Abstract

A closed-loop vertical tubular photobioreactor (PBR), specially designed to operate under conditions of scarce flat land availability and irregular solar irradiance conditions, was used to study the potential of Scenedesmus obliquus biomass/sugar production. The results obtained were compared to those from an open-raceway pond and a closed-bubble column. The influence of the type of light source and the regime (natural vs artificial and continuous vs light/dark cycles) on the growth of the microalga and the extent of the sugar accumulation was studied in both PBRs. The best type of reactor studied was a closed-loop PBR illuminated with natural light/dark cycles. In all the cases, the relationship between the nitrate depletion and the sugar accumulation was observed. The microalga Scenedesmus was cultivated for 53 days in a raceway pond (4,500 L) and accumulated a maximum sugar content of 29 % g/g. It was pre-treated for carrying out ethanol fermentation assays, and the highest ethanol concentration obtained in the hydrolysate fermented by Kluyveromyces marxianus was 11.7 g/L.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The promotion of ethanol use as a fuel in the last decades has been mostly driven by environmental concerns, oil prices and depletion of oil reserves as well as to reduce the dependency on oil. Microalgal biomass as a feedstock for bioethanol production seems to be a good alternative to sugar crops as it does not compete with food supplies, water or arable lands and has a very short harvesting cycle.

Bioethanol, an already well-established fuel mainly in Brazil and the USA (Goldemberg 2007), is usually obtained by alcoholic fermentation from starch (cereal grains, such as corn or wheat), sugar (sweet sorghum, sugar cane and sugar beet) and lignocellulosic feedstocks (Antolin et al. 2002).

Starch processing is a mature industry and commercial enzymes required for starch hydrolysis are widely used and available at low cost. The glucose released is readily metabolized by different strains of yeasts or bacteria, among which are Saccharomyces cerevisiae, the most common organism used for ethanol production, and Zymomonas mobilis, respectively (Drapcho et al. 2008). The ethanol is then extracted from the mixture and purified by distillation and dehydration.

Bioethanol from microalgal biomass can be produced through two distinct pathways: direct dark fermentation or yeast fermentation of saccharified biomass. The dark fermentation of microalgae consists of the anaerobic production of bioethanol by the microalgae itself through the consumption of intracellular starch. In spite of being a low-energy intensive process, the yields reported were 1 % g/g for Chlamydomonas reinhardii (Hirano et al. 1997) strain and 2.07 % g/g for Chlorococcum littorale (Ueno et al. 1998), values that do not make this process appealing to the industry.

The yeast fermentation process is very well-established industrially and a low-energy intensive process. Using algae raw material is strongly advantageous as algae sugars are not only obtained from intracellular starch but also from cell wall. Nevertheless, to achieve higher yields, it is still necessary to screen for high starch producing algae strains and to identify mechanisms and culture conditions for inducing the accumulation of intracellular starch.

The production of bioethanol from the fermentation of microalgal biomass presents the advantage of using whole biomass as well as microalgae residues from other processes (e.g. oil extraction).

Many authors have already found out that it is essential to introduce a pre-treatment stage to release and convert the complex carbohydrates entrapped in the cell wall into simple sugars necessary for yeast fermentation. The need for breaking down the complex sugars into simple ones, prior to the fermentation has also been corroborated by our previous studies with Scenedesmus obliquus (Miranda et al. 2012).

Matsumoto et al. (2003) have screened several strains of marine microalgae with high carbohydrate content and identified a total of 76 strains with a carbohydrate content ranging from 40 % to 53 % g/g. In spite of some microalgae having a high starch content (Table 1), and therefore a high potential for bioethanol production, which has been mentioned by many authors (e.g. Schenk et al. 2008), only some research (Rosenberg et al. 2008; Eshaq et al. 2010, 2011; Sulfahri et al. 2011) has been done on this subject. It has been estimated that approximately 46,760 to 140,290 L of ethanol/(ha year) can be produced from microalgae (Mussatto et al. 2010). This yield is several orders of magnitude higher than yields obtained from other feedstocks (Table 2).

Ueda et al. (1996) found that microalgae such as Chlorella, Dunaliella, Chlamydomonas, Scenedesmus and Spirulina contain large amounts (>50 % g/g) of starch and glycogen which are useful as raw materials for ethanol production. Hirano et al. (1997) conducted an experiment with Chlorella vulgaris microalga (37 % g/g of starch content) through fermentation and yielded a 65 % g/g ethanol-conversion rate, when compared to the theoretical conversion rate from starch. The microalgae Chlorococum sp. have also been studied as a feedstock for ethanol production (Harun et al. 2010).

