Abstract

In a previous study, biogenic silver nanoparticles were produced by Lactobacillus fermentum which served as a matrix preventing aggregation. In this study the antibacterial activity of this biogenic silver was compared to ionic silver and chemically produced nanosilver. The minimal inhibitory concentration (MIC) was tested on Gram-positive and Gram-negative bacteria and was comparable for biogenic silver and ionic silver ranging from 12.5 to 50 mg/L. In contrast, chemically produced nanosilver had a much higher MIC of at least 500 mg/L, due to aggregation upon application. The minimal bactericidal concentration (MBC) in drinking water varied from 0.1 to 0.5 mg/L for biogenic silver and ionic silver, but for chemically produced nanosilver concentrations, up to 12.5 mg/L was needed. The presence of salts and organic matter decreased the antimicrobial activity of all types of silver resulting in a higher MBC and a slower inactivation of the bacteria. The mode of action of biogenic silver was mainly attributed to the release of silver ions due to the high concentration of free silver ions measured and the resemblance in performance between biogenic silver and ionic silver. Radical formation by biogenic silver and direct contact were found to contribute little to the antibacterial activity. In conclusion, biogenic nanosilver exhibited equal antimicrobial activity compared to ionic silver and can be a valuable alternative for chemically produced nanosilver.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silver has been used for its strong antimicrobial properties for many years. Even Alexander the Great used silver vessels to store drinking water (Silver et al. 2006). However, the formulation of silver has changed during history, from bulk silver in vessels and coins during Antiquity, to ionic silver supplemented as silver salts (e.g., AgNO3) or adsorbed on carrier materials (e.g., zeolite; Kwakye-Awuah et al. 2008) and now to silver nanoparticles.

Silver nanoparticles can be produced by several procedures, through either chemical or physical processes. However, these methods can encounter problems such as particle aggregation and upscaling difficulties (Tavakoli et al. 2007). Additionally, due to the use of toxic solvents and stabilizers, there is need for more eco-friendly production methods which is why the focus is now towards developing biological processes using microorganisms. Fungi, as well as bacteria, are able to form silver nanoparticles, also known as biogenic silver, by reducing silver ions (Shahverdi et al. 2007; Mukherjee et al. 2001; Kathiresan et al. 2009; Klaus et al. 1999; Fu et al. 2006). Recently, we have developed a new method using Lactobacillus sp. which precipitates biogenic silver on their cell wall (Sintubin et al. 2009). Depending on the species used, biogenic silver with different characteristics was obtained, with Lactobacillus fermentum (L. fermentum) having particles with the smallest diameter (average 11 nm) and the most narrow size distribution. A common problem with nanoparticles during application is aggregation which decreases the specific surface of the nanoparticles and, therefore, their antimicrobial and/or catalytic activity (Mafune et al. 2000). Because the biologically produced silver nanoparticles are attached with the microscale surface of the bacterium on which they were formed, they are prevented from aggregation, making them an interesting alternative for chemically produced silver nanoparticles.

Silver nanoparticles have been demonstrated to exhibit biocidal activity towards a broad range of Gram-positive and Gram-negative bacteria, viruses, and fungi (Elechiguerra et al. 2005; Morones et al. 2005; Yoon et al. 2007; Edwards-Jones 2009). Moreover, compared to other metals, the toxicity of silver is very low towards humans (Lansdown 2007). This makes nanosilver an interesting candidate for a number of applications such as water decontamination and surface disinfection in particular since some commonly used disinfection methods such as chlorination and ozone can produce toxic by-products (Li et al. 2008; Boorman et al. 1999; Gopal et al. 2007). Though several mechanisms have been proposed, the antimicrobial activity of silver nanoparticles is not fully understood. Silver nanoparticles are considered to be a slow release source of silver ions which react with thiol groups of proteins and interfere with DNA replication (Morones et al. 2005; Liau et al. 1997; Feng et al. 2000). Alternatively, silver is also known to generate free radicals which damage the bacterial membrane (Kim et al. 2007; Kumar et al. 2007). In addition, it is suggested that antibacterial activity can also occur through direct physical contact between the nanoparticles and bacterial cells causing structural damage to their cell wall (Sondi and Salopek-Sondi 2004; Kim et al. 2007).

Until now, little research has been done on the antibacterial activity of biologically produced nanosilver and its specific mode of action. The aim of this study was to examine the antibacterial properties of biogenic silver associated with Lactobacillus sp. cell walls and to compare these properties with those of chemically produced nanosilver. This current study investigates the antibacterial activity of biogenic silver in drinking water and in culture conditions with salts and organic matter. Additionally, the results of this study have brought us closer to elucidating the underlying antibacterial mechanisms of biogenic silver.

