Abstract

A previously established improved two-phase reaction system has been applied to analyze the substrate specificities and polymerization activities of polyhydroxyalkanoate (PHA) synthases. We first analyzed the substrate specificity of propionate coenzyme A (CoA) transferase and found that 2-hydroxybutyrate (2HB) was converted into its CoA derivative. Then, the synthesis of PHA incorporating 2HB was achieved by a wild-type class I PHA synthase from Ralstonia eutropha. The PHA synthase stereoselectively polymerized (R)-2HB, and the maximal molar ratio of 2HB in the polymer was 9 mol%. The yields and the molecular weights of the products were decreased with the increase of the (R)-2HB concentration in the reaction mixture. The weight-average molecular weight of the polymer incorporating 9 mol% 2HB was 1.00 × 105, and a unimodal peak with polydispersity of 3.1 was observed in the GPC chart. Thermal properties of the polymer incorporating 9 mol% 2HB were analyzed by DSC and TG-DTA. T g, T m, and T d (10%) were observed at −1.1°C, 158.8°C, and 252.7°C, respectively. In general, major components of PHAs are 3-hydroxyalkanoates, and only engineered class II PHA synthases have been reported as enzymes having the ability to polymerize HA with the hydroxyl group at C2 position. Thus, this is the first report to demonstrate that wild-type class I PHA synthase was able to polymerize 2HB.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyhydroxyalkanoates (PHAs) are a class of aliphatic polyesters that are accumulated as carbon and energy storage materials in numerous bacteria under nutrient-limited conditions (Chen 2009; Sudesh et al. 2000) and generally produced by in vivo methods using whole bacterial cells. The PHAs have attracted much attention because they have properties similar to those of common thermoplastics. They also have the advantages that they can be produced from renewable resources, such as sugars and plant oils, and degraded in the natural environment. However, the applications of poly(3-hydroxybutyrate) [P(3HB)], which is one of the most common PHAs produced in nature by bacteria, are limited because of its brittle and stiff properties. Copolymerization with other hydroxyalkanoate (HA) units is one of the effective methods to improve the physical properties of PHA; therefore, the syntheses of various copolymers have been attempted to date (Dai et al. 2008; Fukui et al. 1999; Han et al. 2009; Nomura et al. 2004; Page et al. 1992; Shozui et al. 2009; Tanadchangsaeng et al. 2009; Valentin et al. 2000a, b). However, it is still necessary to incorporate various HA monomers that may offer improved functional properties in order to expand the application range of PHA.

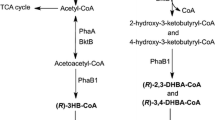

PHA synthases, which are the key enzymes for PHA biosynthesis, catalyze the polymerization reaction of (R)-hydroxyalkanoyl moieties in (R)-hydroxyalkanoyl coenzyme As (HACoAs) with concomitant release of CoA molecules (Rehm 2003; Taguchi and Doi 2004). The substrate specificity of the PHA synthases is the most important factor to determine the monomer structures that can be incorporated into PHAs and can be analyzed by both in vivo and in vitro PHA synthesis methods. For in vivo methods, the substrate specificity is estimated by analyzing the monomer composition accumulated in the cells. However, the structures of HACoAs supplied to PHA synthase are restricted by the metabolic pathways in the cells; therefore, it is too difficult to analyze the substrate specificities towards unnatural HAs of which have never been incorporated into PHA. On the other hand, in vitro methods have several attractive features such as incorporation of the unnatural monomer units with controlled monomer fractions and the sensitive monitoring of monomer incorporation, which cannot be performed by in vivo methods. In fact, we have succeeded in finding a lactate-polymerizing enzyme (LPE) for the first time from engineered PHA synthases by a water–organic solvent two-phase reaction system (TPRS) (Taguchi et al. 2008; Tajima et al. 2009). It means that the “first LPE” should be clearly found by the in vitro system, not the in vivo system. This finding of LPE could suggest that PHA synthases might be able to polymerize other 2-hydroxy monomers such as 2-hydroxybutyrate (2HB) and glycolate.

