Abstract

A sulfate-reducing bacterium, strain WW1, was isolated from a thermophilic bioreactor operated at 65°C with methanol as sole energy source in the presence of sulfate. Growth of strain WW1 on methanol or acetate was inhibited at a sulfide concentration of 200 mg l−1, while on H2/CO2, no apparent inhibition occurred up to a concentration of 500 mg l−1. When strain WW1 was co-cultured under the same conditions with the methanol-utilizing, non-sulfate-reducing bacteria, Thermotoga lettingae and Moorella mulderi, both originating from the same bioreactor, growth and sulfide formation were observed up to 430 mg l−1. These results indicated that in the co-cultures, a major part of the electron flow was directed from methanol via H2/CO2 to the reduction of sulfate to sulfide. Besides methanol, acetate, and hydrogen, strain WW1 was also able to use formate, malate, fumarate, propionate, succinate, butyrate, ethanol, propanol, butanol, isobutanol, with concomitant reduction of sulfate to sulfide. In the absence of sulfate, strain WW1 grew only on pyruvate and lactate. On the basis of 16S rRNA analysis, strain WW1 was most closely related to Desulfotomaculum thermocisternum and Desulfotomaculum australicum. However, physiological properties of strain WW1 differed in some aspects from those of the two related bacteria.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Methanol is the main organic pollutant in the kraft evaporator condensate from pulp and paper industry (Minami et al. 1991). Thermophilic anaerobic treatment represents an attractive option for such types of wastewaters (van Lier et al. 1993). Methanol is used as a carbon and energy source by three groups of strictly anaerobic microorganisms, namely, sulfate-reducing bacteria (SRB), homoacetogenic bacteria, and methanogenic archaea.

Different microbial populations and the pathways in the sludges involved in thermophilic reactors fed with methanol with and without sulfate were studied by Weijma et al. (2000), Weijma and Stams (2001), Paulo et al. (2001) and Roest et al. (2005). Methanol conversion to acetate by (homo)acetogens is only possible in the presence of sufficient CO2 (Ljungdahl 1986). Methanol can be utilized directly by SRB, or indirectly, if homoacetogens first convert methanol to the products, acetate or butyrate which can then be oxidized to CO2 by SRB. Direct utilization of methanol by sulfate reducers under thermophilic conditions has only been described for a few Desulfotomaculum species (Nazina et al. 1987; Rosnes et al. 1991; Fardeau et al. 1995; Goorissen et al. 2003). Because of their possible toxic effects, sulfide concentrations are known to play an important role in anaerobic systems (Maillacheruvu and Parkin 1996). Clearly, possibilities for competition for substrates, complex syntrophic relationships, formation of granules and flocs, in addition to toxic effects of products, together make the outcome of laboratory-scale and pilot-plant studies not easily predictable.

Previously, we studied methanol degradation in the presence of sulfate in an anaerobic laboratory-scale bioreactor operated at thermophilic conditions (Weijma et al. 2000). Ultimately, more than 90% of the methanol consumed was oxidized to CO2 in a process coupled to sulfate reduction, while the remainder was converted to acetate. To gain a better insight into the microbiology of methanol conversion, we could isolate two novel homoacetogens from this bioreactor (Balk et al. 2002, 2003). Here, we describe the isolation, characterization, and the possible role of a thermophilic sulfate-reducing bacterium, strain WW1, originating from the same bioreactor.

Materials and methods

Source of organisms

Strain WW1 was isolated from anaerobic sludge obtained from a thermophilic (65°C) laboratory-scale granular sludge bed (EGSB) reactor. The source originated from a pilot plant to reduce sulfate and sulfite from a flue-gas scrubber of a coal-fired power plant in Geertruidenberg in the Netherlands. The laboratory-scale reactor was fed with methanol in the presence of sulfate and sulfite as described by Weijma (2000). The pH in the reactor was 7.5.

The medium composition in the EGSB-reactor was similar to that used for enrichment and cultivation of WW1 (see below), except for vitamins and cobalt in trace elements solution, which were omitted to suppress unwanted methane and acetate formation from methanol. Methanol and sulfate concentrations of the bioreactor influent were 56 and 42 mM, respectively. The sludge sample was taken after 79 days of operation of this reactor, and at that time point, 92% of the methanol oxidized was used for sulfate reduction and about 2 and 6% of the methanol oxidized was used for acetate and methane formation, respectively. The bioreactor was overloaded with methanol before day 79, and it resulted in an effluent methanol concentration of 2 to 31 mM from days 32 to 79 as described by Weijma (2000).

