Abstract

Conventional vat dyeing involves chemical reduction of dyes into their water-soluble leuco form generating considerable amounts of toxic chemicals in effluents. In the present study, a new β-nicotinamide adenine dinucleotide disodium salt (NADH)-dependent reductase isolated from Bacillus subtilis was used to reduce the redox dyes CI Acid Blue 74, CI Natural Orange 6, and CI Vat Blue 1 into their water-soluble leuco form. Enzymatic reduction was optimized in relation to pH and temperature conditions. The reductase was able to reduce Acid Blue 74 and Natural Orange 6 in the presence of the stoichiometrically consumed cofactor NADH; meanwhile, Vat Blue 1 required the presence of mediator 1,8-dihydroxyanthraquinone. Oxygen from air was used to reoxidize the dyes into their initial forms. The enzymatic reduction of the dyes was studied and the kinetic constants determined, and these were compared to the chemically-reduced leuco form. The enzyme responsible for the reduction showed homology to a NADH-dependent reductase from B. subtilis based on results from the MS/MS peptide mass mapping of the tryptically digested protein. Additionally, the reduction of Acid Blue 74 to its leuco form by reductase from B. subtilis was confirmed using NADH regenerated by the oxidation of formic acid with formate dehydrogenase from Candida boidinii in the same solution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Redox dyes are increasingly used for chiral synthesis in pharmaceutical and medical chemistry as well as coloring agents in the food, cosmetic, and textile industries (Badri and Burkinshaw 1993; Božič and Kokol 2008; Kirkland and Marzin 2003; Kohno et al. 2005; Leonida 2001; Othman et al. 2006). With very few exceptions (sulfur dyes with sulfide bonds), redox dyes fall into two clearly defined groups, anthraquinonoid dyes, including heterocyclic quinines and indigoid dyes containing two or more keto (=O) groups separated by a conjugated system of double bonds (Fig. 1; Božič and Kokol 2008). A common characteristic of these dyes is the need for reduction during processing in order to form a water-soluble dye known as the leuco compound. The redox potential required for reduction differs for each group of dyes depending on their chemical constitution, especially the number of keto groups, and can lie between −100 mV (Acid Blue 74) and −600 mV (Vat Blue 1 known as indigo) or even up to −1,000 mV (vs. Ag/AgCl) in the case of complex textile vat dyes (Božič and Kokol 2008; Božič et al. 2009). Accordingly, harsh sulfide-containing reducing agents such as sodium dithionite or sodium sulfide have to be applied in a highly alkaline medium (pH 11–13) in order to achieve reduction. Their replacement with more environmentally friendly reducing systems (Blackburn and Harvey 2004; Božič and Kokol 2008; Vuorema et al. 2008) is thus of great interest.

Microbial reduction could be a very attractive alternative from among several proposed technologies due to mild temperatures when processing and the absence of by-product formations. Recently, Clostridium isatidis has been shown to be a unique indigo-reducing bacterium isolated from a woad vat dye that could be employed during the indigo-reduction process (Padden et al. 2000). The mechanism of bacterial indigo reduction is unknown, but C. isatidis cultures generating redox potentials from −476 to −602 mV vs SCE were able to reduce indigo within 1 day at 40°C and pH 9 (Nicholson and John 2004; Nicholson and John 2005; Yumoto et al. 2004). However, enzymes as highly specific biocatalysts instead of whole cells would be considerably easier to handle in this application.

