Abstract

Recently, we succeeded in isolating a thermotolerant bacterium, Pseudomonas sp. SG4502, which is capable of accumulating polyhydroxyalkanoate (PHA) even at 55 °C, as a source of thermostable enzymes. In this study, we cloned a pha locus from the bacterium and identified two genes encoding PHA synthases (PhaC1SG and PhaC2SG). Two mutations, Ser324Thr and Gln480Lys, corresponding to those of a lactate (LA)-polymerizing enzyme (LPE) from mesophilic Pseudomonas sp. 61-3 were introduced into PhaC1SG to evaluate the potential of the resulting protein as a “thermostable LPE”. The mutated PhaC1SG [PhaC1SG(STQK)] showed high thermal stability in synthesizing P(LA-co-3HB) in an in vitro reaction system under a range of high temperatures. Requirement of 3HBCoA as a priming unit for LA polymerization by the LPE has been suggested in both of the in vitro and in vivo experiments. Based on the finding, the PhaC1SG(STQK)-mediated synthesis of a LA-based copolymer with a block sequence was achieved in the in vitro system by sequential feeding of the corresponding two substrates. This in vitro reaction system using the thermostable LPE provides us with a versatile way to synthesize the various types of LA-based copolymers with desired sequence patterns, random or block, depending on the way of supplying hydroxyalkanoates (mixed or sequential feeding).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyhydroxyalkanoates (PHAs) are a class of aliphatic polyesters that are accumulated as carbon and energy storage materials in numerous bacteria under nutrient-limited conditions (Anderson and Dawes 1990; Lee 1996). The PHAs have attracted much attention because they have properties similar to those of common thermoplastics and can be produced from renewable resources (Jendrossek et al. 1996; Jendrossek and Handrick 2002). Because of their superior properties, PHAs are expected to be applicable to a wide range of agricultural, marine, and medical fields. PHA synthases are the key enzymes for PHA synthesis and produce PHA by polymerizing (R)-hydroxyalkanoyl moieties of (R)-hydroxyalkanoyl coenzymeAs (HACoAs) with concomitant release of CoA molecules (Rehm 2003; Taguchi and Doi 2004), and the types of repeating units incorporated into PHAs are mainly based on the substrate specificities of the PHA synthases employed. PHA synthases are divided into four classes (classes I to IV) on the basis of their activities toward substrates with different carbon chain lengths and their subunit compositions (Rehm 2003). PHAs are generally produced by in vivo methods using bacterial whole-cells, and in vivo methods are suitable for large-scale PHA production from renewable carbon sources. On the other hand, in vitro methods are not suitable for large-scale PHA production, but they have several attractive features, such as incorporation of the unnatural repeating units with controlled fractions and the ability to sensitively monitor this incorporation, which cannot be performed by in vivo methods. In particular, the reactivity and polymerization activity of PHA synthase toward unnatural substrates can be efficiently evaluated by in vitro methods (Han et al. 2011; Taguchi et al. 2008; Tajima et al. 2009) by measuring yield and molecular weight and analyzing the structure of a product.

Like PHA, polylactate (PLA) is also a bio-based polyester produced from biomass. PLA is the most popular biodegradable plastic and has been widely studied all over the world (Carrasco et al. 2010; Fukushima et al. 2009; Inkinen et al. 2011; Nampoothiri et al. 2010; Pang et al. 2010; Saulnier et al. 2004; Tsuji 2005). It is a very attractive material, but its application is limited in part due to its brittle properties, such as poor elongation, slow crystallization rate, and so on. One of the methods to improve the properties of PLA is copolymerization (Abe et al. 1997; Haynes et al. 2007) with another repeating unit. For example, Abe et al. (1997) and Haynes et al. (2007) reported the synthesis of copolymers containing LA and 3HA units by the ring-opening copolymerization of (S, S)-lactide with (R)-β-butyrolactone and by the ring-opening copolymerization of (S, S)-lactide using PHA as a macroinitiator. The synthesized copolymers had better properties than those of the PLA homopolymer (Abe et al. 1997; Haynes et al. 2007).

We recently developed a copolymerization method using an LA-polymerizing enzyme (LPE) (Taguchi et al. 2008; Tajima et al. 2009), which was engineered from the PHA synthase from Pseudomonas sp. 61-3 by evolutionary engineering (Matsumoto and Taguchi 2010; Taguchi and Doi 2004; Taguchi 2010). In other studies, we attempted to screen the LPE among various natural and mutant PHA synthases belonging to classes I to IV (Rehm 2003) by using a two-phase reaction system (Taguchi et al. 2008; Taguchi 2010; Tajima et al. 2009). As a result of these screenings, a double mutant [PhaC1Ps(STQK)] of PHA synthase from Pseudomonas sp. 61-3, which had two amino acids substitutions, Ser325Thr and Glu481Lys, was found to exhibit LA-polymerizing activity, and Escherichia coli carrying an LACoA supply pathway and this engineered enzyme produced LA-based polyesters (Taguchi et al. 2008; Tajima et al. 2009). To date, only class II PHA synthases from Pseudomonas species have been reported as LPEs (Matsumoto and Taguchi 2010; Taguchi et al. 2008; Tajima et al. 2009; Yamada et al. 2010; Yang et al. 2011), and active efforts to obtain superior LPEs capable of incorporating LA units with high ratios and of efficiently producing LA-based copolymers with high yields have been made throughout the world (Yamada et al. 2010; Yang et al. 2011).

Thermostable PHA synthesis enzymes are required in order to develop in vitro systems for sustainable, long-term reactions for producing PHA. However, the isolation of enzymes involved in PHA synthesis has been limited to mesophilic strains thus far. In our efforts to realize this goal, we very recently succeeded in isolating a thermotolerant bacterium, Pseudomonas sp. SG4502, which is capable of accumulating PHA even at 55 °C, as a potential source of thermostable enzymes (Satoh et al. 2011). This bacterium was able to grow between 30 °C and 55 °C and to synthesize polymers composed of various repeating units with 4 to 12 carbon atoms, suggesting that it could serve as a thermostable catalyst efficient in incorporating LA unit into the PHA chain. In this study, therefore, we attempted to clone and analyze PHA synthase genes from Pseudomonas sp. SG4502 and to evaluate the PHA synthase (PhaC1SG) as a thermostable catalyst. Furthermore, we have presented here the first in vitro synthesis of PHA containing LA unit with a block sequence by utilizing the LPE derivative with STQK mutation of the newly isolated PhaC1SG. This finding provides us with the attractive potentiality of the in vitro system equipped with thermostable PHA synthase in order to synthesize the various types of any copolymers with desired sequence patterns such as random or block sequence.