Material and methods

Bacterial strains and media

Escherichia coli LMG 10266 (E. coli) was grown on Luria Bertani agar containing 5 g/L NaCl (Prolabo, VWR International, Leuven, Belgium), 10 g/L trypton (Biochemica, Applichem, Darmstadt, Germany), 5 g/L yeast extract (Oxoid, Basingstoke, UK), and 15 g/L agar–agar (Oxoid, Basingstoke, UK). Pseudomonas aeruginosa LMG 9009 (P. aeruginosa) and Staphylococcus aureus LMG 8064 (S. aureus) were grown on tryptic soy agar (Difco BD, Sparks, MD, USA). All bacteria were incubated for 24 h at 37 °C. Liquid cultures were prepared in tryptic soy broth (TSB), except for E. coli which was grown in Luria Bertani broth (LB). To prepare a working culture, a liquid culture grown overnight was washed three times with autoclaved bottled drinking water (Spa blauw, Spadel, Brussels, Belgium), followed by adjustment of the optical density (OD) at 610 nm to obtain a predetermined number of cells. All strains were obtained from the BCCM collection in Belgium.

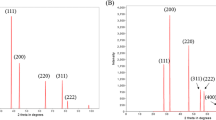

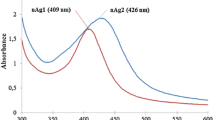

Biogenic silver, chemically produced nanosilver and ionic silver

Biogenic silver was prepared as described earlier (Sintubin et al. 2009). Briefly, after L. fermentum LMG 8900 biomass was harvested by subsequent centrifugation and washing in MilliQ water, the pH was increased with NaOH to 11.5, followed by the addition of a diamine silver complex in a ratio of 1:4.6 Ag to cell dry weight (CDW). After 24 h, the produced biogenic silver was harvested by centrifugation at 10,000×g and washed with MilliQ water. This was followed by measuring the concentration of Ag(0) in the suspension with atomic absorption spectroscopy (AAS). The average particle size measured with transmission electron microscopy (TEM) was approximately 11.2 ± 0.9 nm (Sintubin et al. 2009).

The chemically produced nanosilver, as described by De Gusseme et al. (2010) had a concentration of 131 g/L, containing particles with a size of 20 ± 10 nm according to scanning electron microscopy analysis. The size of aggregates was measured with dynamic light scattering (DLS) using a Malvern PCS 1005M photon correlation spectrophotometer with Malvern K7032CN digital correlator (Malvern, UK) at a fixed scattering angle of 150° and a duration time of 120 s. AgNO3 (Sigma-Aldrich, St. Louis, MO, USA) was used as the source of silver ions. All experiments with silver ions were performed in the dark by covering the recipient with aluminium foil or by incubating the recipient inside a dark cabinet.

Determination of the minimal inhibitory concentration

A series of dilutions of ionic silver, chemically produced nanosilver, and biogenic silver was made in a transparent flat-bottomed 96-well microtiter plate (VWR Prolabo, Leuven, Belgium). To every well of the microtiter plate, 100 μL of double concentrated broth inoculated with E. coli, S. aureus, or P. aeruginosa was added. The final silver concentrations were 0, 1, 3.1, 6.3, 12.5, 25, 50, 100, 200, and 500 mg/L. Final cell suspensions contained 5 × 107 CFU/mL of bacteria. A series of wells without silver were used as a first control. As an additional control without silver, L. fermentum was processed in the same way as described for the production of biogenic silver without the addiction of AgNO3. The plate was incubated at 37 °C in a PowerWave 340 microtiter plate reader (BioTek Instruments, Winooski, USA), and growth in each well was assessed during 24 h by measuring the optical density at 620 nm every 20 min. Before every measurement, the microtiter plate was shaken for 5 s. It should be mentioned that in the above 100 mg/L, the color of the nanosilver interfered with the spectrophotometric OD measurement; however, bacterial growth could still be distinguished visually.

Determination of the minimal bactericidal concentration

Tests were performed in liquid medium (LB or TSB broth) or bottled drinking water (Spa blauw, Spadel, Brussels, Belgium) containing 1.45 mg/L Cl−, 0.46 mg/L NO −3 , 0.48 mg/L PO 3−4 , and 1.11 mg/L SO 2−4 (pH 6.2). A set of test tubes containing biogenic silver, chemically produced silver or ionic silver were inoculated with 5 × 107 CFU/mL bacteria and incubated on a shaker (120 rpm) at 37 °C or 28 °C. The final silver concentrations were 0.05, 0.1, 0.25, 0.5, 0.75, 1, 3.1, 6.3, 12.5, 25, 50, 100, 200, and 500 mg/L. Plain water or medium was used as a control. After 24 h of incubation, a 1-mL sample was taken and free silver was quenched by adding 5 g/L Na2S2O3 to stop the antimicrobial reaction as described in the European quality standards (NEN-EN 1276, 1997). A sequential series of 1:10 dilutions was made in saline solution (8.5 g/L NaCl) and plated by pour plating according to the European standards (NEN-EN 1997). After incubating the plates during 24 h at 37 °C, colonies were counted.

Disinfection kill rate assay

All disinfection assays were performed in drinking water. Disinfection assays were carried out in 100-mL Erlenmeyer flasks on a shaker (120 rpm) at 28 °C. To 50 mL of bottled water, biogenic silver or ionic silver was supplemented to a final concentration of 0.5 or 12.5 mg/L. This was followed by the addition of E. coli up to a concentration of 5 × 107 CFU/mL. At regular time intervals, samples were taken and immediately quenched with 5 g/L Na2S2O3, subsequently followed by serial dilution in saline solution and plating as described previously.