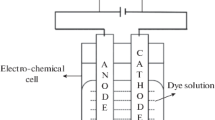

Among enzymes, NAD(P)H-dependent reductases could have a potential. Due to the high cost of the cofactors, their regeneration has been intensively investigated (Kroutil et al. 2004; Siu et al. 2007) and several systems, such as those based on formate dehydrogenase (FDH), are commercially available. The advantages of FDH from Candida boidinii involve the use of formate as an innocuous substrate and the production of CO2, which renders the process essentially irreversible, providing a strong driving force for NADH regeneration. Alternatively, the more complex “coupled-enzyme” approach where cofactor-recycling is performed to convert the reacted pyridine nucleotides from the oxidized form to its reduced counterparts by using a second enzymatic reaction was also introduced (Kroutil et al. 2004). Recently, it was reported that various commercial and systematically substituted azo and indigoid compounds can be reduced with azo reductase from Bacillus subtilis (Božič et al. 2009; Pricelius et al. 2007a, b). The present study demonstrates the potential of using reductase from B. subtilis for reducing complex redox dyes to their leuco forms. To elucidate the NADH regeneration on the substrate conversion, an FDH from C. boidinii was incorporated (Fig. 2).

Methods

Chemicals and enzymes

Dyes (CI Acid Blue 74 or indigo Carmine, CI Natural Orange 6 or lawsone, and CI Vat Blue 1 or indigo), FDH from C. boidinii, mediator 1,8-dihydroxyanthraquinone (1,8-DHAQ), NADH, and Na2S2O4 were supplied from Aldrich. All other chemicals were of the highest grade available commercially.

B. subtilis (DSM: 1970/ATCC: 21228) was cultivated for 12 h in 1-l baffled Erlenmeyer flasks on a rotary shaker at 160 rpm and 38°C in 500 ml standard I nutrient medium (Merck). Cells were harvested by centrifugation for 15 min at 3,000 × g and the pellet was resuspended in a 50-mM sodium phosphate buffer, pH 7.0 (2-ml buffer per gram of wet-cell paste). Cell lysis was carried out using a French press (American Instrument Company, Maryland, USA) by performing three passes. The cell debris was removed by centrifugation at 34,000 × g for 60 min at 4°C, and the supernatant (= enzyme preparation) was filtered through a prefilter (Glass Fiber Filter with binder, AP20, 75 mm, Millipore, Billerica, USA), a 45-µm filter with pressure filtration and through a Minisart single-use EO sterile syringe filter using a 0.2-µm membrane (Sartorius, Hannover, Germany).

Chemical reduction and oxidation

The reducing agent (Na2S2O4) was dissolved in distilled water with NaOH and used immediately. Assays were carried out in cuvettes with a total volume of 1 ml at 25°C. The reaction mixtures in distilled water contained 0.04 mM of appropriate dye solutions (Acid Blue 74, Natural Orange 6, and Vat Blue 1), 0.6 mM of the reducing agent, and 0.3% NaOH. Reoxidation was achieved with oxygen from the air by mixing solutions. The reaction was followed spectrophotometrically within 700 to 350 nm (Fig. 3).

Enzyme assays

Assays were carried out in cuvettes with total volume of 1 ml in the absence of oxygen at 25°C. One unit of enzyme activity (U) was defined as the amount of enzyme that transformed 1 µmol of substrate per milliliter per minute. Protein content was determined by the Lowry method (Lowry et al. 1951).

Assays for NADH reductase activity

The reaction mixture contained 500 μl of 50-mM sodium phosphate buffer (pH 7.0), 100 μl of the enzyme, and 200 μl of Acid Blue 74 (final concentration 0.04 mM). The reaction was initiated by the addition of 200 μl of NADH (final concentration 2 mM) and followed spectrophotometrically at 610 nm. The slope of the initial linear absorption decrease was used to calculate enzyme activity based on the molar absorption coefficient of Acid Blue 74 (ε 610 = 6.309 mmol−1cm−1), as described previously (Maier et al. 2004).

