (DMC) and is thoroughly reviewed by Lynd et al. (2005). Briefly, in CBP, ethanol and all required enzymes are produced by a single microorganism, in a single reactor. CBP is gaining increasing recognition as a potential breakthrough for low-cost biomass processing. Application of CBP implies no capital or operating costs for dedicated enzyme production (or purchase), reduced diversion of substrate for enzyme production, and compatible enzyme and fermentation systems. In addition, enzyme–microbe synergy and the use of complexed cellulase systems support the possibility of realizing higher hydrolysis rates. Interestingly, cellulose-adherent cellulolytic microorganisms are likely to successfully compete for products of cellulose hydrolysis with non-adhered microbial contaminants, which could increase the stability of industrial processes (Lynd et al. 2005). However, there is no industrially robust organism available that can produce cellulases or other cell wall-degrading enzymes in conjunction with ethanol with high yields. Fungal candidates for CBP belong to Neurospora, Fusarium, Monilia, Rhizopus, Aspergillus, and Trichoderma genus, which are able to produce the required hydrolytic enzymes as well as ferment to ethanol the produced sugars, but with low conversion rates.

Cellulases and hemicellulases production by N. crassa

Utilizing lignocellulosic biomass requires the action of specific hydrolytic enzymes, such as cellulases and hemicellulases, which decompose the biomass into simple fermentable sugars. Several microorganisms exist that naturally grow on lignocellulosic substrates, producing the required hydrolytic enzymes. Numerous bacteria as well as fungi, aerobic or anaerobic, mesophile or thermophile, have been reported to produce cellulases and hemicellulases (Tergerdy and Szakacs 2003; Balat et al. 2008; Kumar et al. 2008; Olofsson et al. 2008). However, filamentous fungi are still the main source for commercial cellulases and hemicellulases (Gusakov et al. 2007; Kumar et al. 2008).

The fungus N. crassa

Neurospora is a mesophile filamentous fungus belonging to ascomycetes, commonly seen following agricultural burning in warm, moist climates (Perkins 1992). The genus was first described in 1927 by Shear and Dodge, and thousands of papers have been published on Neurospora research since. Numerous natural populations of Neurospora have been identified and their characteristics extensively studied (Perkins et al. 1976; Perkins and Turner 1988; Turner et al. 2001). The genus includes the heterothallic species N. crassa, Neurospora discreta, Neurospora intermedia, and Neurospora sitophila, the pseudohomothallic Neurospora tetrasperma, and the homothallic species Neurospora africana, Neurospora dodgei, Neurospora galapagosensis, Neurospora lineolata, and Neurospora terricola (Perkins and Turner 1988). Karyotypes, karyogamy, and meiotic chromosome behavior are similar for all the known Neurospora species, with seven chromosomes and a single terminal nucleolus organizer (Turner et al. 2001). Only the nonhomothalic Neurospora species produce conidia (asexual reproduction), usually abundant, powdery, and readily airborne, forming large colonies with vivid orange or orange-yellow colors due to carotenoids (Perkins and Turner 1988; Perkins 1992).

N. crassa is the best known Neurospora species and has been used extensively for genetic, biochemical, and molecular studies as a model organism (Davis 2000; Davis and Perkins 2002). It is a saprophyte microorganism, obtaining nutrition from substrates, and growing equally well in simple liquid or on solid media of known composition. It is nonpathogenic, although it is very closely phylogenetically related to pathogens. Both asexual development and sexual differentiation are highly influenced by environmental factors such as nutrient, light, and temperature (Dunlap et al. 2007). The genome sequence of N. crassa was recently reported (Galagan et al. 2003; Mannhaupt et al. 2003). It possesses a large number of genes without homologues in Saccharomyces cerevisiae. Some of the unshared genes encode for sugar transporters, transcription factors, and environmental sensing pathways, as well as a diversified metabolic machinery (Borkovich et al. 2004).

Mode of action

Eberhart et al. (1964, 1977) were the first to investigate cellulase production by Neurospora. The degradation of cellulose to glucose in N. crassa appears to be a sequential process involving the participation of three enzyme activities: endoglucanase, exoglucanase, and β-glucosidase (Eberhart et al. 1964, 1977; Mahadevan and Eberhart 1964; Yazdi et al. 1990a, b, c). These three types of enzymes act synergistically for the hydrolysis of cellulose and are common to all cellulolytic fungi (Gray et al. 2006; Kumar et al. 2008; Margeot et al. 2009). Briefly, the endoglucanases (EC 3.2.1.4) attack regions of low crystallinity and cleave internal β-1,4-glucosidic bonds. The exoglucanases or cellobiohydrolases (EC 3.2.1.91) act on the reducing and non-reducing ends of cellulose chains to release short-chain cello-oligosaccharides such as cellobiose. Finally, β-glucosidases (EC 3.2.1.21) hydrolyze soluble cello-oligosaccharides, such as cellobiose, to glucose molecules. A quantitative proteomics approach of the secretome of N. crassa during growth on microcrystalline cellulose led to the characterization of 13 proteins, including two cellobiohydrolases (CBH-1 and GH6-2), an endoglucanase (GH5-1), and a β-glucosidase (GH3-4) (Phillips et al. 2012).

Hemicellulose decomposition is also required for the efficient exploitation of lignocellulosic biomass. Xylan, the main hemicellulose polymer, is hydrolyzed to xylo-oligosaccharides by endo-β-1,4-xylanases (endoxylanases, EC 3.2.1.8), followed by the action of β-xylosidases (EC 3.2.1.37) on the produced xylo-oligosaccharides (mainly xylobiose) to release xylose molecules (Gray et al. 2006; Kumar et al. 2008; Margeot et al. 2009). Studies on the mode of action of N. crassa β-xylosidase and xylanase (Deshpande et al. 1986) revealed that xylanase has no action on lower xylo-oligosaccharides (X3 and X4), whereas β-xylosidase can hydrolyze them. Thus, β-xylosidase complements the action of xylanase during the hydrolysis of xylan. The authors suggested that this may be attributed to the substantial transferase activity exhibited by the β-xylosidase of N. crassa. In addition, the differential kinetic parameters of the N. crassa xylanase towards the hydrolysis of xylan and CM-cellulose showed that the pure enzyme has two catalytic sites. The enzyme hydrolyzed both β-1,4-xylosidic and glucosidic linkages. Auxiliary enzymes that act on various hemicellulose side chains include α-glucuronidases (EC 3.2.1.139), α-l-arabinofuranosidases (EC 3.2.1.55), acetyl esterases (EC 3.1.1.72), and ferulic acid esterases (FAEs) (EC 3.1.1.73) (Gray et al. 2006; Kumar et al. 2008; Margeot et al. 2009). Other hemicellulose polymers, such as glucomannans, are decomposed by mannanases and β-mannosidases (Kumar et al. 2008).

Induction and regulation

Regulating enzyme synthesis is crucial for the economics of biofuel production from lignocellulosic biomass. Generally, production of hydrolytic enzymes associated with plant cell wall degradation is induced to high levels only in the presence of plant cell wall biopolymers (cellulose, hemicellulose, or mixtures of plant polymers) or their derivatives (Sun and Glass 2011; Znameroski et al. 2012). Because these naturally inducing substances cannot enter fungal cells, it is believed that oligosaccharides released from polymers and their derivatives function as the actual molecules that trigger enzyme induction (Kubicek et al. 1993). Cellulase production on a commercial scale is induced by growing the fungus on solid cellulose or by culturing in the presence of a disaccharide inducer such as lactose. However, on an industrial scale, both methods of induction result in high costs (Sukumaran et al. 2005).

The fungus N. crassa can use a wide variety of carbon sources for its growth. This requires an optimal adaptation to the environment by synthesizing transporters and secreting enzymes, which are induced by specific substrates or metabolites. For N. crassa to grow on plant cell wall material, a low constitutive level of extracellular or cell wall-associated enzymes releases metabolites from plant biomass. These metabolites are transported into the cell and serve as inducers directly or are converted to signal molecules required for triggering transcription of genes encoding plant cell wall-degrading enzymes (Sun et al. 2012). Analysis of the N. crassa genome predicted genes for approximately 100 glycosyl hydrolases (Borkovich et al. 2004). N. crassa genome is also predicted to contain twice as many cellulases as in the industrially important species Trichoderma reesei, as well as many hemicellulases and other enzymes involved in plant biomass degradation (Tian et al. 2009).

