Abstract

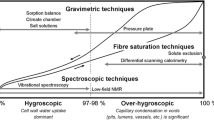

Wood is a porous, hygroscopic material that can take up water both within cell walls (cell-wall water) and in the macrovoid structure (capillary water). Therefore, moisture transport in wood occurs through multiple pathways and phases of water, that is, both cell-wall water, liquid water, and water vapor can be transported through the material structure. The amount of water in wood is quantified by the moisture content (mass of water in relation to the dry mass), which changes with the surrounding environmental conditions (relative humidity and temperature). This relation is commonly depicted in sorption isotherms that plot the equilibrium moisture content as function of relative humidity for specific, constant temperatures. How water is taken up by wood changes over the relative humidity range. In the hygroscopic range (0% to 97–98% relative humidity), water is predominantly taken up in cell walls, whereas capillary condensation of liquid water in the macrovoid structure becomes dominant in the over-hygroscopic range (>98% relative humidity). The equilibrium illustrated in sorption isotherms for specific environmental conditions is not singular, but depends on the sorption history; this phenomenon is known as sorption hysteresis. Sorption isotherms are generally modeled using mathematical expressions that are fitted to data in the hygroscopic range. Some of these models include quantities describing the physical reality of wood-water interactions; however, these quantities rarely match up to the experimentally determined reality for wood. The same can be said of the mathematical models describing the kinetics of water uptake in wood cell walls.

One of the most well-known concepts concerning water in wood is the fiber saturation point (FSP). It can be found as the threshold moisture content above which physical wood properties do not change significantly with moisture content. The FSP is, however, lower than the maximum moisture content of wood cell walls which occurs in the fully water saturated state. A change in moisture content below the FSP is accompanied by dimensional changes, that is, shrinkage and swelling, which reflect changes in the amount of water within cell walls. While this phenomenon originates at the nanoscale, it is observed on all length scales of wood. Such dimensional changes as well as other physical wood properties and fundamental wood-water interactions can be altered by chemical modification of wood. How these relations are affected depends on the chemical nature of the modification. At the end of this chapter, a broad overview is given of experimental methods for characterizing moisture in wood, including determination of moisture content, sorption isotherms, moisture state and location, and moisture transport in wood.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Moisture

- Sorption

- Cell-wall water

- Capillary water

- Sorption isotherms

- Fiber saturation

- Sorption hysteresis

- Chemical modification

- Swelling

- Diffusion

1 Wood-Water Interactions

In this chapter, the term absorption is used for water uptake. According to the International Union of Pure and Applied Chemistry (IUPAC) [1], absorption is the “process of one material (absorbate) being retained by another (absorbent); this may be the physical solution of a gas, liquid, or solid in a liquid, attachment of molecules of a gas, vapour, liquid, or dissolved substance to a solid surface by physical forces, etc.” For water uptake in wood, the term absorption therefore covers uptake by any mechanism. Adsorption is defined by IUPAC as an “increase in the concentration of a dissolved substance at the interface of a condensed and a liquid phase due to the operation of surface forces.” In the case of water uptake in materials, adsorption describes the adhesion of water molecules to a surface. For wood, this is not a dominating mechanism for water uptake. Moreover, this chapter deals mainly with wood-water relations in wood and modified wood. For detailed information about wood-water relations in wood-based materials, please see [2, 3, 6, 8, 9].

1.1 Cell-Wall Water

Water molecules within wood cell walls are commonly referred to as “bound water,” and they are closely interacting with the constituent cell-wall polymers. The polar water molecules mainly interact by hydrogen bonding with cell-wall hydroxyl (OH) groups that are found on all cell-wall polymers [4, 5]. The aggregated cellulose microfibrils are, however, impenetrable for water, and it is therefore only hydroxyls on exposed surfaces which can interact directly with water [6, 7]. The hydroxyls capable of interacting with water are often referred to as “accessible hydroxyls,” and the concentration of these in a given material is termed the “hydroxyl accessibility” and can be determined by various methods, see Sect. 7.11.4. Since cellulose is the main cell-wall constituent and the microfibrils have a significant fraction of their hydroxyls within the microfibrillar structure, the relative hydroxyl accessibility (in %) in wood is typically found to be less than half of the total hydroxyl concentration, while the absolute hydroxyl accessibility (in mmol g−1) is in the range 6–10 mmol g−1, see Table 7.1.

The properties of water within cell walls differ from those of water in the solid (ice) and liquid states, which suggests that it is a state distinctly different from other states of water. The confinement of water molecules between the solid cell-wall constituents and the close association by hydrogen bonds between water and the solid substance would suggest a state of cell-wall water comparable to ice. On the other hand, the population of cell-wall water molecules exhibit a larger variation in hydrogen bond lengths and bond angles in the interactions with the cell-wall polymers than in ice as well as retain much higher mobility than in ice. This suggests a state of cell-wall water close to that of liquid water. In fact, the behavior of cell-wall water falls somewhere between that of ice and liquid water, but cell-wall water behaves increasingly more like liquid water as the concentration of water within the cell walls increases.

It has since long been debated whether the overall population of water molecules within cell walls can be described as comprised of two or more distinct subpopulations or types of water. Several theoretical models for describing equilibria between cell-wall water and the ambient environment contain at least two types of water molecules, see Sect. 7.3.2. These interact either directly with the cell-wall constituents or indirectly via bonding to other water molecules within the cell walls. The separation of cell-wall water into several types was in the 1980s corroborated by experimental data from differential scanning calorimetry (DSC) on cellulosic materials that distinguished two types of water within cell walls: freezing and nonfreezing [8,9,24], see Sect. 7.11.1. Based on an observed phase change in the temperature range −20 °C to −10 °C during cooling and a small peak shoulder on the melting peak of liquid water, the freezing cell-wall water was suggested to be less tightly associated with the polymeric material and able to freeze. On the other hand, no phase change was observed for the nonfreezing part of the cell-wall water down to −70 °C [23]. Although a peak shoulder on the water melting peak has been observed with DSC for wood [25, 26], the existence of freezing cell-wall water in wood and other cellulosic materials is controversial. Thus, several studies using DSC have not identified any freezing cell-wall water even for high concentrations of water [23, 27, 28] and other experimental techniques have similarly failed in identifying any phase change of cell-wall water [29, 30]. Recently, Zelinka et al. [28] showed that the occurrence of a freezing peak around −20 °C to −10 °C is an artifact from the specimen preparation and only occurred for isolated ball-milled cellulose and not for solid or milled wood.

Although cell-wall water in wood cannot be partitioned based on phase changes, several experimental techniques have shown the existence of two distinct subpopulations of water within cell walls. The two populations of water encounter different local environments in the cell walls in terms of pore size and chemical interactions as shown by 2D low-field nuclear magnetic resonance (LFNMR) correlation spectroscopy [31, 32], see Sect. 7.11.2. It is, however, not clear what or where these populations are. The presence of different subpopulations of cell-wall water appears to be linked to the presence of the stiff, solid aggregated cellulose microfibrils in cell walls. Close proximity of water molecules to cellulose surfaces reduces the water mobility [5], and the various crystallographic planes of cellulose microfibrils affect the water dynamics differently [4, 19,20,21,36]. Moreover, the water molecules may not be distributed evenly in the regions of the cell walls accessible to water, since some studies find increased concentrations at interfaces between cellulose and the amorphous cell-wall polymers [37, 38]. This might explain why the presence of cellulose microfibrils in the wood cell walls may be able to affect the overall population of water in cell walls so significantly, even though cellulose microfibrils only constitute half of the cell-wall chemistry and only have about 1/3 of their hydroxyls exposed to water [12].