Thermotoga lettingae (DSM 14385T) and Moorella mulderi (DSM 14980T) were isolated from the same bioreactor as strain WW1 and were described previously (Balk et al. 2002, 2003). Methanothermobacter thermoautotrophicus ΔH (DSM 1053), formerly known as Methanobacterium thermoautotrophicum ΔH, was provided kindly by J.T. Keltjens (Radboud University, Nijmegen, The Netherlands).

Media and cultivation

The basal liquid culture medium contained (g l−1): NaCl (7), NaHCO3 (4), Na2SO4 (2.8), MgCl2·6H2O (1.2), KCl (0.5), NH4Cl (0.3), KH2PO4 (0.2), CaCl2 (0.15), Na2S·7–9H2O (0.3), yeast extract (0.02), and trace element solution (1 ml l−) containing (mg l−1): FeCl2·4H2O (1,500), CoCl2·2H2O (190), MnCl2·4H2O (100), ZnCl2 (70), H3BO3 (62), Na2MoO4·2H2O (36), NiCl2·6H2O (24), CuCl2·2H2O (17), EDTA (500), and HCl 37% (7 ml l−1). In addition, vitamins were added from a concentrated stock solution according to Stams et al. (1983).

The cultures were routinely grown in 117-ml serum vials with butyl rubber stoppers and aluminum crimp seals. The vials contained 50 ml basal medium and a gas phase of 1.7 bar N2/CO2 or H2/CO2 (80/20%, v/v). Concentrated stock solutions of substrates were prepared anoxically, sterilized by filtration and added to the medium to final concentrations of 5–20 mM. The pH of the medium was 7. By varying the CO2 concentration in the headspace and adding a few drops of 0.1 N HCl or NaOH per vial, the pH of the medium could be adjusted within the range 5.5–8.5. In all growth experiments in liquid medium, the inoculum size was 1% (v/v).

Isolation

A sludge sample obtained from the bioreactor was used as a source for isolation. Under a nitrogen gas atmosphere, 2 ml of sludge was disintegrated using a mortar. The sludge was transferred into an anaerobic tube and after fivefold dilution in the medium, the sludge was further disintegrated by pressing it repeatedly through a syringe needle (Microlance 3, 0.6 × 25 mm). Serial dilutions of the sludge were prepared in liquid media containing 30 mM methanol, 2 mM acetate, and 20 mM sulfate. The highest dilution showing growth at 65°C was designated SRC-11 (sulfate-reducing culture from 1011-times diluted sludge). The culture was further purified by repeated serial dilutions and subsequent incubation in liquid medium. The resulting culture was diluted in agar media (1.5%, w/v, Agar Noble). Colonies from the highest dilution were picked and diluted again in agar shake tubes. This procedure was repeated twice until a pure culture was obtained. Purity of the isolate was confirmed by incubations at 30 and 65°C under anaerobic and aerobic conditions in media containing 10 g l−1 yeast extract (BBL-Becton Dickinson, Cockeyesville, MD, USA) or in anaerobic Wilkins–Chalgren broth (Oxoid, Basingstroke, UK).

Cell morphology and purity were examined with a phase-contrast microscope. Gram staining was carried out according to the standard procedure (Doetsch 1981). Transmission electron microscopy was perfomed as described by Plugge et al. (2000).

Substrate utilization tests

The ability of strain WW1 to metabolize substrates was tested in the bicarbonate-buffered medium. Substrates were added from sterile, anoxic concentrated stock solutions to final concentrations of 20 mM, unless otherwise indicated. To test the use of potential electron acceptors, sodium sulfate (20 mM), sodium thiosulfate (20 mM), sodium sulfite (5 mM), and sodium nitrate (10 mM) were added to the medium at the indicated concentrations.

