Abstract

β-1,3-1,4-Glucanase has been applied in the brewing and animal feed additive industry. It can effectively improve digestibility of barley-based diets and reduce enteritis. It also reduces viscosity during mashing for high-quality brewers malt. The aim of this work is to clone β-1,3-1,4-glucanase-encoding gene and express it heterogeneously. The gene was amplified by polymerase chain reaction using Bacillus licheniformis genomic DNA as the template and ligated into the expression vector pET28a. The recombinant vector was transformed into Escherichia coli. The estimated molecular weight of the recombinant enzyme with a six-His tag at the N terminus was about 28 kDa, and its activities in cell lysate supernatant were 1,286 and 986 U ml−1 for 1% (w/v) barley β-glucan and 1% (w/v) lichenan, respectively. Accordingly, the specific activities were 2,479 and 1,906 U mg−1 for these two substrates. The expression level of recombinant β-1,3-1,4-glucanase was about 60.9% of the total protein and about 12.5% of the total soluble protein in crude cell lysate supernatant. Acidity and temperature optimal for this recombinant enzyme was pH 5.6 and 40°C, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

β-Glucan is a principal cell wall component of barley, rye, rice, and wheat, and it consists of about 1,200 glucose units joined by β-1,3 and β-1,4 glycosidic bonds. The β-1,3 glycosidic linkages account for about 25–30% in the whole β-glucan molecule (Parrish et al. 1960). The β-1,3-1,4-glucanase (EC 3.2.1.73) can only hydrolyze β-1,4-glycosidic bonds adjacent to β-1,3-glycosidic bonds in mixed glycosidic linkages of β-glucan and lichenan but cannot split the β-1,4-glycosidic bonds in carboxymethylcellulose (Parrish et al. 1960; Wolf et al. 1995; Bielecki and Galas 1991). Cellobiosyltriose and cellotriosyltetraose are the major hydrolysis products of β-glucan and lichenan by β-1,3-1,4-glucanase (Anderson and Stone 1975).

The barley glucan is an anti-nutritional factor especially for chicken and piglets, and the glucan in cereal-grain-based diet has deleterious side effects such as sticky droppings. Addition of β-1,3-1,4-glucanase improves the digestibility of barley-based diets and reduces enteritis (Planas 2000; Li et al. 1996; Mathlouthi et al. 2002). During malting, the β-1,3-1,4-glucanase is heat inactivated, leaving high content of β-glucan in brewers wort. This may cause severe problems such as low filtration rate and extract yields, as well as the undesirable appearance from hazes and gelatinous precipitates in beer. Thus, the β-1,3-1,4-glucanase is often added to reduce viscosity for high-quality brewers malt during mashing (Bielecki and Galas 1991).

The β-1,3-1,4-glucanase from bacteria belongs to glycosyl hydrolase family 16 (GH16). The β-1,3-1,4-glucanase-encoding genes have been cloned from many Bacillus species such as Bacillus subtilis (Hinchliff and Wendy 1984; van Rensburg et al. 1997; Olsen et al. 1991), Bacillus amyloliquefaciens (Olsen et al. 1991), Bacillus licheniformis (Lloberas et al. 1991), Bacillus macerans (Borriss et al. 1990), Bacillus halodurans (Akita et al. 2005), Bacillus circulans (Kim 2003), and Bacillus polymyxa (Gosalbes et al. 1991) and expressed heterogeneously. The proteins encoded by these genes share a conserved amino acid motif EIDIEF (Meldgaard and Harthill 1994; Michel et al. 2001), in which two glutamic acid residues are involved in the hydrolytic activity (Hahn et al. 1995; Juncosa et al. 1994). Those genes encoding β-1,3-1,4-glucanase from non-Bacillus species such as Clostridium thermocellum (Schimming and Schwarz 1991) and cellulolytic rumen anaerobe Streptococcus bovis (Ekinci et al. 1997; Ekinci and Flint 2001), and F. succinogenes (Wen et al. 2005) have also been isolated and expressed. In addition, many studies on gene and protein engineering of this enzyme have been reported. These works include thermostability improvement by constructing the chimeric β-1,3-1,4-glucanase from B. amyloliquefaciens and B. macerans (Olsen et al. 1991) and improvement of enzyme activity, structural stability, thermotolerance, and catalysis efficiency of F. succinogenes β-1,3-1,4-glucanase by mutagenesis (Chen et al. 2001, 2002) and truncation modification (Wen et al. 2005).

