Abstract

Effect of heat treatment intensity on some conferred properties like elemental composition, durability, anti-swelling efficiency (ASE) and equilibrium moisture content (EMC) of different European softwood and hardwood species subjected to mild pyrolysis at 230 °C under nitrogen for different durations has been investigated. Independently of the wood species studied, elemental composition is strongly correlated with the mass losses due to thermal degradations which are directly connected to treatment intensity (duration). In all cases, an important increase in the carbon content associated with a decrease in the oxygen content was observed. Heat-treated specimens were exposed to several brown rot fungi, and the weight losses due to fungal degradation were determined after 16 weeks, while effect of wood extractives before and after thermal treatment was investigated on mycelium growth. ASE and EMC were also evaluated. Results indicated important correlations between treatment intensity and all of the wood conferred properties like its elemental composition, durability, ASE or EMC. These results clearly indicated that chemical modifications of wood cell wall polymers are directly responsible for wood decay durability improvement, but also for its improved dimensional stability as well as its reduced capability for water adsorption. All these modifications of wood properties appeared simultaneously and progressively with the increase in treatment intensity depending on treatment duration. At the same time, effect of extractives generated during thermal treatment on Poria placenta growth indicated that these latter ones have no beneficial effect on wood durability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wood heat treatment has been reported as an attractive alternative to improve decay resistance of low natural durability wood species (Patzelt et al. 2002; Militz 2002; Esteves and Pereira 2009). During thermal treatment, cell wall polymers are more or less modified according to their chemical structure: Lignin is partially depolymerized and subjected to thermo-reticulation reactions (Zaman et al. 1984; Tjeerdsma et al. 1998; Tjeerdsma and Militz 2005; Brosse et al. 2010), cellulose crystallinity modified (Sivonen et al. 2002; Hakkou et al. 2005) and hemicelluloses strongly degraded (Nuopponen et al. 2004; Nguila Inari et al. 2007). Mass loss, which is in direct relation with treatment intensity (Hakkou et al. 2006; Mburu et al. 2008; Welzbacher et al. 2007), has been reported as one of the main parameter influencing wood decay durability. Recently, the authors have reported that elemental composition could be a reliable and accurate marker to predict mass losses caused by thermo-degradation reactions during thermal treatment and consequently wood decay resistance (Nguila Inari et al. 2009; Šušteršic et al. 2010; Chaouch et al. 2010). However, even if improvement of wood decay durability is strongly connected with evolution of its elemental composition, other parameters like equilibrium moisture content, dimensional stability or generation of degradation products with biocidal properties could be also involved to explain higher durability of heat-treated wood (Kamdem et al. 2000). The aim of this work is to investigate the evolution of all these different parameters as a function of treatment intensity to get better insight into the reasons for improved wood durability. For this purpose, several softwood and hardwood species were treated at 230 °C under nitrogen for different duration to reach mass losses of approximately 5, 10 and 15 % and their elemental composition, durability to brown rot fungi, dimensional stability, moisture content recorded and correlated treatment intensity.

Materials and methods

Materials

Samples were cut from defect-free air-dried heartwood boards of different softwood and hardwood species: beech, Fagus sylvatica L.; poplar, Populus nigra; ash, Fraxinus excelsior L.; pine, Pinus sylvestris and Silver fir, Abies pectinata.

Heat treatment

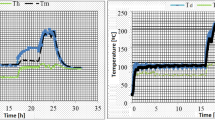

Heat treatment was performed under nitrogen on the different species by conduction between two metallic heating plates placed on a precision balance allowing for recording of dynamic mass loss as a function of time and temperature as previously described (Chaouch et al. 2010). Dimension of the boards used for heat treatment was 2.5 × 11 × 25 cm3 (R, T, L). Wood specimens were oven-dried at 103 °C during 48 h prior to heat treatment. Weight of the sample was recorded automatically all along the experiment, and mass loss due to thermo-degradation was calculated according to the formula:

where m 0 is the initial oven-dried mass of the sample before heat treatment and m 1 is the oven-dried mass of the same sample after heat treatment.