For microalgal biomass production, the choice of the PBR is fundamental, and temperature, nutrients and light should be adequately controlled in the PBR. The light requirements of microalgae are one of the most important parameters to be addressed so that light can be provided at the appropriate intensity, duration and wavelength. Excessive intensity may lead to photo-oxidation and photo-inhibition, whereas low light levels will become growth limiting (Gouveia 2011).

In this work, a closed-loop vertical tubular photobioreactor (50 L of capacity; Sousa and Gouveia 2009) was used to study the potential of S. obliquus biomass/sugar production and compared to an open-raceway pond (4,500 L) and a PVC bubble column (40 L). The influence of the light source and regime (natural vs artificial and continuous vs light/dark cycles) on the growth of the microalgae S. obliquus was also evaluated. The evaluation of sugar content as well as nitrate depletion was assessed in all the cultures.

The biomass collected from the raceway pond was than treated with sulfuric acid in an autoclave and the hydrolysate was fermented by different yeasts in order to choose the best one for the fermentation of S. obliquus’ sugars.

Materials and methods

Microorganisms

The microalga used in this work was Scenedesmus obliquus (Sc) ACOI 204/07 from Coimbra University Algotec, Portugal. The yeasts used for the microalgae hydrolysate fermentation were Kluyveromyces marxianus IGC 2671, Saccharomyces carlsbergensis ATCC 6269 and Saccharomyces bayanus (industrial strain distributed by Institut Oenologique de Champagne and prepared by LALVIN (Canada) in the form of active dry granulated material).

Inocula

The microalga inocula for the photobioreactor assays were grown in a 1-L glass bubble column reactors (0.8 L Bristol medium, pH 7 (Starr and Zeikus 1987)), with bubbling filtered air, at a constant temperature of 25 ± 1 °C under low light (150 μ/(Em2s)).

Previous to inoculation of the fermentation assays, yeasts were grown in media containing yeast extract (5 g/L), ammonium sulfate (5 g/L), magnesium sulfate heptahydrate (1 g/L) and glucose (50 g/L) as a carbon source (pH = 5; T = 30 °C).

Microalga production—type of PBRs and light source

Two closed PBRs were used for microalgal biomass production:

-

a.

A closed-loop vertical tubular PVC photobioreactor (50 L capacity), with agitation/aeration by a ventury system and culture recirculation through a pump (Grundfos CH2-50 AA-cube) and a chiller used as a temperature control device (T = 24 °C; Sousa and Gouveia 2009; Fig. 1a). The study was performed outdoors under natural light with light/dark cycles (average radiation during the illumination time was 502.2 W/m2−14 h daily).

-

b.

A PVC bubble column photobioreactor (10 L capacity) illuminated continuously by artificial light (fluorescent lights Philips TL-D Food Pro 36 W/54–765; 400–700 nm) with agitation/aeration by a compressed air system (Fig. 1b).

The third PBR used for S. obliquus microalgae growth was an open-raceway pond of 4,500 L capacity and 48 m2, built in concrete covered with a canvas and agitated (Olimar V5CPDF2) by paddle wheels at approximately 5 m/min (linear speed; Fig. 1c). This raceway pond was inoculated with the biomass cultivated in three smaller raceway ponds (300 L capacity, 2 m2) and the assay was performed under natural light/dark cycles (average radiation during the illumination time was 382.8 W/m2−10.5 h daily; average air temperature was 16.9 °C (from 6.8 °C to 29.8 °C)).

All PBRs were inoculated with the same inoculum concentration of cells (initial biomass = 80 mg dw/L) and all of the experiments were performed at LNEG’s Lumiar Campus in the city of Lisbon, located on the western coast of Portugal (38º 42′ N, 9º 11′ W). Samples were taken whenever needed and analysed directly for pH and growth. Sugars and ion evaluations were carried out in the pellet and supernatant respectively obtained by centrifugation at 10,000 rpm and 4 °C for 15 min (Beckman, Avanti J25). Regarding the open-raceway pond experiments, the values obtained were corrected taking into account the pluviometric/evaporation data.

Microalgal biomass fermentation

The fermentation experiments were done with the biomass produced in the raceway pond and collected after 55 days as it allowed obtaining a higher biomass quantity for the fermentation assays.

Biomass harvesting and drying

The recovery of the microalgal biomass from the raceway pond was done by decantation prior to centrifugation at 10,000 rpm and 4 °C for 15 min. The concentrated biomass was dried in an oven at 80 °C until it reached a constant weight.

Sugar extraction

The extraction of sugars from S. obliquus dried biomass was performed as previously optimized (Miranda et al. 2012): by the addition of H2SO4 2 N (1 L to 500 g dw) and autoclaving for 30 min at 120 °C.