Materials and methods

Materials

Chloroform, methanol, adenosine triphosphate (ATP), and coenzymeA (CoA) were purchased from Wako Pure Chemical Industries (Osaka, Japan). (R)-LA lithium salt and (R)-3HB sodium salt were products of Sigma-Aldrich Japan (Tokyo, Japan) and MP Bio Japan K.K. (Tokyo, Japan), respectively. All other chemicals were of reagent grade or better.

Strains, plasmids, primers, and growth conditions

The strains, plasmids, and primers used in this study are shown in Table 1. E. coli was grown at 37 °C in Luria–Bertani (LB) medium. When needed, ampicillin (Ap, 100 μg mL−1) or kanamycin (Km, 25 μg mL−1) was added to medium. Pseudomonas SG4502 (NITE P-578) was grown at 45 °C in LB medium (Satoh et al. 2011).

Cloning of pha locus from Pseudomonas sp. SG4502

Two primers, ORF1_FW and phaD_RV (Table 1) (Zhang et al. 2001), were used to obtain a PHA operon from Pseudomonas sp. SG4502. DNA was amplified by two-step touchdown polymerase chain reaction (PCR) using genomic DNA from Pseudomonas sp. SG4502 as a template. Takara LA Taq polymerase (Takara Shuzo, Kyoto, Japan) was used as a DNA polymerase. The temperature protocol consisted of an initial 1-min denaturation at 94 °C, followed by 10 cycles of 94 °C for 30 s and 70 °C for 5 min, followed by 20 cycles of 94 °C for 30 s and 68 °C for 5 min, with a final elongation step of 68 °C for 10 min. The PCR product was ligated with a vector, pCR2.1-TOPO. The ligation mixture was used for the transformation of E. coli JM109 and then was plated onto LB agar plates with ampicillin, isopropylthiogalactoside, and 5-bromo-4-chloro-3-indolyl-β-d-galactoside. Approximately 2,000 white colonies with ampicillin resistance were obtained, and candidates for plasmid preparation were selected by confirming DNA insertion into a vector with colony-direct PCR using universal primers. A plasmid containing the PCR product was designated as pCR-phaSG.

Sequencing of a DNA fragment from Pseudomonas sp. SG4502

The plasmid, pCR-phaSG, was isolated from E. coli with a Quantum Prep Plasmid Midiprep Kit (Bio-Rad Laboratories, Hercules, CA, USA). The nucleotide sequence was determined by the dye-terminator method using an ABI PRISM Big-Dye Terminator Cycle Sequencing Ready Reaction Kit (Perkin Elmer, Wellesley, MA, USA) and an ABI PRISM 310 Genetic Analyzer (Perkin Elmer). Primer walking method was used for sequencing the DNA insert and specific primers were designed based on the results of sequencing.

Preparation and assay of AcoE, PCT, and PHA synthases

AcoE from Ralstonia eutropha (currently Cupriavidus necator) ATCC17699 (H16 strain) was used as acetyl-CoA synthetase (ACS) to form acetyl-CoA (AcCoA) (Priefert and Steinbüchel 1992). A gene encoding AcoE was amplified by PCR using a set of specific primers (Table 1), and then the amplified DNA fragment was introduced into pQE80 (Qiagen Japan K.K. Tokyo, Japan). Propionate CoA transferase (PCT) from Clostridium propionicum was employed for supplying LACoA and 3HBCoA to a PHA synthase. ACS and PCT were prepared according to the methods previously described (Han et al. 2009). Pseudomonas sp. 61-3 and SG4502 were used as sources of PHA synthases. The PHA synthases (PhaC1s) from Pseudomonas sp. 61-3 and Pseudomonas sp. SG4502 were described as PhaC1Ps and PhaC1SG, respectively. The reactivities of PHA synthase from Pseudomonas sp. 61-3 towards LACoA and 3HBCoA were acquired and increased, respectively, by the introduction of double mutations (Taguchi and Doi 2004; Taguchi et al. 2008; Tajima et al. 2009). A gene encoding PHA synthase with two mutations [PhaC1SG(STQK)], Ser324Thr and Gln480Lys, was chemically synthesized by GenScript USA Inc. (NJ, USA). The engineered PHA synthases, PhaC1Ps(STQK) from Pseudomonas sp. 61-3 and PhaC1SG(STQK) from Pseudomonas sp. SG4502, were prepared by using a His-tag system according to the method described in a previous paper (Satoh et al. 2003; Tajima et al. 2009). The activities towards (R, S)-3HBCoA of the purified enzymes were measured according to the methods described in previous papers (Han et al. 2009; Satoh et al. 2003; Tajima et al. 2004).

Thermal stability test

PHA synthase dissolved in 100 mM sodium phosphate buffer (pH 7.5) was maintained at 30 °C, 37 °C, 45 °C, and 55 °C for 10 min. Then other enzymes and reagents required for enzymatic synthesis of PHA (please refer next section) were added to a reaction mixture for PHA production. After incubation at 30 °C for 72 h, the formed polymer was purified and weighed.

The protein particle size was observed to evaluate thermal stability of PHA synthase (Golub et al. 2007). Four hundred microliters of PHA synthase (0.5 mg mL−1) dissolved in 100 mM sodium phosphate buffer (pH 7.5) was put into a sample cell kept at 37 °C. The time course change in a protein particle size at 37 °C was measured by the dynamic light scattering method using a particle size analyzer UPA-UT151 (Nikkiso Co., Ltd., Tokyo, Japan). The same experiment was conducted twice to confirm the reproducibility of the experiments.

