Abstract

The oleaster (Elaeagnus angustifolia L.) plant grown in three different locations in Nevşehir, Turkey was analyzed to determine its phenolic component profile, total phenolic compound, total carotenoid, total flavonoid, and antioxidant capacity values. Ultrasonic extraction of the oleaster’s flour, shell, core, flower, and leaf parts was carried out under solvent and acidic hydrolysis conditions using eight different polarity solvents (water, methanol, ethanol, acetone, ethyl acetate, butanol, petroleum ether, and hexane). The phenolic component profiles were determined using high-performance liquid chromatography with diode array detector (HPLC–DAD), and the main phenolic components in the oleaster samples were gallic acid, catechin, and their derivatives. At the same time, antioxidant properties of oleaster samples were evaluated by Folin–Ciocalteu (FC), ABTS, FRAP, DPPH, and CHROMAC methods. Various parts of oleaster, whose phenolic component content was determined in this study, are thought to be a natural source that can be used against degenerative diseases in future studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Foods are natural sources of various health-promoting substances with important biological activities. In recent years, the functional and nutritional properties of food components have gained importance with regards to improving human health. The relationship between different phenolic contents of fruits, vegetables, and plants and their antioxidant properties has been the focus of research for many years [1].

Elaeagnus angustifolia L., also called oleaster, Russian olive, wild olive or silver berry, belongs to the Elaeagnus genus of the Elaeagnacea (Araliaceae) family. Oleaster, which has small reddish-brown elliptical fruits and has more than 90 species, is mostly grown in parts of Asia, Europe, and North America [2]. It is a plant with potential use in food, cosmetics, and pharmaceutical fields, especially when grown in the Southeast and Central Anatolia regions of Turkey [3]. Oleaster is a good source of essential fatty acids (especially palmitoleic, palmitic, and linoleic fatty acids), vitamins (especially A, C, and E), and minerals, as well as being fruit rich in carotenoids, flavonoids, and other bioactive components (sitosterol, cardiac glycoside, terpene, alkaloid, polysaccharides, triterpenoids, coumarin, amino acids, saponins, phytoene, tannins, etc.) [3,4,5,6,7]. Various parts of the oleaster (such as the flower, fruit, leaf, shell, flour, oil, and gum) are also used as herbal medicine due to their therapeutic properties such as antioxidant, anti-inflammatory, antimutagenic, antitussive, antitumor, antiarthritic, antimicrobial, and hepatoprotective [3, 4, 7,8,9].

The increase in free radicals in the body due to external factors causes oxidative damage by attacking biomolecules such as proteins, lipids, enzymes, RNA, and DNA. These free radicals play a role in the formation and progression of many diseases such as cancer, cardiovascular diseases, atherosclerosis, Parkinson's, and Alzheimer's, after oxidative damage. Phenolic compounds, which are naturally found in herbal products and have different biological activities, are used to inhibit free radicals [10]. Phenolic compounds are known for their antioxidant and radical scavenging properties, as well as their antimicrobial, anti-fungal, anti-radiation, immunomodulatory, anti-inflammatory, and anti-cancer activities [11,12,13]. There are various methods that differ in terms of experimental principles and conditions for the investigation of phenolic compounds and the determination of antioxidant capacity [14]. Therefore, it is extremely important to use robust, sensitive, selective, and reliable analytical techniques [15].

In this study, it was aimed to characterize the phenolic compound profile of the oleaster samples collected from Nevşehir, Turkey. For this purpose, phenolic compound profiles of oleaster’s various parts: flour, shell, core, flower, and leaf, which extracted under different conditions, were determined by HPLC–DAD. While antioxidant capacity and total phenolic content of oleaster samples were determined using the FC, ABTS, FRAP, and CHROMAC methods, at the same time, total carotenoid and total flavonoid contents were determined.

Materials and methods

Chemical and reagent

Ethanol, methanol, acetone, hexane, butanol, petroleum ether, ethyl acetate, sodium nitrate, aluminum chloride, potassium persulfate, sodium dihydrogen phosphate, iron (III) chloride, vanillic acid, formic acid, phosphoric acid, acetic acid, and hydrochloric acid were purchased from Merck (Darmstadt, Germany). Acetonitrile, 2,2-Diphenyl-1-picrylhydrazyl, 2,2-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt, 2,4,6-Tris(2-pyridyl)-s-triazine, β-carotene, potassium dichromate, sodium hydroxide, 1,5-diphenylcarbazide, Folin–Ciocalteu reagent, potassium sodium tartrate, copper(II) sulfate pentahydrate, sodium carbonate, sodium acetate trihydrate, 2-hydroxycinnamic acid, caffeic acid, p-coumaric acid, ferulic acid, resveratrol, gallic acid, trolox, gallic acid, quercetin, isoquercitrin, rutin, chlorogenic acid, rosmarinic acid, ellagic acid, myricetin, kaempferol, kaempferol glycoside, p-hydroxybenzoic acid, and protocatechuic acid in HPLC grade were purchased from Sigma-Aldrich (St. Louis, MO., USA). (−)-Epigallocatechin, (−)-epigallocatechin gallate, (+)-catechin, (−)-epicatechin, and (−)-epicatechin gallate in HPLC grade were purchased from Extrasynthese (Genay Cedex, France). Luteolin was purchased Applichem (Darmstadt, Germany). Water was purified with Purelab Option-Q from Elga Laboratory (UK).

Oleaster (Elaeagnus angustifolia L.)

