Abstract

In Bacteria, the pathways of polyamine biosynthesis start with the amino acids l-lysine, l-ornithine, l-arginine, or l-aspartic acid. Some of these polyamines are of special interest due to their use in the production of engineering plastics (e.g., polyamides) or as curing agents in polymer applications. At present, the polyamines for industrial use are mainly synthesized on chemical routes. However, since a commercial market for polyamines as well as an industry for the fermentative production of amino acid exist, and since bacterial strains overproducing the polyamine precursors l-lysine, l-ornithine, and l-arginine are known, it was envisioned to engineer these amino acid-producing strains for polyamine production. Only recently, researchers have investigated the potential of amino acid-producing strains of Corynebacterium glutamicum and Escherichia coli for polyamine production. This mini-review illustrates the current knowledge of polyamine metabolism in Bacteria, including anabolism, catabolism, uptake, and excretion. The recent advances in engineering the industrial model bacteria C. glutamicum and E. coli for efficient production of the most promising polyamines, putrescine (1,4-diaminobutane), and cadaverine (1,5-diaminopentane), are discussed in more detail.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

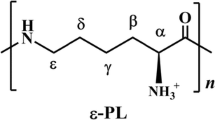

Alkaline organic compounds with an aliphatic, saturated carbon backbone, at least two primary amino groups, and a varying number of secondary amino groups are referred to as polyamines (Fig. 1). They are present in virtually every living cell and it has been shown that they can modulate diverse cellular processes, including transcription and translation, possibly due to their positive charge distribution at physiological pH (Wallace et al. 2003). However, a detailed understanding of the mechanisms remains unclear. Various additional functions of bacterial polyamines have also been uncovered: they are part of outer membranes of Gram-negative bacteria (Takatsuka and Kamio 2004), are involved in the biosynthesis of siderophores (Brickman and Armstrong 1996), take part in acid resistance (Foster 2004), protect from oxygen toxicity (Jung et al. 2003), play a role in signaling for cellular differentiation (Sturgill and Rather 2004), and are essential for plaque biofilm formation (Patel et al. 2006). It was assumed that polyamines are essential for life and this might still be true for several species, especially eukaryotes. However, in a recent publication, a polyamine-free Escherichia coli strain, which was able to grow under the selected conditions, has been described (Chattopadhyay et al. 2009).

Depending on the species, the relative intracellular concentrations of the different polyamines may vary, and they can reach high concentrations, up to the millimolar range (Miyamoto et al. 1993). The most common polyamines in Bacteria and Archaea are putrescine, a diamine also named 1,4-diaminobutane, and the triamine spermidine, whereas cadaverine, a diamine also named 1,5-diaminopentane, is much less abundant. Although the tetraamine spermine has been detected in Bacteria and Archaea (Hamana and Matsuzaki 1992), spermine synthase (EC 2.5.1.22) activity has yet to be proved. It could be possible that spermine is synthesized in these species by a non-specific aminopropyltransferase. In addition to the above-mentioned polyamines, the pathways for the biosynthesis of 1,3-diaminopropane, norspermidine, homospermidine, and thermine are known in some Bacteria and Archaea. This set of polyamines is extended by a number of uncommon longer- or branched-chain polyamines, which were found in extremophiles (Fig. 1a, b) and which seem to play an essential role for growth under such extreme conditions (Oshima 2007). The branched-chain polyamines (Fig. 1b) are no polyamines sensu stricto as they contain tertiary and quaternary amino groups. However, except for caldopentamine, the biosynthetic pathways for these uncommon longer- or branched-chain polyamines have not yet been investigated in detail (Knott 2009; Oshima, 2010).

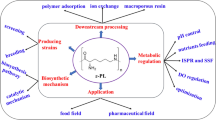

Polyamines are applied in a wide variety of commercial applications due to their unique combination of reactivity, basicity, and surface activity. With a few exceptions, they are used predominantly as intermediates in the production of functional products (e.g., polyamides/epoxy curing, fungicide, anthelmintics/pharmaceuticals, petroleum production, oil and fuel additives, paper resins, chelating agents, fabric softeners/surfactants, bleach activator, asphalt chemicals) (Kroschwitz and Seidel 2004). The main commercial interest in biogenic polyamines is their use in the polymer industry. Diamines can be used as monomers for the production of polyamides, whereas higher amines can be applied as curing agents in epoxy-resins.

Polyamides are synthetic polymers containing amid-linker, which are formed by a condensation reaction between an amino and a carboxy moeity. The polyamide monomers can either be lactams comprising an intramolecular cyclic amide (AB-type, e.g. Nylon-6, Nylon-11) or they are monofunctional comprising either amino or carboxy moeities (AA/BB-type, e.g. Nylon-4,6). The properties of polyamides depend on the chosen monomer-type, with influences of, e.g., the aliphatic or aromatic carbon backbone or the length of the backbone. In principle, a vast of number of combinations is possible. Today, the only example of an industrial polyamide containing a biogenic diamine, which can also be synthesized by Bacteria, is nylon-4,6. This polyamide is produced from putrescine and adipic acid (hexanedioic acid) and is marketed, e.g., under the trademark Stanyl by DSM, Netherlands.

The total market for plastics grew in the last six decades with an average of 9% per year and the polyamide fraction grew with 4.5% per year in the last years, reaching a predicted production volume of 2.4 million tons per year in 2007 (Platt 2003). The market share of Stanyl and other special polyamides is about 2% of this market. At present, the production of monomers for use in the polyamide industry is mainly based on chemical routes, with few exceptions like 1,10-decamethylenediamine which is isolated from castor oil and used for production of PA-10,10 (e.g., Vestamid TerraDS by Evonik Degussa, Germany), but a drive towards low-carbon footprints of materials and applications and towards the development of sustainable processes might further promote biotechnological polyamine production.

In Bacteria, the pathways of polyamine biosynthesis start with the amino acids l-lysine, l-ornithine, l-arginine, or l-aspartic acid. Since a million-ton-scale industry for the fermentative production of amino acid thrives and strains overproducing l-lysine, l-ornithine, and l-arginine are available, it is reasonable to engineer these amino acid-producing bacteria for polyamine production. Biotechnological production of polyamines, which necessitates tolerance to high product concentrations, has been not investigated until recently. This might be due to toxicity of polyamines or their derivatives if they accumulate in the producer cells (Limsuwun and Jones 2000). However, the toxic effects seem to be relevant for few polyamines in general, as recent publications concerning polyamine production by bacteria show very promising results (Table 1).

The focus of this mini-review is on the biotechnological production of polyamines by means of Bacteria. For information on polyamines in eukaryotes, we refer to other reviews (Seiler 1990; Seiler 2004). In the following, a survey on polyamine metabolism in Bacteria and Archaea will be given, and recent metabolic engineering approaches for production of diamines by E. coli and C. glutamicum will be discussed.

Polyamine metabolism in Bacteria and Archaea

This paragraph provides an overview on anabolic and catabolic polyamine pathways investigated so far in Bacteria and Archaea. The currently known pathways are summarized in Fig. 2.