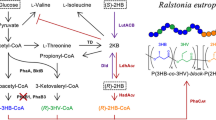

Enzymatic synthesis of P(LA-co-3HB) by an in vitro reaction system using an LPE

To evaluate PHA synthase as a thermostable LPE under conditions close to those of an in vivo production system (Matsumoto and Taguchi 2010; Taguchi et al. 2008; Taguchi 2010), we attempted to synthesize the P(LA-co-3HB) by employing an in vitro PHA synthesis system developed by R. Jossek and A. Steinbüchel (Fig. 1) (Jossek and Steinbüchel 1998). PHA synthesis using the in vitro reaction system was initiated by the addition of the purified PHA synthase [PhaC1Ps(STQK) or PhaC1SG(STQK): 0.5 mg mL−1] into a reaction mixture containing 100 mM sodium phosphate buffer (pH 7.5), total 200 mM substrates [(R)-LA and (R)-3HB], 10 mM acetate, 30 mM ATP, 2 mM CoA, 10 mM MgCl2, BSA (0.2 mg mL−1), pyrophosphatase (0.4 U), AcoE (0.2 mg mL−1), and PCT (0.2 mg mL−1). Reactions were performed in 5 mL of total volume at 30 °C, 37 °C, and 45 °C. After incubation for 72 h, 5 mL of chloroform was poured into the reaction tube. The chloroform and aqueous phases were mixed by a vortex mixer, and then the tube was incubated for 3 h at 70 °C to completely dissolve the product into the chloroform. After cooling the solution to room temperature, the chloroform (lower) phase was filtered through a 0.2-μm poly(tetrafluoroethylene) (PTFE) membrane to remove insoluble materials such as denatured enzymes, and then the filtrate was concentrated to approximately 1 mL using an evaporator. Ten milliliters of methanol was added, and then the solution was stored at 4 °C for 16 h to precipitate the polymer. The obtained precipitate was collected using a 0.2-μm PTFE membrane, and the dried powder was used for the analysis.

Measurements

The 1H NMR spectra of the polymers were obtained using a Bruker MSL400 spectrometer (400 MHz) at a 90° pulse with a 4-ms, 3,000-Hz spectral width and a 4-s repetition rate. The COSY spectrum was recorded in deuterated chloroform (CDCl3) at 25 °C using a Bruker MSL400 spectrometer (400 MHz) and the chemical shifts were reported in parts per million using tetramethylsilane (TMS) as an internal reference. The molar ratios of 3HB and LA units in copolymers were calculated from the ratios of the area of methine protons in 3HB units to that in LA units. The molecular weights of the obtained polymers were determined by gel-permeation chromatography (GPC) using tandem TSKgel Super HZM-H columns (6.0 mm I.D. × 150 mm; TOSOH, Tokyo) using chloroform as an eluate, and the calibration was performed using polystyrene samples as standards. The formation of CoA derivatives was confirmed HPLC analysis as previously described (Han et al. 2011; Satoh et al. 2003; Tajima et al. 2004).

Results

Cloning of the pha locus from Pseudomonas sp. SG4502

To date, class II pha gene loci have been cloned from several Pseudomonas strains, including P. stutzeri (Chen et al. 2004), P. mendocina (Hein et al. 2002), P. aeruginosa (Timm and Steinbüchel 1992), P. putida (Kim et al. 2003), and Pseudomonas sp. 61-3 (Matsusaki et al. 1998). In the pha loci, there are two PHA synthase genes (phaC1 and phaC2) and one PHA depolymerase gene (phaZ), which is located between phaC1 and phaC2. An expected gene fragment of about 5.2 kbp was obtained by PCR using genomic DNA of Pseudomonas sp. SG4502 as a template. A plasmid containing the 5.2 kbp DNA fragment was designated as pCR-phaSG. The nucleotide sequencing analysis of the inserted gene fragment revealed three ORFs of 1680 bp, 906 bp, and 1692 bp in length (accession no. AB448740). The polypeptides designated as PhaC1SG, PhaZSG, and PhaC2SG were composed of 559, 301, and 563 amino acid residues with molecular masses of 62.6 kDa, 33 kDa, and 63.0 kDa, respectively. A database search with the Protein BLAST program (http://blast.ncbi.nlm.nih.gov/Blast.cgi) for the ORFs showed that their amino acid sequences had high homology with those of PhaC1, PhaZ, and PhaC2 from Pseudomonas species (Chen et al. 2004; Hein et al. 2002; Kim et al. 2003; Matsusaki et al. 1998; Timm and Steinbüchel 1992) (Table 2). Figure 2 shows the partial sequence alignments of PhaC1s and PhaC2s from Pseudomonas strains. It has been reported that all PHA synthases contain a putative lipase box, [Gly − Xaa − (Ser/Cys) − Xaa − Gly − Gly], in which the essential active site serine is replaced with a cysteine in the PHA synthase (Rehm et al. 2002; Steinbüchel et al. 1992). In both PhaC1SG and PhaC2SG, the putative lipase boxes including a cysteine residue were also conserved (Fig. 2). Furthermore, Amara et al. have reported that the highly conserved Cys-296, Asp-452, and His-453 in PhaC1 from P. aeruginosa ATCC 15692 were considered to constitute the catalytic triad (Amara and Rehm 2003). Since these amino acids (Fig. 2: Cys-295, Asp-450, and His-451 for PhaC1SG; Cys-298, Asp-455, and His-456 for PhaC2SG) were conserved in the sequences deduced from phaC1 SG and phaC2 SG , they may constitute a catalytic triad in each PHA synthase.