The simultaneous induction of all three cellulase enzymes on N. crassa was first reported by Eberhart et al. (1964) using cellobiose as substrate. The induction properties of β-glucosidases of N. crassa have been later reported by Eberhart and Beck (1973), who suggested two different disaccharidases classes: (a) aryl-β-glucosidases, a broadly inducible (or derepressible) class of enzymes, and (b) cellobiases, enzymes with a highly specific induction requirement. In later studies, cellulase induction was reported on other substrates such as carboxymethyl cellulose, microcrystalline cellulose, plant cell walls, and absorbant cotton (Yazdi et al. 1990b; Tian et al. 2009). According to Myers and Eberhart (1966), the gluc-1 gene regulates the expression of β-glucosidases, and the cell-1 gene regulates the production of cellobiase and cellulase in N. crassa. Taleb and Radford (1995) reported a high homology of the cellobiohydrolase 1 (EC 3.2.1.91)-encoding gene (cbh-1) of N. crassa with cellulase genes from related fungi, such as T. reesei, Humicola grisea, and Phanerochaete chrysosporium, with clear signal, catalytic, hinge, and substrate-binding domains.

The induction of hemicellulose hydrolytic enzymes by N. crassa such as xylanase and β-xylosidase was first studied using xylan as a carbon source (Mishra et al. 1984). Recently, a secretome and transcriptome analysis of N. crassa grown on beechwood xylan led to the identification of 34 secreted proteins and 353 genes with elevated transcription on xylan (Sun et al. 2012). A transcription factor XLR-1 (xylan degradation regulator 1) was identified to be essential for hemicellulose degradation by N. crassa, and it is an ortholog to XlnR (Aspergillus sp.) and XYR1 (Trichoderma sp.), two major transcriptional regulators of genes encoding both cellulases and hemicellulases (Sun et al. 2012).

In filamentous fungi, genes encoding hydrolytic enzymes involved in plant cell wall deconstruction are repressed during growth on easily metabolized carbon sources, such as glucose, by the carbon catabolite repression (CCR) mechanism. Some aspects of CCR are mediated by Mig1/CreA/CRE1 (a zinc-finger transcription factor conserved in most fungal species), and deletion of cre-1 causes sustained expression of cellulase genes in N. crassa, resulting in higher cellulolytic enzyme activity (Sun and Glass 2011). When switched from a favored carbon source such as sucrose to cellulose, N. crassa dramatically upregulates expression and secretion of a wide variety of genes encoding lignocellulolytic enzymes (Znameroski et al. 2012). However, the means by which N. crassa and other filamentous fungi sense the presence of cellulose in the environment remains unclear. Znameroski et al. (2012) suggested that the induction of lignocellulose-degrading enzymes in N. crassa may be accounted to cellodextrins, such as cellobiose, but that the action of extracellular and intracellular β-glucosidases and CCR mask this inducing activity.

In addition to substrate availability, it has been shown that light modulates transcription of cellulase genes in T. reesei (Schmoll et al. 2005). Photoreceptors and their cognate signaling cascades have numerous regulatory targets and impact almost every aspect of physiology in N. crassa and other filamentous fungi (Chen et al. 2009; Smith et al. 2010; Tisch and Schmoll 2010; Schmoll 2011). Recently, Schmoll et al. (2012) reported that the N. crassa photoreceptor genes wc-1, wc-2, and vvd are involved in regulation of cellulase gene expression, indicating that this phenomenon is conserved among filamentous fungi.

Localization

Plant cell wall-degrading enzymes exist either in complexed or non-complexed systems. The complexed systems are known as cellulosomes and tend to be present in anaerobic bacteria and fungi, whereas the aerobic microorganisms produce discrete enzymes secreted into the growth media (Gray et al. 2006; Kumar et al. 2008).

Eberhart and Beck (1970) attempted to determine the location of β-glucosidases within the cellular structure of N. crassa, using various wild-type strains from several genetic backgrounds. They found two β-glucosidases, an “aryl-β-glucosidase” and a “cellobiase,” based on their distinct difference in specificity on p-NPG (p-nitrophenyl-β-d-glucopyranoside) and cellobiose, respectively. Aryl-β-glucosidase is primarily a detectable or cell wall-bound enzyme during any stage of the vegetative life cycle of Neurospora in which it is induced. On the other hand, cellobiase is predominantly internal and cryptic at all stages, but its activity can be detected in intact cell assays by specific physical or chemical treatments that alter the cell membrane. The authors also demonstrated that the ratio of external to cell-bound β-glucosidase was characteristic of each strain and suggested that cellular location of enzymes is not determined by molecular size alone.

Mishra et al. (1984) reported secreted as well as intracellular hemicellulose activities by N. crassa 870. The intracellular xylanase activity was only 7 % of the extracellular xylanase, but the β-xylosidase activity was almost equally distributed between the cell-free and cell-bound fractions.

Production of saccharolytic enzymes

Commercial production of cellulases and hemicellulases has been tried in either solid-state cultures (SSC) or submerged fermentations (SmF), including batch, fed batch, and continuous flow processes (Sukumaran et al. 2005). Most manufacturers produce enzymes using submerged fermentation techniques (Couto and Sanromán 2005). However, during the last decades, an increased interest towards solid-state conditions for the production of enzymes has been reported. Solid-state fermentation should define any fermentation process occurring in the absence or near-absence of free water, employing a natural substrate or an inert substrate used as solid support (Pandey et al. 2000; Couto and Sanromán 2005). SSC processes have shown to be particularly suitable for the production of enzymes by filamentous fungi, since they reproduce the natural living conditions of such fungi (Tergerdy and Szakacs 2003; Couto and Sanromán 2005).

N. crassa is able to synthesize and secrete all three enzyme types involved in cellulose degradation, as well as enzymes with hemicellulolytic activities. Reported growth conditions and enzyme activities are presented in Tables 1 and 2. The fungus has been grown successfully and produced cellulases and hemicellulases on various substrates, in both submerged (Table 1) and solid-state cultures (Table 2), at temperatures 25–30 °C and culture medium pH set at 5.0–7.0.

As discussed earlier, Eberhart et al. (1964; Eberhart and Beck 1970, 1973) reported the presence of cellulases and β-glucosidases of N. crassa, as well as the conditions that foster their release into the external media (Eberhart et al. 1977). Yazdi et al. (1990a, c, 2003) demonstrated the production of cellulase by N. crassa FGSC 4335 cell-1 mutant strain (with elevated uninduced levels of both cellulase and cellobiase) when grown in liquid medium with 1 % or 2 % (w/v) microcrystalline cellulose (MC). Addition of readily metabolized soluble carbon sources to the MC medium increased growth and improved cellulase production (Yazdi et al. 1990b). Rao et al. (1983) have identified two strains of N. crassa, NCIM 870 and NCIM 1021, which utilize cellulose and produce extracellular endoglucanase, and β-glucosidase were grown on alkali-treated cellulose powder (CP). The production of the cellulase complex of N. crassa using low-cost lignocellulosic agricultural residues, such as wheat straw (WS), was first reported by Macris et al. (1987, 1989). The strains of N. crassa 40b (Macris et al. 1987) and STA (Macris et al. 1989) were grown on untreated WS in SSC. WS was also studied for the production of N. crassa cellulases by Romero et al. (1999) using the fungal strain 4335 cell-1. The authors also reported that changes in the initial pH (6.5) lowered the enzymes production, but favored fungal growth. In addition, the β-glucosidase and endoglucanase activities showed fluctuations with fermentation time that could be attenuated by adding a protease inhibitor.

Hemicellulases production by N. crassa was first reported by Mishra et al. (1984). The strain NCIM 870 produced extracellular xylanase and β-xylosidase when grown on commercial 2 % xylan. Later, the extracellular β-xylosidase from N. crassa NCIM 870 was purified (Deshpande et al. 1986). Other enzymes that take part in hemicellulose hydrolysis have also been identified in N. crassa, including β-galactosidases (Landman and Bonner 1952; Landman 1954; Johnson and DeBusk 1970a, b; Perry and Lester 1973; Stephens and DeBusk 1975), α-l-arabinofuranosidases (Xiros et al. 2008; Takata et al. 2010), and ferulic acid esterases (FAEs) (Crepin et al. 2003, 2004; Xiros et al. 2008). Crepin et al. (2003) reported the ability of N. crassa wildtype ST A (74 A) to produce multiple FAE activities in response to the availability of plant cell wall carbohydrates.

