Abstract

Antibacterial activity of an optimized formulation (edible coating), gaseous ozone, γ-irradiation treatments, and their combinations on ready-to-eat frozen pre-cut green peppers against Escherichia coli, Salmonella enteric, and Listeria innocua as foodborne pathogen bacteria, was assessed. In situ results showed that the antibacterial coating presented a large spectrum activity against Gram-positive and Gram-negative bacteria. In addition, ozone gaseous treatment at concentration of 10 ppm during 5 min allowed a total inhibition of E. coli after 4 days and a noticeable log reduction in Listeria and Salmonella during storage time. According to the obtained results, irradiation was the most effective technique to inhibit the growth of bacteria in alone or combined treatments. Different treatments had no significant impact on color parameters of pre-cut green peppers. Furthermore, no significant effect on chlorophyll content of pre-cut green peppers was also observed which is in accordance with the colorimetric results. Some statistical differences were noted in vitamin C content of pre-cut green peppers after coating treatment due to the additional ascorbic acid content in coating formulation, although no negative effect of treatments on the quality of pre-cut green peppers (total AA + DHA content) was observed. Furthermore, the sensory analysis confirmed that treatments had no significant effect (p > 0.05) on sensory attributes of peppers (color, odor, and taste).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Demand for consumption of green peppers has increased recently, and especially used as an ingredient in ready-to-eat (RTE) foodstuffs [1, 2]. In addition, consumption of fruits and vegetables was generally increased due to the recommendations by nutritionists for eating five fruits and vegetables per day [3]. In this regard, green pepper (Capsicum annuum, L.) whether fresh, cooked, or ready to eat salad is among the vegetables highly sold in markets not only for its nutritional value including vitamins C, E and A, minerals, fibers, and content of antioxidants compounds (i.e., phenols, chlorophyll, carotenoides, and ascorbic acid) [4] but also for its low caloric content [5].

In other side, foodborne disease affects one on six US residents every year with 128,000 hospitalizations and 3000 deaths annually [6].

To remove pathogens from the surface of vegetables, water-containing NaClO is generally used to wash products [7], but many harmful by-products are then produced which are carcinogens; for example, chloramines and trihalomethanes [8]. Furthermore, the reduction of bacteria obtained by this treatment is < 2 log CFU/g [9,10,11]. For this reason, alternative treatments with natural highly antibacterial compounds (safer than chlorine) are needed to inhibit human pathogens in fresh product [11].

In recent years, citrus essential oils (EOs) have attracted great attention due to their strong antibacterial properties, high yields, aromas, and flavors, and particularly the presence of flavonoids. Flavonoids are a group of polyphenolic compounds that include flavanones, flavones, and their derivatives [12]. Citrus flavonoids have been reported to have many biological activities such as antioxidant, antibacterial, and anti-inflammatory properties [13]. Citrus flavonoids have a large spectrum of biological activity against a wide range of Gram (+/−) bacteria [14].

Cranberry juice also presented biological activities such as antioxidant, anti-inflammatory effects, and anti-cancer [15]. These activities are assigned to pro-anthocyanidins (PACs), also known as condensed tannins which are the most consumed polyphenolic compounds in the human diet. The antibacterial effect of cranberry juice and its extracts was investigated against some bacterial strains like as E. coli O157:H7, Listeria monocytogenes, Pseudomonas aeruginosa, Salmonella typhimurium, and Staphylococcus aureus. The results indicated that all the bacterial strains, both Gram (+) and Gram (−), were selectively inhibited by the cranberry phenolic compounds [15].

A recent study by Harich et al. showed that concentrated cranberry juice reduced significantly the level of E. coli, S. typhimurium, and L. monocytogenes in RTE red peppers and cranberries [16].

Due to the strong desire to reduce the use of chemicals applied to fruits and vegetables, the non-residual/non-thermal feature of ionizing radiation is also an important advantage. Food irradiation is a physical means of food processing that involves exposing the pre-packaged or bulk foodstuffs to gamma rays, X-rays, or electrons to induce bacterial demise that can cause food poisoning, to control insect infestation, to delay fruit ripening, or prevent vegetables from sprouting [17,18,19]. For example, gamma irradiation was employed to restrain potato sprouting and also kill pests in grain. It allowed a high reduction of microorganism on red and black peppers compared to pasteurization [20]. According to Thayer and Rajkowski, the shelf life of strawberries, sweet onions, carrots, and lettuce was increased when ionizing irradiation was used for reducing microorganisms’ spoilage [21]. The irradiation dose 1 kGy allowed a reduction on population of microorganisms and preserved the nutritional value of fresh-cut lettuce during 9 days of storage at 4 °C [22]. Furthermore, in some cases, the radiation processing also leads to increase the nutritional values of irradiated fruits and vegetables such as vitamin C content and phenolic compounds [23, 24].