16S RNA sequence analysis and G+C content of DNA

For the phylogenetic characterization of strain WW1, chromosomal DNA was isolated from a liquid culture as described previously (van der Maarel et al. 1996). The 16S rRNA gene was selectively amplified by polymerase chain reaction (PCR), using oligonucleotide primers complementary to conserved regions of the eubacterial 16S rDNA. The following primer pair was used: 5′ ACCTAATACGACTACTATAGGGAGAGTTTG-ATCCTGGCTCAG 3′ (positions 8–27, E. coli numbering) and 5′ ATTGTAAAACGACGGCCAGT-GGTTACCTTGTTACGACTT 3′ (positions 1,492–1,510, E. coli numbering). The PCR amplification products were sequenced with an amplified Biosystems model 373A DNA sequencer by using the Taq DyeDeoxy terminator cycle sequencing method and custom primers based on conserved regions. The sequences were checked for reading errors with the alignment programs of the ARB package (Ludwig et al. 2004), and homology searches of the ARB, EMBL, and GenBank DNA databases for these partial sequences were done with FASTA.

The 16S rRNA gene sequence of strain WW1 has been deposited in the GenBank database under the accession number AF442687. The EMBL database accession numbers of the strains most closely related to strain WW1 are Desulfotomaculum thermocisternum (DSM 10259T), U33455 and Desulfotomaculum australicum (DSM 11792T), M96665. Isolation and purification of DNA was carried out according to Marmur (1961). The G + C content of the genomic DNA was determined by thermal denaturation method (Owen et al. 1969).

Co-culture experiments

The culture medium and the conditions used for co-culture experiments were as described for strain WW1. To detect sulfide formation of strain WW1, the two other methanol-oxidizing bacteria originating from the same bioreactor were cocultivated in batch cultures with strain WW1 pregrown on hydrogen. Strain WW1 was inoculated into medium containing with Thermotoga lettingae (DSM 14385) and/or Moorella mulderi (DSM 14980) on methanol (20 mM). Inoculation size of each of the cultures was 1% (v/v). Sulfide formation by strain WW1 was also tested in the medium containing H2/CO2 (80/20%, v/v). In all bottles, 20 mM sulfate was present as electron acceptor.

To test syntrophic growth on methanol, the mixed culture SRC-11 was inoculated into medium containing Methanothermobacter thermoautotrophicus ΔH pregrown on hydrogen. Before inoculation, the gas phase was changed to N2/CO2 (80/20%, v/v) and methanol was added. Growth experiments were conducted in duplicates.

Analytical methods

Most substrates were measured by HPLC as described previously by Stams et al. (1993). Methanol was analyzed using a Chrompack gas chromatograph (model CP 9000) equipped with a Sil5 CB column (25 m× 0.32 mm) and flame ionization detector at 300°C. The column temperature was 50°C and the injection port temperature was 250°C. The carrier gas was N2-saturated with formic acid. Acetate, propionate and other fatty acids were measured by gas chromatography (GC) with a Hewlett Packard (model 5890) gas chromatograph equipped with a glass column (inside dimensions, 6 m by 2 mm) filled with Supelco port (100/120 mesh) coated with 10% Fluorad FC 431 (3M). The temperatures of the injection port and the detector were 200 and 280°C, respectively. The temperature of the column was maintained at 130°C. Methane and hydrogen levels were measured by GC with a Packard-Becker 406 gas chromatograph equipped with a thermal conductivity detector and molecular sieve 13 × (1.8 m by 1/4 in., 60/80 mesh). The column temperature was 100°C, and the carrier gas was argon. Sulfide was determined as described by Trüper and Schlegel (1964).

Results

Isolation and morphological characterization

A stable enrichment culture was obtained from thermophilic sludge at 65°C in a sulfate-containing bicarbonate-buffered medium with methanol as the growth substrate. The culture formed mainly carbon dioxide and sulfide as products, but no methane was formed. Pure sulfate-reducing cultures were obtained by using the agar dilution method (Fig. 1). One of these, designated strain WW1, was used for further study. Strain WW1 is a rod-shaped, spore-forming bacterium. When grown on methanol, cells were 0.8 μm in diameter and 2–5 μm in length and on H2/CO2, lactate, or pyruvate, the cells were 0.8 μm in diameter and 5–20 μm in length. Spores were located centrally and 0.5 μm×0.5 μm in size and developed in the late-exponential phase. Cells stained Gram-negative, but the cell wall ultrastructure resembled that of Gram-positive bacteria (data not shown).

