Abstract

The aim of this study was to characterize the chemical composition of different granulometric fractions obtained by milling of the bark of two softwood [Norway spruce, Picea abies (L.) Karst., and Scots pine, Pinus sylvestris L.] and two hardwood species (birch, Betula pendula Roth, and eucalypt, Eucalyptus globulus Labill.), and to discriminate between them on the basis of their chemical composition content via pattern recognition techniques [principal component analysis (PCA), cluster analysis (CA), and discriminant analysis (DA)]. Bark chemical composition differed between species, and chemical variables could be used to differentiate between them. Size reduction yields granulometric fractions that are not chemically homogeneous and that can also be discriminated. Therefore, potential applications of bark in valorization programs have to carefully consider the species-specific composition and their size reduction patterns. PCA and CA were adequate tools to characterize the different bark fractions within each species. DA allowed identifying the bark samples according to species and independently from particle size. Pattern recognition statistical methods were shown to be useful tools to analyse bark fractions and chemically discriminate species and fractions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tree bark is an important residual biomass arising from forestry operations and industrial processing of wood stems for timber or pulping. The present availability of bark in the mills where logs are debarked is very large (representing about 12 million m3 in Europe), while its actual use is mostly only as solid biofuel. However, barks have a high potential as a biomass resource for biorefineries that allow considering different conversion platforms (Demirbas 2001).

Due to their structural and chemical complexity, barks feature a large diversity allowing their use as chemical feedstock in various fields, from pharmaceutical and bioactive compounds to green polymers and bio-based materials industries (Conde et al. 1996; Pietarinen et al. 2006; Pizzi 2008; Sen et al. 2010; Valentín et al. 2010). The knowledge of bark structural and chemical features is, however, very limited.

The analysis of bark is complex, and sampling, characterization and processing have specificities that should be taken into account prior to valorization. Fractionation into small sized particles, a unit operation usually involved in biomass pre-processing, is one example. In addition to the usual objectives of increasing accessible surface area, eliminating mass and heat transfer limitations and facilitating digestibility and hydrolysis, fractioning may also allow separating fractions with specific compositions (Silva et al. 2011). The bark heterogeneity also induces different grinding behaviour with separation of granulometric fractions that may be selectively enriched in certain types of tissues and chemical compounds, thereby allowing more focused applications. This line of work has been recently explored for several hardwood and softwood barks, and fractionation was proposed as a pre-treatment prior to further bark processing (Miranda et al. 2012, 2013; Baptista et al. 2013).

In this study, a chemometric approach via pattern recognition techniques (principal component analysis, cluster analysis, and discriminant analysis) was used to handle multivariate data concerning chemical composition of different granulometric fractions obtained from solid bark of several species by milling and to discriminate between them. This type of statistical tool is increasingly used to interpret multivariate data for application in different fields, such as authentication and classification of agricultural products (e.g. vegetables, fruits, wines, juices, cereals, bakery products, vegetable oils, tea, coffees, salad dressings) (Tzouros and Arvanitoyannis 2001; Brodnjak-Voncina et al. 2005; Matos et al. 2007; Ruiz-Méndez et al. 2008), discrimination between Quercus species based on acorns oil content and composition (Ferreira-Dias et al. 2003), between lipase-catalysed or chemically interesterified fat blends to be incorporated into margarines (Pires et al. 2008) or between cardoon plants grown in different stands based on seed oil content and chemical composition (Pereira et al. 2012).

It is the aim of this work to test whether such a chemometric approach is useful for chemical differentiation between barks and granulometric fractions and may therefore be envisaged as a didactical tool for the prospective study of the potential of bark (or other materials) regarding different conversion routes and targeted chemicals within a forest biorefinery platform.

Materials and methods

Sampling

The grinding behaviour and characterization of granulated fractions were studied on bark samples from two softwood and two hardwood species: Norway spruce (Picea abies L. Karst.), Scots pine (Pinus sylvestris L.), birch (Betula pendula Roth), and eucalypt (Eucalyptus globulus Labill.). The barks were obtained as material removed by stem debarking in pulp mills and were provided by Södra (Sweden) and Celbi (Portugal).

