Abstract

This study was undertaken to identify the relationship between the performance of dark H2 fermentation and expression of the key functional gene (i.e., hydrogenase gene) involved in the bioH2 production process. Clostridium butyricum CGS5 isolated from anaerobic sewage sludge was used as the model strain for this study. Copy number of the hydrogenase gene (hydA) and mRNA transcripts (cDNA hydA) (after amplification) and the total DNA and RNA (before amplification) were measured over the course of the growth of strain CGS5. Cell concentration was also determined by optical density and converted to dry weight. After amplification, the hydA gene increased 1,500-fold during late exponential growth phase after normalization to the copy number at time 0, and cDNA from mRNA transcripts of hydA also increased 500-fold after normalization. mRNA transcripts of hydA lagged behind the increase of total DNA and RNA, and increases in hydA more closely mimicked those of total DNA. Increases in both of these parameters corresponded with hydrogen production. Transcripts of 16s ribosomal RNA reached a maximum value earlier (38 h) than did those of hydA (47 h). All molecular characteristics matched those for sucrose utilization, growth, and hydrogen production. These experiments indicated that transcription as measured by cDNA can be related to hydrogen production and possesses the potential to be used as tool for process control.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to recent oil price increases and global warming arising from intensive utilization of fossil fuel, much research effort has been devoted to developing new energy alternatives. Hydrogen is considered a promising energy carrier of the future since it is clean, CO2 neutral, renewable, and efficient (Das and Veziroglu 2001; Levin et al. 2004; Nath and Das 2004). Both abiotic and biotic pathways can be used to produce hydrogen. For instance, hydrogen gas can be produced from electrolysis of water (Rao and Hall 1996), thermocatalytic destruction of hydrogen-rich organic compounds such as natural gas and coal, as well as biomass conversion via fermentation or carbon fixation via photosynthesis using water as the terminal electron acceptor (Levin et al. 2004; Nandi and Sengupta 1998). Biological production of hydrogen (called biohydrogen), using microorganisms, a newer technological development offering usable hydrogen particularly as stationary energy sources, is more environmentally friendly and has been the subject of intensive studies. Biohydrogen systems are composed of direct biophotolysis, indirect biophotolysis, photo-fermentation, or dark fermentation (Das and Veziroglu 2001; Levin et al. 2004; Nandi and Sengupta 1998; Nath and Das 2004; Woodward et al. 1996). Recently, research has focused on the fermentative production of hydrogen from renewable substrates, such as mixed waste, animal, and human waste sources (Fan et al. 2004; Hussy et al. 2003; Kapdan and Kargi 2006; Lay 2000; Mizuno et al. 1997; Nandi and Sengupta 1998; Oh et al. 2003).

Biohydrogen production by dark fermentation (Das and Veziroglu 2001; Levin et al. 2004; Nath and Das 2004; Wu et al. 2005) has been demonstrated as a viable approach in converting organic compounds (like carbohydrates) into H2 energy with a variety of anaerobic bacteria (Haruhiko et al. 2001). However, the hydrogen production rate and yield must be further upgraded to increase the economical feasibility of bioH2 production (Hallenbeck and Benemann 2002; Wu et al. 2005). Previous investigators have suggested strategies for the enhancement of bioH2 production, including redirection of metabolic pathways to avoid butyrate as an end product, gas sparging to remove H2 and/or CO2, maintenance of low partial pressure of hydrogen in the head gas for efficient removal of product, and finally some combination of light and dark production (Collet et al. 2005; Mahyudin et al. 1997; Park et al. 2005; Nath and Das 2004).

Although fermentative H2 production has been intensively studied, very few research works have analyzed bioH2 production from molecular genetic aspects (Fang et al. 2006; Chang et al. 2006; Li et al. 2007). In particular, no studies to date have linked the characteristics of hydrogen production to multiple molecular parameters of the copy number of the hydrogenase gene (hydA), mRNA transcripts of hydA, transcripts of 16s ribosomal RNA as well as total DNA and RNA. Since few studies of this nature have been conducted, initial work in our laboratory has focused batch reactor experiments using pure cultures of Clostridium butyricum CGS5 in a defined medium, PM medium. This organism has been described in previous works, and both culture and hydrogen production characteristics have been well described by Chen et al. (2005); thus, it provided a useful model to determine if mRNA transcripts of the hydA gene, hydrogen production, characteristics of growth phase based on both RNA and DNA would corroborate earlier biochemical studies.