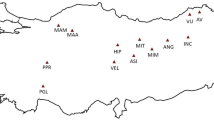

Oleaster (Elaeagnus angustifolia L.) samples were collected from three different locations in Nevşehir, Türkiye in 2019. The samples were divided into five parts as flour, shell, core, leaf, and flower and were dried under laboratory conditions (22–24 °C). The samples were divided into small pieces after drying and stored at 4 °C until the extraction processes.

Preparation of phenolic fractions of oleaster samples

Ultrasonic extractions for both solvent extraction and acidic hydrolysis of the oleaster’s flour, shell, core, flower, and leaf were performed using eight different solvents with water, methanol, ethanol, acetone, ethyl acetate, n-butanol, petroleum ether, and hexane. For solvent extraction, x g of oleaster sample was extracted with y mL of solvent for 60 min at 45 °C (x: 2 g, y: 20 mL for oleaster’s flour; x: 2 g, y: 20 mL for oleaster’s shell; x: 1 g, y: 20 mL for oleaster’s core; x: 0.1 g, y: 10 mL for oleaster’s flower; x: 1 g, y: 20 mL for oleaster’s leaf). In acidic hydrolysis, x g of oleaster sample was extracted with y mL of solvent for 60 min at 45 °C (x: 1 g, y: 10 mL for oleaster’s flour; x: 1 g, y: 10 mL for oleaster’s shell; x: 1 g, y: 10 mL for oleaster’s core; x: 0.1 g, y: 10 mL for oleaster’s flower; x: 0.5 g, y: 10 mL for oleaster’s leaf). Then, 0.02 M HCl was added (pH adjusted to 2) and was extracted for 60 min at 45 °C. After extraction, the samples were filtered with filter paper. The extracts of n-butanol, acetone, hexane, ethyl acetate, and petroleum ether were evaporated in the evaporator, and the remaining residues were dissolved in 5 mL of methanol. All extracts were kept at 4 °C until analysis.

Determination of phenolic compounds in oleaster samples

The HPLC–DAD (high-performance liquid chromatography–diode array detector) system (Agilent 1200 Series) is equipped with an auto-sampler, vacuum degasser, and binary pump, and were used for the chromatographic analysis of phenolic compounds in the oleaster samples. Flow rate and injection volume were adjusted as 0.5 mL/min and 20 µL, respectively. XBridge C18 (4.6 × 250 mm, 3.5 μm) column was used for the separation of phenolic components. During the analysis, a gradient solvent program consisting of 1% aqueous formic acid (phase A) and acetonitrile (phase B) was applied. The gradient elution program was arranged according to the percent of B as: 10% in 0–10 min, 13% in 10–20 min, 41% in 20–25 min, 70% in 25–35 min, and 10% in 35–36 min [16]. Limit of detection (LOD: 3 s/m, s: standard deviation, m: slope) and limit of quantitation (LOQ: 10 s/m) were determined.

Spectroscopic analysis

Total phenolic content analysis

Total phenolic content of oleaster samples were determined by the Folin–Ciocalteu method [16, 17]. According to the method, x mL extract of oleaster samples, (2-x) mL of distilled water, 2.5 mL of Lowry C solution, and 0.25 mL of Folin reagent (1:3 diluted with distilled water) were put into the test tube. The test tubes were mixed and kept in the dark for 30 min. And then UV–Vis absorption of the samples was analyzed at 750 nm. Total phenol contents of the samples were determined using the calibration curve prepared with gallic acid.

The antioxidant capacity analysis

The antioxidant capacities of oleaster samples were determined by the ABTS [18, 19], FRAP [16, 20], DPPH [21, 22], and CHROMAC [16, 23] methods. The calibration curve obtained using trolox was used to determine antioxidant capacity values.

For the ABTS method, ABTS• radical solution was prepared as 2.45 mM K2S2O8 in 7 mM ABTS solution by distilled water. In test tubes, x mL oleaster extract, (4-x) mL ethanol, and 1 mL ABTS• radical solution (1:10 diluted with distilled water) were taken and mixed. 6 min later, absorptions of samples were measured at 734 nm by UV–Vis Spectrophotometer.

In the FRAP method, pH 3.6 acetate buffer and 20 mM FeCl3 by distilled water and 10 mM TPTZ solution by 40 mM HCl solution were prepared. FRAP reagent was prepared by mixing acetate buffer, FeCl3, and TPTZ in a ratio of 10:1:1. The mixtures were kept for 30 min at 37 °C by adding x mL of oleaster extract and (3-x) mL of FRAP reagent, analyzed at 593 nm using the UV–Vis Spectrophotometer.

Free radical scavenging activity of oleaster samples was determined with a DPPH reagent. The extracts of oleaster (x mL) and 0.18 mL of 1 mM DPPH reagent (dissolved with methanol) were mixed, and the final volume in the test tubes was filled to 3 mL with methanol. The samples were kept in the dark for 30 min, and then, the absorbance values were recorded at 515 nm using the UV–Vis Spectrophotometer.

For the CHROMAC method, x mL of oleaster extract, (0.5-x) mL of distilled water, 3.5 mL of pH 2.8 phosphate buffer, and 0.5 mL of K2Cr2O7 (50 mg/L, dissolved in pH 2,8 phosphate buffer) were mixed. One minute later, 0.5 mL of 1,5-diphenylcarbazide (3.4 × 10–4 mol/L, dissolved in pH 2,8 phosphate buffer) was added and the samples were kept in the dark for 50 min. Then, the samples were analyzed at 540 nm using the UV–Vis Spectrophotometer.