1.2 Capillary Water

At high levels of relative humidity, water is not only present within cell walls, but also in macrovoids in the wood structure such as cell lumina and pit chambers. Here, water uptake is dominated by capillary condensation, that is, water vapor is condensed in pores even below the saturation vapor pressure. At which relative humidity capillary condensation occurs is described by the Kelvin equation:

where ϕ (Pa Pa−1) is the relative humidity, γ (N m−1) is the surface tension of water, Mw (0.018 kg mol−1) is the molar mass of water, θ (rad) is the contact angle, R (8.314 J mol−1 K−1) is the gas constant, ρw (kg m−3) is the density of water, T (K) is temperature, and r (m) is defined by

where r1 and r2 (m) are the two radii of condensation. For surfaces that are wetted by water, the contact angle is zero. For a cylindrical pore, the two radii of condensation equal the pore radius r, that is, r1 = r2 = r, and Eq. (7.1) is then written:

For a slit-shaped pore, r1 = r and r2 = ∞, and Eq. (7.1) is then written:

From Eqs. (7.3) and (7.4), it is seen that capillary condensation occurs at a lower relative humidity in small pores than in large pores. Based on the water properties at a given temperature, the relative humidity at which capillary condensation occurs in different pore sizes can be determined assuming either cylindrical or slit-shaped pores, see Table 7.2. In wood, the macrovoids where capillary condensation occurs are neither cylindrical (apart from vessels) nor slit-shaped. However, to get a sense of the relation between relative humidity and capillary condensation in cell lumina, these can be assumed to be cylindrical. Since cell lumina in wood are typically in the range of 10–40 μm, they are not filled by capillary condensation until above approximately 99.99% relative humidity during absorption, see Table 7.2. This is the reason for the steep absorption isotherm for wood above 99% relative humidity, see Fig. 7.1. However, in smaller voids, such as ends of the tapered tracheids and pit chambers, capillary condensation occurs at slightly lower, but still high, relative humidity levels [39].

(a) Sorption isotherm of Norway spruce (Picea abies (L.) Karst.) as a function of relative humidity based on data from [49]. (b) Over-hygroscopic moisture range plotted as a function of water potential which gives a higher resolution in this range. (c) Schematic softwood tracheid with water located in different parts of the wood structure. The relative humidity levels where water uptake in these parts is significant are indicated by the letters A–D

2 Moisture Content

Within wood science, the moisture content is most commonly determined by the ratio

where ω (g g−1) is the moisture content, mw (g) is the mass of water, and mdry (g) is the dry mass. Since water in wood can be present both in cell walls and in the macrovoid structure, the maximum moisture content is the sum of the amounts of water present in cell walls and macrovoids. The macrovoid porosity, Pmv, is determined by:

where ρb (kg m−3) is the bulk density of wood, and ρs (kg m−3) is the solid (skeletal) density, that is, cell-wall density which is in the range 1430–1530 kg m−3 [40,41,42,43,44,45,46,47,48]. The maximum mass of capillary water in macrovoids in a volume V (m3) of wood is thus:

where ρw (kg m−3) is the density of water. The moisture content of water-filled macrovoids can then be determined as:

where ωcap (g g−1) is the moisture content of water-filled macrovoids. Finally, the maximum moisture content is obtained by adding the contributions from capillary water in voids and the maximum cell-wall moisture content

where ωmax (g g−1) is the maximum moisture content and ωcell wall (g g−1) is the maximum cell-wall moisture content, see Sect. 7.4.

3 Sorption Isotherms

The relation between the moisture content of a material and the state of the water in equilibrium with the ambient climate at constant temperature is described by sorption isotherms. In the hygroscopic moisture range, sorption isotherms are often given as a function of relative humidity. In the over-hygroscopic range, sorption isotherms are generally presented as a function of pore water pressure (Pa) or water potential (J kg−1) on a logarithmic scale, see Fig. 7.1. The latter is related to relative humidity by Eq. (7.57) in Sect. 7.10.2 and gives a higher resolution at high levels of relative humidity.

In the over-hygroscopic range, the water uptake is dominated by capillary condensation in the macrovoid structure (cell lumina and pit chambers). The amount of water taken up in this range is therefore highly related to the bulk density of the wood; the lower density, the more macrovoid volume is available for water. In the hygroscopic range, the moisture concentration (kg m−3) is density dependent since water here is found within cell walls; the more cell-wall material (higher density) the higher moisture concentration (kg m−3). However, since the moisture content of wood most often is related to the dry mass (Eq. (7.5)), the sorption isotherm in the hygroscopic range is not strongly influenced by density [50]. Full sorption isotherms for some wood species and hygroscopic sorption isotherms for several wood species are shown in Figs. 7.2 and 7.3, respectively.

Hygroscopic sorption isotherms for several wood species. (a) Pine (Pinus sylvestris L.), (b) Western white pine (Pinus monticola D. Don), (c) Douglas fir (Pseudotsuga menziesii (Mirb.) Franco), (d) White spruce (Picea glauca (Moench) Voss), (e) Redwood (Sequoia sempervirens (D. Don) Endl.), (f) Birch (Betula sp.), (g) Oak (Quercus robur L.), (h) Teak (Tectona grandis L.f.), (i) Mahogany (Swietenia sp.). (Data from [51] (o) and [53] (+))

The equilibrium moisture content of a material does not only depend on the ambient climate, but also on the moisture history of the material. The sorption isotherm determined in absorption (uptake) from dry state is lower than the sorption isotherm determined in desorption (drying) from the water-saturated state. This phenomenon is termed sorption hysteresis and is observed in many porous materials, see Sect. 7.3.1. Sorption isotherms initiated from any other state than the dry or water-saturated state are generally referred to as scanning isotherms. These connect the desorption and absorption isotherms and describe the equilibrium moisture content of a specimen exposed first to desorption and then to absorption, or vice versa. For example, if a dry specimen is placed in a high relative humidity ϕ1 (e.g., 95%) until equilibrium is reached and then is dried to a lower relative humidity ϕ2 (e.g., 80%), the equilibrium moisture content will be lower than if drying to ϕ2 was initiated from the water-saturated state, see Fig. 7.4. Both moisture contents obtained are, however, equilibrium moisture contents. Many desorption isotherms in literature are in fact scanning isotherms as they are initiated from 90% to 95% reached by absorption [56], whereas less data is available for absorption scanning isotherms and desorption scanning isotherms from lower initial relative humidity levels. At present, no data for scanning isotherms in the over-hygroscopic range is available.

A schematic illustration of a desorption isotherm (upper curve), absorption isotherm (lower curve), and a scanning isotherm. Drying from a high humidity ϕ2 reached by absorption (1) to a lower humidity ϕ1 (2) will give a lower equilibrium moisture content than if drying to ϕ2 is initiated from water saturated state (3)

In older literature, it is sometimes stated that the initial desorption isotherm for wood after harvesting is higher than any desorption isotherm obtained after re-saturating dry specimens [53]. However, Hoffmeyer et al. [57] showed that the initial desorption isotherm can be reproduced after vacuum water-saturation. It is important to keep in mind that initiation of desorption from another state that the water-saturated state yields scanning isotherms and not desorption isotherms. Due to the large sorption hysteresis in wood above 98–99% relative humidity, conditioning to a high moisture state by vapor absorption does not give a high enough moisture content for the specimen to follow the desorption isotherm when drying (Fig. 7.1).

The sorption isotherm also depends on temperature; a higher temperature lowers the sorption isotherm in the hygroscopic [58] and the over-hygroscopic moisture ranges [59], see Fig. 7.5 In the over-hygroscopic range, one possible explanation for this could be the temperature dependence of the surface tension of water. However, this cannot fully explain the temperature dependence of the over-hygroscopic sorption isotherm [59]. The reasons for temperature dependence of the hygroscopic sorption isotherms are further discussed in Sect. 7.3.1.