Microanalysis

Wood was ground to fine sawdust and passed through different sieves to obtain a particle size between 0.2 and 0.5 mm. Sawdust was conditioned at 103 °C for 24 h and stored in a closed bottle before analysis. Elemental analyses were performed on a Thermofinnigam Flash EA1112 microanalyser.

Fungal durability

Wood blocks of 5 × 10 × 30 mm3 were cut from heat-treated boards for fungal durability evaluations. Petri dishes (9 cm diameter) were filled with sterile medium (20 mL) prepared from malt (40 g) and agar (20 g) in distilled water (1 L) and inoculated with a piece of mycelium of a freshly grown culture. Petri dishes were incubated at 22 °C and 70 % HR until full colonization of the surface’s medium by the mycelium. Two heat-treated specimens and one untreated sample were placed in each Petri dish and exposed to the brown rot fungus (Poria placenta, Coniophora puteana or G. trabeum) for 16 weeks. Each experiment was duplicated. At the end of the test period, mycelia were removed and the blocks were dried at 103 °C and weighed (m 2) to determine the weight loss caused by the fungal decay:

where m 0 or 1 are, respectively, the initial oven-dried mass of untreated or heat-treated wood blocks before fungal exposure and m 2 is the oven-dried mass after fungal attack.

Effect of extractives on fungal growth

Extraction

Removal of extractives was performed from sawdust of untreated and 15 % mass loss heat-treated samples by Soxhlet extraction with toluene/ethanol (2/1, v/v) for 8 h.

Growth inhibition test

Mycelium was grown in 9 cm Petri dishes filled with 20 ml of malt agar medium prepared as above containing 50, 100, 250 or 500 ppm of extractives solubilized in the minimum amount of ethanol. Introduction of the extractives was carried out after medium sterilization (20 min, 120 °C, 1 bar) by addition of the necessary quantity of solution under sterile conditions. Plates were inoculated in their center with a small portion of a freshly grown malt agar P. placenta colony. The cultures were kept at 22 °C and 70 % RH. Growth inhibition was determined when the diameter of the control culture reached 9 cm by measuring the diameter of the colony estimated from the mean of three diameters and calculated according to the following formula:

where d 0 is the diameter of the control culture and d 1 is the diameter of the culture in the presence of tested solution. Each experiment was triplicated and the values averaged.

Anti-swelling efficiency measurements

Anti-swelling efficiency (ASE) was determined by measuring the increase in volume after humidification of treated and untreated wood blocks (20 × 10 × 10 mm3, the higher dimension corresponding to longitudinal direction). Blocks (6 replicates) were immersed in distilled water in a beaker placed in a desiccator and water soaked by placing the desiccator under vacuum (30 mbar during 30 min). Vacuum was then released and pressure returned to atmospheric. A cycle of 5 water soakings was applied (changing the water every day) before determination of the water-saturated volume. Blocks were then removed from water, wiped and measured. The volumetric swelling coefficients were calculated according to the formula:

where V 2 is the volume of water-saturated wood and V 0 or 1 is the volume of dry untreated or heat-treated wood.

The percentage of swelling was calculated from the wet and oven-dried volumes of treated and untreated blocks according to:

where Sc = volumetric swelling coefficient of unmodified samples and Sm = volumetric swelling coefficient of modified samples.

EMH determination

Wood blocks (10 × 25 × 25 mm3, the smaller dimension corresponding to longitudinal direction, 6 replicates) were placed in a climatic chamber WTB BINDER type KBF 115 at a temperature of 22 °C and different relative humidity of 30, 50, 65, 80 and 90 RH %. Blocks were kept for each HR % until stabilization of their mass before increase in relative humidity. Equilibrium moisture content (EMC) was calculated according to the formula:

where m h is the humid mass of the sample for a given HR % and m d is the oven-dried mass before experiment.

