Abstract

Recombinant DNA (rDNA) technologies allow the production of a wide range of peptides, proteins and metabolites from naturally non-producing cells. Since human insulin was the first heterologous compound produced in a laboratory in 1977, rDNA technology has become one of the most important technologies developed in the 20th century. Recombinant protein and metabolites production is a multi-billion dollar market. The development of a new product begins with the choice of the cell factory. The final application of the compound dictates the main criteria that should be taken into consideration: (1) quality, (2) quantity, (3) yield and (4) space time yield of the desired product. Quantity and quality are the most predominant requirements that must be considered for the commercial production of a protein. Quantity and yield are the requirements for the production of a metabolite. Finally, space time yield is crucial for any production process. It therefore becomes clear why the perfect host does not exist yet, and why—despite important advances in rDNA applications in higher eukaryotic cells—microbial biodiversity continues to represent a potential source of attractive cell factories. In this review, we compare the advantages and limitations of the principal yeast and bacterial workhorse systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Industrial biotechnology has traditionally employed numerous bacterial and eukaryotic organisms as production platforms. Traditionally, the first criterion for choosing a certain host was its natural ability to produce the desired compound, be it a primary or secondary metabolite, an enzyme or a biopharmaceutical protein. Many microbial products have indeed been available in the industrial biotechnology market for a long time now (Table 1).

With the advent of recombinant DNA technology, it has become possible, however, to introduce traits for the production of desired compounds into non-natural producers. This has first been employed for the production of human proteins in microbial cells, like insulin in Escherichia coli, which was obtained for the first time in a laboratory in 1977 by Herbert Boyer. Partnering with Genentech founded by Boyer, Eli Lilly went on in 1982 to sell the first commercially available biosynthetic human insulin under the brand name Humulin™ (a first successful laboratory production of human insulin announced, New Release Genentech, 6 September 1978; http://www.gene.com/gene/news/pressreleases/display.do?method=detail&id=4160).

While it has become clear soon after that not all proteins can be easily produced in E. coli, the biotechnology industry is still highly interested in developing and applying rather few well characterized platform strains.

A similar concept has been followed for the production of metabolites. Metabolic engineering has enabled the introduction of metabolic pathways into host strains that do not naturally produce a desired compound (Bailey 1991). Thus beneficial traits of certain platform host organisms such as easy cultivation, substrate utilization, easy genetic manipulation, stress resistance, etc., can be combined with the synthesis of desired metabolites.

Among microbial production, yeasts and bacteria share beneficial features as single cell growth, easy cultivation on cheap media and easy genetic manipulation. While this statement is compromised by specific features of some strains such as complex nutrient requirements or recalcitrance to genetic engineering, this supports the platform strain concept even more, as it enables to choose strains with the most beneficial features. Consequently, the art is to choose platform strains that provide the required features for the specific product, and enable high productivity at suitable quality.

In the following, we discuss the criteria in selecting suitable microbial production hosts both for recombinant proteins and metabolites. Both classes of products share requirements to be met by the production host, mainly concerning productivity. As a major determinant for process costs, the space time yield (or volumetric productivity) should be maximized. Space time yield depends on specific growth rate and high turnover rates (specific productivity). As a general rule, bacteria feature higher turnover rates than yeasts, which would naturally put them into an advantageous position. However, specific requirements of single products may counteract this general concept and require careful consideration when selecting a platform host. These requirements mainly relate to product quality, e.g., posttranslational modification requirements may constrain the host selection for a heterologous protein, or low pH resistance may be desired for the production of organic acids. Additional criteria are the achievable product concentration (essential for downstream processing costs) and, mainly for metabolites, the yield of product per substrate (defining the substrate costs per unit product).

Heterologous protein production

Recombinant protein production is a multi-billion dollar market, comprising biopharmaceuticals and industrial enzymes. Global sales for biopharmaceutical proteins reached US$87 billion in 2008, and is expected to rise up to US$169 billion in 2014 (Goodman 2009; Macdonald, http://www.in-pharmatechnologist.com).

In 2009, out of the 151 approved recombinant biopharmaceutical products in the US and EU, 29 monoclonal antibodies contributed to more than 40% of the revenues, followed by vaccines, TNF blockers, hormones like insulins and erythropoietins. In this respect, about 50% of the different proteins were produced using only two microbial host platforms: E. coli (~30%) or Saccharomyces cerevisiae (~20%), respectively; the remaining fraction was produced using higher eukaryotic host cells: insect cells (~1%), hybridomas (~10%), mammalian cells (~39%) and transgenic animals (~1%) (Ferrer-Miralles et al. 2009).

The market for industrial enzymes was US$5.1 billion, with a predicted annual increase of 6.3% (Freedonia Group Inc 2009). Indeed, the growing demand in the animal feed and biofuels market as well as in speciality enzymes requires high production of industrial enzymes such as proteases, lipases and carbohydrases.

Any production process has to be highly productive, efficient and economic. The development of a new product or a new process usually begins with the choice of an appropriate production host; in this respect a comparative view on available expression hosts and their respective production processes is worthwhile.

We already underlined that E. coli is the working horse of recombinant protein production (Ferrer-Miralles et al. 2009). This has several reasons such as well-established molecular biological methods, its role as model organism leading to a wealth of knowledge on the annotated genome sequences and metabolic pathways, high yield of recombinant protein (up to 50% of total biomass; Panda 2003), and the availability of protocols for high cell density cultivation (HCDC) are established, reaching up to 100 g biomass/l (Tripathi et al. 2009).