Schematic representation of known anabolic and catabolic polyamine pathways in Bacteria and Archaea. Enzymatic side reactions which were shown only in vitro are not included. dcSAM decarboxylated S-adenosylmethionine, MTA methylthioadenosine, OxAc oxidized electron acceptor, RedAc reduced electron acceptor, 1 lysine decarboxylase (EC 4.1.1.18), 2 ornithine decarboxylase (EC 4.1.1.17), 3 arginase (EC 3.5.3.1), 4 arginine decarboxylase (EC 4.1.1.19), 5 agmatinase (EC 3.5.3.11), 6 agmatine deiminase (EC 3.5.3.12), 7 N-carbamoylputrescine amidohydrolase (EC 3.5.1.53), 8 putrescine transcarbamylase (EC 2.1.3.6), 9 agmatine aminopropyltransferase (EC 2.5.1.-), 10 aminopropylagmatine ureohydrolase (EC 3.5.3.-), 11 spermidine synthase (EC 2.5.1.16), 12 spermidine oxidase (EC 1.5.3.B4), 13 spermidine dehydrogenase (EC 1.5.99.6), 14 diaminobutyric acid transaminase (EC 2.6.1.76), 15 diaminobutyric decarboxylase (EC 4.1.1.86), 16 carboxy(nor)spermidine dehydrogenase (EC unknown), 17 carboxy(nor)spermidine decarboxylase (EC 4.1.1.-), 18 carboxy(nor)spermidine dehydrogenase (EC unkown), 19 carboxy(nor)spermidine decarboxylase (EC 4.1.1.-), 20 aminopropyl transferase (EC 2.5.1.-), 21 aminopropyl transferase (EC 2.5.1.-), 22 homospermidine synthase (EC 2.5.1.44), 23 cadaverine aminopropyltransferase (EC 2.5.1.-), 24 diamine acetyltransfease (EC 2.3.1.57), 25 cadaverine aminotransferase (EC 2.6.1.-), 26 α-piperideine dehydrogenase (EC 1.5.-), 27 δ-aminovaleric acid aminotransferase (EC 2.6.1.-), 28 γ-glutamylputrescine synthase (EC 6.3.1.11), 29 γ-glutamylputrescine oxidase (EC 1.4.3.-), 30 γ-glutamyl-γ-aminobutyraldehyde dehydrogenase (EC 1.2.1.-), 31 γ-glutamyl-γ-aminobutyrate hydrolase (EC 3.5.1.94), 32 γ-aminobutyric acid aminotransferase (EC 2.6.1.19), 33 succinic acid semialdehyde dehydrogenase (EC 1.2.1.16), 34 putrescine aminotransferase (EC 2.6.1.82), 35 aminobutyraldehyde dehydrogenase (EC 1.2.1.19), 36 putrescine oxidase (EC 1.4.3.10), 37 N-acetylputrescine decetylase (EC 3.5.1.62), 38 spermidine acetyltransferase (EC 2.3.1.57), 39 primary amine oxidase (EC 1.4.3.21), 40 aldehyde dehydrogenase (EC 1.2.1.3), 41 β-alanine transaminase (EC 2.6.1.19), 42 malonic acid semialdehyde decarboxylase (EC 1.2.1.18)

Anabolic pathways

Cadaverine

The formation of cadaverine occurs through the decarboxylation of l-lysine (Fig. 2, reaction 1), and this polyamine is only present in minor amounts in E. coli under normal growth conditions (Tabor and Tabor 1985). In E. coli, two isozymes catalyze l-lysine decarboxylation: the acid-inducible CadA (Sabo et al. 1974) and the constitutive LdcC (Kikuchi et al. 1997). The production of CadA is induced at low pH and plays a role in the acid resistance system of E. coli. As l-lysine decarboxylation consumes one proton, the intracellular pH increases, which contributes to pH homeostasis (Foster 2004).

Putrescine

Putrescine can be formed in vivo via the ODC or ADC pathway, named after the enzymes ornithine decarboxylase (ODC) and arginine decarboxylase (ADC), respectively, which catalyze the initial reaction of the pathways. As described above for l-lysine decarboxylation, the ODC and ADC pathways also contribute to acid resistance in E. coli by proton-consuming decarboxylation of l-ornithine and l-arginine, respectively (Foster 2004). Two isozymes for both decarboxylation reactions are encoded by the genome of E. coli: the acid-inducible decarboxylases SpeF (l-ornithine-specific) and AdiA (l-arginine-specific) as well as the constitutive decarboxylases SpeC (l-ornithine-specific) and SpeA (l-arginine-specific) (Applebaum et al. 1975, Blethen et al. 1968, Applebaum et al. 1977, Wu and Morris 1973). The acid-inducible decarboxylases are sometimes referred to as degradative enzymes, while the constitutive decarboxylases are named biosynthetic enzymes. In the ODC pathway, l-ornithine is directly converted to putrescine by ornithine decarboxylase (Fig. 2, reaction 2). By contrast, decarboxylation of l-arginine represents only the first step of the ADC pathway (Fig. 2, reaction 4). The product of l-arginine decarboxylation, agmatine, is converted in one of three species-specific reactions. In E. coli, agmatine is directly hydrolyzed to putrescine and urea by agmatinase SpeB (Fig. 2, reaction 5) (Satishchandran and Boyle 1986). In some bacterial species, agmatine is converted to putrescine in a two-step reaction (Fig. 2, reactions 6 + 7): hydrolytic deimination of agmatine to N-carbamoylputrescine by agmatine deiminase AguA followed by hydrolysis of the carbamoyl group to yield ammonia, carbon dioxide, and putrescine in a reaction catalyzed by N-carbamoylputrescine amidohydrolase AguB (Nakada and Itoh 2003). A variation of the last step is found in Enterococcus faecalis, where putrescine transcarbamylase releases carbamoylphosphate from N-carbamoylputrescine and inorganic phosphate to yield putrescine (Fig. 2, reaction 8) (Wargnies et al. 1979).

Spermidine and norspermidine

The common pathway for spermidine formation is the aminopropylation of putrescine with decarboxylated S-adenosylmethionine (dcSAM) as the donor molecule (Fig. 2, reaction 11) (Bowman et al. 1973), but recently, another pathway starting from agmatine was discovered in extremophiles (Ohnuma et al. 2005; Morimoto et al. 2010). In these bacteria, agmatine aminopropyltransferase uses dcSAM as a donor to produce aminopropylagmatine which is subsequently hydrolyzed to spermidine and urea by aminopropylagmatine ureohydrolase (Fig. 2, reactions 9 + 10). A third pathway for spermidine formation is known (Tait 1976), and the relevant enzymes have been characterized in members of the genus Vibrio (Fig. 2, reactions 18 + 19). In Vibrio, l-aspartic-semialdehyde, an intermediate in l-lysine biosynthesis, and putrescine are reductively condensed by carboxy(nor)spermidine dehydrogenase (CANSDH) (Nakao et al. 1991). The reaction product, carboxyspermidine, is then decarboxylated to spermidine by carboxy(nor)spermidine decarboxylase (CANSDC) (Nakao et al. 1990).

Vibrio species also synthesize norspermidine from l-aspartic-semialdehyde which is condensed with 1,3-diaminopropane (Fig. 2, reaction 14–17) (Yamamoto et al. 1986). Amination of l-aspartic-semialdehyde to 2,4-diaminobutyric acid and subsequent decarboxylation yields 1,3-diaminopropane, which is condensed with another molecule of l-aspartic-semialdehyde by CANSDH to yield carboxynorspermidine. Carboxynorspermidine is decarboxylated to norspermidine by CANSDC. These reactions were investigated in detail in Vibrio cholerae but homologs of the key enzymes were found to be widespread among Bacteria (Lee et al. 2009). As alternative to the Vibrio pathway, aminopropyl transferase activity which uses dcSAM to synthesize norspermidine from 1,3-diaminopropane was detected in Clostridium thermohydrosulfuricum (Fig. 2, reaction 20) (Paulin et al. 1983).

Other polyamines

Besides the reactions involved in the synthesis of the polyamines mentioned above, enzymes catalyzing formation of homospermidine, thermine, and caldopentamine have been characterized. Homospermidine can be formed by condensation of two molecules of putrescine (Fig. 2, reaction 22). This reaction is catalyzed by a single enzyme, which oxidatively deaminates putrescine to yield ammonia, aminobutyraldehyde, and NADH. The latter two remain enzyme-bound and the enzyme-bound aminobutyraldehyde forms an imine with a second molecule of putrescine. This enzyme-bound imine is reduced by the enzyme-bound NADH to yield homospermidine (Tait 1979). It was shown that aminopropyl transferase from Pyrobaculum aerophilum has the highest activity towards thermine formation with the substrate norspermidine and the aminopropyldonor dcSAM (Fig. 2, reaction 20) (Knott 2009). The aminopropyl transferase from C. thermohydrosulfuricum also accepts norspermidine as a substrate in addition to 1,3-diaminopropane which leads to thermine formation (Fig. 2, reaction 20) (Paulin et al. 1983). In Hyperthermus butylicus, a polyamine synthase is present which catalyzes the formation of caldopentamine from thermine and dcSAM (Knott 2009). This is at present the only known enzyme for synthesis of long-chain polyamine synthesis beyond the tetraamines.