A comparable test was set up to investigate the effect of organic matter and chloride ions on the disinfection efficiency. In this case 6 g/L bovine serum albumin (BSA) or 8.5 g/L NaCl was added to a sample containing 12.5 mg/L biogenic silver or ionic silver. All experiments were performed in triplicate.

Mode of action tests

To test the mode of action of biogenic silver, we investigated the influence of reactive oxygen species (ROS) production, direct contact, and silver ion release on the antimicrobial activity. The antibacterial activity of biogenic silver was compared with ionic silver as a benchmark. The mode of action of biogenic and chemical nanosilver was considered to be the same, and therefore the latter was not taken into account for these set of tests. All the tests were performed in triplicate with E. coli which was spiked into 50 mL of bottled drinking water up to a concentration of 7.5 × 107 CFU/mL.

ROS production was measured by fluorescence spectroscopy according to Gerber and Dubery (2003). In brief, to 100 μL sample, 200 μM 2′,7′-dichlorodihydrofluorescein diacetate (H2DCF-DA; Sigma-Aldrich, St. Louis, MO, USA) stock in DMSO was added to a final concentration of 100 μM. Oxidation of H2DCF-DA was measured with a Tecan Infinite M200 microtiter plate reader (Männedorf, Switzerland) with excitation at 485 nm and emission at 538 nm. The silver (12.5 mg/L biogenic silver) catalysed decomposition of 0.3% H2O2 was used as a positive control for ROS production (Bagg 1962).

In order to investigate the influence of ROS on the disinfection efficiency, penicillin bottles with 0.5 mg/L biogenic silver or ionic silver were incubated under different degrees of O2 saturation: anaerobic (0% O2), aerobic (20% O2), and hyperoxic (60% O2). To establish anaerobic conditions, 120-mL penicillin bottles were flushed with N2 gas for 30 min. To create hyperoxic conditions, 50 mL of pure O2 gas was added to the headspace of the bottles. After predetermined time intervals, samples were taken, quenched with Na2S2O3, diluted, and plated as described earlier.

To determine if direct contact contributes to the antimicrobial activity, two setups were constructed (Fig. S1). In setup 1, a dialysis membrane was used to shield the E. coli bacteria in the Erlenmeyer from direct contact with biogenic silver. Dialysis tubing which was obtained from Sigma-Aldrich as it retains molecules with a molecular weight of 12,000 kDa or higher. Since biogenic silver consists of nanoparticles on a bacterial carrier, it is prevented from migrating through the membrane. In setup 2 biogenic silver and E. coli were added together to the Erlenmeyer making direct contact feasible. However, to take into account the influence of possible sorption of silver, a dialysis membrane was present. Similar setups were used for ionic silver. After 24 h of incubation at 28 °C on a shaker (120 rpm), samples were taken and quenched, diluted, and plated as described previously.

Free silver ions were measured using an ion-selective silver electrode (Prosense, Oosterhout, Netherlands). Before measurement, the ionic strength of every sample was adjusted by adding 1 mL of a 5 M NaNO3 stock solution to 100 mL sample.

Measurement of membrane permeability and esterase activity

To measure the membrane permeability of E. coli cells after treatment with 0.5 mg/L of biogenic silver or ionic silver, a LIVE/DEAD staining was performed by adding 10 μL of propidiumiodide and Sybr Green (Invitrogen, Eugene, OR, USA) and 10 μL Na2EDTA (pH 8, 500 mM) to 980 μL of sample. The sample was incubated for 15 min in the dark in order to stain the bacterial cells.

To measure the esterase activity 100 μL of a phosphate buffer (pH 8, 1 M), 50 μL Na2EDTA (pH 8, 500 mM) and 5 μL 5,6-carboxyfluorescein diacetate (10 mM in DMSO) (Invitrogen, Eugene, OR, USA) to 900 μL sample. The sample was incubated at 35 °C for 30 min. Samples were analyzed with a CyanTM LX flow cytometer (Dakocytomation, Heverlee, Belgium) equipped with a 50-mW sapphire solid state diode laser (488 nm) and SummitTM 4.0 software (Dakocytomation). Green (FL1) and red (FL2) fluorescence emissions were collected with photomultiplier tubes by using 530/40 and 613/20 bandpass filters, respectively (Boon et al. 2006). To quantify the number of cells, 25 μL of counting beads (Dako, Glostrup, Denmark) were added and each sample was analyzed in triplicate.

Statistical analysis

SPSS for Windows version 16.0 was used for statistical analysis. Results were considered significantly different at an α two-tailed level of 0.05. Tests for normality of the data and equality of the variances were performed using the Kolmogorov–Smirnov and Levene's test respectively. Comparison of normal distributed data was performed with one-way ANOVA. The nonparametric Kruskal–Wallis and Mann–Whitney U test were used to compare non-normal distributed data.

Results

Antimicrobial activity

The minimal inhibitory concentrations (MIC) of ionic silver, biogenic silver, and chemically produced nanosilver were performed in growth medium and compared for three bacterial species (E. coli, P. aeruginosa, and S. aureus). The OD was measured during 24 h and for all strains, the OD immediately increased for the control without silver. A silver-free control containing only L. fermentum biomass showed no inhibition of growth. When biogenic silver or ionic silver was present, however, the growth of the bacteria was delayed compared to the control as shown for S. aureus in Fig. 1 (other data not shown). A lag of 40 min increased with higher silver concentrations up to 22 h. In the case of chemically produced nanosilver, hardly no delay in growth could be observed for all concentrations.