One of the most prominent datasets concerning wood moisture sorption is the USDA Wood Handbook data presented in numerous publications from the Forest Products Laboratory. The historical origin of the sorption data was thoroughly tracked by Glass et al. [50]. They found that the sorption data is mainly based on experimental measurements performed between 1910 and 1930 with more data occasionally added in the following years. While the original purpose of the data was for practical uses, for example, in wood drying or in conditioning wood before test of mechanical or other physical properties, several studies have used the data for scientific investigations of fundamental wood-water relations. However, Glass et al. [50] clearly document that this data is not reliable for detailed scientific investigations of fundamental wood-water interactions. For instance, the documentation for the experimental methodologies used to obtain the underlying experimental data is often lacking or of poor quality. In addition, the USDA Wood Handbook sorption data represents an undocumented mixture of experimental sorption data for various wood species with extrapolated and interpolated data, and several methods for establishing equilibrium (absorption, desorption, or a mixture of both) have been used. Therefore, this sorption isotherm data should only be used as originally intended by the Forest Products Laboratory, that is, for predicting approximate moisture contents in various environments, and not for detailed scientific studies [50].

3.1 Sorption Hysteresis

Sorption hysteresis is observed as a difference in moisture content between moisture states reached by absorption, desorption, or scanning; for instance, the moisture content reached by desorption is higher than that reached by absorption at similar relative humidity and temperature. The mechanisms behind sorption hysteresis are different in the hygroscopic and over-hygroscopic moisture ranges. In the hygroscopic range, sorption hysteresis for wood decreases with increasing temperature and reportedly vanishes above 75 °C [58]. A similar phenomenon is observed for polymer films of hemicelluloses and cellulose [62, 63]. Sorption hysteresis has been suggested to be related to softening of the amorphous matrix polymers (hemicelluloses and lignin) as they pass their glass transition point and enter the rubbery state [62,63,64]. Hemicelluloses soften above 0.15–0.16 g g−1 moisture content at room temperature which corresponds to about 75% relative humidity, while lignin softens above 60–70 °C at high moisture content [64]. Sorption hysteresis has also been linked with a change in hydroxyl accessibility upon drying; as water is removed and the cell-wall structure shrinks, parts of the constituents have been suggested to form hydrogen-bonded configurations that cannot be re-opened by water [65, 66]. This phenomenon of lower hydroxyl accessibility after drying is known as hornification and has been observed in never-dried, isolated cellulose microfibrils from various origins [67, 68]. In the composite wood cell wall, however, cellulose microfibrils are embedded in hemicelluloses and lignin which prevent hornification [69, 70]. Thus, no change in hydroxyl accessibility is observed in native wood upon full re-saturation with water [12].

Sorption hysteresis is often quantified as either absolute sorption hysteresis or relative sorption hysteresis where the former describes the absolute difference in moisture content between two isotherms (e.g., absorption and desorption), and the latter normalizes this difference with the moisture content reached through absorption. Many studies characterize sorption hysteresis based on absorption and scanning isotherms initiated from 95% relative humidity reached by absorption. Hysteresis curves calculated from these two isotherms exhibit markedly different behavior than sorption hysteresis based on absorption and desorption isotherms, see Fig. 7.6 [52]. In the first case, nonlinear curves are observed with a peak in absolute hysteresis around 75% relative humidity when scanning desorption is initiated from 95% relative humidity. When desorption is initiated from water-saturated conditions, the absolute hysteresis curves are nearly linear (Fig. 7.6).

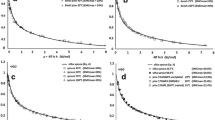

(a) Desorption and absorption isotherms (-), scanning isotherms from 95% (--), and 80% relative humidity (..). (b and c) Absolute and relative sorption hysteresis calculated from the sorption isotherms in a. (Data from [52])

In the over-hygroscopic range, capillary condensation of water first occurs in small voids, for example pit chambers, and in larger voids such as cell lumina at higher relative humidity levels, see Sect. 7.1.2. The sorption hysteresis in this range is large as seen in Fig. 7.1. One well-established theory for explaining sorption hysteresis in porous materials is the ink-bottle or pore blocking effect [71]. That is, when a pore is filled, capillary condensation is controlled by the radius of curvature of the pore (Eq. (7.1)), but if the pore has a narrow neck, the emptying of the pore is controlled by the radius of the neck. Such a pore is thus emptied at a lower relative humidity than the relative humidity at which it is filled during absorption. In wood, cell lumina of adjacent cells are connected by small pit openings and the ink-bottle effect is therefore considered to be the main mechanism behind sorption hysteresis in the over-hygroscopic moisture range [72]. During absorption, capillary condensation occurs in lumina at a relative humidity corresponding to the lumen size (10–40 μm), but the removal of this water during desorption will only occur below a relative humidity corresponding to the size of the pit openings (<4 μm). For example, assuming cylindrical cell lumina and pit openings with radii 20 μm and 2 μm, respectively, the cell lumina would fill at 99.9946% relative humidity during absorption and be emptied at 99.9461% relative humidity during desorption (Table 7.2).

3.2 Sorption Isotherm Models

Theoretical models for describing water sorption isotherms are frequently used to fit experimental hygroscopic sorption data for wood. A large number of sorption isotherm models exist for the hygroscopic range; 77 are listed by Van den Berg and Bruin [73] but many of these are mathematically equivalent [74]. Many empirical sorption isotherm models have been published which only attempt to provide smooth fitting curves between discrete data points; however, a number of sorption isotherm models have been derived from various theoretical frameworks and therefore claim to be able to derive physical quantities related to water uptake in solid materials. Some of the most well-known and commonly used for wood sorption data are the Brunauer-Emmett-Teller (BET), Guggenheim-Anderson-de Boer (GAB), and Hailwood-Horrobin (HH) sorption isotherm models seen in Eqs. (7.10), (7.11), and (7.12). BET was developed based on a statistical mechanical framework which was expanded in the development of the GAB model. The latter model is equivalent to that of Dent [75] that occasionally has been applied to wood sorption data. The HH model was derived from solution thermodynamics. All three models share the common characteristic that they partition water within the cell wall into at least two types. These go under various names, but are commonly described as primary water and secondary water, and they can be thought of as: (1) water molecules interacting directly with functional groups (“sorption sites”) within the cell walls and (2) water molecules interacting with the other water molecules, including those associated with sorption sites. Although experimental evidence points to the possibility of two populations of absorbed water molecules, see Sect. 7.1.1, these are not necessarily equivalent with the types of water suggested in the sorption isotherm models.

where ω is the moisture content (g g−1), ωmono is termed the monolayer moisture content (g g−1), aw is the water activity (similar to relative humidity) (Pa Pa−1), and K, K1, K2, K3, K4, and Mp are model-specific parameters. The monolayer moisture content, ωmono, is a central physical quantity that is commonly derived in literature with sorption isotherm models. It describes the amount of water molecules directly associated with sorption sites, that is, the maximum amount of primary water. For the HH model, the monolayer moisture content, ωmono, is not a parameter in the original equation but can be found as

For comparison with the BET and GAB models, it can be worthwhile to divide Eq. (7.12) with Eq. (7.13) in order to obtain HH in the form

The BET equation is known to only fit well to wood sorption data in the lower (<70% relative humidity) hygroscopic regime, whereas the GAB and HH models fit the experimental sorption data for wood equally well and better than the BET model, typically with R2 > 0.96. The reason for how the three models perform can be found in their mathematical form. Re-arrangement of Eqs. (7.10), (7.11), and (7.12) yields

From Eqs. (7.15), (7.16) to (7.17), it is seen that the models plotted against aw/ω describe a parabola [82] of the form

where C can be freely selected via tuning ωmono. The A/C and B/C in Eq. (7.18) are, however, not equally free to vary in the three sorption isotherm models which is seen from their ratios

These ratios show that the three parameters A, B, and C are described by three independent model parameters in the GAB and HH models, but only two independent model parameters in the BET model. Thus, the GAB and HH models are mathematical equivalent, and it is not surprising that they give better fits to experimental sorption data than the BET model which is constrained by Eq. (7.19). From the fit of the BET, GAB, and HH sorption isotherm models, the monolayer moisture content can be derived from the fitting parameters of the ABC parabola model (Eq. (7.18)) as

The derived monolayer moisture content depends on the sorption isotherm model used for the derivation as evident in Eqs. (7.23), (7.26), and (7.29), where K2 and K4 are seen to be equal. Since the GAB and HH models are mathematically equivalent, they produce the exact same fit to data of the ABC parabola (Eq. (7.18)), and also predict similar monolayer moisture contents. The constraints of the BET model yield a different fit of the ABC parabola to the data.