Catabolic pathways

In the view of metabolic engineering, an ideal production host cannot degrade or utilize the product. However, if the desired product is consumed rather than excreted and the overall yield of the process decreases, the corresponding pathways become an important engineering target. Therefore, knowledge about these pathways is required and in the following, the catabolism of cadaverine, putrescine, and spermidine is described. Degradation or utilization of the other known bacterial or archaeal polyamines has not yet been investigated.

Cadaverine

Several bacteria are known to degrade l-lysine through decarboxylation, which leads to cadaverine as the first intermediate. This pathway has been studied in detail in members of the genus Pseudomonas (Fothergill and Guest 1977; Hofle 1984; Madduri et al. 1989). Cadaverine is then further metabolized by transamination to α-piperidine and oxidized to δ-aminovaleric acid (AMV). This intermediate is eponymous for the so-called AMV pathway that leads to acetyl-CoA (Revelles et al. 2005) (Fig. 2, reactions 25–27). It is also known that cadaverine is a substrate for aminopropylation and acetylation in some species (Fig. 2, reactions 23 and 24) (Cacciapuoti et al. 2007; Kind et al. 2010a). The utilization or degradation of cadaverine has not been observed for E. coli and C. glutamicum.

Putrescine

Besides dcSAM-dependent conversion to spermidine, putrescine can be utilized as a carbon source by two pathways, which have been investigated in E. coli. Both pathways lead to GABA (γ-aminobutyric acid), which is then deaminated and oxidized to the tricarboxylic acid cycle intermediate succinic acid (Fig. 2, reactions 32 + 33). In E. coli, the latter two enzymes are encoded by the constitutive gabT/gabD and by the putrescine inducible puuE/yneI (Kurihara et al. 2010).

The initial step of the first pathway for putrescine degradation, the Puu pathway, is the glutamylation of putrescine to γ-glutamylputrescine. In three subsequent reactions, γ-glutamylputrescine is oxidized to GABA (Kurihara et al. 2005) (Fig. 2, reactions 28–31). The second pathway, the YgjG–YdcW pathway, involves the transamination of putrescine to γ-aminobutanal followed by oxidization to GABA (Shaibe et al. 1985) (Fig. 2, reactions 34 + 35). Besides transamination of putrescine to γ-aminobutanal, putrescine can also be reductively deaminated by putrescine oxidase in a reaction yielding hydrogen peroxide (van Hellemond et al. 2008) (Fig. 2, reaction 36). Specific deacetylation of N-acetyl-putrescine was detected in Bacteria (Fig. 2, reaction 37) (Suzuki et al. 1986), even though acetylation of putrescine has not yet been described in Bacteria or Archaea.

Spermidine

Spermidine is catabolized via 1,3-diaminopropane and γ-aminobutanal either by spermidine oxidase or by spermidine dehydrogenase (Bachrach 1962b; Hisano et al. 1990) (Fig. 2, reactions 12 + 13). The further degradation of γ-aminobutanal to succinic acid has already been described above for putrescine degradation. 1,3-Diaminopropane can be further metabolized via β-alanine and malonic semialdehyde to acetyl-CoA (Bachrach 1962a) (Fig. 2, reactions 39–42). The utilization of spermidine has neither been shown for E. coli nor for C. glutamicum, but the acetylation of spermidine has been described for E. coli (Fig. 2, reaction 38) (Limsuwun and Jones 2000; Matsui et al. 1982).

Transport processes across the cell membrane

In the following paragraph, transport capabilities of bacterial species concerning amino acids and polyamines are described with respect to metabolic engineering of polyamine production hosts. The enhancement of product formation by modulation of transport processes across the cell membrane is well known (Lee et al. 2007; Gunji and Yasueda 2006). Hence, genes encoding proteins for product export might be good targets for overexpression, whereas genes encoding proteins facilitating re-uptake of the secreted product or the efflux of precursors might be deletion targets. Overexpression of transporter genes may be very challenging as, e.g. a wide substrate range could cause a drastic decrease in the overall strain fitness and/or the membrane integrity might be compromised. Also, the inhibition of excretion capabilities can drastically influence the cell metabolism.

As a good review article on polyamine transport in E. coli was published by Igarashi and Kashiwagi (2010), only a brief overview is given here and some extensions of known transport processes to other bacteria are made. To our knowledge, for bacteria, only information on transport of the polyamines cadaverine, putrescine, and spermidine has been published. In Fig. 3, biochemically characterized or observed transport processes of polyamines, derivatives, and precursors in bacterial species are outlined.

Polyamine transport across the cell membrane in Bacteria. The known transport reactions mediating the uptake or secretion of polyamines, derivatives and precursors are shown. Genes encoding corresponding transport-systems are given for E. coli and C. glutamicum. Question marks indicate obviously present, but uncharacterized transport processes; n.d. not determined

Cadaverine

The uptake and excretion of cadaverine in E. coli is mediated by CadB, a protein of the amino acid-polyamine-organocation (APC) family. Members of this family function as solute:cation symporter and/or as solute:solute antiporter. CadB is responsible for cadaverine uptake at neutral pH by proton-linked symport while at acidic pH, CadB mediates excretion of cadaverine in antiport with l-lysine (Soksawatmaekhin et al. 2004). Accumulation of N-acetylated cadaverine in the fermentation broth was observed for C. glutamicum, but the transport system is unknown (Kind et al. 2010b; Kind et al. 2010a). In E. coli, export of the cadaverine precursor l-lysine involves YahN (Park and Lee 2010), and l-lysine uptake may be mediated by LysP (Steffes et al. 1992) or ArgT-HisJQMP (Rosen 1971). YahN is a member of the resistance to homoserine/threonine (RhtB) family and catalyzes export of l-lysine coupled to proton import. Uptake of l-lysine into the E. coli cell is catalyzed by APC-type permease LysP or by the ATP-binding cassette (ABC) transporter ArgT-HisQJMP.

In C. glutamicum, LysI is the uptake system for l-lysine (Seep-Feldhaus et al. 1991) and LysE mediates the export. LysE from C. glutamicum was the first amino acid export system discovered in Bacteria (Vrljic et al. 1996) and is eponymous for the LysE superfamily of export proteins (Vrljic et al. 1999). Besides l-lysine, LysE also catalyzes export of d-lysine (Stäbler et al. 2011) and l-arginine (Bellmann et al. 2001). It was also shown that LysE contributes to cadaverine export in C. glutamicum (Stäbler et al. 2011).

Putrescine

PotE is a member of the APC family and mediates the uptake and excretion of putrescine in E. coli. Like CadB, the uptake of putrescine occurs by a proton-linked symport and the excretion is done in antiport mode with l-ornithine as further substrate (Kashiwagi et al. 1992; Kashiwagi et al. 1997). In addition, PuuP, a member of the same family, is known to be involved in the uptake of putrescine (Kurihara et al. 2009). The ABC transporter PotFGHI also catalyzes putrescine uptake (Pistocchi et al. 1993). Two putative putrescine importers, YdcSTUV and YeeF, are encoded in the genome of E. coli K12-MG1655, and recently, the uptake of putrescine by YeeF was shown (Kurihara et al. 2011). In E. faecalis, which is able to use agmatine as a sole carbon source, an agmatine–putrescine antiporter has been described (Driessen et al. 1988).

The putrescine precursors l-ornithine and l-arginine are transported in many ways across the cell membrane. The same proteins, which are responsible for l-lysine uptake, typically also use l-ornithine as a substrate (Fig. 3). The export of l-ornithine has been less investigated in E. coli, but a putative arginine–ornithine antiporter ArcD is encoded. In E. coli, ArgO, a member of the LysE superfamily, catalyzes efflux of l-arginine and possibly also of l-lysine and canavanine (Nandineni and Gowrishankar 2004). In C. glutamicum, LysE is required both for export of l-lysine and of l-arginine (Bellmann et al. 2001). Uptake of l-arginine may occur via the ABC transporters ArtPMQJI as well as ArgT-HisPMQJ (Wissenbach et al. 1995). A putative l-arginine uptake system is encoded by cg3045 in C. glutamicum (Ren and Paulsen 2005). AdiC constitutes an arginine–agmatine antiporter of the APC family, which plays a role in acid resistance of E. coli like PotE and CadB (Gong et al. 2003). Agmatine excretion was also observed in C. glutamicum when arginine decarboxylase genes were overexpressed (Schneider and Wendisch 2010), but the transport mechanism is still unclear in this bacterium.