Recently, Tsuji et al. reported the pioneering works on physical properties and stereocomplex formation of chemically synthesized 2-hydroxybutyrate (2HB) homopolymer, as cited in Tsuji and Okumura (2009) and Tsuji et al. (2010). From these interesting findings on 2HB homopolymer, we challenged to create 2HB-incorporating polymers in the bioprocess. For this purpose, we attempted to find a 2HB-polymerizing enzyme from wild-type PHA synthases. First, we confirmed that 2HB was converted into its CoA derivative by propionate CoA transferase (PCT). Next, a representative of each class (I through IV; Rehm 2003) of wild-type PHA synthase was introduced into the improved TPRS (iTPRS) (Han et al. 2009), which has been developed on the basis of both in vitro PHA synthesis system with PCT (Valentin and Steinbüchel 1994; Jossek and Steinbüchel 1998) and the TPRS (Tajima et al. 2004), to analyze its substrate specificities and polymerization activities. As a result, we found that PHA synthase from Ralstonia eutropha (R. eutropha, currently Cupriavidus necator) had the potential to polymerize (R)-2HB. In general, major components of PHAs are 3-hydroxyalkanoates, and only one engineered class II PHA synthase, LPE, has been reported as an enzyme having the ability to polymerize HA with the hydroxyl group at C2 position (Taguchi et al. 2008; Tajima et al. 2009). Thus, this is the first report to demonstrate that wild-type class I PHA synthase was able to polymerize 2HB.

Materials and methods

Chemicals

Hexane, chloroform, ethyl acetate, dichloromethane, ethyl thioglycolate (ETG), dicyclohexyl carbodiimide, acetic acid, methanol, and CoA lithium salt were purchased from Wako Pure Chemical Industries (Osaka, Japan). (R)- and (S)-2HB and lithium (R)-lactate were products of Sigma–Aldrich Japan K.K. (Tokyo, Japan). (R)-3-hydroxybutyrate was obtained from MP Biomedicals Inc. (Solon, OH). All other chemicals were of reagent grade or better.

Preparation of PHA synthases and PCT

Class I PHA synthase (accession no. J05003) from R. eutropha (currently designated C. necator) H16 (ATCC17699), class II PHA synthase (accession no. AB448740) from Pseudomonas sp. SG4502 (NITE P-578), class III PHA synthase (accession no. BA000022) from Synechocystis sp. PCC6803, and class IV PHA synthase (accession no. AB077026) from Bacillus sp. INT005 (FERM-18327) were used as representative PHA synthases belonging to class I through IV (Rehm 2003). All PHA synthases and propionate CoA transferase (PCT) from Clostridium propionicum JCM1430 were respectively prepared according to the methods previously described (Han et al. 2009; Tajima et al. 2004).

Analysis of substrate specificity of PCT

To confirm the formation of HACoAs, each of the HAs (final concentration, 10 mM) was added to a reaction mixture (500 μl) containing 2 mM acetylCoA (AcCoA) and PCT (0.5 mg ml−1) in 100 mM sodium phosphate (pH 7.5). Then the reaction mixture was incubated for 3 h at 30°C under static conditions. The formation of CoA derivatives was confirmed by HPLC analysis as previously described (Satoh et al. 2003; Tajima et al. 2004).

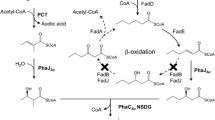

Chemo-enzymatic synthesis of PHA by using an iTPRS

Acetyl thioester of ethyl thioglycolate (AcETG) was prepared as previously described (Han et al. 2009). The water phase (5 ml) contained 100 mM sodium phosphate (pH 7.5), 2.0 mM CoA, 100 mM appropriate HAs, PCT (0.5 mg ml−1), and PHA synthase (0.5 mg ml−1) (Han et al. 2009). The water phase without PHA synthase was added to a test tube with a screw cap, and then hexane (500 μl) containing 1 M AcETG was gently poured into the tube to be stratified. The reaction was started by the addition of PHA synthase to the water phase (Fig. 1). The reaction mixture was incubated at 30°C under static conditions until the end of the reaction (for 72 h). The product was collected and purified as previously described (Tajima et al. 2004).