Materials and methods

Strain source and fermentable condition

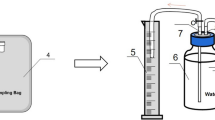

C. butyricum CGS5 (accession no. AY540109) was maintained by culture transfer every 72 h between experiments using PM medium. For hydrogen production experiments, 5 ml of a 72-h culture of C. butyricum CGS5 was injected into 100 ml of sterile and oxygen-free PM culture medium (Chen et al. 2005) in a 150-ml serum vial batch bioreactor and then incubated at 37°C in the water bath, and biogas was continuously collected. Biogas was also collected by syringe at each sampling time and H2 and CO2 concentrations were measured by gas chromatography. The initial pH of medium was 7.2 and the culture pH was not controlled over the course of the experiment. One-milliliter samples were taken at designated times to measure cell density (DU 7400 Spectrophotometer, Beckman). The sample was then centrifuged, supernatant removed, and the pH measured (Orion Research Inc). The supernatant was preserved for the determination of total sugar concentration (Dubois et al. 1956). DNA and RNA were extracted from each corresponding pellet.

Cell density, sugar, and gas determinations

The cell concentration was calculated from absorbance at 600 nm (Van Ginkel and Logan 2005). Total sugar concentration was determined by the phenol–sulfuric acid method (Dubois et al. 1956). The total biogas was collected by water displacement and gas capture. The biogas products were analyzed by gas chromatography (GC) using a thermal conductivity detector (Hewlett Packard 5890 Series II, TCD). The carrier gas was argon at a flow rate of 15.3 ml/min and the capillary column (0.53 mm × 30 m) packed with carboxen-1010 (PLOT, Supelco, USA). The injection, oven, and detector temperatures were 70°C, 50°C, and 175°C, respectively. Volatile fatty acids and ethanol were also detected by GC using flame ionization detector (Shimadzu GC-14A, FID). Nitrogen was used as the carrier gas at a flow rate of 20 ml/min and the capillary column (0.53 mm × 15 m) packed with FON (contains polyethylene glycol and 2-nitroterephthalic acid, Stabilwax-DA, Vercotech Inc.). A ramping temperature program was used beginning with an initial column temperature of 90°C for 2 min, after which the temperature was increased at a rate of 10°C/min to get the final temperature of 210°C for 1 min. The injection and detector temperature was 250°C.

Primer and probe design

Ten hydrogenase gene (hydA) sequences for Clostridia spp. (accession numbers: CAU15277, AF148212, AB016775, AB016820, AB035092, CAU09760, AP003193, AE007516, NC003366, and AB159510) from the NCBI (National Center for Biotechnology Information) database were aligned using ClustalW (Workbench, SDSC, UCSD) to form 5′–3′ and 3′–5′ consensus sequences. The alignment of eleven 16s rRNA gene sequences from Clostridia spp. (accession numbers: M59113, X81021, U16147, AJ237756, AJ 427628, AY458857, X68178, AY699288, AY534872, Y18184, and AY442812) from the NCBI database was also performed using ClustalW (Workbench, SDSC, UCSD). These were then submitted to Primer 3 (Workbench, SDSC, UCSD) to develop the primer and probe sets designated as HGf, HGr, and HGPr for the hydrogenase gene and 16Sf, 16Sr, and 16SPr for the 16S ribosomal gene (Table 1). The hydA and 16s rDNA amplicon sequences were screened using BLAST (NCBI) to determine cross reactivity. The primer sets were synthesized by Sigma Genosys (Woodlands, TX, USA), and the probe sets were synthesized by Biosearch Technologies (Novato, CA, USA). Amplicon fragment sizes of hydrogenase (hydA) and 16s rRNA gene were 259 and 182 bp, respectively.