The MIC was defined as the lowest silver concentration, which showed no increase in OD, (no bacterial growth) during 24 hours (Table 1). S. aureus still showed growth at a concentration of 500 mg/L chemically produced nanosilver, which was the highest concentration tested. In the case of E. coli and P. aeruginosa, however, no growth could be observed at 500 mg/L chemically produced nanosilver. In the case of biogenic silver and ionic silver, the MIC was 12.5 mg/L for the Gram-negative bacteria E. coli and P. aeruginosa, while for S. aureus, the MIC was 25 and 50 mg/L for ionic silver and biogenic silver respectively.

The minimal bactericidal concentrations (MBCs) were determined in growth medium and water by plating the bacteria after 24 h of exposure to ionic silver, biogenic silver, or chemically produced nanosilver. The minimal concentration of silver, which gave rise to plates without bacterial colonies, was considered as the MBC. For all three bacteria, the MBC of chemically produced nanosilver in growth medium was above 500 mg/L which was the highest concentration tested. Biogenic silver had an MBC of 25, 100, and 200 mg/L for E. coli, P. aeruginosa, and S. aureus respectively. The MBC of ionic silver was the same as for biogenic silver, with the exception of P. aeruginosa where it was 50 mg/L. For all silver species, the MBC in water was up to 125 times lower than the MIC in growth medium and 400 times lower than the MBC in growth medium (Table 1).

To examine the rate of inactivation of E. coli, the log decrease was observed in function of time 0.5 and 12.5 mg/L of ionic silver and biogenic silver in water (Fig. 2). Initially, 3.2 × 107 or 7.5 log CFU/mL of E. coli cells were present. Within 10 min a decrease of at least 1 log unit could be observed with 12.5 mg/L ionic silver and biogenic silver. In the case of 12.5 mg/L ionic silver, no colonies could be detected after 1 h of exposure, while in the case of biogenic silver, a total 7.5 log decrease was obtained after 2 h. Although it took more time to inactivate all bacteria with 0.5 mg/L of both types of silver, the same trend was observed. Ionic silver tended to be slightly faster than biogenic silver. After 3 h no colonies of the initial 7.5 log CFU/mL were detected when E. coli was exposed to 0.5 mg/L of ionic silver, while in the case of ionic silver, a total decrease of 7.5 log was only observed after 4 h.

To assess the impact of organic ligands, BSA was added to the setup. In a second setup, NaCl was added to investigate the presence of salts on antimicrobial activity. Both compounds considerably decreased the inactivation of E. coli by ionic silver and biogenic silver (Fig. 3). In pure water, biogenic silver only needed 2 h for the total elimination of 7.5 log bacteria. However, inactivation time was extended to 6 and 7 h in the presence of NaCl and BSA respectively. In the presence of BSA and NaCl, ionic silver required 4–7 h compared to plain water to achieve a complete kill off.

The mode of action

To measure the release of silver ions by biogenic silver, the concentration of free silver ions was quantified with an ion-selective silver electrode (Fig. 4). The release of silver ions increased with higher biogenic silver concentrations reaching a maximum release of 5.8 mg/L ionic silver for 25 mg/L of biogenic silver (Fig. 4). Higher biogenic silver concentrations did not show a further increase in ion release; therefore, a steady state was obtained. The supply of 12.5 mg/L silver to plain water resulted in a free silver ion concentration of 0.56 and 1.01 mg/L respectively for biogenic silver and ionic silver (data not shown). In the presence of BSA or NaCl, the free silver ion concentration decreased considerately. BSA diminished the concentration to 0.02 mg/L in the case of biogenic silver and 0.12 mg/L in the case of ionic silver. In the case of sodium chloride, the free silver ion concentration was below the detection limit of the silver electrode for both types of silver (data not shown).

Radical production was quantified by the addition of the non-fluorescent precursor molecule 2′,7′-dichlorodihydrofluorescein diacetate (DCDF). In the presence of ROS, DCDF is oxidized to a fluorescent molecule of which the emitted light was measured. In the case of ionic silver, no increase in fluorescence, and therefore no substantial production of ROS, was observed compared to the control (Fig. 5). In contrast, biogenic silver formed twice as many radicals than ionic silver with ROS production stabilizing after 12 h. The silver catalysed decomposition of H2O2 catalysed was used as a positive control for ROS production. This positive control showed a maximum fluorescence increase of 24.5 times compared to the general control (data not shown).

The effect of radical formation on the antibacterial activity of 0.5 mg/L biogenic silver and ionic silver was investigated by observing the log decrease of E. coli under different degrees of O2 saturation: anaerobic (0% O2), aerobic (20% O2), and hyperoxic (60% O2; Fig. 6). No significant differences in killing rates could be observed for biogenic silver under the diverse conditions. For ionic silver a nonsignificant log decrease could be noticed under the several O2 saturation degrees. No significant difference was observed between ionic and biogenic silver.