Ozonation is another technique that largely used in food industry all over the world and is “Generally Recognized As Safe” (GRAS) by FDA and classified as a disinfectant for food industry in the USA, especially for the good manufacturing practice (GMP) associated with the treatments of bottled water [25]. Xu reported that ozone is 1.5 times more efficient than chlorine, since it allowed a significant reduction but also inhibition of a large number of microorganisms compared to chlorine [26]. Graham also reported that the efficacy of ozone is 3000 times faster than chlorine without producing dangerous by-products after decomposition [25]. In addition, ozone allowed the inhibition of bacteria, molds, yeasts, parasites, and viruses, therefore, showing a bactericidal broad spectrum [27]. Indeed, gaseous ozone is not much toxic when used at low concentration [28]. However, at high levels, it can be lethal for humans by mainly affecting the respiratory tract.

Beside the efficiency of disinfection techniques, maintaining the quality of vegetable is also a determinative factor to choose the technique. The appearance of green pepper is one of the fundamental factors affecting the quality, acceptability, and pleasantness of such dressing. Chlorophylls, responsible of color in green pepper, are highly susceptible to degradation during processing. Chlorophyll degradation was significantly affected by different factors such as enzyme chlorophyllase, heat, light, oxygen, chemicals, and acids that result in color shift of chlorophylls from brilliant green to olive brown compounds such as pheophytin and pheophorbide [29, 30].

Many studies confirmed that fresh peppers are an excellent source of vitamins and phenolic compounds. The genotype, maturity and growing, and storage conditions can influence the concentration of all compounds present in peppers [31,32,33,34]. Vitamin C concentration of peppers cultivar was found to be between 46 and 243 mg/100 g [32,33,34,35]. Vitamin C, l-ascorbic acid (AA), is a well-known antioxidant that efficiently scavenges free radicals. More than 90% of AA in human diet is supplied by fruits and vegetables. AA seems to increasingly have beneficial effects on the aging processes and on the prevention of age-related diseases as atherosclerosis, cardiovascular diseases, cancer, and neurodegenerative diseases [36].

Dehydroascorbic acid (DHA) also exhibits a biological activity, because it can be converted into ascorbic acid in human body. Therefore, it is crucial to quantify both AA and DHA [37].

The objectives of this study were to evaluate the in situ antibacterial activity of an optimized antibacterial formulation (edible coating), gaseous ozone, γ-irradiation treatments, and their combinations on ready-to-eat frozen green peppers against Gram-negative bacteria (E. coli and S. enterica) and Gram-positive bacteria (Listeria innocua) as foodborne pathogen bacteria. Furthermore, physicochemical quality of samples such as vitamin C content and color attributes regarding to chlorophyll content was assessed.

Finally sensorial properties of the green peppers treated with different treatments were evaluated according to a nine-point hedonic scale.

Materials and methods

Raw material

Pre-cut green peppers were provided by Bonduelle Americas Inc. (Saint-Denis-sur-Richelieu, QC, Canada) and were stored at − 20 °C until used.

Preparation of bacterial cultures

Stock cultures of E. coli (ATCC 25922), S. enterica (ATCC 53648 chi 4064), and L. innocua (LSPQ 3285) were stored at − 80 °C in tryptic soy broth (TSB) medium (Alpha Biosciences Inc., Baltimore, MD, USA) containing glycerol (10% v/v). Prior to each experiment, stock cultures were grown through two consecutive 24–48 h growth cycles in TSB at 37 °C. Working cultures were diluted in peptone water to obtain the bacterial concentration of 103–104 CFU/mL for in situ studies.

Preparation of the natural antibacterial formulation (coating)

The antibacterial formulation (coating) was prepared under sterile conditions, based on the preliminary results of inhibiting properties of this formulation on vegetable. Antibacterial formulation (coating) containing Asian plant extract (lemongrass essential oil) (Bio Lonreco Inc., Dorval, QC, Canada), commercially citrus extract—Biosecur F440D® (Biosecur Lab Inc., Mont St. Hilaire, QC, Canada), fermented dextrose Prolong 2 (BSA-Quebec, Montreal, QC, Canada), and concentrated cranberry juice (CCJ) (Atoka Cranberries Inc., Manseau, QC, Canada) with respective ratio of 0.1:1:2.5:10, prepared in distilled water (under agitation) contains 0.06% of Tween® 80 as emulsifier. The antibacterial solution was then homogenized with an Ultra-Turrax T25 disperser (IKA Works Inc., Wilmington, NC, USA) at 15,000 rpm for 5 min, at room temperature.

Spraying treatment of the antibacterial formulation on pre-cut green peppers

The sample of pre-cut green peppers (25 g) was placed in a plastic cup and inoculated with 100 µL of bacterial suspension at concentration of 106 CFU/mL. Then, all samples were left to dry during 90 min at 4 °C in a cold room. Then after, coating formulation was uniformly sprayed under sterile conditions on each sample using an electrostatic sprayer BSL-DS1 (BSL Technologies Inc., Brossard, QC, Canada), at a distance of 18–24 inches with an outlet air pressure of 25 psi (reservoir pressure of 30 psi). Samples were sprayed at each side by 0.3 mL of formulation per 25 g of peppers, and thereafter left to dry for 30 min before storage and microbiological analyses.

