Abstract

Biofilm is a natural form of cell immobilization in which microorganisms attach onto solid support. In this study, a pigment-reduced pullulan-producing strain, Aureobasidium pullulans (ATCC 201253), was used for continuous pullulan fermentation in a plastic composite support (PCS) biofilm reactor. Optimal conditions for the continuous pullulan production were determined by evaluating the effects of the feeding medium with various concentrations of ammonium sulfate and sucrose and dilution rate. Pullulan concentration and production rate reached maximum (8.3 g/l and 1.33 g/l/h) when 15 g/l of sucrose, 0.9 g/l of ammonium sulfate, and 0.4 g/l of yeast extract were applied in the medium, and the dilution rate was at 0.16 h−1. The purity of produced pullulan was 93.0%. The ratio of hyphal cells of A. pullulans increased when it was grown on the PCS shaft. Overall, the increased pullulan productivity can be achieved through biomass retention by using PCS biofilm reactor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pullulan, a water-soluble exopolysaccharide synthesized by a yeast-like fungus, Aureobasidium pullulans, is often described as α-1,6-linked maltotriose (Ueda et al. 1963; Catley et al. 1986). With this unique linkage pattern, pullulan demonstrates distinctive physical properties, such as the adhesive ability, the capacity to form fibers, and the capacity to form thin and biodegradable film, which is transparent and highly impermeable to oxygen (Yuen 1974). Accordingly, pullulan has been used for various applications, such as blood plasma substitutes, food and cosmetic additives, adhesive additives, flocculants, resins, and environmental remediation agents (Leathers 2003; Rekha and Sharma 2007; Iyer et al. 2005).

For pullulan production, the effect of nitrogen source and its concentration has drawn much attention, and it is generally accepted that the exopolysaccharide is only produced under nitrogen-limiting conditions (Seviour et al. 1992). The depletion of nitrogen is regarded as a signal for exopolysaccharide formation of A. pullulans fermentation (Gibbs and Seviour 1996). Catley et al. (1986) examined the nitrogen limitation effect on A. pullulans for pullulan production. Their results indicated that, with similar rates of carbon utilization, the diversion of glucose from incorporation into cellular material to the production of polysaccharide relied on ammonium ion concentration. Campbell et al. (2003) also reported that NH +4 might impact the production of pullulan-degrading enzymes controlling carbon flow within the cell. Excess nitrogen supply could contribute to the accumulation of biomass, but not polysaccharide (Orr et al. 2009; Cheng et al. 2011).

Batch pullulan fermentation has been studied thoroughly in the past decade, and the highest pullulan concentration reached 60.7 g/L (Cheng et al. 2010c). Continuous fermentation, compared with batch fermentation, provides several advantages, such as constant environmental conditions for biological systems, elimination of substrate inhibition, and reduction of toxicity due to metabolite accumulation (Calcott 1981). In fact, several attempts have been made to enhance pullulan production by using chemostat fermentations. However, the results were not significant when compared with those in the batch fermentation. It was found that either the proposed dilution rate was extremely low (0.015 h−1) with a productivity of 1.17 g/L/h (Seo et al. 2006) or the production rate was not significantly improved (0.16 and 0.73 g/L/h, respectively) (Schuster et al. 1993; Reeslev et al. 1997).

Other pullulan fermentation methods using cell immobilization have been investigated, including agar, calcium alginate, carrageenan, and polyurethane (Mulchandani and Luong 1988; Lebrun et al. 1994; West 2000; West and Strohfus 2001; Ürküt et al. 2007). However, the main concern of these immobilization materials is their durability. Calcium alginate beads, for example, only worked for four 120-h repeated batch fermentations. Pullulan production decreased from 25 to 15 g/L, and the beads lost their hardness and were disintegrated at the end of the seventh run (Ürküt et al. 2007).

