Abstract

Pullulan is a linear homopolysaccharide that is composed of glucose units and often described as α-1, 6-linked maltotriose. In this study, response surface methodology using Box–Behnken design was employed to study the effects of sucrose and nitrogen concentrations on pullulan production. A total of 15 experimental runs were carried out in a plastic composite support biofilm reactor. Three-dimensional response surface was generated to evaluate the effects of the factors and to obtain the optimum condition of each factor for maximum pullulan production. After 7-day fermentation with optimum condition, the pullulan production reached 60.7 g/l, which was 1.8 times higher than the result from initial medium, and was the highest yield reported to date. The quality analysis demonstrated that the purity of produced pullulan was 95.2%, and its viscosity was 2.5 centipoise (cP), which is higher than the commercial pullulan and related to its molecular weight. Fourier transform infrared spectroscopy (FTIR) also suggested that the produced exopolysaccharide was pullulan.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pullulan, an exopolysaccharide (EPS) synthesized by a yeast-like fungus Aureobasidium pullulans, is often described as an α-1, 6-linked maltotriose polymer [7]. With this unique linkage pattern, pullulan demonstrated distinctive physical properties, such as adhesive ability, the capacity to form fibers, and the ability to be formed into thin and biodegradable films which are transparent and impermeable to oxygen. As a result, pullulan has been used for a wide range of applications in food, pharmaceutical, chemical, and environmental remediation applications [23]. At present, the number of patents related to pullulan has exceeded 300 [24] and has been produced commercially as products, such as edible packaging film, capsules, gelling agents, and emulsifiers [19, 20].

The effects of carbon source [27], nitrogen source [32], shear stress, agitation, aeration and dissolved oxygen levels [16], production enhancers such as zinc and iron [29], temperature [31], and cell morphology [30], have been studied to improve pullulan production. Each of the factors mentioned above will affect pullulan production and its materials property. A one-factor-at-a-time method has also been carried out for the cultivation parameters by Cheng et al. [9]. However, a more statistical method to determine the interaction among cultivation parameters for pullulan production is needed.

Sucrose is a favorable carbon source for pullulan production by A. pullulans [17, 34]; however, some studies reported that excess sucrose (i.e., above 5%) will inhibit pullulan production and hence limit the application of a batch fermentation system [35]. Nitrogen source also plays a significant role on pullulan production. Catley [8] examined the nitrogen limitation effect when producing pullulan by A. pullulans. The results indicated that for similar rates of carbon utilization, the diversion of glucose from incorporation into cellular material to the elaboration of polysaccharide is dependent on ammonium ion concentration. Depletion of nitrogen from the fermentation medium might also be a signal for exopolysaccharide synthesis [32].

Medium optimization by using the one-factor-at-a-time approach is time-consuming, expensive, and often leads to misinterpretation of results, because the interactions among parameters are not considered. On the other hand, a statistical experimental design can not only evaluate the effects of each parameter but also simultaneously and systematically evaluate the effects of their interactions [25]. Response surface methodology (RSM) is a powerful statistical design method commonly used for optimization of a multivariable system with a minimum number of experimental runs [4, 26], and has been applied to the production of value-added materials, such as bacterial cellulose [1] and amylase [38]. Basically, RSM optimization involves three major steps: (1) performing a series of statistically designed experiments; (2) estimating the coefficients in a polynomial equation; and (3) predicting the response and validating the model. Box–Behnken [3] designs are response surface designs chosen when performing non-sequential experiments. This design has been used to examine the relationship between one or more response variables with a set of quantitative experimental parameters. The advantage of this method is a reduced number of samples and replicates (12 edges for three factors with three levels; for a total of 12 data points) and the center of the factor space (center point is replicated three times, in total 15 data points), whereas the full factorial design has 27 data points (3 factors × 3 levels × 3 replicates). The three variables (X 1, X 2, and X 3) can predict what the response of product production (Y; i.e., pullulan) is and the constructed model as a response function of the variables on product production is a second-order polynomial as shown in Eq. (1).

where β 0 is the intercept, and β i , β ii , and β ij are linear, quadratic, and cross-product regression terms, respectively. X i and X j are coded independent variables, linearly related to X 1, X 2, and X 3.