Another analysis method for characterizing sorption isotherm data which has gained popularity in the last few decades is the “Excess Surface Work” theory (ESW) [83]. In its core, ESW is the depiction of the number of absorbed water molecules per dry mass versus the excess surface work.

where nads (mol g−1) is the number of absorbed water molecules, Φ (J g−1) is the excess surface work, ω (g g−1) is moisture content, Mw (18 g mol−1) is the molar mass of water, R (8.3145 J mol−1 K−1) is the gas constant, and T (K) is temperature. The excess surface work is seen to be defined by the product of the chemical potential of water vapor and the number of absorbed water molecules. A plot of nads versus Φ produces curves starting at the origin and going to negative values with increasing moisture content before reaching a minimum and increasing again. While this procedure is without assumptions regarding the nature of water sorption in wood, typical ESW analysis proceeds to assign the nads value of the minimum Φ, that is, the valley of the plot, to the formation of a complete monolayer of water on internal surfaces [83]. Beyond this moisture content, all absorbed water molecules are assumed to be secondary water. Thus, the monolayer of primary water is completed before secondary water is taken up.

The formation of a complete monolayer of primary water differs between ESW analysis and the BET, GAB, and HH sorption isotherm models. In the latter three models, water molecules absorbed by a material is distributed unevenly among sorption sites, and the proportion of primary and secondary water varies with the moisture content. Only at full saturation is the water monolayer completely filled in the BET model, whereas it remains incompletely filled in the GAB and HH models. None of these two physical images of how water molecules are distributed between primary and secondary water as function of moisture content fits the experimental data of the possible two populations of water molecules. Thus, the experimental evidence suggests that both types of water are present in wood even at low moisture contents [31, 32] contradicting the ESW analysis. Moreover, the relative proportion of these two experimentally found types of water is not reproduced by any of the sorption isotherm models.

A crucial test of the validity of the physical quantities derived from theoretically based sorption isotherm models is how they compare with experimental measurements of the same quantities. For instance, derived monolayer moisture contents can be compared with experimentally determined hydroxyl accessibility, which is the amount of hydroxyls in the wood capable of binding to water molecules, see Sect. 7.11.4. Figure 7.7a shows sorption isotherm data for Klinki pine at four temperatures with fitted BET, GAB, and HH models in Fig. 7.7b, while Fig. 7.7c depicts the derived monolayer moisture content from these three models and ESW analysis. The predicted monolayer moisture contents range from 0.03 g g−1 to 0.06 g g−1, which are commonly reported values in literature for a range of wood species. These values correspond to water contents of 1.5–3.5 mmol g−1, but as described in Sect. 7.1.1, the hydroxyl accessibility for a range of wood species falls within 6–9 mmol g−1. Most of the experimental data for hydroxyl accessibility is based on deuterium exchange which in fact provides a lower limit of the hydroxyl accessibility. This is because one-third of the surface hydroxyls on cellulose microfibrils cannot be probed by deuterium exchange, even though they interact with water molecules [85, 86]. Thus, the four sorption isotherm models described here all predict monolayer moisture contents which are 2–6 times lower than the experimentally determined amount of accessible hydroxyl sorption sites in the wood which is moreover slightly lower than the actual hydroxyl accessibility. This is a significant failure of the sorption isotherm models in providing realistic physical quantities for wood. Other studies have analyzed the predicted thermodynamic quantities of wood based on various theoretically derived sorption isotherm models [87]. Similarly to the failure in predicting correct monolayer moisture contents, these studies have concluded that the physical reality described by the sorption isotherm models does not match up to the experimentally determined reality for wood [87, 88] .

(a) Absorption isotherms for klinki pine (Araucaria klinkii Lauterb.) at four different temperatures [84], (b) example of fit by the GAB, HH, and BET sorption isotherm models to the sorption data at 10 °C, (c) monolayer moisture content derived by the GAB, HH, and BET sorption isotherm models and ESW analysis as function of temperature

4 Fiber-Saturation Point and Maximum Cell-Wall Moisture Content

One of the most well-known concepts concerning water in wood is the fiber saturation point (FSP). It was originally described by Tiemann [89] who investigated the change in mechanical properties for wood with moisture contents from 0.02 g g−1 to above 0.9 g g−1. Like many other properties of wood, the mechanical performance is heavily influenced by moisture as described in Chaps. 8 and 9. Tiemann obtained different moisture contents by drying in steam atmosphere at 27–60 °C for various durations. Although the drying was carefully undertaken to prevent large moisture gradients, the wood was not conditioned to equilibrium in the sense discussed in Sect. 7.10. The results of the mechanical tests showed that the stiffness and strength increased nonlinearly with decreasing moisture content below a certain threshold value, while remaining constant above this value [89]. The nonlinear change in mechanical properties was later shown to be exponential [90]. Therefore, the logarithm of the mechanical properties exhibits a nearly bi-linear behavior with two distinct regimes: one in which properties change with moisture content and one in which they are constant. Tiemann also found that the bulk wood dimensions change nearly linearly with moisture content in a certain intermediate moisture range while remaining constant at high moisture content [89], see Sect. 7.7. The transition point between the regime where properties change with moisture content to the regime with properties independent of moisture content is defined as the FSP. Thus, the FSP can be found as the inflection point between the regimes after linearizations of either dimensions or the logarithm of mechanical properties. In the original definition, it was envisioned that upon drying all liquid water evaporates before cell-wall drying starts, which then causes a change in properties. Similarily, it was envisioned that during absorption, the strength decreases until cell walls were thought to be saturated. Tiemann discussed that the FSP is less distinct if moisture gradients are present in the specimen [89]. Since moisture content influences more than just dimensions and mechanical properties, see Chap. 6, the change in several other properties with moisture content has also been used to determine the FSP. For instance, Stamm measured electrical conductivity as function moisture content upon drying from water saturation [91]. This property decreases by several orders of magnitude upon drying, and an infliction point can be determined from linearization of the nearly constant conductivity at high moisture contents and the sharply changing conductivity in the hygroscopic range [91]. However, Zelinka et al. [92] have shown that the Stamm-data fits a theoretical model for electrical conductivity derived from percolation theory, at least up to a moisture content of 0.63 g g−1. This questions whether a shift in where the water is found within the wood can actually be deduced from electrical conductivity measurements.

The definitions of the FSP based on changes in properties with moisture content have two important problems. Firstly, most of the experimental data is based on specimens conditioned by interrupted drying of the wood at elevated temperature or low humidity. This will inevitably result in moisture gradients within the material, even in the case where the wood is sealed and left to re-distribute the moisture. The outer part will then, unlike the inner parts, reach equilibrium by absorption and this leads, due to sorption hysteresis, to moisture gradients. Measurements of properties determined for a material with moisture gradients will not be representative of the material when conditioned to uniform moisture content. This is because the moisture content in the former case will be either underestimated or overestimated depending on if the moisture gradients were obtained during water uptake or drying. In the hygroscopic moisture range, conditioning can be done with a variety of methods to control the relative humidity in the surrounding climate. However, in the over-hygroscopic moisture range, methods such as the pressure plate or pressure membrane techniques are needed to condition the wood material to equilibrium without generating internal moisture gradients, see Sect. 7.10. By conditioning wood using these techniques, experimental data on changes in mechanical properties, dimensions, and electrical conductivity with moisture content has been obtained for some wood species [55, 93].