About 60% of the commercially available technical enzymes are produced by Bacillus species, but it should be underlined that most of them are homologous proteins (Westers et al. 2004). In contrast to E. coli, B. subtilis has an enormous secretion potential and is considered as a GRAS (Generally Recognized As Save) organism. However, the Bacillus expression system also bears some unsolved challenges, such as lack of suitable expression vectors, plasmid instability, presence of proteases, and less productive protocols for HCDC (Huang et al. 2004).

Bacterial expression systems in general suffer from plasmid instability, which makes sustained production strategies difficult, and they lack of complex post transcriptional modification (PTM). If very high expression rates are reached, some proteins tend to aggregate and form inclusion bodies (IB) (Baneyx and Mujacic 2004; Carrio and Villaverde 2002), which is advantageous in terms of cultivation productivity and primary recovery, but also adds additional process costs for refolding. Recently, production of otherwise toxic proteins was achieved by C-terminal fusion to the IB promoting autoprotease Npro, which is cleaved off autocatalytically during the refolding process yielding soluble, purified protein (Achmuller et al. 2007).

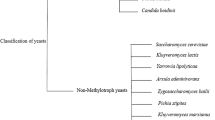

Despite this, the initial limitations have led to the development of yeast expression systems, such as the conventional yeast host S. cerevisiae as well as other yeasts. Indeed, S. cerevisiae has been the second organism which was used to produce commercial recombinant human insulin (Walsh 2005). The combination of secretion optimization and an autoselection system for plasmid retention, enabled the set up of a long-term, large-scale, continuous production of insulin with the required quality of the pharmaceutical polypeptide (Kjeldsen 2000). Alternatively, expression systems based on other yeasts including Pichia pastoris, Hansenula polymorpha, Schizosaccharomyces pombe, Kluyveromyces lactis, Yarrowia lipolytica, Pichia methanolica, Pichia stipitis, Zygosaccharomyces rouxii and Z. bailii, Candida boidinii, Schwanniomyces (Debaryomyces) occidentalis, and Arxula adeninivorans to mention just a few, have been developed (reviewed by Porro et al. 2005 and Graf et al. 2009 and references herein).

The molecular biological methods for manipulating most of these yeasts are well established, a stable integration of the gene of interest is routinely done by homologous recombination, growth on inexpensive, chemical defined media to very high cell densities is possible (Gellissen et al. 2005); yeasts do have a great secretion capacity including a strict quality control (Stolz and Wolf 2010) and, most importantly, yeasts can perform complex PTM.

Benefits and pitfalls of bacterial and yeast production platforms have extensively been discussed previously (e.g., reviews by Demain and Vaishnav 2009, Graumann and Premstaller 2006 and Sørensen 2010).

Table 2 compares the main host features. As outlined in the introduction section, quantity and quality (and space time yield) are the most predominant requirements that must be met for the commercial production of a protein. Generally speaking, reaching high yields is more important for the production of industrial enzymes, while high quality is crucial for the production of biopharmaceutical proteins.

As a rule of thumb, usually bacterial systems such as E. coli are used for intracellular protein production of less complex proteins, while secretory production is commonly achieved with yeasts or higher eukaryotic hosts. One example is the production of recombinant insulin, which has successfully been achieved in both types of hosts employing these strategies (reviewed by Walsh 2005) (Table 3). Generally, the averaged specific productivity is higher in bacterial systems, but as the maximum biomass concentration is higher in yeasts, the overall space–time yield of the production process remains similar. The reason for this is the much smaller maintenance coefficient, q m. For instance, P. pastoris has a q m_glucose = 0.016 g/g h (Maurer et al. 2006) compared to E. coli, which has q m_glucose = 0.04 g/g h (Sundström and Enfors 2008). Maintenance becomes predominant at low specific growth rates and adds significantly to oxygen demand and heat production at high biomass concentrations, thus limiting biomass yield and maximum cell density of bacterial production processes. Consequently, E. coli based production processes usually have a higher oxygen demand, and they lead to more by-product formation than for example P. pastoris based processes. Another advantage of the yeast systems is the low amount of host cell protein in the supernatant (e.g., for P. pastoris; Mattanovich et al. 2009), thus facilitating the downstream processing of soluble secreted recombinant proteins.

For the production of biopharmaceutical products, addressing the required quality standards is today as crucial as obtaining high quantities and excellent space time yields. In a structural genomics initiative, production of more than 300 human proteins was attempted in E. coli, S. cerevisiae and P. pastoris. Out of these, the success rate was 58% for intracellular expression in S. cerevisiae, whereas only 39% could be produced soluble in E. coli (Holz et al. 2003). Up to 70% of the mammalian proteins that have not been expressed at all or were insoluble in E. coli were expressible in the yeast systems (Prinz et al. 2004). One of the critical success factors identified was the presence of a homologous yeast protein to the mammalian protein (Boettner et al. 2007), thus making yeast hosts a reasonable choice to produce proteins for structural biology purposes. Though, the dogma that E. coli cannot secrete or glycosylate recombinant proteins became obsolete due to extensive genetic engineering efforts: both extracellular protein production (reviewed by Ni and Chen 2009) as well as glycosylation (reviewed by Pandhal and Wright 2010) has been reported also for prokaryotic hosts. However, the yields achieved (up to max. of 100 mg/l secreted protein), or the authenticity of the glycans are far from the eukaryotic systems. In this respect, glycoengineered P. pastoris enables the production of human proteins with authentic uniform N-glycans. For example, production of full length antibodies—even up to gram per liter (g/l) scale—have been reported both for E. coli (Mazor et al. 2010; McLaughlin and Reilly 2008) and P. pastoris (Potgieter et al. 2009); however, only the P. pastoris derived mAb carried the uniform N-glycan critical for biological effector functions, while E. coli derived mAbs do not possess any glycosylation. On the other hand, separate production of light chain and aglycosylated heavy chain as IBs in E. coli with refolding of mixed IBs was reported yielding around 50 mg/l IgG (Hakim and Benhar 2009), thereby overcoming previous hurdles of only partially assembled IgGs in E. coli (Simmons et al. 2002).