Assays for formate dehydrogenase activity

The reaction mixture contained 100 μl of 100-mM sodium formate, 600 μl of 100-mM sodium phosphate buffer (pH 7.0), 200 μl nicotinamide adenine dinucleotide (NAD+; final concentration 2.5 mM), and the 100 μl of the enzyme. The enzyme activity was assayed by the decrease of NAD+ concentration (ε 340 = 6.225 mmol−1cm−1), monitored at 340 nm.

pH and temperature optima and stability of reductase

The pH activity profile of the reductase was determined within the range pH 7 to 11 at 25°C, using Acid Blue 74 as substrate. Using the standard conditions for reductase assay (chapter Enzymatic reduction of redox dyes), the temperature optimum activity was determined at pH 9 within the range 25°C to 70°C, for 30 min.

Protein purification

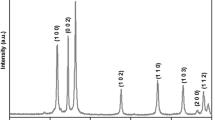

A reductase was purified based on the activity on Acid Blue 74. The cell lysate of B. subtilis was subjected to fractionated ammonium sulfate precipitation at 20% saturation in order to remove impurities, followed by 70% saturation in a second step to precipitate the reductases. The precipitated proteins from the second precipitation step were collected by centrifugation, and the pellet was dissolved in 30 ml of Tris-HCl buffer (50 mM, pH 7.0). The solution was desalted by dialysis against Tris-HCl buffer (10 mM, pH 7.0) overnight. The desalted solution after ammonium sulfate precipitation was filtrated through a 0.45-µm filter, and 1.5-ml aliquots of the resulting solution were applied to a HiTrap DEAE column (Amersham Biosciences) installed in an Amersham Pharmacia biotech ÄKTA purifier 900; Pump P-903; Monitor pH/Cond-900; Monitor UV-900; Autosampler Frac-900 (Amersham Biosciences Europe GmbH, Austria). Proteins were eluted at 1 ml/min with the sample buffer and with a stepwise-increasing concentration of buffer containing 1 M of NaCl. The active fractions were collected and stored as purified enzyme preparation. The protein content of the samples was measured by the Lowry method (Lowry et al. 1951).

Gel electrophoresis

Polyacrylamide gel electrophoresis (PAGE) was carried out as described previously (Pricelius et al. 2007b), with some modifications for native PAGE, i.e., both components, sodium dodecyl sulfate and 2-mercaptoethanol, were omitted. Twelve percent polyacrylamide gel was utilized and broad-range molecular weight markers from Pharmacia were used as standards. The method of Maier et al. (2004) was used for activity staining.

The gel was immediately immersed in approximately 50 ml of 50-µM Acid Blue 74 solution for 25 min. After removal of the staining solution, the gel was put into a desiccator under the vacuum. Afterwards, the desiccator was filled with N2, and a degassed NADH solution (2-mM NADH in 50-mM Tris-HCl buffer, pH 7.0) was added under the N2 atmosphere. Vacuum generation and N2 scavenging were repeated alternately several times during the procedure in order to avoid oxygen presence in the test vessel. Bands of the active enzyme appeared after approximately 10 min as white spots within a blue background.

Total proteins were stained using Coomassie Blue G-250 (Roth, Karlsruhe, Germany). To characterize the enzyme, protein bands of interest were cut from polyacrylamide gels and digested overnight using trypsin (Sigma) as described elsewhere (Shevchenko et al. 1996a, b).

The resulting peptides were eluted, concentrated by vacuum centrifugation, and separated by RP nano-LC (LC1100 series, Agilent Technologies, Palo Alto, California; column, Zorbax 300SB-C18, 3.5 μm, 150 mm × 0.075 mm; eluate, 0.1% formic acid in 0–60% acetonitrile). The peptides were analyzed online by an MS/MS (LC/MSD TRAP XCT mass spectrometer, Agilent Technologies).