The second, and perhaps main problem with the FSP concept, is the picture of how water is removed from the wood structure. In the common definition of the FSP, the transition point between the moisture regime with moisture-dependent properties and the moisture regime with moisture independent properties is often argued to correspond to a transition in how water is taken up or removed from the wood structure. Thus, upon drying from a water-saturated state, water outside cell walls is thought to fully evaporate before moisture in cell walls is removed, while conversely in absorption cell walls are thought to be saturated before significant amounts of water are present outside cell walls. This coupling between a transition point for some physical property and the picture of the sequencing of water uptake or removal in the wood structure is often stated in literature. However, Fredriksson and Thybring [94] found that the cell-wall moisture content of Douglas fir (Pseudotsuga menziesii (Mirb.) Franco) increased during absorption and decreased in desorption, even in the over-hygroscopic moisture range when capillary water was present. Additionally, water within cell walls exhibited sorption hysteresis in the entire moisture range. The study by Fredriksson and Thybring [94] thus showed that water uptake in cell walls occurs simultaneously as capillary condensation occurs in macrovoids in the over-hygroscopic moisture range, and cell walls are not saturated until the whole wood specimen is saturated with water.

As an alternative to deriving the FSP from a change in material properties with moisture content, the maximum cell-wall moisture content, that is, the amount of moisture within cell walls of water-saturated wood, can be measured by, for example, differential scanning calorimetry (DSC), low-field nuclear magnetic resonance (LFNMR), or solute exclusion, see Sect. 7.11. A large amount of experimental data exists for maximum cell-wall moisture content of different wood species and, in general, the moisture content obtained is 0.05–0.15 g g−1 higher than the FSP found by measurements of changes in physical properties, see Table 7.3. In light of the results by Fredriksson and Thybring [94], this difference is logical, since cell walls are not fully saturated until the whole wood specimen is saturated with water.

Another method that has been used in literature for determining the maximum cell-wall moisture content is based on extrapolation of sorption isotherm models such as BET, HH, GAB, see Sect. 7.3.2. After fitting a given model to hygroscopic moisture sorption data, the derived model parameters are used to predict the cell-wall moisture content at saturation by extrapolating the sorption isotherm to 100% relative humidity [100]. While extrapolation is often regarded as highly uncertain, it has been justified by arguing that only minor changes in the shape of the sorption isotherm are likely to occur above 97% relative humidity [100], that is, in the over-hygroscopic moisture range. This is of course incorrect since the actual wood sorption isotherm is steep above 97% relative humidity as seen in Fig. 7.1. Nonetheless, the extrapolation is based on hygroscopic sorption data without significant contributions from water outside cell walls. Therefore, the assumption of only minor changes to the sorption isotherm could be valid for the water within cell walls. Then, predictions using sorption isotherm extrapolation should agree with measured maximum cell-wall moisture contents. This is, however, not the case as the values based on sorption isotherm extrapolations fall within the range of the FSP values determined from changes in physical properties with moisture content [100]. Extrapolation of hygroscopic sorption isotherms is thus not an adequate method for determination of the maximum cell-wall moisture content.

In summary, values of the FSP derived from physical properties do represent an important characteristic which is useful, for example, for engineering calculations of the expected change in properties with moisture. This FSP is, however, not the same moisture content as the maximum moisture content of the cell walls as illustrated in Fig. 7.8. The FSP concept should, tentatively, be used as it originally was defined, that is, the threshold moisture content at which physical properties no longer change significantly with moisture content.

5 Effect of Chemical Modification

Modification of the cell-wall chemistry by physical and chemical processes affects the wood-water relations, most notably how much water is absorbed under given environmental conditions.

5.1 Modes of Action of Cell-Wall Modifications

Three modes of action in terms of how cell-wall modifications affect water sorption can be recognized: bulking, cross-linking, and thermal degradation, see Fig. 7.9. Bulking occurs when modification agents are added into cell walls and take up space otherwise available for water, hereby reducing the sorption of water. One example of bulking is in acetylated wood where acetic anhydride is reacted with cell-wall hydroxyls, see Chap. 16. Although this decreases the number of hydroxyls available for interacting with water [10, 19], it has been shown that bulking is the primary effect of acetylation on water sorption [105]. Another example of a modification affecting water sorption by bulking is furfurylation where furfuryl alcohol is polymerized inside cell walls, see Chap. 16. The formed polymer may chemically react with lignin [106, 107], but the reduced water sorption is a consequence of bulking since furfurylation does not affect hydroxyls [107].

For the second mode of action, cross-linking, the modification agents added are capable of reacting with at least two functional groups, for example, hydroxyls. Examples of such modifications include treatments with 1,6-diisocyanatohexane (HDI), 1,3-dimethylol-4,5-dihydroxyethylenurea (DMDHEU), formaldehyde, glutaraldehyde, or glyoxal [108,109,110,111], see Chap. 16. The cross-linking of cell-wall polymers limits the available space for water by increasing the cell-wall stiffness, hereby restraining expansion of the cell wall, see Sect. 7.7. The last mode of action of modification on water sorption is thermal degradation by thermal modification, see Chap. 16. During this type of modification, the cell-wall material is degraded to a certain extent, in particular hemicelluloses, and hereby the number of hydroxyls accessible to water is reduced [15, 21]. Depending on the process conditions, the reaction products formed during thermal modification may re-polymerize inside the cell walls, hereby causing cross-linking of the cell-wall polymers [112, 113]. The final wood material has less affinity for water under hygroscopic conditions (<98% relative humidity) than untreated material to an extent that depends on the process conditions [112].

5.2 Terminology to Describe Effect of Chemical Modification

The effect of chemical modification on wood-water relations depends on both the chemistry itself and the extent of the modification. A common descriptor for the degree of modification is the relative change in mass as a result of the modification process. Modifications that increase the mass of wood are often described by the “weight percent gain” (WPG) in literature, while those modifications that decrease the mass, most notably thermal modification, are described by the “mass loss” (ML). It has, however, been suggested to characterize the degree of modification of all types of modifications by the “modification ratio,” Rmod (−) defined as [114]:

where mmod,d (g) is the dry mass of the wood material after modification and muntr,d (g) is the dry mass of the untreated material, that is, prior to modification.

The effect of modification on water sorption is referred to as the “moisture exclusion efficiency” (MEE) in literature. This is calculated as the relative difference in equilibrium moisture content between unmodified and modified materials under the same environmental conditions

where ξω (−) is the moisture exclusion efficiency, ωmod (g g−1) is the moisture content of the modified wood material, and ωuntr (g g−1) is the moisture content of the untreated material; both moisture contents are determined after conditioning to equilibrium with the same environmental conditions and sorption history (absorption or desorption).

In order to correctly compare the effect on water sorption across different types of modifications or different degrees of modification, it is necessary to correct ωmod for any mass increase related to the modification itself. Otherwise, an added mass due to modification, that is, Rmod > 0, will automatically decrease the moisture content as calculated by Eq. (7.5), even if the mass of water absorbed in the wood material is unaffected by modification, see Fig. 7.10. Therefore, for modifications with Rmod > 0, the moisture content of modified wood is often reported by the “reduced moisture content” [115, 116] found as

where ωmod (g g−1) is the moisture content of modified wood calculated by Eq. (7.5), ωmod,R (g g−1) is the reduced moisture content, mwood,d (g) is the dry mass of the modified material related only to the wood itself, mw (g) is the mass of absorbed water, and Rmod (−) is the modification ratio. No correction for added mass is needed for Rmod < 0.

In the same manner, the moisture exclusion efficiency needs to be corrected for added mass from the modification itself in order to be comparable across types of modifications and degrees of modification. This is represented in the “reduced moisture exclusion efficiency”

where ξω,R (−) is the reduced moisture exclusion efficiency, ωmod (g g−1) is the moisture content of the modified wood material, ωmod,R (g g−1) is the reduced moisture content of the modified wood material, ωuntr (g g−1) is the moisture content of the untreated material, and Rmod (−) is the modification ratio. Moisture contents must of course be determined after conditioning to equilibrium with the same environmental conditions and sorption history (absorption or desorption). No correction for added mass is needed for Rmod < 0 .