Pullulan production has been successfully carried out in batch fermentation. However, A. pullulans usually takes 2 days to reach its late exponential phase and hence limits the time for pullulan production [9]. To further investigate the potential for higher productivity for pullulan production, the applications of cell immobilization, including agar, calcium alginate, and carrageenan immobilized A. pullulans, have been studied and proven their feasibility [37]. However, the total length of fermentation is limited since the artificial carrier will gradually break with time after a couple of cycles [14]. On the other hand, biofilm which grows on the solid support is a natural form of cell immobilization. Plastic composite support (PCS) has been developed to provide an ideal surface for biofilm formation, which is an extrusion product of a mixture of polypropylene and nutritious compounds [28]. Many studies have shown that PCS biofilm reactors can enhance production of ethanol [13], organic acid [36], and bacterial cellulose [11]. Moreover, the slow release of the ingredients on PCS, such as carbon sources, nitrogen sources, and minerals, can persist for more than 1 year without affecting its efficiency when performing continuous fermentation [12, 13, 18]. Our previous study also demonstrated that a PCS biofilm reactor can be implemented for pullulan production [10]. As mentioned earlier, studies in the literature suggested that sucrose as the carbon source and ammonium sulfate and yeast extract as the nitrogen source for pullulan production. Therefore, the objective of this study was to further investigate the optimal sucrose, ammonium sulfate, and yeast extract concentration in the medium for pullulan production using A. pullulans in a biofilm reactor, because especially nitrogen content of the medium might be required at a different level due to slow-release of nutrient from PCS in the biofilm reactor.

Materials and methods

Microorganism and medium

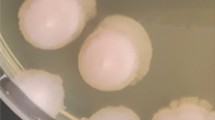

Aureobasidium pullulans (ATCC 201253) was obtained from the American Type Culture Collection (Rockville, MD), which was grown at 30°C for 24 h in a medium containing 50 g of glucose, 5 g of yeast extract, 5 g (NH4)2SO4, 1 g of NaCl, 5 g of KH2PO4, and 0.2 g of MgSO4·7H2O per liter of deionized water at an initial pH of 5.0 with agitation at 150 rpm. The working culture was stored at 4°C and subcultured bi-weekly in order to maintain its viability. For long-term storage, stock cultures were maintained at −80°C in a 20% glycerol solution.

Plastic composite support (PCS)

PCS tubes were manufactured at Iowa State University using a twin-screw co-rotating Brabender PL2000 extruder (model CTSE-V; C.W. Brabender Instruments, South Hackensack, NJ) as described by Pometto et al. [28]. Polypropylene (50% (w/w)) and other ingredients (35% (w/w) of soybean hulls, 5% (w/w) of soybean flour, 5% (w/w) of yeast extract, 5% (w/w) of dried bovine red blood cell, and 0.272% (w/w) of sodium acetate, 0.0004% (w/w) of MgCl2·6H2O, and 0.002% (w/w) of NaCl) were mixed together and extruded at 13 rpm through a medium pipe die with barrel temperatures of 200, 220, and 200°C and a die temperature of 165°C. The nutrition composition of PCS (soybean hulls, defatted soy bean flour, yeast extract, dried bovine red blood cell, and mineral salts) was selected as described in our previous study based on the amount of biofilm formation on the PCS (CFU per gram PCS) and pullulan production (g/l) [10]. The extruded tubes with a wall thickness of 2.5 mm and an outer diameter of 10.5 mm were cut into 6.5-cm-length tubes with both ends cut at a 45-degree angle (Fig. 1a).