The heterogeneous expression level of β-1,3-1,4-glucanase depends on vector and host strain used (Table 1). The truncation modification special for deletion of all five repeat serine-rich region PXSSSS at the C terminus of F.succinogenes β-1,3-1,4-glucanase (TF-glucanase) resulted in great increment of catalysis efficiency from 2,065 to 7,980 U mg−1 when expressed in E. coli (Wen et al. 2005). Morever, the specific activity of glycosylated TF-glucanase expressed in Pichia pastoris reached 10,800 U mg−1, the most active reported so far as we know (Wen et al. 2005). For industrial use, recombinant β-1,3-1,4-glucanase should have its thermostability as high as the native from B. macerans (Borriss et al. 1990), C. thermocellum (Schimming and Schwarz 1991) and F.succinogenes (Chen et al. 2001, 2002). It shoud be highly expressed on a production scale at low cost (van Rensburg et al. 1997; Akita et al. 2005; Kim 2003; Ekinci et al. 1997; Ekinci and Flint 2001; Wen et al. 2005). We reported in this study the cloning of B. licheniformis β-1,3-1,4-glucanase gene (eg1314) and its expression in E. coli BL21 (DE3).

Materials and methods

Bacterial strains, plasmids and media

The donor strain B. licheniformis EGW039 was registered in Chinese General Microbiological Culture Collection Center (CGMCC 0635) from previous work (stored at our laboratory) (Teng et al. 2005). It is prototrophic and spore-forming and can synthesize and secrete β-1,3-1,4-glucanase. E. coli DH5á (stored at our laboratory) (SupE44 lacU169 hsdR17 recA gray 966 thi-1) and E. coli BL21 (DE3) (Novagen) (F−ompThsdSB (rB−mB−) gal dcm (DE3)) is a λ lysogen of E. coli BL21 wherein the prophage contains the RNA polymerase gene of T7 bacteriophage under the control of the lac UV5 promoter (Studier and Moffatt 1986). Plasmid pET28a(+) and its host strain E. coli (Novagen) [Kan, T7 lac, His tag (N, C), T7 tag (I)] (Dubendorff and Studier 1991) were purchased from Novagen (Beijing, China).

Bacteria were grown at 37°C in Luria–Berntani (LB) medium (Ausubel et al. 1999), dYT medium (Akita et al. 2005), and modified MBL (MMBL) medium (Stemberger 1981). The transformed cells were grown at 37°C on SOC plate (Ausubel et al. 1999) with (30 μg ml−1) or without kanamycin (Sigma) used for selection of plasmid.

Cloning of the gene eg1314 from B. licheniformis EGW 039

Genomic DNA of donor strain B. licheniformis EGW039 (CGMCC 0635) grown in LB medium was prepared according to neutral lysis method (Hirt 1967). The eg1314 gene was amplified by polymerase chain reaction using such DNA as the template and a pair of primers, Pf (5′-ACA ACG GAA TTC ATG CAA ACA GGT GGA TCG TTT TTT G-3′) and Pr (5′-ATA GTT TAG CGG CCG C TTA TTT TTT TGT ATA GCG CAC CCA G-3′). The underlined bases are EcoRI and NotI recognition sites, respectively. The amplified product was purified using PCR purification kit (QIAGEN) and sequenced by Shanghai BioAsia Biotechonology Co. (Shanghai, China).

Construction of expression vector

The PCR fragments containing eg1314 (2 μg) were double-digested in a 100 μl volume consisting of 60 μl PCR product, 10 μl 10×EcoRI buffer, 3 μl EcoRI (10 U μl−1, NEB) and 2 μl NotI (5 U μl−1, NEB), 1 μl 100×BSA (100 μg ml−1), 24 μl dH2O at 37°C for 3 h. The gene was purified and ligated with pET28a(+) (3 μg) open by the same enzymes at 16°C for 30 min, yielding an expression vector pET28a(+)-eg1314. The ligation system contained 2-μl purified PCR fragment, 1 μl linearized pET28a, 2 μl dH2O, and 5 μl Ligation Solution I (TakaRa).