Growth and substrate utilization

Strain WW1 grew at temperatures ranging from 45 to 75°C; optimum growth occurred between 62 and 68°C. Growth was obtained between pH 6.3 and 8.3, with optimum growth at pH 7.6. Optimum pH and temperature values reflected the operating conditions (pH 7.5, 65°C) of the bioreactor. In the presence of sulfate (20 mM), strain WW1 was able to grow on methanol, H2/CO2 (80/20%, v/v), ethanol, propanol, butanol, isobutanol, formate, propionate, butyrate, malate, succinate, fumarate, lactate and pyruvate, but not on isopropanol, fructose, and glucose. Very slow growth was also observed on benzoate. Sulfite (5 mM) and thiosulfate (20 mM) were utilized as electron acceptor but nitrate (10 mM) was not.

Strain WW1 was able to grow with methanol or acetate and sulfate (Fig. 2). However, growth on these substrates was very poor with specific growth rates of 0.09 day−1. Acetate was not formed during growth on methanol. When methanol (30 mM) and acetate (2 mM) were present, both substrates were utilized simultaneously. However, growth was not faster than with either of the substrates alone. Strain WW1 grew autotrophically on H2/CO2 in the presence of sulfate with a specific growth rate of 0.5 day−1. Acetate was not formed during growth on H2/CO2. No measurable methanol and acetate decrease was observed in the presence of an excess of H2/CO2 (1.7 bar).

16S rRNA and G+C content analyses

A nearly complete sequence consisting of 1,403 bp of the amplified 16S rRNA gene of strain WW1 was obtained. On the basis of the 16S rRNA sequence, strain WW1 was most closely related to Desulfotomaculum thermocisternum (99% similarity value) and Desulfotomaculum australicum (98% similarity value). The topology of the phylogenetic tree constructed was almost identical with earlier data from Desulfotomaculum species (Stackebrandt et al. 1997). This clearly indicates that strain WW1 is a member of the genus Desulfotomaculum. Strain WW1 was located in subcluster IC, consisting of closely related thermophilic Desulfotomaculum species with similarity values of more than 93% (Fig. 3). The DNA base composition (G+C) of strain WW1 (49.6 mol%) was lower than that of the most closely related species, Desulfotomaculum thermocisternum (Table 1).

Dendrogram showing the position of strain WW1 among the members of the genus Desulfotomaculum. Roman numerals refer to the cluster and subclusters of the Desulfotomaculum species as described by Stackebrandt et al. (1997). The neighbor-joining tree was reconstructed from distance matrices; bootstrap values above 50 are expressed at the branching points. Bacillus methanolicus served as outgroup. Bar: evolutionary distance of 0.10

Sulfide toxicity

Growth of strain WW1 on methanol or acetate was rather poor; only 200 mg l−1 of sulfide was produced in 20 days of incubation and sulfide concentration no longer increased thereafter. The rate of sulfide formation in five other pure sulfate-reducing cultures obtained from culture SRC-11, which morphologically strongly resembled strain WW1, also proceeded up to maximum levels of around 200 mg l−1 while methanol was still available. At initial concentrations of 220 mg l−1 of sulfide, no growth occurred with methanol and sulfate. Elevating the initial pH from 7.0 to 7.5 or 8.0 did not result in formation of more sulfide. Poor growth of strain WW1 was not caused by toxicity of impurities of the commercial sodium sulfide that was used to reduce the medium, as suggested by Widdel (1992), because substituting commercial sodium sulfide by sterile biogenic sulfide which was obtained by repeatedly filter-sterilizing effluent from a sulfate-reducing bioreactor, did not improve formation of sulfide. Higher final sulfide levels of 500 mg l−1 were reached in 10 days when H2/CO2 was added as electron donor and carbon source.

Growth of strain WW1 in co-cultures

The mixed culture SRC-11 from which strain WW1 was isolated, formed methane from methanol when it was incubated with the hydrogenotrophic methanogen M. thermoautotrophicus ΔH (Fig. 4). This indicated the presence of bacteria able to convert methanol to H2 and CO2. T. lettingae and M. mulderi were isolated in our laboratory from the same mixed starting culture SRC-11 as strain WW1 (Balk et al. 2002, 2003). These strains indeed were able to oxidize methanol to H2 and CO2. To test if strain WW1 likewise possessed methanol-oxidizing capacity, it was inoculated together with a dense culture of H2/CO2 pre-grown M. thermoautotrophicus ΔH in the absence of sulfate. Methanol was not degraded and only a small amount of methane was formed, revealing that strain WW1 was not responsible for the methanol-oxidizing capacity of the mixed culture SRC-11.