5.3 Effect of Modification on Cell-Wall Water and Capillary Water

The effect of modification on water sorption in the hygroscopic moisture range is illustrated in Fig. 7.11 for three types of wood modifications representing the three modes of action in Fig. 7.9: acetylation (bulking), HDI modification (cross-linking), and thermal modification. The reduced water sorption in modified wood is typically accompanied by a decrease in absolute sorption hysteresis in the hygroscopic range for wood modified by bulking and cross-linking modifications [19, 53, 110]. For thermally modified wood, sorption hysteresis depends on the process conditions, but many studies find only small effects of thermal modifications on absolute sorption hysteresis, although some report increased hysteresis [134] or decreased hysteresis [135] with thermal modification. With very few exceptions, however, sorption hysteresis of the various types of modified wood is evaluated in literature based on the absorption and scanning isotherms rather than absorption and desorption isotherms.

Reduced moisture-exclusion efficiency (ξω,R) in the hygroscopic range above 50% relative humidity for acetylated (closed diamonds), 1,6-diisocyanatohexane (HDI) modified (crosses), and thermally-modified wood (open diamonds) of various softwood and hardwood species as function of modification ratio, Rmod. (Based on experimental data [53, 119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,133])

Few studies are available which investigate the influence of chemical modification on capillary water. Furfurylation has been shown to decrease the lumen volume due to deposits of the polymer and changes in lumen cross-section, especially in rays [136]. Still, the over-hygroscopic sorption isotherm for furfurylated wood is higher than for untreated wood above about 96% relative humidity [29]. The reasons for this are not known, but it is possibly due to capillary condensation in cracks in the cell wall caused by the furfurylation or by capillary condensation between the cell wall and the furfuryl alcohol-based polymer [29]. The over-hygroscopic sorption isotherm of acetylated wood is however lower than for untreated wood [29] even though acetylation does not appear to change the lumen volume [136]. The change in the over-hygroscopic sorption isotherm could be due to weakened interactions between water and lumen surfaces [97, 137]. No or minor effects on the over-hygroscopic sorption isotherm have been observed for thermally modified wood [138] .

6 Cell-Wall Sorption Kinetics

At equilibrium between wood and the ambient environmental conditions (relative humidity and temperature), the constant exchange of water molecules between the absorbed phase and the gaseous phase is not noticeable. However, upon a change in the environmental conditions, a net transport of water molecules is observed as a gradual change in the moisture content as the new equilibrium state is approached. For larger wood specimens, this transport involves the diffusion of water vapor and absorbed water from the macroscopic surface of the bulk specimen, both of which are described in Sect. 7.8. An important part of the response of a wood specimen to a change in environmental conditions is, however, the exchange of water molecules between absorbed water and vapor in adjacent macrovoids in the wood structure in all locations, that is, the sorption process. Since this can easily be masked by macroscopic moisture transport, very thin wood specimens are needed for investigating sorption and eliminating or at least distinguishing it from macroscopic diffusion processes [139,140,141,142,143].

The water sorption process in wood and other polymeric materials after a step change in ambient air humidity is characterized by a gradually decreasing rate of mass change over time. Since sorption involves the transport of water molecules into or from the core of the solid material from/to the interface with the water vapor phase, it is natural to consider diffusion of absorbed water as the process governing sorption. For thin wood specimens or free polymer films of known thickness, it is possible to derive the diffusivity of the material from sorption experiments based on the initial slope of mass gain versus square root of time [144], see Sect. 7.12.2. Diffusivities derived from such an approach are not, however, consistent with results from other investigations. For instance, the sorption process is slower and takes longer time to equilibrium when the initial moisture content is increased with similar steps in relative humidity [139]; this is also seen for thin films of hemicelluloses [145]. This contradicts the finding that the diffusivity of the wood cell wall increases with amount of absorbed water, at least from dry to moderate moisture contents, see Sect. 7.8.1. Moreover, the approach to equilibrium seems to be independent of the wood cell-wall thickness [141], although the sorption process should correlate inversely with the square of the thickness if the process was governed by diffusion. Thus, it seems that diffusion of water molecules into or out of the cell walls is not the rate-limiting process governing sorption. A better indication of this can be seen for free polymer films of known thickness for which the diffusivity can be directly examined in steady-state diffusion experiments, see Sect. 7.12.1. For these, sorption of molecules which cause dimensional changes in the film, that is, shrinkage/swelling, is not related to the diffusivity of the molecules observed in steady-state diffusion experiments. Instead, the sorption process has been suggested to be limited by the relaxation of the swelling stresses related to the dimensional changes induced by sorption [144]; however, the actual mechanism governing sorption has not been convincingly documented yet.

The sorption process in wood is often reported to exhibit two-stage behavior [141, 146] similar to sorption in swelling polymer films [144, 145]. The approach to equilibrium during sorption thus appears to be the sum of at least two processes with different rates. Therefore, it is common in literature to model water sorption in cellulosic materials as a sum of exponentials processes, each responsible for a certain change in mass of absorbed water

where t (s) is time, m(t) (g) is mass of absorbed water at time t, m0 (g) is initial mass of absorbed water content (at time t = 0), Δmi (g) is the change in the ith water component, and τi (s) is the characteristic time constant associated with the ith water component. The most common version of Eq. (7.36) has n = 2 and is termed the Parallel Exponential Kinetics (PEK) model and it usually fits experimental sorption data well with R2 > 0.99. The name was coined by Kohler et al. [147] in a study of cellulosic fibers, but has increasingly been used to describe water sorption in wood as well. The mechanisms associated with the two processes are not agreed upon in literature, and the two components have been claimed to represent, for example, different sorption sites in the material, water molecules bound in different ways, or arising from different mechanical responses of the material. One crucial aspect of acquiring sorption data which influences the fitting of Eq. (7.34) is the duration of the sorption step, also termed hold time, that is, whether data collection is continued until equilibrium is attained or ended before this occurs. A meticulous study by Glass et al. [148] clearly documents that the most commonly employed criterion for ending data collection of 0.002% mass change per minute mischaracterizes the sorption process. In fact, the moisture content when sorption is interrupted may be more than 0.01 g g−1 moisture content away from the true equilibrium value [148]. Of greater concern to the fitting of the PEK model, data from a sorption measurement interrupted prior to equilibrium does not capture all of the kinetic behavior [148]. Thus, Thybring et al. [149] have shown that the PEK model parameters depend strongly on the hold time, and for sorption continued until equilibrium, the PEK model is incapable of mathematically capturing the form of the sorption curve. Therefore, the model cannot be used to obtain insights into moisture relations in wood or other cellulosic materials, and its use as a tool for exploring properties of materials interacting with water is not recommended .

7 Shrinkage and Swelling

The dimensions of wood depend on the moisture content. During desorption from the water-saturated state, the volume decreases, reaching a minimum in the completely dry state. This is called shrinkage and is quantified by the volume ratio

where Ssh (−) is the shrinkage, Vω (m3) is the wood volume at a given moisture content, and Vsat (m3) is the wood volume in water-saturated or green condition. Shrinkage is often used to describe changes in volume upon first drying of wood after harvesting. During absorption of water, the dimensions increase which is known as swelling and is quantified based on the dry wood volume as

where Ssw (−) is the swelling, Vω (m3) is the wood volume at a given moisture content, and Vd (m3) is the wood volume in dry condition.

7.1 Shrinkage and Swelling on Different Length Scales

Shrinkage or swelling upon a change in moisture content reflects a change in the amount of cell-wall water within cell walls. The phenomenon originates at the nanoscale and is observed on all length scales of wood, see Fig. 7.12.

As voids are virtually absent in the dry wood cell wall [150, 151], absorption of water results in the creation of nanopores within cell walls, increasing the total wood volume. During desorption, the removal of cell-wall water will cause a collapse of these nanopores. As water molecules are not absorbed in the interior of the cellulose microfibrils, increasing the amount of water results in increased distances between microfibrils [152] and conversely results in a decrease in intermicrofibrillar distances during desorption. However, the microfibrils themselves also undergo deformation during absorption or desorption as a result of the forces associated with the change in cell-wall water content [153, 154].