The competent cells were freshly prepared by the CaCl2 method (Ausubel et al. 1999). A 10 μl DNA ligation product was mixed with 100 μl of competent cells, incubated on ice for 30 min, and heat shocked at 42°C for 2 min. After adding 900 μl LB medium and incubating at 37°C for 60 min, 100 μl of transformed cells was inoculated on SOC plate (Ausubel et al. 1999) containing 30 μg ml−1 kanamycin. The plate was incubated at 37°C for 16 h.

Colony PCR screening of the recombinant

Colony PCR screening of the positive recombinant was performed according to pET System Manual (10th edn, TB055 Rev B 0403, Novagen, 2003) and reference (Ausubel et al. 1999). In a 25-μl PCR mixture, some bacterial cells picked with a pipette tip were mixed with 5 pmol l−1 T7 promoter primer, 5 pmol l−1 of T7 terminator primer, 0.5 μl dNTPs (2.5 mmol l−1 each), 1.0 μl Taq DNA polymerase (2.5 U μl−1), and 2.5 μl 10× PCR buffer. The parameters of 30 cycles PCR were denaturing at 94°C for 1 min, annealing at 55°C for 1 min, and extension at 72°C for 1 min. Five-microliter PCR product was loaded onto 1.0% agarose gel and separated at 100 V constant voltage using the DYY-2C electrophoresis system (Beijing Liuyi Life Science Instrument, Beijing, China). The positive plasmid DNAs were extracted and sequenced.

Expression and electrophoresis of recombinant enzyme

The E. coli BL21 (DE3) containing pET28a(+)-eg1314 cultured overnight was inoculated at 5% ratio into 30 ml dYT (Kan 30 μg ml−1) or 30 ml MMBL medium (Kan 30 μg ml−1) in a 150 ml conical flask and cultured at 37°C in a shaker set at 250 rpm until the culture reached a logarithmic phase (OD600=0.40–0.60). Isopropyl-β-d-thiogalactoside (IPTG, Merck) was added to a final concentration of 1 mmol l−1 and the temperature was adjusted down to 30°C. After 4 h of induction, a 1 ml culture was pelleted down by centrifuging at 8,000 rpm for 5 min. The cell pellet was resuspended in 60 μl of 20 mmol l−1 PBS (140 mmol l−1 NaCl, 2.7 mmol l−1 KCl, 10 mmol l−1 Na2HPO4, 1.8 mmol l−1 KH2PO4, pH 7.3) and denatured in 5× denaturing buffer [60 mmol l−1 Tris–HCl, 25% glycerol, 2% sodium dodecyl sulfate (SDS) (Sigma), 0.1% bromophenol blue] at 100°C for 10 min. After centrifugation at 12,000 rpm for 5 min, 15 μl of supernatant was loaded onto a 12.0% SDS–polyacrylamide gel and the gel was run at 80 and 180 V constant voltage for protein concentration and separation gel, respectively, using the Mini-protean III system (Bio-Rad, Beijing, China). Protein bands were visualized by Coomassie brilliant blue R-250 staining (Ausubel et al. 1999).

Purification of the recombinant β-1,3-1,4-glucanase

The cell pellet was gently resuspended in 4 ml of BugBuster Protein Extract Reagent containing 1.0 μl of benzonase (25 U μl−1, Novagen) and 5 μl of lysozyme (10 mg ml−1, Amresco) and kept at room temperature for 20 min. After centrifugation at 12,000 rpm for 5 min, the supernatant was gently mixed with 1 ml 50% Ni–NTA His bind resin (Novagen) pre-washed with Ni–NTA bind buffer (300 mmol l−1, 50 mmol l−1 sodium phosphate, 10 mmol l−1 imidazole, pH 8.0). the mixture was incubated at 4°C for 60 min and loaded onto an empty column (Novagen). After washing with 4 ml wash buffer (300 mmol l−1 NaCl, 50 mmol l−1 sodium phosphate, 20 mmol l−1 imidazole, pH 8.0) twice, the recombinant protein was eluted with 4× 0.5 ml elute buffer (300 mmol l−1 NaCl, 50 mmol l−1 sodium phosphate, 50 mmol l−1 imidazole, pH 8.0). Fractions were collected and analyzed using SDS-polyarylamide gel electrophoresis (PAGE). The protein concentration and proportion were assayed by Bradford (1976) method and Glyko BandScan Version 5.0, respectively.