For the production of heterologous industrial enzymes, secretion in P. pastoris also seems to be an excellent choice. To give a short overview, in the following we focus on studies directly comparing the production of fungal enzymes in yeast and bacterial production hosts. The secretory levels of Candida antarctica lipase B (CALB, 24 kDa, non-glycosylated, three disulfide bridges) obtained in P. pastoris exceeded the yields obtained in various folding engineered E. coli strains several fold (44.5 mg/l compared to a maximum of 5.2 mg/l, respectively (Larsen et al. 2008). In addition, for proteins containing no disulfide bonds such as xylanases, secretion in eukaryotic hosts is beneficial to production in E. coli, not only in terms of productivity (250 vs. 50 U/ml), but also regarding enzyme activity and purity (McHunu et al. 2009). We may conclude that the production of eukaryotic enzymes is often favoured in an eukaryotic (e.g., yeast) host.

Heterologous metabolite productions

Microorganisms have also been employed in the past several decades for large-scale natural production of a variety of metabolites such as amino acids, nucleotides, organic acids, carbohydrates, lipids, vitamins, solvents, antibiotics, etc. (see Table 1).

Increasing energy costs and environmental concerns have emphasized the need to produce sustainable renewable fuels and chemicals. Even if much younger, also the recombinant metabolite production is a multi-billion dollar market. In fact, the production of metabolites through microbial fermentation is one of the desirable alternatives to petrochemical-based productions (Carothers et al. 2009; Jarboe et al. 2010; Keasling 2008; Otero and Nielsen 2010).

The different feedstocks available can be classified based on their environmental and economical sustainability (Somerville et al. 2010). Feedstock deconstruction/treatment releases inhibitors and elementary building blocks such as pentoses, hexoses, polyols, fatty acids, etc., that can be converted to different metabolites by microbes. In this respect, the microbial factory has to quickly and efficiently convert sugars to the desirable compound at costs, which must be competitive with existing petrochemical-based processes. Consequently, the microbial biocatalysts must be robust to extreme fermentation conditions, as well as to biomass-derived inhibitors and, of course, to the target products.

Natural and engineered cell factories are used for commercial productions. Still few metabolites that are on, or soon going to be on, the market are produced by recombinant bacterial or yeast cell factories. Among bacteria, we should cite the production of 1,3-propandiol (DuPont, USA) and different amino acids (different companies), while among yeasts citations should be devoted to the production of artimisinin (Amyris, USA), lactic acid (Nature Works, USA), bioethanol of second generation (different companies), succinic acid (DSM, The Netherlands), hydrocortisone (Aventis, France), resveratol (Fluxome, Denmark) and farnesene (Amyris, USA).

As example, we analysed and compared both traditional and advanced productions in bacteria and yeasts of a vitamin (riboflavin), an organic acid (lactic acid) and a couple of biofuels (ethanol and butanol).

Riboflavin

The biotechnological production of riboflavin (vitamin B2) has replaced chemical synthesis today. Initially, natural riboflavin producers were employed such as the flavinogenic fungi Candida famata and Ashbya gossypii, followed by engineering of bacteria such as B. subtilis and recently Corynebacterium ammoniagenes, which do not naturally overproduce riboflavin (reviewed by Stahmann et al. 2000). The product titers achieved with these different production organisms are similar in a range of 15–20 g/l, so that no clear advantage of one host is apparent. However, when analysing the published processes in more detail it becomes obvious that the bacterial processes are shorter, thus achieving higher volumetric productivities. Table 4 compares riboflavin titers, process times and volumetric productivities of these hosts. Apparently, the non-natural flavin producers have gained an advantage due to their higher specific productivity, thus pointing out that natural producers of a desired metabolite are not necessarily the better choice as a production platform. An additional selection criterion for a production organism is the required culture medium. Ideally, mineral media containing the carbon source as only organic compound should be used, both to limit costs of goods, and to achieve simple and cheap recovery and purification. C. ammoniagenes was reported to produce riboflavin on mineral media with glucose as carbon source (Koizumi et al. 2000), while B. subtilis required the addition of yeast extract (Wu et al. 2007) and C. famata was supplemented with glycine as precursor of the product (Heefner et al. 1992). Additionally C. famata is sensitive to iron, which has to be limited in the culture medium. A. gossypii produces the vitamin on vegetable oil with the addition of glycine (Sugimoto et al. 2010). While vegetable oil exerts lower osmotic stress on the producing culture than glucose, it poses additional constraints on the final preparation of the product. In conclusion, several yeasts and fungi, being natural riboflavin overproducers, have been the first organisms employed in large scale production, but engineered bacteria may have advantages such as shorter process times and simpler culture media.

Lactic acid

Lactic acid is one example of an important metabolite of the central carbon and energy metabolism, which is commercially available and produced by microorganisms (about 150,000 tons/year) (Sauer et al. 2008).

In particular, its use as monomer for the fabrication of the biodegradable plastic PLA (polylactic acid) is a reason for biotechnological production, because the demand for optical purity is high (Okano et al. 2010; Sauer et al. 2010).