Ozonation treatment

The bacterial inoculation on pre-cut green peppers (25 g) was done by bacterial suspension at concentration of 106 CFU/mL, as mentioned above. Ozonation treatment was performed using an ozone generator C-10 portable unit equipped with an OM controller and a calibration probe of 10 ppm (Ozone Innovations Inc., Drummondville, QC, Canada). Each sample was deposited onto a stainless steel (SS) perforated plate and transferred into an SS ozone diffusion chamber. Ozonation was carried out at 10 ppm for 5 min of ozone exposure at a flow rate of approximately 15 standard cubic feet per hour (SCFH). Thereafter, samples were removed and stored at − 20 °C before microbiological analyses (as requested by the supplier company to evaluate the antibacterial effect of treatments on frozen peppers during storage time). The combined treatment consisted of ozone treatment + antibacterial coating on pre-cut green peppers was also assessed.

Gamma irradiation

Samples of pre-cut green peppers (25 g) were put into a sterile Deli*1 bag (nylon/ethylene–vinyl acetate/polyethylene; thickness 3 mil; Winpak Division Ltd, St-Leonard, QC, Canada) and sealed using a packaging machine (model 250 Single Chamber, Sipromac Inc., St-Germain-de-Grantham, QC, Canada). Then, gamma irradiation treatment was done at dose of 0.5 kGy at Canadian Irradiation Center (CIC, Laval, QC, Canada) in a UC-15 A irradiator (Nordion Inc., Kanata, ON, Canada) equipped with a 60Cobalt source and having a dose rate of 16.74 kGy/h. Combined treatment with coating and ozonation has also done.

Microbiological analysis

The antibacterial capacity of the coating formulation, ozonation, irradiation, and combined treatments was evaluated in situ on pre-cut green peppers at days 0, 1, 4, 7, and 10 of storage, against food pathogens. Samples (25 g) were homogenized for 30 s at 230 rpm in 50 mL of sterile peptone water (0.1% w/v) with a Stomacher® 400-Circulator (Seward Laboratory Systems Inc., Davie, FL, USA). From each homogenate, serial dilutions were prepared, plated onto the surface of appropriate media (Difco, Becton Dickinson, Franklin Lakes, NJ, USA), and incubated for 24–48 h at 37 °C before bacteria enumeration. MacConkey agar supplemented with sorbitol, DCLS agar, and PALCAM agar were used for the enumeration of E. coli, S. enterica and L. innocua, respectively (detection limit was about 10 CFU/g).

Colorimetry

The color of the treated pre-cut green peppers was measured using a Color reader CR-10 (Konica Minolta, Ramsey, NJ, USA). Measurements of spectral reflectance were performed directly onto the vegetables surface (viewing area 10 × 10 mm). The L*, a*, and b* system (CIELab) was employed; the L* axis represents the lightness from black (L* = 0) to absolute white (L* = 100), a* axis varies from green (− 300) to red (+ 299), and the b* axis varies from blue (− 300) to yellow (+ 299). To characterize more precisely the color of pre-cut green peppers, the hue angle (h°) was determined to indicate color changes between a* (green color) and the intersection of a* and b*, from green (h° = 180°) to yellow color (h° = 0), according to the following equation:

The total color difference (ΔE*) between samples and control was also determined by the following equation:

Determination of chlorophyll content

Determination of chlorophyll content in pre-cut green peppers was performed according to a procedure of Al-Dabbas et al. [38]. A quantity of 10 g of mortared green pepper was added to 2 mL of acetone–water 80:20 (v/v) for 2 min to extract the chlorophyll content. Filtration was followed using a 0.45 µm PTFE filter and the filtrate was transferred to a falcon tube covered with aluminum foil to prevent the photo-oxidation of chlorophyll. Absorbance was measured at 663 and 645 nm using a Scinco S-3100 UV–visible spectrophotometer (Betatek Inc., Toronto, ON, Canada). The concentration of chlorophyll (a, b, total) was expressed as µg/mL extract and calculated from the following equations:

Determination of vitamin C content

The determination of vitamin C (l-ascorbic acid + l-dehydroascorbic acid) content in green peppers was performed using a VitaFast® Vitamin C P1010 enzymatic test kit (detection limit: 7.8 mg/100 mL; R-Biopharm AG, Darmstadt, Germany). The test was based on a colorimetric method by Boehringer Mannheim GmbH Biochemica [39].

Sample preparation

A quantity of 10 g of pre-cut green peppers was added to 50 mL of meta-phosphoric acid 1.5% (pH 3.5). The mixture was homogenized with an Ultra-Turrax T25 disperser (IKA Works Inc) at 15,000 rpm, for 15 min at room temperature. The homogenate was then filtered (0.45 µm) before using directly for the assays.

Determination of l-(+)-ascorbic acid (AA) and dehydroascorbic acid (DHA)

Two assays were performed to determine the contents of AA and DHA, based on (1) indirect quantification by ascorbate oxidase (AAO; from Cucurbita sp.) to differentiate them from the other reducing substances and (2) indirect quantification by dithiothreitol (DTT) for the specific determination of AA and AA + DHA.