Assay for β-1,3-1,4-glucanase activity

The β-1,3-1,4-glucanase activity was assayed using 1% (w/v) barley β-glucan (Sigma), 1% (w/v) lichenan (Sigma), and 1% (w/v) CM-cellulose (Sigma) as the substrate, respectively. Reducing sugar content was measured using the 3,5-dinitrosalicylic acid (DNS) method (Miller 1959). The assay was carried out at 40°C for 10 min in 1-ml volume containing appropriate amount of enzyme solution and 1% substrate (w/v) dissolved in 0.05 mol l−1 sodium acetate, pH 5.6. One activity unit was defined as the amount of enzyme needed for releasing 1 μmol reducing sugar from β-glucan per minute (using glucose as the reference). The assay of intracellular activity was measured using the diluted cell lysate supernatant with 0.05 mol l−1 sodium acetate buffer (pH 5.6). The extracellular activity was measured for culture using DNS method as well, which were verified further according to the transparent zone formed on a plate of barley powder. Accordingly, the specific activity of the enzyme was calculated from the protein concentration and the activity determined.

Results

Cloning of eg1314

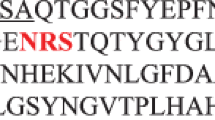

The β-1,3-1,4-glucanase gene was PCR-cloned from B. licheniformis EGW039 using the genomic DNA as the template. The eg1314 PCR DNA fragment was about 650 bp (not shown) and registered with GenBank accession no. 160109. The sequencing result is presented in Fig. 1. The open reading frame of 645 bp encodes 215 amino acids with a calculated molecular weight of 23.6 kDa. The conserved motif EIDIEF of glycoside hydrolase family 16 (Michel et al. 2001) was found (Fig. 1). The DNA sequence similarities of gene eg1314 cloned are 90, 80, 34, and 44% to those of B. subtilis, B. alkalophilus, B. circulans, and truncated F. succinogenes β-1,3-1,4-glucanase, respectively (van Rensburg et al. 1997; Borriss et al. 1990; Chen et al. 2001). Their corresponding protein similarities are 83, 55, 22, and 34%, respectively.

Construction of the expression vector

The PCR fragments containing eg1314 were digested with restriction enzymes EcoRI and NotI (NEB), and ligated into pET28a(+) digested with the same pair of restriction enzymes. The resulting plasmid pET28a-eg1314 as the expression vector was then transformed into E. coli BL21 (DE3). The positive construct was confirmed and chosen by PCR and sequencing analysis.

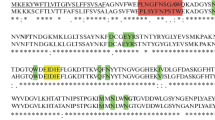

SDS-PAGE analysis of the recombinant β-1,3-1,4-glucanase

E.coli BL21 (DE3) (control 1) and E.coli BL21 (DE3) harboring empty vector (control 2) and recombinant vector pET28a(+)-eg1314 were cultured and induced. As shown in Fig. 2, among the profiles of SDS-PAGE bands with Coomassie brilliant blue R-250 staining of the recombinant and two controls, only the cells containing recombinant vector pET28a(+)-eg1314 expressed an extra 28-kDa protein band. This is recombinant β-1,3-1,4-glucanase, about 4.0-kDa heavier than 23.6 kDa of the native. This difference resulted from the N terminus extra 36 amino acids including six-His tag coded by a fragment between 192 and 299 upstream of the forward insert site EcoRI. Based on SDS-PAGE and Glyko BandScan Version 5.0 analyses, the amount of the recombinant β-1,3-1,4-glucanase accounted for about 60.9% (159.86:262.50 mg l−1) of the total protein in the crude lysate (Fig. 2). It revealed that the recombinant β-1,3-1,4-glucanase was dominantly expressed in E. coli under the control of T7 lac promoter in a favorable way over non-target proteins.