Various residues from agri-food processes have been used for cellulases and hemicellulase production by N. crassa under SSC (Table 2). Large-scale production of cellulases (endoglucanase, cellobiohydrolase, and β-glucosidase) and xylanase using spent grain from brewing (BG) and WS (ratio 1:1) by the strain DSM 1129 has been reported by Xiros et al. (2008). Orange peels, the principal solid by-product of the citrus processing industry, were reported as a suitable substrate for cellulase (endoglucanase and β-glucosidase) and xylanase production by N. crassa DSM 1129 (Mamma et al. 2008). In our previous work (Dogaris et al. 2009b), we demonstrated the ability of N. crassa DSM 1129 to produce a complete cellulolytic (endoglucanase, cellobiohydrolase, and β-glucosidase) and hemicellulotic (xylanase and β-xylosidase) system under SSC on various agro-industrial byproducts, such as WS, WB, corncobs (CC), and sorghum bagasse (SB). The mixture 5:1 (w/w) WS–WB was found the best inducer for cellulases as well as hemicellulases production. The hydrolytic potential of the produced multi-enzyme system was tested successfully for the saccharification of SB into fermentable carbohydrates (Dogaris et al. 2009a, b). Using egg shell wastes as calcium additive to WB has been reported to increase total cellulase production (filter paper activity) by N. crassa NCIM 1021 (Verma et al. 2012).

Ethanol production by N. crassa

Ethanol fermentation is a biological process in which organic material is converted by microorganisms to simpler compounds, such as sugars. These fermentable compounds are then fermented by microorganisms to produce ethanol and CO2. Several reports and reviews have been published on production of ethanol fermentation by microorganisms, and several bacteria, yeasts, and fungi have been reportedly used for the production of ethanol (Lin and Tanaka 2006). The general requirements on an organism to be used in ethanol production is that it should give a high ethanol yield, a high productivity, and be able to withstand high ethanol concentrations in order to keep distillation costs low. In addition to these general requirements, efficient de-polymerization of cellulose and hemicellulose to soluble sugars, ability to utilize multiple sugars (hexoses and pentoses), and inhibitor and temperature tolerance are essential for lignocellulosic biomass fermentations (Hahn-Hägerdal et al. 2006; Olofsson et al. 2008). The ability of a microorganism to efficiently ferment both hexoses and pentoses under anaerobic conditions is advantageous as it can reduce contamination risks (Junker et al. 2006).

Fermentation of hexoses

Glycolysis is the process where sugars are metabolized to acetyl-CoA or pyruvate before oxidation during the citric acid cycle or fermentation to ethanol or lactate. Three metabolic pathways for the biosynthesis of ethanol from glucose have been described in various microorganisms, the Embden–Meyerhof–Parnas (EM), hexose monophosphate (HM), and Entner–Doudoroff (ED) pathways. The EM and HM pathways are prevalent in fungi, while evidence for the ED pathway has been demonstrated for only a few species (Griffen 1994). It has been suggested that the predominant route for glycolysis in Neurospora is the entry of glucose-6-phosphate into the EM pathway (80 % to 90 %), with the remainder diverted to the HM pathway (Davis 2000). The analysis of the genome sequence is consistent with intact EM and HM glycolytic pathways in Neurospora (Borkovich et al. 2004).

The fermentation of glucose to ethanol in aerobic cultures of N. crassa has been documented more than 40 years ago (Perlman 1950a, b; Tissieres et al. 1953; Strauss and Pierog 1954; Kobr et al. 1967; Colvin et al. 1973). Weiss and Turian (1966) observed that, in standing (anoxic) cultures of N. crassa, ethanol production was greater on media containing ammonia than on media containing nitrate as the nitrogen source. Howell et al. (1971) also observed that, in anaerobic cultures of a facultative anaerobic mutant of N. crassa in media containing ammonia as nitrogen source, ethanol production was proportional to the initial glucose concentration. Colvin et al. (1973) demonstrated that aerobic fermentation of glucose by wild-type N. crassa 74Α8 can also occur, and the ethanol yield is proportional to the initial glucose concentration. The authors reported that at high glucose concentrations, N. crassa cultures can accumulate up to 2 % ethanol, and the efficiency of conversion of glucose to ethanol can approach 100 %. In addition, the time for maximum ethanol accumulation depended on initial glucose concentration, and thereafter, in stationary phase, the ethanol concentration declined to zero. Upon exhaustion of glucose from the media, the repression of the assimilatory isozyme of alcohol dehydrogenase (Zink 1969) and the synthesis of glyoxylate cycle enzymes (Flavell and Fincham 1968) are initiated. Thus, the stage may be set for the utilization of ethanol (via acetate) as a carbon source in gluconeogenesis. Comparison of the specific rates of glucose utilization and ethanol accumulation during the fermentation by N. crassa with 2 % initial glucose reveals a stoichiometric relationship on the basis of the Embden–Meyerhof glycolytic pathway, with 2 mol of ethanol being produced per mole of glucose utilized (Colvin et al. 1973).

According to Xie et al. (2004), transcript levels in N. crassa cells for pyruvate decarboxylase (PDC), which catalyzes the unidirectional rate-limited step of fermentation, were higher in the presence of glucose than in its absence. Therefore, acetaldehyde should be produced in abundance and may be efficiently reduced to ethanol using NADH via alcohol dehydrogenase (ADH). In S. cerevisiae, ADH1 generates ethanol, and ADH2 is involved in its degradation. Two predicted N. crassa ADHs (NCU02476.1 and NCU01754.1) have strong identity (>50 %) to S. cerevisiae ADH1, ADH2, and ADH3. NCU02476.1 was not strongly regulated by glucose, while NCU01754.1 is strongly repressed by glucose. These two N. crassa proteins likely play roles in ethanol synthesis and degradation, respectively.

The fungus T. reesei primarily utilizes glucose via respiration and carries out a low rate of conversion of pyruvate to acetate (Chambergo et al. 2002). In contrast, N. crassa utilizes glucose in a manner in which the rate of glycolysis exceeds the rate at which the products of glycolysis are utilized by the TCA cycle and respiration. Fermentation to ethanol rather than acetate is required to generate NAD+ to support the high rate of glycolysis. N. crassa is well known for its rapid growth rate, and energy demands to support this high growth rate may require fermentation as well as respiration. In addition, rapid removal of glucose from a glucose-rich environment and production of ethanol may represent a strategy that N. crassa utilizes for competition with other microbes (Xie et al. 2004).

Two glucose transport systems have been characterized in N. crassa, a constitutive low-affinity transport system and a glucose-repressible high-affinity transport system (Scarborough 1970; Schneider and Wiley 1971). Thirty-three hexose transporter homologs have been identified in the N. crassa genome sequence, representing one of the largest multigene families, and phylogenetic analyses indicate that the relationship between S. cerevisiae and N. crassa hexose transporter paralogs is poor, and no clear orthologs for comparison of gene expression are present (Galagan et al. 2003).

Rao et al. (1983) reported ethanol production from d-glucose by N. crassa strains NCIM 870 and 1021. The strains readily fermented d-glucose, producing 4–4.4 % (w/v) ethanol in quantitative conversion in 10 days. Ethanol production was carried out in two stages, an aerobic growth for 2 days and a non-aerated fermentation at 28 °C. Deshpande et al. (1986) reported the fermentation of various simple sugars to ethanol by N. crassa NCIM 870. Ethanol production was carried out in two stages as described by Rao et al. (1983). d-Mannose was fermented rapidly giving 100 % conversion of sugar to ethanol in 2 days. d-Galactose gave 75 % conversion in 6 days.