The costs for the required high degree of purification still contribute significantly to the overall production costs and this relates directly to the choice of the production organism. Lactic acid bacteria are natural producers of the desired acid. Processes based on lactic acid bacteria have been established long time ago. High concentrations of lactate (well over 100 g/l) and high volumetric productivities (10–23 g/l h) are reached (Hofvendahl and Hahn-Hägerdal 2000). However, lactic acid bacteria have complex nutrient requirements and do not tolerate a pH below 5, which are both detrimental for purification. Venkatesh (1997), for example, reports about Lactobacillus delbrueckii producing lactic acid at pH 5.6 with a productivity of 11 g/l h. Already at a pH of 5.0 the productivity drops to 3.1 g/l h; at pH 4.5 the value reaches 0.68 g/l h, which is far below of what is required for any industrial use. Similar data have been obtained for the production of lactic acid by Streptococcus bovis (Yuwono and Kokugan 2008).

Metabolic engineering allows the heterologous production of lactic acid with bacteria and yeasts. However, only the production from yeasts appears well suited for this task due to their tolerance to low pH conditions and the possibility of growing them on mineral media. Nevertheless, volumetric productivities are significantly lower compared to bacterial values under optimal conditions. A process employing Candida utilis obtains an overall productivity of 3.1 g/l h with a final pH of 4 (reaching a maximum of 4.9 g/l h during the process, (Ikushima et al. 2009). For S. cerevisiae, production rates of about 1 g/l h, reaching a pH of about 2.5, have been published (Valli et al. 2006). While data for industrially achieved productivities are not available, the order of magnitude can be estimated from the values above. They remain way behind the values of bacterial production hosts. Nevertheless, the advantage of the easier downstream processing outweighs this fact, so industrial production of lactic acid is taking place with recombinant yeast as production host.

Even if it is still far away from industrial production, specific mention should be dedicated to the direct production of PLA from metabolically engineered E. coli factories (Jung et al. 2010; Yang et al. 2010).

Biofuels

Biofuels, such as bio-ethanol and bio-butanol, are of huge interest as alternatives to petroleum-based transportation fuels, mainly because they offer the long-term promise of fuel-source regenerability and reduced climatic impact (Clomburg and Gonzalez 2010; Dellomonaco et al. 2010; Peralta-Yahya and Keasling 2010; Rude and Schirmer 2009; Steen et al. 2010; Yan and Liao 2009).

Ethanol is the metabolite produced today in the highest quantity (about 80 million tons/year). The most employed microorganism used is S. cerevisiae, because of its capability to hydrolyze cane sucrose into glucose and fructose, two easily assimilable 6-C sugars. High concentrations (over 100 g/l) and high yields (close to the theoretical values) can be obtained. Aeration is an important factor for growth and ethanol production by S. cerevisiae. Although this microorganism has the ability to grow under anaerobic conditions, small amounts of oxygen are needed for the synthesis of substances such as fatty acids and sterols. However, S. cerevisiae is unable to ferment C-5 sugars. Batch, fed-batch, repeated batch, continuous and continuous removal of ethanol processes have been proposed.

Many bacteria, on the other hand, produce ethanol as a natural product of hexose fermentation, but this biofuel represents only a small fraction of the product mixture (mixed-acid fermentation). Among bacteria, the most promising microorganism is Zymomonas mobilis, which has a low energy efficiency resulting in a higher ethanol yield (up to 97% of theoretical maximum). However, its range of fermentable substrates is too narrow (glucose, fructose and sucrose) (Claassen et al. 1999).

Metabolic engineering approaches have been extensively used in S. cerevisiae and Z. mobilis to allow the formation of ethanol from 5-C sugars. Different plants in the US and one in the EU are currently operating in this respect. The main problems are related to the inhibitors released by the deconstruction/treatment of the biomasses. In this respect, S. cerevisiae seems to offer more opportunities for further developments.

On the other hand, many microorganisms are able to efficiently utilize pentose sugars, but cannot naturally produce ethanol at sufficient yield and productivity. Some microorganisms that utilize pentoses, such as the bacteria E. coli and Klebsiella oxytoca and the yeast Pichia stipitis, have been successfully engineered for ethanol production (Ingram et al. 1998).

In recent years, interest in converting sugars into butanol rose strongly. Due to its physical properties, the four-carbon alcohol is a better replacement for gasoline than ethanol. Various Clostridium spp. have been utilized in butanol fermentation, although these Gram-positive anaerobes coproduce butanol with a few byproducts, such as butyric acid, acetone, ethanol, therefore lowering its yield (Jones and Woods 1986). Genetic manipulation of both bacteria (Clostridium, Escherichia spp.) and yeast (S. cerevisiae) have been proposed as a potential tool for obtaining or increasing the production of butanol. Essentially, the engineering strategy in Clostridium looks over the redirection of the carbon flux towards the sole butanol production. Since expression of the butanol pathway resulted in low butanol synthesis, some endogenous pathways were disrupted to avoid the flow of carbon to by-products (Huang et al. 2010 and references therein). In the other cell factories, two strategies have been applied. Initially, the strategy involved the re-construction of the synthetic CoA-dependent clostridial pathway (Atsumi et al. 2008; Clomburg and Gonzalez 2010; Inui et al. 2008; Steen et al. 2008). The second approach considered the production of butanol and other fusel alcohols following the Ehrlich (non-fermentative) pathway (Dellomonaco et al. 2010 and references therein). By combining all of the optimization strategies, the maximum butanol titer and yield obtained were observed in engineered E. coli (1.2 g/l and 0.061 g/g) (Inui et al. 2008), while the highest production in S. cerevisiae were of only 2–3 mg/l (Steen et al. 2008). However, the production from yeasts seems to offer interesting opportunities for this task due to their better tolerance to butanol.