Spermidine

In E. coli, proteins responsible for uptake and excretion of spermidine are known. The uptake of spermidine is mediated by PotABCD (Furuchi et al. 1991) and the excretion by MdtJI (Higashi et al. 2008). PotABCD is a member of the ABC superfamily and catalyzes ATP-driven spermidine uptake. MdtJI belongs to the drug/metabolite transporter (DMT) superfamily, members of which are usually responsible for excretion of toxic compounds or waste metabolites.

Metabolic engineering for putrescine production

Putrescine can be overproduced from l-arginine and l-ornithine via the ADC and ODC pathway, respectively. However, the ODC pathway is preferable as it comprises only a single reaction compared to two or three reactions of the ADC pathway. To increase l-ornithine formation, its conversion to l-arginine may be blocked; however, this results in unfavorable auxotrophy for l-arginine. Thus, the maintenance of prototrophy with concomitant high l-ornithine supply is a focus in strain construction.

The pathway for biosynthesis of l-arginine and l-ornithine, the substrates of the initial decarboxylase reactions in the ADC and ODC pathway, respectively, are similar in E. coli and C. glutamicum. l-glutamic acid is converted in eight enzymatic steps to l-arginine. Five steps involving N-acetylated intermediates lead to l-ornithine, and three additional steps are required to convert l-ornithine to l-arginine. The differences between E. coli and C. glutamicum in this pathway are as follows. In the so-called “cyclic pathway” for ornithine synthesis in C. glutamicum, two steps are catalyzed by ornithine acetyltransferase (OAT, ArgJ, EC 2.3.1.35), as it converts l-glutamic acid and N-acetyl-l-ornithine to N-acetyl-l-glutamic acid and l-ornithine (Glansdorff and Xu 2007). In E. coli, the so-called “linear pathway” is found (Glansdorff and Xu 2007) with N-acetylglutamic acid synthase (ArgA, EC 2.3.1.1) and acetylornithinase (AO, ArgE, EC 3.5.1.16) replacing the two steps catabolized by ArgJ from C. glutamicum. As ArgJ recycles the acetyl group between ornithine and glutamic acid, it provides a more economical pathway in terms of metabolic costs for ornithine synthesis than the alternative route via ArgA and ArgE, which leads to concomitant hydrolysis of acetyl-CoA to acetic acid and CoA. The ornithine carbamoylphosphatetransferase ArgF (EC 2.1.3.3) converts l-ornithine to l-citrulline. The genome of E. coli K12-MG1655 contains two genes, argI (b4254) and argF (b0273), both of which encode a functional carbamoylphosphatetransferase. ArgI and ArgF interact to form four trimeric isoenzymes (Legrain et al. 1972). The genome of C. glutamicum comprises only one carbamoylphosphatetransferase encoded by argF (cg1584). The first enzyme of the linear pathway, e.g., ArgA in E. coli, as well as N-acetylglutamic acid kinase (ArgB, EC 2.7.2.8) in C. glutamicum are subject to feedback regulation by l-arginine. Additionally, the synthesis of all enzymes in the pathway is subject to repression by l-arginine, which is mediated by the repressor ArgR in E. coli and C. glutamicum (Glansdorff and Xu 2007).

As mentioned above, a prerequisite for successful use of microorganisms in industrial fermentations or biotransformations is a high tolerance of the desired product. Tolerance tests with C. glutamicum and E. coli showed very promising results. Concentrations of up to 66 g/l reduced the growth rate of C. glutamicum by 34% and that of E. coli by 78% (Schneider and Wendisch 2010). The biomass formation was reduced at the same concentration by 39% and 63%, respectively (Schneider and Wendisch 2010). If also effects of the counterion of putrescine (the dichloride salt of putrescine was used) have to be taken into account, tolerance of putrescine may even be higher.

Engineering of E. coli

E. coli possesses two isozymes for both, ornithine decarboxylase (biosynthetic SpeC, degradative SpeF) and arginine decarboxylase (biosynthetic SpeA, degradative AdiA). The ADC pathway is completed by the agmatinase SpeB, which hydrolyzes agmatine to putrescine and urea. While urea cannot be reused by E. coli, putrescine can be utilized by E. coli as a sole carbon source on two pathways. The first pathway via γ-glutamylputrescine seems to be responsible for using putrescine as a carbon source, whereas the second pathway via γ-aminobutanal seems to be negligible (Kurihara et al. 2008).

The overexpression of speC (b2965) and of speF (b0693) in the wild-type genetic background led to comparable results as 0.72 or 0.87 g/l of putrescine accumulated in batch cultures (Eppelmann et al. 2006). The simultaneous overexpression of speF and speAB (b2938, b2937) slightly increased putrescine accumulation to 1.03 g/l. In fed-batch cultivation, the E. coli (speF) strain produced up to 5.1 g/l putrescine (Table 1) (Eppelmann et al. 2006).

The amount of secreted putrescine was further increased by engineering the genetic background of the host. The combined deletion of argI (Fig. 4, C-1; lowering the flux from l-ornithine towards l-arginine), speE (b0121, reducing putrescine consumption by spermidine synthase), speG (b1584, spermidine acetyltransferase which was active with putrescine at least in vitro), and puuPA (b1296, b1297, putrescine importer and initial enzyme in putrescine degradation pathway via γ-glutamylputrescine) led to a putrescine titer of 1.18 g/l (Qian et al. 2009). A further optimization by 25% was achieved by promoter exchange of genes encoding the enzymes converting l-glutamic acid into l-ornithine (Fig. 4, C-2, C-3) as well as the exchange of speF–potE promoter (potE encodes the ornithine–putrescine antiporter) (Qian et al. 2009). The exchange of the argA promoter failed and deregulation of the transcriptional units argECBH and argD by deletion of argR even decreased production (Qian et al. 2009). The deletion of rpoS (b2741), encoding a global stress regulator, which was chosen due to the assumption that putrescine overproduction might lead to a stress response, led to a 7% increase in product concentration (Qian et al. 2009).

Metabolic engineering targets in the central metabolism applied in a, c putrescine and b, d cadaverine producing strains of C. glutamicum and E. coli. Genetic modifications are numbered and the relevant explanations are given within the text. OXG 2-oxoglutaric acid, l-Glul-glutamic acid, N-AcGlu N-acetylglutamic acid, N-AcGluP N-acetylglutamylphosphate, N-AcGluAld N-acetylglutamatic acid semialdehyde, N-AcOrn N-acetylornithine, l-Ornl-ornithine, l-Citl-cirtulline, l-ArgSucl-argininosuccinic acid, l-Argl-arginine, PEP phosphoenolpyruvic acid, PYR pyruvic acid, ICI isocitric acid, Suc succinic acid, Mal malic acid, OxAc oxalic acid, l-Aspl-aspartic acid, l-Aspl-aspartylphosphate, AspAld aspartic acid semialdehyde, HomSer homoserine, DHPl-2,3-dihydropicolinic acid, THP tetrahydropicolinic acid, l-Lysl-lysine, GlyOx, iciR isocitrate lyase regulator, argR arginine repressor, GdH glutamic acid dehydrogenase (EC 1.4.1.4), ArgA amino acid N-acetyltransferase (EC 2.3.1.1), ArgJ bifunctional ornithine acetyltransferase/N-acetylglutamic acid synthase (EC 2.3.1.35/2.3.1.1), ArgB acetylglutamic acid kinase (EC 2.7.2.8), ArgC N-acetylglutamylphosphat reductase (EC 1.2.1.38), ArgD acetylornithine aminotransferase (EC 2.6.1.11), ArgE acetylornithinase (EC 3.5.1.16), ArgF ornithine carbamoyltransferase (EC 2.1.3.3), ArgG argininosuccinic acid synthetase (EC 6.3.4.5), ArgH argininosuccinic acid lyase (EC 4.3.2.1), Pepck phosphoenolpyruvic acid carboxykinase (EC 4.1.1.32), Ppc phosphoenolpyruvic acid carboxylase (EC 4.1.1.31), Pyc pyruvic acid carboxylase (EC 6.4.1.1), AspC aspartic acid aminotransferase (EC 2.6.1.1), LysC aspartokinase (EC 2.7.2.4), Asd aspartic acid semialdehyde dehydrogenase (EC 1.2.1.11), MetL, ThrA bifunctional aspartokinase/homoserine dehydrogenase (EC 2.7.2.4/1.1.1.3), DapA dihydrodipicolinic acid synthase (EC 4.2.1.52), DapB dihydrodipicolinic acid reductase (EC 1.3.1.26), DdH meso-diaminopimelic acid dehydrogenase (EC 1.4.1.16), LysA diaminopimelic acid decarboxylase (EC 4.1.1.20)

The activity of ornithine decarboxylases is regulated on multiple levels. Besides feedback inhibition by l-ornithine, putrescine, and spermidine, the activity of ornithine decarboxylases is stimulated by GTP and inhibited by ppGpp, an alormone of the stringent response (Tabor and Tabor 1985). In E. coli, l-ornithine decarboxylase is also regulated by the antizyme AtoC (Filippou et al. 2007). Deletion of atoC (b2220) led to a slight increase in putrescine production, however, at the expense of the ability to grow to high cell densities (Qian et al. 2009), which might be due to the other physiological functions of AtoC.