Partial alignments of the deduced amino acid sequence of the PHA synthases from Pseudomonas sp. SG4502 (SG4502-C1, C2) with those from P. stutzeri (Pstu-C1, C2), P. mendocina (Pmen-C1, C2), P. aeruginosa PAO1 (Paer-C1, C2), P. putida (Pput-C1, C2), and Pseudomonas sp. 61-3 (Pseu613-C1, C2). PhaC1s and PhaC2s refer to PhaC1SG and PhaC2SG, respectively

Assay of PhaC1SG(STQK)

It has been reported that the reactivities of PHA synthase from Pseudomonas sp. 61-3 towards LACoA and 3HBCoA were acquired and increased, respectively, by the introduction of the double mutations (Taguchi and Doi 2004; Taguchi et al. 2008; Tajima et al. 2009). Therefore, the corresponding mutations, Ser324Thr and Gln480Lys, were introduced into PhaC1SG from Pseudomonas sp. SG4502 to make PhaC1SG(STQK). As expected, the reactivity of PhaC1SG(STQK) towards 3HBCoA was increased in the same manner as that of PhaC1Ps(STQK) (Table 3, Run 2) (Matsumoto et al. 2009; Taguchi and Doi 2004; Taguchi 2010). The specific activities of PhaC1SG(STQK) and PhaC1Ps(STQK) were examined at 30 °C, 37 °C, and 45 °C. The specific activity of PhaC1SG(STQK) at 45 °C reached almost four times that at 30 °C and was temperature dependent (Table 3, Runs 2−4). We also tried to measure the specific activity at 55 °C, but the substrate, 3HBCoA, decomposed at this high temperature. On the other hand, the specific activity of PhaC1Ps(STQK) decreased at 37 °C and was completely diminished at 45 °C (Table 3, Runs 5–7), probably because of the low thermal stability of PhaC1Ps(STQK).

Thermal stability of PhaC1SG(STQK)

To compare the thermal stabilities of PhaC1SG(STQK) and PhaC1Ps(STQK), polymers were synthesized by the in vitro reaction system (Fig. 1) after heat treatment at various temperatures for 10 min. The yields of polymers are shown in Fig. 3 as relative yields compared to those produced by PHA synthases treated at 30 °C. While the yields by PhaC1Ps(STQK) drastically decreased above 37 °C, the yields by PhaC1SG(STQK) were constant up to 45 °C, suggesting PhaC1SG(STQK) had a higher thermal stability than PhaC1Ps(STQK).

In addition, the time course changes in protein particle sizes of PhaC1SG(STQK) and PhaC1Ps(STQK) at 37 °C were also measured by the dynamic light scattering method as an index of the thermal stabilities of PHA synthases. The protein particle size of PhaC1Ps(STQK) rapidly increased and then decreased (Fig. 4). This drastic change in the particle size of PhaC1Ps(STQK) could be explained by the denaturation and aggregation of the protein molecules. In contrast, the particle size of PhaC1SG(STQK) remained virtually constant, suggesting that PhaC1SG(STQK) was more stable than PhaC1Ps(STQK). From these results, it was suggested that PhaC1SG(STQK) had higher thermal stability than that of PhaC1Ps(STQK) from a mesophilic Pseudomonas and could be used as a thermostable PHA synthase.

Enzymatic synthesis of P(LA-co-3HB) by an in vitro reaction system using PhaC1SG(STQK) or PhaC1Ps(STQK) as a catalyst

To analyze the potential of PhaC1SG(STQK) as a thermostable LPE, in vitro synthesis of P(LA-co-3HB) was performed at various temperatures. Before the in vitro synthesis, a reaction mixture without PHA synthase was prepared and then incubated at 30 °C to confirm the formation of (R)-LACoA and (R)-3HBCoA in the in vitro reaction system. HPLC analyses clearly showed the formations of (R)-3HBCoA and (R)-LACoA (data not shown). Then, PhaC1SG(STQK) or PhaC1Ps(STQK) was added to a reaction mixture containing 100 mM each (R)-LA and (R)-3HB as substrate precursors. The reaction mixtures became turbid after several hours, and precipitates formed in all the reaction mixtures. 1H NMR spectra and GPC analyses of the products confirmed the production of P(LA-co-3HB) by both PhaC1SG(STQK) and PhaC1Ps(STQK) (Table 4). The molar ratios of LA units in the polymers were around 65 mol% (Table 4, Runs 2, 3, 5, and 6), and the temperature-dependent LA incorporation ratios were not observed for either PhaC1SG(STQK) or PhaC1Ps(STQK). The yields of P(LA-co-3HB)s by PhaC1SG(STQK) were higher than those by PhaC1Ps(STQK) (Table 4, Runs 2, 3, 5, and 6). Whereas PhaC1SG(STQK) had the polymerizing activity at 45 °C (Table 3, Run 4), polymer was not obtained at 45 °C (Table 4, Run 4). Since ACS and PCT originated from mesophilic bacteria, therefore, this could be due to the denaturation of ACS and/or PCT during a reaction. From the results of the characterization and in vitro synthesis, PhaC1SG(STQK) and PhaC1Ps(STQK) would have similar reactivities towards LACoA and 3HBCoA.

Control of molar ratios of LA and 3HB units in polymers

In general, the physical properties of PHA vary with the repeating unit compositions in the polymers. It is easy to control the repeating unit composition in PHA in vitro, that is one advantage of in vitro PHA synthesis. To confirm the possibility of control in the repeating unit composition, (R)-LA and (R)-3HB were added to the reaction mixture at various molar ratios (LA/3HB—0:100, 50:50, 75:25, 90:10, and 100:0). The proton NMR spectra of the copolymers obtained from the reaction mixtures with PhaC1SG(STQK) are shown in Fig. 5. The intensities of methine (5.16 ppm) and methyl (1.59 ppm) proton peaks in LA-LA*-LA increased with the increase of LA fraction in the copolymers. The methine and methylene proton peaks (LA-3HB*-LA) were shifted to the low magnetic field side by the direct linkages with LA units. These data provide direct evidence for the increased concentration of LA repeating unit in the copolymers. The 3HB unit molar ratios in copolymers were calculated from the ratios of the area of methine protons in 3HB units to that in LA units. The repeating unit compositions, yields, and molecular weights of products synthesized by PhaC1SG(STQK) or PhaC1Ps(STQK) at various LA/3HB ratios are summarized in Table 5. The molar ratios of LA in the polymer increased with the increase of the (R)-LA concentration in the reaction mixture, suggesting that it is possible to control the repeating unit ratios in the polymers. The maximal molar ratios of LA in the polymers synthesized by the PhaC1Ps(STQK) and PhaC1SG(STQK) were 60 mol% (Table 5, Run 7) and 87 mol% (Table 5, Run 4), respectively. The yields of the polymers decreased with the increase in the ratio of (R)-LA (Table 5, Runs 1–4). In the experiment using only (R)-LA, the PLA homopolymer could not be synthesized (Table 5, Runs 5 and 10).