Pullulan fermentation

A Sartorius Biostat B Plus bioreactor (Allentown, PA) equipped with a 2-l vessel (1.5-l working volume) was used for this study. For the biofilm reactor, 12 PCS tubes were tied to the agitator shaft in a gridlike fashion, with six rows of two parallel tubes with plastic tide strips (Fig. 1b). The reactor vessel with PCS was autoclaved with water at 121°C for 45 min. Sucrose and nitrogenous components with mineral salts were autoclaved separately and added to the reactor aseptically after draining the water from the reactor as recommended by Pometto et al. [28]. After inoculating with a 24-h grown culture of A. xylinum (1% v/v), five repeated-batch pre-fermentations were carried out with original medium obtained from previous study [10], including 75 g/l of sucrose, 3 g/l of yeast extract, 5 g/l of ammonium sulfate, 1 g of NaCl, 5 g of KH2PO4, and 0.2 g of MgSO4·7H2O per liter of deionized water, at a constant pH 5.0 with 200 rpm agitation at 30°C for 168 h by decanting broth and adding fresh sterile fermentation medium each time in order to establish biofilm on PCS supports. Batch fermentation medium containing different concentrations of sucrose, yeast extract, and ammonium sulfate generated by RSM design were subsequently performed to evaluate pullulan production along with following ingredients: 1 g of NaCl, 5 g of KH2PO4, and 0.2 g of MgSO4·7H2O per liter of deionized water, at a constant pH 5.0 with agitation at 200 rpm and aeration at 1.5 vvm, at 30°C for 168 h.

Experimental design

RSM was employed to optimize three experimental factors, namely, yeast extract (X 1), ammonium sulfate (X 2), and sucrose (X 3), for optimization of pullulan production in a biofilm reactor. RSM with a three-factor, three-level Box–Behnken design [3] was used to optimize the response (pullulan production) of three variables (Eq. 1). The actual factor level corresponding to coded factor levels are shown in Table 1. The ranges of factor levels for experimental design were selected based on our previous results [9, 10]. The optimal culture conditions for maximum pullulan production were estimated by statistical analysis using Minitab (Version 13.3; Minitab Inc., State College, PA). The coefficients in the second-order polynomial (Eq. 1) were calculated by multiple regression analysis on the experimentally obtained data. The pullulan production by using biofilm reactor under optimum conditions was then compared with the predicted value obtained from the model. The suspension cell culture was also carried out with optimum medium for comparison.

Biomass

Biomass was measured by means of dry weight. Samples (1 ml) from culture broth were centrifuged at 12,000 × g, 4°C for 20 min. For biomass, the precipitated pellets were washed twice with distilled water and centrifuged again to remove impurities. The pellets were dried at 80°C overnight to determine biomass dry weight.

Crude pullulan

After culture broth (5 ml) was centrifuged at 3,300 × g, 4°C for 20 min, 4 ml of supernatant was mixed with 8 ml of 95% ethanol and incubated at 4°C for 12 h to precipitate the crude polysaccharides, which were precipitated by centrifuging at 3,300 × g for 30 min. The precipitated material was dried at 80°C overnight to determine the weight of crude pullulan.

Sugar analysis

For sucrose concentration, fermentation broth (3 ml) was centrifuged at 3,300 × g for 10 min and hydrolyzed by hydrochloric acid before analyzing with the dinitrosalicylic (DNS) method [26].

Quality analysis

Pullulan purity

Polysaccharides produced from A. pullulans were assayed for sensitivity to pullulanase to determine the pullulan content [23]. Each sample was firstly ethanol-precipitated, dried, and subsequently resuspended at a final concentration of 1 mg/ml in 50 mM sodium acetate buffer (pH 5.0). Pullulanase from Bacillus acidopullulyticus (Sigma, St. Louis, MO) was added at a concentration of 0.5 U/ml. After mixing, the mixture was incubated for 24 h at 25°C. Pure pullulan (Cat # P4516; Sigma, St. Louis, MO) was used as control (99.9%), and data are reported as percentage of reducing sugars relative to total polysaccharide. Reducing sugar content was determined using DNS method. The calibration curve used for reducing-sugar determination was generated by using a pullulan standard (0–1 mg/ml) purchased from Sigma.

Viscosity measurement

Pullulan samples produced from A. pullulans were dissolved in D.I. water (5 mg/ml). Viscosity was measured using a viscometer (Model LV 2020, Cannon Instrument Co., State College, PA) and LV-1 spindle (Brookfield Engineering Lab. Inc., Middleboro, MA) at 25°C with a rotation of 100 rpm. Pure pullulan from Sigma was used as control.