Plasmid-based overexpression of the putrescine exporter gene potE failed so far, but the promoter exchange of the potE–speF operon successfully increased putrescine production, as mentioned above. As both speF and potE are affected, it is impossible to distinguish between positive effects due to increased levels of putrescine export or ornithine decarboxylase.

Engineering of C. glutamicum

The metabolism of polyamines has not been investigated in C. glutamicum. In contrast to E. coli, C. glutamicum is unable to degrade and utilize putrescine as a carbon source (Schneider and Wendisch 2010). In order to overproduce putrescine, heterologous genes were expressed. The expression of genes of the ADC and ODC pathway from E. coli in the wild-type background of C. glutamicum only led to minor amounts of putrescine (Schneider and Wendisch 2010). As C. glutamicum is able to reuse urea, which is released by the agmatinase reaction, the feasibility of the ADC pathway was further investigated. Deletion of argR (Fig. 4, A-1) in combination with plasmid-based overproduction of feedback-insensitive ArgB (Fig. 4, A-2) led to substantial amounts of l-arginine. However, the combinatorial expression of genes for ADC enzymes clearly indicated that l-arginine decarboxylase and agmatinase limited the overall reaction. In the supernatant, 1.6 g/l l-arginine and 1.7 g/l agmatine, but only 0.1 g/l putrescine could be detected (Schneider and Wendisch 2010). No differences between the biosynthetic and degradative arginine decarboxylases were observed (Schneider and Wendisch 2010).

The deletion of argR and argF (Fig. 4, A-3) led to accumulation of l-ornithine but rendered the resulting strain arginine auxotrophic. When speC and speF from E. coli were expressed in the argR–argF deletion strain, production of 5 g/l putrescine resulted, which was about 50 times higher than strains endowed with the ADC pathway. As only minor amounts of l-ornithine were observed towards the end of the cultivation and as the in vitro activity of SpeF was 24-fold higher than that of SpeC, it was tested whether supply of the decarboxylase cofactor pyridoxal phosphate (PLP) might be limiting. However, the addition of PLP to the medium did not increase putrescine production (Schneider and Wendisch 2010) indicating that l-ornithine supply might be limiting putrescine formation.

Metabolic engineering for cadaverine production

Cadaverine can be overproduced by introduction of an overproduced lysine decarboxylase. The corresponding substrate, l-lysine, is synthesized in E. coli and C. glutamicum by similar pathways covering ten enzymatic steps initiating from the TCA-cycle intermediate oxaloacetate. The three initial steps in this pathway lead to aspartic acid semialdehyde, which is the branch point for biosynthesis of the amino acids l-methionine, l-threonine, l-isoleucine, and l-lysine.

In E. coli, three aspartic acid kinases (EC 2.7.2.4) exist (LysC, ThrA, and MetL), which phosphorylate l-aspartic acid to l-aspartyl-phosphate. ThrA and MetL are bifunctional enzymes and also have homoserine dehydrogenase activity. By contrast, C. glutamicum possesses LysC as only aspartic acid kinase. The presence of a diaminopimelic acid dehydrogenase (EC 1.4.1.16, cg2900) in C. glutamicum is another difference. This enzyme catalyzes the direct conversion of tetrahydropicolinic acid to meso-diaminopimelic acid. Feedback inhibition by l-lysine is observed for LysC and dihydrodipicolinic acid synthase (DapA) (Park and Lee 2010). LysC from C. glutamicum is additionally feedback-inhibited by l-threonine, whereas ThrA from E. coli is subject to feedback-inhibition by l-threonine (Park and Lee 2010). In E. coli, lysC and thrA are controlled by transcriptional attenuation by l-threonine and l-lysine (Park and Lee 2010). The third aspartic acid kinase from E. coli encoded by metL is controlled by the MetJ repressor mediated by l-methionine (Park and Lee 2010).

The tolerance of E. coli for cadaverine seems to be lower compared to putrescine. The biomass formed in the presence of 51 g/l cadaverine was reduced by 30% in comparison to the same molar concentration of putrescine (Qian et al. 2011, Qian et al. 2009). This is an example of different polyamine toxicity, which might depend on the carbon chain length and the number of amino groups. C. glutamicum was only tested for growth on solid medium and grew even at concentrations of up to 31 g/l (Mimitsuka et al. 2007).

Engineering E. coli

The first report on cadaverine production by use of microorganisms was published in 2007 (Nishi et al. 2007). The inventors overexpressed the lysine decarboxylase gene cadA (b4131) in E. coli and used resting cells to produce 69 g/l cadaverine (Table 1).

The plasmid-based overexpression of cadA in the wild-type genetic background led to accumulation of 0.8 g/l cadaverine by growing cells (Qian et al. 2011). Interestingly, the authors reported that repeated attempts to overexpress the biosynthetic lysine decarboxylase ldcC (b0186) always failed. The cloning of cadA instead led in repeated trials to mutated versions of cadA with a 5′ insertion (Qian et al. 2011). The author suggested that this insertion might form a stable stem loop in front of the start codon, which sequesters the ribosome binding site and, thus, lowers the translation efficiency.

To avoid side reactions of enzymes active with putrescine towards cadaverine, a number of genes were deleted: the spermidine synthase gene speE, the spermidine acetyltransferase gene speG, the putrescine importer gene puuP, the putrescine amino transferase gene puuA and ygjG, which encodes the initial enzyme of the second putrescine degradation pathway and is known to be active in vitro with cadaverine (Qian et al. 2011). The resulting strain was able to accumulate 1.2 g/l cadaverine. Production of cadaverine was increased by 10% as a consequence of enhancing the flux of l-aspartic acid towards l-lysine by overexpression of dapA via promoter exchange (Fig. 4, D-1). In fed-batch cultivation, this strain produced 9.6 g/l cadaverine (Qian et al. 2011). Overexpression of lysC (Fig. 4, D-6) or use of a feedback insensitive LysC variant did not increase productivity (Qian et al. 2011). Similarly, combined overexpression of dapB (b0031, Fig. 4, D-2) and lysA (b2838, Fig. 4, D-4), the increased activity of the glyoxylate shunt (Fig. 4, D-5), and the heterologous expression of ddh (cg2900, Fig. 4, D-3, 5) from C. glutamicum did not further improve cadaverine formation. Therefore, the authors assumed that precursor supply, oxaloacetic acid from the TCA cycle, might be limiting (Qian et al. 2011).