Principle of the determination of AA content

AA (which is present in the sample extract as reductant ascorbate) and some other reducing substances reduce the tetrazolium salt MTT [3(4,5-dimethylthiazolyl-2)-2,5-diphenyl tetrazolium bromide] into MTT-formazan, in the presence of the electron carrier PMS (5-methylphenazinium methyl sulfate) at pH 3.5. The sum of all reducing substances is then measured in the sample, namely corresponding to the sample determination (without AAO). For the specific determination of AA content, the AA fraction of the sample is oxidized into DHA by AAO in the presence of oxygen. The DHA formed does not react with MTT/PMS, and then, the remaining reductants reduce the MTT into formazan, namely corresponding to the sample blank determination (with AAO). The formazan formed in the assays is proportional to the sum of reductants and was measured at 578 nm using a microplate reader BioTek ELx800 (Winooski, VT, USA). Hence, the AA specific content was calculated based on the difference in absorbance of the sample assay and the blank, according to the equation:

Results were expressed based on an ascorbic acid standard curve.

Principle of the determination of (AA + DHA) content

The determination of the (AA + DHA) content was performed similarly to the AA content, but the DHA fraction initially present in the sample was reduced by DTT into AA, before the reaction with MTT. Hence, the (AA + DHA) specific content was calculated based on the difference in absorbance of the sample assay and the blank, according to the equation:

The difference between the total (AA + DHA) (Eq. 7) and free AA (Eq. 6) resulted in the DHA content. Table 1 summarizes the combined tests of indirect quantification of AA and AA + DHA.

Calculations

Based on the standard curve, the weighed amount of solid sample and the dilution factor (F), the concentration of ascorbic acid (free AA or total AA + DHA) was calculated as follows:

Sensory analysis of pre-cut green peppers

Sensory properties, such as color, odor, taste, texture, and global appreciation of the pre-cut green peppers treated with different treatments in compared to non-treated samples (control), were evaluated by a panel comprising 20 persons, according to a nine-point hedonic scale test (1 = dislike extremely; 5 = neither like nor dislike; 9 = like extremely). This method was used to measure the degree of acceptance or rejection of the treated samples on organoleptic properties of the peppers.

Statistical analysis

All measurements were performed in triplicate (n = 3). Analysis of variance (ANOVA), Duncan’s multiple range tests (for equal variances), and Student t test (for independent samples) were performed for statistical analysis (PASW Statistics 18; IBM Corporation, Somers, NY, USA). Differences between means were considered significant when the confidence interval was lower than 5% (p ≤ 0.05).

Results and discussion

Inhibiting properties of the coating, ozonation, irradiation, and the combined treatments

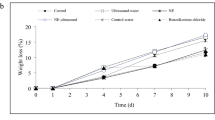

Inhibiting activities against E. coli

The antibacterial properties of different treatments were evaluated in situ against E. coli in green peppers. Results showed that frozen green peppers (− 20 °C) without antibacterial treatment (control) allowed a reduction of E. coli during 10 days of storage (4 to 2.1 log CFU/g). It is important to mention that freezing process is a conservation method that reduces the microbial development, and here also, freezing process reduces the level of E. coli (Fig. 1). Samples coated with natural antibacterial formulation showed a rapid reduction of E. coli level after day 1 (0.8 log reduction), followed by a continuous decrement to arrive below the limit of detection at day 4 of storage. No growth was observed after day 4. Samples treated with ozone showed a 1.2 log reductions after 24 h followed by a total inhibition at days 4 and population of E. coli stayed below detection limit during the rest of storage time. Bermúdez-Aguirre and Barbosa-Cánovas also reported that the treatment of tomatoes using ozone gas at 5 ppm during 3–15 min led to reduce the concentration of E. coli about 2.2 logs [40].

Combined treatment of coating/ozonation allowed a 2.1 log reduction after 24 h of storage, followed by a total inhibition at day 4 which stayed below the detection limit during the storage time. Irradiated peppers and all combined treatments with irradiation allowed a total inhibition of E. coli at day 0 (4 log reduction) and no growth was observed during storage time. Wang et al. reported that E. coli was sensitive to irradiation, and can be reduced by 7 log cycles at 1 kGy in juice [41]. Furthermore, Prakash et al. also reported that a dose of 1 kGy eliminated E. coli from diced celery [42]. Furthermore, microbiological studies carried out in cantaloupes showed that samples irradiated had a lower and more stable rate of respiration than non-irradiated samples over about 20 days and total plate counts were significantly higher in non-irradiated control samples through storage [43].

Inhibiting activities against S. enterica

The results of antibacterial activity of different treatments against S. enterica are presented in Fig. 2. Frozen peppers without antibacterial treatment (control) allowed a negligible decrement in growth of Salmonella during the storage time at − 20 °C (between 3.6 and 3.4 log CFU/g). Peppers treated with coating allowed a 0.7 log reduction after 24 h of storage, followed by a 1.2 log reduction at day 4, and then after, again, 0.2 log reduction was also observed at day 7 and a negligible increment about 0.3 log was observed at day 10. Ozone treatment allowed a 1 log reduction after 24 h, followed by a 0.2 log reduction again at day 4 and 7, but a 0.6 log increment was observed at day 10.