Methanol degradation in culture SRC-11 in the presence of M. thermoautotrophicus strain ΔH without sulfate. Symbols: open circles (◯) methanol, filled circles (•) methane, closed triangles (▴) acetate, open squares (□) hydrogen partial pressure. The methane concentration is expressed as mmol methane produced per l of medium

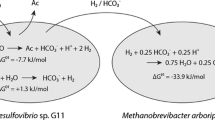

M. mulderi and T. lettingae oxidized methanol to H2/CO2 in the presence of a hydrogen-utilizing methanogen, but did not reduce sulfate. When a methanogen was added to the starting culture and sulfate was omitted in the batch experiments, T. lettingae became the dominant bacterium, and methanol was completely converted to methane and CO2. Both acetogenic bacteria in pure cultures were able to ferment methanol to H2 and CO2, and then, the subsequent reactions might have been effected by strain WW1. To study the possible role of these bacteria for methanol degradation in the starting culture SRC-11, they were co-cultured with strain WW1 in the presence of methanol and sulfate. In the co-cultures, substantially more sulfide was formed than in the culture of strain WW1 alone. As more yeast extract was required for good growth of T. lettingae on methanol than present in the medium used, methanol was only partially (8 mM) converted to H2 and acetate in the co-culture with T. lettingae in 20 days of incubation. Although methanol was completely converted (20 mM) to H2 and acetate in 10 days in the co-culture with M. mulderi, maximum sulfide concentrations formed by strain WW1 in both co-culture experiments were similar (420 and 430 mg l−1, respectively), indicating the inhibitory effect of sulfide on strain WW1.

Discussion

The isolation of strain WW1 from the highest methanol-degrading, sulfate-reducing serial dilution of disintegrated sludge strongly suggests that this bacterium is the most abundant sulfate reducer in the sludge. With respect to pH and temperature, strain WW1 was well adapted to the environmental conditions prevailing in the reactor, whereas, optimum pH was 7.5 and temperature was 62–68°C.

Phylogenetic analysis and morphological characteristics show that strain WW1 is a species of the genus Desulfotomaculum. The closest relatives of strain WW1 are Desulfotomaculum australicum and D. thermocisternum based on 16S rRNA sequence analysis (98 and 99% similarity, respectively). On the basis of the physiological properties, it is obvious that strain WW1 differs from both D. australicum and D. thermocisternum (Table 1). In contrast to strain WW1, D. australicum does not utilize methanol, formate, propionate, and butyrate and D. thermocisternum does not utilize methanol, formate, and acetate. Based on its physiological characteristics in pure and mixed cultures, the role of strain WW1 in methanol conversion in the sulfate-reducing bioreactor was unexpected. The sulfate-reducing starting culture SRC-11 possessed the capacity to oxidize methanol to H2 and CO2. However, this characteristic could not be demonstrated for strain WW1. Obviously, strain WW1 and related bacteria most likely grew by sulfate reduction in the starting culture. Nevertheless, growth of strain WW1 on methanol was already completely inhibited at a sulfide concentration of 200 mg l−1, which is far lower than the final sulfide levels reached in the starting culture, which was 600 mg l−1 or the bioreactor which was up to 700 mg l−1. Strain WW1 grown on methanol could only reach substantially higher sulfide levels than 200 mg l−1 when it was co-cultured with T. lettingae or M. mulderi.

These results showed that sulfate reduction by strain WW1 was possible with hydrogen as electron donor up to 430 mg l−1 sulfide concentration. This is further supported by the observation that growth of strain WW1 on H2 and sulfate was not inhibited at a sulfide level of 200 mg l−1. In such a continuously operated bioreactor, strain WW1-like bacteria are continuously exposed to these high sulfide levels, suggesting that growth on H2 and sulfate may be favored over growth on methanol and sulfate in the bioreactor. These types of microbial interactions are crucial for the competitive success of certain anaerobic bacteria in the reactors. The results of this study confirm that sulfide toxicity represents a major bottleneck for SRB in methanol conversion. Although sulfide is a characteristic end product for SRB, concentrations as low as 60 mg l−1 can be inhibitory for Desulfotomaculum species (Min and Zinder 1990). Apparently, strain WW1 could not compete with homoacetogenic bacteria for methanol, indicating that it depended on hydrogen formed by the homoacetogens from methanol in the reactor. However, Goorissen et al. (2004) showed that a sulfate reducing bacterium, Desulfotomaculum kuznetsovii, easily outcompeted Moorella thermoautotrophica for methanol; both bacteria were relatively insensitive to sulfide. Except M. glycerini, all Moorella species isolated so far are able to grow on methanol (Wiegel et al. 1981; Slobodkin et al. 1997; Balk et al. 2003; Drake and Daniel 2004; Jiang 2006).