Total flavonoid analysis

Total flavonoid content of oleaster samples was determined by a colorimetric method [24]. According to the method, x mL of oleaster extract, (2.7-x) mL of distilled water and 0.15 mL of 5% NaNO3 were mixed, and the mixture was kept in the dark for 6 min. Then, 0.15 mL of 10% AlCl3 was added to the mixture and was kept in the dark for 6 min again. Finally, 2 mL of 1 M NaOH was added to the mixture and kept in the dark for 15 min. The absorbance at the end of the reaction was read at 510 nm and results were given as a catechin equivalent (CAE).

Total carotenoid analysis

The absorbance of oleaster extracts were measured at 450 nm by UV–Vis Spectrophotometer [25]. To calculate the average carotenoid concentrations (mol/L), the following equation was used:

with A450: absorbance of 450 nm, F: dilution factor, d: light path (1 cm), and ε: molar absorptivity coefficient (ε = 136,400 for methanol, ε = 135,800 for ethanol). Using molecular weight of β-carotene, the results were expressed as β-carotene equivalent.

Statistical analysis

The analysis data were statistically analyzed using the MINITAB 17.0 (Minitab Inc., Stage College, PA) statistical program with one-way ANOVA (solvent and acidic hydrolysis extracts separately for each method, p < 0.05).

Results and discussion

Method validation of phenolic compounds

Validation parameters of standard phenolic compounds analyzed by HPLC–DAD for the qualitative and quantitative analysis of phenolic content in oleaster are shown in Table 1. A total of 24 phenolic compounds were detected in extracts of oleaster. Calibration curves of the standard phenolic compounds occurred in the range of 1–20 mg/L and the correlation coefficient of phenolic compounds with determined linearity was found to be higher than 0.9900. Recovery studies were done to the yield of extraction of phenolic compounds in different solvent environments. The results obtained showed that the recovery of phenolic compounds varies according to the solvent polarity and the acidity of the medium.

Phenolic composition of oleaster

An HPLC phenolic profile of oleaster’s flour is given in Table 2. Major differences have been identified between solvent media and extraction applications. A total of 15 phenolic compounds (catechin, epicatechin, epicatechin gallate, epigallocatechin, caffeic acid, p-coumaric acid, ferulic acid, rosmarinic acid, resveratrol, protocatechuic acid, vanillic acid, gallic acid, kaempferol glycoside, and rutin) were identified in extracts of oleaster’s flour. It has been established that the main components are catechin, and catechin derivatives (epicatechin, epicatechin gallate, and epigallocatechin). While the amount of catechin in water and methanol solvent media decreased with acidic hydrolysis compared to solvent extractions, it increased in other solvent media. At the same time, while no catechin was detected in ethyl acetate, petroleum ether, and hexane solvent extracts, it was detected in acidic hydrolysis. While epicatechin was not seen in methanol, ethanol, petroleum ether, and hexane solvent extracts, it was detected in acidic hydrolysis. In general, it was observed that the amount of epicatechin in the samples increased with acidic hydrolysis. While epicatechin gallate was detected in all solvent extracts, it was detected only in methanol and ethanol extracts when acidic hydrolysis was performed. The amount of epicatechin gallate in the samples decreased with acidic hydrolysis. Epigallocatechin gallate was detected only in the methanol extract, but the amount of epigallocatechin gallate increased with the application of acidic hydrolysis and was detected in all solvent extracts. Formation and an increase in the amount of gallic acid have been observed after acidic hydrolysis in water, ethanol, and acetone solvents.

The phenolic compounds of 19 (catechin, epicatechin, epicatechin gallate, epigallocatechin, epigallocatechin gallate, caffeic acid, p-coumaric acid, ferulic acid, rosmarinic acid, resveratrol, protocatechuic acid, vanillic acid, gallic acid, ellagic acid, myricetin, kaempferol, kaempferol glycoside, isoquercitrin, and rutin) were determined in the oleaster’s shell (Table 3). Catechin, epicatechin gallate, and epigallocatechin (in acidic medium) were determined as main compounds. The catechin amount decreased as the solvent polarity decreased, and increased with acidic hydrolysis, except with water and methanol solvents. While epicatechin gallate was found at high amounts in solvent extractions, it could not be detected except in methanol and ethanol extracts after acidic hydrolysis, and the amounts were found to be low in these two-solvent media. While it was not observed in solvent extraction, it was observed that the amount of epicatechin–epigallocatechin gallate and epigallocatechin increased with acidic hydrolysis. At the same time, gallic acid was formed after acidic hydrolysis in ethanol and acetone solvents.

Twenty phenolic compounds: catechin, epicatechin, epicatechin gallate, epigallocatechin, epigallocatechin gallate, chlorogenic acid, caffeic acid, p-coumaric acid, ferulic acid, rosmarinic acid, resveratrol, protocatechuic acid, vanillic acid, gallic acid, ellagic acid, quercetin, myricetin, kaempferol, isoquercitrin, and rutin were detected in the oleaster’s core under different extraction conditions (Table 4). Generally, the amount of catechin and derivatives (epicatechin, epigallocatechin, and epigallocatechin gallate) have been seen to decrease as the solvent polarity decreased. Also, their amounts have been seen to increase by acidic hydrolysis except water and methanol solvents. While gallic acid could not be detected in solvent extractions, gallic acid was detected in all solution media except ethanol.