To investigate if direct contact between bacteria and silver nanoparticles is needed for biogenic silver to perform its antibacterial activity, physical contact was prevented by isolating the silver nanoparticles behind a dialysis membrane (setup 1, Fig. S1). In the second setup, E. coli could directly interact with biogenic silver although a dialysis membrane was added to take possible sorption of silver ions into account (setup 2, Fig. S1). The results were compared to similar setups with ionic silver. Biogenic silver decreased the number of bacteria with 3.9 ± 0.7 log CFU/mL in setup 1 where direct contact was prevented. According to ANOVA, this removal was not significantly different from the 5.5 ± 1.2 log CFU/mL decrease in setup 2 where E. coli could directly interact with the silver nanoparticles. Similar results were observed where silver ions were added: in setup 1, 4.2 ± 1.5 log CFU/mL was inactivated, while in setup 2, a decrease of 5.2 ± 0.4 log CFU/mL was observed. To relate the exhibited antibacterial activity with the available silver ions, the concentration of free silver ions was measured. In the case of biogenic silver, the concentration of free silver ions was below the detection limit (0.01 mg/L) of the silver electrode. While for ionic silver, a concentration of 0.12 mg/L was measured in both setups.

Esterase activity and membrane permeability

Flow cytometry was used to measure the membrane permeability and esterase activity of E. coli when exposed to 0.5 mg/L biogenic silver or ionic silver. E. coli was stained with 5,6-carboxy fluorescein diacetate to measure the esterase activity. The negative control consisting only out of biogenic silver without E. coli being present showed a number of counts (green fluorescence) below 102. Therefore, this value was considered as the background and only results above this number were taken into consideration. After 4 h of incubation, the esterase activity decreased significantly with 28% for biogenic silver and 67%. for ionic silver, both compared to the control (P < 0.05).

To assess membrane permeability, samples were stained with Sybr Green and propidium iodide. The negative control, consisting of biogenic silver without E. coli, contained a number of counts which corresponded to the cells of the L. fermentum matrix of biogenic silver. This value was subsequently subtracted from the test samples with biogenic silver. The number of red fluorescence counts, and therefore permeabilised cells, amounted 41.0 ± 2.1% in the case biogenic silver and was significantly different from ionic silver which contained 45.4 ± 1.1 of permeabilised cells (P < 0.05). This meant an increase of the membrane permeability with respectively 22% and 26% compared to the control.

Discussion

The antimicrobial activity of biogenic silver

Biogenic silver consists of silver nanoparticles which can be produced by the bacterium L. fermentum. As described in a previous paper (Sintubin et al. 2009), these nanoparticles are mainly situated on the cell wall of the bacterial cells, consist of pure Ag(0), and have a mean diameter of 11.2 ± 0.9 nm (Fig. S2). Since the nanoparticles are still attached to the bacterial matrix, this could seriously affect their antimicrobial activity during application. Yet, biogenic silver was highly effective against the three tested bacteria. The MIC and MBC of biogenic silver were comparable with those of ionic silver (Table 1). In contrast, chemically produced nanosilver showed MIC and MBC values up to twenty times higher which may be due to the larger size of the nanoparticles. These nanoparticles had a diameter of 20 ± 10 nm and were also observed to aggregate. DLS revealed that chemically produced nanosilver formed clusters of 249.8 ± 4.1 nm (results not shown). As previously mentioned, the size of nanoparticles is known to influence the antimicrobial properties (Pal et al. 2007; Morones et al. 2005; Lok et al. 2007) so larger nanoparticles have less specific surface area for interaction with the bacteria and show a decreased release of silver ions (Liu and Hurt 2010; Sotiriou and Pratsinis 2010). Therefore, 12.5 mg/L of chemically produced nanosilver only released 0.04 mg/L of free silver ions (results not shown) compared to the release of 0.56 mg/L ions by the smaller biogenic nanoparticles. Moreover, the higher antimicrobial activity of biogenic silver could be explained by the stabilization of the nanoparticles on the cells of L. fermentum, preventing them from aggregation.

The mode of action of biogenic silver

During the investigation of the mode of action, biogenic silver was compared with ionic since both showed a comparable antibacterial activity according to MIC and MBC. Moreover, the release of silver ions is one of the proposed antibacterial mechanisms (Morones et al. 2005). However, the mode of action of silver nanoparticles is not fully understood and two other mechanisms have been considered important: the production of radicals and direct contact with the nanoparticles (Sondi and Salopek-Sondi 2004; Kim et al. 2007).

Silver ions are known to inhibit the activity of essential enzymes by the reaction with thiol groups (Holt and Bard 2005; Liau et al. 1997). Indeed, when the esterase activity was measured, there was a significant decrease in enzyme activity compared to the control. For biogenic silver this decrease in esterase activity was slightly lower compared to the inhibition caused by ionic silver. Pal et al. (2007) speculated that the action of silver nanoparticles is similar to that of silver ions which was also observed in this current study with the behaviour of biogenic silver compared to ionic silver during antibacterial tests. Indeed, the MIC and MBC values of biogenic silver were the same or a bit higher compared to ionic silver (Table 1). Also, the disinfection killing rate was comparable: the log decrease caused by biogenic silver was only a bit slower than the one by ionic silver (Fig. 2). Interestingly, also a substantial release of silver ions by biogenic silver was noticed which may be related to its high level of antimicrobial activity.