Engineering C. glutamicum

Heterologous expression of cadA from E. coli, and inactivation of the homoserine dehydrogenase gene hom (cg1337, Fig. 4, B-1) was achieved by insertion of cadA into hom. The expression of cadA was driven by the strong kanamycin resistance gene promoter. The resulting strain accumulated 2.6 g/l cadaverine in the supernatant, but was auxotrophic for l-methionine, l-threonine, and l-isoleucine (Mimitsuka et al. 2007). Moreover, this strain still accumulated substantial amounts of l-lysine, which could be overcome by plasmid-based expression of cadA. In a different approach, the authors opted for the biosynthetic lysine decarboxylase LdcC from E. coli because of its near neutral pH optimum. Overexpression of ldcC led to 30% more cadaverine than overexpression of cadA (Kind et al. 2010b). The flux towards l-lysine was improved by amplification of a gene for feedback-insensitive aspartokinase (lysC) and overexpression of dapB (dihydrodipicolinate reductase), ddh (diaminopimelate dehydrogenase), and lysA (diaminopimelate decarboxylase), drain to side-products was reduced by introducing hom leaky alleles (Fig. 4, B-2,3,4,5), and oxaloacetate supply was strengthened by expression of a gene encoding a variant of pyruvate carboxylase (pyc P458S), the major anaplerotic enzyme in C. glutamicum (Peters-Wendisch et al. 2001; Peters-Wendisch et al. 1998) as well as by deletion of the gene for phosphoenolpyruvate carboxykinase (Fig. 3, B-6,7) (Riedel et al. 2001). By integration of codon optimized ldcC into the genome of this strain, an increase of 20% was achieved (Kind et al. 2010b). This was further increased by 35% due to addition of the lysine decarboxylase cofactor PLP, indicating this as one bottleneck in cadaverine production by this strain (Kind et al. 2010b).

N-acetylcadaverine was formed as a byproduct of cadaverine production (up to 20%). Among 17 possible N-acteyltransferases encoded in the genome of C. glutamicum, the enzyme encoded by cg1722 was found to be responsible for this reaction as deletion of cg1722 led to a yield increase of 11% and N-acetylcadaverine could no longer be detected in the supernatant (Kind et al. 2010a).

Conclusion and perspective

In this mini-review, we outlined the anabolic and catabolic polyamine pathways known so far in Bacteria and Archaea as well as the transport processes of polyamines, their precursors and derivatives across the cell membrane. This knowledge has recently been applied to engineer C. glutamicum and E. coli strains for cadaverine and putrescine production as described above. But where do we go from here?

The production of putrescine and cadaverine benefits both from single thermodynamically favorable decarboxylation reactions and from the wealth of knowledge about precursor amino acid biosynthesis in these organisms. Together, this led to reasonable titers and productivities (Table 1). However, the effect of several known engineering targets has not been investigated in putrescine and cadaverine production strains until now. For example, the engineering for putrescine production focused on reactions downstream of l-glutamic acid. The effect of deregulation of the 2-oxolglutaric acid dehydrogenase complex (ODHC), which has been shown to be relevant for l-glutamic acid overproduction (Shimizu and Hirasawa 2007), remains uninvestigated. For l-lysine production, the effect of NADPH supply is known to be important (Wittmann and Becker 2007), which remains also uninvestigated in cadaverine production strains. Hence, there are still engineering targets known which might be worth investigating in putrescine and cadverine overproducing strains.

Higher polyamines such as the triamines aminopropylcadaverine and spermidine are derived directly from cadaverine and putrescine, respectively (Fig. 2; reactions 11, 22). However, all known aminopropyltransferases require decarboxylated S-adenosylmethionine (dcSAM) as the aminopropyl donor. In these organisms, dcSAM is generated from S-adenosylmethionine (SAM), a central intermediate of sulfur and C1 metabolism involved in many crucial reactions. Its synthesis is costly as three ATP equivalents are required for transferring adenine from ATP to l-methionine. Moreover, 5′-methylthioadenosine (MTA) formed as co-product of dcSAM-dependent aminopropyltransferase reactions has to be recycled and the only known pathway for MTA recycling involves a multiple reaction cascade leading to adenine and l-methionine (Sekowska and Danchin 2002). Because of the energy requirements, the complex cofactor recycling pathway, and the intricate network of SAM converting pathways, metabolic engineering for the overproduction of polyamines involving SAM-dependent aminopropyltransferases is extremely challenging.

The approaches described here focused exclusively on bacterial pathways. However, the potential of archaeal and eukaryotic pathways to polyamines may be tapped in the future within the framework of synthetic biology.

References

Applebaum DM, Dunlap JC, Morris DR (1977) Comparison of the biosynthetic and biodegradative ornithine decarboxylases of Escherichia coli. Biochemistry 16:1580–1584

Applebaum D, Sabo DL, Fischer EH, Morris DR (1975) Biodegradative ornithine decarboxylase of Escherichia coli. Purification, properties, and pyridoxal 5′-phosphate binding site. Biochemistry 14:3675–3681

Bachrach U (1962a) Formation of pyrroline and propane diamine from spermidine by extracts of Serratia marcescens. Nature 194:377–378

Bachrach U (1962b) Spermidine oxidase from Serratia marcescens. J Biol Chem 237:3443–3448

Bellmann A, Vrljic M, Patek M, Sahm H, Krämer R, Eggeling L (2001) Expression control and specificity of the basic amino acid exporter LysE of Corynebacterium glutamicum. Microbiology 147:1765–1774

Blethen SL, Boeker EA, Snell EE (1968) Arginine decarboxylase from Escherichia coli I. Purification and specificity for substrates and coenzyme. J Biol Chem 243:1671–1677

Bowman WH, Tabor CW, Tabor H (1973) Spermidine biosynthesis. Purification and properties of propylamine transferase from Escherichia coli. J Biol Chem 248:2480–2486

Brickman TJ, Armstrong SK (1996) The ornithine decarboxylase gene odc is required for alcaligin siderophore biosynthesis in Bordetella spp.: putrescine is a precursor of alcaligin. J Bacteriol 178:54–60

Buschke N, Schröder H, Wittmann C (2011) Metabolic engineering of Corynebacterium glutamicum for production of 1,5-diaminopentane from hemicellulose. Biotechnol J 6:306–317

Cacciapuoti G, Porcelli M, Moretti MA, Sorrentino F, Concilio L, Zappia V, Liu Z, Tempel W, Schubot F, Rose JP, Wang B, Brereton PS, Jenney FE, Adams MWW (2007) The first agmatine/cadaverine aminopropyl transferase: biochemical and structural characterization of an enzyme involved in polyamine biosynthesis in the hyperthermophilic archaeon Pyrococcus furiosus. J Bacteriol 189:6057–6067

Chattopadhyay MK, Tabor CW, Tabor H (2009) Polyamines are not required for aerobic growth of Escherichia coli: preparation of a strain with deletions in all of the genes for polyamine biosynthesis. J Bacteriol 191:5549–5552

Driessen AJ, Smid EJ, Konings WN (1988) Transport of diamines by Enterococcus faecalis is mediated by an agmatine–putrescine antiporter. J Bacteriol 170:4522–4527

Eppelmann K, Nossin PMM, Kremer SM, Wubbolts MG (2006) Biochemical synthesis of 1,4-butanediamine. WO 2006005604

Filippou P, Lioliou E, Panagiotidis C, Athanassopoulos C, Garnelis T, Papaioannou D, Kyriakidis D (2007) Effect of polyamines and synthetic polyamine-analogues on the expression of antizyme (AtoC) and its regulatory genes. BMC Biochem 8:1

Foster JW (2004) Escherichia coli acid resistance: tales of an amateur acidophile. Nat Rev Micro 2:898–907

Fothergill JC, Guest JR (1977) Catabolism of l-lysine by Pseudomonas aeruginosa. J Gen Microbiol 99:139–155

Furuchi T, Kashiwagi K, Kobayashi H, Igarashi K (1991) Characteristics of the gene for a spermidine and putrescine transport system that maps at 15 min on the Escherichia coli chromosome. J Biol Chem 266:20928–20933

Gong S, Richard H, Foster JW (2003) YjdE (AdiC) is the arginine:agmatine antiporter essential for arginine-dependent acid resistance in Escherichia coli. J Bacteriol 185:4402–4409

Glansdorff N, Xu Y (2007) Microbial arginine biosynthesis: pathway, regulation and industrial production. In: Wendisch VF (ed) Amino acid biosynthesis—pathways, regulation and metabolic engineering. Springer, Berlin

Gunji Y, Yasueda H (2006) Enhancement of l-lysine production in methylotroph Methylophilus methylotrophus by introducing a mutant LysE exporter. J Biotechnol 127:1–13

Hamana K, Matsuzaki S (1992) Polyamines as a chemotaxonomic marker in bacterial systematics. Crit Rev Microbiol 18:261–283