Enzymatic reduction of redox dyes

Enzymatic reduction of Acid Blue 74 and Natural Orange 6 was performed in cuvettes with a total volume of 1 ml at pH 7, 9, and 11. The reaction mixtures contained 2.5 μM of appropriate dye solution, a 50-mM Tris-HCl (pH 7 and pH 9), or Tris-NaOH (pH 11) buffer, 0.05-U ml−1 reductase of crude cell extract, and the purified enzyme from B. subtilis. The reaction was initiated by the addition of various concentrations of NADH ranging from 0.625 to 125 μM. Reduction of Vat Blue 1 with 0.2-U ml−1 reductase activity of crude cell extract and the purified enzyme from B. subtilis was measured in 50-mM Tris-HCl (pH 7 and pH 9) or Tris-NaOH (pH 11) buffer at 60°C, with 2.5 to 45 μM of NADH and 0.75 to 2.25 μM of 1,8-DHAQ. Formation of the dye leuco form was measured at the selected wavelengths (610 nm for Acid Blue 74, 450 nm for Natural Orange 6, 660 nm for Vat Blue 1) at 25°C. K m and V max values were calculated by nonlinear regression to the Michaelis–Menten equation:

where υ is a reaction velocity; V max is maximum velocity; [S] is substrate concentration, and K m is a Michaelis–Menten constant using the program Origin 7.5.

Nitrogen gas was employed for deaeration in all the assays. Subsequently, dyes were reoxidized by exposure of solutions to air oxygen, and reactions were followed spectrophotometrically within the range of 350 to 700 nm.

Redox potential determination

The redox potential of enzymatic mixtures was measured using platinum electrode versus the Ag/AgCl reference electrode with KCl electrolyte, connected to a pH meter (see previously mentioned), incubated for 30 min at the corresponding temperature in a water bath, and recorded over time. Each experiment was conducted in triplicate, and the average value was given as final the result. Cleaning of the electrode and standardization of the measuring instrument was performed as described previously (Božič et al. 2008).

Enzymatic reduction of Acid Blue 74 coupled with the regeneration of cofactor NADH using FDH

Assays were carried out in quartz cuvettes with a total volume of 4 ml at 25°C and pH 9. The reaction mixtures contained 2.5 μM of Acid Blue 74 solution, 50-mM Tris-HCl (pH 9) buffer, (0.05 to 0.1 U ml−1) reductase from B. subtilis, and NADH ranging from 0.5 to 2.0 μM. Regeneration of NADH was achieved by the addition of various amounts of formic acid (62.5 to 250 μM) and 0.9 to 2.7 U ml−1 of FDH. Nitrogen gas was employed for deaeration in all assays. The dye was reoxidized by the solutions' exposure to oxygen from air. The reaction was followed spectrophotometrically within the range 250 to 700 nm.

Results

Reductase activity and stability

The reductase enzyme preparation from B. subtilis had an activity of 10.1 U mg−1 in the cell lysate. For purification, the first step was ammonium sulfate precipitation. Afterwards, the sample had an activity of 19.5 U ml−1. The resulting solution was desalted and loaded onto a HiTrap DEAE QFF column (5 × 1) connected to an AEKTA purifier. The purified enzyme had an activity of 0.33 mU mg−1. Active fractions were pooled and concentrated, with a cutoff from 10 kDa.

The reductase was active within pH range between 7 and 11 with a maximum at pH 9 while the temperature maximum was reached at 65°C. Above 70°C, fast thermal inactivation occurred with half-life times below 1 min.

Enzymatic redox dyes reduction

The purified and crude enzyme preparations were used in a series of enzyme assays to identify its substrate specificity and cofactor (NADH) dependence. As shown in Fig. 4, NADH concentration decreased with the time from 2.5 μM to approximately 0.003 μM while leuco Acid Blue 74 and leuco Natural Orange 6 concentrations increased from 0 to 2.5 μM. Thus, 2.5 μM of the dye was successfully reduced by enzymes in the presence of 2.5 μM of NADH at pH 9 and 25°C. For efficient reduction of Vat Blue 1, 45 μM of NADH was present in the enzymatic reduction bath at 60°C and pH 9 (Fig. 5) which decreased with the time to 3.1 μM, and leuco Vat Blue 1 concentration increased from 0 to 2.5 μM (Fig. 5).