Measurements

The 1H nuclear magnetic resonance (NMR) spectra of the polymers were obtained using a Bruker MSL400 spectrometer (400 MHz) at a 90° pulse with a 4-ms, 3,000-Hz spectral width and a 4-s repetition rate. The correlation spectroscopy (COSY) spectrum was recorded in deuterated chloroform (CDCl3) at 25°C using a JEOL JNM-A400II instrument (400 MHz), and the chemical shifts reported in parts per million with tetramethylsilane (TMS) as the internal reference. The molecular weights of the obtained polymers were determined by gel-permeation chromatography (GPC) using tandem TSKgel Super HZM-H columns (6.0 mm I.D. × 150 mm; TOSOH, Tokyo) with chloroform as an eluent, and the calibration was performed using polystyrene samples as standards. Differential scanning calorimetry (DSC) data were recorded at temperatures ranging from −50°C to 220°C on a Bruker AXS DSC3100 under nitrogen flow rate of 100 ml min−1. The products were encapsulated in aluminum pans and heated from −50°C to 220°C at 10°C min−1 (first heating scan). The melted samples were then quenched to −50°C at −40°C min−1. They were also heated from −50°C to 220°C at 10°C min−1 (second heating scan). The glass-transition temperature (T g) was taken as midpoint on the heat capacity change. The melting temperature (T m) was determined from positions of the endothermic peaks. Thermal gravimetry-differential thermal analysis (TG-DTA) data were recorded at temperatures ranging from 50°C to +300°C on a Bruker AXS DSC3100 under nitrogen flow rate of 200 ml min−1.

Results

Substrate specificity of PCT

We previously succeeded in the synthesis of 3-hydroxybutyrylCoA (3HBCoA), 3-hydroxypropionylCoA (3HPCoA), and 3-mercaptopropionylCoA (3MPCoA) from corresponding HAs by using the iTPRS with PCT from C. propionicum (Han et al. 2009). The broad substrate specificity of the enzyme (Valentin and Steinbüchel 1994) suggested the possibility that CoA derivatives could be produced from free HA by the PCT. Therefore, we examined the substrate specificity of PCT towards (R)- or (S)-2HB, of which have never been incorporated into PHA either in vitro or in vivo to date and could be supplied via a metabolic pathway in a cell. 2HB was added to the reaction mixture including AcCoA and PCT, and then, the reaction mixture was incubated for an appropriate time at 30°C under static conditions. The formation of CoA derivatives was confirmed by HPLC analysis. As expected, new peaks were eluted at the same retention times as those of (R)- and (S)-2HBCoA when (R)- and (S)-2HB were used as the substrates, respectively (Fig. 2), suggesting that (R)- and (S)-2HB were converted to their CoA derivatives by PCT.

Chemo-enzymatic synthesis of PHA by using an iTPRS

Since the formation of 2HBCoA was suggested, we then examined whether (R)- and (S)-2HBCoA were incorporated into PHA by wild-type PHA synthases. Based on their primary structures and substrate specificities, PHA synthases have been divided into four classes, I to IV (Rehm 2003). In this study, we used representative PHA synthases belonging to the individual classes. In the iTPRS, the ability of enzymes to polymerize substrates can be easily judged by turbidity arising from polymer precipitation in the reaction mixture. However, the water phases were clear throughout the reaction with both (R)- and (S)-2HBCoA, suggesting that all the PHA synthases employed resulted in no polymerization of (R)- or (S)-2HBCoA when either was provided as the sole substrate.

Previously, we demonstrated that polymerization of an unnatural substrate (R)-LACoA by PHA synthase was progressed by the coexistence of a more preferable substrate (R)-3HBCoA (Taguchi et al. 2008; Tajima et al. 2009). In this study, therefore, we attempted to polymerize (R)-2HB in the presence of (R)-3HB. No product was obtained when class II PHA synthase was used. In contrast, the reaction mixtures gradually became turbid, and white precipitates appeared as the reaction progressed when class I, III, and IV PHA synthases were used. However, the products formed by classes III and IV PHA synthases were confirmed to be composed of only (R)-3HB by NMR analysis. On the other hand, 1H NMR analysis (Fig. 3) suggested that the product of class I PHA synthase from R. eutropha could have (R)-2HB units. In Fig. 3, the strong signals at 5.3, 2.6, and 1.3 ppm were assigned to the methine, methylene, and methyl protons of P(3HB), respectively. In addition to those peaks, small peaks were observed at 5.1, 2.0, and 1.0 ppm. The intensity ratio of these small peaks was 1:2:3, which was in good agreement with the ratio estimated from the structure of 2HB.