SDS-PAGE analysis for crude protein extract from recombinant cell lysate. Lane 1 The protein MW marker, from top to bottom: 94.0, 66.2, 45.0, 35.0, 28.5, 20.0, and 14.4 kDa; lane 2 the cell lysate band of E. coli BL21 induced by IPTG as a control 1; lane3 the cell lysate band of E. coli BL21/pET28a by IPTG as a control 2; lanes 4, 5, and 6 repetition samples from the cell lysate of E. coli BL21/pET28a-eg1314

Purification of recombinant β-1,3-1,4-glucanase

The Ni–NTA His bind resin (Novagen) was used for the purification of the His tag recombinant β-1,3-1,4-glucanase. The eluted fractions were analyzed by SDS-PAGE. It was shown in Fig. 3 that the yield of purified recombinant β-1,3-1,4-glucanase can reach 50.26 mg g−1 (cell, FW), which is about 12.5% (23.88:191.00 mg l−1) of total soluble protein of cell lysate supernatant. It was estimated that about 70% of recombinant protein formed the inclusion body. As determined (Fig. 3, Table 2), the soluble recombinant protein was effectively purified; as high as 82.7% of the soluble protein was recovered and purified 8.74-folds (Fig. 3, Table 2). The specific activity of the purified enzyme was 2,479 and 1,906 U mg−1 for 1% (w/v) β-glucan (Sigma) and 1% (w/v) lichenan, respectively, being within the range reported (Table 1).

Substrate specificity of recombinant enzyme

The substrate specificities of the recombinant enzyme for β-glucan, lichenan, and CM-cellulose (Sigma) were determined. The activities in dYT medium towards 1% (w/v) β-glucan and 1% (w/v) lichenan were 610 and 473 U ml−1, respectively, and that in MMBL medium towards 1% β-glucan and 1% lichenan were 1,286 and 986 U ml−1, respectively. In contrast, activity against 1% CM-cellulose was not observed. The recombinant enzyme showed high substrate/bond specificity. The activity of this enzyme for β-glucan is much higher than that for lichenan, probably due to the difference in the numbers of β-1,3 and β-1,4 glycosidic bonds and their distribution. It is known that β-glucan and lichenan have both β-1,3 and β-1,4 glycosidic lineages (Parrish et al. 1960; Wolf et al. 1995; Bielecki and Galas 1991), but the ratio of the β-1,3 and β-1,4 glycosidic bonds is 1:3 for β-glucan and 2:1 for lichenan, respectively (Akita et al. 2005). It is possible that more β-1,4 glycosidic bonds in β-glucan contribute to the higher activity observed.

An obvious transparent zone was observed on the assaying plate stained with Congo red (Fig. 4), indicating that E. coli BL21 containing pET28a-eg1314 can secrete β-1,3-1,4-glucanase into the medium despite the fact that only 3.64 U ml−1 of extracellular activity in MMBL medium for 1% barley glucan was detected. In addition, such assaying suggested also that the β-1,3-1,4-glucanase digests barley glucan and lichenan but CMC (plate assaying for lichenan and CMC are not shown). In contrast, endo-β-1,4-glucanase hydrolyzes all the three substrates (Bielecki and Galas 1991). In fact, the crude culture mixture of B. licheniformis EGW039 showed hydrolysis activity on glucan, lichenan, and CMC plate respectively (not shown), indicating that the bacterium secreted both β-1,3-1,4-glucanase and cellulase into one’s plate. This unique substrate/bond specificity of enzyme should benefit its quick isolation and screening.

Hydrolysis transparent zone of secreted β-1,3-1,4-glucanase on barley powder plate observed after induction. 1E. coli BL21, 2E. coli BL21/pET28a, 3E. coli BL21/ pET28a-eg1314. E. coli BL21, E. coli BL21/pET28a, and E. coli BL21/ pET28a-eg1314 were grown on plate for 24 h at 37°C and subjected to IPTG induction for 48 h at 30°C on LB plate (1% barley powder and 1 mmol l−1 IPTG) and followed by Congo red reaction for 1 h, then washed with 1 mol l−1 NaCl to clear away spare Congo red not binding with the barley glucan

Properties of recombinant β-1,3-1,4-glucanase

The temperature and acidity dependencies of the recombinant β-1,3-1,4-glucanase were determined. The measuring reaction was run for 10 min. The activity of the recombinant β-1,3-1,4-glucanase activity for 1% barley glucan in 0.05 mol l−1NaAc–HAc buffer (pH 5.6) was measured at 30, 40, 45, 50, 55, 60, 70, and 80°C for 10 min, respectively. Such activity was also determined in an acidity range (pH 3.0–8.0) formed by Na2HPO4–citrate buffer system at 40°C. From above, the optimal temperature and acidity for recombinant β-1,3-1,4-glucanase expressed in E. coli are 40°C and pH 5.6, respectively (Figs. 5 and 6). The recombinant enzyme remained with 50% activity at 70°C for 10 min, exhibiting a higher thermostability for industrial use (Fig. 5).