The phenolic compounds of 16 (catechin, epicatechin, epigallocatechin gallate, 2-hydroxycinnamic acid, caffeic acid, p-coumaric acid, ferulic acid, resveratrol, protocatechuic acid, vanillic acid, gallic acid, ellagic acid, myricetin, kaempferol, kaempferol glycoside, and isoquercitrin) have been determined in the oleaster’s flower extracts (Table 5). The most abundant phenolic compound in the oleaster’ flower extracts was determined as catechin. While catechin was found only in water, methanol, and ethanol extracts by solvent extraction, it was detected in high amounts in solvent environments other than petroleum ether, and hexane after acidic hydrolysis. Epicatechin and epigallocatechin gallate were seen in some solvents after acidic hydrolysis. Likewise, gallic acid was not observed in solvent extracts (except acetone), but was detected in most solvent media after acidic hydrolysis.

In the oleaster’s leaf extracts, catechin, epicatechin, epicatechin gallate, epigallocatechin, epigallocatechin gallate, 2-hydroxycinnamic acid, p-coumaric acid, ferulic acid, resveratrol, protocatechuic acid, vanillic acid, gallic acid, ellagic acid, quercetin, myricetin, luteolin, kaempferol, kaempferol glycoside, and isoquercitrin were determined (Table 6). Catechin, epicatechin, and epigallocatechin gallate were determined as the main components. After acidic hydrolysis, catechin and epicatechin amounts decreased in water extract and increased in other solvent extracts. While epicatechin gallate, epigallocatechin, and epigallocatechin gallate were seen in some solvent extracts, they could not be detected after acidic hydrolysis.

As a result of epigallocatechin gallate and epicatechin gallate epimerization, there was an increase in the amounts of gallic acid, epigallocatechin, and epicatechin as degradation products. Likewise, as a result of epicatechin gallate and epicatechin epimerization, their amounts decreased, while catechin gallate and catechin amounts increased. When heat treatment was applied during extraction, epigallocatechin gallate and epicatechin gallate degrade and their amounts decreased. As a result of this decrease, an increase in the amount of gallic acid was observed. In addition, as the concentration of epigallocatechin gallate increased, its stability at low pH increases and its degradation decreased. Since epigallocatechin is dominant in epimerization, its amount appears to increase during heat treatment, but it starts to degrade when exposed to heat treatment for a long time [26]. In general, catechin is stable in an acidic environment, since the oxidation rate of catechin increases directly with increasing pH [27, 28].

Total phenolic content

Total amount of phenolic substances in different extracts of oleaster were determined by the Folin–Ciocalteu method and results were expressed by mg GAE/g sample. There were variations between phenolic contents of the parts of the plant, at different solvent environments and different extraction conditions. The amount of total phenolic compounds contents were found as follows; they ranged from 0.13 to 24.57 mg GAE/g of oleaster flour for solvent extracts and 15.67 to 34.89 mg GAE/g of oleaster flour for acidic hydrolysis (Table 7), 0.37 to 16.99 mg GAE/g of oleaster shell for solvent extracts and 13.78 to 36.16 mg GAE/g of oleaster shell for acidic hydrolysis (Table 8), 1.12 to 44.93 mg GAE/g of oleaster core for solvent extracts and 22.82 to 158.73 mg GAE/g of oleaster core for acidic hydrolysis (Table 9), 2.36 to 44.55 mg GAE/g of oleaster flower for solvent extracts and 36.79 to 205.26 mg GAE/g of oleaster flower for acidic hydrolysis (Table 10), and 0.95 to 34.12 mg GAE/g of oleaster leaf for solvent extracts and 8.86 to 77.49 mg GAE/g of oleaster leaf for acidic hydrolysis (Table 11). Total phenolic compound values of the solvent extractions of the oleaster parts increased as the solvent polarity increased. The highest total phenol values were observed in water extracts. In acidic hydrolysis, total phenol contents of the samples increased compared to the solvent extraction.

Incilay [8] reported TP contents of methanolic extracts of leaf (average amount 1.07 µg GAE/g DW), flower (average amount 1.66 µg GAE/g DW), fruit (average amount 2.96 µg GAE/g DW), and fruit peel (average amount 1.85 µg GAE/g DW) parts of the Elaeagnus angustifolia L. Ishaq et al. [3] reported TP contents in water, methanol, acetone, and hexane extracts of the Elaeagnus umbellate berry as 20.0 ± 2.1, 18.6 ± 1.5, 18.2 ± 1.3, and 16.3 ± 0.8 mg GAE/g autumn olive fruit, respectively. It is seen that TP contents increase with increasing solvent polarity. Ozen et al. [29] studied TP content of the extracts of fruit and leaf parts of Elaeagnus umbellate Thunb. in increasing concentrations (50–500 µg/mL) and different solvent media. According to the results, TP contents of the fruit’s water and methanol extracts and the leaf’s methanol, ethanol, and acetone extracts have been found to be significantly high. TP contents of petroleum ether, chloroform, methanol, and water extracts of Elaeagnus kologa leaf were determined as 23.11 ± 0.31, 9.42 ± 0.43, 18.99 ± 0.24, and 20.04 ± 0.09 mg catechol/g, respectively [30]. TP values of 70% methanolic extract of Elaeagnus latifolia Linn. were determined as 7.04 ± 0.27 mg GAE/100 g extract [31]. In another study, TP contents in peel and pulp extracts (85% methanol) of Elaeagnus angustifolia L. fruit collected from different genotypes were determined [32]. According to the results, TP contents of the peel were in the range of 1179.04 and 262.36 mg GAE/100 g FW. Also, the highest and lowest TP contents of the pulp were 820.88 and 250.55 mg GAE/100 g FW, respectively. TP contents in different genotypes of Elaeagnus umbellate Thunb. fruit were in the range of 168.9 and 258.1 mg GAE/100 g FW [33]. Saboonchian et al. [34] determined TP contents using ethanoic and methanolic extract of leaf and flower of Elaeagnus angustifolia L. For both varieties, the phenolic content of the methanol extract is higher; at the same time, the leaf has a higher phenolic content than the flower. The leaf of Eleagnus oldhamii Maxim. was extracted with methanol and the result of TP content was found as 106.09 ± 3.83 µg catechin/mg sample [9].