Hydrolysate detoxification

The high concentration of sulfate in the hydrolysate was reduced by precipitation with Ca(OH)2 (107 g/L). The process was slow and the removal efficiency was monitored by ion chromatography after sample filtration (cellulose acetate filters, ∅ 13 mm and 0.45 μm, Sartorius GmbH). Finally, the hydrolysate was centrifuged at 10,000 rpm for 15 min to separate the calcium sulfate precipitate; and subsequently, the pH was adjusted to 5.2 through the addition of phosphoric acid.

Fermentation

The assays were performed in 1-L erlenmeyer flasks provided with a rubber stopper and a needle and containing 500 mL of microalga hydrolysate which was inoculated with 300 mg dw/L of yeast. Three different yeast strains were used separately and the inoculated cells were harvested from glucose pre-cultures in the exponential phase and concentrated by centrifugation at 10,000 rpm for 7 min followed by washing with sterilized water. The fermentation experiments were carried out at 30 °C in an orbital shaker (150 rpm; G5, New Brunswick Scientific). Samples were taken whenever needed and centrifuged at 15,000 rpm for 10 min (CT 15E, Himac) prior to biomass, ethanol, sugars and other extraction products quantification.

Analytical determinations

Growth

Microalgal biomass growth was evaluated by measuring optical density (OD; 540 nm; Hitachi U-2000) and dry weight (dw; GF/C, 47 mm, Whatman) at 80 °C overnight. Regarding yeast growth, all OD measurements were made at 640 nm.

Total sugars and other extraction products

The total sugar content in the microalga samples was evaluated after sample hydrolysis. The centrifugation pellet was dried at 80 °C until it reached a constant weight and was then hydrolysed with H2SO4 2 N (5 mL to 0.5 g) in an autoclave for 30 min at 120 °C. The hydrolysate was then filtered (∅13 mm, 0.45 μm, Acrodisc GHP filters from Pall Life Sciences) and analysed by the phenol–sulfuric method (PS; Dubois et al. 1956). Samples from fermentation experiments were also quantified for total sugars directly after centrifugation.

The identification and quantification of sugar degradation products and acids were done by HPLC, with a LaChrom Merck (Darmstadt, Germany) system, with an Aminex HPX-87H column (Bio-Rad Laboratories) and refraction index detector. The column’s temperature was set to 50 °C and the volume of injection was 20 μL. The eluent consisted of a previously filtered solution of sulfuric acid 5 mM (0.5 m/min).

The monosaccharide analysis was carried out in the same device using a UV–VIS detector and an Aminex HPX-87P column (Bio-Rad Laboratories) kept at 85 °C. Millipore water was used as eluent at 0.6 mL/min.

Anions

The determination of chloride, nitrate, nitrite, phosphate and sulfate amounts during PBRs and detoxification experiments was performed in a Dionex ICS—1000 chromatograph equipped with an ASRS—ULTRA II suppressor, an AG14 A 4 × 50 mm pre-column, an IONPAC AS14 A 4 × 250 mm column and a conductivity detector. A fixed volume of 25 μL was injected in the eluent that consisted of a solution containing a mixture of sodium carbonate 8 mM and sodium bicarbonate 1 mM, previously filtered through hydrophilic polypropylene (47 mm, 0.2 μm), and degasified. The eluent flow was 1 mL/min.

Ethanol

The ethanol amount in the fermentation samples was evaluated by gas chromatography in a Hewlett-Packard 5890 device equipped with a flame ionization detector, on-column injector and a 2-m and 1/8″ diameter column (4 % Carbowax 20 M, 1 % trimesilic acid, 80–120 Carbopack BDA). The temperatures for injector, detector and oven were 150 °C, 200 °C and 110 °C, respectively. Helium was used as a carrier gas.

Results

Effect of light source and regime on microalgal growth and sugar production

Growth

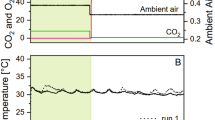

In Fig. 2, biomass growth, pH variation, nitrate consumption and biomass sugar content during the different experiments performed under natural light/dark cycles and artificial continuous light are depicted having the results regarding the raceway pond experiment been corrected taking into account rainfall dilution. This study revealed that the highest growth rate was obtained with artificial continuous illumination (Table 3); however, that observation did not correspond to the maximum biomass concentration which was obtained under natural light/dark cycles’ regime. In the raceway pond, the lowest growth rate values were detected, probably due to a higher exposure to daily climate changes, mainly to a broader temperature range.

Effect of PBR design and light cycle in pH change, nitrate consumption, sugars accumulation, and biomass production for different Scenedesmus obliquus cultures (closed-loop vertical PBR located outdoors (gray circle), vertical PVC PBR under continuous artificial light (white square) and raceway pond located outdoors (black triangle))

In all the cases, an alkalinisation of the media from pH 7.3 to 11 was observed until the highest sugar content was reached.