DNA and RNA extraction

Total DNA extraction was carried out following the procedures of Yu and Mohn (1999). The extracted crude nucleic acid was re-suspended in 50 μl of TE buffer or sterile distilled water to quantify DNA concentration. Extraction of total RNA was carried out using a similar protocol combined with the RQ1 RNase-free DNase kit (Promega Corporation, Madison, WI, USA) for DNA removal.

Reverse transcriptase PCR

Reverse transcription was carried out using a GeneAmp RNA PCR kit (Applied Biosystems, Foster, CA, USA). For each reaction, 3 μl of sample was added to the master mixture which was made according to manufacturer’s instructions. The cycle process for reverse transcriptase polymerase chain reaction (RT-PCR) was 45°C for 15 min, 99°C for 5 min, and 5°C for 5 min using GeneAmp PCR system 2700 (Applied Biosystem, Foster, CA, USA).

Quantitative PCR amplification

Quantitative polymerase chain reaction (qPCR) reactions were conducted using Rotor Gene 3000 (Corbett Research, Melbourne, Australia) employing a total volume of 25 μl with 5 μl of sample. The qPCR master mixture contained 1× PCR buffer, 3.5 mM of MgCl2, 200 μM of dNTP, 300 nM of each primer, 100 ng/μl bovine serum albumin, 50 nM probe, and 1 U of Taq DNA polymerase. Each sample was run in triplicate. The qPCR cycling included an initial holding time of 2 min at 95°C, followed by 40 cycles of denaturation at 95°C for 20 s and annealing at 58.3°C for 45 s. The median chromosome size for Clostridia was used to determine the MW of the chromosome. Based on this calculated value, concentrations for the standard curves were derived (Methrel et al. 1990).

Results

The standard curve was established to calculate the qPCR detection at various time intervals. The median chromosome size for Clostridia was used to determine the MW of the chromosome, based on which DNA concentrations for the standard curves were derived (Methrel et al. 1990). We obtained a linear relationship between the serial-diluted DNA concentrations and the number of cycles needed to reach the detection threshold (C t). The detection limit for 16s ribosomal RNA gene was 500 copies/5 μl or 5 × 105 copies/100 ml of culture media, while the limit for hydA was 5 × 104 copies/5 μl or 5 × 107 copies/100 ml of culture media. In Fig. 1, examples of typical standardization curves achieved for the hydA and the 16s ribosomal gene are shown using different concentrations of direct extracts of C. butyricum CGS5. It can be seen that the PCR efficiency as measured by the coefficient of variation for the hydA gene was 0.9 which was below that achieved for the 16s ribosomal gene. The mean efficiency across all the standard curves generated in this study was 0.9 ± 0.02 and 0.97 ± 0 for hydA and 16s rDNA, respectively. It was likely that the decrease in efficiency for the hydA was due to the larger amplicon size and the use of total cell DNA extracts (Devers et al. 2004; Fang et al. 2006; Zhang and Fang 2006). While the efficiency we achieved for the hydA gene was lower than optimum, reproducibility was excellent, target copy number of cells made the detection limit, and the efficiency was acceptable.

The cell dry weight increased until 47 h, while sucrose decreased steadily until 68 h (Fig. 2). Approximately, 75% of the sugar was utilized by the time additional sugar was added at 68 h. Cell dry weight did not increase after the addition of sugar at 68 h, although the decrease in biomass stopped. The additional nutrient supplied did not result in patterns of cell growth or nutrient utilization observed during the earlier growth period (i.e., between 0 and 34 h in Fig. 1).

The concentrations of total RNA and DNA (Fig. 3a) followed the same pattern over the course of the experiment, which lagged behind sucrose utilization by about 4 h. It was clear that maximum production of total RNA and DNA occurred 47 h after the initiation of the experiment. The extended lag time was likely due to addition of a 72-h culture which might have already undergone sporulation (Wrigley et al. 1995) as shown in Fig. 2. As would be expected, sucrose utilization increased more rapidly (Fig. 3b) than total DNA or RNA, and initial hydrogen production lagged slightly behind that of total DNA and RNA. The rapid rise in hydrogen gas after the addition of sucrose at 68 h suggested that hydrogenase was still present. Additionally, the findings suggested that increases in transcription, measured as cDNA, of the hydA gene would occur slightly later than initial DNA increases (Fig. 4a,b).