Antioxidant capacity values of oleaster extracts in different extraction conditions were determined using FRAP, ABTS, CHROMAC, and DPPH methods, and the results were expressed as mg TE/g sample. The FRAP method is based on the reduction of Fe3+–TPTZ (ferricripyridyltriazine) complex to the ferrous form at low pH. For the FRAP method, the antioxidant capacity values ranged from 0.43 to 15.10 mg TE/g of oleaster flour for solvent extracts and from 2.68 to 46.66 mg TE/g of oleaster flour for acidic hydrolysis (Table 7), from 0.45 to 2.12 mg TE/g oleaster shell for solvent extracts and from 1.85 to 16.77 mg TE/g oleaster shell for acidic hydrolysis (Table 8), from 1.32 to 47.99 mg TE/g oleaster core for solvent extracts and from 7.64 to 336.12 mg TE/g oleaster core for acidic hydrolysis (Table 9), from 4.93 to 20.62 mg TE/g oleaster flower for solvent extracts and from 20.70 to 146.40 mg TE/g oleaster flower for acidic hydrolysis (Table 10), and from 1.08 to 21.68 mg TE/g oleaster leaf for solvent extracts and from 5.82 to 98.45 mg TE/g oleaster leaf for acidic hydrolysis (Table 11). In a study [32], the antioxidant capacities of the oleaster fruit's seed and pulp with different genotypes were examined. The results showed that the antioxidant capacity of peel was in the range of 57.00–131.33 mg Fe2+/100 g FW. The highest antioxidant capacity of pulp was found as 164.67 mg Fe2+/100 g FW and the lowest was found as 86.00 mg Fe2+/100 g FW. In the other study, according to Faramarz et al. [35], the antioxidant capacity of peel and pulp extracts of Elaeagnus angustifolia L. collected from different genotypes were determined as 0.246 and 548 mM Fe2+/mg, respectively [35].

The ABTS method is based on the reduction of ABTS• radical formation by phenolic compounds. For the ABTS method, the antioxidant capacity values ranged from 0.89 to 30.99 mg TE/g oleaster flour for solvent extracts and from 3.04 to 22.43 mg TE/g oleaster flour for acidic hydrolysis (Table 7), from 1.60 to 23.30 mg TE/g oleaster shell for solvent extracts and from 4.76 to 19.85 mg TE/g oleaster shell for acidic hydrolysis (Table 8), from 2.34 to 51.20 mg TE/g oleaster core for solvent extracts and from 15.05 to 129.26 mg TE/g oleaster core for acidic hydrolysis (Table 9), from 13.67 to 49.68 mg TE/g oleaster flower for solvent extracts and from 37.98 to 200.30 mg TE/g oleaster flower for acidic hydrolysis (Table 10), and from 1.55 to 43.15 mg TE/g oleaster leaf for solvent extracts and from 7.66 to 119.73 mg TE/g oleaster leaf for acidic hydrolysis (Table 11). According to Incilay [8], the antioxidant capacities of methanol extracts of oleaster’s leaf were found to be in the range of 0.385 ± 0.027 and 1.955 ± 0.000 µg TE/g, flowers were 0.623 ± 0.000 and 1.689 ± 0.029 µg TE/g, fruits were 0.031 ± 0.003 and 4.642 ± 0.133 µg TE/g, and fruit peels were 0.434 ± 0.027 and 1.651 ± 0.027 µg TE/g. The antioxidant capacity value of Elaeagnus latifolia Linn. was measured as 0.070 ± 0.003 µg trolox/mL extract [31]. In Nazir et al.’s [10] study, IC50 values of methanol, hexane, chloroform, ethyl acetate, n-butanol, and aqueous extracts of Elaeagnus umbellate Thunb. were found as 760, 135, 57, 70, 120, and 1175 µg trolox/mL extract, respectively. In another study, the average antioxidant capacity values in different genotypes of Elaeagnus umbellate Thunb. fruit were in the range of 20.3 and 29.9 µmol TE/g sample [33].

The CHROMAC method is based on the measurement of the remaining Cr (VI) as a result of the transformation of antioxidants reacting with excessive Cr (VI) in acidic environment into radical structures and reduction of Cr (VI) to Cr (III) form. With the CHROMAC method, the antioxidant capacity values ranged from 29.72 to 62.32 mg TE/g oleaster flour for solvent extracts and from 64.83 to 122.07 mg TE/g oleaster flour for acidic hydrolysis (Table 7), from 35.00 to 76.04 mg TE/g oleaster shell for solvent extracts and from 49.37 to 117.86 mg TE/g oleaster shell for acidic hydrolysis (Table 8), from 24.70 to 100.11 mg TE/g oleaster core for solvent extracts and from 93.02 to 336.94 mg TE/g oleaster core for acidic hydrolysis (Table 9), from 245.93 to 859.08 mg TE/g oleaster flower for solvent extracts and from 454.83 to 699.48 mg TE/g oleaster flower for acidic hydrolysis (Table 10), and from 74.84 to 196.96 mg TE/g oleaster leaf for solvent extracts and from 122.59 to 233.95 mg TE/g oleaster leaf for acidic hydrolysis (Table 11).