The cultures under light/dark cycles regime presented a different behaviour when compared to the one with continuous illumination. In the first case, a second exponential growth phase was observed, slower than the initial one (Fig. 2; Table 3). The highest biomass production was achieved in the open reactor although the real concentration detected in the pond was only 0.40 g/L as a result of rainfall dilution (Fig. 2).

Sugar content

In all the experiments, nitrate was observed to be the nutrient which was assimilated most by this microalga (Table 4). Besides nitrate, phosphate was the only macronutrient which was also consumed.

In the experiment with continuous light, the consumption of nitrate was slower (16 days to reach 1 mg/L than with day/night cycles in closed PBRs which may be due to the eventual difficulties of protein synthesis resulting from stress.

In spite of the different metabolic response, the depletion of nitrate was in all cases followed by an accumulation of sugars (Fig. 2). Only when the nitrate was totally consumed did the content of sugars begin to rise. For the culture in the closed-loop PBR with natural light/dark cycles, a maximum sugar content of approximately 24 % g eqglu/g dw was obtained, corresponding to a total sugar production in the PBR of 0.153 g eqglu /L after 22 days of cultivation (Table 3). Meanwhile in the continuously illuminated closed PBR, the cells achieved a higher sugar content (45 % g eqglu/g dw) 21 days after inoculation. Nevertheless, the overall sugar production (0.081 g eqglu/L) was heavily compromised by the very low cell dry weight at this point (0.18 g/L). In the raceway open pond, the maximum sugar content obtained was approximately 29 % g eqglu/g dw (0.225 g eqglu/L) corresponding to a cell dry weight of 0.76 g/L (0.32 g dw/L—really measured value corrected from rainfall dilution) at the end of 53 days.

Besides the accumulation of sugars related to nitrate depletion from the culture medium, further analysis of algae acid hydrolysates by HPLC at this point revealed an increase in the relative content of glucose to approximately 70 % g/g of all sugars (Fig. 3).

In the hydrolysates, monosaccharides were also identified other than glucose: galactose, mannose, arabinose and xylose. The second most abundant monosaccharide was mannose followed by galactose, xylose and arabinose.

Bioethanol production from S. obliquus microalgae biomass through yeast fermentation

The whole process of production of bioethanol was designed, from cultivation of biomass, biomass harvesting, downstream processing to release sugars, hydrolysate desulfurization, to the final step, the alcoholic fermentation.

The biomass used was exclusively harvested from the raceway pond after nitrate depletion and sugar accumulation (55 days; 29 % g eqglu/g dw; Fig. 2), as the high volume of the pond provided more biomass to carry more significant fermentation assays (500 mL) from the same biomass batch production. The harvested biomass was dried and the sugars were released by sulfuric acid using a biomass concentration of 500 g dw/L as previously optimised taking into account the goal of producing a fermentation media with a sugar concentration of around 100 g/L (Miranda et al. 2012). The hydrolysate was then detoxified by calcium sulfate precipitation with a 94 % efficiency of desulfurization and also promoting the removal/reduction of nitrate, phosphate and chloride (Table 5). To perform the fermentation assays, the algal extract pH was adjusted to 5.2 with phosphoric acid. This acid was chosen as phosphate is the anion that exerts lower inhibition effects over yeasts because phosphate is needed to produce metabolic ATP. The final concentration of phosphate in the hydrolysate was then 6.3 g/L.

The total sugar concentration present in the hydrolysate was 63.2 g eqglu/L when evaluated by the phenol–sulfuric method. This value represented a low efficiency of sugar extraction from the biomass as it contained 29 % g eqglu/g dw when the harvest started. This observation was corroborated by the HPLC determination of sugar monomers that showed a relative concentration of glucose of 56 % g/g (Table 6).

After desulfurization and pH adjustment, the hydrolysate was inoculated with yeasts. In this work, three yeast strains were used for the fermentation assays: K. marxianus YPCC 2671, S. carlsbergensis ATCC 6269 and S. bayanus (LALVIN).

The lowest ethanol concentration was produced by S. bayanus (9 g/L) while with K. marxianus and S. carlsbergensis higher values (11.7 and 11.2 g/L, respectively) were obtained (Fig. 4). These production levels were attained in less than 30 h and resulted from similar sugar consumption taking into consideration the total sugar variation. Nevertheless, the more specific HPLC analysis showed that the metabolised sugars were mainly simple sugars. As expected, these yeasts were capable to use hexoses (glucose and mannose) more easily then pentoses (arabinose and xylose) although S. carlsbergensis and K. marxianus seemed to be able to slightly remove xylose (26 % in 78 h; Fig. 5). Glucose and mannose were almost totally consumed in all the cases, but S. bayanus did not consume galactose while the other yeasts reduced galactose concentration to half the initial value.