Fractioning

Fractioning of bark was made by laboratorial-scale grinding after air-drying at ambient conditions (25 days at 20 °C) using a knife mill (Retsch SM 2000) with an output sieve of 10 × 10 mm2 and screened using a vibratory sieving apparatus. The following sieve mesh sizes were used: 80 (0.180 mm), 60 (0.250 mm), 40 (0.45 mm), 20 (0.850 mm), 15 (1.0 mm), and 10 (2.0 mm). The samples were coded B, E, P, S for birch, eucalypt, pine, and spruce bark, respectively, and 1–7 for the granulometric fractions of >80 mesh, 60–80 mesh, 40–60 mesh, 20–40 mesh, 20–25 mesh, 10–15 mesh, and <10 mesh.

Chemical characterization

Prior to chemical analysis, the granulometric fractions with a particle size over 40 mesh (20–40, 15–20, 10–15, and <10 mesh) were carefully ground to obtain particles that passed through the 40-mesh sieve. Determination of chemical composition included the following: ash content after incineration; extractives content using successive Soxhlet extractions with different polarity solvents (dichloromethane, ethanol and water); total lignin content using a standard acid hydrolysis on the extractive-free material. The cell wall polysaccharides were determined as holocellulose of the extractive-free samples using the chlorite method (Rowell 2005). Each chemical determination was made in duplicated samples.

Statistical analysis

Principal components analysis (PCA), cluster analysis (CA), and discriminant analysis (DA) were used to analyse the chemical composition of the seven granulometric fractions obtained from the samples of the four barks. PCA, CA, and DA were performed using the software Statistica™, version 6, from Statsoft, Tulsa, USA.

PCA is an unsupervised pattern recognition technique, aimed at best describing the shape of a multivariate distribution by considering selected linear combinations of the original variables, instead of the original variables (Bofinger 1975). The initial system of m axis (one for each variable) is replaced by another system where the new axes are the principal components, uncorrelated with each other. The first component shows the maximum correlation with all the original variables and explains the highest proportion of the global variance. This method allows the geometric representation of the original objects (in this case the bark fractions) in a space of reduced dimensions defined by a new set of axis (principal components) and, consequently, the identification of groups of similar samples. It may also provide a particular interpretation of the components and subsequently of the original variables (Alvin 2002).

The second stage of multivariate data analysis consisted of a CA on the data matrices in order to confirm the groups of samples suggested by PCA. The single linkage method was used as coefficient of comparison while the Euclidean distance was used as coefficient of similarity between samples in the 7-dimensional hyperspace. In the single linkage method, the distance (similarity) between two clusters, A and B, is defined as the minimum distance between the nearest neighbours. At each step, the distance was found for every pair of clusters, and the two clusters with the smallest distance (i.e. the largest similarity) were merged. After merging the two clusters, the procedure was repeated for the next step; the distances between all pairs of clusters were recalculated, and the pair with the minimum distance was merged into a single cluster. The results of a hierarchical clustering procedure can be displayed graphically using a dendrogram, which shows all the steps in the hierarchical procedure (Alvin 2002; Mirkin 1996).

For PCA and CA analysis, one 7 × 6 matrix for each species was performed: seven samples, corresponding to the seven granulometric fractions characterized by 6 variables corresponding to the chemical composition variables (ash, dichloromethane, ethanol and water extracts, lignin, and holocellulose).

After PCA and CA, a DA was used on a 28 × 6 matrix, containing all the samples characterized by their chemical composition, to determine which variables discriminate between the groups of the different species a priori defined (Burgard and Kuznicki 1990; Morrison 1967). Discriminant analysis is a supervised pattern recognition technique since the membership is known, and the objective is to find a rule for allocating a new object of unknown group to the correct group. The basic underlying idea is to see whether groups differ with regard to the mean of a variable and then use that variable to predict group membership. The procedure is identical to the one-way analysis of variance or to the multivariate analysis of variance if several variables are used (Bofinger 1975; Burgard and Kuznicki 1990).