Composition analysis by FTIR

FTIR spectra of pullulan samples were acquired using the KBr pellet technique on a Bruker IFS/66s (Bruker Optics, Billerica, MA) spectrometer equipped with a MCT detector. Each sample was loaded into a stainless-steel vial containing a ball pestle and ground for 30 s using a Wig-L-Bug vibratory mill. The ground sample was then diluted with KBr (International Crystal Laboratories, Garfield, NJ) to a concentration of around 0.5% (v/v) and mixed using the Wig-L-Bug mill with the pestle removed. Then 60 mg of this mixture was loaded into a 7-mm Quick Press die and pressed until clear. All spectra are referenced to a blank KBr pellet.

Statistical analysis

Results of pullulan production were analyzed using analysis of variance (ANOVA). The goodness of the obtained equation is evaluated by several criteria. The coefficient of determination (R 2) explains not only the percentage of the sample variation, which is contributed by independent variables, X 1, X 2, and X 3, but also the total deviation, which can not be explained by the model.

Results

In this study, an RSM based on the Box–Behnken design was used to optimize the cultivation conditions for pullulan production and the matrix of the experiment is presented in Table 1. Three levels for each factor were chosen based on our previous studies (10, 11). The results of the Box–Behnken are shown in Table 2 as the average of duplicates. Fifteen runs were carried out and the experimental results of pullulan production ranged from 8.5 to 47.6 g/l, which were close to their related prediction values.

RSM model development

By applying multiple regression analysis on the experimentally determined data in Eq. (1), the regression coefficients were estimated as shown in Table 3 and the following second-order polynomial equations were obtained using Minitab software:

The predicted optimum levels of X 1, X 2, and X 3 were obtained by applying regression analysis of Eq. (2), using MATLAB software, and they were −1 (0 g/l of YE), −1 (0 g/l of ammonium sulfate), and 1 (100 g/l of sucrose), respectively. The prediction of pullulan production was 62.8 g/l. The coefficient of determination (R 2) value of the regression for the response related to significant effects on the model was 0.955, which means that the sample variation of 95.5% for pullulan production was attributed to the factors, indicating that only 4.5% of the total variation was not explained by the model.

The adequacy of the full quadratic model of pullulan production was also tested with the use of ANOVA. The model summary statistics in Table 4 indicate the adequacy of models including linear, two-factor interactions, and quadratic. The linear model for pullulan production was significant at the 1% level. The model, with a satisfactory R 2 value of 0.9924, was significant (p < 0.05), and lack-of-fit for the model was insignificant. As a result, it can be concluded that the second-order model (Eq. 2) adequately approximated the true surface of pullulan production.

Effects of factors on pullulan production

The three-dimensional response surface was generated to study the interaction among three factors tested and to visualize the combined effects of factors on the response of pullulan production (Fig. 2). When the effect of two factors was plotted, the other one factor was set at the coded value zero, which was 2.5 g/l of yeast extract, 2.5 g/l of ammonium sulfate, and 75 g/l of sucrose as described in Table 1. The combined effects of each pair of factors demonstrated that pullulan production increased with the increase of sucrose and decrease of yeast extract (Fig. 2). The maximum pullulan production was predicted in maximum sucrose concentration, indicating that sucrose has the highest effect on pullulan production. In combined effects of yeast extract and ammonium sulfate, the optimum value of pullulan production corresponded to the coded value, −1, for each factor, indicating that both yeast extract and ammonium sulfate exhibited a negative effect on pullulan production.

Verification of optimization

To validate predicted pullulan production, a verification fermentation was carried out with the predicted optimum level of X 1, X 2, and X 3 (0 g/l yeast extract, 0 g/l ammonium sulfate, and 100 g/l sucrose) by A. pullulans. The pullulan production after 7-day fermentation was 60.7 g/l (Table 5), which was 1.8 times higher than the one from original medium and agreed with the predicted value (i.e., 62.8 g/l). Moreover, in order to validate the effect of sucrose concentration on pullulan production, 115 and 125 g/l of sucrose with other optimal fermentation conditions were performed. The results demonstrated that excess sucrose will adversely reduce pullulan yield and they were 58.2 and 50.8 g/l, respectively. The results of suspension cell fermentation with optimal fermentation conditions were summarized in Fig. 3, and demonstrated that A. pullulans cannot grow and produce pullulan due to the lack of nitrogen sources, which are essential for biomass production. However, pullulan production in the PCS biofilm reactor can be achieved since PCS itself contains nitrogen ingredients, which were released slowly to the environment [18].