A small production of ROS by biogenic silver was observed (Fig. 5) which was comparable with the results of Su et al. (2009). Additionally, silver ions are considered to generate radicals by the inhibition of respiratory enzymes (Matsumura et al. 2003), however, in this study, an increased production of ROS was not observed compared to the control. Although it has been reported that radicals which are generated from the surface of silver nanoparticles are responsible for the antimicrobial activity (Su et al. 2009; Kumar et al. 2007), the effect on the survival of the cells was minimal in this current study (Fig. 6). Choi et al. (2009) noted that silver nanoparticles produce less radicals than TiO2 but inhibit bacteria at the same level, and therefore stated that ROS cannot serve as a chemical marker for toxicity determination. Therefore, radicals generated by biogenic silver most probably contribute only to a minor extend to the dissimilation of the bacterial cells as observed in this study.

Direct contact of the nanoparticles with bacteria disrupts the membrane morphology, inducing uncontrolled transport through the membrane. Thus, the nanoparticles which are accumulated inside the membrane can subsequently penetrate into the cells causing further damage (Sondi and Salopek-Sondi 2004). In this current study, the membrane permeability of the cells was measured with flow cytometry after staining them first with a combination of Sybr Green and propidium iodide. An increase in membrane permeability was observed of about 22% for biogenic silver, which was similar to the increase in membrane permeability of 26% caused by ionic silver. According to Kim et al. (2007), association between nanoparticles and the bacterial cells is needed to release the silver ions which are chemisorbed on the surface of the nanoparticles. However, the results of this study did not show a significant decrease in antibacterial activity when direct contact was impaired. The amount of free silver ions which was released in the situation where direct contact was possible, and where it was prevented, was below the detection limit of the ion-selective electrode. However, this may have been due to sorption to the dialysis membrane. Since the antibacterial activity of biogenic silver was similar to the one of ionic silver, it appears that the release of ions is the most important factor for the antimicrobial activity of biogenic silver although the influence of direct contact cannot be excluded. In this study, the biogenic nanoparticles were fixed on the L. fermentum bacterium where they were formed. The scaffold might interfere in the direct contact of the metal surface of the nanoparticles with the bacteria subjected to disinfection. It is possible that upon extraction of the nanoparticles, direct contact can enhance a stronger antimicrobial activity.

Application of biogenic silver

Silver nanoparticles can be applied in many fields for their antimicrobial properties and their use in consumer products is growing worldwide (Edwards-Jones 2009; Benn and Westerhoff 2008). One major concern of the public is the release of nanoparticles into the environment having a possible impact on human health and ecosystems (Maynard 2007). De Gusseme et al. observed that the L. fermentum carrier matrix of biogenic silver ensured anchoring of the silver to a filter cartridge used to remove viruses from drinking water. Due to this anchoring, biogenic silver was retained and no remarkable silver release was observed into the effluent, which could possibly decrease nanotoxicity (De Gusseme et al. 2010). As was indicated before, the bacterial carrier of biogenic silver did not inhibit the antibacterial activity. In contrast, the attachment of the nanoparticles to this matrix seemed to be advantageous by preventing the aggregation of the nanoparticles. The maintenance of a high specific surface of the individual nanoparticles is not only favourable when using them as disinfectants but also when they are used as catalysts (Hennebel et al. 2009). In addition, the bacterial carrier also allows for straightforward concentration of the nanoparticles by simple centrifugation.

As variations in cleanliness can influence the antimicrobial activity of disinfectants (Nanavaty et al. 1998), the European Committee for Standardization advises to test antimicrobial agents in clean and dirty conditions (NEN-EN 1997). In this study, dirty conditions were simulated by the addition of BSA as recommended by the committee. Also, the addition of NaCl was tested, since chlorides form an insoluble complex with silver ions. Both compounds decreased the disinfection rate of biogenic silver and ionic silver considerably due to a decrease of the free silver ion concentration as measured by an ion-selective silver electrode (Fig. 3). The diminished release of silver ions in the presence of salts and organic compounds was also confirmed by Liu and Hurt (2010). The presence of organic matter and salts in growth medium explains the higher MBC values compared to the ones in plain water. These results indicate that a longer contact time and/or higher concentrations are needed to obtain substantial antimicrobial activity in environments where these compounds are present.

In conclusion, the focus of this manuscript was on the antibacterial mechanism of biogenic silver nanoparticles. The comparative results, between biogenic silver and ionic silver, suggest that the release of silver ions by the biogenic silver is of direct importance to the antibacterial performance. Direct contact and radical formation were found to be of secondary importance in terms of the antibacterial performance of biogenic silver. The fact that these particles are attached to the cell walls of Lactobacillus has advantageous effects with respect to activity by preventing aggregation. Biogenic nanoparticles might be safer because the metal particles are retained in a biological matrix and might be less bioavailable to higher organisms. The latter, however, still needs to be investigated further.