Synthesis of a copolymer with a block sequence by PhaC1SG(STQK) treated with 3HBCoA

Currently, the active polyester synthase has been suggested to form a homodimer considering class I and II polyester synthases (Rehm 2007), and dimerization of PHA synthase is significantly induced in the presence of substrate (Rehm et al. 2001) or trimeric CoA analogs (3-hydroxybutyryl)3CoA (Wodzinska et al. 1996), respectively. To date, complete LA-homopolymer has not been synthesized in our in vitro experiments, in which only LACoA was supplied to a LPE (Taguchi et al. 2008; Tajima et al. 2009). Therefore, synthesis of a polymer by PhaC1SG(STQK) treated with 3HBCoA was performed to confirm that a priming step by a favorable substrate such as 3HBCoA was necessary for LA polymerization by a LPE. PhaC1SG(STQK) was incubated with 1 mM (R)-3HBCoA for 9 h in 100 mM sodium phosphate buffer (pH 7.5). After the confirmation of a disappearance of (R)-3HBCoA by HPLC analysis, LA and other components (ATP and enzymes) were added into the reaction mixture. After additional incubation (total 72 h), a product was purified by the same method described in the “Materials and methods” section.

The proton NMR spectra of P(3HB), a chemically synthesized block copolymer P(3HB-b-LA), and a product obtained from a reaction mixture including PhaC1SG(STQK) pretreated with 3HBCoA are shown in Fig. 6. The proton NMR spectrum of the product obviously differs from that of P(LA-co-3HB) with a random sequence (Fig. 5b and c) and is the same with that of the chemically synthesized block copolymer (Fig. 6b). A unimodal peak was observed in the GPC chart of the product. In addition, no polymer was synthesized by PhaC1SG(STQK) untreated with 3HBCoA. The repeating unit composition and weight average molecular weight of the product were 3HB/LA = 30/70 and 2.7 ⋅ 105, respectively. Form these results, it was suggested that the product synthesized by PhaC1SG(STQK) treated by 3HBCoA was a copolymer with a block sequence.

Discussion

For efficient in vitro enzymatic production of PHA, the stability of an enzyme is essential because denaturation of the enzyme occurs during the course of the reaction. The thermal stability of the enzyme is a key factor. In general, the reaction rate increases depending on the reaction temperature. It is therefore significantly important to obtain thermostable enzyme for efficient enzymatic production with high yields. In this study, we have succeeded in cloning the genes encoding PHA synthases from the previously isolated thermotolerant bacterium Pseudomonas sp. SG4502, which was capable of producing PHA even at 55 °C (Satoh et al. 2011). Moreover, the thermal stability test of the recombinant enzyme clearly showed the high thermal stability. To date, various PHA synthases have been obtained from Pseudomonas species, but there have been no reports on a PHA synthase with high thermal stability. Therefore, this is the first report of a thermostable PHA synthase from Pseudomonas species.

At this stage, we have not addressed the exact reason why the PHA synthase of Pseudomonas sp. SG4502 is thermostable. As mentioned above, the result of the homology search using the BLAST program showed that PhaC1SG had high homology to PhaC1Ps (86% amino acid identity; Table 2). Therefore, we next compared the amino acid compositions of PhaC1SG and PhaC1Ps to reveal the reasons for the differences in their thermal stabilities. PhaC1SG has more hydrophobic residues, especially proline and leucine (Fig. 7). A plausible hydrophobic interaction formed by these amino acids could be effective to gain resistance against high temperature-induced protein denaturation. In addition, proline has also been reported to play crucial roles in the thermal stability because of its rigid structure (Watanabe et al. 1997). On the other hand, the numbers of cationic and anionic amino acids and cysteine residues were the same in both PHA synthases (PhaC1SG and PhaC1Ps), suggesting that electrostatic interactions and disulfide linkages are not related to the differences in thermal stability between PhaC1SG and PhaC1Ps.

Since the two amino acid substitutions, Ser325Thr and Gln481Lys, in a PHA synthase from Pseudomonas sp. 61-3 were previously demonstrated to gain reactivity towards LACoA and enhance reactivity towards 3HBCoA, the corresponding mutations were introduced into PhaC1SG to evaluate the potential of the resulting protein as a thermostable LPE. As expected, the reactivities of the thus constructed PhaC1SG(STQK) towards 3HBCoA and LACoA were increased and acquired, respectively, in the same manner as those of the PHA synthase from Pseudomonas sp. 61-3 (Tables 3 and 4). Since the repeating unit compositions in the polymers produced by PhaC1SG(STQK) and PhaC1Ps(STQK) were almost the same (Table 4), PhaC1SG(STQK) and PhaC1Ps(STQK) would have similar substrate specificities towards 3HBCoA and LACoA. Considering the high homologies between PhaC1SG and PhaC1Ps (Table 2), the alteration of the substrate specificity in PhaC1SG(STQK) could be due to conformational changes identical to those occurring in PhaC1Ps(STQK).