Viscosity and Purity

The pure pullulan content (95.2%) and viscosity (2.5 cP) of produced pullulan under optimal conditions also demonstrated that there is no significant difference between original and optimum media on pullulan properties as shown in Table 5.

FTIR of pullulan

The FTIR spectra of pullulans produced from optimum medium demonstrated similar features in comparison to the pullulan standard (Fig. 4). The absorption around 850 cm−1 characterized the α-configuration of α-d-glucopyranose units [2]. Absorption at 755 and 929 cm−1 demonstrated that the predominant linkages between glucose units were α (1, 4) and α (1, 6), which indicated the dominant of pullulan within produced EPS. Other features of polysaccharide were also found from the spectra, O–H stretch (3,431 cm−1), CH stretch (2,928 cm−1), O–C–O stretch (1,645–1,650 cm−1), C–O–H bend (1,366–1,678 cm−1), and C–O–C stretch (1,154–1,160 cm−1), as reported earlier [34]. The medium ingredients were also performed FTIR analysis and exhibited no contribution to the absorbance mentioned previously.

Discussion

Instead of optimizing medium composition by a one-factor-at-a-time approach, the statistical optimization using experimental design provides the opportunity to determine the optimal conditions in any given parameters by establishing the relationship between factors and predicted responses. In this study, optimal concentrations of three crucial nutrition ingredients, sucrose, yeast extract, and ammonium sulfate, were generated using RSM with Box–Behnken design, and they were 0, 0, and 100 g/l, respectively. The pullulan production under optimum medium was 60.7 g/l, which was 1.8-fold higher than the result from original medium, and was 2.4-fold higher than the result obtained from suspension culture [9].

Both carbon source and nitrogen source are crucial factors for cell growth and the production of its metabolites. Although depletion of nitrogen from fermentation medium was reported as a signal for exopolysaccharide synthesis [6, 8], 0.3% of yeast extract and 0.5% of ammonium sulfate were still needed [9]. However, it was surprisingly noted that the optimum medium without nitrogen source gave the highest pullulan production. The reason for this was due to the implementation of the PCS biofilm reactor. The contributions of PCS can be explained as follows: first of all, PCS tubes, which contained soybean hulls, defatted soybean flour, yeast extract, dried bovine red blood cells, and mineral salts, were a mixture of polypropylene and nutrition ingredients. The moderate nitrogen-leaching rate reported by Ho et al. [18] satisfied the minimum requirement of nitrogen. Secondly, PCS provided an ideal surface for biofilm formation. Cells of A. pullulans had accumulated on the PCS during pre-cultivation and hence reduced the demand on the nitrogen source for biomass production [10]. Thirdly, the cells on the PCS were maintained in stationary phase, which was reported as a favored state for pullulan production [23]. A control fermentation with the optimum medium obtained in the biofilm reactor was carried out in a suspension culture. The results demonstrated that both biomass and pullulan productions were extremely low after 7-day fermentation due to the lack of nitrogen sources, which are essential for bacterial growth (Fig. 3).

Excess carbon source was reported exhibiting an inhibition effect on pullulan production [21, 33]. The reason for this could be due to the suppression effect of sugars on enzymes related to pullulan production, such as α-phosphoglucose mutase, UDPG-pyrophosphorylase, and glycosyltransferase [15]. Kumar et al. [22] also proposed a 10:1 carbon/nitrogen ratio which was most favorable for maximal exopolysaccharide production in suspension cell. Our results demonstrated that A. pullulans grew on PCS can overcome this limitation. The produced pullulan was 60.7 g/l, which is the highest value to date. There is one report that claimed that they can obtain 80 g/l of pullulan [35]. However, the result seemed to be erroneous, since the initial carbon source was only 50 and 80 g/l of pullulan was produced.

Many factors, such as pH profile, carbon and nitrogen sources, and oxygen and aeration rate, could affect the properties of produced pullulan (molecular weight and distribution, purity, and viscosity) [21, 32]. In our study, 95.2% of produced exopolysaccharide was characterized as pullulan, which is higher than most of the reports to date, and close to the commercial product (99.9%; Cat # P4516; Sigma, St. Louis, MO). The viscosity results also indicated that our pullulan sample exhibited higher average molecular weight toward commercial pullulan (1.4 cP) [5, 10]. Further studies on molecular weight distribution of produced pullulan can be performed using high-performance size-exclusion chromatography (HPSEC). The FTIR results also served as supporting evidence that pullulan dominated the polysaccharide produced by A. pullulans.