The pH dependence of K m and V max for the cofactor NADH in the reduction of Acid Blue 74 and Natural Orange 6 is presented in Table 1. At Acid Blue 74 reduction, V NADHmax decreased from pH 11 to 7; meanwhile, in Natural Orange 6 reduction, V NADHmax was relatively constant in pH range between 7 and 9 but increased by 50% at the basic edge of the enzyme's pH stability. Apparent K NADHm at pH 9 was a 3.7-fold lower than at pH 7, and a 3-fold lower value was obtained at pH 11 for Acid Blue 74, and its catalytic efficiency was the highest (269 min−1) at pH 9 and 4.9 times lower at pH 7. In the case of Natural Orange 6, K NADHm was a 6-fold higher at pH 7 from K NADHm at pH 9, and its catalytic efficiency was the highest (253 min−1) at pH 9 and 6 times lower at pH 7.

The redox potential of NADH-dependent reductase in the presence of the individual dyes between pH 7 and 11 was not significantly affected and reached a maximum around −180 ± 10 mV versus Ag/AgCl at 25°C.

In the case of Vat Blue 1 reduction, kinetic measurements were determined at 60°C by varying the concentrations of two substrates (NADH and 1,8-DHAQ; Table 2 ). V max values for both NADH and 1,8-DHAQ remained constant within a pH range between 9 and 11 but increased around 1.4-fold at pH 7. Apparent K m NADH at pH 9 and 11 was a 1.4-fold lower than at pH 7, and its catalytic efficiency was the highest (406 min−1) at pH 9, 1.6 times lower at pH 11, and 1.4 times lower at pH 7. Apparent K m 1,8-DHAQ at pH 11 was 1.1- and 1.4-fold lower at pH 9 and 7, respectively. Mediator catalytic efficiency was the highest at pH 11 (24.5 min−1), 24.11 min−1 at pH 9, and 1.7-fold lower at pH 7.

Redox potentials of NADH-dependent reductase at 60°C were about 220 ± 10 mV more negative than those at 25°C and reached approximately −395 mV at pH 7, −407 mV at pH 9, and −411 mV versus Ag/AgCl at pH 11 in the presence of indigo. At 60°C and in the presence of 1,8-DHAQ, mediator redox potentials were decreased to −576 mV (pH 7), −595 mV (pH 9), and −592 mV (pH 11) versus Ag/AgCl.

Enzymatic reduction of Acid Blue 74 coupled with cofactor regeneration using FDH

Biocatalytic conversion of Acid Blue 74 to its leuco form and NADH regeneration by FDH were spectrophotometrically investigated by monitoring the absorbance decrease at 610 nm (Acid Blue 74) and absorbance increase at 340 nm (NADH).

To provide a first proof of the concept that FDH can be used together with reductases in a high-temperature process to convert oxidized dye form directly to leuco dye form and at the same time regenerating NADH, leuco Acid Blue 74 production from Acid Blue 74 was assayed in the presence of FDH. Initial concentration of NADH was decreased to 1.25 μM which was insufficient for complete reduction. As shown in Fig. 6, Acid Blue 74 concentration decreased with the time from 2.5 to 1.3 μM while the leuco Acid Blue 74 concentration increased from 0 to 1.2 μM when the reaction was stopped. At this point, 1.25 μM of NADH was consumed/converted into NAD+. After addition of FDH and formic acid, final conversion to leuco Acid Blue 74 proceeded with the time.

Figure 7 shows varying formate (62.5 to 250 μM) concentrations when 62.5 μM of NADH and 0.05 U ml−1 of reductase were present in the reaction system. Higher initial formate concentration improved the leuco Acid Blue 74 formation at 1.8 U ml−1 of FDH.