Higashi K, Ishigure H, Demizu R, Uemura T, Nishino K, Yamaguchi A, Kashiwagi K, Igarashi K (2008) Identification of a spermidine excretion protein complex (MdtJI) in Escherichia coli. J Bacteriol 190:872–878

Hisano T, Abe S, Wakashiro M, Kimura A, Murata K (1990) Microbial spermidine dehydrogenase: purification and properties of the enzyme in Pseudomonas aeruginosa and Citrobacter freundii. J Ferment Bioeng 69:335–340

Hofle MG (1984) Degradation of putrescine and cadaverine in seawater cultures by marine bacteria. Appl Environ Microbiol 47:843–849

Igarashi K, Kashiwagi K (2010) Characteristics of cellular polyamine transport in prokaryotes and eukaryotes. Plant Physiol Biochem 48:506–512

Jung IL, Oh TJ, Kim G (2003) Abnormal growth of polyamine-deficient Escherichia coli mutant is partially caused by oxidative stress-induced damage. Arch Biochem Biophys 418:125–132

Kashiwagi K, Miyamoto S, Suzuki F, Kobayashi H, Igarashi K (1992) Excretion of putrescine by the putrescine–ornithine antiporter encoded by the potE gene of Escherichia coli. Proc Natl Acad Sci USA 89:4529–4533

Kashiwagi K, Shibuya S, Tomitori H, Kuraishi A, Igarashi K (1997) Excretion and uptake of putrescine by the PotE protein in Escherichia coli. J Biol Chem 272:6318–6323

Kikuchi Y, Kojima H, Tanaka T, Takatsuka Y, Kamio Y (1997) Characterization of a second lysine decarboxylase isolated from Escherichia coli. J Bacteriol 179:4486–4492

Kind S, Jeong WK, Schröder H, Zelder O, Wittmann C (2010a) Identification and elimination of the competing N-acetyldiaminopentane pathway for improved production of diaminopentane by Corynebacterium glutamicum. Appl Environ Microbiol 76:5175–5180

Kind S, Jeong WK, Schröder H, Wittmann C (2010b) Systems-wide metabolic pathway engineering in Corynebacterium glutamicum for bio-based production of diaminopentane. Metab Eng 12:341–351

Knott JM (2009) Biosynthesis of long-chain polyamines by crenarchaeal polyamine synthases from Hyperthermus butylicus and Pyrobaculum aerophilum. FEBS Lett 583:3519–3524

Kroschwitz JI, Seidel A (2004) Kirk–Othmer encyclopedia of chemical technology, 5th edn. Wiley-Interscience, Hoboken

Kurihara S, Suzuki H, Oshida M, Benno Y (2011) A novel putrescine importer required for type 1 pili-driven surface motility induced by extracellular putrescine in Escherichia coli K-12. J Biol Chem. doi:https://doi.org/10.1074/jbc.M110.176032

Kurihara S, Oda S, Tsuboi Y, Kim HG, Oshida M, Kumagai H, Suzuki H (2008) Gamma-glutamylputrescine synthetase in the putrescine utilization pathway of Escherichia coli K-12. J Biol Chem 283:19981–19990

Kurihara S, Kato K, Asada K, Kumagai H, Suzuki H (2010) A putrescine-inducible pathway comprising PuuE-YneI in which gamma-aminobutyrate is degraded into succinate in Escherichia coli K-12. J Bacteriol 192:4582–4591

Kurihara S, Tsuboi Y, Oda S, Kim HG, Kumagai H, Suzuki H (2009) Putrescine importer PuuP of Escherichia coli K-12. J Bacteriol 191:2776–2782

Kurihara S, Oda S, Kato K, Kim HG, Koyanagi T, Kumagai H, Suzuki H (2005) A novel putrescine utilization pathway involves gamma-glutamylated intermediates of Escherichia coli K-12. J Biol Chem 280:4602–4608

Lee J, Sperandio V, Frantz DE, Longgood J, Camilli A, Phillips MA, Michael AJ (2009) An alternative polyamine biosynthetic pathway is widespread in bacteria and essential for biofilm formation in Vibrio cholerae. J Biol Chem 284:9899–9907

Lee KH, Park JH, Kim TY, Kim HU, Lee SY (2007) Systems metabolic engineering of Escherichia coli for l-threonine production. Mol Syst Biol 3:149

Legrain C, Halleux P, Stalon V, Glansdorff N (1972) The dual genetic control of ornithine carbamoyltransferase in Escherichia coli: a case of bacterial hybrid enzymes. Eur J Biochem 27:93–102

Limsuwun K, Jones PG (2000) Spermidine acetyltransferase is required to prevent spermidine toxicity at low temperatures in Escherichia coli. J Bacteriol 182:5373–5380

Madduri K, Stuttard C, Vining LC (1989) Lysine catabolism in Streptomyces spp. is primarily through cadaverine: beta-lactam producers also make alpha-aminoadipate. J Bacteriol 171:299–302

Matsui I, Kamei M, Otani S, Morisawa S, Pegg AE (1982) Occurrence and induction of spermidine-N1-acetyltransferase in Escherichia coli. Biochem Biophys Res Commun 106:1155–1160

Mimitsuka T, Sawai H, Hatsu M, Yamada K (2007) Metabolic engineering of Corynebacterium glutamicum for cadaverine fermentation. Biosci Biotechnol Biochem 71:2130–2135

Miyamoto S, Kashiwagi K, Ito K, Watanabe S, Igarashi K (1993) Estimation of polyamine distribution and polyamine stimulation of protein synthesis in Escherichia coli. Arch Biochem Biophys 300:63–68

Morimoto N, Fukuda W, Nakajima N, Msuda T, Terui Y, Kanai T, Oshima T, Imanaka T, Fujiwara S (2010) Dual biosynthesis pathway for longer-chain polyamines in the hyperthermophilic archaeon Thermococcus kodakarensis. J Bacteriol 192:4991–5001

Nakada Y, Itoh Y (2003) Identification of the putrescine biosynthetic genes in Pseudomonas aeruginosa and characterization of agmatine deiminase and N-carbamoylputrescine amidohydrolase of the arginine decarboxylase pathway. Microbiology 149:707–714

Nakao H, Shinoda S, Yamamoto S (1991) Purification and some properties of carboxynorspermidine synthase participating in a novel biosynthetic pathway for norspermidine in Vibrio alginolyticus. Microbiology 137:1737–1742

Nakao H, Shinoda S, Yamamoto S (1990) Purification and properties of carboxynorspermidine decarboxylase, a novel enzyme involved in norspermidine biosynthesis, from Vibrio alginolyticus. Microbiology 136:1699–1704

Nandineni MR, Gowrishankar J (2004) Evidence for an arginine exporter encoded by yggA (argO) that is regulated by the LysR-Type transcriptional regulator ArgP in Escherichia coli. J Bacteriol 186:3539–3546

Nishi K, Endo S, Mori Y, Totsuka K, Hirao Y (2007) Method for producing cadaverine dicarboxylate. US 7189543 B2

Ohnuma M, Terui Y, Tamakoshi M, Mitome H, Niitsu M, Samejima K, Kawashima E, Oshima T (2005) N1-aminopropylagmatine, a new polyamine produced as a key intermediate in polyamine biosynthesis of an extreme thermophile, Thermus thermophilus. J Biol Chem 280:30073–30082

Oshima T (2007) Unique polyamines produced by an extreme thermophile, Thermus thermophilus. Amino Acids 33:367–372

Oshima T (2010) Enigmas of biosyntheses of unusual polyamines in an extreme thermophile, Thermus thermophilus. Plant Physiol Biochem 48:521–526

Park JH, Lee SY (2010) Metabolic pathways and fermentative production of l-aspartate family amino acids. Biotechnol J 5:560–577

Patel CN, Wortham BW, Lines JL, Fetherston JD, Perry RD, Oliveira MA (2006) Polyamines are essential for the formation of plague biofilm. J Bacteriol 188:2355–2363

Paulin L, Ruohola H, Nykänen I, Pösö H (1983) The incorporation of 1,3-diaminopropane into thermine by an extreme thermophile: a novel route for the biosynthesis of polyamines. FEMS Microbiol Lett 19:299–302