Fermentation of pentoses

Although the pentose sugars d-xylose and l-arabinose represent the most abundant components of hemicellulose in this biomass (Lee 1997; van Maris et al. 2006), the inability of established ethanol production organisms such as S. cerevisiae to effectively harness these pentose sugars represents a significant biotechnological bottleneck (Margeot et al. 2009). For example, the predominant ethanol producer S. cerevisiae, as well as the ethanologen bacterium Zymomonas mobilis, are unable to utilize these hemicellulosic pentose sugars without the introduction of exogenous pathway genes (Zaldivar et al. 2001; Matsushika et al. 2009). Enteric bacteria and some fungi and yeasts are able to ferment pentoses, but with low ethanol yields. Furthermore, in the case of xylose-fermenting yeasts (Pachysolen tannophilus, Candida shehatae, and Pichia stipitis), large-scale utilization is hampered by their sensitivity to high concentrations of ethanol (≥40 g/l), the requirement for carefully monitored micro-aerophilic conditions, high sensitivity to inhibitors, and the inability to ferment xylose at low pH (Hahn-Hägerdal et al. 1994; Chandrakant and Bisaria 1998).

In fungi, xylose is reduced to xylitol by NADH- or NADPH-dependent xylose reductase (XR) and thereafter is oxidized to xylulose by NAD+-dependent xylitol dehydrogenase (XDH). The xylulose is phosphorylated by xylulose kinase (XK), channeled into the pentose phosphate pathway (PPP) (Skoog and Hahn-Hägerdal 1988; Zaldivar et al. 2001). The enzymes XR and XDH of N. crassa have been identified and characterized (Rawat et al. 1993; Rawat and Rao 1996; Phadtare et al. 1997), as well as a XR gene (Woodyer et al. 2005). Rawat et al. (1993) reported the induction of two XRs in N. crassa, one NADH-linked and one NADPH-linked, with the latter being the most abundant and stable. Maximum ethanol from xylose was obtained when high NADH-linked XR and NAD-linked XDH activities were observed. Two isoenzymes (EI and EII) with NADPH-linked xylose reductase activities were identified from N. crassa, one of which (EII) also had NADH-linked activity (Zhao et al. 1998). XR of most fungi, including most yeasts, prefers NADPH to NADH. Because of the cofactor preference of XR (NADPH) and XDH (NAD+), redox imbalance may occur under anaerobic fermentations of pentoses (Vandeska et al. 1995). Rawat et al. (1993) also suggested that the presence of NADH-linked XR in N. crassa probably prevents that imbalance, thus allowing the conversion of xylose to ethanol.

l-Arabinose and d-xylose can be catabolized through a common intermediate, d-xylulose 5-phosphate, via distinct pathways in bacteria (Dien et al. 2003) and fungi (Jennings 1984). l-Arabinitol 4-dehydrogenase (LAD) catalyzes the second step of l-arabinose assimilation by oxidation of l-arabinitol to l-xylulose, with concomitant reduction of NAD+ to NADH (Richard et al. 2001). l-Xylulose reductase (LXR) produces xylitol in the successive step. An LXR identified from the genome sequence of N. crassa has been biochemically characterized (Nair and Zhao 2007). LAD and LXR are the two unique enzymes required for l-arabinose utilization, while the other enzymes in the pathway are shared in the d-xylose pathway (Chiang and Knight 1960). Due to their importance in cost-effective pentose sugar catabolism, several LADs from different fungal sources have been biochemically characterized, and N. crassa LAD was among the most active and stable LADs (Sullivan and Zhao 2007). N. crassa LAD is predominantly NAD+ dependent, as is the case with all LADs characterized to date, and is a member of the superfamily of medium-chain dehydrogenases/reductases (Eklund and Ramaswamy 2008) with homology to xylitol dehydrogenase and sorbitol dehydrogenase. The preferred substrate is l-arabinitol, with oxidation activity also present with the epimeric sugar alcohols xylitol and adonitol. In addition, N. crassa LAD shows low yet detectable activity with the NADP+ cofactor, suggesting inherent relaxed cofactor specificity (Sullivan and Zhao 2007). The crystal structure of LAD from N. crassa has been reported by Bae et al. (2010).

Deshpande et al. (1986) reported the fermentation of pentose sugars to ethanol by N. crassa NCIM 870, in two stages as described by Rao et al. (1983). The pentose sugars, d-xylose and d-arabinose, were fermented at a lower rate than hexoses, yielding 65 % and 44 % conversion to ethanol, respectively, in 6 days (based on the assumption that theoretically 1 mol d-xylose yields 1.7 mol ethanol). Zhang et al. (2008) studied xylose metabolism of N. crassa AS3.1602 under oxygen-limited conditions. Ethanol production reached 6.7 g/l, leading to 66 % conversion yields, but productivity was low, 0.093 g/l h.

Fermentation of lignocellulosics

Yeasts cannot metabolize cellulose or hemicellulose, while other fungal systems that could grow on lignocellulosic substrates and directly ferment them to ethanol have been reported. These technologically very attractive systems may lead to alternative and more cost-efficient consolidated bioprocesses for bioethanol production, compared to establish technologies (SHF, SSF) with added hydrolytic enzyme production costs. The fungus N. crassa is one of the few microorganisms that can convert cellulose and hemicellulose to ethanol in two stages, by producing the required hydrolytic enzymes during aerobic growth stage and fermenting the produced simple sugars to ethanol when switched to anaerobic or micro-aerobic conditions (fermentation stage). However, the reported rates of alcohol fermentation by N. crassa are lower than yeasts. A summary of SSF by N. crassa of cellulosic, hemicellulosic, and lignocellulosic substrates to ethanol is presented in Table 3.

Rao et al. (1983) screened a number of Neurospora cultures for cellulase activity and ethanol production. Two strains of N. crassa, NCIM 870 and NCIM 1021, were selected, and the direct fermentation of alkali-treated CP and steam-treated bagasse to ethanol was reported with periodic addition of substrate. Both strains were grown aerobically at 28 °C in 100 ml culture medium (growth stage) and transferred to non-aerated flasks containing 1 g of substrate (fermentation stage). Additional substrate (1 g each in 5 ml H2O) was added on the fifth and seventh day of fermentation, and the fermentation continued up to 10 days. The alkali-treated CP conversion was 80–90 % at the end of the fermentation, and the obtained ethanol concentrations were 18 and 11 g/l for NCIM 870 and NCIM 1021, respectively. Bagasse conversion to ethanol reached 60 % (based on cellulose and hemicellulose content) by both strains in 10 days. In addition, N. crassa NCIM 870 converted 86 % microcrystalline cellulose (Avicel), 66 % powdered cellulose (Solka-Floc), 60 % alkali-treated straw, and >80 % alkali-treated bagasse to ethanol.

Work on bioethanol production from lignocellulosic substrates by N. crassa continued by Rao et al. (1985) and Deshpande et al. (1986). Rapidly growing tropical woods and other agricultural residues (Rao et al. 1985), as well as cellulose (Avicel, alkali-treated CP), xylan, gum arabic, and treated bagasse (Deshpande et al. 1986), were utilized as substrates for N. crassa NCIM 870 two-stage bioconversion, as described above. The direct fermentation of pretreated wood (20 g/l) gave 90–100 % conversion of available hemicellulose/cellulose to ethanol in 5 days. Maximum ethanol concentration of 11 g/l was obtained in 5 days when the woods were pretreated with cold alkali. Increasing the substrate concentration to 50 g/l lowered the conversion to 40–60 %, yielding 12 g/l of ethanol. Fermentation of wood (50 g/l) pretreated with hot 1 M NaOH followed by neutralization with HCl gave only 6 g/l of ethanol. Furthermore, 12–13 g/l of ethanol were obtained from ethanolic NaOH treated bagasse or straw. The optimization of fermentation conditions resulted in yields of 5.5 and 10 g/l of ethanol from 1 % Avicel and 2 % (w/v) alkali-treated CP, corresponding to 100 % and 90 % conversion, respectively, in 4 days. The direct fermentation of d-xylan, gum arabic (a branched polymer of d-galactose, l-rhanmose, l-arabinose, and d-glucuronic acid), and treated bagasse yielded 58 %, 70 %, and 90 % conversion to ethanol, respectively, in 4–6 days. Increasing the substrate concentration of treated bagasse (5 %) yielded increased concentration of ethanol (11 g/l) corresponding to 75 % conversion of available cellulose to ethanol in 6 days.