Occurrence of hydA gene copy number, transcripts of the hydA gene (measured as cDNA) and 16s RNA transcripts (measured as cDNA) of C. butyricum in batch reactor culture experiments. Copy numbers per nanogram of total DNA and copy numbers per nanogram of cDNA were normalized to time zero. ahydA copy number from total DNA and dry cell weight per 100 ml of batch culture. bhydA copy number from cDNA and hydrogen production in 100 ml of batch culture. c 16s rRNA copy number from cDNA and sucrose utilization in 100 ml of batch culture

In Fig. 4a, cell dry weight and hydA copy number tracked each other as would be expected. Transcripts, measured as cDNA, of the hydA gene increased later than cell biomass (dry cell weight), and the increase was initially far smaller (Fig. 4a,b). The 500-fold amplification of hydA transcripts was measured at 47 h, suggesting that transcription of this operon occurred during late log phase and was short lived quickly returning to initial levels at 60 h.

Another peak in cDNA (transcripts) of the hydA gene was seen at 68 h (Fig. 4b), which corresponded to the time at which 30 ml of fresh medium was added, suggesting the response was almost instantaneous or the increase was not due to the additional substrate. The number of transcripts of the hydA gene produced may be cyclical in fashion with the magnitude becoming smaller over time, if no new substrate was supplied. In our case, the additional substrate was supplied very late in the growth phase precluding us from discerning how rapidly transcript production from the hydA could rebound when variables were examined independently. The utilization of the additional sucrose should have produced additional growth which would have peaked at approximately 115 h, if the initial patterns of increase were followed. However, the changes in cell biomass, hydA genes, and transcripts as well as sucrose utilization and hydrogen production over time after the addition of fresh medium were quite different.

A negative feedback mechanism has been demonstrated if hydrogen was allowed to build up in the headspace (Park et al. 2005). However, in these studies, this negative feedback mechanism was unlikely because of the manner in which hydrogen gas was removed (see Fig. 1). In Fig. 3b, the continued production of hydrogen and a low level of transcript production from the hydA gene (Fig. 4b) suggested that enzyme was still available. In Fig. 4c, it can be seen that cDNA for 16s ribosomal gene increased prior to the increase the transcripts of the hydA gene again suggesting that growth precedes the initiation of hydrogen production. The effect of the new media addition can be seen in the continued increase in sugar utilization at 68 h and a modest increase in 16s ribosomal RNA measured as cDNA. However, the rate of sucrose utilization (138.67 μmol/h) between 38 and 48 h was considerably greater than that seen (5.77 μmol/h) between 60 and 70 h which likely relates to the cell age of the culture or a reduction in culture pH (data not shown). Also, when the transcripts between the 16s ribosomal gene and the hydA gene were compared (Fig. 4b,c), a cyclical pattern for both was seen over the time course.

In Fig. 5, the maximum activity for hydrogen production was 0.0874 fmol H2/h/cell. A second peak, 0.0602 fmol H2/h/cell, was achieved between 68 and 82 h which corresponded to the addition of fresh media. The majority of hydrogen production would have concluded by 47 h without the addition of new medium. Comparing the first maxima of hydrogen production in Fig. 6 with the increase in hydA gene copy number and the 16s ribosomal gene transcripts (Fig. 4b,c) clearly showed that increases in these measurements occurred prior to the H2 maximum, but hydA transcripts more closely mirrored the activity for H2 production.

In Fig. 6, cumulative cell growth ends after 60 h, and hydrogen production also stopped. Hydrogen gas production was reinitiated after the addition of fresh medium (additional substrate), and the response was rapid, again indicating that enzyme hydrogenase was likely to have been present in the cells. Calculated cell concentration per liter did increase after the addition of new media, while DNA concentration stopped declining and remained stable over the rest of the study. If the experiment had been extended longer, the addition of 30 ml of medium might have identified additional growth or it may be that cell function had switched to mainly hydrogen production.