The PCS biofilm reactor system appears to have several advantages, such as advancing pullulan production profile, overcoming the sugar-suppression effect, and producing pullulan under a moderate nitrogen-leaching rate. Apart from their well-known benefits of being highly stable systems with lower capital cost, biofilm reactors also possesses great potential to be developed into a more productive process, such as continuous fermentation.

References

Bae S, Shoda M (2005) Statistical optimization of culture conditions for bacterial cellulose production using Box–Behnken design. Biotechnol Bioengin 90:20–28

Barker SA, Bourne EJ, Stacey M, Whiffen DH (1954) Infrared spectra of carbohydrates. Part I. Some derivatives of d-glucopyranose. J Chem Soc 75:171–176

Box GEP, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrices 2:455–475

Box GEP, Hunter WG, Hunter JS (1978) Statistics for experimenters: an introduction to design, data analysis, and model building. Wiley, New York

Buliga GS, Brant DA (1987) Temperature and molecular weight dependence of the unperturbed dimensions of aqueous pullulan. Int J Biol Macromol 9:71–76

Bulmer MA, Catley BJ, Kelly PJ (1987) The effect of ammonium ions and pH on the elaboration of the fungi extracellular polysaccharide pullulan, by Aureobasidium pullulans. Appl Microbiol Biotechnol 25:362–365

Catley BJ, Ramsay A, Servis C (1986) Observations on the structure of the fungal extracellular polysaccharide, pullulan. Carbohydr Res 153:79–86

Catley BJ (1971) Role of pH and nitrogen limitation in the elaboration of the extracellular polysaccharide pullulan by Pullularia pullulans. Appl Microbiol 22:650–654

Cheng KC, Demirci A, Catchmark MJ (2009a) Evaluation of medium composition and fermentation parameters on pullulan production by Aureobasidium pullulans. Food Sci Technol Int (in press)

Cheng KC, Demirci A, Catchmark MJ (2009b) Effects of plastic composite support and pH profiles on pullulan production in a biofilm reactor. Appl Microbiol Biotechnol. doi:10.1007/s00253-009-2332-x)

Cheng KC, Catchmark MJ, Demirci A (2009) Enhanced production of bacterial cellulose by using a biofilm reactor and its material property analysis. J Biol Eng 3:12

Cotton JC, Pometto AL, Gvozdenovic-Jeremic J (2001) Continuous lactic acid fermentation using a plastic composite support biofilm reactor. Appl Microbiol Biotechnol 57:626–630

Demirci A, Pometto AL III, Ho KLG (1997) Ethanol production by Saccharomyces cerevisiae in biofilm reactors. J Ind Microbiol 19:299–304

Demirci A, Pongtharangkul T, Pometto AL III (2006) Applications of biofilm reactors for production of value-added products by microbial fermentation. In: Blaschek HP, Wang H, Agle M (eds) Biofilms in the food environment. Blackwell Publishing, Ames, pp 167–189

Duan X, Chi Z, Wang L, Wang X (2008) Influence of different sugars on pullulan production and activities of α-phosphoglucose mutase, UDPG-pyrophosphorylase and glucosyltransferase involved in pullulan synthesis in Aureobasidium pullulan Y68. Carbohydr Polymers 73:587–593

Gibbs PA, Seviour RJ (1996) Does the agitation rate and/or oxygen saturation influence exopolysaccharide production by Aureobasidium pullulans in batch culture? Appl Microbiol Biotechnol 46:503–510

Gibson LH, Coughlin RW (2002) Optimization of high molecular weight pullulan production by Aureobasidium pullulans in batch fermentations. Biotechnol Prog 18:675–678

Ho KLG, Pometto AL III, Hinz PN, Demirci A (1997) Nutrient leaching and end product accumulation in plastic composite support for l-(+)-lactic acid biofilm fermentation. Appl Environ Microbiol 63:2524–2532

Iyer A, Mody KH, Jha B (2005) Biosorption of heavy metals by a marine bacterium. Mar Poll Bull 50:340–343