Discussion

B. licheniformis β-1,3-1,4-glucanase-encoding gene was successfully inserted into pET 28a and expressed in E. coli BL21 (DE3). The recombinant β-1,3-1,4-glucanase accounted for 60.9% of the total crude protein. The intracellular activities of recombinant β-1,3-1,4-glucanase are 1,286 and 986 U ml−1 for β-glucan and lichenan, respectively. This expression efficiency was as high as expected for pET system in which T7 RNA polymerase is selective and active that, when fully induced, almost all of the cell’s resources can be converted to target gene expression. The desired expressed product can comprise more than 50% of the total cell protein a few hours after induction (Studier and Moffatt 1986; Dubendorff and Studier 1991).The codon bias of E. coli will certainly affect the expression of foreign β-1,3-1,4-glucanase-encoding gene; therefore, codon modification is necessary, at least for the improvement of expression efficiency (Olsen et al. 1991; Schimming and Schwarz 1991; Supek and Vlahovicek 2005).

In this study, about 70% of the recombinant β-1,3-1,4-glucanase existed in the form of inclusion body, probably resulting from overexpression of this target gene (Teng et al. 2005). In addition, significant differences of specific activity and substrate specificity were found between our findings and those of Akita et al. (2005). They expressed B. halodurans C-125 β-1,3-1,4-glucanase in E. coli BL21 (DE3) using pET-15b. The specific activity obtained in this study was 34 times higher than what they obtained. For 1% lichenan, such difference was 23 times. The reasons for this difference were not clear. Intensive studies should be focused on understanding mechanism of protein secretion and inclusion body formation.

The substrate specificity of this recombinant enzyme was different with substrates. The activities were 1,286 and 986 U ml−1 on β-glucan and lichenan, respectively, which is similar to those reported by Kim (2003). This substrate specificity may relate to different numbers of β-1,3 and β-1,4 glycosidic linkages, branching mode, and their distribution among these substrates. It is known that the ratio of the β-1,3 and β-1,4 glycosidic bonds is 1:3 for β-glucan and 2:1 for lichenan (Parrish et al. 1960; Wolf et al. 1995; Bielecki and Galas 1991; Akita et al. 2005). The activity of the recombinant enzyme was proportional to the number of β-1,4 bonds in β-glucan or lichenan.

In another aspect, the optimal temperature for the recombinant β-1,3-1,4-glucanases expressed in E. coli BL 21 (Fig. 5), in yeast Pichia methanolica (Teng et al. 2005), and in the native one of B.licheniformis EGW039 were 40, 55, and 37°C, respectively; There was not a significant difference between the native and the recombinant forms expressed in E. coli BL 21. The recombinant enzyme was very interestingly found to remain with 50% activity at 70°C for 10 min. Such higher thermostability may be explained by its structural feature. Five key amino acids, Gly113, Trp104, Trp152, Trp159, and Trp209, were located similarly to Gly63, Trp54, Trp141, Trp148, and Trp203 of F.succinogenes β-1,3-1,4-glucanase (Chen et al. 2001; 2002). Glycosylation in yeast expression system may contribute to the increase of thermostability from 37 to 55°C as the optimal temperature showed (Meldgaard and Harthill 1994). Three potential glycosylation sites at Asn32, Asn39, and Asn65 of the deduced amino acid sequence of β-1,3-1,4-glucanase were predicable on the basis of the consensus sequence of protein glycosylation, Asn-Xaa-Ser/Thr, where Xaa can be any amino acid except for Pro (Cereghino and Cregg 2000; Teng et al. 2005) (Fig. 1). This prediction was similar to what was made by Wen et al. (2005) for recombinant truncated β-1,3-1,4-glucanase. Two potential N-glycosylation sites, Asn44 and Asn129, may contribute to the significant improvement of thermotelerance of the truncated β-1,3-1,4-glucanase expressed in P.pastoris.