Concluding remarks

In this mini-review, we discussed the criteria in selecting suitable microbial production hosts for the production of recombinant proteins and/or metabolites. Among these criteria, the application area (chemistry, pharmacy, energy, food, agriculture) essentially determines the (1) quality standards of the final compound, being higher when a direct contact of humans and animals is forecast. Also related to the quality standards, (2) high concentrations of the compound are desirable for reducing the purification costs. While the heterologous proteins production ranges from milligrams to few grams/liter, the production of metabolites should look over productions spanning more dozens of grams. Consequently, particularly relevant for metabolites is the (3) yield of product per substrate (defining the substrate costs per unit product) and, for any compound, the (4) space time yield.

E. coli and S. cerevisiae are today the two microbial workhorses for commercialization of recombinant human proteins. This is a direct reflection of the familiarity of molecular biologists with these two hosts, combined with the deep knowledge about their genetics, biochemistry, physiology and fermentation technologies. Despite the significantly lower production costs of heterologous proteins using microbial cells compared to mammalian cells, the number of approved recombinant biopharmaceuticals from E. coli/S. cerevisiae and mammalian host systems has increased over the years with the same rate (Ferrer-Miralles et al. 2009).

However, an analysis of the manuscripts published during the last few years clearly indicates a transition in the choice of the yeast host. Either at laboratory and pilot level, today the most established yeast host used for the production of heterologous proteins is the yeast P. pastoris.

E. coli and S. cerevisiae are still the predominant hosts used for industrial metabolite productions. Commercially produced metabolites are not accumulated in subcellular organelles or in inclusion bodies, but are generally released in the culture medium. Many more heterologous metabolites are commercially produced in S. cerevisiae than in E. coli (see above), this fact being mainly related to a better cellular robustness against adverse fermentation conditions and high concentration of the final compound offered by the eukaryotic host system. Indeed, even if many different heterologous metabolites have been produced in E. coli, only a few went on to be introduced into the market because optimal yields and/or productions and/or productivities have not been achieved. Nevertheless, the role of model organism for E. coli remains essential. This could be related to the great variety offered by E. coli metabolism (fermentation, aerobic respiration of organic and inorganic compounds, anaerobic respiration, etc.). Indeed, many biological functions of E. coli metabolism can be sustained against single-gene or even multiple-gene modulations by using redundant or alternative pathways (Kim et al. 2007). At the same time these metabolic opportunities could also be the reason why it is difficult to channel the flux toward a single compound.

Of course, the perfect production host does not exist, as yet. In this respect and looking to the main drivers for the future, we definitely have to mention the exponentially growing number of sequenced genomes, or even metagenomes. Essentially, this is mainly due to the cheapest sequencing procedures, but also to a rising interest in the potential biotech applications deriving from a detailed understanding of cellular metabolism. Indeed, sequencing, comparative global (the so called “omics”) analyses and systems biology approaches provide a background for understanding and predicting the biological functions of a cell. Generally speaking, the microbial world is the main target of said projects and in the past 5–10 years the attention moved from pathogenic bacteria to industrially relevant microorganisms (Otero and Nielsen 2010). On the other hand, the tremendous power of rDNA technologies leads to the development of the synthetic biology platform (Jarboe et al. 2010). What will come out from all this? The ideal scenario would be a laboratory-created biological system capable of replication and evolution, fed only by simple carbon and energy sources. In this case, it will be possible to combine (1) multiple foreign pathways in a single chassis for diverse proteins and metabolites productions, (2) design-efficient de novo pathway and (3) engineering tolerance to adverse conditions and/or inhibitory compounds looking to high quality and quantity standards, high yields and productivities. The chemical synthesis, assembly, and cloning of a bacterial genome in the model yeast S. cerevisiae have been already described in several reports (Gibson et al. 2008; Lartigue et al. 2009; Benders et al. 2010). Nevertheless, since we are still very likely quite far from the knowing the secret of life, manipulation of natural properties is still the quickest path to reach the goal. One way or the other, we are now ready for a new generation of hosts to appear and these probably will be the last years of S. cerevisiae and E. coli “sensu stricto” as workhorses for recombinant protein and metabolite productions.

References

Achmuller C, Kaar W, Ahrer K, Wechner P, Hahn R, Werther F, Schmidinger H, Cserjan-Puschmann M, Clementschitsch F, Striedner G, Bayer K, Jungbauer A, Auer B (2007) N(pro) fusion technology to produce proteins with authentic N termini in E. coli. Nat Methods 4:1037–1043

Atsumi S, Cann A, Connor M, Shen C, Smith K, Brynildsen M, Chou K, Hanai T, Liao J (2008) Metabolic engineering of Escherichia coli for 1-butanol production. Metab Eng 10:305–311

Bailey J (1991) Toward a science of metabolic engineering. Science 252:1668–1675

Baneyx F, Mujacic M (2004) Recombinant protein folding and misfolding in Escherichia coli. Nat Biotechnol 22:1399–1408

Benders GA, Noskov VN, Denisova EA, Lartigue C, Gibson DG, Assad-Garcia N, Chuang RY, Carrera W, Moodie M, Algire MA, Phan Q, Alperovich N, Vashee S, Merryman C, Venter JC, Smith HO, Glass JI, Hutchison CA 3rd (2010) Cloning whole bacterial genomes in yeast. Nucleic Acids Res 38:2558–2569