Results and discussion

Evolution of elemental composition, decay durability, equilibrium moisture content and anti-swelling efficiency of the different wood species treated for different durations is reported in Table 1. Utilization of a heat treatment device specially conceived to record dynamic mass loss as a function of time and temperature (Chaouch et al. 2010), makes it possible to adapt treatment durations to obtain mass losses near to 5, 10 and 15 % for each wood species allowing further comparisons of heat treatment intensity on conferred properties.

As expected, mass losses depend of the treatment duration and the nature of the wood species. Treatment duration necessary to obtain mass losses of 5 % is quite similar for all the treated species, but become more and more different as the mass loss increases. For final mass loss of 15 %, time to treat softwoods is two to three times longer than that for treating hardwoods. These differences may be explained by quite similar reactions at the beginning of the thermo-degradation processes involving mainly removal of associated water and vaporization of volatile extractable compounds, while the nature of the wood species becomes more important in a second time due to the difference in chemical composition between softwoods and hardwoods. Indeed, softwoods contain galactoglucomannan and arabinoglucuronoxylan, while hardwoods contain mainly glucuronoxylan and low amount of glucomannan. Moreover, xylan units of hardwood glucuronoxylan are strongly acetylated, comparable to softwood hemicelluloses (Sjöström 1981). Deacetylation of hemicelluloses causes liberation of acetic acid, which catalyses depolymerization of the less ordered carbohydrates. The higher amount of acetic acid generated from hardwood hemicelluloses may be the reason of the higher susceptibility of deciduous wood to thermal degradation reported in the literature compared to coniferous wood (Prins et al. 2006; Chaouch et al. 2010; Reppelin et al. 2010; Candelier et al. 2011).

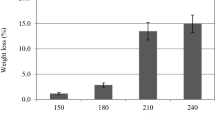

Carbon content increases with treatment intensity, while oxygen content decreases. Decay durability is also strongly connected to treatment intensity and increases progressively as the treatment intensity increases. All wood species can be considered as resistant to the tested basidiomycetes for mass losses between 10 and 15 %. Similarly, wood dimensional stability increases progressively with treatment intensity, while the equilibrium moisture content decreases as the level of wood thermo-degradation increases. Figures 1 and 2 represent the evolution of the different properties as a function of mass loss depending on treatment intensity. According to the nature of the wood species tested, these evolutions may be more or less linear in the range of the mass losses studied. However, more experiments will be necessary to be able to exactly define the general evolution trends of these different properties.

From these data, it appears that all the wood properties, which have been previously proposed to explain wood durability improvement, are simultaneously and progressively modified as the treatment intensity increases corroborating previous findings indicating that chemical modification of the wood cell wall polymers was the main reason for improved durability of heat-treated wood (Lekounougou et al. 2009). Indeed, according to literature (Kamdem et al. 2002; Weiland and Guyonnet 2003; Hakkou et al. 2006), improved durability of heat-treated wood against fungi may be due to different factors: (1) an increase in wood hydrophobicity, which limits the sorption of water into the material causing unfavorable conditions for the development of fungi, (2) generation of new extractives during thermal treatment which can act as fungicides, (3) modification of the wood polymers leading to non-recognition of these latter by enzymes involved in fungal degradation and (4) important degradation of the hemicelluloses, which constitute one of the main nutritive sources for fungi. Taking into account, the reactions occurring during wood mild pyrolysis, involving mainly degradation of amorphous polysaccharides and reactions of depolymerization/recondensation of lignins (Zaman et al. 1984; Sivonen et al. 2002; Nuopponen et al. 2004; Tjeerdsma and Militz 2005; Hakkou et al. 2005; Nguila Inari et al. 2007; Brosse et al. 2010), wood properties are progressively modified during treatment leading to a decrease in oxygen content due to dehydration reactions explaining EMC diminution in parallel with the increase in carbon content and dimensional stability associated with formation of carbonaceous material and thermo-reticulation reactions (Nguila Inari et al. 2007). At the same time, all these modifications, which are strongly interconnected, conferred to wood improved resistance to decay. Improvement of durability is the result of the chemical changes caused by the treatment which have a direct effect on ASE, EMC, chemical and elemental composition. Treatment intensity is therefore the main parameter conditioning final properties of heat-treated wood.