Peppers treated with combined treatment of coating/ozonation allowed 1.3 log reduction after 24 h; then after 0.1, 0.2 reductions were observed at days 4 and 7, and then here again a 0.6 log increment was observed at day 10. Daş et al. reported that treatment of tomatoes with ozone gas (5–30 mg/L ozone gas for 0–20 min) led to reduce the Salmonella level by 7 log CFU/g [44].

Irradiated green peppers and all combined treatments with irradiation allowed a total inhibition of S. enterica from day 0 (with 3.6 log CFU/g reduction) until the end of storage. Some studies showed that irradiated fresh-cut lettuce at 1 kGy led to decrease the microbial spoilage and improved the quality of the products [22]. According to Ahn et al., irradiation at 1 kGy or above (2 or 3 kGy) can be used to enhance the microbial safety of minimally process Chinese cabbage without affecting the quality [45].

Inhibiting activities against L. innocua

The antibacterial activity of different antibacterial treatments was evaluated against L. innocua and results are presented in Fig. 3. Results showed that, in frozen peppers without antibacterial treatment (control), growth of Listeria stayed relatively stable during storage time at − 20 °C (3.95 and 3.5 log CFU/g). Coating treatment allowed a reduction of 0.7 log after 4 days, followed by a decrease of 0.6 log at day 7 and then after 0.2 log increment at day 10. Ozone treatment showed a similar behavior like as coating treatment during the 4 first days, with a reduction of 0.8 log at day 4, followed by 0.3 log reduction at day 7 and 0.2 log increment at day 10. These treatments presented slight effect on the reduction of L. innocua’ population at 104 CFU/g concentration because of bacterial resistance.

Combined treatment of coating/ozonation allowed a 0.8 log reduction after 4 days followed by 0.2 log reduction at day 7 and then after 0.2 log augmentation at day 10.

It was reported that the efficiency of ozone on the reduction of microbial count in fresh products depends on the dose, exposition time, and initial microbial concentration [46]. Samples treated with irradiation alone allowed a decrease of 2.2 log at day 0 and then stayed stable until the end of storage. The combined treatment of coating/irradiation allowed a 2.38 log reduction at day 0 and then stayed relatively stable until the end of storage. Finally, the combined treatment of coating/ozonation/irradiation inhibited totally the growth of Listeria from day 0 until the end of storage.

Formulated coating contains different kinds of natural ingredients presented a synergistic antibacterial effect with a large spectrum activity against Gram-positive and Gram-negative bacteria. According to Côté et al., a large variety of bioactive compounds are found in cranberries such as flavanols, flavan-3-ols (catechin and epicatechin), anthocyanins, tannins, and phenolic acid derivatives [47]. These phenolic compounds are able to inhibit pathogenic bacteria. Furthermore, many studies also confirmed the antibacterial activity of citrus extract that contains phenolic and flavonoid compounds with noticeable antibacterial activity [48, 49]. Fermented dextrose, by-product of fermentation, can be also used as bio-preservative in food systems. Dussault et al. have demonstrated the antibacterial effect of fermented dextrose containing bacterial metabolites as food additives to reduce the growth rate of the total bacterial flora in vegetables [50]. According to the obtained results, it should be noted that the total antibacterial activity of this coating cannot be only attributed to its phenolic compounds, but rather to a synergistic effect of all its constituents.

Although an additive effect in coating/ozonation combination was observed against E. coli, but no synergic/additive effect between ozone and coating was observed in compared to alone treatment against Salmonella and Listeria.

According to the obtained results, irradiation was the most effective technique to inhibit the growth of bacteria. However, irradiation in combination with coating and coating/ozonation also presented promising results with totally inhibiting the growth of bacteria at day 0 until the end of storage. The order of treatment efficiency against targeted bacteria is in the following: Coating/Ozonation/Irradiation > Coating/Irradiation > Irradiation > Coating/Ozonation ≥ Coating > Ozonation.

Severino et al. evaluated the antibacterial activity of three different combined non-thermal treatments against Listeria innocua on green bean samples [51]. The coating and γ-irradiation combined treatment against L. innocua gave promising results, showing 3.3 log CFU/g initial microbial reduction, and exhibiting a strong synergistic antibacterial effect.

Furthermore, a combined treatment of an edible coating composed of trans-cinnamaldehyde with γ-irradiation was investigated against Listeria inoculated in peeled mini-carrots. Results indicated that the combination of irradiation with antibacterial coating played an important role to inhibit Listeria [24]. Our results are in good agreements with the mentioned studies.

Colorimetry of green peppers

Results of colorimetric measurements of green peppers are presented in Table 2.

Analysis of the lightness (L*) parameter

At day 0, a significant increase of L* value (p ≤ 0.05) was observed after ozonation (slight whitening from 32.6 to 34.6%), whereas no significant difference (p > 0.05) was noted after coating, irradiation, and combined treatments. At day 1, no significant change (p > 0.05) was measured after all treatments. At day 3, a significant decrease of L* value (p ≤ 0.05) was noted after ozonation (slight darkening from 35.5 to 33.4%) and also in the presence of combined treatment of coating/ozonation/irradiation (from 35.5 to 33.7%), and finally, at day 7, no significant change (p > 0.05) was obtained for all the treatments compared to control samples, with L* values ranging at 33.9–35.3%.