Biofilm, on the other hand, grows on the solid support, which is a natural form of cell immobilization (Characklis and Marshall 1990). Plastic composite support (PCS) provides an ideal surface for biofilm formation and is an extrusion product of a mixture of polyprolylene and nutritious compounds (Pometto III et al. 1997). Polypropylene acts as a matrix and integrates agricultural mixtures, including ground soybean hulls, soybean flour, and microbial nutrients (such as bovine albumin, red blood cells, yeast extract, peptone, and mineral salts). Therefore, PCS not only provides an ideal physical structure for biofilm formation but also slowly releases nutrients during fermentation (Ho et al. 1997a). Detailed summary of advantages of biofilm reactors over suspended cell reactors, including higher biomass density and operation stability, reducing the risk of washing out when operating at high dilution rates during continuous fermentation, and eliminating need for reinoculation during repeated batch fermentation, can be found in the review articles (Demirci et al. 2007; Cheng et al. 2010a).

With these advantages of biofilm reactor mentioned previously, the scope of the present work was to investigate the effectiveness of continuous pullulan production by using a PCS biofilm reactor. Variation of initial ammonium sulfate and sucrose concentration on pullulan production was also investigated.

Materials and methods

Microorganism culture preparation

A. pullulans (ATCC 201253) was obtained from the American Type Culture Collection (Rockville, MD, USA) and was a reduced pigmentation mutant of A. pullulans NYS-1 (West and Strohfus 2001). The culture was grown at 30 °C for 24 h in a medium containing 50 g of glucose, 5 g of yeast extract, 5 g of (NH4)2SO4, 1 g of NaCl, 5 g of KH2PO4, and 0.2 g of MgSO4·7H2O per liter of deionized water at an initial pH 5.0 with agitation at 150 rpm. The working culture was stored at 4 °C and subcultured bi-weekly in order to maintain its viability. For long-term storage, stock cultures were maintained at −80 °C in a 20% glycerol solution.

Plastic composite support

PCS tubes were manufactured using a twin-screw co-rotating Brabender PL2000 extruder (model CTSE-V; C.W. Brabender Instruments, South Hackensack, NJ, USA) as described by Pometto III et al. (1997). Polypropylene (50% (w/w)) and other ingredients (35% (w/w) of soybean hulls, 5% (w/w) of soybean flour, 5% (w/w) of yeast extract, 5% (w/w) of dried bovine red blood cell, and 0.272% (w/w) of sodium acetate, 0.0004% (w/w) of MgCl2·6H2O, and 0.002% (w/w) of NaCl) were mixed together and extruded at 13 rpm through a medium pipe die with barrel temperatures of 200 °C, 220 °C, and 200 °C and a die temperature of 165 °C. The nutrition composition of PCS (soybean hulls, defatted soy bean flour, yeast extract, dried bovine red blood cell, and mineral salts) was selected as described in our previous study based on the amount of biofilm formation on the PCS (CFU per gram PCS) and pullulan production (grams per liter; Cheng et al. 2009). The extruded tubes with a wall thickness of 2.5 mm and an outer diameter of 10.5 mm were cut into 6.5-cm length tubes with both ends cut at a 45° angle (Cheng et al. 2009).

Continuous fermentation system

A continuous stir tank Sartorious Biostat B Plus bioreactor (Allentown, PA, USA) equipped with a 2-L vessel (1.5 L working volume) was implemented for studies. Twelve PCS tubes were bound to the agitator shaft in a grid-like fashion, with six rows of two parallel tubes. The reactor vessel with PCS was autoclaved with water at 121 °C for 45 min. Sucrose and nitrogenous components with mineral salts were autoclaved separately and added to the reactor aseptically after draining the water from the reactor as recommended by Pometto III et al. (1997). In order to establish biofilm on the PCS, after inoculating with a 24-h grown culture of A. pullulans (1%, v/v), five repeated batch fermentations were carried out with original medium obtained from our previous study (Cheng et al. 2010b), including 75 g of sucrose, 3 g of yeast extract, 5 g of ammonium sulfate, 1 g of NaCl, 5 g KH2PO4, and 0.2 g of MgSO4·7H2O per liter of deionized water, at a constant pH 5.0 with 200 rpm agitation at 30 °C for 120 h for each run.