N. crassa has also been reported to convert various food industry wastes such as corncobs, sugarcane bagasse, and sugarcane molasses into ethanol with high yields, after incubation for 96 h at a temperature of 37 °C (Okonko et al. 2009). Xiros et al. (2008) studied the ethanol production from brewing spent grain (BG), a brewing industry by-product, by N. crassa DSM 1129. Aerobic growth was carried out in SSC (BG/WS as carbon source, moisture 61.5 % w/w), while submerged culture was employed for the fermentation (production phase) of 75 g/l alkali-treated or untreated BG, in a 2-l bioreactor under anaerobic and microaerobic (air flow 0.1 vvm) conditions, at 30 °C and pH maintained at 5.0. The authors reported that alkali pretreatment increased substantially the ethanol production from BG, and the potential presence of inhibitors did not hamper the fermentation. Maximum ethanol yield was 74 g ethanol per kilogram dry BG. Ethanol production from sorghum bagasse (SB), the solid residue obtained after extraction of sugars from the energy plant sweet sorghum, has been described in our previous works (Dogaris et al. 2009b, 2012). N. crassa DSM 1129 was grown under SSC optimum conditions (Dogaris et al. 2009b), followed by micro-aerobic fermentation of SB at 30 °C. The bioconversion of untreated SB to ethanol resulted in low ethanol production (Dogaris et al. 2009b), thus a dilute-acid pretreatment of SB prior to SSF was later investigated (Dogaris et al. 2012). We demonstrated an alternative cost-efficient bioconversion of SB to ethanol by the fungus N. crassa DSM 1129 at high solids loadings (16 % at pretreatment and 8 % at fermentation), low external cellulase loadings (6 FPU/g SB), and co-fermentation of hexoses and pentoses (Dogaris et al. 2012). Ethanol production from SB by N. crassa (supplemented with cellulase at 6 FPU/g SB) reached 27.6 g/l or 84.7 % ethanol yield (based on SB cellulose and hemicellulose sugar content). In order to improve the sugar assimilation rate, mixed cultures of N. crassa DSM 1129 with S. cerevisiae 2541 were also applied with the same bioconversion setup. However, the bioconversion efficiency of N. crassa single cultures was found superior to S. cerevisiae as well as to their mixed cultures.

Factors affecting the fermentation

Various factors such as temperature, substrate concentration, aeration, as well as pretreatment inhibitors have been studied that may significantly affect ethanol production from lignocellulosics by N. crassa. A small increase in the temperature of N. crassa fermentations has been reported to increase conversion yields as well as reduce the fermentation time (Rao et al. 1983, 1985). At 37 °C, an almost quantitative conversion of cellulose to ethanol in 4 days was observed (Rao et al. 1985), compared to 66–80 % conversion in 7 days at 28 °C (Rao et al. 1983). The increased rates of alcohol production may be due to the faster sugar production from the cellulose by the increased cellulase activity of N. crassa at 37 °C (Deshpande et al. 1986). Temperatures higher than 37 °C seem unfavorable for alcohol production but favorable for cellulase activity. The rate-limiting step in the overall conversion of cellulose to ethanol appears to be the inability of N. crassa to produce ethanol at higher temperatures (Deshpande et al. 1986). Hence, the development of thermotolerant mutants of N. crassa with higher cellulase activity might increase the rate of fermentation of cellulose to ethanol.

Colvin et al. (1973) reported that ethanol yield from glucose fermentation by wild-type N. crassa 74Α8 is proportional to the initial glucose concentration. Initial glucose concentrations of up to 10 % were converted to ethanol without inhibition. However, the time for maximum ethanol accumulation depended on initial glucose concentration. Increasing the substrate concentration of treated bagasse from 2 % to 5 % (w/v) resulted in increased ethanol concentration, but lowered the conversion yields from 90 % to 75 % and prolonged fermentation by 2 days (Deshpande et al. 1986). Rao et al. (1985) also reported that increasing concentration of wood and straw from 2 % to 5 % (w/v) lowered the percentage conversion, although a higher concentration of ethanol was obtained. The decreased conversion of cellulose to ethanol at increased substrate concentrations may not be due to the product inhibition as N. crassa is able to ferment d-glucose and produce ethanol up to the level of 45 g/l (Rao et al. 1983). In order to obtain increased bioconversion of cellulose to ethanol at higher substrate concentrations, the amount of inoculum should be proportionately increased.

The work by Zhang et al. (2008) provided valuable insight on xylose metabolism of N. crassa under oxygen-limited conditions. By lowering oxygen levels, xylose uptake and cell growth rates decreased, and the metabolic fluxes of ethanol production changed gradually. Concentrations of most of the intracellular metabolites decreased with oxygen limitation. Intracellular enzyme activities of XR, XDH, and XK decreased with the increase in oxygen limitation, resulting in the decreased xylose uptake rate. Oxygen limitation activated pyruvate kinase (PK) in the downstream of glycolysis, converting phosphoenolpyruvate (PEP) to pyruvate. Oxygen limitation had little effect on transaldolase (TAL) and transketolase (TKL) activities (enzymes involved in pentose phosphate pathway), which were maintained at low levels, showing control effects on xylose metabolism. In addition, change in oxygen levels during N. crassa xylose fermentations seem to affect pyruvate decarboxylase (PDC) and ADH, enzymes involved in ethanol production. PDC decreased and ADH increased with the increase in oxygen limitation. The authors suggested that oxygen-limited rather than anaerobic conditions are ideal for bioconversion of xylose to ethanol by N. crassa, so that the accumulated reduced cofactor can be oxidized to reach redox balance. The requirement for low oxygen conditions for N. crassa lignocellulosic fermentations was also demonstrated by Xiros et al. (2008) on a hemicellulose-rich brewing by-product (BG). By slightly increasing the aeration levels in the submerged bioreactor, maximum ethanol concentration was doubled. Therefore, a critical level of oxygen should exist for the highest ethanol yield and productivity by N. crassa.

Depending on the pretreatment process of lignocellulosic biomass, some sugar degradation compounds such as furfural and 5-hydroxymethyl furfural (HMF) and aromatic lignin degradation compounds are detected, and may affect the microorganism metabolism in the fermentation step (Sánchez and Cardona 2008; Alvira et al. 2010). HMF and furfural decrease the volumetric ethanol yield and productivity, inhibit growth, or give rise to a longer lag phase (Almeida et al. 2007). More specifically, furfurals inhibit cellular enzymes such as ADH, aldehyde dehydrogenase (ALDH), pyruvate dehydrogenase (Modig et al. 2002), and two key glycolytic enzymes, hexokinase (HK) and glyceraldehyde-3-phosphate dehydrogenase (G3PDH) (Banerjee et al. 1981). In general, microorganisms appear to have the ability to convert both HMF and furfural to less inhibitory compounds, and inhibitory effects are therefore gradually reduced, as long as initial concentrations are not too high, but at the cost of cellular energy and co-factors, thus resulting in an increased lag phase (Palmqvist et al. 1999; Almeida et al. 2007, 2009). According to Olofsson et al. (2008), detoxification should be avoided if possible, due to additional process cost as well as possible loss of fermentable sugars. The effect of inhibitors formed during different pretreatment conditions of SB, on the fermentability by N. crassa DSM 1129, was evaluated in our previous work (Dogaris et al. 2012). Monitoring the time course of the bioconversion by N. crassa of dilute-acid pretreated SB showed that the ethanol production phase starts after the substantial decrease of inhibitor concentrations (HMF and furfural) in the fermentation broth. This pattern indicates that metabolic activity of the fungus N. crassa halts until furfural levels drop enough, either by assimilating or transforming the inhibitors into less toxic compounds, such as furfuryl alchohol and furoic acid (Eilers and Sussman 1970), after which, sugar metabolism to ethanol can occur. A similar phenomenon has also been observed on fermentations by S. cerevisiae (Almeida et al. 2007, 2009). In addition, the initial furfural concentrations seemed to account more for the observed lag phases than HMF or acetic acid (Dogaris et al. 2012). Specific toxicity levels have not been reported so far for N. crassa.