The discrimination model was built by forward stepwise analysis using the following options: tolerance of 0.010; F to enter equal to 1.00; and F to remove equal to 0.00. At each step, it was evaluated which variable would contribute most to the discrimination between groups. That variable would then be included in the model, beginning the next step. The maximum number of discriminant functions (or canonical roots) will be equal to the number of groups minus one or to the number of variables in the analysis, whichever is smaller. The best combination of variables for DA includes variables that represent independent measures of product similarities and differences. In addition, the classification functions can be used to determine to which group each case most likely belongs. The classification matrix shows the number of cases that were correctly classified and those that were misclassified.

Results

Effect of particle size on chemical composition

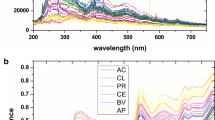

The chemical composition of the seven granulometric fractions (from >80 to <10 mesh) obtained by grinding of the four barks is given in Table 1. The data show that there are differences between species and fractions. The first analysis was made on the bark of each species using principal component and cluster analyses to differentiate granulometric fractions upon their chemical composition.

Birch bark

The principal component analysis of the birch matrix showed that 81 % of the total variance of the chemical data could be explained by the first two principal components (PC1 and PC2). The plot of the samples onto the plane defined by these factors suggests a partial separation of samples into two groups: the first principal component factor allowed separating the fractions with smaller particles [B1 and B2] from the medium and higher particle sizes [B3, B4, B5, B6, and B7] (Fig. 1a). The fine fractions are mainly located in the positive region of PC1 because of their higher ash and extractives contents. The other fractions are plotted mainly in the negative region of PC1 due to their higher holocellulose and lignin contents (Fig. 1b). This classification showed that for birch bark the fine particle sized fractions are chemically different from the medium and coarse fractions.

Principal component analysis of chemical composition of the different granulometric fractions obtained by grinding of birch and eucalypt barks: a Graph of scores plot and b of loads plot of birch bark; c: Graph of scores plot and d of loads plot of eucalypt bark on the plane defined by the first two principal components

Agglomerative hierarchical CA resulted in dendrograms, as shown in Fig. 2. This analysis confirms the possibility of grouping the seven granulometric fractions of birch bark at a linkage distance of about 5.5 into the two clusters suggested by PCA (Fig. 2a).

Eucalypt bark

By PCA, the eucalypt data can be represented on a plane defined by the first two factors with 97 % of variance, which means that only about 3 % of the information contained in the original data is lost. As also observed for the birch bark samples, the fine fractions seem to be separated from the medium and coarse fractions (Fig. 1c). PCA score plot showed a separation in different quadrants similar to that observed for birch bark, except for the amount of lignin (Fig. 1d). The contents of extractives and ash were the variables that contributed most to the separation and chemical differentiation of the fractions. The fine fractions concentrated higher amounts of ash, extractives, and lignin, while holocellulose content showed an increased proportion in the coarse fraction (Fig. 1c, d).

The dendrogram resulting from the agglomerative hierarchical CA for the eucalypt data confirms the presence of the following groups at a linkage distance of about 10: a group formed by medium and coarse fractions (samples E4–E7), another with samples E2 and E3, and E1 as an isolated sample (Fig. 2b).

Pine bark

For the pine bark data, the first and second PC were found to describe 49 and 28 % of the variation, respectively, i.e. the first plane accounts for about 77 % of the information in the original data. The scores plot showed that the first PC separated fractions with smaller particle sizes from higher particle size fractions (Fig. 3a, b). The fine fractions were mainly located in the positive region and characterized by higher ethanol extractives and ash contents. The coarse fractions were plotted mainly in the negative region of the first principal component due to their higher lignin and holocellulose contents.