Regarding more complex sugars, K. marxianus was the only one unable to degrade glucose dimers (cellobiose deriving from glucose and/or maltose deriving from starch; Fig. 5). The dimers removal occurred only after the monomers disappearance between the 30th and the 78th hour of process.

HPLC analysis also allowed for changes in the amounts of acetic acid, glycerol and hydroxymethylfurfural to be evaluated and these were quite similar for the three yeasts in all the assays. Hydroxymethylfurfural, formed during the acid saccharification process (Miranda et al. 2012), was consumed by all yeasts, but mainly by K. marxianus, reaching final concentrations of 0.5 g/L for S. bayanus and S. carlsbergensis and 0.3 for K. marxianus. On the contrary, and as expected because they are fermentation by-products, acetic acid and glycerol increased around 25 % (final glycerol concentration = 5.9–6.0 g/L; final acetic acid concentration = 2.7–2.8 g/L) as they were produced and released during the fermentation process. Regarding propionic and lactic acid concentrations in the fermented hydrolysate, no significant changes were detected.

As the assays were not strictly anaerobic, biomass growth besides ethanol production was also observed having attained concentration levels of 4.4, 5.0 and 5.3 g dw/L, respectively, for K. marxianus, S. bayanus and S. carlsbergensis (Fig. 4).

Discussion

Effect of light source and regime on microalgal growth and sugar production

The aim of this study was to define among the different PBRs and light conditions, which would be the better combination for S. obliquus microalgal biomass cultivation regarding its further use as a carbohydrate source for bioethanol production.

Culture agitation, air mixing and temperature control during the whole cultivation period are the main problems in actual PBRs, which lead to costly operational procedures. To compensate for daylight, day/night and seasonal variations maintaining an optimal temperature while operating outdoors, and to promote a good air/liquid mixing, a ventury system was installed in a closed-vertical tubular PBR (Sousa and Gouveia 2009; Fig 1a). In addition, microalgae growth is also strongly affected by light (source, intensity and regime), temperature, pH and medium composition (Olguin et al. 2001; Renaud et al. 2002). Light should be provided at the appropriate intensity, duration and wavelength (Gouveia 2011). Excessive intensity may lead to photo-oxidation and photo-inhibition, whereas low light levels may become growth limiting. So, in this work, the comparison of light source and regime (natural light/dark cycles vs artificial continuous) on the development of the cultures was evaluated for two column PBRs, one located outdoors and the other indoors.

The results of the closed PBRs under different light regimes are in agreement with those of Bouterfas et al. (2006), Foy and Gibson (1993) and Nicklish (1998). Bouterfas et al. (2006) observed that the growth rates of Selenastrum minutum, Coelastrum microporum f. astroidea and Cosmarium subprotumidum were higher when grown under a 15-h light regime.

Cultures under continuous light are often used because they achieve maximal growth rates as observed in this work. However, many authors suggest the use of light/dark cycles because this regime allows for either an increase in final biomass concentration and/or a reduction in production costs. The need for a cycle regime is explained by the photosynthesis being governed by two phases, a photochemical (I) that is light dependent and another, a biochemical dark (II) that is light independent. Compounds that are produced in the light dependent phase (ATP, NADPH) are used in the dark phase to synthesize metabolic molecules essential for growth. A dark phase remains therefore necessary at least for the regeneration of cofactors (NAD+, NADP+) required for phase I of photosynthesis (Bouterfas et al. 2006). Furthermore, some enzymes of the pentose cycle of photosynthesis and CO2 fixation are inactive during illumination (Laval and Mazliak 1995).

Dauta (1982) using a 15/9-h photoperiod cycle, and taking photographs every hour showed that cell division occurs under dark conditions for many unicellular Chlorophyceaen. Similarly, Dermoun (1987), working with a 16/8-h photoperiod, has shown for Porphyridium cruentum that cell division occurs in both, dark and light phases. However, it is preferable to use a photoperiod with a light phase between 12 and 15 h in order to allow an equilibrium to be established between the anabolic and catabolic phenomena during the photoperiod cycle (Bouterfas et al. 2006). Furthermore, for industrial applications and considering the ratio between the cost of energy and the corresponding biomass production, 12 to 15 h of light is generally considered as optimal for algae growth (Bouterfas et al. 2006).

Regarding the PBR type, many authors describe that in open-raceway ponds the growth efficiency is not as high as in closed PBRs, yielding lower biomass concentrations (Pulz 2001; Harun et al. 2010), mainly due to the lack of growth conditions control. On the contrary, in this work, the highest biomass production was achieved in the open reactor although the real maximum concentration detected in the pond was only 0.40 g/L as a result of rainfall dilution.