Homoacetogenic bacteria do not compete with SRB or methanogenic archaea for the utilization of H2/CO2. For this reason, methanol can be either oxidized syntrophically to CO2 by homoacetogenic and sulfate-reducing bacteria or by methanol-utilizing methanogens and sulfate reducers (Phelps et al. 1985). The formation of acetate and methane from methanol was established by a thermophilic microorganism, called Methanobacillus kuzneceovii, for the first time (Pantskhava and Pchelkina 1969). However, it was shown later that this microorganism was not pure and there was a microbial association including Moorella thermoautotrophica (formerly Clostridium thermoautotrophicum) and hydrogen-utilizing microorganisms, similar to Methanothermobacter thermoautotrophicus (formerly Methanobacterium thermoautotrophicum) (Ilarionov 1986). Similarly, when the sludge sample from a continuous methanol-fed thermophilic (55°C) anaerobic laboratory-scale bioreactor was enriched with methanol in the presence of M. thermoautotrophicus strain Z245, a bacterium closely related to Moorella glycerini became most dominant (Roest et al. 2005). It is noteworthy that the presence of Moorella species in different associations is an indication for their importance in methanol metabolism.

The role of Thermotoga lettingae was not very clear in the reactor because it requires either more yeast extract (0.5 g l−1) or a methanogenic syntrophic partner for growth on methanol as was described earlier (Balk et al. 2002). When M. thermoautotrophicus was added to the enrichment culture, T. lettingae was the dominant organism in the enrichment culture. The amount of yeast extract which was only 0.02 g l−1 in the medium, most probably, limited the growth of T. lettingae, thus, M. mulderi was the major homoacetogen for methanol utilization in the reactor.

In conclusion, our data strongly indicate that strain WW1 in the continuously fed reactor, despite its ability to reduce sulfate with methanol as a substrate directly, mainly grows by accepting the reducing equivalents produced by the acetogenic methanol-utilizing bacteria. Strain WW1 was not able to use acetate in the presence of hydrogen. Methanol was mainly utilized by the two homoacetogens, Moorella mulderi and Thermotoga lettingae. The lack of acetate degradation in the reactor might be explained by assuming that hydrogen is the main electron donor for sulfate reduction. Growth of strain WW1 on methanol and sulfate was inhibited by 200 mg l−1 sulfide; on the other hand, strain WW1 could grow on hydrogen and sulfate up to a sulfide concentration of 500 mg l−1. The latter sulfide concentration was in the same range as total sulfide concentration in the bioreactor from which the strain was isolated. Therefore, the high sulfide levels produced in the bioreactor might be explained by assuming the growth of strain WW1-like sulfate reducers on hydrogen rather than on methanol. Although some sulfate-reducing bacteria can grow on methanol (Braun and Stolp 1985; Goorissen et al. 2003), our experiments showed that some may also be involved indirectly in the anaerobic conversion of methanol at 65°C.

References

Balk M, Weijma J, Stams AJM (2002) Thermotoga lettingae sp. nov., a novel thermophilic, methanol-degrading bacterium isolated from a thermophilic anaerobic reactor. Int J Syst Evol Microbiol 52:1361–1368

Balk M, Weijma J, Friedrich MW, Stams AJM (2003) Methanol conversion by novel thermophilic homoacetogenic bacterium Moorella mulderi sp. nov. isolated from a bioreactor. Arch Microbiol 179:315–320

Braun M, Stolp H (1985) Degradation of methanol by a sulfate-reducing bacterium. Arch Microbiol 142:77–80

Doetsch RN (1981) Determinative methods of light microscopy. In: Gerhardt P, Murray RGE, Costilow RN, Nester EW, Wood WA, Krieg NR, Philips GB (eds) Manual methods for general microbiology. American Society for Microbiology, Washington, DC