To determine the assignments for the 1H-peaks, the 2D NMR (COSY) chemical shift correlation was measured (Fig. 4). The peaks at around 2.6 ppm appeared to be the methylene protons in 3HB units, and the assignment of the methine proton and methyl protons in 3HB units could be determined by the correlation between methine and methylene protons and methyl and methine protons. Similarly, the peaks at around 5.1 ppm appeared to be the methine proton in 2HB units, and the assignment of the methylene and methyl protons in 2HB units could be determined by the correlation between methine and methylene protons and methylene and methyl protons. In addition, the chemical shift of these resonances was identical to that of chemically synthesized P(2HB) (Tsuji and Okumura 2009; Tsuji et al. 2011), and the chemical shift of methine proton peak (5.1 ppm) differed from that (4.3 ppm) of 2HB monomer. The NMR result showed that the 2HB peaks are not from residual unpolymerized 3HB monomers that may have been co-purified with the polymer. Based on the integration of the methine protons of these units, the monomer composition was estimated at 9 mol% 2HB. The copolymerization of (R)-LA with (R)-3HB was attempted under the same condition with PHA synthase from R. eutropha; however, the incorporation of (R)-LA into a polymer was not observed as reported in the previous paper (Tajima et al. 2009).

1H-1H chemical shift correlation NMR spectrum (COSY) of PHA incorporating 9 mol% 2HB (run 3) obtained from a reaction mixture containing (R)-3HB and (R)-2HB (1:1) as substrate precursors and PHA synthase from R. eutropha as a catalyst. CDCl3 and TMS were used as a solvent and an internal standard, respectively

The weight-average molecular weight of the PHA incorporating 9 mol% 2HB was 1.00 × 105 (Table 1, run3), and a unimodal peak with polydispersity of 3.1 was observed in the GPC chart (Fig. 5). Thermal properties of the polymer incorporating 9 mol% 2HB were analyzed by DSC and TG-DTA. T g, T m, and T d (10%) were observed at −1.1°C, 158.8°C, and 252.7°C, respectively, as shown in Figs. 6 and 7. A significant decrease in melting temperature was observed in comparison to that (176°C) of P(3HB), and the peaks for crystallization and melting were unimodal (Fig. 6). From these results, we concluded that the product was a PHA incorporating 2HB.

In general, PHA synthase has a high stereoselectivity and thereby polymerizes only (R)-HAs. No information on enzymatic stereoselectivity has been presented for 2HB enantiomeric monomer substrates. Thus, an experiment using a mixture of (R)-3HB and (S)-2HB as the substrate precursors was carried out, because we also succeeded in synthesizing (S)-2HBCoA by PCT as described above. In the 1H NMR spectrum of the product obtained from the reaction mixture, only peaks derived from P(3HB) were observed (Fig. 8). Considering that (S)-2HB was converted into the CoA derivative (Fig. 2), the PHA synthase from R. eutropha was perhaps unable to polymerize (S)-2HB.

Control of molar ratio of 2HB in polymer

In general, the physical properties of PHA vary with the monomer compositions in the polymers; therefore, it is significantly important to control the monomer composition in PHA. To examine whether the monomer composition in PHA could be varied by feeding of different ratios of the monomer substrates, (R)-2HB and (R)-3HB (0/100, 25/75, 50/50, 75/25, 100/0) were added to the reaction mixture. The monomer compositions and molecular weights of PHAs synthesized at various 2HB/3HB ratios are summarized in Table 1. The yields of the polymers decreased with the increase in the ratio of (R)-2HB–e.g., 1.90 g l−1 for 0/100 of 2HB/3HB (run 1), 0.64 g l−1 for 25/75 of 2HB/3HB (run 2), and 0.32 g l−1 for 50/50 of 2HB/3HB (run 3). In the case of 75/25 (run 4) and 100/0 (run 5) of 2HB/3HB, no polymer was synthesized. The polydispersity of the polymers was relatively high, and this could be due to the slow initiation step. The molar ratios of 2HB in the products increased with the increase of the (R)-2HB concentration in the reaction mixture, suggesting that it is possible to vary the monomer ratios in the polymers. However, only a portion of the (R)-2HB in the reaction mixture was used for PHA synthesis. To address the reason for this, the production rates of 3HBCoA and 2HBCoA in a reaction mixture including both (R)-3HB and (R)-2HB without PHA synthase were analyzed by HPLC. The production rates of 3HBCoA and 2HBCoA were 25 and 1.0 μmol min−1, respectively (Fig. 9). In addition, the yields and the molecular weights of the products were decreased with the increase of the (R)-2HB concentration in the reaction mixture (Table 1). Taking these results together, we concluded that the low production rate of 2HBCoA by PCT (Fig. 9) resulted in the low molar ratio of 2HB in the polymers. In addition, the low substrate specificity of PHA synthase towards 2HBCoA could be also one of the reasons.