To complete the results of this study, the role of extractives on decay durability has been investigated for heat-treated and untreated samples. For this purpose, untreated and heat-treated samples presenting mass losses of 15 % were Soxhlet extracted with a mixture of toluene/ethanol (2/1, v/v) for 8 h and the effect of extractives on fungal growth was tested at different concentration. Results are presented in Table 2.

Contrary to the results described by Peters et al. (2009), the results of this study indicated clearly that extractives have no or very limited effect on the durability of heat-treated wood. Indeed, all wood species treated for mass losses of 15 % were totally resistant to the three brown rot fungi tested, extractives contained in wood present very limited effects or no effect on P. placenta fungal growth inhibition confirming previous studies described in the literature (Kamdem et al. 2002; Hakkou et al. 2006). Extractives present in heat-treated hardwood species have lower antifungal activities than those present initially in each wood species. Extractives of heat-treated softwood species can cause some retardation of fungal growth similarly to results described by Peters et al. (2009), but they possess in our opinion insufficient fungicidal properties to explain alone improvement of decay durability as proposed by these authors.

Conclusion

The results presented in this study confirm that all new properties conferred to wood after thermal treatment depend directly on the level of thermo-degradation and consequently on treatment intensity. Decay durability, equilibrium moisture content and oxygen content decrease progressively as the intensity of treatment increases, while anti-swelling efficiency and carbon content increase. Extractives generated during thermal treatment possess no or very weak antifungal activities as demonstrated by their inefficacy to inhibit growth of P. placenta mycelium. A wood thermo-degradation level between 10 and 15 % is required to achieve full durability to brown rot fungi, which is the result of chemical modifications occurring in wood during treatment responsible for the modifications of different properties of the material. These modifications including hemicelluloses degradation and lignin network modifications influence indirectly equilibrium moisture content and dimensional stability. All these changes are consequently more or less involved in the decay durability improvement, the main reason being the level of thermo-degradation. Further studies are currently under investigation to evaluate the effect of treatment temperature on the nature of thermo-degradation reactions and their effect on wood properties.

References

Brosse N, El Hage R, Chaouch M, Pétrissans M, Dumarçay S, Gérardin P (2010) Investigations of chemical modifications of Beech Wood Lignin during heat treatment. Polym Degrad Stab 95(9):1721–1726

Candelier K, Chaouch M, Dumarçay S, Pétrissans A, Pétrissans M, Gérardin P (2011) Utilization of thermodesorption coupled to GC–MS to study stability of different wood species to thermodegradation. J Anal Appl Pyrolysis 92(2):376–383

Chaouch M, Pétrissans M, Pétrissans A, Gérardin P (2010) Use of wood elemental composition to predict heat treatment intensity and decay resistance of different softwood and hardwood species. Polym Degrad Stab 95:2255–2259

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. Bioresources 4(1):370–404

Hakkou M, Pétrissans M, Zoulalian A, Gérardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stab 89(1):1–5

Hakkou M, Pétrissans M, Gérardin P, Zoulalian A (2006) Investigation of the reasons for fungal durability of heat-treated beech wood. Polym Degrad Stab 91:393–397

Kamdem D, Pizzi A, Triboulot M (2000) Heat-treated timber: potentially toxic byproducts presence and extent of wood cell wall degradation. Holz Roh Werkst 58:253–257

Kamdem DP, Pizzi A, Jermannaud A (2002) Durability of heat-treated wood. Holz Roh Werkst 60:1–6