References

Bagg J (1962) The catalytic decomposition of hydrogen peroxide solutions by single crystals of silver. Aust J Chem 15:201–210

Benn TM, Westerhoff P (2008) Nanoparticle silver released into water from commercially available sock fabrics. Environ Sci Technol 42:4133–4139

Boon N, Depuydt S, Verstraete W (2006) Evolutionary algorithms and flow cytometry to examine the parameters influencing transconjugant formation. FEMS Microbiol Ecol 55:17–27

Boorman GA, Dellarco V, Dunnick JK, Chapin RE, Hunter S, Hauchman F, Gardner H, Cox M, Sills RC (1999) Drinking water disinfection byproducts: review and approach to toxicity evaluation. Environ Health Perspect 107:207–217

Choi O, Hu Z (2009) Role of reactive oxygen species in determining nitrification inhibition by metallic/oxide nanoparticles. J Environ Eng 135:1365–1370

De Gusseme B, Sintubin L, Baert L, Thibo E, Hennebel T, Vermeulen G, Uyttendaele M, Verstraete W, Boon N (2010) Biogenic silver for disinfection of water contaminated with viruses. Appl Environ Microbiol 76:1082–1087

Edwards-Jones V (2009) The benefits of silver in hygiene, personal care and healthcare. Lett Appl Microbiol 49:147–152

Elechiguerra JL, Burt JL, Morones JR, Camacho-Bragado A, Gao X, Lara HH, Yacaman MJ (2005) Interaction of silver nanoparticles with HIV-1. J Nanobiotechnol 3:6

Feng QL, Wu J, Chen GQ, Cui FZ, Kim TN, Kim JO (2000) A mechanistic study of the antibacterial effect of silver ions on Escherichia coli and Staphylococcus aureus. J Biomed Mater Res 52:662–668

Fu MX, Li QB, Sun DH, Lu YH, He N, Deng X, Wang HX, Huang JL (2006) Rapid preparation process of silver nanoparticles by bioreduction and their characterizations. Chin J Chem Eng 14:114–117

Gerber IB, Dubery IA (2003) Fluorescence microplate assay for the detection of oxidative burst products in tobacco cell suspensions using 2′,7′-dichlorofluorescein. Methods Cell Sci 25:115–122

Gopal K, Tripathy SS, Bersillon JL, Dubey SP (2007) Chlorination byproducts, their toxicodynamics and removal from drinking water. J Hazard Mater 140:1–6

Hennebel T, De Gusseme B, Boon N, Verstraete W (2009) Biogenic metals in advanced water treatment. Trends Biotechnol 27:90–98

Holt KB, Bard AJ (2005) Interaction of silver(I) ions with the respiratory chain of Escherichia coli: an electrochemical and scanning electrochemical microscopy study of the antimicrobial mechanism of micromolar Ag. Biochemistry 44:13214–13223

Kathiresan K, Manivannan S, Nabeel MA, Dhivya B (2009) Studies on silver nanoparticles synthesized by a marine fungus, Penicillium fellutanum isolated from coastal mangrove sediment. Colloid Surf B Biointerfaces 71:133–137

Kim JS, Kuk E, Yu KN, Kim JH, Park SJ, Lee HJ, Kim SH, Park YK, Park YH, Hwang CY, Kim YK, Lee YS, Jeong DH, Cho MH (2007) Antimicrobial effects of silver nanoparticles. Nanomed Nanotechnol Biol Med 3:95–101

Klaus T, Joerger R, Olsson E, Granqvist CG (1999) Silver-based crystalline nanoparticles, microbially fabricated. Proc Natl Acad Sci USA 96:13611–13614

Kumar SA, Abyaneh MK, Gosavi SW, Kulkarni SK, Pasricha R, Ahmad A, Khan MI (2007) Nitrate reductase-mediated synthesis of silver nanoparticles from AgNO3. Biotechnol Lett 29:439–445

Kwakye-Awuah B, Williams C, Kenward MA, Radecka I (2008) Antimicrobial action and efficiency of silver-loaded zeolite X. J Appl Microbiol 104:1516–1524

Lansdown ABG (2007) Critical observations on the neurotoxicity of silver. Crit Rev Toxicol 37:237–250

Li QL, Mahendra S, Lyon DY, Brunet L, Liga MV, Li D, Alvarez PJJ (2008) Antimicrobial nanomaterials for water disinfection and microbial control: potential applications and implications. Water Res 42:4591–4602

Liau SY, Read DC, Pugh WJ, Furr JR, Russell AD (1997) Interaction of silver nitrate with readily identifiable groups: relationship to the antibacterial action of silver ions. Lett Appl Microbiol 25:279–283

Liu J, Hurt RH (2010) Ion release kinetics and particle persistence in aqueous nano-silver colloids. Environ Sci Technol 44:2169–2175

Lok CN, Ho CM, Chen R, He QY, Yu WY, Sun H, Tam PKH, Chiu JF, Che CM (2007) Silver nanoparticles: partial oxidation and antibacterial activities. J Biol Inorg Chem 12:527–534

Mafune F, J-y K, Takeda Y, Kondow T, Sawabe H (2000) Structure and stability of silver nanoparticles in aqueous solution produced by laser ablation. J Phys Chem B 104:8333–8337