Discussion

The importance of sodium dithionite in vat dyeing lies in its high reduction capacity (E 0 is −970 mV using 5 g l−1 Na2S2O4 and 15 ml l−1 30% NaOH at 60°C; Baumgarte 1987), which allows less complex redox dyes to be reduced at room temperature (Wolf 2000) while dyes with complex structure require even higher reduction potential and temperature for their proper and complete reduction (Bechtold and Turcanu 2006). However, sodium dithionite is toxic and causes various problems in the disposal of the dyeing bath and the washing water; therefore, ecological alternatives are required.

The reduction of redox dyes CI Acid Blue 74 and CI Natural Orange 6 by using NADH-dependent reductase isolated from B. subtilis was investigated at 25°C. It is clear from both values, K m and V max/K m ratio (Table 1), that NADH-dependent reductase is very efficient in reducing dyes at pH 9. Although reductases have a higher V max at pH 11 than at pH 9, its catalytic efficiency is higher at pH 9 than at pH 11. Reduction velocity difference between the dyes corresponds to the redox potential needed for complete reduction. Accordingly, Natural Orange 6 is reduced within −125 to −155 mV, Acid Blue 74 within −115 to −135 mV while Vat Blue 1 requires a reduction potential of −550 to −600 mV (Božič and Kokol 2008; Heo et al. 2001). Therefore, for efficient Vat Blue 1 reduction (generating a sufficiently negative reducing potential), the presence of mediator 1,8-dihydroxyanthraquinone was required (Božič et al. 2009). Redox mediators accelerate reactions by lowering the activation energy of the total reaction (Van der Zee and Cervantes 2009).

Acid Blue 74 and Natural Orange 6 were successfully reduced by enzymes at 25°C in the presence of stoichiometrically consumed NADH at pH 9 and 11 while Vat Blue 1 required a higher amount of NADH and higher temperature (60°C) at all pHs. Reductases from B. subtilis become highly active at higher temperatures where they become flexible enough for catalysis and the substrates, with higher reduction potential. Reaction rates increased with increasing temperatures because a higher fraction of the molecules had a kinetic energy higher than the activation energy (Van der Zee and Cervantes 2009).

Dyes remained stable in the reduced state under nitrogen atmosphere, which is useful for textile dyeing application, because the dye particles need to be distributed evenly after their diffusion into the fiber before they are reoxidized to produce equal coloring. In contrast to enzymatic reduction, acid reaction products of sodium dithionite with oxygen lead to decomposition of dyes, thus preventing reoxidation (Gasana et al. 2003). Ensuring an oxygen-free atmosphere in the experimental setup was very important as comparable tests were done without nitrogen atmosphere (data not shown) where the reduction was possible only at very high amounts of NADH. In contrast, stoichiometric consumption of NADH was achieved when all solutions were continuously degassed with the nitrogen.

Because biocatalytic reduction of the dye molecule is initiated by electron transfer from NADH to the dye, the reduction reaction will be terminated when NADH is completely consumed. Thus, to ensure maximum speed throughout the whole reaction, NADH concentration should be close to V max plus concentration of the dye. Because of the relatively high cost of NADH, cofactor regenerating was demonstrated to be a powerful strategy for enhancing of the potential of reductase (Kroutil et al. 2004; Siu et al. 2007).

Acid Blue 74 was used as substrate in regeneration experiments as it is a soluble derivate of indigo and thus offers the opportunity to assess the extent to which the solubility of indigo is a barrier in its reduction by mediated enzymes. The FDH from C. boidinii are well-known enzymes for NADH regeneration with a wide pH optimum for catalytic activity. The activity is unchanged within the range of рН 5.5 to 11.0, and Michaelis–Menten constants for NAD+ and formate are constant in the range of рН 6.0 to 9.5 (Mesentsev et al. 1997).

The enzymatic NADH-regeneration process shown in Fig. 6 provides the first proof of the concept that reductase and FDH can be combined in a single reaction vessel to produce leuco dye forms and regenerated NADH. As expected in the absence of a cofactor-regenerating system, the final leuco Acid Blue 74 concentration only reached 1.2 μM.