Boettner M, Steffens C, von Mering C, Bork P, Stahl U, Lang C (2007) Sequence-based factors influencing the expression of heterologous genes in the yeast Pichia pastoris — a comparative view on 79 human genes. J Biotechnol 130:1–10

Carothers JM, Goler JA, Keasling JD (2009) Chemical synthesis using synthetic biology. Curr Opin Biotechnol 20:498–503

Carrio MM, Villaverde A (2002) Construction and decostruction of bacterial inclusion bodies. J Biotechnol 96:2–12

Cereghino JL, Cregg JM (2000) Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol Rev 24:45–66

Claassen PAM, van Lier JB, López Contreras AM, van Niel EWJ, Sijtsma L, Stams AJM, de Vries SS, Weusthuis RA (1999) Utilisation of biomass for the supply of energy carriers. Appl Microbiol Biotechnolol 52:741–755

Clomburg J, Gonzalez R (2010) Biofuel production in Escherichia coli: the role of metabolic engineering and synthetic biology. Appl Microbiol Biotechnol 86:419–434

Dellomonaco C, Fava F, Gonzalez R (2010) The path to next generation biofuels: successes and challenges in the era of synthetic biology. Microb Cell Fact 9:3

Demain AL, Vaishnav P (2009) Production of recombinant proteins by microbes and higher organisms. Biotechnol Adv 27:297–306

Ferrer-Miralles N, Domingo-Espín J, Corchero J, Vázquez E, Villaverde A (2009) Microbial factories for recombinant pharmaceuticals. Microb Cell Fact 8:17

Fieschko JC, Egan KM, Ritch T, Koski RA, Jones M, Bitter GA (1987) Controlled expression and purification of human immune interferon from high-cell-density fermentations of Saccharomyces cerevisiae. Biotechnol Bioeng 29:1113–1121

Freedonia Group Inc (2009) World enzymes to 2013, www.freedoniagroup.com

Gellissen G, Kunze G, Gaillardin C, Cregg JM, Berardi E, Veenhuis M, van der Klei I (2005) New yeast expression platforms based on methylotrophic Hansenula polymorpha and Pichia pastoris and on dimorphic Arxula adeninivorans and Yarrowia lipolytica — a comparison. FEMS Yeast Res 5:1079–1096

Georgiou G, Segatori L (2005) Preparative expression of secreted proteins in bacteria: status report and future prospects. Curr Opin Biotechnol 16:538–545

Gibson D, Benders G, Axelrod K, Zaveri J, Algire M, Moodie M, Montague M, Venter J, Smith H, Hutchison CR (2008) One-step assembly in yeast of 25 overlapping DNA fragments to form a complete synthetic Mycoplasma genitalium genome. Proc Natl Acad Sci USA 105:20404–20409

Goodman M (2009) Market watch: Sales of biologics to show robust growth through to 2013. Nat Rev Drug Discov 8:837

Graf A, Dragosits M, Gasser B, Mattanovich D (2009) Yeast systems biotechnology for the production of heterologous proteins. FEMS Yeast Res 9:335–348

Graumann K, Premstaller A (2006) Manufacturing of recombinant therapeutic proteins in microbial systems. Biotechnol J 1:164–186

Gurramkonda C, Polez S, Skoko N, Adnan A, Gabel T, Chugh D, Swaminathan S, Khanna N, Tisminetzky S, Rinas U (2010) Application of simple fed-batch technique to high-level secretory production of insulin precursor using Pichia pastoris with subsequent purification and conversion to human insulin. Microb Cell Fact 9:31

Hakim R, Benhar I (2009) "Inclonals": IgGs and IgG-enzyme fusion proteins produced in an E. coli expression-refolding system. MAbs 1:281–287

Heefner D, Weaver C, Yarus M, Burdzinski L (1992) Method for producing riboflavin with Candida famata. US Patent No. 5164303

Hofvendahl K, Hahn-Hägerdal B (2000) Factors affecting the fermentative lactic acid production from renewable resources(1). Enzyme Microb Technol 26:87–107

Holz C, Prinz B, Bolotina N, Sievert V, Bussow K, Simon B, Stahl U, Lang C (2003) Establishing the yeast Saccharomyces cerevisiae as a system for expression of human proteins on a proteome-scale. J Struct Funct Genomics 4:97–108

Huang H, Ridgway D, Gu T, Moo-Young M (2004) Enhanced amylase production by Bacillus subtilis using a dual exponential feeding strategy. Bioprocess Biosyst Eng 27:63–69

Huang H, Liu H, Gan YR (2010) Genetic modification of critical enzymes and involved genes in butanol biosynthesis from biomass. Biotechnol Adv 28:651–657

Ikushima S, Fujii T, Kobayashi O, Yoshida S, Yoshida A (2009) Genetic engineering of Candida utilis yeast for efficient production of l-lactic acid. Biosci Biotechnol Biochem 73:1818–1824

Ingram L, Gomez P, Lai X, Moniruzzaman M, Wood B, Yomano L, York S (1998) Metabolic engineering of bacteria for ethanol production. Biotechnol Bioeng 58:204–214

Inui M, Suda M, Kimura S, Yasuda K, Suzuki H, Toda H, Yamamoto S, Okino S, Suzuki N, Yukawa H (2008) Expression of Clostridium acetobutylicum butanol synthetic genes in Escherichia coli. Appl Microbiol Biotechnol 77:1305–1316