Matsumura Y, Yoshikata K, Kunisaki S, Tsuchido T (2003) Mode of bactericidal action of silver zeolite and its comparison with that of silver nitrate. Appl Environ Microbiol 69:4278–4281

Maynard AD (2007) Nanotechnologies: overview and issues. In: Simeonova PP, Opopol N, Luster MI (eds) Nanotechnology—toxicological issues and environmental safety. Nato science for peace and security series C: environmental security. Springer, Dordrecht, pp 1–14

Morones JR, Elechiguerra JL, Camacho A, Holt K, Kouri JB, Ramirez JT, Yacaman MJ (2005) The bactericidal effect of silver nanoparticles. Nanotechnology 16:2346–2353

Mukherjee P, Ahmad A, Mandal D, Senapati S, Sainkar SR, Khan MI, Parishcha R, Ajaykumar PV, Alam M, Kumar R, Sastry M (2001) Fungus-mediated synthesis of silver nanoparticles and their immobilization in the mycelial matrix: a novel biological approach to nanoparticle synthesis. Nano Lett 1:515–519

Nanavaty J, Mortensen JE, Shryock TR (1998) The effects of environmental conditions on the in vitro activity of selected antimicrobial agents against Escherichia coli. Curr Microbiol 36:212–215

NEN-EN (1997) Chemical disinfectants and antiseptics—quantitative suspension test for the evaluation of bactericidal activity of chemical disinfectants and antiseptics used in food, industrial, domestic, and institutional areas—test method and requirements (phase 2, step1), vol 1276. European committee for standardization, Brussels

Pal S, Tak YK, Song JM (2007) Does the antibacterial activity of silver nanoparticles depend on the shape of the nanoparticle? A study of the gram-negative bacterium Escherichia coli. Appl Environ Microbiol 73:1712–1720

Shahverdi AR, Minaeian S, Shahverdi HR, Jamalifar H, Nohi AA (2007) Rapid synthesis of silver nanoparticles using culture supernatants of Enterobacteria: a novel biological approach. Process Biochem 42:919–923

Silver S, le Phung T, Silver G (2006) Silver as biocides in burn and wound dressings and bacterial resistance to silver compounds. J Ind Microbiol Biotechnol 33:627–634

Sintubin L, De Windt W, Dick J, Mast J, van der Ha D, Verstraete W, Boon N (2009) Lactic acid bacteria as reducing and capping agent for the fast and efficient production of silver nanoparticles. Appl Microbiol Biotechnol 84:741–749

Sondi I, Salopek-Sondi B (2004) Silver nanoparticles as antimicrobial agent: a case study on E. coli as a model for Gram-negative bacteria. J Colloid Interface Sci 275:177–182

Sotiriou GA, Pratsinis SE (2010) Antibacterial activity of nanosilver ions and particles. Environ Sci Technol 44:5649–5654

Su H-L, Chou C-C, Hung D-J, Lin S-H, Pao IC, Lin J-H, Huang F-L, Dong R-X, Lin J-J (2009) The disruption of bacterial membrane integrity through ROS generation induced by nanohybrids of silver and clay. Biomaterials 30:5979–5987

Tavakoli A, Sohrabi M, Kargari A (2007) A review of methods for synthesis of nanostructured metals with emphasis on iron compounds. Chem Paper 61:151–170

Yoon KY, Byeon JH, Park JH, Hwang J (2007) Susceptibility constants of Escherichia coli and Bacillus subtilis to silver and copper nanoparticles. Sci Total Environ 373:572–575

Acknowledgments

This work was supported by a project grant 71333 (L. Sintubin) of the Institute for the Promotion of Innovation by Science and Technology in Flanders (IWT) and by a Ph.D. grant (B. De Gusseme) from the Research Foundation of Flanders (FWO). This research was part of project no. G.0808.10 N (2010–2013), funded by the FWO. We gratefully thank Hedwig Stepman and Griet Vermeulen for their technical assistance, Karen De Roy for support with flow cytometry, Maarten Verbrugghe for the DSL measurements, and Kim Verbeken for the SEM. We acknowledge Anthony Hay, Willem De Muynck, Simon De Corte, and Suzanne Read for critically reviewing this manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Fig. S1

Setups to test direct contact as one of the possible modes of action. a Setup 1 where biogenic silver was added in a dialysis membrane preventing direct contact with E. coli in the surrounding drinking water. b Setup 2 where biogenic silver and E. coli were added together to the Erlemeyer and therefore direct contact was possible; an empty dialysis membrane was present to account for possible sorption of silver ions. Biogenic silver is presented by dashed lines (DOC 216 kb)

Fig. S2

Scanning electron microscopy image of biogenic silver. The black dots are silver nanoparticles attached on the cell wall of the bacterial carrier L. fermentum. The bacterium looks black due to closely packed layers of silver nanoparticles covering its surface (DOC 412 kb)

Rights and permissions

About this article

Cite this article

Sintubin, L., De Gusseme, B., Van der Meeren, P. et al. The antibacterial activity of biogenic silver and its mode of action. Appl Microbiol Biotechnol 91, 153–162 (2011). https://doi.org/10.1007/s00253-011-3225-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3225-3