Efficient cofactor regeneration is critical to the overall reaction rate and requires proper and balanced enzyme activities. An appropriate FDH to reductase ratio is required to provide prompt cofactor regeneration and thus can improve the whole reaction system and productivity. Therefore, the proper amounts of NADH and reductase to be used with the FDH and formic acid in the biotransformation of Acid Blue 74 to leuco Acid Blue 74 were investigated at reductase optimal pH 9. Varying reductase activity had no significant effect on the production of leuco Acid Blue 74 when leuco Acid Blue 74 production rate increased with increasing the initial NADH concentration (data not shown). Clearly, the cofactor concentration was a key factor in affecting the efficiency of leuco Acid Blue 74 biotransformation.

There was also no significant change observed on transformation of leuco Acid Blue 74 with varying FDH; however, a higher initial formate concentration improved the leuco Acid Blue 74 transformation, probably because it improved the FDH-catalyzed reaction and thus made NADH regeneration more efficient (Fig. 7).

The results indicate that enzyme preparations could be a useful substitute for existing environmentally unacceptable chemical-based reduction technologies and a faster alternative to time-consuming bacterial reduction. Despite the environmental benefits of this first successful enzyme-based reduction of highly important textile dyes such as indigo (Božič et al. 2009), future investigations should focus on the extended regeneration system to different types of oxidoreductases and redox dyes.

References

Badri BM, Burkinshaw SM (1993) Dyeing of wool and nylon 6.6 with henna and lawsone. Dyes Pigm 22(1):15–25

Baumgarte U (1987) Reduction and oxidation processes in dying with vat dyes. Melliand Textilber Int 68:189–195

Bechtold T, Turcanu A (2006) Iron-complexes of bis(2-hydroxyethyl)-amino-compounds as mediators for the indirect reduction of dispersed vat dyes—cyclic voltammetry and spectroelectrochemical experiments. J Electroanal Chem 591:118–126

Blackburn RS, Harvey A (2004) Green chemistry methods in sulfur dyeing: application of various reducing d-sugars and analysis of the importance of optimum redox potential. Environ Sci Technol 38(14):4034–4039

Božič M, Kokol V (2008) Ecological alternatives to the reduction and oxidation processes in dyeing with vat and sulphur dyes. Dyes Pigm 76:299–309

Božič M, Crepinsek Lipus L, Kokol V (2008) Magnetic field effects on redox potential of reduction and oxidation agents. Croat Chem Acta 81(3):413–421

Božič M, Kokol V, Guebitz GM (2009) Indigo dyeing of polyamide using enzymes for dye reduction. Tex Res J 79(10):895–907

Gasana E, Westbroek P, Temmerman E, Thun HP, Kiekens P (2003) A wall-jet disc electrode for simultaneous and continuous on-line measurement of sodium dithionite, sulfite and indigo concentrations by means of multistep chronoamperometry. Anal Chim Acta 486(1):73–83

Heo J, Halbleib CM, Ludden PW (2001) Redox-dependent activation of CO dehydrogenase from Rhodospirillum rubrum. Proc Natl Acad Sci USA 98(14):7690–7693

Kirkland D, Marzin D (2003) An assessment of the genotoxicity of 2-hydroxy-1,4-naphthoquinone, the natural dye ingredient of henna. Mutat Res 537(2):183–199

Kohno Y, Kitamura S, Yamada T, Sugihara K, Ohta S (2005) Production of superoxide radical in reductive metabolism of a synthetic food-coloring agent, indigocarmine, and related compounds. Life Sci 77(6):601–614

Kroutil W, Mang M, Edegger K, Faber K (2004) Recent advances in the biocatalytic reduction of ketones and oxidation of sec-alcohols. Curr Opin Chem Biol 8:120–126