Regarding the evolution of L* parameter for each treatment in function of storage time, results showed that L* value was stable in control samples (32.6–35.5%), and all samples treated by ozonation (33.2–35.0%), coating (32.6–34.8%), combined treatment of coating/ozonation (33.9–35.4%), irradiation (32.2–35.5%), and combined treatments of coating/irradiation (34.8–35.2%) and coating/ozonation/irradiation (32.4–34.3%). Although some treatments led to a significant increase (p ≤ 0.05) of L* value over storage, but this whitening variation is not so important at a macroscopic level (no visual change) and can be attributed to slight variations of darkness in peppers lots, therefore, suggesting a relative stability of lightness in green peppers throughout storage.

Analysis of the a* parameter (green area)

At day 0, a significant decrease of a* value (p ≤ 0.05) was measured after coating and combined treatment of coating/ozonation, with values varying from − 5.8 for control samples to − 6.5 and − 6.6 for the respective treatments that emphasis slightly green color. Thereafter, no significant change (p > 0.05) was observed for all the treatments until day 7, suggesting a high stability of green color in peppers over storage.

Regarding the evolution of a* value for each treatment, results showed a stability of a* parameter (p > 0.05) in control samples (range of − 5.8 to − 5.5) and samples treated by ozonation (− 5.5 to − 5.3), coating (− 6.5 to − 5.2), combined treatments of coating/ozonation (− 6.6 to − -5.2), irradiation (− 5.9 to − 5.7), combined treatments of coating/irradiation (− 5.4 to − 5.0), and coating/ozonation/irradiation (− 5.3 to − 5.1).

During storage time, a significant increase of a* value (p ≤ 0.05) indicative of a slight decrease of green color was detected for sample treated with coating (− 6.5 to − 5.2) and combined treatments (− 6.6 to − 5.4). Here again, these variations are not sufficient at a macroscopic visual level and can be related to intrinsic green changes in peppers lots and also the presence of coating.

Analysis of the b* parameter (yellow area)

The b* parameter tended to be more stable at the detection level of the analyses compared to the L* and a* parameters. Indeed, at day 0, no significant change (p > 0.05) was measured between the samples with a value ranging at 13.3–16.9. At day 1, no significant difference (p > 0.05) was noted between treatments, except an increase of b* value (p ≤ 0.05) between the control (13.3) and samples treated by ozonation (16.1), suggesting a slight increase of yellowness in peppers. However, these variations could be related to the slight whitening (increase of L*) of peppers at day 0 after ozonation, which were not sufficient to involve visible changes and could be neglected. Thereafter, no significant change (p > 0.05) was noted within the groups until day 7, with a stable b* value ranging from 14.8 to 16.2. This stability of the b* parameter is supposed to generate constant values of hue (h°) as a more suitable parameter to quantify the color properties in vegetables. Regarding the evolution of b* value for each treatment, results showed a stability of b* (p > 0.05) in all sample groups except for samples treated with combined treatment (coating/ozonation) for which a significant increase of b* value (p ≤ 0.05) occurred during storage time (from 13.8 at day 1 to 16.2 at day 7). Here again, this increase of yellowness parameter could be associated with the increase of L* value after treatment by coating, but these changes are not susceptible to produce visual macroscopic modifications.

Analysis of the hue angle (h°)

The hue (h°) is a color parameter mostly used to define the variation of color, implying a* and b* axes altogether in the CIELab space as a mathematical reciprocal angle, indicating in this case a variation in the yellow–green quarter (90–180°) of the color system. In consequence to the previous observations of a* and b* parameters, no significant change of h° (p > 0.05) was measured within all the treatments during storage, which means that notwithstanding the kind of treatment, the color of peppers was not changed significantly over storage time with h° range of 108.0°–114.5°. This high stability of h° is a quality parameter to indicate that all treatments applied on green peppers are suitable by considering the visual properties of vegetables. Regarding the evolution of h° for each treatment, results showed no significant changes (p > 0.05) during storage.

Analysis of the total color difference (ΔE)

The total change of color (ΔE) of green peppers throughout storage was determined to evaluate the impact of the treatments in comparison to control samples (ΔE = 0) at each day of analysis. However, ΔE, maybe, presents the lower accuracy due to the fact that it computes the difference in the three axes of the CIELab system. It is interesting to note that the variation in total color difference was more noticeable in samples treated by ozonation and irradiation at day 0. Indeed, ΔE was constant in samples treated by coating with a typical ΔE value ranging (from 1.3 to 2.3), combined treatment of coating/ozonation with (1.0–2.3), combined treatment of coating/irradiation with (1.4–1.9), and combined treatment of coating/ozonation/irradiation with (1.6–2.7). Besides, the samples treated by ozonation generated a significant increase of ΔE (p ≤ 0.05) at day 3 compared to the other treatments. However, this color difference is not relevant, since no difference (p > 0.05) was determined between treatments at day 7. Regarding the evolution of ΔE for each treatment, results showed no significant variation of ΔE (p > 0.05) between day 0 and day 7, which demonstrates no color variation when comparing the three treatments compared to control samples. Furthermore, such low variations in index ΔE did not implicate any perceptible visual changes of color between samples. Therefore, from these experiments, it can be postulated that ΔE < 4 do not indicate noticeable visual changes in green peppers.