Lastly, examining the ratios of hydA cDNA to hydA gene copy and hydA cDNA with 16s rRNA copies (shown in Fig. 7) may provide more insight into what was actually occurring in the cell culture than examining the individual molecular variables. Both produced very similar patterns. Importantly, hydA transcripts increased, while those of the hydA gene copies and 16s rRNA transcripts remained the same or decreased, respectively. Thus, it did appear that the culture was no longer producing precursors to cell growth, but rather had centered on hydrogen production. Hence, the ratio data for hydA transcripts to those of 16s rRNA tracked the pattern of hydrogen production shown in Fig. 3.

Discussion

Overall, this work has shown that transcripts of the hydA gene and 16s rRNA can be measured over the course of a batch bioreactor experiment and easily used to anticipate, validate, or augment biochemical studies. This research also provided insight into molecular processes which underlie biohydrogen production by C. butyricum. Most importantly, examining the ratio of the hydA transcripts to gene, hydA and to transcripts of 16s rRNA strongly suggested that the addition of substrate late in the growth phase did not stimulate additional growth, but only hydrogen production. The ability to rapidly obtain qPCR data suggested that molecular indices could be combined with other physical and chemical parameters in fermentation reactors to more quickly optimize processes in biotechnology.

The qPCR calibration curve data for hydA were similar to that published by Fang et al. (2006), but the level of detection for the hydA primer and probe sets used in this study had a detection limit of one log less with a corresponding lower efficiency of 0.9 (Fig. 1). Studies have examined 16s rDNA and functional genes qPCR efficiencies which ranged from 0.94 to 0.99 (Chang et al. 2006; Fang et al. 2006), and our data was slightly outside of that range.

A variety of approaches to normalize mRNA transcripts have been published in the literature. Chang et al. (2006) correlated hydrogenase A (hydA) transcripts with hydrogen production in media supplemented with brewery waste. They normalized the mRNA transcript data by standardizing the amount of total RNA in each qPCR reaction. These investigators did not quantify transcripts produced to copy number but rather expressed valued as 1 / C t over the 48-h experiment. Although these investigators worked with mixed cultures, by following the cDNA of hydA and 16s rRNA over time and amplifying and sequencing those of gene fragments, they were able to identify that C. pastueurianium-like was the dominant strain in the batch culture reactor and correspondingly produced the greatest amount total hydrogenase transcripts as measured by 1 / C t. While C. saccharobutylicum-like hydrogenase strains produced more hydA transcripts based on total RNA concentrations, C. butyricum also initially produced less hydA transcripts than 16s rRNA but after 70 h, produced far more (Fig. 7). Expression of the results as ΔC t values meant that the results of Chang et al. (2006) were not directly comparable with those from our study. Overall, in this research and that using 1 / C t demonstrated similar trends in increases of hydA and 16s rRNA over the experiment.

Alternatively, Shin et al. (2006) normalized mRNA transcript copy number of botulism neurotoxin type A (BoNT/A) (cntA) to those for 16s ribosomal RNA. These researchers examined five different strains of C. botulinum and described the production of cntA transcripts as relative expression. They found that 80% of the strains expressed the gene in late log phase of the growth cycle, while one clinical isolates KN1H1 produced the toxin early in growth phase, but at a substantially lower level. In the present study, different amounts of cDNA were added to each qPCR reaction, but each was normalized to total RNA or DNA in the nucleic acid extraction volume of 100 μl (Fig. 3). Furthermore, to examine the change in mRNA transcripts of hydA measured as cDNA, results were normalized to time zero (Fig. 4). Thus, the presentation of data in our study was based on log-fold change of cDNA of the target gene which was similar to relative expression used by Shin et al. (2006) as opposed to 1 / C t. Often, the variation in copy numbers among replicates has made the use of C t or 1 / C t advantageous because of the lower variability. The drawback being the interpretation data across studies, whereas relative expression or log-fold change in copy number was easily compared.