Very recently, Shozui et al. reported that a copolymer containing 96 mol% LA was produced in recombinant E. coli expressing PhaC1Ps(STQK) (Shozui et al. 2010a, b). However, in our in vitro study, the maximal molar ratios of LA in the polymers synthesized by the PhaC1Ps(STQK) and PhaC1SG(STQK) were up to 60 mol% (Table 5, Run 7) and 87 mol% (Table 5, Run 4), respectively. Since PhaC1SG(STQK) and PhaC1Ps(STQK) had similar substrate specificities towards 3HBCoA and LACoA, the higher production of P(87 mol% LA-co-3HB) by PhaC1SG(STQK) in the in vitro reaction system may have been due to the increase in the reaction rate with the reaction temperature elevation. Therefore, the increase in the reaction rate is essential for the high yield production of LA-enriched polymers, and the high thermal stability of PhaC1SG(STQK) could be a significantly useful feature as an LPE. Furthermore, LPEs are derived from class II PHA synthases that can polymerize various kinds of 3HAs. In fact, the in vivo synthesis of P[LA-co-3HB-co-3-hydroxyvalerate], P[LA-co-3HB-co-3-hydroxyhexanoate (3HHx)], and P[LA-co-3-hydroxyalkanoates (3HAs)] has been achieved by PhaC1Ps(STQK) (Matsumoto et al. 2011; Shozui et al. 2010a, b, 2011). For PhaC1SG, it has been confirmed that P. putida GPp104 expressing PhaC1SG was able to produce various PHAs, including 3HB, 3HHx, 3-hydroxyoctanoate, 3-hydroxydecanoate, and 3-hydroxydodecanoate (unpublished data), and it would be possible to synthesize various polyesters including LA by using PhaC1SG(STQK) as an LPE. Thus, the synthesis of various kinds of polyesters including LA is one of the advantages of the enzymatic synthesis using an LPE (Taguchi 2010), and more efficient enzymatic production will be achieved by using the thermostable LPE from Pseudomonas sp. SG4502.

However, to date, a polyester consisting of the complete 100 mol% LA (PLA) has not been produced by PhaC1SG(STQK) and PhaC1Ps(STQK) either in vitro or in vivo (Matsumoto and Taguchi 2010; Shozui et al. 2010a, b, 2011; Song et al. 2011; Taguchi et al. 2008; Tajima et al. 2009). Notably, the fact that a polymer was not produced an in vitro system that contained only LACoA without other HACoAs strongly suggests the necessity of coexistence of preferable substrates such as 3HBCoA in LA-based polyester production by LPEs. So far, copolymers containing 96 mol% LA and 99.3 mol% LA were produced in recombinant E. coli (Shozui et al. 2010a, b) and Corynebacterium glutamicum (Song et al. 2011) by using PhaC1Ps(STQK), respectively. As demonstrated in these bacterial systems, a small amount of an intrinsic HACoA exists within a cell; therefore, it may act as a priming molecule for the reaction of LPE in vivo also.

Currently, the trial synthesis of homopolymers and block copolymers has been attempted by using natural or artificially mutated bacterial strains (Hu et al. 2011; Penderson et al. 2006). In microbial polymer production system, however, finely regulated synthesis of the repeating units might be difficult because of a significant effect of metabolic background of the microbial cells. On the other hand, the in vitro polymerization system has a potential for generation of various copolymers finely incorporating unnatural repeating units with a block sequence. Considering the necessity of 3HBCoA for LA incorporation, we attempted to make LA-based copolymer with PhaC1SG(STQK) by supplying 3HBCoA as a primary substrate and followed by LACoA as a secondary substrate into the reaction system. Based on the identical NMR profiling with chemically synthesized P(3HB-b-LA), we have finally demonstrated the first synthesis of the block-type polymer containing LA (Fig. 6). For this achievement, requirement of 3HBCoA as a priming unit for LA incorporation into the polymer chain is very advantageous to prepare structurally finely regulated P(3HB-b-LA), while P(LA-b-3HB) generation seems to be not easy. Most recently, the in vitro system provided us with the first finding that 2-hydroxybutyrate can be incorporated into the polymer by class I PHA synthase from Ralstonia eutropha (Han et al. 2011) as well as LPE [PhaC1Ps(STQK)] (will be soon published elsewhere). Moreover, another unnatural 2-hydroxyalkanoate, glycolate, was found to be a repeating unit incorporated into the polymer chain using the same LPE (Matsumoto et al. 2011). To our knowledge, this is the first report to synthesize a copolymer with block sequence by an in vitro reaction system, and it will be possible to produce novel biopolyesters incorporating natural and unnatural repeating units with random or block sequences, depending on the way of supplying substrates.

In conclusion, we cloned a pha locus from thermotolerant Pseudomonas sp. SG4502 and revealed that the locus contained two genes encoding PHA synthases (PhaC1SG and PhaC2SG) to establish a PHA production system with long-term stability and high yield. The two amino acid substitutions, Ser324Thr and Gln480Lys, which were previously demonstrated to confer the reactivity towards LACoA with enhanced 3HBCoA reactivity in a PHA synthase from Pseudomonas sp. 61-3, were introduced to construct a mutated PHA synthase [PhaCSG(STQK)] (Ser324Thr/Gln480Lys). The enzyme also showed high activity even at 45 °C and was able to synthesize P(LA-co-3HB)s with high yields. The molar ratios of LA in the copolymers were controllable in the range of 0 to 87 mol%, and the yield and weight average molecular weight of P(80 mol% LA-co-3HB) were 0.70 g L−1 and 1.4 ⋅ 105, respectively. To date, although several mutated PHA synthases from mesophilic Pseudomonas species have been reported as LPEs (Matsumoto and Taguchi 2010; Taguchi et al. 2008; Taguchi 2010; Tajima et al. 2009; Yamada et al. 2010; Yang et al. 2011), there have been no reports of LPEs with high thermal stabilities. Therefore, PhaC1SG(STQK) is the first thermostable LPE. The P(LA-co-3HB) production at higher temperature (45 °C) could not be performed, probably because of the low thermal stabilities of the enzymes, ACS and PCT, employed for HACoAs supply; however, such production will be possible with thermostable ACSs and PCTs. Such studies of this line are now in progress and will be reported in the near future.