The DPPH method is based on the decrease in the amount of radicals as a result of the interaction between DPPH• radical and antioxidants. For the DPPH method, the antioxidant capacity IC50 values ranged from 11.60 to 24.08 mg TE/g oleaster flour for solvent extracts and from 22.66 to 39.71 mg TE/g oleaster flour for acidic hydrolysis (Table 7), from 14.48 to 22.27 mg TE/g oleaster shell for solvent extracts and from 23.50 to 34.42 mg TE/g oleaster shell for acidic hydrolysis (Table 8), from 23.72 to 38.28 mg TE/g oleaster core for solvent extracts and from 47.25 to 67.55 mg TE/g oleaster core for acidic hydrolysis (Table 9), from 148.70 to 898.99 mg TE/g oleaster flower for solvent extracts and from 238.97 to 620.75 mg TE/g oleaster flower for acidic hydrolysis (Table 10), and from 24.00 to 364.96 mg TE/g oleaster leaf for solvent extracts and from 47.54 to 78.10 mg TE/g oleaster leaf for acidic hydrolysis (Table 11). In a study done with extracts of the different parts of Elaeagnus angustifolia L., the highest antioxidant capacity was seen in fruit extract (from 1.109 to 4.450 µg TEAC/g DW) and the lowest antioxidant capacity was seen in leaf extract (from 0.713 to 1.620 µg TEAC/g DW). Also, the antioxidant capacity of the flower extract had ranges of 0.541 and 2.425 µg TEAC/g DW, while the antioxidant capacity of the fruit peel extract had ranges of 0.756 and 2.063 µg TEAC/g DW [8]. Antioxidant capacity (IC50) values of different solvents extracts of Elaeagnus umbellate Thunb. were found in the ranges of 40 and 1300 µg trolox/mL extract, respectively. It was observed that the higher the polarity of the solvent, the higher the antioxidant capacity values [10]. According to Hassanzadeh and Hassanpour (2018), the mean antioxidant capacity of peel and pulp was found as 74.71% and 53.76%, respectively. Faramarz et al. [35] revealed that the mean antioxidant capacities (IC50) in different genotypes of Elaeagnus angustifolia L. peel, flesh, and seed were 86.95, 91.79, and 32.68 mg Trolox/mL, respectively.

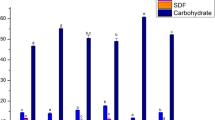

Total flavonoid content (TFC) of oleaster’s flour, shell, core, flower, and leaf were expressed mg catechin (CAE)/g sample. The TFC of oleaster’s flour were found between 0.40 and 6.45 mg CAE/g sample for solvent extracts and ranged from 0.63 to 6.63 mg CAE/g sample for acidic hydrolysis (Table 7). The highest flavonoid contents showed in water extracts of solvent extraction and in water and ethanol extracts of acidic hydrolysis, while the lowest flavonoid contents were identified in methanol extracts of solvent extraction and in butanol and acetone extracts of acidic hydrolysis. The TFC of oleaster’s shell range from 0.16 to 0.88 mg CAE/g sample for solvent extracts and 0.12 to 5.13 mg CAE/g sample for acidic hydrolysis (Table 8). The highest flavonoid contents were found in butanol extracts of solvent extraction and in ethanol extracts of acidic hydrolysis, while water extracts showed the least for both of them. The TFC of oleaster’s core ranged between 1.57 and 14.82 mg CAE/g sample for solvent extracts and 2.01 and 42.30 mg CAE/g sample for acidic hydrolysis (Table 9). The highest flavonoid contents were shown by methanol extracts in solvent extraction and by butanol extracts in acidic hydrolysis, while the lowest flavonoid contents were identified in water extracts for both of them. The TFC of oleaster’s flower were determined as ranging from 1.47 to 13.17 mg CAE/g sample for solvent extracts and 2.13 to 21.79 mg CAE/g sample for acidic hydrolysis (Table 10). Butanol extracts of solvent extraction and water extracts of acidic hydrolysis showed the lowest flavonoid contents, while the highest flavonoid contents were determined in hexane, and petroleum ether extracts of solvent extraction, and acetone, and hexane extracts of acidic hydrolysis. The TFC of oleaster’s leaf ranged between 0.33 and 2.61 mg CAE/g sample for solvent extracts and 0.26 and 5.56 mg CAE/g sample for acidic hydrolysis (Table 11). Water extracts showed the lowest flavonoid contents, while the highest flavonoid contents were determined in hexane extracts for both of them. Ishaq et al. [3] reported flavonoid content of Elaeagnus umbellata ranged between 1.5 ± 0.15 and 3.8 ± 0.3 mg quercetin/g sample. The highest flavonoid content was seen in water, methanol, and hexane extracts, while acetone extracts showed the least. Earlier studies by Merculieff et al. (2014) identified total flavonoid content of Elaeagnus kologa leaf’s different solvent extracts ranged from 5.20 ± 0.06 to 21.19 ± 0.45 mg rutin/g sample. The results indicate that total flavonoid content was highest in petroleum ether extract, moderate in water and methanol extracts, and lower in chloroform extract. In another study, total flavonoid content of Elaeagnus latifolia Linn. fruit’s 70% methanolic extract was found as 5.44 ± 0.16 mg quercetin/100 g extract [31]. According to the results of Hassanzadeh and Hassanpour (2018), the highest TF content of peel was 489.58 mg catechin/100 g FW and the lowest TF content of peel was 23.50 mg catechin/100 g FW. The highest and the lowest TF contents of pulp were 318.75 and 17.00 mg catechin/100 g FW, respectively. In the present study, TF content of Elaeagnus angustifolia L. fruit was 1.35 mg catechin/g sample [36]. Also, Faramarz et al. [35] showed that the TF content of peel and pulp was reported as 121.55 and 148.52 mg catechin/100 g FW, respectively.