Peters-Wendisch PG, Schiel B, Wendisch VF, Katsoulidis E, Möckel B, Sahm H, Eikmanns BJ (2001) Pyruvate carboxylase is a major bottleneck for glutamate and lysine production by Corynebacterium glutamicum. J Mol Microbiol Biotechnol 3:295–300

Peters-Wendisch PG, Kreutzer C, Kalinowski J, Pátek M, Sahm H, Eikmanns BJ (1998) Pyruvate carboxylase from Corynebacterium glutamicum: characterization, expression and inactivation of the pyc gene. Microbiology 144:915–927

Pistocchi R, Kashiwagi K, Miyamoto S, Nukui E, Sadakata Y, Kobayashi H, Igarashi K (1993) Characteristics of the operon for a putrescine transport system that maps at 19 minutes on the Escherichia coli chromosome. J Biol Chem 268:146–152

Platt DK (2003) Engineering and high performance plastics market report. A Rapra market report. Rapra Technology Ltd., Shawbury

Qian Z, Xia X, Lee SY (2009) Metabolic engineering of Escherichia coli for the production of putrescine: a four carbon diamine. Biotechnol Bioeng 104:651–662

Qian Z, Xia X, Lee SY (2011) Metabolic engineering of Escherichia coli for the production of cadaverine: a five carbon diamine. Biotechnol Bioeng 108:93–103

Ren Q, Paulsen IT (2005) Comparative analyses of fundamental differences in membrane transport capabilities in prokaryotes and eukaryotes. PLoS Comp Biol 1:e27

Revelles O, Espinosa-Urgel M, Fuhrer T, Sauer U, Ramos JL (2005) Multiple and interconnected pathways for l-lysine catabolism in Pseudomonas putida KT2440. J Bacteriol 187:7500–7510

Riedel C, Rittmann D, Dangel P, Möckel B, Petersen S, Sahm H, Eikmanns BJ (2001) Characterization of the phosphoenolpyruvate carboxykinase gene from Corynebacterium glutamicum and significance of the enzyme for growth and amino acid production. J Mol Microbiol Biotechnol 3:573–583

Rosen BP (1971) Basic amino acid transport in Escherichia coli. J Biol Chem 246:3653–3662

Sabo DL, Boeker EA, Byers B, Waron H, Fischer EH (1974) Purification and physical properties of inducible Escherichia coli lysine decarboxylase. Biochemistry 13:662–670

Satishchandran C, Boyle SM (1986) Purification and properties of agmatine ureohydrolyase, a putrescine biosynthetic enzyme in Escherichia coli. J Bacteriol 165:843–848

Schneider J, Wendisch VF (2010) Putrescine production by engineered Corynebacterium glutamicum. Appl Microbiol Biotechnol 88:859–868

Seep-Feldhaus AH, Kalinowski J, Pühler A (1991) Molecular analysis of the Corynebacterium glutamicum lysl gene involved in lysine uptake. Mol Microbiol 5:2995–3005

Seiler N (2004) Catabolism of polyamines. Amino Acids 26:217–233

Seiler N (1990) Polyamine metabolism. Digestion 46:319–330

Sekowska A, Danchin A (2002) The methionine salvage pathway in Bacillus subtilis. BMC Microbiol 2:8

Shaibe E, Metzer E, Halpern YS (1985) Metabolic pathway for the utilization of l-arginine, l-ornithine, agmatine, and putrescine as nitrogen sources in Escherichia coli K-12. J Bacteriol 163:933–937

Shimizu H, Hirasawa T (2007) Production of glutamate and glutamate-related amino acids: molecular mechanism analysis and metabolic engineering. In: Wendisch VF (ed) Amino acid biosynthesis—pathways, regulation and metabolic engineering. Springer, Berlin

Soksawatmaekhin W, Kuraishi A, Sakata K, Kashiwagi K, Igarashi K (2004) Excretion and uptake of cadaverine by CadB and its physiological functions in Escherichia coli. Mol Microbiol 51:1401–1412

Steffes C, Ellis J, Wu J, Rosen BP (1992) The lysP gene encodes the lysine-specific permease. J Bacteriol 174:3242–3249

Stäbler N, Oikawa T, Bott M, Eggeling L (2011) Corynebacterium glutamicum as a host for synthesis and export of d-amino acids. J Bacteriol 193:1702–1709

Sturgill G, Rather PN (2004) Evidence that putrescine acts as an extracellular signal required for swarming in Proteus mirabilis. Mol Microbiol 51:437–446

Suzuki O, Ishikawa Y, Miyazaki K, Izu K, Matsumoto T (1986) Acetylputrescine deacetylase from Micrococcus luteus K-11. Biochim Biophys Acta Gen Subj 882:140–142

Tabor CW, Tabor H (1985) Polyamines in microorganisms. Microbiol Rev 49:81–99

Tait GH (1976) A new pathway for the biosynthesis of spermidine. Biochem Soc Trans 4:610–612

Tait GH (1979) The formation of homospermidine by an enzyme from Rhodopseudomonas viridis. Biochem Soc Trans 7:199–201

Takatsuka Y, Kamio Y (2004) Molecular dissection of the Selenomonas ruminantium cell envelope and lysine decarboxylase involved in the biosynthesis of a polyamine covalently linked to the cell wall peptidoglycan layer. Biosci Biotechnol Biochem 68:1–19

Tateno T, Okada Y, Tsuchidate T, Tanaka T, Fukuda H, Kondo A (2008) Direct production of cadaverine from soluble starch using Corynebacterium glutamicum coexpressing alpha-amylase and lysine decarboxylase. Appl Microbiol Biotechnol 82:115–121

van Hellemond EW, van Dijk M, Heuts DPHM, Janssen DB, Fraaije MW (2008) Discovery and characterization of a putrescine oxidase from Rhodococcus erythropolis NCIMB 11540. Appl Microbiol Biotechnol 78:455–463

Verseck S, Häger H, Karau A, Eggeling L, Sahm H (2008) Verfahren zur fermentativen Herstellung von Cadaverin. DE 102007005072 A1

Völkert M, Zelder O, Ernst B, Jeong WK (2010) Method for fermentatively producing 1,5-diaminopentane. US 20100292429 A1

Vrljic M, Sahm H, Eggeling L (1996) A new type of transporter with a new type of cellular function: l-lysine export from Corynebacterium glutamicum. Mol Microbiol 22:815–826

Vrljic M, Garg J, Bellmann A, Wachi S, Freudl R, Malecki MJ, Sahm H, Kozina VJ, Eggeling L, Saier MH (1999) The LysE superfamily: topology of the lysine exporter LysE of Corynebacterium glutamicum, a paradyme for a novel superfamily of transmembrane solute translocators. J Mol Microbiol Biotechnol 1:327–336

Wallace HM, Fraser AV, Hughes A (2003) A perspective of polyamine metabolism. Biochem J 376:1–14

Wargnies B, Lauwers N, Stalon V (1979) Structure and properties of the putrescine carbamoyltransferase of Streptococcus faecalis. Eur J Biochem 101:143–152

Wittmann C, Becker J (2007) The l-lysine story: from metabolic pathways to industrial production. In: Wendisch VF (ed) Amino acid biosynthesis—pathways, regulation and metabolic engineering. Springer, Berlin

Wissenbach U, Six S, Bongaerts J, Ternes D, Steinwachs S, Unden G (1995) A third periplasmic transport system for l-arginine in Escherichia coli: molecular characterization of the artPIQMJ genes, arginine binding and transport. Mol Microbiol 17:675–686

Wu WH, Morris DR (1973) Biosynthetic arginine decarboxylase from Escherichia coli: subunit interactions and the role of magnesium ion. J Biol Chem 248:1696–1699

Yamamoto S, Hamanaka K, Suemoto Y, Ono B, Shinoda S (1986) Evidence for the presence of a novel biosynthetic pathway for norspermidine in Vibrio. Can J Microbiol 32:99–103

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schneider, J., Wendisch, V.F. Biotechnological production of polyamines by Bacteria: recent achievements and future perspectives. Appl Microbiol Biotechnol 91, 17–30 (2011). https://doi.org/10.1007/s00253-011-3252-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3252-0