Continuous fermentation was carried out initially in a optimized basal medium, including 100 g of sucrose, 1 g of NaCl, 5 g of KH2PO4, and 0.2 g of MgSO4·7H2O per liter of deionized water, at a constant pH 5.0 with 200 rpm agitation at 30 °C (Cheng et al. 2010c). Suspension cultures without PCS were also carried out as control. Different ammonium sulfate concentrations (0.3 to 1.2 g/L) and sucrose concentration (10 to 100 g/L) on pullulan production were evaluated. Dilution rate was set from 0.05 to 0.2 h−1. The results of each condition were the average of duplicates.

Sample analysis

For each change of fermentation condition, at least three volume exchanges were allowed before sampling was initiated. Samples were then collected every 12 h until consistent data were obtained.

Biomass

Biomass in suspension medium was measured to evaluate the detachment of microorganism and suspension growth. Samples (1 ml) from culture broth were centrifuged at 12,000×g, 4 °C for 20 min. The precipitated pellets were washed twice with distilled water and centrifuged again to remove impurities. Finally, the pellet was dried at 80 °C overnight to determine biomass dry weight.

Crude pullulan

After culture broth (5 ml) was centrifuged at 3,300×g, 4 °C for 20 min, 4 ml of supernatant was mixed with 8 ml of 95% ethanol and incubated at 4 °C for 12 h to precipitate the crude polysaccharides, which were then separated by centrifuging at 3,300×g for 30 min. Finally, the pellet was dried at 80 °C overnight to determine the weight of crude pullulan.

Sugar analysis

For sucrose concentration, fermentation broth (3 ml) was centrifuged at 3,300×g for 10 min and hydrolyzed by hydrochloric acid (6 N) before analyzing with the dinitrosalicylic (DNS) method (Miller 1959).

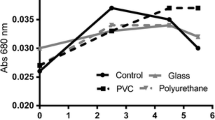

Ammonium sulfate concentration

For residual ammonium sulfate concentration, a modified indophenol method was adopted from Scheiner (1976). Briefly, 2 ml of fermentation broth samples was centrifuged at 3,000×g to remove biomass and insoluble debris. The supernatants were then diluted with 100-fold DI H2O and neutralized to pH 7 with NaOH (4 N). Twenty-five milliliters of each sample was added with 10 ml phenol-nitroprusside buffer and mixed. Hypochlorite reagent (15 ml) was then added to the test and placed in room temperature, 45 min for color development. The absorbance of the sample was red under 630 nm using a spectrophotometer (DU series 500, Beckman, Fullerton, CA, USA). Reagent blank was used as control.

Cell morphology analysis

At the end of fermentation, the PCS tubes in the biofilm reactor were dissembled and used for cell morphology analysis. A. pullulans cells on the PCS tube were detached by using a sand strip method described earlier (Ho et al. 1997b). The cell suspension was then centrifuged at 6,000×g, 4 °C for 20 min. After decanting the supernatant, the cells were washed three times with potassium phosphate buffer (50 mM, pH 6.8). Images were taken, including about 250 cells per sample, by using an image system consisting of an Olympus digital microscope (Model: CX41; Olympus Co., Center Valley, PA, USA) and processed by an Infinity Capture software (version 4.4.0; Lumenera Co., Lawrenceville, GA, USA).

Results

Effect of PCS biofilm reactor on continuous pullulan fermentation

Results of continuous pullulan fermentation in the PCS biofilm reactor using optimized base medium (Cheng et al. 2010c) were summarized in Table 1. A. pullulans produced 3.5 g/l of pullulan with a 0.17-g/l/h production rate when dilution rate was at 0.05 h−1 and approached zero when dilution rate was at 0.15 h−1. The suspension control (Suspension 1, i.e., without PCS) also demonstrated that, without nitrogen supply, the amount of biomass was low when dilution rate was at 0.05 h−1 and has been completely washed out at 0.1 h−1, which resulted in extremely low pullulan production. Therefore, various ammonium sulfate concentrations and 0.4 g/l of yeast extract were added as new nitrogen sources and evaluated for their effects on pullulan production.