Souza et al. showed that exposure of carrots to ozone as gas and dissolved in water did not alter the weight loss percentage, firmness, and the color of the vegetable. Moreover, O3 as gas increased the shelf life of carrots [52].

Furthermore, it was observed that, among the applied non-thermal treatments, ozonation was the unique treatment that provided microbial reductions in red bell peppers significantly higher than the ones obtained by water washings. Ozonation also allowed satisfactory retention of the quality characteristics of the stored sample. Consequently, it can be considered the elected pre-treatment for frozen storage of red bell peppers [53].

Fan et al. suggested that irradiation had a little effect on firmness or Hunter color parameters of the minimally processed iceberg lettuce, but increased antioxidant and phenolic contents [54]. Marathe et al. irradiated dried red kidney beans (Phaseolus vulgaris), in the dose range of 0.25–10.0 kGy, and they found physical characteristics such as appearance, color, texture, aroma, taste, and overall acceptability stayed stable during the storage time [55].

Determination of chlorophyll content

The effect of treatments on the chlorophyll content in green peppers is presented in Table 3. Results are expressed in content of chlorophyll-a (Cha), chlorophyll-b (Chb), and total chlorophyll (Chtotal = Cha + Chb). Chb differs from Cha in one aldehyde group bounded to the porphyrin ring, and is, consequently, more soluble than Cha in polar solvents [30, 38].

Analysis of Cha content

At day 1, a significant decrease (p ≤ 0.05) of Cha content is observed after ozonation and irradiation treatments alone or combined with other treatments (i.e., in samples treated with ozonation and irradiation alone, a decrease from 3.48 to 3.32 and 3.30 µg/mL, respectively, was observed). However, this decrease is not so important at biological level (slight decrease of 0.16–0.18 µg/mL), possibly due to the intrinsic variation of chlorophyll content in green peppers’ lots.

At days 3 and 7, the Cha content was similar (p > 0.05) in samples, suggesting that the different treatments did not affect the Cha content over time. Regarding the evolution of Cha content for each treatment in function of storage time, results showed that Cha content is stable in control samples (3.48–3.60 µg/mL), samples treated by ozonation (3.32–3.60 µg/mL), coating (3.31–3.41 µg/mL), combined treatment of coating/ozonation (3.31–3.41 µg/mL), irradiation (3.3–3.45 µg/mL), combined treatments of coating/irradiation (3.34–3.45 µg/mL) and coating/ozonation/irradiation (3.32–3.44 µg/mL). Here again, these slight decrements are not so important at a biological level and can be attributed to slight variations in peppers lots.

Analysis of Chb content

The treatments have not affected the Chb content in green peppers at days 1 and 3, with a Chb range of 6.18–6.67 µg/mL in within sample groups. However, at day 7, the Chb content of peppers was significantly reduced (p ≤ 0.05) after coating, combined treatments of coating/ozonation, and also coating/irradiation with a reduction from 6.50 to 6.13 µg/mL. Combined treatment of coating/ozonation/irradiation also showed a reduction from 6.50 to 6.15 µg/mL. Despite a statistical significance (p ≤ 0.05), these slight decreases could be also related to the intrinsic variations of Chb contents in peppers lots. The ozonation and irradiation process did not affect significantly (p > 0.05) the Chb content at day 7, with a respective concentration of 6.26 and 6.30 µg/mL in peppers. Regarding the evolution of Chb content for each treatment, results showed that Chb content is stable in all sample groups, with 6.33–6.50 µg/mL in control samples, 6.13–6.26 µg/mL after coating, 6.26–6.67 µg/mL after ozonation and 6.13–6.26 µg/mL after combined treatment of coating/ozonation, 6.12–6.3 µg/mL after irradiation, 6.13–6.35 µg/mL after combined treatment of coating/irradiation, and, finally, 6.15–6.38 µg/mL after combined treatment of coating/ozonation/irradiation.

Analysis of Chtotal content

As a subsequent result of Cha and Chb analyses, no significant effect of the treatments (p > 0.05) was observed at days 1 and 3, with Ctotal values of 9.81–10.27 µg/mL in control samples, 9.59–9.64 µg/mL after coating, 9.92–10.27 µg/mL after ozonation and 9.59–9.64 µg/mL after combined treatment of coating/ozonation, 9.43–9.73 µg/mL after irradiation, 9.69–9.73 µg/mL after combined treatment of coating/irradiation, and, finally, 9.82–9.67 µg/mL after combined treatment of coating/ozonation/irradiation. At day 7, as precisely observed for Chb analysis, the Chtotal content of peppers was significantly reduced (p ≤ 0.05) after coating and combined treatment of coating/ozonation with a reduction from 10.01 to 9.43 µg/mL for both treatments and also combined treatment of coating/ozonation/irradiation with a reduction of 10.01–9.47 µg/mL. Moreover, the ozonation process did not affect significantly (p > 0.05) the Chtotal content at day 7, with a concentration of 9.79 µg/mL compared to 10.01 µg/mL in control samples. Regarding the evolution of Chtotal content for each treatment, results showed that control samples and samples treated by ozonation and irradiation have an expectedly constant Chtotal content over storage time (p > 0.05). Oppositely, coating alone and in combined treatments generated a significant decrease (p ≤ 0.05) of Chtotal over storage time, although, from a biological point of view, these changes can be considered as minor variations.