Total carotenoid contents (TCC) of oleaster’s flour, shell, core, flower and leaf at different mediums were expressed by mg β-carotene (BC)/g sample. The TCC of oleaster’s flour was determined as ranging from 0.24 to 6.62 mg BC/g sample for solvent extracts and from 1.56 to 11.08 mg BC/g sample for acidic hydrolysis (Table 7). The TCC of solvent extractions of oleaster’s shell were found to range from 0.29 to 7.80 mg BC/g sample, while acidic hydrolysis of oleaster’s shell varies in the range from 2.33 to 34.74 mg BC/g sample (Table 8). TCC of oleaster’s core were found to range from 1.25 to 10.69 mg BC/g sample for solvent extractions and ranged from 3.16 to 46.82 mg BC/g sample for acidic hydrolysis (Table 9). The TCC of solvent extractions of oleaster’s flower were determined to range from 1.12 to 113.61 mg BC/g sample and in the ranged between 25.88 and 193.60 mg BC/g sample for acidic hydrolysis (Table 10). TCC of oleaster’s leaf ranged from 0.22 to 77.57 mg BC/g sample for solvent extractions, while acidic hydrolysis values ranged from 14.12 to 164.81 mg BC/g sample (Table 11). According to Carradori et al. (2020), total carotenoid contents of Elaeagnus angustifolia fruits and leaves were found as 3.2 ± 0.6 and 18.3 ± 2.5 µg BC/g dry extract, respectively [37]. In the present study, total carotenoid contents in different genotypes of Elaeagnus umbellate Thunb. fruit ranged from 43.4 to 59.3 mg BC/100 g fresh mass.

Conclusions

Oleaster is a functional food product that has a high phenolic component content. It is known to have therapeutic properties such as antioxidant, anti-inflammatory, antimutagenic, antitussive, antitumor, antiarthritic, antimicrobial, and hepatoprotective due to its wide phenolic component content. In this study, it was aimed to determine the phenolic component profiles in different extraction environments of the oleaster samples. In general, the antioxidant properties of the oleaster differ according to the geographical region where the plant grows, the parts of the plant, and the extraction conditions. Acidic hydrolysis using water or methanol solvents should be given preference to ensure maximum recovery.

References

Leja M, Mareczek A, Wyzgolik G, Klepacz-Baniak J, Czekońska K (2007) Antioxidative properties of bee pollen in selected plant species. Food Chem 100:237

Hamidpour R, Hamidpour S, Hamidpour M, Shahlari M, Sohraby M, Shahlari N, Hamidpour R (2017) Russian olive (Elaeagnus angustifolia L.): from a variety of traditional medicinal applications to its novel roles as active antioxidant, anti-inflammatory, anti-mutagenic and analgesic agent. J Tradit Complement Med 7:24

Ishaq S, Rathore HA, Sabir SM, Maroof MS (2015) Antioxidant properties of Elaeagnus umbellata berry solvent extracts against lipid peroxidation in mice brain and liver tissues. Food Sci Biotechnol 24:673

Khan SU, Khan AU, Shah AUHA, Shah SM, Hussain S, Ayaz M, Ayaz S (2016) Heavy metals content, phytochemical composition, antimicrobial and insecticidal evaluation of Elaeagnus angustifolia. Toxicol Ind Health 32:154

Okmen G, Turkcan O (2014) A study on antimicrobial, antioxidant and antimutagenic activities of Elaeagnus angustifolia L. leaves. Afr J Tradit Complement Altern Med 11:116

Sabir MS, Ahmad DS, Hussain IM, Tahir KM (2007) Antibacterial activity of Elaeagnus umbellata (Thunb.) a medicinal plant from Pakistan. Saudi Med J 28:259

Saleh AI, Mohamed I, Mohamed AA, Abdelkader M, Yalcin HC, Aboulkassim T, Batist G, Yasmeen A, Al Moustafa AE (2018) Elaeagnus angustifolia plant extract inhibits angiogenesis and downgrades cell invasion of human oral cancer cells via Erk1/Erk2 inactivation. Nutr Cancer 70:297

Incilay G (2014) Volatile composition, antimicrobial and antioxidant properties of different parts from Elaeagnus angustifolia L. J Essent Oil-Bearing Plants 17:1187

Liao CR, Chang YS, Peng WH, Lai SC, Ho YL (2012) Analgesic and anti-inflammatory activities of the methanol extract of Elaeagnus oldhamii Maxim. in mice. Am J Chin Med 40:581

Nazir N, Zahoor M, Nisar M, Khan I, Karim N, Abdel-Halim H, Ali A (2018) Phytochemical analysis and antidiabetic potential of Elaeagnus umbellata (Thunb.) in streptozotocin-induced diabetic rats: pharmacological and computational approach. BMC Complement Altern Med 18:1

Medeiros KCP, Figueiredo CAV, Figueredo TB, Freire KRL, Santos FAR, Alcantara-Neves NM, Silva TMS, Piuvezam MR (2008) Anti-allergic effect of bee pollen phenolic extract and myricetin in ovalbumin-sensitized mice. J Ethnopharmacol 119:41