For S. obliquus, the fast consumption of nitrate and its accumulation as a protein by this microalga has already been described (Krauss and Thomas 1954). Nevertheless, when this macronutrient was depleted, the growth of the microorganism under natural light was not affected (Fig. 2). At this point, nitrogen may be released (in forms other than nitrate), becoming available for other cells and stimulating them to grow. This mechanism could explain the second growth phase detected in the day/night cycle experiments following the depletion of nitrate.

Following nitrate depletion was observed a sugar production increase. Brányiková et al. (2011) reported similar observations concerning sugar content variation along microalga growth. The sugar content of a microalgae culture is determined by two factors: the light intensity, which regulates the chloroplast starch synthesis and the starch consumption by other metabolisms, such as cellular division. According to these authors, the content of starch is highest prior to cell division, nevertheless during the course of division its cellular level rapidly decreases. To produce biomass with high starch content, it is necessary to suppress cell division events, but not to disturb the synthesis of starch in the chloroplasts.

Besides the accumulation of sugars related to nitrate depletion from the culture medium, an increase in the relative content of glucose to approximately 70 % g/g of all sugars was observed. This can be explained by the synthesis of glucose polysaccharides like starch as a response to nutrient deficiency. Starch has previously been described as a product of S. obliquus metabolism (Senger and Bishop 1979).

In the hydrolysates, other monosaccharides than glucose were also identified: galactose, mannose, arabinose and xylose. The second most abundant monosaccharide was mannose followed by galactose, xylose and arabinose. All of these monosaccharides have already been observed in this microalgae species by Takeda (1996) and result from cell wall polymer hydrolysis.

Bioethanol production from S. obliquus microalgae biomass through yeast fermentation

The total sugar concentration present in the hydrolysate was 63.2 g eqglu/L when evaluated by the phenol–sulfuric method. This value represented a low efficiency of sugar extraction from the biomass as it contained 29 % g eqglu/g dw when the harvest started. This fact was probably due to the time needed for decantation and drying of the biomass. Without access to CO2 and/or other nutrients, the biomass may have used the starch in the protoplasts as a carbon source to assure viability.

Besides sugar concentration, the hydrolysate composition obtained from 500 g dw/L of dried algae was quite similar to the one obtained in our previous studies performed to evaluate the effect of biomass concentration in the efficiency of acid hydrolysis (Miranda et al. 2012).

In this work, three yeast strains were used for the fermentation assays, being the K. marxianus the best producer of ethanol (11.7 g/L). Some studies have already been published using a strategy similar to the one tested in this work although with different algae. Harun et al. (2010) have produced a maximum of 7.2 g/L of ethanol after a hydrolysis step (1 % (v/v) of sulfuric acid; 140 °C; 30 min) with 15 g/L of microalgae Chlorococcum humicola. Nguyen et al. (2009) have also performed a study using Chlamydomonas reinhardtii dry cells (5 % (dw/v)) pre-treated with sulfuric acid (3 %; 110 °C; 30 min) whose hydrolysate generated an ethanol yield of 29.2 % g/g dw).

In this work, the final ethanol concentration was higher (11.7 g/L) due to the fact that saccharification was performed with a substantially higher algae concentration (500 g dw/L). However, the simple fermentable sugars’ extraction presented a low value (8.3 % g/g dw); and consequently, the ethanol production yield was also low 2.34 % (g/g dw). Only monomeric sugars were metabolised. During the fermentation process, the yeasts have also consumed the hydroxymethylfurfural generated in the acid hydrolysis step. This behaviour was already observed with other yeasts which presented the ability of metabolising hydroxymethylfurfural converting it into an alcohol derivative (Taherzadeh et al. 2000). Also, and as expected, because they are fermentation by-products, acetic acid and glycerol were released to the medium. Similar observations have already been reported by other authors with S. cerevisiae (Liu et al. 2004).

The microalga S. obliquus has been proving to be very versatile alga to be used as raw material for biofuels production (biodiesel, bioethanol and biohydrogen). This alga has been widely studied for biodiesel production, including by our group (Gouveia and Oliveira 2009; Silva et al. 2009; Mandal and Malick 2009; Ho et al. 2010, 2012; Tang et al. 2011). Scenedesmus was also proved, by many authors, to be a good source for hydrogen production (e.g. Yang et al. 2010, 2011; Choi et al. 2011). However, only a few works related this alga with bioethanol production, through alcoholic fermentation (Miranda et al. 2012).

As a conclusion of this study, the microalga S. obliquus has a high capacity to produce starch, envisaged to be promising for bio-ethanol production. The best type of reactor studied for promoting carbohydrate accumulation was the closed-loop PBR illuminated with natural light/dark cycles, which was obtained after nitrate depletion (153 mg/L after 22 days).