Drake HL, Daniel SL (2004) Physiology of the thermophilic acetogen Moorella thermoacetica. Res Microbiol 155:869–883

Fardeau ML, Ollivier B, Patel BKC, Dwivedi P, Ragot M, Garcia JL (1995) Isolation and characterization of a thermophilic sulfate-reducing bacterium, Desulfotomaculum thermosapovorans. Int J Syst Bacteriol 45:218–221

Goorissen HP, Stams AJM, Hansen TA (2003) Isolation of thermophilic Desulfotomaculum strains with methanol and sulphite from solfataric mud pools, and characterization of Desulfotomaculum solfataricum sp. nov. Int J Syst Evol Microbiol 53:1223–1229

Goorissen HP, Stams AJM, Hansen TA (2004) Methanol utilization in defined mixed cultures of thermophilic anaerobes in the presence of sulfate. FEMS Microbiol Ecol 49:489–494

Ilarionov SA (1986) Isolation of Clostridium thermoautotrophicum, an anaerobic methylotrophic spore-forming organism. Mikrobiologiya 54:533–537

Jiang B (2006) The effect of trace elements on the metabolism of methanogenic consortia. Ph.D. Thesis. Wageningen University. Wageningen, The Netherlands

Ljungdahl LG (1986) The autotrophic pathway of acetate synthesis in acetogenic bacteria. Annu Rev Microbiol 40:415–450

Love CA, Patel BKC, Nichols PD, Stackebrandt E (1993) Desulfotomaculum australicum, sp. nov., a thermophilic sulfate-reducing bacterium isolated from the Great Artesian Basin of Australia. Syst Appl Microbiol 16:244–251

Ludwig W, Strunk O, Westram R, Richter L, Meier H, Yadhukumar, Buchner A, Lai T, Steppi S, Jobb G, Forster W, Brettske I, Gerber S, Ginhart AW, Gross O, Grumann S, Hermann S, Jost R, Konig A, Liss T, Lussmann R, May M, Nonhoff B, Reichel B, Strehlow R, Stamatakis A, Stuckmann N, Vilbig A, Lenke M, Ludwig T, Bode A, Schleifer KH (2004) ARB: a software environment for sequence data. Nucleic Acids Res 25:32(4):1363–1371

Maillacheruvu KM, Parkin GF (1996) Kinetics of growth, substrate utilization and sulfide toxicity for propionate, acetate, and hydrogen utilizers in anaerobic systems. Water Environ Res 68:1099–1106

Marmur J (1961) A procedure for the isolation of deoxyribonucleic acid from microorganisms. J Mol Biol 3:208–218

Min H, Zinder SH (1990) Isolation and characterization of a thermophilic sulfate-reducing bacterium Desulfotomaculum thermoacetoxidans sp. nov. Arch Microbiol 153:399–404

Minami K, Okamura K, Ogawa S, Naritomi T (1991) Continuous anaerobic treatment of wastewater from kraft pulp mill. J Ferment Bioeng 71:270–274

Nazina TN, Ivanova AE, Kanchaveli LP, Rozanova EP (1987) A new sporeforming thermophilic methylotrophic sulfate-reducing bacterium, Desulfotomaculum kuznetsovii sp. nov. Mikrobiologiya 57:823–827

Nilsen RK, Torsvik T, Lien T (1996) Desulfotomaculum thermocisternum sp. nov., a sulfate reducer isolated from a hot North Sea oil reservoir. Int J Syst Bacteriol 46:397–402

Owen RJ, Hill RL, Lapage SP (1969) Determination of DNA base composition from melting profiles in dilute buffers. Biopolymers 7:503–516

Pantskhava ES, Pchelkina VV (1969) The methane fermentation of methanol by Methanobacillus kuzneceovii. Prikladnaya Biokhimiya i Mikrobiologiya 5:416–420

Paulo PL, Jiang B, Rebac S, Hulshoff-Pol L, Lettinga G (2001) Thermophilic anaerobic digestion of methanol in UASB reactor. Water Sci Technol 44:129–136

Phelps TJ, Conrad R, Zeikus JG (1985) Sulfate dependent interspecies H2 transfer between Methanosarcina barkeri and Desulfovibrio vulgaris during co-culture metabolism of acetate or methanol. Appl Environ Microbiol 50:589–594