Iyer A, Mody KH, Jha B (2006) Emulsifying properties of a marine bacterial exopolysaccharide. Enzyme Microb Technol 38:220–222

Kim JH, Kim MR, Lee JH, Lee JW, Kim SK (2000) Production of high molecular weight pullulan by Aureobasidium pullulans using glucosamine. Biotechnol Lett 22:987–990

Kumar AS, Mody K, Jha B (2007) Bacterial exopolysaccharides—a perception. J Basic Microbiol 47:103–117

Leathers TD (2002) Pullulan. In: Steinbuchel A (ed) Polysaccharides II. Wiley-VCH, New York, pp 1–10

LeDuy A, Zajic JE, Luong JHT, Choplin L (1988) Pullulan. In: Mark HF, Bikales NM, Overberger CG, Menges G (eds) Encyclopedia of polymer science and engineering, 2nd edn. Wiley, New York

Maddox IS, Richert SH (1977) Use of response surface methodology for the rapid optimization of microbiological media. J Appl Bacteriol 43:197–204

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Mohammad FHA, Badr-Eldin SM, El-Tayeb OM, Abd El-Rahman OA (1995) Polysaccharide production by Aureobasidium pullulans III. The influence of initial sucrose concentration on batch kinetics. Biomass Bioenergy 8:121–129

Pometto AL III, Demirci A, Johnson KE (1997) Immobilization of microorganisms on a support made of synthetic polymer and plant material. U.S. patent 5,595,893

Reeslev M, Jensen B (1995) Influence of Zn2+ and Fe3+ on polysaccharide production and mycelial/yeast dimorphism of Aureobasidium pullulans in batch cultivations. Appl Microbiol Biotechnol 42:910–915

Ronen M, Guterman H, Shabtai Y (2002) Monitoring and control of pullulan production using vision sensor. J Biochem Biophy Methods 51:243–249

Roukas T (1999) Pullulan production from brewery wastes by Aureobasidium pullulans. World J Biotech 15:447–450

Seo HP, Son CW, Chung CH, Jung DI, Kim SK, Richard AG, David LK, Lee JW (2004) Production of high molecular weight pullulan by Aureobasidium pullulans HP-2001 with soybean pomace as a nitrogen source. Bioresour Technol 95:293–299

Shin YC, Han JK, Lee HS, Byun SM (1987) Inhibition effect of sugar concentrations on the cell growth and the pullulan production of Aureobasidium pullulans. Korean J Microbiol 25:360–366

Singh RS, Saini SK (2007) Pullulan-hyperproducing color variant strain of Aureobasidium pullulans FB-1 newly isolated from phylloplane of Ficus sp. Bioresour Technol 99:3896–3899

Thirumavalavan K, Manikkandan TR, Dhanasekar R (2008) Batch fermentation kinetics of pullulan from Aureobasidium pullulans using low-cost substrates. Biotechnology 7:317–322

Velazquez AC, Pometto AL III, Ho KLG, Demirci A (2001) Evaluation of plastic-composite supports in repeated fed-batch biofilm lactic acid fermentation by Lactobacillus casei. Appl Microbiol Biotechnol 55:434–441

West TP (2000) Exopolysaccharide production by entrapped cells of the fungus Aureobasidium pullulans ATCC 201253. J Basic Microbiol 40:397–401

Yang CH, Cheng KC, Liu WH (2003) Optimization of medium composition for the production of extracellular amylase by Thermobifida fusca using a response surface methodology. Food Sci Agric Chem 5:35–40

Acknowledgments

This project was partly funded by the Pennsylvania Agricultural Experiment Station. The authors thank Dr. Josh Stapleton from the Materials Research Institute at the Pennsylvania State University for his assistance with the FTIR measurements. Thanks also to Dr. John Coupland from the Food Science Department at Pennsylvania State University for his assistance with viscosity measurements. The authors thank the Statistical Consulting Center at Pennsylvania State University for useful consulting of data processing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, KC., Demirci, A. & Catchmark, J.M. Enhanced pullulan production in a biofilm reactor by using response surface methodology. J Ind Microbiol Biotechnol 37, 587–594 (2010). https://doi.org/10.1007/s10295-010-0705-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0705-x