Acid pre-treatment was the best procedure to extract S. obliquus biomass’ sugars for fermentation as it enables starch and algal cell wall oligosaccharides to be released/hydrolysed with high efficiency. Fermentable simple sugars, mainly hexoses, were converted into 11.7 g/L of ethanol by the yeast K. marxianus. A detailed economic, environmental and energetic evaluation, using the best PBR and culture conditions determined in this study, is currently on-going.

References

Antolin G, Tinaut FV, Briceno Y, Castano V, Perez C, Ramirez AI (2002) Optimization of biodiesel production by sunflower oil transesterification. Bioresour Technol 83:111–114

Bouterfas R, Belkoura M, Dauta A (2006) The effects of irradiance and photoperiod on the growth rate of three freshwater green algae isolated from a eutrophic lake. Limnetica 25:647–656

Brányiková I, Marsálková B, Doucha J, Brányik T, Bisová K, Zachleder V, Vítová M (2011) Microalgae—novel highly efficient starch producers. Biotechnol Bioeng 108:766–776

Choi J-A, Hwang J-H, Dempsey BA, Abou-Shanab RAI, Min B, Song H, Lee DS, Kim JR, Cho Y, Hongi S, Jeon BH (2011) Enhancement of fermentative bioenergy (ethanol/hydrogen) production using ultrasonication of Scenedesmus obliquus YSW15 cultivated in swine wastewater effluent. Energ Environ Sci 4:3513–3520

Dauta A (1982) Conditions de développement du phytoplankton. Etude comparative du comportement de huit espèces en culture. Ann Limnol 18:217–226

Dermoun D (1987) Ecophysiologie de Porphyridium cruentum: validation expérimentale d’un modèle de croissance. Etude de la production de polysaccharide, PhD Dissertation, Université de Technologie de Compiègne, France, 211 p

Drapcho CM, Nhuan NP, Walker TH (2008) Biofuels engineering process technology. Mc Graw Hill, New York

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Eshaq FS, Ali MN, Mohd MK (2010) Spirogyra biomass a renewable source for biofuel (bioethanol) production. Int J Eng Sci Technol 2:7045–7054

Eshaq FS, Ali MN, Mohd MK (2011) Production of bioethanol from next generation feedstock alga Spirogyra species. Int J Eng Sci Technol 3:1749–1755

Foy RH, Gibson CE (1993) The influence of irradiance, photoperiod and temperature on the growth kinetic of three planktonic diatoms. Eur J Phycol 28:203–212

Goldemberg J (2007) Ethanol for a sustainable energy future. Science 315:808–810

Gouveia L (2011) Microalgae as a feedstock for biofuels. Springer Berlin Heidelberg Publisher, Berlin, pp 73

Gouveia L, Oliveira AC (2009) Microalgae as a raw material for biofuels production. J Ind Microbiol Biotechnol 36:269–274

Harun R, Danquah MK, Forde GM (2010) Microbial biomass as a fermentation feedstock for bioethanol production. J Chem Technol Biotechnol 85:199–203

Hirano A, Ryohei U, Shin H, Yasuyuki O (1997) CO2 fixation and ethanol production with microalgal photosynthesis and intracellular anaerobic fermentation. Energy 22:137–142

Ho SH, Chen WM, Chang JS (2010) Scenedesmus obliquus CNW-N as a potential candidate for CO2 mitigation and biodiesel production. Bioresour Technol 101:8725–8730

Ho SH, Chen CH, Chang JS (2012) Effect of light intensity and nitrogen starvation on CO2 fixation and lipid/carbohydrate production of an indigenous microalga Scenedesmus obliquus CNW-N. Bioresour Technol 113:244–252

Krauss RW, Thomas WH (1954) The growth and inorganic nutrition of Scenedesmus obliquus in mass culture. Plant Physiol 29:205–214

Laval D, Mazliak PM (1995) Nutrition et métabolisme (Physiologie végétale). Hermann (ed), Paris, 539 pp

Liu ZL, Slininger PJ, Dien BS, Berhow MA, Kurtzman CP, Gorsich SW (2004) Adaptive response of yeasts to furfural and 5-hydroxymethylfurfural and new chemical evidence for HMF conversion to 2,5-bis-hydroxymethylfuran. J Ind Microbiol Biotechnol 31:345–352

Mandal S, Malick N (2009) Microalga Scenedesmus obliquus as a potential source for biodiesel production. Appl Microbiol Biotechnol 84:281–291

Matsumoto M, Hiroko Y, Nobukazu S, Hiroshi O, Tadashi M (2003) Saccharification of marine microalgae using marine bacteria for ethanol production. Appl Biochem Biotechnol 105:247–254

Miranda J, Passarinho PC, Gouveia L (2012) Pre-treatment optimization of Scenedesmus obliquus biomass for bioethanol production. Bioresour Technol 104:342–348