Industrial application potential

The yeast S. cerevisiae has been the preferred organism for industrial fermentative ethanol production but lacks the ability to utilize the pentose sugars xylose and arabinose. Therefore, most efforts have been made to obtain pentose-fermenting recombinant strains of bacteria and yeasts (Viikari et al. 2012). Despite the development of numerous industrial recombinant yeasts, genetically engineered microorganisms (GEMs) have not been used commercially for ethanol production (Chandel et al. 2011).On the other hand, the fungus N. crassa is able to both hydrolyze lignocellulose to its constituent hexose and pentose sugars and produce ethanol, but is fairly slow for competitive industrial processes. The majority of large-scale industrial fungal fermentations involve fed-batch mode cultivations with a high concentration of active biomass (Papagianni 2004). N. crassa has not been previously used for industrial scale fermentations, to the authors' best knowledge. Reported small (bench)-scale bioreactor growth of N. crassa includes biosynthesis of tyrosinase (Rajan and Virkar 1987), extracellular acid phosphatase production (Su and He 1997), and ethanol production from pretreated BG (Xiros et al. 2008). However, the strain N. sitophila has been cultured in a 1,300-l pilot-plant scale airlift fermenter in order to study oxygen transfer rates and gas holdups (Moo-Young et al. 1987). The authors reported that N. sitophila cultures exhibited highly non-Newtonian flow behavior coupled with a substantial decrease in oxygen transfer rates. The growing fungal hyphal elements tend to entangle, and therefore, many fungal fermentations suffer from the same problem—high viscosity of the fermentation broth that often leads to mass transfer limitations (Mcneil and Harvey 1993; Olsvik and Kristiansen 1994; Li et al. 2000). In mechanically agitated tank bioreactors, one frequently used method to overcome oxygen limitations is simply to increase impeller power. However, in addition to being energy intensive, this can also affect cells by changing their morphology or fragmentation behavior (Rajan and Virkar 1987; Li et al. 2000). One way to overcome this problem is to induce the fungus to grow as discrete spherical pellets. N. crassa has been reported to grow as pellets by the addition of trace amounts of Triton N-101 (ethoxylated nonyl phenol) for the biosynthesis of tyrosinase enzyme in low-shear, aerated airlift fermenters (Rajan and Virkar 1987). Su and He (1997) developed a continuous process for extracellular production of acid phosphatase in long-term pelletized N. crassa cultures based on the perfusion bioreactor technology. The authors reported that N. crassa pellets were successfully cultivated in the bioreactor for over 30 days.

In industry, application of immobilized cells during microbial fermentations is an important parameter for obtaining the required yields and economizing the process. A higher cell mass per unit fermentation volume can be achieved than with batch, continuous, or cell recycle system, resulting in a corresponding increase in ethanol production (Chandel et al. 2011). In addition, the risk of contamination is reduced due to fast dilution rates and high cell densities (Norton and D'Amore 1994). Ryan et al. (1998) have demonstrated the growth and development of a N. crassa biofilm on capillary membrane supports in a bioreactor. This immobilization of N. crassa biofilm allowed production of laccases for 4 months continuously, for the biodegradation of toxic phenolic pollutants (Luke and Burton 2001). Application of immobilization enables cell recycling, and both methods are advantageous when the process microorganism is either slow growing or strongly affected by product inhibition (Chandel et al. 2011). Therefore, N. crassa lignocellulosic fermentations could be improved by applying immobilized cell cultures, and the option of cell recycling should also be investigated.

Adaptation of microorganisms to lignocellulosic hydrolysates is another important parameter to improve ethanol yields (Hahn-Hägerdal et al. 1991). Lignocellulosic hydrolysates contain a variety of inhibitory products (furans, furfurals, and weak acids) along with the sugars. The formed inhibitors during dilute-acid pretreatment of SB induced extended lag time on N. crassa ethanol fermentation and therefore led to low productivity levels (Dogaris et al. 2012). Adaptation of the fermenting biocatalyst to the above hydrolysates prior to using them in fermentation of lignocellulosic hydrolysates has the potential to yield improved ethanol productivities (Parawira and Tekere 2011). Another important aspect of the adaptation of microorganisms is to get rid of detoxification step by saving the total cost incurred for ethanol production (Chandel et al. 2011).

Microbial contamination is a pervasive problem in any industrial fermentation process. These infections can at minimum affect the efficiency of the fermentation and at their worse lead to stuck fermentations causing plants to shut down for cleaning before beginning anew (Skinner and Leathers 2004). No matter the precautions taken, infections will occur and in all likelihood will be comprised of lactic acid bacteria and non-Saccharomyces yeast species (Beckner et al. 2011). Various approaches have been implemented to reduce contamination risk in industrial processes, such as equipment design and maintenance, operational procedures, validation/verification testing, medium selection, culture purity/sterility analysis, and contamination investigation (Junker et al. 2006). Specific cultivation factors decreasing the likelihood of contamination for a particular process include low or high pH outside the range of 5–8, low dissolved oxygen, presence of potent antibiotics or high solvent concentrations, and high or very low sugar concentrations (Junker et al. 2006). In general, the application of SSF process reduces the risk of contamination with external microflora due to the accumulation of ethanol in the fermenter and the rapid conversion of the formed glucose, which remains at low concentrations throughout the fermentation (Zaldivar et al. 2001; Lin and Tanaka 2006). Yeast cells are able to ferment sugars at low pH values, which minimize the contamination risk. The initial pH values generally employed for N. crassa cellulosic ethanol fermentations by various workers were within the range of 5.0–6.0 (Rao et al. 1983, 1985; Deshpande et al. 1986; Dogaris et al. 2009b, 2012; Xiros et al. 2008). Maximum ethanol production by N. crassa was found to be in the pH range of 5.0–6.0 (Deshpande et al. 1986). Production of all three components of N. crassa cellulose-degrading system was maximized at acidic pH values 4.0–5.0, and the optimum endoxylanase activity was observed at initial pH 4.0 (Dogaris et al. 2009b). Therefore, N. crassa fermentations should not be run on pH values lower than 5.0 for optimum hydrolysis and bioconversion. Further reduction of contamination risk in N. crassa fermentations should be focused on other process variables than pH, and the application of SSF appears advantageous for this purpose. According to Lynd et al. (2005), cellulose-adherent cellulolytic microorganisms are likely to successfully compete for products of cellulose hydrolysis with non-adhered microbes, including contaminants, which could increase the stability of industrial processes.

Conclusion

Microbial production of ethanol might be a potential route to partially replace oil and chemical feedstocks. Bioethanol production generally utilizes derivatives from food crops such as corn grain and sugarcane, but the limited supply of these crops can lead to competition between their use in bioethanol production and food provision.

Lignocellulosic biomass is the most promising feedstock considering its great availability and low cost, but the large-scale commercial production of fuel bioethanol from lignocellulosic materials has still not been implemented. Lignocellulosic biomass can be converted to bioethanol by hydrolysis and subsequent fermentation by microorganisms such as yeast or bacteria which have a limited range of substrate assimilation. Because such lignocellulosic hydrolysate contains not only glucose but also various monosaccharides (e.g., xylose, mannose, fructose, galactose, and arabinose) and oligosaccharides, microorganisms should be required to efficiently ferment these sugars for the successful industrial production of bioethanol.

Some fungal strains, particularly N. crassa, have been found to possess the ability of metabolizing a wide range of substrates, including cellulose and hemicelluloses, making it a promising candidate for bioethanol production from lignocellulosic biomass. However, no available Neurospora strain is completely satisfactory for an industrial process of lignocellulosic biomass to ethanol. The most limiting factor is the slow fermentation rate that needs further improvement. N. crassa fermentations could be improved by applying immobilized cell cultures, as well as adaptation to the lignocellulosic hydrolysates, and the option of cell recycling should also be investigated. Nevertheless, the abilities of N. crassa for single-step direct conversion of low-cost biopolymeric substrates and pentoses into ethanol as well as in situ production of cellulolytic and hemicellulolytic enzymes may have a significant impact on the production economics.