Lekounougou S, Pétrissans M, Jacquot JP, Gelhaye E, Gérardin P (2009) Effect of heat treatment on extracellular enzymatic activities involved in beech wood degradation by Trametes versicolor. Wood Sci Technol 43:331–341

Mburu F, Dumarçay S, Bocquet JF, Pétrissans M, Gérardin P (2008) Effect of chemical modifications caused by heat treatment on mechanical properties of Grevillea robusta wood. Polym Degrad Stab 93(2):401–405

Militz H (2002) Thermal treatment of wood: European processes and their background. The International Research Group on Wood Preservation. IRG/WP 02-40241

Nguila Inari G, Mounguengui S, Dumarçay P, Pétrissans M, Gérardin P (2007) Evidence of char formation during heat treatment by pyrolysis. Polym Degrad Stab 92:997–1002

Nguila Inari G, Pétrissans M, Pétrissans A, Gérardin P (2009) Elemental composition of wood as a potential marker to evaluate heat treatment intensity. Polym Degrad Stab 94:365–368

Nuopponen M, Vuorinen T, Jamsa S, Viitaniemi P (2004) Thermal modifications in softwood studied by FTIR and UV resonance Raman spectroscopy. J Wood Chem Technol 24(1):13–26

Patzelt M, Stingl R, Teischinger A (2002) Termische Modifikation von Holz und deren Einfluß auf ausgewählte Holzeigenschaften. In: Modifiziertes Holz Eigenschaften und Märkte. Lignovisionen Band 3, pp 101–149. ISSN: 1681-2808

Peters J, Pfriem A, Horbens M, Fischer S, Wagenführ A (2009) Emissions from thermally modified beech wood, their reduction by solvent extraction and fungicidal effect of the organic solvent extracts. Wood Mat Sci Eng 1(2):61–66

Prins MJ, Ptasinski KJ, Janssen FJJG (2006) Torrefaction of wood. Part 2. Analysis of products. J Anal Appl Pyrolysis 77:35–40

Reppelin V, Govin A, Rolland M, Guyonnet R (2010) Modelling anhydrous weight loss of wood chips during torrefaction in a pilot kiln. Biomass Energy 34:602–609

Sivonen H, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56:648–654

Sjöström E (ed) (1981) Wood polysaccharides, Chap. 3. In: Wood chemistry. Fundamentals and applications. Academic Press, Inc. (Harcourt Brace Jovanovitch Publishers), Orlando, Florida, pp 49–67

Šušteršic Ž, Mohareb A, Chaouch M, Pétrissans M, Petrič M, Gérardin P (2010) Prediction of the decay resistance of heat treated wood on the basis of its elemental composition. Polym Degrad Stab 95:94–97

Tjeerdsma B, Militz H (2005) Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat treated wood. Holz Roh Werkst 63:102–111

Tjeerdsma B, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterization of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56(3):149–153

Weiland JJ, Guyonnet R (2003) Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz Roh Werkst 61:216–220

Welzbacher C, Brischke C, Rapp A (2007) Influence of treatment temperature and duration on selected biological, mechanical, physical and optical properties of thermally modified timber. Wood Mat Sci Eng 2(2):66–76

Zaman A, Alen R, Kotilainen R (1984) Heat behavior of Pinus sylvestris and Betula pendula at 200–230°C. Wood Fiber Sci 32(2):138–143

Acknowledgments

The authors gratefully acknowledge the financial support of the CPER 2007-2013 “Structuration du Pôle de Compétitivité Fibres Grand’Est” (Competitiveness Fibre Cluster).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chaouch, M., Dumarçay, S., Pétrissans, A. et al. Effect of heat treatment intensity on some conferred properties of different European softwood and hardwood species. Wood Sci Technol 47, 663–673 (2013). https://doi.org/10.1007/s00226-013-0533-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0533-z