Discussion

We have demonstrated that class I PHA synthase from R. eutropha had the potential to polymerize (R)-2HB and have succeeded in synthesizing PHA incorporating 2HB by using the iTPRS. To the best of our knowledge, this is the first report to provide direct evidence that PHA synthase was able to polymerize 2HB. The molar ratios of 2HB in the PHA incorporating 2HB were variable up to 9 mol% by controlling the ratio of (R)-3HB and (R)-2HB fed into the iTPRS. Recently, Tsuji et al. reported the formations and the thermal properties of P[(S)-2HB]]/P[(R)-2HB]] stereocomplex (Tsuji and Okumura 2009) and P[(S)-2HB]]/P[(R)-lactide] heterostereocomplex (Tsuji et al. 2010). Stereocomplexation of these polymers has become a novel versatile method for developing attractive polymer properties. In this regard, the enzymatically synthesized PHAs incorporating (R)-2HB as a monomer unit would be significantly important in the development of novel polymers.

In general, substrate specificity of PHA synthase is analyzed based on the amounts of the cleavage of a thioester linkage in HACoA (conventional in vitro assay system). Some researchers reported the substrate specificities of PHA synthase from R. eutropha examined by using the conventional in vitro assay system (Yuan et al. 2001; Zhang et al. 2001), however, in which the cleavage of thioester linkages occurred by both polymerization and hydrolysis of HACoA is simultaneously observed thereby make it difficult to explore the precise substrate specificity. In addition, CoA molecules released from HACoA with the progress of polymerization reaction are very effective competitive inhibitors of PHA synthase, and it is hard to obtain an adequate amount of polymers for various analyses such as NMR, GPC, DSC, and TG-DTA in the conventional method. In contrast, the iTPRS can recycle CoA molecules as HACoA and synthesize an adequate amount of polymers that allowed us to provide the direct evidence of the incorporation of an unnatural HA into PHA (Han et al. 2009). In addition, iTPRS is able to synthesize copolymers by adding two kinds of HAs (unnatural HA and preferable HA such as 3HB) that was essential to screen a PHA synthase with unnatural HA-polymerizing activity because the enzyme could require a preferable substrate such as 3HBCoA for the incorporation of an unnatural HA unit. By using the conventional in vitro assay system, Zhang et al. reported that PHA synthase from R. eutropha had relative reactivity of 1.4% for 2HBCoA in comparison with that for 3HBCoA (Zhang et al. 2001); however, the authors did not examine the formation of a polymer. Compared to this, we have succeeded in finding a PHA synthase with 2HB-polymerizing activity and in synthesizing an adequate amount of PHA incorporating 2HB by adding 3HB to the iTPRS including 2HB as an unnatural HA, indicating the usefulness of the iTPRS for exploring the substrate specificity and polymerization activity of PHA synthase toward unnatural HAs.

Since the PHA synthase from R. eutropha can produce homopolymers of 3-hydroxybutyrate (3HB), 3-hydroxypropionate (3HP), 4-hydroxybutyrate (4HB), and 3-hydroxyvalerate (3HV), it was expected that P(2HB) homopolymer will also be synthesized by the PHA synthase, considering the structural similarities among them. Although the production of P(2HB) homopolymer by the enzyme was not achieved by the iTPRS, PHA incorporating 2HB could be achieved by feeding (R)-3HB into the reaction mixture (Fig. 1). This strongly indicated that polymerization of an unnatural HA was progressed by the coexistence of a more preferable substrate, such as (R)-3HBCoA. This phenomenon was also observed in an engineered PHA synthase, LPE, capable of polymerizing an unnatural substrate, (R)-LACoA (Taguchi et al. 2008; Tajima et al. 2009), suggesting that the coexistence of a favorable substrate would be necessary in polymerizing unnatural HAs like 2HB. Namely, 3HB would serve as a priming unit at the initial step of polymerization, followed by incorporation of 2HB operated by R. eutropha PHA synthase, as observed for the case of incorporation of LA using LPE into PHA (Taguchi et al. 2008; Tajima et al. 2009). Considering this intrinsic property of PHA synthase, the synthesis of the complete homopolymers of 2HB, as contrastively described in the up to nearly 100% PLA reports (Taguchi 2010; Shozui et al. 2011) and the 100% PLA report (Yang et al, 2010) should be very carefully discussed.