Leonida MD (2001) Redox enzymes used in chiral syntheses coupled to coenzyme regeneration. Curr Med Chem 8:345–369

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the folin phenol reagent. J Biol Chem 193:265–275

Maier J, Kandelbauer A, Erlacher A, Cavaco-Paulo A, Guebitz GM (2004) A new alkali-thermostable azoreductase from Bacillus sp strain SF. Appl Environ Microbiol 70:837–844

Mesentsev AV, Lamzin VS, Tishkov VI, Ustinnikova TB, Popov VO (1997) Effect of pH on kinetic parameters of NAD-dependent formate dehydrogenase. Biochem J 321:475–480

Nicholson SK, John P (2004) Bacterial indigo reduction. Biocatal Biotransfor 22(5&6):397–400

Nicholson SK, John P (2005) The mechanism of bacterial indigo reduction. Appl Microbiol Biot 68:117–123

Othman I, Mohamed RM, Ibrahim IA, Mohamed MM (2006) Synthesis and modification of ZSM-5 with manganese and lanthanum and their effects on decolorization of indigo carmine dye. Appl Catal A-Gen 299:95–102

Padden AN, John P, Colins MD, Hutson R, Hall AR (2000) Indigo-reducing Clostridium isatidis isolated from a variety of sources, including a 10th-century Viking dye vat. J Archaeol Sci 27:953–956

Pricelius S, Held C, Sollner S, Deller S, Murkovic M, Ullrich R, Hofrichter M, Cavaco-Paulo A, Macheroux P, Guebitz GM (2007a) Enzymatic reduction and oxidation of fibre-bound azo-dyes. Enzyme Microb Technol 40(7):1732–1738

Pricelius S, Held C, Murkovic M, Bozic M, Kokol V, Cavaco-Paulo A, Guebitz GM (2007b) Enzymatic reduction of azo and indigoid compounds. Appl Microbiol Biotechnol 77(2):321–327

Shevchenko A, Jensen ON, Podtelejnikov AV, Sagliocco F, Wilm M, Vorm O, Mortensen P, Boucherie H, Mann M (1996a) Linking genome and proteome by mass spectrometry: large-scale identification of yeast proteins from two dimensional gels. Proc Natl Acad Sci USA 93:14440–14445

Shevchenko A, Wilm M, Vorm O, Mann M (1996b) Mass spectrometric sequencing of proteins from silver-stained polyacrylamide gels. Anal Chem 68:850–858

Siu E, Won K, Park CB (2007) Electrochemical regeneration of NADH using conductive vanadia–silica xerogels. Biotechnol Prog 23(1):293–296

Van der Zee FP, Cervantes FJ (2009) Impact and application of electron shuttles on the redox (bio)transformation of contaminants: a review. Biotechnol Adv 27:256–277

Vuorema A, John P, Keskitalo M, Kulandainathan MA, Marken F (2008) Electrochemical and sonoelectrochemical monitoring of indigo reduction by glucose. Dyes Pigm 76(2):542–549

Wolf M (2000) Sulfites, thiosulfates, and dithionites, Ulmann's encyclopedia of industrial chemistry. Wiley-VCH Verlag, Weinheim

Yumoto I, Hirota K, Nodasaka Y, Yokota Y, Hoshino T, Nakajima K (2004) Alkalibacterium psychrotolerans sp. nov., a psychrotolerant obligate alkaliphile that reduces an indigo dye. Int J Syst Evol Microbiol 54:2379–2383

Acknowledgements

This research was supported by the Slovenian Research Agency (J2-7018-0795) and the Slovenia–Austria 2007–2008 scientific and technological collaboration program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Božič, M., Pricelius, S., Guebitz, G.M. et al. Enzymatic reduction of complex redox dyes using NADH-dependent reductase from Bacillus subtilis coupled with cofactor regeneration. Appl Microbiol Biotechnol 85, 563–571 (2010). https://doi.org/10.1007/s00253-009-2164-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2164-8