On the cell wall and tissue levels, a change in moisture content in normal, mature wood cells causes dimensional changes that are much smaller in the longitudinal direction than in the transverse directions. This is due to the orientation of the majority of microfibrils with only a small angle to the longitudinal direction, that is, the microfibril angle (MFA), hereby stiffening the cell wall mechanically in this direction. For wood cells and tissue with a larger MFA, such as compression wood in softwoods, the dimensional changes increases in the longitudinal direction, see Fig. 7.13. At the same time, the transverse shrinkage and swelling decreases with increasing MFA as expected theoretically [155,156,157]. The swelling and shrinkage are equal in the longitudinal and transverse directions at an MFA of 45°. The dimensional changes cause only a very slight shift in the MFA with moisture content [152].

Shrinkage in the longitudinal (open symbols) and tangential direction (closed symbols) from green to oven-dry condition of earlywood (diamonds) and latewood tissue (triangles) as function of microfibril angle. Data for radiata pine (Pinus radiata D. Don) [155]. The gray boxes and arrows around the schematic wood cells indicate the magnitude of shrinkage in different directions

In the transverse directions, wood shows a marked shrinkage and swelling anisotropy, that is, the dimensional changes differ between radial and tangential directions with the latter being about twice as large as the previous, that is, the shrinkage and swelling anisotropy is around two. This may cause distortions in sawn wood, depending on the orientation of growth rings in these, see Fig. 7.14.

Distortions of rectangular, square, and round pieces of wood causes by shrinkage and swelling anisotropy [158]

The shrinkage and swelling anisotropy can be observed on several length scales, but the exact origin is not properly understood. Isolated cell-wall material exhibits larger dimensional changes in directions normal to the interface between lumen and cell walls [159] which may be due to the organization of cellulose microfibrils in concentric lamellas [160]. However, this does not explain why the thickness swelling of tangential cell walls is about twice as large as the swelling in radial cell walls in both earlywood and latewood [161,162,163]. Additionally, isolated tissue of latewood exhibits nearly similar shrinkage and swelling in the transverse directions, whereas the shrinkage and swelling anisotropy in earlywood is higher [163,164,165,166,167]. The higher anisotropy in earlywood may be caused by restraints on the radial swelling from the radially aligned rays that are relatively stiffer compared with thin-walled earlywood cells than thick-walled latewood cells [164, 166]. In bulk wood, the early- and latewood are adjacent to each other and their interaction affects the overall shrinkage and swelling behavior [162, 164, 165]. The shrinkage and swelling anisotropy on the bulk-wood scale is around two. The dimensional changes in the longitudinal direction are for normal wood significantly lower [166] as observed on smaller length scales, but increase with increasing MFA as described previously [155].

The dimensional changes in wood are linearly correlated with the equilibrium moisture content in the range 0.05–0.20 g g−1 [168], although this linearity can extend above this range for wood conditioned without moisture gradients [55, 169], see Fig. 7.15. Table 7.4 gives the maximum swelling as well as the linear swelling coefficient for a range of wood species. The linearity is also observed at the cell-wall level [167]. However, the dimensions of bulk wood do not only depend on the moisture content but also on the moisture history, that is, the swollen volume is slightly larger in desorption than in absorption for the exact same amount of water within the wood [168, 172, 173], see Fig. 7.16.

Volumetric shrinkage (Ssh) of beech (Fagus grandifolia Ehrhart) (black, open diamonds) and yellow birch (Betula alleghaniensis Britton) (gray, closed diamonds) as function of equilibrium moisture content in desorption from water saturation in the hygroscopic and over-hygroscopic moisture range. (Based on experimental data [55, 169])

Swelling (Ssw) in the longitudinal, radial, and tangential directions as function of equilibrium moisture content at 25 °C during absorption (open diamonds) and desorption (closed squares) from nonsaturated condition. Experimental results for spruce [172]

7.2 Effect of Modification on Shrinkage and Swelling

Modification of the cell-wall chemistry affects the shrinkage and swelling of wood. Since the dimensional changes of wood are large compared with those of many other materials, a lot of the early research on wood modifications specifically aimed at reducing the moisture-related dimensional changes. In Sect. 7.5.1, three modes of action of wood modifications on the wood-water relations are described, which also differ in their effect on shrinkage and swelling. Bulking modifications such as acetylation cause an increase in the wood volume, that is, a preswelling or bulking of the material, but do not otherwise prevent swelling. This is apparent when comparing the water-swollen volume of untreated and acetylated wood specimens with similar initial volume. While the total water-swollen volume is similar, the amount of cell-wall water and the volume increase caused by this water is lower for the acetylated wood [117, 122, 174]. Cross-linking modifications reduce shrinkage and swelling beyond what can be expected from pure bulking of the cell wall. This is due to the restricted expansion of the cell wall by cross-linking of adjacent wood polymers. Thus, reductions in water-induced volume changes are gained with less preswelling of the material compared with bulking modifications [115]. Thermal degradation as induced by thermal modification of the wood is highly variable in its effect on shrinkage and swelling. Although the hygroscopic moisture uptake is reduced by thermal modification, the effect of swelling depends on the process parameters. Re-polymerization and cross-linking of cell-wall polymers during modification reduce swelling but in their absence may actually cause the modified material to swell more than untreated wood in the water-saturated state [112]. The initial change in wood volume due to modification is described by the bulking coefficient calculated as

where RV,mod (−) is the bulking coefficient, Vmod,d (m3) is the dry wood volume after modification, and Vuntr,d (m3) is the dry wood volume of the untreated material, that is, prior to modification.

The effect of modification on shrinkage and swelling is referred to as the “antiswelling efficiency” (ASE) in literature. This is calculated as the relative difference in swelling between unmodified and modified materials under similar environmental conditions

where ξsw (−) is the antiswelling efficiency, Ssw,mod (−) is the swelling of the modified wood material, and Ssw,untr (−) is the swelling of the untreated material determined by Eq. (7.38). Swelling is determined after conditioning to equilibrium with the same environmental conditions and sorption history (absorption or desorption). It is often determined in the water-saturated state.

In order to compare the effect of different types of modification or modification intensities on shrinkage and swelling, it is desirable to base the evaluation on a parameter that only includes the effect of modification on wood-water interactions, as described for the moisture exclusion efficiency, see Sect. 7.5.2. Otherwise, two types of modifications that result in similar volume increases upon sorption will be evaluated differently if the initial increase in volume due to modification differs. This is illustrated in Fig. 7.17 for modifications with similar volume increase but different bulking coefficient.

The quantification of reduction in swelling should preferably exclude the direct increase in volume that typically accompanies modification. This is done by relating the dimensional change in modified wood to the original wood volume by calculation of the “reduced swelling”

where Ssw,mod (−) is the swelling of the modified wood, Ssw,mod,R (−) is the reduced swelling, Vmod,ω (m3) is the volume of the modified material at given moisture content, Vmod,d (m3) is the dry volume of the modified material, Vuntr,d (m3) is the dry volume of the modified material related only to the wood itself, and RV,mod (−) is the bulking coefficient. The antiswelling efficiency can then be corrected for the increased volume due to modification as done in the “reduced antiswelling efficiency”

where ξsw,R (−) is the reduced antiswelling efficiency, Ssw,mod (−) is the swelling of the modified wood material, Ssw,mod,R (−) is the reduced swelling of the modified wood material, Ssw,untr (−) is the swelling of the untreated material, and RV,mod (−) is the bulking coefficient.

While the mass change due to modification is a commonly reported descriptor for wood modifications in literature, the volume change is rarely reported. This makes it difficult to evaluate the effect of modification on the wood-water relations as described by dimensional changes across different types of modification or modification intensities. However, the antiswelling efficiency calculated by Eq. (7.40) directly reflects the product performance in terms of dimensional stability and is therefore a valuable parameter for application of the modified product. The antiswelling efficiency in the water-saturated state without correction for initial volume increases is illustrated in Fig. 7.18 for three types of wood modifications representing the three modes of action in Fig. 7.9: acetylation (bulking), HDI modification (cross-linking), and thermal modification .