In general, the monomer units incorporated in PHAs are HAs with the hydroxyl group at C3, and so far, there has been no report about polymer formation of LA, a typical HA with the hydroxyl group at C2 position. Thus, the exploration of PHA synthase, which is able to polymerize HAs with the hydroxyl group at C2 position, has been a challenging target. Using the in vitro PHA synthesis system, we reported the first PHA synthase (LPE) capable of polymerizing 2-hydroxypropionate (LA), which is an engineered class II enzyme (Taguchi et al. 2008; Tajima et al. 2009). Therefore, LPE has a potential to incorporate 2HB into the polymer like LA (unpublished data). Furthermore, Taguchi et al. have succeeded in creating several LPEs that enhanced incorporation of LA into PHA through function–structure relationship studies employing evolutionary enzyme engineering (Taguchi 2010; Yamada et al. 2010). To reinforce the enzymatic activity of the class I PHA synthase from R. eutropha toward 2HBCoA, this successful case study has prompted us to apply this engineering methodology to this target enzyme.

In the case of CoA transferase, PCT from C. propionicum successfully converted 2HB, 3HB, 3HP, and 3MP to the corresponding CoA derivatives. For the creation of new types of PHAs, it is significantly important to supply various HACoAs by CoA transferases with a wide range of substrate specificities. For example, CoA transferases from Clostridium aminobutyricum and Clostridium kluyveri preferred 4HB rather than 3HB as a substrate (Gerhardt et al. 2000; Scherf and Buckel 1991; Valentin et al. 2000a, b), and Escherichia coli expressing the 4HB CoA transferase from C. kluyveri and PHA synthase from R. eutropha produced PHA incorporating 4HB unit (Valentin et al. 2000a, b). In addition, it has been reported that AtoAD (Sramek and Frerman 1975) and YdiF (Rangarajan et al. 2005), both of which are CoA transferases of E. coli, showed broad substrate specificities for short-chain-length HAs. Thus, the iTPRS with these enzymes would expand the possibility to create new types of PHAs.

In conclusion, we have succeeded in synthesizing a new PHA incorporating 2HB by using the iTPRS with the PHA synthase from R. eutropha. Namely, 2HB has become a new member of the PHA family. A previous study showed that (R)-2HB was produced from 2-ketobutyrate, which exists as a metabolic intermediate in microbial cells, by d-lactate dehydrogenase from Lactobacillus plantarum (Taguchi and Ohta 1991). Therefore, introduction of this artificial (R)-2HB supply pathway, PCT, and the PHA synthase from R. eutropha into a host cell would enable us to produce a (R)-2HB-incorporating polymer in vivo. Such studies of this line are now in progress and will be reported in the near future.

References

Chen GQ (2009) A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem Soc Rev 38:2434–2446

Dai Y, Lambert L, Yuan Z, Keller J (2008) Characterisation of polyhydroxyalkanoate copolymers with controllable four-monomer composition. J Biotechnol 134:137–145

Fukui T, Yokomizo S, Kobayashi G, Doi Y (1999) Co-expression of polyhydroxyalkanoate synthase and (R)-enoyl-CoA hydratase genes of Aeromonas caviae establishes copolyester biosynthesis pathway in Escherichia coli. FEMS Microbiol Lett 170:69–75

Gerhardt A, Cinkaya I, Linder D, Huisman G, Buckel W (2000) Fermentation of 4-aminobutyrate by Clostridium aminobutyricum: cloning of two genes involved in the formation and dehydration of 4-hydroxybutyryl-CoA. Arch Microbiol 174(3):189–199