The optimum reaction acidities of the native β-1,3-1,4-glucanase of B.licheniformis EGW039 and the recombinant enzymes expressed in E. coli BL 21 (Fig. 6) and P.methanolica (Teng et al. 2005) were interestingly retained the same, pH 5.6. It was lower than the optimum reaction acidity range (pH 6–8) of the native from F.succinogenes and those of two recombinant truncated enzymes expressed in yeast and E. coli (Wen et al. 2005). The difference in optimum reaction acidity may be explained by the source difference of genes.

As feed additive applicable in animal husbandry, the enzymes including β-1,3-1,4- glucanase with lower optimum reaction acidity and higher thermostability are more attractive to users because they are much more suitable for animal utilization.

References

Akita M, Kaytama K, Hatada Y, Ito S, Horikoshi K (2005) A novel β-glucanase gene from Bacillus halodurans C-125. FEMS Microbiol Lett 248:9–15

Anderson MA, Stone BA (1975) A new substrate for investigating the specifity of beta-glucan hydrolases. FEBS Lett 52:202–207

Ausubel FM, Brent R, Kingston RE, Moore DD (1999) Short protocols in molecular biology, 4th edn. Wiley, New York

Bielecki S, Galas E (1991) Microbial β-glucanase different from cellulases. Crit Rev Biotechnol 10:275–305

Borriss R, Buettner K, Maentsaelae P (1990) Structure of the β-1,3-1,4- glucanase of Bacillus macerans: homologies to other β-glucanase. Mol Gen Genet 222:278–283

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Cereghino JL, Cregg JM (2000) Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol Rev 24:45–66

Chen JL, Tsai LC, Wen TN, Tang JB, Yuan HS, Shyur LF (2001) Directed mutagenesis of specific active site residues on Fibrobacter succinogenes 1,3-1,4- β-glucanase significantly affects catalysis and enzyme structural stability. J Biol Chem 276:17895–17901

Cheng HL, Tsai LC, Lin SS, Yuan HS, Yang NS, Lee SH, Shyur LF (2002) Mutagenesis of Trp(54) and Trp(203) residues on Fibrobacter succinogenes 1,3-1,4-beta-d- glucanase significantly affects catalytic activities of the enzyme. Biochemistry 41:8759–8766

Dubendorff JW, Studier FW (1991) Controlling basal expression in an inducible T7 expression system by blocking the target T7 promoter with lac repressor. J Mol Biol 219:45–59

Ekinci MS, Flint HJ (2001) Expression of bifunctional genes encoding xylanase and β(1,3-1,4)-glucanase in Gram-positive bacteria. Turk J Vet Anim Sci 25:771–775

Ekinci MS, Mccrae SI, Flint HJ (1997) Isolation and overexpression of a gene encoding an extracellular 1,3-1,4-glucanase from Streptococcus bovis. Appl Environ Microbiol 63:3752–3756

Gosalbes MJ, Perez-Gonzalez JA, Gonzalez R, Navarro A (1991) Two β-glucanase genes are clustered in Bacillus polymyxa molecular cloning, expression, and sequence analysis of genes encoding a xylanase and an endo-β-(1,3)-(1,4)- glucanase. J Bacteriol 9:7705–7710

Hahn M, Olsen O, Politz O, Borriss R, Heinemann U (1995) Crystal structure and site-directed mutagenesis of Bacillus maceransendo-1,3-1,4-glucanase. J Biol Chem 270:3081–3088

Hinchliff E, Wendy GB (1984) Expression of the cloned endo-β-1,3-1,4-glucanase gene of Bacillus subtilis in Saccharomyces cerevisiae. Curr Genet 8:471–475

Hirt B (1967) Selective extraction of polyoma DNA from infected mouse cell culture. J Mol Biol 26:365–369

Juncosa M, Pons J, Dot T, Querol E, Planas A (1994) Identification of active site carboxylic residues in Bacillus licheniformis 1,3-1,4-beta-d-glucan 4- glucanohydrolase by site-directed mutagenesis. J Biol Chem 269:14530–14535

Kim JY (2003) Overproduction and secretion of Bacillus circulansendo-β-1,3-1,4- glucanase gene (bglBC1) in B. subtilis and B. megaterium. Biotechnol Lett 25:1445–1449