Cluster analysis of pine bark fractions showed a tendency to group the granulometric fractions (P4–P7) according to the respective chemical composition (Fig. 4a).

Spruce bark

PCA of spruce data, although not allowing a clear separation of the fractions associated with the particle sizes, showed a tendency (Fig. 3c, d) to the finer fractions (S1 and S3) mainly located in the positive region of the second principal component, related with higher average values of ethanol extractives and ash contents. S1 fraction is also characterized by a high content of dichloromethane extractives. The fractions with medium particle sizes (S4 and S5) are located in the positive region of the second principal component due to their higher lignin content. The sample with coarse particles (S6) was located in the positive region of the first principal component due to the higher polysaccharide and water extractives contents.

The following groups are suggested by CA for the spruce bark samples at a linkage distance of about 4.5: a group containing some medium and coarse particle fractions (S2, S4, S5, S7), a group with S3 and S6, while the finest fraction (S1) appears isolated from the others (Fig. 4b).

Sample characterization by DA

When a PCA was performed on a matrix containing all the bark fractions from the four species and the scores of these samples were plotted as a function of PC1 versus PC2 (71 % of variance), the segregation between samples from each species was not complete (data not shown). Therefore, a DA, which is a more specific tool for discrimination, was used to discriminate between the four different tree species (Ruiz-Méndez et al. 2008). A matrix containing the 28 samples, identified by the group (species) to which they really belong (birch, eucalypt, pine, or spruce), was used.

Table 2 presents the coefficients of the linear classification functions, derived by stepwise DA, describing each bark species. In these functions, all the six original variables showed to have discriminant power among samples from the different species. These functions can be used to determine to which group each case most likely belongs.

When comparing the observed classifications with those predicted by these classification functions (Table 3), 96.4 % of the samples were correctly classified into the four groups a priori defined. Only one pine sample (P1) was misclassified as a spruce sample. Figure 5 shows the projections of the bark samples on the planes defined by the canonical roots 1 and 2, and 1 and 3 for the four groups a priori defined. In both plots, the clustering of the samples into the groups previously defined is well illustrated.

Discussion

The bark samples of the four species have distinguishable differences in their chemical composition (Table 1). For instance, a considerable difference is shown for eucalypt bark which is characterized by a high holocellulose content (on average 56.3 %) and low extractives content (average total extractives of 6.5 %) in comparison with pine and spruce barks which have low holocellulose content (36.1 and 47.6 %, respectively) and high extractives content (19.1 and 22.0 %, respectively).

There were also differences between the barks related to the proportion of the different soluble compounds in the total extractives. For instance, dichloromethane soluble compounds represent a large proportion of total extractives in birch bark, while this type of extractives was smaller in the other barks. These results show the between-species chemical variability of bark, as also reported by Miranda et al. (2012, 2013) and Kofujita et al. (1999).

The use of bark as a biomass resource requires a pre-treatment step of size reduction and eventually of fractionation. It is expectable that the physical and structural characteristics of bark will influence its behaviour upon mechanical handling and allow separation of fractions with differing physical properties (such as particle size). As reported in previous works (Miranda et al. 2012, 2013), this was observed for these four barks and the grinding yields by particle size differed between them: for spruce and pine barks, the yield of fines was low and the major fractions were larger particles; for birch bark, the yield of fines was low and the major fraction corresponded to the largest particles; for eucalypt bark, a significant amount of fines was obtained and the fractions with the larger particles showed comparatively lower yields.

The question arises whether the different granulometric fractions have similar chemical composition or possible differences are species related. Bridgeman et al. (2007) reported that the process of size reduction does not apply in a uniform manner and that cellulose, hemicelluloses, and lignin tend to remain in the larger-sized particle fraction. Ottone and Baldwin (1981) reported that extractives increased with decreasing particle size. A particle size effect was observed for content of ash and extractives of these four barks, but overall trends for structural and non-structural chemical components were difficult to scrutinize, especially when considering the species variation (Miranda et al. 2012, 2013). The structural complexity of barks, e.g. with different anatomical tissues and cell characteristics, may influence the size distribution after grinding and the chemical composition of the different fractions (Baptista et al. 2013).