References

Agarwal AK (2008) Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust 33:233–271

Almeida JR, Modig T, Petersson A, Hahn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Almeida JRM, Bertilsson M, Gorwa-Grauslund MF, Gorsich S, Lidén G (2009) Metabolic effects of furaldehydes and impacts on biotechnological processes. Appl Microbiol Biotechnol 82(4):625–638

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Bae B, Sullivan RP, Zhao H, Nair SK (2010) Structure and engineering of L-arabinitol 4-dehydrogenase from Neurospora crassa. J Mol Biol 402:230–240

Baker CL, Loros JJ, Dunlap JC (2012) The circadian clock of Neurospora crassa. FEMS Microbiol Rev 36(1):95–110

Balat M, Balat H, Öz C (2008) Progress in bioethanol processing. Prog Energy Combust 34(5):551–573

Banerjee N, Bhatnagar R, Viswanathan L (1981) Inhibition of glycolysis by furfural in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 11:226–228

Beckner M, Ivey ML, Phister TG (2011) Microbial contamination of fuel ethanol fermentations. Lett Appl Microbiol 53:387–394

Borkovich KA, Alex LA, Yarden O, Freitag M, Turner GE, Read ND, Seiler S, Bell-Pedersen D, Paietta J, Plesovsky N, Plamann M, Goodrich-Tanrikulu M, Schulte U, Mannhaupt G, Nargang FE, Radford A, Selitrennikoff CP, Galagan JE, Dunlap JC, Loros JJ, Catcheside D, Inoue H, Aramayo R, Polymenis M, Selker EU, Sachs MS, Marzluf GA, Paulsen I, Davis RH, Ebbole DJ, Zelter A, Kalkman ER, O’Rourke R, Bowring F, Yeadon J, Ishii C, Suzuki K, Sakai W, Pratt RJ (2004) Lessons from the genome sequence of Neurospora crassa: tracing the path from genomic blueprint to multicellular organism. Microbiol Mol Biol Rev 68:1–108

Cardona CA, Sánchez OJ (2007) Fuel ethanol production: process design trends and integration opportunities. Bioresour Technol 98(12):2415–2457

Catalanotto C, Nolan T, Cogoni C (2006) Homology effects in Neurospora crassa. FEMS Microbiol Lett 254(2):182–189

Chambergo FS, Bonaccorsi ED, Ferreira AJ, Junior JR, Abrahao-Neto J, Farah JP, El-Dorry H (2002) Elucidation of the metabolic fate of glucose in the filamentous fungus Trichoderma reesei using expressed sequence tag (EST) analysis and cDNA microarray. J Biol Chem 277:13983–13988

Chandel AK, Chan ES, Rudravaram R, Narasu ML, Rao LV, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol Rev 2(1):14–32

Chandel AK, Chandrasekhar G, Radhika K, Ravinder R, Ravindra P (2011) Bioconversion of pentose sugars into ethanol: a review and future directions. Biotechnol Mol Biol Rev 6(1):008–020

Chandrakant P, Bisaria VS (1998) Simultaneous bioconversion of cellulose and hemicellulose to ethanol. Crit Rev Biotechnol 18:295–331

Chen CH, Ringelberg CS, Gross RH, Dunlap JC, Loros JJ (2009) Genome-wide analysis of light-inducible responses reveals hierarchical light signaling in Neurospora. EMBO J 28(8):1029–1042

Chiang C, Knight SG (1960) A new pathway of pentose metabolism. Biochem Biophys Res Commun 3:554–559

Colvin HJ, Sauer BL, Munkres KD (1973) Glucose utilization and ethanolic fermentation by wild type and extrachromosomal mutants of Neurospora crassa. J Bacteriol 116(3):1322–1328

Couto SR, Sanromán MA (2005) Application of solid-state fermentation to ligninolytic enzyme production. Biochem Eng J 22:211–219

Crepin VF, Faulds CB, Connerton IF (2003) A non-modular type B feruloyl esterase from Neurospora crassa exhibits concentration-dependent substrate inhibition. Biochem J 370:417–427

Crepin VF, Faulds CB, Connerton IF (2004) Identification of a type-D feruloyl esterase from Neurospora crassa. Appl Microbiol Biotechnol 63:567–570

Crosthwaite SK, Heintzen C (2010) Detection and response of the Neurospora crassa circadian clock to light and temperature. Fungal Biol Rev 24(3–4):114–122

Davis RH (2000) Neurospora: contributions of a model organism. Oxford University Press, New York

Davis RH, Perkins DD (2002) Neurospora: a model of model microbes. Nat Rev Genet 3:397–403

Demain AL (2009) Biosolutions to the energy problem. J Ind Microbiol Biotechnol 36:319–332

Deshpande V, Keskar S, Mishra C, Rao M (1986) Direct conversion of cellulose/hemicellulose to ethanol by Neurospora crassa. Enzyme Microb Technol 8(3):149–152

Dien BS, Cotta MA, Jeffries TW (2003) Bacteria engineered for fuel ethanol production: current status. Appl Microbiol Biotechnol 63:258–266

Dogaris I, Karapati S, Mamma D, Kalogeris E, Kekos D (2009a) Hydrothermal processing and enzymatic hydrolysis of sorghum bagasse for fermentable carbohydrates production. Bioresour Technol 100(24):6543–6549

Dogaris I, Vakontios G, Kalogeris E, Mamma D, Kekos D (2009b) Induction of cellulases and hemicellulases from Neurospora crassa under solid-state cultivation for bioconversion of sorghum bagasse into ethanol. Ind Crop Prod 29(2–3):404–411

Dogaris I, Gkounta O, Mamma D, Kekos D (2012) Bioconversion of dilute-acid pretreated sorghum bagasse to ethanol by Neurospora crassa. Appl Microbiol Biotechnol 95(2):541–550

Dunlap JC, Borkovich KA, Henn MR, Turner GE, Sachs MS, Glass NL, McCluskey K, Plamann M, Galagan JE, Birren BW, Weiss RL, Townsend JP, Loros JJ, Nelson MA, Lambreghts R, Colot HV, Park G, Collopy P, Ringelberg C, Crew C, Litvinkova L, DeCaprio D, Hood HM, Curilla S, Shi M, Crawford M, Koerhsen M, Montgomery P, Larson L, Pearson M, Kasuga T, Tian C, Baştürkmen M, Altamirano L, Xu J (2007) Enabling a community to dissect an organism: overview of the Neurospora functional genomics project. Adv Genet 57:49–96

Eberhart BM, Beck RS (1970) Localization of the β-glucosidases in Neurospora crassa. J Bacteriol 101:408–417

Eberhart BM, Beck RS (1973) Induction of β-glucosidase in Neurospora crassa. J Bacteriol 116:295–303

Eberhart BM, Cross DF, Chase LR (1964) β-Glucosidase system of Neurospora crassa. I. β-Glucosidase and cellulase activities of mutant and wildtype strains. J Bacteriol 87:761–770

Eberhart BM, Beck RS, Goolsby KM (1977) Cellulase of Neurospora crassa. J Bacteriol 130:181–186

Eilers FI, Sussman AS (1970) Conversion of furfural to furoic acid and furfuryl alcohol by Neurospora ascospores. Planta (Berl) 94:253–264

Eklund H, Ramaswamy S (2008) Medium- and short-chain dehydrogenase/reductase gene and protein families: three-dimensional structures of MDR alcohol dehydrogenases. Cell Mol Life Sci 65:3907–3917

Festel GW (2008) Biofuels—economic aspects. Chem Eng Technol 31(5):715–720

Flavell RB, Fincham JRS (1968) Acetate-nonutilizing mutants of Neurospora crassa. II. Biochemical deficiencies and the roles of certain enzymes. J Bacteriol 95:1063–1068

Galagan JE, Calvo SE, Borkovich KA, Selker EU, Read ND, Jaffe D, FitzHugh W, Ma LJ, Smirnov S, Purcell S, Rehman B, Elkins T, Engels R, Wang SG, Nielsen CB, Butler J, Endrizzi M, Qui DY, Ianakiev P, Pedersen DB, Nelson MA, Werner-Washburne M, Selitrennikoff CP, Kinsey JA, Braun EL, Zelter A, Schulte U, Kothe GO, Jedd G, Mewes W, Staben C, Marcotte E, Greenberg D, Roy A, Foley K, Naylor J, Stabge-Thomann N, Barrett R, Gnerre S, Kamal M, Kamvysselis M, Mauceli E, Bielke C, Rudd S, Frishman D, Krystofova S, Rasmussen C, Metzenberg RL, Perkins DD, Kroken S, Cogoni C, Macino G, Catcheside D, Li WX, Pratt RJ, Osmani SA, DeSouza CPC, Glass L, Orbach MJ, Berglund JA, Voelker R, Yarden O, Plamann M, Seller S, Dunlap J, Radford A, Aramayo R, Natvig DO, Alex LA, Mannhaupt G, Ebbole DJ, Freitag M, Paulsen I, Sachs MS, Lander ES, Nusbaum C, Birren B (2003) The genome sequence of the filamentous fungus Neurospora crassa. Nature 422:859–868