A number of variables have been shown to affect the production of hydrogen by Clostridia. Each strain has demonstrated slightly different optima in regard to pH, substrate utilization, and by product production, but general trends were clear (Chen et al. 2005; Ferchichi et al. 2005; Nath and Das 2004; Van Ginkel and Logan 2005; Wu et al. 2005). Growth conditions have been shown to influence both hydrogen production and rate of hydrogen production (Ferchichi et al. 2005) which was also seen in this study when additional sucrose was added at 68 h. Acid conditions depress hydrogen production, especially if produced by the culture as opposed to the addition of acid from another source (Van Ginkel and Logan 2005). Thus, the production of acid or solvent is important to hydrogen production. In our study, pH was not controlled which may also have been an explanation of why the addition of sucrose did not result in the same increases of DNA or RNA as seen earlier in the time course. Although this investigation focused on monitoring changes in hydA genes and its transcripts as well as 16s rRNA, Dürre et al. (2002) was able to identify some of the promoters in Clostridium species involved in switching from acidogenesis to solventogenesis. Combining the study of hydA transcript production with transcription of the promoters identified in the work of Dürre et al. (2002) could provide additional understanding of hydrogen production because the solventogenic phase required more NAD(P)H than can be produced by glycolysis causing the reoxidation of ferroxdoxin which in turn reduced hydrogen production.

In conclusion, hydA transcripts measured as cDNA followed the patterns suggested in earlier works (Haruhiko et al. 2001; Van Ginkel and Logan 2005) and relative to the hydA gene and 16s rRNA transcripts, continued to increase after the addition of fresh medium (Fig. 7). Examining the ratios of the various components of growth and specific gene function, 16s rRNA and hydA genes and transcripts (Fig. 7) provided a clearer view of how the culture functioned as opposed to examining the changes in these individual variables (Figs. 3 and 4). Even though pH was not controlled in this study hydA transcripts increased relative to the other nucleic acid measures, which suggested that pH did not affect hydrogen production.

References

Chang J-J, Chen W-E, Shih S-Y, Yu S-J, Lay J-J, Wen F-S, Huang C-C (2006) Molecular detection of the Clostridia in an anaerobic biohydrogen fermentation system by hydrogen mRNA-targeted reverse transcription PCR. Appl Microbiol Biotechnol 70:598–604

Chen W-M, Tseng Z-J, Lee K-S, Chang J-S (2005) Fermentive hydrogen production with Clostridium butyricum CGS5 isolated from anaerobic sewage sludge. Int J Hydrogen Energy 30:1063–1070

Collet C, Gaudard O, Peringer P, Schwitzguebel J-P (2005) Acetate production from lactose by Clostridium thermolacticum and hydrogen-scavenging microorganisms in continuous culture—effect of hydrogen partial pressure. J Biotechnol 118:328–338

Das D, Veziroglu TN (2001) Hydrogen production by biological processes: a survey of literature. Int J Hydrogen Energy 26:13–28

Devers M, Soulas G, Martin-Lanurent F (2004) Real-time PCR reverse transcription PCR analysis of expression of atazine catabolism genes in two bacterial strains isolated from soil. J Microbiol Methods 56:3–15

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Dürre P, Böhringer M, Nakotte S, Schaffer S, Thormann K, Zickner B (2002) Transcriptional regulation of solventogenesis in Clostridium acetobutylicum. J Mol Microbiol Biotechnol 3:295–300

Fan YT, Li CL, Lay J-J, Hou HW, Zhang GS (2004) Optimization of initial substrate and pH levels for germination of sporing hydrogen-producing anaerobes in cow dung compost. Bioresour Technol 91:189–193

Fang HHP, Zhang T, Li C (2006) Characterization of Fe-hydrogenase gene diversity and hydrogen-producing population in an acidophilic sludge. J Biotechnol 126:357–364

Ferchichi M, Crabbe E, Hintz W, Gil G-H, Almadidy A (2005) Influence of culture parameters on biological hydrogen production by Clostridium saccharoperbutylacetonicum ATCC 27021. World J Microbiol Biotechnol 21:855–862

Hallenbeck PC, Benemann JR (2002) Biological hydrogen production: fundamentals and limiting processes. Int J Hydrogen Energy 27:1185–1194

Haruhiko Y, Akio S, Hiroyuki U, Jun H, Sachio H, Yoshiyuki T (2001) Microbial hydrogen production from sweet potato starch residue. J Biosci Bioeng 91:58–63

Hussy I, Hawkes FR, Dinsdale R, Hawkes DL (2003) Continuous fermentation hydrogen production from a wheat starch co-product by mixed microflora. Biotechnol Bioeng 84:619–626