Effects of ammonium sulfate concentration on continuous pullulan fermentation

Results of continuous pullulan fermentation with various ammonium sulfate concentrations in the PCS biofilm reactor were summarized in Table 2. With the addition of 0.9 g/l of ammonium sulfate at 0.17 h−1 dilution rate, A. pullulans produced 7.5 g/l of pullulan with a 1.28-g/l/h production rate, which was the highest value among all tested conditions. The pullulan production yield was 82.4%. The biomass in suspension was only 0.3 g/l, indicating that the biofilm was still firmly attached on the PCS tubes. At the mean time, ammonium sulfate was completely consumed. The result of pullulan production with the presence of ammonium sulfate was higher than that without ammonium sulfate. A predicted optimal dilution rate, 0.16 h−1, was obtained when plotting the results of pullulan production rate vs. dilution rate. The maximum pullulan production rate reached 1.33 g/l/h at the dilution rate of 0.16 h−1 when ammonium sulfate was at 0.9 g/l (Table 3).

Effects of sucrose concentration on continuous pullulan fermentation

Due to the economic concern, the reduced amount of sucrose was applied to evaluate pullulan production with the optimal dilution rate and ammonium sulfate concentration obtained in the previous section. Significant decrease of pullulan concentration and production rate were observed when 10 g/l or lower sucrose concentration was used (Table 3). As a result, 15 g/l of sucrose was selected as the optimal concentration for continuous fermentation.

Morphology of A. pullulans

The microscopic results (Fig. 1) clearly showed that the cell type of A. pullulans switched from yeast-like form to hyphal form when performing pullulan fermentation in PCS biofilm reactor. The ratio of hyphal cells detached from PCS tubes was higher than that obtained in the suspension culture.

Discussion

It was reported that pullulan was a secondary metabolite and began to be synthesized by A. pullulans in the late exponential phase, which can be better produced when the growth becomes limited or as the cells approach stationary phase (Pouliot et al. 2005). Nevertheless, in a continuous fermentation system, cells were maintained in a growth phase, and hence the pullulan production was limited. Accumulation of less productive variants during fermentation could be another reason (Seo et al. 2006).

In this study, a PCS biofilm reactor, which can grow biomass on the solid support, was implemented for pullulan fermentation. Reasonable biomass retention on the PCS improved both dilution rate and pullulan production and resulted in the increase of production rate. Moreover, the biomass (biofilms) grown on the solid support is considered as a pseudo-steady state, which was reported as a favored stage for pullulan production (Pouliot et al. 2005).

The PCS was noted for slowly releasing nitrogen source to the broth during fermentation (Ho et al. 1997a); however, both low pullulan concentration and production rate indicated that the slow release of nitrogen ingredients from PCS tubes can not compensate the absence of nitrogen sources in the medium during continuous fermentation. The possible reason is that A. pullulans in a chemostat system may need more nitrogen to maintain its physical functions. In this study, additional 0.9 g/l of ammonium sulfate yielded the highest pullulan production rate (1.28 g/l/h; Table 2). Meanwhile, the extremely low residual ammonium sulfate also indicated that the high utilization of nitrogen source may prevent A. pullulans from growing excess biomass and/or producing pullulan-degrading enzymes.

Although the major type of cell which is responsible for pullulan production is still under debate, yeast-like cells and chlamydospores are considered as the main polysaccharide producers in the culture (Ronen et al. 2002; Campbell et al. 2004; Li et al. 2009). The hyphal forms of A. pullulans may produce exopolysaccharide which is different from pullulan (Simon et al. 1995). In this study, the ratio of hypha cells of the biomass detached from the PCS was higher than that obtained from the suspension culture. The possible reason is that the solid support is more suitable for the attachment of filamentous cells. A. pullulans may adjust themselves during fermentation. However, an adequate amount of pullulan-producing cells is still on the PCS, which prevent A. pullulans from producing other exopolysaccharides. The purity of produced pullulan maintains around 93% after 60 volume exchanges were performed at optimized condition (data not shown).