Gray KA, Zhao L, Emptage M (2006) Bioethanol. Curr Opin Chem Biol 10(2):141–146

Griffen DH (1994) Fungal physiology, 2nd edn. Wiley-Liss Inc., New York

Gusakov AV, Salanovich TN, Antonov AI, Ustinov BB, Okunev ON, Burlingame R (2007) Design of highly efficient cellulase mixtures for enzymatic hydrolysis of cellulose. Biotechnol Bioeng 97:1028–1038

Hahn-Hägerdal B, Linden T, Senac T, Skoog K (1991) Ethanolic fermentation of pentoses in lignocellulose hydrolyzates. Appl Biochem Biotechnol 28(29):131–144

Hahn-Hägerdal B, Jeppsson H, Skoog K, Prior BA (1994) Biochemistry and physiology of xylose fermentation by yeasts. Enzyme Microb Technol 16:933–943

Hahn-Hägerdal B, Galbe M, Gorwa-Grauslund MF, Liden G, Zacchi G (2006) Bioethanol-the fuel of tomorrow from the residues of today. Trends Biotechnol 24:549–556

Howell N, Zuiches CA, Munkres KD (1971) Mitochondrial biogenesis in Neurospora crassa. I. An ultrastructural and biochemical investigation of the effects of anaerobiosis and chloramphenicol inhibition. J Cell Biol 50:721–736

Jennings DH (1984) Polyol metabolism in fungi. Adv Microb Physiol 25:149–193

Johnson HN, DeBusk A (1970a) The beta-galactosidase system of Neurospora crassa. I. Purification and properties of the pH 4.2 enzyme. Arch Biochem Biophys 138(2):408–411

Johnson HN, DeBusk A (1970b) The beta-galactosidase system of Neurospora crassa. II. Extracellular nature of the pH 4.2 enzyme. Arch Biochem Biophys 138(2):412–417

Junker B, Lester M, Leporati J, Schmitt J, Kovatch M, Borysewicz S, Maciejak W, Seeley A, Hesse M, Connors N, Brix T, Creveling E, Salmon P (2006) Sustainable reduction of bioreactor contamination in an industrial fermentation pilot plant. J Biosci Bioeng 102(4):251–268

Kobr MJ, Bianchi DE, Oulevey N, Turian G (1967) The effect of oxygen tension on growth, conidiation, and alcohol production of Neurospora crassa. Can J Microbiol 13:805–817

Koh LP, Ghazoul J (2008) Biofuels, biodiversity, and people: understanding the conflicts and finding opportunities. Biol Conserv 141:2450–2460

Kritsky MS, Belozerskaya TA, Sokolovsky VY, Filippovich SY (2005) Photoreceptor apparatus of the fungus Neurospora crassa. Mol Biol 39(4):514–528

Kubicek CP, Messner R, Gruber F, Mach RL, Kubicek-Pranz EM (1993) The Trichoderma cellulase regulatory puzzle: from the interior life of a secretory fungus. Enzyme Microb Technol 15:90–99

Kumar R, Singh S, Singh OV (2008) Bioconversion of lignocellulosic biomass: biochemical and molecular perspectives. J Ind Microbiol Biotechnol 35(5):377–391

Landman OE (1954) Neurospora lactase. II. Enzyme formation in the standard strain. Arch Biochem Biophys 52(1):93–109

Landman OE, Bonner DM (1952) Neurospora lactase. I: Properties of lactase preparations from a lactose utilizing and a lactose non-utilizing strain. Arch Biochem Biophys 41(2):253–265

Lee J (1997) Biological conversion of lignocellulosic biomass to ethanol. J Biotechnol 56:1–24

Lee J-S, Parameswaran B, Lee J-P, Park S-C (2008) Recent developments of key technologies on cellulosic ethanol production. J Sci Ind Res 67:865–873

Li ZJ, Shukla V, Fordyce AP, Pedersen AG, Wenger KS, Marten MR (2000) Fungal morphology and fragmentation behavior in a fed-batch Aspergillus oryzae fermentation at the production scale. Biotechnol Bioeng 70:300–312

Lin Y, Tanaka S (2006) Ethanol fermentation from biomass resources: current state and prospects. Appl Microbiol Biotechnol 69:627–642

Luke AK, Burton SG (2001) A novel application for Neurospora crassa: progress from batch culture to a membrane bioreactor for the bioremediation of phenols. Enzyme Microb Technol 29:348–356

Lynd LR, Weimer PJ, van Zyl WH, McBride JE, Laser M (2005) Consolidated bioprocessing of cellulosic biomass: an update. Curr Opin Biotechnol 16:577–583

Macris BJ, Kekos D, Evangelidou X, Galiotou-Panayotou M, Rodis P (1987) Solid state fermentation of straw with Neurospora crassa for CMCase and β-glucosidase production. Biotechnol Lett 9(9):661–664

Macris BJ, Kekos D, Evangelidou X (1989) A simple and inexpensive method for cellulase and beta-glucosidase production by Neurospora crassa (Short Contribution). Appl Microbiol Biotechnol 31:150–151

Mahadevan PR, Eberhart BM (1964) The beta-glucosidase system of Neurospora crassa. II. Purification and characterization of aryl beta-glucosidase. Arch Biochem Biophys 108:22–29

Maheshwari R (1999) Microconidia of Neurospora crassa. Fungal Genet Biol 26:1–18

Mamma D, Kourtoglou E, Christakopoulos P (2008) Fungal multienzyme production on industrial by-products of the citrus-processing industry. Bioresour Technol 99(7):2373–2383

Mannhaupt G, Montrone C, Haase D, Mewes HW, Aign V, Hoheisel JD, Fartmann B, Nyakatura G, Kempken F, Maier J, Schulte U (2003) What's in the genome of a filamentous fungus? Analysis of the Neurospora genome sequence. Nucleic Acids Res 31:1944–1954

Margeot A, Hahn-Hägerdal B, Edlund M, Slade R, Monot F (2009) New improvements for lignocellulosic ethanol. Curr Opin Biotechnol 20:372–380

Matsushika A, Inoue H, Kodaki T, Sawayama S (2009) Ethanol production from xylose in engineered Saccharomyces cerevisiae strains: current state and perspectives. Appl Microbiol Biotechnol 84:37–53

Mcneil B, Harvey LM (1993) Viscous fermentation products. Crit Rev Biotechnol 13:275–304

Mishra C, Keskar S, Rao M (1984) Production and properties of extracellular endoxylanase from Neurospora crassa. Appl Environ Microbiol 48:224–228

Modig T, Lidén G, Taherzadeh MJ (2002) Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem J 363:769–776

Moo-Young M, Halard B, Allen G, Burrell R, Kawase Y (1987) Oxygen transfer to mycelial fermentation broths in an airlift fermentor. Biotechnol Bioeng 30:746–753

Myers MG, Eberhart B (1966) Regulation of cellulase and cellobiase in Neurospora crassa. Biochem Biophys Res Commun 24(5):782–785

Nair N, Zhao H (2007) Biochemical characterization of an L-xylulose reductase from Neurospora crassa. Appl Environ Microbiol 73(6):2001–2004

Norton S, D'Amore T (1994) Physiological effects of yeast cell immobilization: application for brewing. Enzyme Microb Technol 16:365–375

Okonko IO, Adeola OT, Aloysius FE, Damilola AO, Adewale OA (2009) Utilization of food wastes for sustainable development. Electron J Environ Agric Food Chem 8(4):263–286

Olofsson K, Bertilsson M, Lidén G (2008) A short review on SSF—an interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol Biofuel 1:7. doi:10.1186/1754-6834-1-7 (http://www.biotechnologyforbiofuels.com/content/1/1/7)

Olsvik E, Kristiansen B (1994) Rheology of filamentous fermentations. Biotechnol Adv 12:1–39

Palmqvist E, Almeida JS, Hahn-Hägerdal B (1999) Influence of furfural on anaerobic glycolytic kinetics of Saccharomyces cerevisiae in batch culture. Biotechnol Bioeng 62:447–454