Antiswelling efficiency (ξsw) at water saturation for acetylated (closed diamonds), 1,6-diisocyanatohexane (HDI) modified (crosses), and thermally modified wood (open diamonds) as function of modification ratio, Rmod. (Based on experimental data [111, 117, 121, 122, 125, 126, 128, 129, 133,134,133, 175,176,177,178,179,180,181,182,183,184,185,186,187])

8 Moisture Transport in Wood

Three phases of water can exist in wood above the freezing point of water: cell-wall water and liquid water and water vapor in macrovoids (vessels, lumina, pits), see Sect. 7.1. At lower moisture levels, when no liquid water is present in the wood structure, moisture transport occurs through diffusion including both water vapor diffusion and diffusion of cell-wall water. At higher moisture levels, where liquid water is present, moisture transport also occurs by bulk flow of liquid water.

8.1 Diffusion of Water in Wood

Moisture diffusion in wood involves two of the three phases of water in wood: water vapor and cell-wall water. Diffusion describes a mass flow as a result of a gradient in chemical potential. It is caused by random molecular motion, yet with an overall migration of molecules in the opposite direction of gradients in chemical potential. Even in cases without such gradients, the molecules are continuously performing random walks but no overall net migration can be detected.

Multiple pathways are available for diffusion of moisture in wood as indicated in Fig. 7.19. This is a result of the anatomical structure of wood and the possibility of moisture transport in several phases. Moisture diffusion in the macrovoid structure has much lower diffusion resistance than the diffusion of cell-wall water [188]. Therefore, the diffusion resistance of the various pathways, and thus also the resistance to diffusion in the three anatomical directions, differs widely [189]. The transport of each phase of water should not be viewed as an isolated diffusion process as all diffusion processes are coupled via the continuous exchange of molecules between phases, see Fig. 7.19. This will cause absorption or desorption of cell-wall water if local nonequilibrium conditions occur, for example, when the moisture content in cell walls is different locally from the equilibrium moisture content corresponding to the relative humidity present in adjacent lumina. The kinetics of the absorption or desorption processes following these conditions is governed by the mechanisms discussed in Sect. 7.6.

Transport pathways for water in the longitudinal direction of wood. (Adapted from [190])

8.1.1 Fickian and Non-Fickian Moisture Transport

For isothermal conditions, gradients in chemical potential and concentration are correlated, and the diffusion of moisture can be described by the latter using Fick’s law:

where q (kg m−2 s−1) is the flux, c (kg m−3) is the moisture concentration, Dc (m2 s−1) is the diffusion coefficient with moisture concentration as driving potential, and x (m) is the length. This equation is analogous to, for example, Fourier’s law for heat transport; that is, there is a flux, which is driven by a gradient in concentration, and a transport coefficient. In the case of heat transport, temperature is the only potential that causes flow. However, since the state of water in a material can be described in different ways, there are several possible potentials for describing isothermal moisture diffusion and thus several formulations of Fick’s law:

where p (Pa) is the vapor pressure, v (kg m−3) is the vapor concentration in the gas phase, ω (g g−1) is the moisture content, ϕ (−) is the relative humidity, and D is the diffusion coefficient with units dependent on driving potential for diffusion as indicated by indices p, v, ω, and ϕ. In Eqs. (7.44), (7.45), (7.46), and (7.47), q and dx are the same, but there is one diffusion coefficient for each potential. This is important to keep in mind when comparing diffusion coefficients since comparison requires that the transport coefficients have the same potential. Especially Dv and Dc are easily confused since they have the same unit (m2 s−1). It is however possible to transform a diffusion coefficient based on potential a to a diffusion coefficient based on potential b by setting q = q for two of Eqs. (7.43), (7.44), (7.45), (7.46), and (7.47) above. This gives the relation:

Below are some examples on how to transform between different potentials.

Relation between Dv and Dω:

where dω/dϕ (−) is the slope of the sorption isotherm, and vsat (Pa) is the saturation vapor pressure. Equally, transformation from Dv to Dc can be made by using the sorption isotherm expressed as moisture concentration (kg m−3). The relation between moisture content and moisture concentration is:

where ρ (kg m−3) is the dry density of the wood.

Relation between Dv and Dp:

The flux q in Eq. (7.44) equals q in Eq. (7.45). This gives:

The ideal gas law gives the relation between vapor pressure and vapor content:

where R is the gas constant (8.314 J mol−1 K−1), V (m3) is volume, T (K) is temperature, and n (mol) is the amount of substance:

where m (g) is the mass of water vapor and Mw (g mol−1) is the molar mass of water. Therefore, m/V equals the vapor content and Eq. (7.52) can be written as:

The relation between Dv and Dp can therefore be expressed as:

For isothermal moisture transport, the different potentials give the same direction of the flux. For nonisothermal transport, however, different potentials can give opposite directions of the flux.

Another complexity with moisture transport is that the diffusion coefficient cannot be considered to be constant, as is commonly done for heat transport. The diffusion coefficient depends on the moisture state, and this moisture dependence in turn depends on which potential that is used to express the diffusion coefficient. For example, Dv and Dω are related by the slope of the sorption isotherm (Eq. (7.47)) which is nonlinear (Fig. 7.1) and the shape of the curve describing the diffusion coefficient as a function of moisture content or relative humidity is therefore different for the two potentials, see Table 7.5. For example, a peak in the diffusion coefficient with moisture content as potential has been found at moisture contents around 0.15–0.20 g g−1 [192], that is, in the range where the slope of the hygroscopic sorption isotherm increases. Results from cup measurements, see Sect. 7.12.1, which gives the diffusion coefficient with vapor content as potential, on the other hand yield diffusion coefficients which increase with increasing moisture content. In addition to the moisture dependence, diffusion coefficients are also temperature dependent [193].

Despite the complexity of moisture diffusion in wood with several coupled processes as illustrated in Fig. 7.19, a single diffusion coefficient is often assigned for transport in a given direction using one of Eqs. (7.41), (7.42), (7.43), (7.44), and (7.45). Such overall diffusion coefficients can be determined from steady-state experiments on macroscopic specimens, see Table 7.6. In these, a constant moisture gradient is maintained and the flux of moisture determined, see Sect. 7.12.1. No change in moisture content occurs either globally or locally despite the overall transport of moisture. It is, however, difficult to gain insights about the underlying mechanisms governing the various processes involved in water diffusion from such steady-state experiments. Moreover, the simplification of using a single diffusion coefficient breaks down for transient (nonsteady state) conditions, for example, when a bulk wood specimen in equilibrium with the ambient conditions is exposed to a change in relative humidity. In this case, the moisture content changes both globally and locally by processes governed by sorption kinetics as discussed in Sect. 7.6. It is therefore no surprise that moisture diffusion in cases involving a change in moisture content cannot adequately by described by Fick’s laws [189, 196, 197].

8.1.2 Diffusion of Water Vapor

The wood structure is typically dominated by elongated cells oriented along the longitudinal direction, for example, tracheids in softwoods and vessels in hardwoods. These cells contain long tubular macrovoids available for water vapor diffusion. As the diameter of the tubular elements is much smaller than their length, the unbroken transport pathway in such a macrovoid is shorter in the transverse directions than in the longitudinal direction. Therefore, diffusion coefficients in the longitudinal direction for water vapor and other gases are higher than those in the tangential and radial directions [189, 198,199,200,201]. The water transport pathway of lowest diffusion resistance between adjacent tubular elements is through pits, that is, through apertures and pores in the pit membrane (margo), see Fig. 7.19. The resistance to diffusion through nonaspirated pits is about three times larger than free vapor diffusion in lumina [202]. In aspirated pits, however, the diffusion resistance is significantly higher as the pit border is closed by the membrane and water transport is forced to occur as diffusion of cell-wall water through the solid torus. In the transverse directions, moisture diffusion resistance is dominated by the diffusion resistance of pits and whether these are aspirated or not [199,200,201,202]. The diffusion coefficient of water vapor decreases with increasing vapor pressure due to shorter mean free path of the water molecules [203].

8.1.3 Diffusion of Cell-Wall Water