Jahic M, Rotticci-Mulder JC, Martinelle M, Hult K, Enfors SO (2002) Modeling of growth and energy metabolism of Pichia pastoris producing a fusion protein. Bioprocesses Biosyst Eng 385–393

Jarboe LR, Zhang X, Wang X, Moore JC, Shanmugam KT, Ingram LO (2010) Metabolic engineering for production of biorenewable fuels and chemicals: contributions of synthetic biology. J Biomed Biotechnol 2010:761042

Jones D, Woods D (1986) Acetone–butanol fermentation revisited. Microbiol Rev 50:484–524

Jung Y, Kim T, Park S, Lee S (2010) Metabolic engineering of Escherichia coli for the production of polylactic acid and its copolymers. Biotechnol Bioeng 105:161–171

Keasling J (2008) Synthetic biology for synthetic chemistry. ACS Chem Biol 3:64–76

Kim PJ, Lee DY, Kim TY, Lee KH, Jeong H, Lee SY, Park S (2007) Metabolite essentiality elucidates robustness of Escherichia coli metabolism. P Natl Acad Sci USA 104:13638–13642

Kjeldsen T (2000) Yeast secretory expression of insulin precursors. Appl Microbiol Biotechnol 54:277–286

Knoll A, Bartsch S, Husemann B, Engel P, Schroer K, Ribeiro B, Stockmann C, Seletzky J, Buchs J (2007) High cell density cultivation of recombinant yeasts and bacteria under non-pressurized and pressurized conditions in stirred tank bioreactors. J Biotechnol 132:167–179

Koizumi S, Yonetani Y, Maruyama A, Teshiba S (2000) Production of riboflavin by metabolically engineered Corynebacterium ammoniagenes. Appl Microbiol Biotechnol 53:674–679

Larsen MW, Bornscheuer UT, Hult K (2008) Expression of Candida antarctica lipase B in Pichia pastoris and various Escherichia coli systems. Protein Expr Purif 62:90–97

Lartigue C, Vashee S, Algire M, Chuang R, Benders G, Ma L, Noskov V, Denisova E, Gibson D, Assad-Garcia N, Alperovich N, Thomas DW, Merryman C, Hutchison CA 3rd, Smith HO, Venter C, Glass JI (2009) Creating bacterial strains from genomes that have been cloned and engineered in yeast. Science 325:1693–1696

Macdonald G, on http://www.in-pharmatechnologist.com. Accessed 18 June 2009

Mattanovich D, Graf A, Stadlmann J, Dragosits M, Redl A, Maurer M, Kleinheinz M, Sauer M, Altmann F, Gasser B (2009) Genome, secretome and glucose transport highlight unique features of the protein production host Pichia pastoris. Microb Cell Fact 8:29

Maurer M, Kuehleitner M, Gasser B, Mattanovich D (2006) Versatile modeling and optimization of fed batch processes for the production of secreted heterologous proteins with Pichia pastoris. Microb Cell Fact 5:37

Mazor Y, Van Blarcom T, Carroll S, Georgiou G (2010) Selection of full-length IgGs by tandem display on filamentous phage particles and Escherichia coli fluorescence-activated cell sorting screening. FEBS J 277:2291–2303

McHunu NP, Singh S, Permaul K (2009) Expression of an alkalo-tolerant fungal xylanase enhanced by directed evolution in Pichia pastoris and Escherichia coli. J Biotechnol 141:26–30

McLaughlin B, Reilly D (2008) Expression of soluble full length antibodies in E. coli. 5th Recombinant Protein Production Conference. Sardinia, Italy

Mergulhão F, Taipa M, Cabral J, Monteiro G (2004) Evaluation of bottlenecks in proinsulin secretion by Escherichia coli. J Biotechnol 109:31–43

Najafpour DG (2006) Biochemical engineering and biotechnology. Elsevier, Amsterdam

Ni Y, Chen R (2009) Extracellular recombinant protein production from Escherichia coli. Biotechnol Lett 31:1661–1670

Okano K, Tanaka T, Ogino C, Fukuda H, Kondo A (2010) Biotechnological production of enantiomeric pure lactic acid from renewable resources: recent achievements, perspectives, and limits. Appl Microbiol Biotechnol 85:413–423

Olmos-Soto J, Contreras-Flores R (2003) Genetic system constructed to overproduce and secrete proinsulin in Bacillus subtilis. Appl Microbiol Biotechnol 62:369–373

Otero J, Nielsen J (2010) Industrial systems biology. Biotechnol Bioeng 105:439–460

Panda AK (2003) Bioprocessing of therapeutic proteins from the inclusion bodies of Escherichia coli. Adv Biochem Eng Biotechnol 85:43–93

Pandhal J, Wright PC (2010) N-Linked glycoengineering for human therapeutic proteins in bacteria. Biotechnol Lett 32:1189–1198

Park EJ, Zhang JH, Tajima S, Dwiarti L (2007) Isolation of Ashbya gossypii mutant for an improved riboflavin production targeting for biorefinery technology. J Appl Microbiol 103:468–476

Peralta-Yahya P, Keasling J (2010) Advanced biofuel production in microbes. Biotechnol J 5:147–162

Porro D, Sauer M, Branduardi P, Mattanovich D (2005) Recombinant protein production in yeasts. Mol Biotechnol 31:245–259

Potgieter TI, Cukan M, Drummond JE, Houston-Cummings NR, Jiang Y, Li F, Lynaugh H, Mallem M, McKelvey TW, Mitchell T, Nylen A, Rittenhour A, Stadheim TA, Zha D, d'Anjou M (2009) Production of monoclonal antibodies by glycoengineered Pichia pastoris. J Biotechnol 139:318–325