In summary, the use of PCS biofilm reactors demonstrated a positive effect on biomass density, pullulan production rate, and dilution rate. A dilution rate at 0.16 h−1 with 15 g/l of sucrose and 0.9 g/l of ammonium sulfate addition resulted in the highest production rate (1.33 g/l/h), which is the highest number reported to date. Utilization of low-nutrient medium is an important factor to reduce fermentation cost. Further study is needed to improve the bioreactor design for industrial purposes. First, the optimal type and quantity of nitrogen ingredients on the PCS and their leaching rate can be further investigated; second, the shape of PCS can be adjusted to accumulate more biomass (e.g., discs). The use of agricultural waste as substitute carbon source may also reduce the cost for industrial production.

References

Calcott PH (1981) Continuous culture: where it came from and where it's going. In: Calcott PH (ed) Continuous culture of cells. CRC, Boca Raton, pp 1–11

Campbell SB, McDougall MB, Seviour JR (2003) Why do exopolysaccaride yields from the fungus Aureobasidium pullulans fall during batch culture fermentation? Enzyme Microb Technol 33:104–112

Campbell SB, Siddique MAB, McDougall MB, Seviour JR (2004) Which morphological forms of the fungus Aureobasidium pullulans are responsible for pullulan production? FEMS Microbiol Lett 232:225–228

Catley BJ, Ramsay A, Servis C (1986) Observations on the structure of the fungal extracellular polysaccharide, pullulan. Carbohydr Res 153:79–86

Characklis WG, Marshall KC (1990) Biofilms. Wiley, New York

Cheng K-C, Demirci A, Catchmark MJ (2009) Effects of plastic composite support and pH profiles on pullulan production in a biofilm reactor. Appl Microbiol Biotechnol 86:853–861

Cheng K-C, Demirci A, Catchmark MJ (2010a) Advances in biofilm reactors for production of value-added products. Appl Microbiol Biotechnol 87:445–456

Cheng K-C, Demirci A, Catchmark MJ (2010b) Evaluation of medium composition and cultivation parameters on pullulan production by Aureobasidium pullulans. Food Sci Technol Intl. doi:https://doi.org/10.1177/1082013210368719

Cheng K-C, Demirci A, Catchmark MJ (2010c) Enhanced pullulan production in a biofilm reactor by using response surface methodology. J Ind Microbiol Biotechnol 37:587–594

Cheng K-C, Demirci A, Catchmark JM, Puri VM (2011) Effects of initial ammonium ion concentration on pullulan production by Aureobasidium pullulans and its modeling. J Food Eng 103:115–122

Demirci A, Pongtharangkul T, Pometto LA III (2007) Applications of biofilm reactors for production of value-added products by microbial fermentation. In: Blaschek PH, Wang HH, Agle EM (eds) Biofilms in the food environment. Blackwell, Ames, pp 167–189

Gibbs PA, Seviour RJ (1996) Does the agitation rate and/or oxygen saturation influence exopolysaccharide production by Aureobasidium pullulans in batch? Appl Biochem Biotechnol 46:503–510

Ho K-LG, Pometto AL III, Hinz PN (1997a) Optimization of L-(+)-lactic aicd biofilm fermentation. Appl Environ Microbiol 63:2533–2542

Ho K-LG, Pometto AL III, Hinz PN, Demirci A (1997b) Nutrient leaching and end product accumulation in plastic composite support for L-(+)-lactic acid biofilm fermentation. Appl Environ Microbiol 63:2524–2532

Iyer A, Mody KH, Jha B (2005) Biosorption of heavy metals by a marine bacterium. Mar Pollut Bull 50:340–343

Leathers TD (2003) Biotechnological production and applications of pullulan. Appl Microbiol Biotechnol 62:468–473