References

Abe H, Doi Y, Hori Y, Hagiwara T (1997) Physical properties and enzymatic degradability of copolymers of (R)-3-hydroxybutyric acid and (S, S)-lactide. Polymer 39:59–67

Amara AA, Rehm BHA (2003) Replacment of the catalytic nucleophile cysteine-296 by serine in class II polyhydroxyalkanoate synthase from Pseudomonas aeruginosa-mediated synthesis of a new polyester: indentification of catalytic residues. Biochem J 374:413–421

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Carrasco F, Pagès P, Gámez-Pérez J, Santana OO, Maspoch ML (2010) Processing of poly(lactic acid): characterization of chemical structure, thermal stability and mechanical properties. Polym Degrad Stab 95:116–125

Chen JY, Liu T, Zheng Z, Chen JC, Chen GQ (2004) Polyhydroxyalkanoate synthases PhaC1 and PhaC2 from Pseudomonas stutzeri 1317 had different substrate specificities. FEMS Microbiol Lett 234:231–237

Fukushima K, Abbate C, Tabuani D, Gennari M, Camino G (2009) Biodegradation of poly(lactic acid) and its nanocomposites. Polym Degrad Stab 94:1646–1655

Golub N, Meremyanin A, Markossian K, Eronina T, Chebotareva N, Asryants R, Muronets V, Kurganova B (2007) Evidence for the formation of start aggregates as an initial stage of protein aggregation. FEBS Lett 581:4223–4227

Han X, Satoh Y, Tajima K, Matsushima T, Munekata M (2009) Chemo-enzymatic synthesis of polyhydroxyalkanoate by an improved two-phase reaction system (TPRS). J Biosci Bioeng 108:517–523

Han X, Satoh Y, Satoh T, Matsumoto K, Kakuchi T, Taguchi S, Dairi T, Munekata M, Tajima K (2011) Chemo-enzymatic synthesis of polyhydroxyalkanoate (PHA) incorporating 2-hydroxybutyrate by wild-type class I PHA synthase from Ralstonia eutropha. Appl Microbiol Biotechnol 92:509–517

Haynes D, Abayasinghe NK, Harrison GM, Burg KJ, Smith DW Jr (2007) In situ copolyesters containing poly(L-lactide) and poly(hydroxyalkanoate) units. Biomacromolecules 8:1131–1137

Hein S, Paletta JR, Steinbüchel A (2002) Cloning, characterization and comparison of the Pseudomonas mendocina polyhydroxyalkanoate synthases PhaC1 and PhaC2. Appl Microbiol Biotechnol 58:229–236

Hu D, Chung AL, Wu LP, Zhang X, Chen JC, Chen GQ (2011) Biosynthesis and characterization of polyhydroxyalkanoate block copolymer P3HB-b-4HB. Biomacromolecules 12:3166–3173

Inkinen S, Hakkarainen M, Albertsson AC, Södergård A (2011) From lactic acid to poly(lactic acid) (PLA): characterization and analysis of PLA and its precursors. Biomacromolecules 12:523–532

Jendrossek D, Handrick R (2002) Microbial degradation of polyhydroxyalkanoates. Annu Rev Microbiol 56:403–432

Jendrossek D, Schirmer A, Schlegel HG (1996) Biodegradation of polyhydroxyalkanoic acids. Appl Microbiol Biotechnol 46:451–463

Jossek R, Steinbüchel A (1998) In vitro synthesis of poly(3-hydroxybutyric acid) by using an enzymatic coenzyme A recycling system. FEMS Microbiol Lett 168:319–324

Kim TK, Shin HD, Seo MC, Lee JN, Lee YH (2003) Molecular structure of PCR cloned PHA synthase genes of Pseudomonas putida KT2440 and its utilization for medium-chain-length polyhydroxyalkanoate production. J Microbiol Biotechnol 13:182–190

Lee SY (1996) Bacterial polyhydroxyalkanoates. Biotechnol Bioeng 49:1–14

Matsumoto K, Taguchi S (2010) Enzymatic and whole-cell synthesis of lactate-containing polyester: toward the complete biological production of polylactate. Appl Microbiol Biotechnol 85:921–932

Matsumoto K, Shozui F, Satoh Y, Tajima K, Munekata M, Taguchi S (2009) Kinetic analysis of engineered polyhydroxyalkanoate synthases with broad substrate specificity. Polym J 41:237–240

Matsumoto K, Ishiyama A, Sakai K, Shiba T, Taguchi S (2011) Biosynthesis of glycolate-based polyesters containing medium-chain-length 3-hydroxyalkanoates in recombinant Escherichia coli expressing engineered polyhydroxyalkanoate synthase. J Biotechnol 156:214–217

Matsusaki H, Manji S, Taguchi K, Kato M, Fukui T, Doi Y (1998) Cloning and molecular analysis of the poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyalkanoate) biosynthesis genes in Pseudomonas sp. strain 61-3. J Bacteriol 180:6459–6467

Nampoothiri KM, Nair NR, John RP (2010) An overview of the recent developments in polylactide (PLA) research. Bioresour Technol 101:8493–8501

Pang X, Zhuang X, Tang Z, Chen X (2010) Polylactic acid (PLA): research, development and industrialization. Biotechnol J 5:1125–1136

Penderson EN, McChalicher CWJ, Srienc F (2006) Bacterial synthesis of block copolymers. Biomacromolecules 7:1904–1911

Priefert H, Steinbüchel A (1992) Identification and molecular characterization of the acetyl coenzyme A synthetase gene (acoE) of Alcaligenes eutrophus. J Bacteriol 174(20):6590–6599

Rehm BHA (2003) Polyester synthases: natural catalysts for plastics. Biochem J 376:15–33

Rehm BHA (2007) Biogenesis of microbial polyhydroxyalkanoate granules: a platform technology for the production of tailor-made bioparticles. Curr Issues Mol Biol 9:41–62

Rehm BHA, Qi Q, Beermann BB, Hinz HJ, Steinbüchel A (2001) Matrix-assisted in vitro refolding of Pseudomonas aeruginosa class II polyhydroxyalkanoate synthase from inclusion bodies produced in recombinant Escherichia coli. Biochem J 358:263–268

Rehm BHA, Antonio RV, Spiekermann P, Amara AA, Steinbüchel A (2002) Molecular characterization of the poly(3-hydroxybutyrate) (PHB) synthase from Ralstonia eutropha: in vitro evolution, site-specific mutagenesis and development of a PHB synthase protein model. Biochim Biophys Acta 1594:178–190

Satoh Y, Tajima K, Tannai H, Munekata M (2003) Enzyme-catalyzed poly(3-hydroxybutyrate) synthesis from acetate with CoA recycling and NADPH regeneration in vitro. J Biosci Bioeng 95:335–341