Pascoal A, Rodrigues S, Teixeira A, Feás X, Estevinho LM (2014) Biological activities of commercial bee pollens: antimicrobial, antimutagenic, antioxidant and anti-inflammatory. Food Chem Toxicol 63:233

Pinto B, Caciagli F, Riccio E, Reali D, Sarić A, Balog T, Likić S, Scarpato R (2010) Antiestrogenic and antigenotoxic activity of bee pollen from Cystus incanus and Salix alba as evaluated by the yeast estrogen screen and the micronucleus assay in human lymphocytes. Eur J Med Chem 45:4122

Mohdaly AAA, Mahmoud AA, Roby MHH, Smetanska I, Ramadan MF (2015) Phenolic extract from propolis and bee pollen: composition, antioxidant and antibacterial activities. J Food Biochem 39:538

Fanali C, Dugo L, Rocco A (2013) Nano-liquid chromatography in nutraceutical analysis: determination of polyphenols in bee pollen. J Chromatogr A 1313:270

Karkar B, Şahin S, Güneş ME (2021) Evaluation of antioxidant properties and determination of phenolic and carotenoid profiles of chestnut bee pollen collected from Turkey. J Apic Res 60(5):765

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods Enzymol 299:152

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231

Şahin S, Aybastıer Ö, Dawbaa S, Karkar B, Çakmak T (2020) Study of the ability of lutein and neoxanthin as standards and in the extract of chlamydomonas reinhardtii to prevent oxidatively induced DNA base damage using ultrasensitive GC–MS/MS analysis. Chromatographia 83:919

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem 239:70

Son S, Lewis BA (2002) Free radical scavenging and antioxidative activity of caffeic acid amide and ester analogues: structure-activity relationship. J Agric Food Chem 50:468

Şahin S, Işık E, Aybastıer Ö, Demir C (2012) Orthogonal signal correction-based prediction of total antioxidant activity using partial least squares regression from chromatograms. J Chemometrics 26:390–399

Şahin S, Karkar B (2019) The antioxidant properties of the chestnut bee pollen extract and its preventive action against oxidatively induced damage in DNA bases. J Food Biochem 43:1

Sarıburun E, Şahin S, Demir C, Türkben C, Uylaşer V (2010) Phenolic content and antioxidant activity of raspberry and blackberry cultivars. J Food Sci 75(4):328–335

Biehler E, Mayer F, Hoffmann L, Krause E, Bohn T (2010) Comparison of 3 spectrophotometric methods for carotenoid determination in frequently consumed fruits and vegetables. J Food Sci 75:55

Li N, Taylor LS, Ferruzzi MG, Mauer LJ (2013) Color and chemical stability of tea polyphenol (−)-epigallocatechin-3-gallate in solution and solid states. Food Res Int 53:909

Li N, Taylor LS, Ferruzzi MG, Mauer LJ (2012) Kinetic study of catechin stability: effects of pH, concentration, and temperature. J Agric Food Chem 60:12531

Roginsky V, Alegria AE (2005) Oxidation of tea extracts and tea catechins by molecular oxygen. J Agric Food Chem 53:4529

Ozen T, Yenigun S, Altun M, Demirtas I (2017) Phytochemical constituents, ches and urease inhibitions, antiproliferative and antioxidant properties of Elaeagnus umbellata Thunb. Comb Chem High Throughput Screen. 20(6):559

Merculieff Z, Ramnath S, Sankoli SM, Venkataramegowda S, Murthy GS, Ceballos RM (2014) Phytochemical, antioxidant and antibacterial potential of Elaeagnus Kologa (Schlecht.) Leaf. Asian Pac J Trop Med 7:S599

Panja S, Chaudhuri D, Baban Ghate N, Le Minh H, Mandal N (2014) In vitro assessment of phytochemicals, antioxidant and DNA protective potential of wild edible fruit of Elaeagnus Latifolia Linn. Fruits 69:303

Hassanzadeh Z, Hassanpour H (2018) Evaluation of physicochemical characteristics and antioxidant properties of Elaeagnus Angustifolia L. Sci Hortic (Amsterdam) 238:83

Wang SY, Fordham IM (2007) Differences in chemical composition and antioxidant capacity among different genotypes of autumn olive (Elaeagnus Umbellate Thunb.). Food Technol Biotechnol 45:402

Saboonchian F, Jamei R, Hosseini Sarghein S (2014) Phenolic and flavonoid content of Elaeagnus Angustifolia L. (leaf and flower). Avicenna J Phytomedicine 4:231

Faramarz S, Dehghan G, Jahanban-Esfahlan A (2015) Antioxidants in different parts of oleaster as a function of genotype. BioImpacts 5:79

Abizov EA, Tolkachev ON, Mal’Tsev SD, Abizova EV (2008) Composition of biologically active substances isolated from the fruits of Russian olive (Elaeagnus Angustifolia) introduced in the European part of Russia. Pharm Chem J 42:696

Carradori S, Cairone F, Garzoli S, Fabrizi G, Iazzetti A, Giusti AM, Menghini L, Uysal S, Ak G, Zengin G, Cesa S (2020) Phytocomplex characterization and biological. Molecules 25:1

Acknowledgements

The authors thank the Scientific Research Projects Foundation (BAP) of the Bursa Uludag University of Turkey [Project No. FGA-2021-416] for its support of this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This study does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karkar, B., Şahin, S. Determination of phenolic compounds profiles and antioxidant properties of oleaster (Elaeagnus angustifolia L.) grown in Turkey. Eur Food Res Technol 248, 219–241 (2022). https://doi.org/10.1007/s00217-021-03875-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03875-y