Mussatto SI, Dragone G, Guimarães P, Silva JP, Carneiro LM, Roberto IC, Vicente A, Domingues L, Teixeira JA (2010) Technological trends, global market, and challenges of bio-ethanol production. Biotechnol Adv 28:817–830

Nguyen MT, Choi SP, Lee J, Lee JH, Sim SJ (2009) Hydrothermal acid pretreatment of Chlamydomonas reinhardtii biomass for ethanol production. J Microb Biotechnol 19:161–166

Nicklish A (1998) Growth and light absorption of some planktonic cyanobacteria, diatoms and chlorophyceae under simulated natural light fluctuations. J Plankton Res 20:105–119

Olguin EJ, Galicia S, Angulo-Guerrero O, Hernández E (2001) The effect of low light flux and nitrogen deficiency on the chemical composition of Spirulina sp. (Arthrospira) grown on digested pig waste. Bioresour Technol 77:19–24

Pulz O (2001) Photobioreactors: production systems for phototrophic microorganisms. Appl Microbiol Biotechnol 57:287–293

Renaud SM, Thinh LV, Lambrinidis G, Parry DL (2002) Effect of temperature on growth, chemical composition and fatty acid composition of tropical Australian microalgae grown in batch cultures. Aquacult 211:195–214

Rosenberg JN, Oyler GA, Wilkinson L, Betenbaugh MJ (2008) A green light for engineered algae: redirecting metabolism to fuel a biotechnology revolution. Biotechnol 19:430–436

Schenk PM, Skye R, Thomas-Hall Stephens E, Marx UC, Mussgnug JH, Posten C, Kruse O, Hankamer B (2008) Second generation biofuels: high-efficiency microalgae for biodiesel production. Bioenergy Res 1:20–43

Senger H, Bishop NI (1979) Observations on the photohydrogen producing activity during the synchronous cell cycle of Scenedesmus obliquus. Planta 145:53–62

Silva TL, Reis A, Medeiros R, Oliveira C, Gouveia L (2009) Oil production towards biofuel from autotrophic microalgae semi-continuous cultivations monitorized by flow cytometry. Appl Biochem Biotechnol 159:568–578

Sousa JM, Gouveia L (2009) Design and study of a thermo efficient closed-loop vertical photobioreactor for microalgae production. Proceedings of the MicroBiotec09 Conference. Vilamoura, Portugal

Starr RC, Zeikus JA (1987) UTEX-the culture collection of algae at the University of Texas at Austin. J Phycol 29:1–106

Sulfahri MS, Sunarto E, Irvansyah MY, Utami RS, Mangkoedihardjo S (2011) Ethanol production from algae Spirogyra with fermentation by Zymomonas mobilis and Saccharomyces cerevisiae. J Basic Appl Sci Res 1:589–593

Taherzadeh MJ, Gustafsson L, Niklasson C, Lidén G (2000) Physiological effects of 5-hydroxymethylfurfural on Saccharomyces cerevisiae. Appl Microbiol Biotechnol 53:701–708

Takeda H (1996) Cell wall sugars of some Scenedesmus species. Phytochem 42:673–675

Tang D, Han W, Li P, Miao X, Zhong J (2011) CO2 biofixation and fatty acid composition of Scenedesmus obliquus and Chlorella pyrenoidosa in response to different CO2 levels. Bioresour Technol 102:3071–3076

Ueda R, Hirayama S, Sugata K, Nakayama H (1996) Process for the production of ethanol from microalgae. US Patent 5:578,472

Ueno Y, Kurano N, Miyachi S (1998) Ethanol production by dark fermentation in the marine green alga Chlorococcum littorale. J Ferment Bioeng 86:38–43

Yang Z, Guo R, Xu X, Fan X, Li X (2010) Enhanced hydrogen production from lipid-extracted microalgal biomass residues through pretreatment. Int J Hydrogen Energy 35:9618–9623

Yang Z, Guo R, Xu X, Fan X, Luo S (2011) Fermentative hydrogen production from lipid-extracted microalgal biomass residues. Appl Energy 88:3468–3472

Acknowledgements

This work is part of a research project “Microalgae as a sustainable raw material for biofuels production (Biodiesel, Bioethanol, Bio-H2 And Biogas)” (PTDC/AAC-AMB/100354/2008) sponsored by the Portuguese Foundation for the Science and Technology (“Fundação para a Ciência e a Tecnologia”—FCT). The authors wish to thank Dr. Stephanie Seddon-Brown for the English revision and the reviewers for their valuable comments to improve the manuscript quality.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miranda, J.R., Passarinho, P.C. & Gouveia, L. Bioethanol production from Scenedesmus obliquus sugars: the influence of photobioreactors and culture conditions on biomass production. Appl Microbiol Biotechnol 96, 555–564 (2012). https://doi.org/10.1007/s00253-012-4338-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-012-4338-z