The selection of processing routes for barks as a source of chemicals and materials may therefore be difficult by the diversity of the data related to species, granulometrics and chemical variables. The use of statistical methods may be a useful tool to detect significant differences and discriminate between groups. This was the aim of this paper, and the results showed that this approach may be applied successfully to bark fractions, principally of hardwoods.

It was shown that the raw material source, i.e. the species, is more important to identify samples based on their chemical composition than their granulometry. Figure 5 shows that the representation of all the samples in a two-component plane allows the grouping of the samples by species. Birch and eucalypt are clearly separated in the PC1 and PC2 plane, while pine and spruce are less discriminated by PC1, but they are differentiated by PC2.

The different barks behaved heterogeneously during grinding reduction as regards their granulometric distribution (Miranda et al. 2012, 2013). They also showed that the distinct sieve fractions differ chemically. The CA rendered dendrograms as shown in Figs. 2 and 4 grouping all granulometric samples at least into two clusters, one formed by medium and coarse fractions and another formed by fine fractions. This result suggests that sieving can constitute a first dry fractionation step resulting in preliminary enrichment of desirable components of biomass into suitable fractions for different applications.

Conclusion

It was shown that bark chemical composition differs between species, and for the four species analysed, the chemical variables may be used to differentiate between them. Size reduction yields granulometric fractions that are not chemically homogeneous and that can also be discriminated. Therefore, the potential applications of barks in valorization programs have to carefully consider the species-specific composition and their size reduction patterns. However, in general, the fine particles concentrate higher amounts of inorganic material, and extractives and therefore should be separated prior to further processing.

Chemometrics statistical methods were shown to be useful tools to analyse bark fractions and chemically discriminate species and granulometric fractions. They are therefore useful to study the chemical potential for biorefineries of different barks.

References

Alvin CR (2002) Methods of multivariate analysis. Wiley, New York

Baptista I, Miranda I, Quilhó T, Gominho J, Pereira H (2013) Characterisation and fractioning of Tectona grandis bark in view of its valorisation as a biorefinery raw-material. Ind Crop Prod 50:166–175

Bofinger VJ (1975) An introduction to some multivariate techniques with applications in field experiment. In: Bofinger VJ, Wheeler JL (eds) Developments in field experiment design and analysis. Commonwealth Agricultural Bureaux, Oxford, pp 73–83

Bridgeman TG, Darvell LI, Jones JM, Williams PT, Fahmi R, Bridgwater AV, Barraclough T, Shield I, Yates N, Thai SC, Donnison IS (2007) Influence of particle size on the analytical and chemical properties of two energy crops. Fuel 86:60–72

Brodnjak-Voncina D, Kodba ZC, Novic M (2005) Multivariate data analysis in classification of vegetable oils characterized by the content of fatty acids. Chemom Intell Lab 75:31–43

Burgard DR, Kuznicki JT (1990) Chemometrics: chemical and sensory data. CRC Press, Boston

Conde E, Cadahía E, Díez-Barra R, García-Vallejo MC (1996) Polyphenolic composition of bark extracts from Eucalyptus camaldulensis, E. globulus and E. rudis. Holz Roh Werkst 54:175–181

Demirbas A (2001) Biorefineries for biomass upgrading facilities (green energy and technology). Springer-Verlag, London

Ferreira-Dias S, Valente DG, Abreu JMF (2003) Pattern recognition of acorns from different Quercus species based on oil content and fatty acid profile. Grasas Aceite 54:384–391

Kofujita H, Ettyu K, Ota M (1999) Characterization of the major components in bark from five Japanese tree species for chemical utilization. Wood Sci Technol 33:223–228