Lebrun L, Junter G-A, Jouenne T, Mignot L (1994) Exopolysaccharide production by free and immobilized microbial cultures. Enzyme Microb Technol 16:1048–1054

Li BX, Zhang N, Peng Q, Yin T, Guan FF, Wang GL, Li Y (2009) Production of pigment-free pullulan by swollen cell in Aureobasidium pullulans NG which cell differentiation was affected by pH and nutrition. Appl Microbiol Biotechnol 84:293–300

Miller GL (1959) Use of DNS reagent for determination of reducing sugar. Anal Chem 31:426–428

Mulchandani A, Luong HTJ (1988) Biosynthesis of pullulan using immobilized Aureobasidium pullulans cells. Biotechnol Bioeng 33:306–312

Orr D, Zheng W, Campbell BS, McDougall BM, Seviour RJ (2009) Culture conditions affecting the chemical composition of the exopolysaccharide synthesized by the fungus Aureobasidium pullulans. J Appl Microbiol 107:691–698

Pometto AL III, Demirci A, Johnson KE (1997) Immobilization of microorganisms on a support made of synthetic polymer and plant material. US Patent No. 5,595,893

Pouliot MJ, Walton I, Nolen-Parkhouse M, Abu-Lail IL, Camesano AT (2005) Adhesion of Aureobasidium pullulans is controlled by uronic acid-based polymers and pullulan. Biomacromolecules 6:1122–1131

Reeslev M, Storm T, Jensen B, Olsen J (1997) The ability of yeast form of Aureobasidium pullulans to elaborate exopolysaccharide in chemostat culture at various pH values. Mycol Res 101:650–652

Rekha MR, Sharma CP (2007) Pullulan as a promising biomaterial for biomedical applications: a perspective. Trends Biomater Artif Organs 20:116–121

Ronen M, Guterman H, Shabtai Y (2002) Monitoring and control of pullulan production using vision sensor. J Biochem Biophys Methods 51:243–249

Scheiner D (1976) Determination of ammonia and Kjeldahl nitrogen by indophenol method. Water Res 10:31–36

Schuster R, Wenzig E, Mersmann A (1993) Production of the fungal exopolysaccharide pullulan by batch-wise and continuous fermentation. Appl Microbiol Biotechnol 39:155–158

Seo HP, Jo KI, Son CW, Yang JK, Chung CH, Nam SW, Kim SK, Lee JW (2006) Continuous production of pullulan by Aureobasidium pullulans HP-2001 with feeding of high concentration of sucrose. J Microbiol Biotechnol 16:374–380

Seviour RJ, Stasinopoulos SJ, Auer DPF, Gibbs PA (1992) Production of pullulan and other exopolysaccharides by filamentous fungi. Crit Rev Biotechnol 12:279–298

Simon L, Bouchet B, Caye-Vaugien C (1995) Pullulan elaboration and differentiation of the resting forms in Aureobasidium pullulans. Can J Microbiol 40:35–45

Ueda S, Fujita K, Komatsu K, Nakashima Z (1963) Polysaccharide produced by the genus Pullularia. I. Production of polysaccharide by growing cells. Appl Microbiol 11:211–215

Ürküt Z, Dağbağli S, Göksungur Y (2007) Optimization of pullulan production using Ca-alginate-immobilized Aureobasidium pullulans by response surface methodology. J Chem Technol Biotechnol 82:837–846

West TP (2000) Exopolysaccharide production by entrapped cells of the fungus Aureobasidium pullulans ATCC 201253. J Basic Microbiol 40:5–6

West TP, Strohfus B (2001) Polysaccharide production by a reduced pigmentation mutant of Aureobasidium pullulans NYS-1. Lett Appl Microbiol 33:169–172

Yuen S (1974) Pullulan and its applications. Process Biochem 9:7–9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, KC., Demirci, A. & Catchmark, J.M. Continuous pullulan fermentation in a biofilm reactor. Appl Microbiol Biotechnol 90, 921–927 (2011). https://doi.org/10.1007/s00253-011-3151-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3151-4