Li S, Sauer WC, Huang SX, Gabert VI (1996) Effect of beta-glucanase supplementation to hulless barley- or wheat-soybean meal diets on the digestibilities of energy, protein, beta-glucans and amino acid in young pigs. J Anim Sci 74:1649–1656

Lloberas J, Perez-Pons JA, Querol E (1991) Molecular cloning, expression and nucleotide sequence of the endo-β-1,3-1,4-d-glucanase gene from Bacillus licheniformis. Eur J Biochem 197:337–343

Mathlouthi N, Serge MS, Luc S, Bernard Q, Michel L (2002) Effects of xylanase and β-glucanase addition on performance, nutrient digestibility, and physico-chemical conditions in the small intestine contents and faecal microflora of broiler chickens fed a wheat and barley-based diet. Anim Res 51:395–406

Meldgaard M, Harthill J (1994) Different effect of N-glycosylation on the thermostability of highly homologous bacterial (1,3-1,4)-beta-glucanase secreted from yeast. Microbiology 140:153–157

Michel G, Chantalat L, Duee E, Barbeyron T, Henrissat B, Kloareg B, Dideberg O (2001) The kappa-carrageenase of P.carrageenovora features a tunnel-shaped active site: a novel insight in the evolution of Clan-B glycoside hydrolases. Structure (Camb) 9:513–525

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Olsen O, Borriss R, Simon O, Thomsen KK (1991) Hybrid Bacillus (1-3,1-4)-β-glucanase: engineering thermostable enzymes by construction of hybrid genes. Mol Gen Genet 225:177–185

Parrish FW, Perlin AS, Reese ET (1960) Selective enzymolysis of poly-β-d glucan, and the structure of the polymers. Can J Chem 38:2094–2104

Planas A (2000) Bacterial 1,3-1,4-β-glucanases: structure, function and protein engineering. Biochim Biophys Acta 1543:361–382

Schimming S, Schwarz WH (1991) Properties of a thermoactive β-1,3-1,4-glucanase (lichenase) from Clostridium thermocellum expressed in Escherichia coli. Biochem Biophys Res Commun 177:447–452

Stemberger RS (1981) A general approach to the culture of planktonic rotifers. Can J Fish Aquat Sci 38:721–724

Studier FW, Moffatt BA (1986) Use of bacteriophage T7 RNA polymerase to direct selective high-level expression of cloned genes. J Mol Biol 189:113–130

Supek F, Vlahovicek K (2005) Comparison of codon usage measures and their applicability in prediction of microbial gene expressivity. BMC Bioinformatics DOI 10.1186/1471-2105-6-182

Teng D, Wang JH, Yao Y, Yang YL, Liu LH (2005) Cloning and expression of Bacillus licheniformis EG039 beta-1,3-1,4-glucanase in Pichia methanolica. In: Wang Jianhua (eds) Research and development of the new safe feed additives. China Science, Beijing, pp 102–109

van Rensburg P, van Zyl WH, Pretorius IS (1997) Over-expression of the Saccharomyces cerevisiaeexo-β-1,3-glucanase gene together with the Bacillus subtilis endo-β-1,3-1,4-glucanase gene and the Butyrivibrio fibrisolvensendo-β-1,4-glucanase gene in yeast. J Biotechnol 55:43–53

Wen TN, Chen JL, Lee SH, Yang NS, Shyur LF (2005) A truncated Fibrobacter succinogenes 1,3-1,4-β-glucanase with improved enzymatic activity and thermotolerance. Biochemistry 44:9197–9205

Wolf M, Geczi A, Simon O, Borriss R (1995) Genes encoding xylan and β-glucan hydrolyzing enzyme in Bacillus subtilis: characterization, mapping and construction of strain deficient in lichenase, cellulose and xylanase. Microbiology 4:281–290

Acknowledgement

This project is funded by the Chinese National Hi-Tech R&D Program (Chinese 863 Program No. 2001 AA 246041 and 2004 AA 246040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teng, D., Wang, Jh., Fan, Y. et al. Cloning of β-1,3-1,4-glucanase gene from Bacillus licheniformis EGW039 (CGMCC 0635) and its expression in Escherichia coli BL21 (DE3). Appl Microbiol Biotechnol 72, 705–712 (2006). https://doi.org/10.1007/s00253-006-0329-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0329-2