Prinz B, Schultchen J, Rydzewski R, Holz C, Boettner M, Stahl U, Lang C (2004) Establishing a versatile fermentation and purification procedure for human proteins expressed in the yeasts Saccharomyces cerevisiae and Pichia pastoris for structural genomics. J Struct Funct Genomics 5:29–44

Rude M, Schirmer A (2009) New microbial fuels: a biotech perspective. Curr Opin Microbiol 12:274–281

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids: expanding the markets. Trends Biotechnol 26:100–108

Sauer M, Porro D, Mattanovich D, Branduardi P (2010) 15 years research on lactic acid production with yeast — ready for the market? Biotechnol Genet Eng Rev 27:1–28

Schmidt FR (2004) Recombinant expression systems in the pharmaceutical industry. Appl Microbiol Biotechnol 363–372

Shin CS, Hong MS, Bae CS, Lee J (1997) Enhanced production of human mini-proinsulin in fed-batch cultures at high cell density of Escherichia coli BL21(DE3)[pET-3aT2M2]. Biotechnol Prog 13:249–257

Simmons L, Reilly D, Klimowski L, Raju T, Meng G, Sims P, Hong K, Shields R, Damico L, Rancatore P, Yansura DG (2002) Expression of full-length immunoglobulins in Escherichia coli: rapid and efficient production of aglycosylated antibodies. J Immunol Methods 263:133–147

Somerville C, Youngs H, Taylor C, Davis S, Long S (2010) Feedstocks for lignocellulosic biofuels. Science 329:790–792

Sørensen HP (2010) Towards universal systems for recombinant gene expression. Microb Cell Fact 9:27

Stahmann KP, Revuelta JL, Seulberger H (2000) Three biotechnical processes using Ashbya gossypii, Candida famata, or Bacillus subtilis compete with chemical riboflavin production. Appl Microbiol Biotechnol 53:509–516

Steen E, Chan R, Prasad N, Myers S, Petzold C, Redding A, Ouellet M, Keasling JD (2008) Metabolic engineering of Saccharomyces cerevisiae for the production of n-butanol. Microb Cell Fact 7:36

Steen E, Kang Y, Bokinsky G, Hu Z, Schirmer A, McClure A, Del Cardayre S, Keasling J (2010) Microbial production of fatty-acid-derived fuels and chemicals from plant biomass. Nature 463:559–562

Stolz A, Wolf DH (2010) Endoplasmic reticulum associated protein degradation: a chaperone assisted journey to hell. Biochim Biophys Acta 1803:694–705

Sugimoto T, Morimoto A, Nariyama M, Kato T, Park E (2010) Isolation of an oxalate-resistant Ashbya gossypii strain and its improved riboflavin production. J Ind Microbiol Biotechnol 37:57–64

Sundström H, Enfors S (2008) Software sensors for fermentation processes. Bioprocess Biosyst Eng 31:145–152

Tripathi NK, Sathyaseelan K, Jana AM, Rao PVL (2009) High yield production of heterologous proteins with Escherichia coli. Defence Sci J 59:137–146

Valli M, Sauer M, Branduardi P, Borth N, Porro D, Mattanovich D (2006) Improvement of lactic acid production in Saccharomyces cerevisiae by cell sorting for high intracellular pH. Appl Environ Microbiol 72:5492–5499

Venkatesh KV (1997) Simultaneous saccharification and fermentation of cellulose to lactic acid. Bioresour Technol 62:91–98

Vuolanto A, von Weymarn N, Kerovuo J, Ojamo H, Leisola M (2001) Phytase production by high cell density culture of recombinant Bacillus subtilis. Biotechnol Lett 761–766

Waites MJ, Morgan NL, Rockey JS, Higton G (2001) Industrial microbiology: an introduction. Blackwell Science, Oxford

Walsh G (2005) Therapeutic insulins and their large-scale manufacture. Appl Microbiol Biotechnol 67:151–159

Westers L, Westers H, Quax WJ (2004) Bacillus subtilis as cell factory for pharmaceutical proteins: a biotechnological approach to optimize the host organism. Biochim Biophys Acta 1694:299–310

Wu Q, Chen T, Gan Y, Chen X, Zhao X (2007) Optimization of riboflavin production by recombinant Bacillus subtilis RH44 using statistical designs. Appl Microbiol Biotechnol 76(4):783–794

Yan Y, Liao J (2009) Engineering metabolic systems for production of advanced fuels. J Ind Microbiol Biotechnol 36:471–479

Yang T, Kim T, Kang H, Lee S, Lee E, Lim S, Oh S, Song A, Park S, Lee S (2010) Biosynthesis of polylactic acid and its copolymers using evolved propionate CoA transferase and PHA synthase. Biotechnol Bioeng 105:150–160

Yuwono SD, Kokugan T (2008) Study of the effects of temeprature and pH on lactic acid production from fresh cassava roots in tofu liquid watse by Streptococcus bovis. Biochem Eng J 40:175–183

Acknowledgements

This work was partially supported by the Italian FAR 2009 12-1-5140000-65. This work was supported by the Austrian Science Fund (FWF), projects I37-B03 and L391-B11, and the Austrian Research Promotion Agency (program FHplus), projects OPTIPRO and METORGANIC.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Porro, D., Gasser, B., Fossati, T. et al. Production of recombinant proteins and metabolites in yeasts. Appl Microbiol Biotechnol 89, 939–948 (2011). https://doi.org/10.1007/s00253-010-3019-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-3019-z