Han XR, Satoh Y, Tajima K, Matsushima T, Munekata M (2009) Chemo-enzymatic synthesis of polyhydroxyalkanoate by an improved two-phase reaction system (iTPRS). J Biosci Bioeng 108(6):517–523

Jossek R, Steinbüchel A (1998) In vitro synthesis of poly(3-hydroxybutyric acid) by using an enzymatic coenzyme A recycling system. FEMS Microbiol Lett 168(2):319–324

Nomura CT, Taguchi K, Taguchi S, Doi Y (2004) Coexpression of genetically engineered 3-ketoacyl-ACP synthase III (fabH) and polyhydroxyalkanoate synthase (phaC) genes leads to short-chain-length-medium-chain-length polyhydroxyalkanoate copolymer production from glucose in Escherichia coli JM109. Appl Environ Microbiol 70(2):999–1007

Page WJ, Manchak J, Rudy B (1992) Formation of poly(hydroxybutyrate-co-hydroxyvalerate) by Azotobacter vinelandii UWD. Appl Environ Microbiol 58:2866–2873

Rangarajan ES, Li Y, Ajamian E, Iannuzzi P, Kernaghan SD, Fraser ME, Cygler M, Matte A (2005) Crystallographic trapping of the glutamyl-CoA thioester intermediate of family I CoA transferases. J Biol Chem 280(52):42919–42928

Rehm BHA (2003) Polyester synthases: natural catalysts for plastics. Biochem J 376:15–33

Satoh Y, Tajima K, Tannai H, Munekata M (2003) Enzyme-catalyzed poly(3-hydroxybutyrate) synthesis from acetate with CoA recycling and NADPH regeneration in vitro. J Biosci Bioeng 95(4):335–341

Scherf U, Buckel W (1991) Purification and properties of 4-hydroxybutyrate coenzyme A transferase from Clostridium aminobutyricum. Appl Environ Microbiol 57(9):2699–2702

Shozui F, Matsumoto K, Sasaki T, Taguchi S (2009) Engineering of polyhydroxyalkanoate synthase by Ser477X/Gln481X saturation mutagenesis for efficient production of 3-hydroxybutyrate-based copolyesters. Appl Microbiol Biotechnol 84:1117–1124

Shozui F, Matsumoto K, Motohashi R, Sun J, Satoh T, Kakuchi T, Taguchi S (2011) Biosynthesis of a (LA)-based plyester with a 96 mol% LA fraction and its application to stereocomples formation. Polym Degrad Stab 96:499–504

Sramek SJ, Frerman FE (1975) Purification and properties of Escherichia coli coenzyme A-transferase. Arch Biochem Biophys 171(1):14–26

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci 25:1503–1555

Taguchi S (2010) Current advances in microbial cell factories for lactate-based polyesters driven by lactate-polymerizing enzymes: towards the further creation of new LA-based polyesters. Polym Degrad Stab 95:1421–1428

Taguchi S, Doi Y (2004) Evolution of polyhydroxyalkanoate (PHA) production system by “enzyme evolution”: successful case studies of directed evolution. Macromol Biosci 4(3):146–156

Taguchi H, Ohta T (1991) D-lactate dehydrogenase is a member of the D-isomer-specific 2-hydroxyacid dehydrogenase family. Cloning, sequencing, and expression in Escherichia coli of the D-lactate dehydrogenase gene of Lactobacillus plantarum. J Biol Chem 266(19):12588–12594

Taguchi S, Yamada M, Matsumoto K, Tajima K, Satoh Y, Munekata M, Ohno K, Kohda K, Shimamura T, Kambe H, Obata S (2008) A microbial factory for lactate-based polyesters using a lactate-polymerizing enzyme. Proc Natl Acad Sci USA 105(45):17323–17327

Tajima K, Satoh Y, Nakazawa K, Tannai H, Erata T, Munekata M, Kamachi M, Lenz RW (2004) Chemoenzymatic synthesis of poly(3-hydroxybutyrate) in a water-organic solvent two-phase system. Macromolecules 37(12):4544–4546

Tajima K, Satoh Y, Satoh T, Itoh R, Han XR, Taguchi S, Kakuchi T, Munekata M (2009) Chemo-enzymatic synthesis of poly(lactate-co-(3-hydroxybutyrate)) by a lactate-polymerizing enzyme. Macromolecules 42(6):1985–1989