Kapdan IK, Kargi F (2006) Bio-hydrogen production from waste materials. Enzyme Microb Technol 38:569–582

Lay J-J (2000) Modeling and optimization of anaerobic digested sludge converting starch to hydrogen. Biotechnol Bioeng 68:269–287

Levin DB, Pitt L, Love M (2004) Biohydrogen production: prospects and limitations to practical application. Int J Hydrogen Energy 29:173–185

Li C, Zhang T, Fang HHP (2007) Use of TaqMan gene probe for real-time PCR monitoring of acidophilic hydrogen-producing bacteria. Biotechnol Lett 29:1753–1757

Mahyudin AR, Furutani Y, Nakashimada Y, Kakizono T, Nishio N (1997) Enhanced hydrogen production in altered mixed acid fermentation of glucose by Enterobacter aerogenes. J Ferment Bioeng 83(4):358–363

Methrel T, Hohl D, Rothnatinocyte JA, Longley MA, Bundman D, Cheng C, Lichti U, Bisher ME, Steven AC, Steinert PM (1990) Identification of a major keratinocyte cell envelope protein, ioricrin. Cell 6:1103–1123

Mizuno O, Ohara T, Noike T (1997) Hydrogen production from food processing waste by anaerobic bacteria. J Environ Syst Eng 573:111–118

Nandi R, Sengupta S (1998) Microbial production of hydrogen: an overview. Crit Rev Microbiol 24:61–84

Nath K, Das D (2004) Improvement of fermentative hydrogen production: various approaches. Appl Microbiol Biotechnol 65:520–529

Oh S-E, Van Ginkel S, Logan BE (2003) The relative effectiveness of pH control and heat treatment for enhancing biohydrogen gas production. Environ Sci Technol 37:5186–5190

Park W, Hyun SH, Oh S-E, Logan BE, Kim IS (2005) Removal of headspace CO2 increases biological hydrogen production. Environ Sci Technol 39:4416–4420

Rao KK, Hall DO (1996) Hydrogen production by cyanobacteria: potential, problems and prospects. J Mar Biotechnol 4:10–15

Shin N-R, Shin J-H, Chun J-H, Yoon S-Y, Kim B-S, Oh H-B, Rhie G-E (2006) Determination of neurotoxin gene expression in Clostridium botulinum type A by quantitative PCR. Mol Cells 22(3):336–342

Van Ginkel S, Logan BE (2005) Inhibition of biohydrogen production by undissociated acetic and butyric acids. Environ Sci Technol 39:9351–9356

Woodward J, Mattingly SM, Danson M, Hough D, Ward N, Adams M (1996) In vitro hydrogen production by glucose dehydrogenase and hydrogenase. Nat Biotechnol 14:872–874

Wrigley DM, Hanwella HDSH, Thon BL (1995) Acid exposure enhances sporulation of certain strains of Clostridium perfringens. Anaerobe 1:263–267

Wu S-Y, Hung C-C, Lin C-N, Chen H-W, Lee A-S, Chang J-S (2005) Fermentative hydrogen production and bacterial community structure in high-rate anaerobic bioreactors containing silicone-immobilized and self-flocculated sludge. Biotechnol Bioeng 93:934–946

Yu Z, Mohn WW (1999) Killing two birds with one stone: simultaneous extraction of DNA and RNA from activated sludge biomass. Can J Microbiol 45:269–272

Zhang T, Fang HHP (2006) Applications of real-time polymerase chain reaction for quantification of microorganisms. Appl Microbiol Biotechnol 70:281–289

Acknowledgments

We thank the EISG grant 06-54324A/05-01 and the UC Pacific Rim Research Program grant 04-1299 for the funding to carry out this work. We also thank the financial support by Taiwan’s National Science Council grant 96-ET-7-006-004-ET and 094-2917-I-000-001.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, MY., Olson, B.H. & Chang, JS. Relationship among growth parameters for Clostridium butyricum, hydA gene expression, and biohydrogen production in a sucrose-supplemented batch reactor. Appl Microbiol Biotechnol 78, 525–532 (2008). https://doi.org/10.1007/s00253-007-1317-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-007-1317-x