Plugge CM, Zoetendal EG, Stams AJM (2000) Caloramator coolhaasii sp. nov., a glutamate-degrading, moderately thermophilic anaerobe. Int J Syst Evol Microbiol 50:1155–1162

Rosnes JT, Torsvik T, Lien T (1991) Spore-forming thermophilic sulfate-reducing bacteria isolated from North Sea oil field waters. Appl Environ Microbiol 57:2302–2307

Roest K, Altinbas M, Paula PL, Heilig HGHJ, Akkermans ADL, Smidt H, de Vos WM, Stams AJM (2005) Enrichment and detection of microorganisms involved in direct methanogenesis from methanol in an anaerobic thermophilic bioreactor. Microbial Ecol 0:1–7

Slobodkin A, Reysenbach AL, Mayer F, Wiegel J (1997) Isolation and characterization of the homoacetogenic thermophilic bacterium Moorella glycerini sp. nov. Int J Syst Bacteriol 47:969–974

Stackebrandt E, Sproer C, Rainey FA, Burghardt J, Pauker O, Hippe H (1997) Phylogenetic analysis of the genus Desulfotomaculum: evidence for the misclassification of Desulfotomaculum guttoidem and description of Desulfotomaculum orientis as Desulfosporosinus orientis gen. nov., comb. nov. Int J Syst Bacteriol 47:1134–1139

Stams AJM, Veenhuis M, Weenk GH, Hansen TA (1983) Occurrence of polyglucose as a storage polymer in Desulfovibrio species and Desulfobulbus propionicus. Arch Microbiol 136:54–59

Stams AJM, van Dijk JB, Dijkema C, Plugge CM (1993) Growth of syntrophic propionate-oxidizing bacteria with fumarate in the absence of methanogenic bacteria. Appl Environ Microbiol 59:1114–1119

Trüper HG, Schlegel HG (1964) Sulphur metabolism in Thiorhodaceae I. Quantitative measurements on growing cells of Chromatium okenii. Antonie van Leeuwenhoek 30:225–238

van der Maarel MJEC, Jansen M, Haanstra R, Meijer WG, Hansen TA (1996) Demethylation of dimethylsulfoniopropionate to 3-S-methylmercaptopropionate by marine sulfate-reducing bacteria. Appl Environ Microbiol 62:3978–3984

van Lier JB, Grole KC, Frijters CT, Stams AJM, Lettinga G (1993) Effects of acetate, propionate, and butyrate on the thermophilic anaerobic degradation of propionate by methanogenic sludge and defined cultures. Appl Environ Microbiol 59:1003–10011

Weijma J (2000) Methanol as electron donor for thermophilic biological sulfate and sulfite reduction. Ph.D. Thesis. Wageningen University. Wageningen, The Netherlands

Weijma J, Stams AJM, Hulshoff Pol LW, Lettinga G (2000) Thermophilic sulfate reduction and methanogenesis with methanol in a high rate anaerobic reactor. Biotechnol Bioeng 67:354–363

Weijma J, Stams AJM (2001) Methanol conversion in high-rate anaerobic reactors. Water Sci Technol 44:7–14

Widdel F (1992) The Genus Desulfotomaculum. The Genus Desulfotomaculum. In: Balows A, Trüper HG, Dworkin M, Harder W, Schleifer KH (eds) The prokaryotes, 2nd. edn. Berlin Heidelberg New York: Springer 19921792–1799

Wiegel J, Braun M, Gottschalk G (1981) Clostridium thermoautotrophicum species novum, a thermophile producing acetate from molecular hydrogen and carbon dioxide. Curr Microbiol 5:255–260

Acknowledgements

This research was supported by the Technology Foundation STW, Applied Science Division and Darwin Center for Biogeology of NWO and the Technology Program of the Ministry of Economic affairs. The authors thank C.J.N. Buisman and H. Dijkman from Paques Natural solutions, Balk, the Netherlands for valuable discussions, and A. Ivanova in Moscow State University for the determination of the G + C-content.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balk, M., Weijma, J., Goorissen, H.P. et al. Methanol utilizing Desulfotomaculum species utilizes hydrogen in a methanol-fed sulfate-reducing bioreactor. Appl Microbiol Biotechnol 73, 1203–1211 (2007). https://doi.org/10.1007/s00253-006-0590-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0590-4