Matos LC, Cunha SC, Amaral JS, Pereira JA, Andrade PB, Seabra RM, Oliveira BPP (2007) Chemometric characterization of three varietal olive oils (Cvs. Cobrançosa, Madural and Verdeal Transmontana) extracted from olives with different maturation indices. Food Chem 102:406–414

Miranda I, Gominho J, Mirra I, Pereira H (2012) Chemical characterization of barks from Picea abies and Pinus sylvestris after fractioning into different particle sizes. Ind Crop Prod 36:395–400

Miranda I, Gominho J, Mirra I, Pereira H (2013) Fractioning and chemical characterization of barks of Betula pendula and Eucalyptus globulus. Ind Crop Prod 41:299–305

Mirkin B (1996) Mathematical classification and clustering. Kluwer Academic Publishers, Dordrecht

Morrison DF (1967) Multivariate statistical methods. Kogakusha International Student Edition, McGraw-Hill

Ottone S, Baldwin RC (1981) The relationship of extractive content to particle size distribution in milled yellow-poplar (Liriodendron tulipifera L.) bark. Wood Fib Sci 13:74–85

Pereira H, Gominho J, Ferreira-Dias S (2012) Chemometric characterization of cardoon oil from large-scale productions in Portugal. In: 20th European Biomass Conference and Exhibition. 18–22 June, Milano

Pietarinen SP, Willför SM, Ahotupa MO, Hemming JE, Holmb BR (2006) Knotwood and bark extracts: strong antioxidants from waste materials. J Wood Sci 52:436–444

Pires AS, Osório NM, Nascimento AC, van Keulen F, da Fonseca MMR, Ferreira-Dias S (2008) Pattern-Recognition of lipase-catalysed or chemically-interesterified fat blends containing omega-3 polyunsaturated fatty acids. Eur J Lipid Sci Technol 110:893–904

Pizzi A (2008) Tannins: Major Sources, Properties and Applications. In: Belgacem MN, Gandini A (eds) Monomers. Polymers and Composites from Renewable Resources, Elsevier, pp 179–199

Rowell RM (2005) Handbook of wood chemistry and wood composites. CRC Press, Madison

Ruiz-Méndez MV, López-López A, Garrido-Fernández A (2008) Characterization and chemometric study of crude and refined oils from table olive by-products. Eur J Lipid Sci Technol 110:537–546

Sen A, Miranda I, Santos S, Graça J, Pereira H (2010) The chemical composition of cork and phloem in the rhytidome of Quercus cerris bark. Ind Crops Prod 31:417–422

Silva GGD, Guilbert S, Rouau X (2011) Successive centrifugal grinding and sieving of wheat straw. Powder Technol 208:266–270

Tzouros NE, Arvanitoyannis IS (2001) Agricultural procedures: synopsis of employed quality control methods for the authentication of foods and application of chemometrics for the classification of foods according to their variety or geographical origin. Crit Rev Food Sci 41:287–319

Valentín L, Kluczek-Turpeinen B, Willför S, Hemming J, Hatakka A, Steffen K, Tuomela M (2010) Scots pine (Pinus sylvestris) bark composition and degradation by fungi: potential substrate for bioremediation. Bioresour Technol 101:2203–2209

Acknowledgments

This work was supported by the EU research project “AFORE—Forest biorefineries: Added-value from chemicals and polymers by new integrated separation, fractionation and upgrading technologies” under the 7th Research Framework Programme, as well as by Strategic Projects PEst-OE/AGR/UI0239/2011 of CEF—Forest Research Centre, and PEst-OE/AGR/UI0245/2011 of CEER, Biosystems Engineering, funded by FCT—Fundação para a Ciência e a Tecnologia, Portugal.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miranda, I., Gominho, J., Ferreira-Dias, S. et al. Pattern recognition as a tool to discriminate softwood and hardwood bark fractions with different particle size. Wood Sci Technol 48, 1197–1211 (2014). https://doi.org/10.1007/s00226-014-0665-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0665-9