Satoh Y, Tajima K, Nakamoto S, Han X, Matsushima T, Ohshima T, Kawano S, Erata T, Dairi T, Munekata M (2011) Isolation of a thermotolerant bacterium producing medium-chain-length polyhydroxyalkanoate. J Appl Microbiol 111:811–817

Saulnier B, Ponsart S, Coudane J, Garreau H, Vert M (2004) Lactic acid-based functionalized polymers via copolymerization and chemical modification. Macromol Biosci 15:232–237

Shozui F, Matsumoto K, Nakai T, Yamada M, Taguchi S (2010a) Biosynthesis of novel terpolymers poly(lactate-co-3-hydroxybutyrate-co-3-hydroxyvalerate)s in lactate-overproducing mutant Escherichia coli JW0885 by feeding propionate as a precursor of 3-hydroxyvalerate. Appl Microbiol Biotechnol 85:949–954

Shozui F, Matsumoto K, Motohashi R, Yamada M, Taguchi S (2010b) Establishment of a metabolic pathway to introduce the 3-hydroxyhexanoate unit into LA-based polyesters via a reverse reaction of β-oxidation in Escherichia coli LS5218. Polym Degrad Stab 95:1340–1344

Shozui F, Matsumoto K, Motohashi R, Sun J, Satoh T, Kakuchi T, Taguchi S (2011) Biosynthesis of a (LA)-based plyester with a 96 mol% LA fraction and its application to stereocomplex formation. Polym Degrad Stab 96:499–504

Song Y, Matsumoto K, Yamada M, Gohda A, Brigham CJ, Sinskey AJ, Taguchi S (2011) Engineered Corynebacterium glutamicum as an endotoxin-free platform strain for lactate- based polyester production. Appl Microbiol Biotechnol. doi:10.1007/s00253-011-3718-0

Steinbüchel A, Hustede E, Liebergesell M, Pieper U, Timm A, Valentin H (1992) Molecular basis for biosynthesis and accumulation of polyhydroxyalkanoic acids in bacteria. FEMS Microbiol Rev 9:217–230

Taguchi S (2010) Current advances in microbial cell factories for lactate-based polyesters driven by lactate-polymerizing enzymes: towards the further creation of new LA-based polyesters. Polym Degrad Stab 95:1421–1428

Taguchi S, Doi Y (2004) Evolution of polyhydroxyalkanoate (PHA) production system by “enzyme evolution”: successful case studies of directed evolution. Macromol Biosci 4:145–156

Taguchi S, Yamada M, Matsumoto K, Tajima K, Satoh Y, Munekata M, Ohno K, Kohda K, Shimamura T, Kambe H, Obata S (2008) A microbial factory for lactate-based polyesters using a lactate-polymerizing enzyme. Proc Natl Acad Sci U S A 105:17323–17327

Tajima K, Satoh Y, Nakazawa K, Tannai H, Erata T, Munekata M (2004) Chemoenzymatic synthesis of poly(3-hydroxybutyrate) in a water-organic solvent two-phase system. Macromolecules 37:4544–4546

Tajima K, Satoh Y, Satoh T, Itoh R, Han XR, Taguchi S, Kakuchi T, Munekata M (2009) Chemo-enzymatic synthesis of poly(lactate-co-(3-hydroxybutyrate)) by a lactate-polymerizing enzyme. Macromolecules 42:1985–1989

Timm A, Steinbüchel A (1992) Cloning and molecular analysis of the poly(3-hydroxyalkanoic acid) gene locus of Pseudomonas aeruginosa PAO1. Eur J Biochem 209:15–30

Tsuji H (2005) Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci 5:569–597

Watanabe K, Yasuo H, Kizaki H, Katsube Y, Suzuki Y (1997) The refined srystal structure of Bacillus cereus oligo-1,6-glucosidase at 2.0 Å thermostabilization. J Mol Biol 269:142–153

Wodzinska J, Snell K, Rhomberg A, Sinskey AJ, Biemann K, Stubbe J (1996) Polyhydroxybutyrate synthase: evidence for covalent catalysis. J Am Chem Soc 118:6319–6320

Yamada M, Matsumono K, Shimizu K, Uramoto S, Nakai T, Shozui F, Taguchi S (2010) Adjustable mutations in lactate (LA)-polymerizing enzyme for the microbial production of LA-based polyesters with tailor-made monomer composition. Biomacromolecules 11:815–819

Yang TH, Jung YK, Kang HO, Kim TW, Park SJ, Lee SY (2011) Tailor-made type II Pseudomonas PHA synthases and their use for the biosynthesis of polylactic acid and its copolymer in recombinant Escherichia coli. Appl Microbiol Biotechnol 90:603–614

Zhang G, Hang X, Green P, Ho KP, Chen GQ (2001) PCR cloning of type II polyhydroxyalkanoate biosynthesis genes from two Pseudomonas strains. FEMS Microbiol Lett 198:165–170

Acknowledgments

First of all, we would like to greatly thank Professor Tohru Dairi of Hokkaido University for his valuable comments on this paper. We thank Mr. Eiji Yamada of Hokkaido University for his technical support in NMR measurements. We also thank Dr. Tokuo Matsushima and Mr. Tetsuya Toriyabe for their technical assistance. This work was supported by a grant from the Global COE Program (Project No. B01: Catalysis as the Basis for Innovation in Materials Science) and by Grant-in-Aid for Scientific Research (No. 21310060 and 21760632) from the Ministry of Education, Culture, Sports, Science, and Technology, Japan. This work was partially supported by the Regional Innovation Cluster Program (Global Type) and by Northern Advancement Center for Science & Technology (NOASTEC).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Kenji Tajima and Xuerong Han contributed equally to this work.

Rights and permissions

About this article

Cite this article

Tajima, K., Han, X., Satoh, Y. et al. In vitro synthesis of polyhydroxyalkanoate (PHA) incorporating lactate (LA) with a block sequence by using a newly engineered thermostable PHA synthase from Pseudomonas sp. SG4502 with acquired LA-polymerizing activity. Appl Microbiol Biotechnol 94, 365–376 (2012). https://doi.org/10.1007/s00253-011-3840-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3840-z