Tanadchangsaeng N, Kitagawa A, Yamamoto T, Abe H, Tsuge T (2009) Identification, biosynthesis, and characterization of polyhydroxyalkanoate copolymer consisting of 3-hydroxybutyrate and 3-hydroxy-4-methylvalerate. Biomacromolecules 10(10):2866–2874

Tsuji H, Okumura A (2009) Stereocomplex formation between enantiomeric substituted poly(lactide)s: blends of poly[(S)-2-hydroxybutyrate] and poly[(R)-2-hydroxybutyrate]. Macromolecules 42(19):7263–7266

Tsuji H, Yamamoto S, Okumura A, Sugiura Y (2010) Heterostereocomplexation between biodegradable and optically active polyesters as a versatile preparation method for biodegradable materials. Biomacromolecules 11(1):252–258

Tsuji H, Shimizu K, Okumura A (2011) Hetero-stereocomplex formation of stereoblock copolymer of substituted and non-substituted poly(lactide)s. Polymer 52:1318–1325

Valentin HE, Steinbüchel A (1994) Application of enzymatically synthesized short-chain-length hydroxy fatty acid coenzyme A thioesters for assay of polyhydroxyalkanoic acid synthases. Appl Microbiol Biotechnol 40:699–709

Valentin HE, Reiser S, Gruys KJ (2000a) Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) formation from gamma-aminobutyrate and glutamate. Biotechnol Bioeng 67(3):291–299

Valentin HE, Mitsky TA, Mahadeo DA, Tran M, Gruys KJ (2000b) Application of a propionyl coenzyme A synthetase for poly(3-hydroxypropionate-co-3-hydroxybutyrate) accumulation in recombinant Escherichia coli. Appl Environ Microbiol 66(12):5253–5258

Yamada M, Matsumono K, Shimizu K, Uramoto S, Nakai T, Shozui F, Taguchi S (2010) Adjustable mutations in lactate (LA)-polymerizing enzyme for the microbial production of LA-based polyesters with tailor-made monomer composition. Biomacromolecules 11(3):815–819

Yang TH, Kim TW, Kang HO, Lee SH, Lee EJ, Lim SC, Oh SO, Song AJ, Park SJ, Lee SY (2010) Biosynthesis of polylactic acid and its copolymers using evolved propionate CoA transferase and PHA synthase. Biotechnol Bioeng 105(1):150–160

Yuan W, Jia Y, Tian J, Snell KD, Müh U, Sinskey AJ, Lambalot RH, Walsh CT, Stubbe J (2001) Class I and III polyhydroxyalkanoate synthases from Ralstonia eutropha and Allochromatium vinosum: characterization and substrate specificity studies. Arch Biochem Biophys 394(1):87–98

Zhang S, Kamachi M, Takagi Y, Lenz RW, Goodwin S (2001) Comparative study of the relationship between monomer structure and reactivity for two polyhydroxyalkanoate synthases. Appl Microbiol Biotechnol 56:131–136

Acknowledgments

We thank Dr. Hideto Tsuji of Toyohashi University of technology for the useful comments on this paper. We also thank Mr. Eiji Yamada of Hokkaido University for his technical support with NMR measurements and Dr. Tokuo Matsushima and Mr. Tetsuya Toriyabe for their technical support. This work was supported by the 2003 Industrial Technology Research Grant Program from the New Energy and Industrial Technology Development Organization (NEDO) of Japan, by the Global COE Program (Project No. B01: Catalysis as the Basis for Innovation in Materials Science), and by Grants-in-Aid for Scientific Research (Nos. 21310060 and 21760632) and a research grant from Grant-in-Aid for Scientific Research on Priority Areas from the Ministry of Education, Culture, Sports, Science, and Technology, Japan. This work was partially supported by the Regional Innovation Cluster Program (Global Type).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Xuerong Han and Yasuharu Satoh contributed equally to this work.

Rights and permissions

About this article

Cite this article

Han, X., Satoh, Y., Satoh, T. et al. Chemo-enzymatic synthesis of polyhydroxyalkanoate (PHA) incorporating 2-hydroxybutyrate by wild-type class I PHA synthase from Ralstonia eutropha . Appl Microbiol Biotechnol 92, 509–517 (2011). https://doi.org/10.1007/s00253-011-3362-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3362-8