Overall, based on the evolution of Cha, Chb, and Chtotal, these results suggest that some statistical differences were noted in chlorophyll content of green peppers after coating and combined treatments, but very slight decreases (non-detrimental at biological level) were obtained. Hence, it can be considered that the different treatments did not affect adversely the chlorophyll content in green peppers, which is in accordance with colorimetric results. Otherwise, ozonation and irradiation processes generally had no effect on chlorophyll content throughout the storage, suggesting that these technologies can be used in combination with antibacterial coating without affecting the quality of green peppers based on their green pigmentation.

Indeed, the experimental results showed positive trends of relative stability in chlorophyll content during storage. The slight differences due to the treatments could be associated with intrinsic variations of chlorophyll content in some peppers lots rather than oxidation generated by the coating components, irradiation, or ozonation process.

Indeed, food-processing conditions greatly influence the rate and pathway of chlorophyll degradation. Therefore, using the innovative methods to preserve the original typical green color of fresh product is one of the fundamental customer demands. Food processing can induce structural and chemical changes on cells and tissues, resulting to the dramatic color changes. As chlorophyll is sensitive to low pH and the temperatures and length of treatment, it may quickly get involved in some enzymatic/chemical reaction, resulting in producing undesirable colorless/brownish products such as pheophytins and also reduction in quality of such products [56]. Chlorophyll breakdown shifts color from bright green to a variety of color shades such as yellow, brown, and orange in the processed products [57].

Turkmen et al. was studied the effect of microwave and conventional cooking methods on chlorophyll pigments and color properties of squash, green beans, peas, leek, broccoli, and spinach [58]. They observed that most of the pheophytin formations occurred in boiled and the least in microwaved vegetables [58].

Irradiation at 2.5 kGy or above can be used to reduce or eliminate the residual chlorophyll in oil processing without developing lipid oxidation during the irradiation process, which would prolong the shelf life of oil products, but it had no effect on chlorophyll content at below 1 KGy [59].

Saitanis et al. exposed seven commercial tobacco varieties (Nicotiana tabacum L.) to two relatively low ozone concentrations (90 or 135 ppb) for 20 consecutive days (8 h per day) [60]. They observed that ozone caused depression of photosynthetic mechanism and chlorophyll diminution. This decrement was obtained because of leaves exposure to high ozone concentration (> 1000 ppb) during long time.

Our findings are in contrast with the mentioned results, because irradiation at 0.5 kGy and exposure to ozone (10 ppm for 5 min) had no negative effect on chlorophyll content of green peppers.

Determination of vitamin C content

The effect of treatments on the vitamin C content in green peppers is presented in Table 4. Results are expressed in content of free ascorbic acid (AA), dehydroascorbic acid (DHA), and total ascorbic acid (AA + DHA) in mg/100 g extract. DHA always occurs in food in conjunction with AA. The simultaneous determination of DHA and AA is, therefore, always necessary. The accuracy of the determination of DHA depends on its relation to AA (the weight ratio of AA/DHA should be < 5:1). The differences related to the treatments could be associated with the intrinsic variations of vitamin C content in some peppers lots rather than oxidation of AA into DHA generated by the coating components or ozonation process. However, it was observed that the combined treatments in the presence of ozone and/or irradiation induced a higher sensitivity of vitamin C than the other treatments, as discussed below.

Analysis of AA content (free ascorbic acid)

At day 1, the AA content is significantly higher (p ≤ 0.05) for peppers treated with coating, the combined treatments of coating/ozonation and coating/irradiation (60.1, 56.2 and 53.86 mg/100 g, respectively), compared to control, Ozonation, and irradiation alone (45.8, 46.6, and 44.35 mg/100 g, respectively). These higher values in the presence of coating could be due to the presence of ascorbic acid in citrus extract. However, at day 14, a lower significant AA content (p ≤ 0.05) is measured for all the treatments at a range of 14.14–15.88 mg/100 g compared to 17.5 mg/100 g for control and 19.2 mg/100 g for coating. These observations supposed that a high proportion of AA was oxidized during storage in all the treatments, whereas the vitamin C available in antimicrobial coating led to increase AA value in samples treated with coating. Furthermore, at day 14, the higher AA content is found in control and samples treated by coating with no significant difference (p > 0.05) between each other, confirming that ozonation and irradiation alone or in combined treatments may have noticeable effect on AA oxidation. Regarding the evolution of AA content for each treatment in function of storage time, results also confirmed a significant reduction of AA content (p ≤ 0.05) for each treatment between day 1 and day 14 (decrease of 62–73%). As observed in the previous results of color and chlorophyll analyses, these reductions can be caused due to inherent oxidation process in green peppers during the second week of storage. This decrement can be explained by increasing DHA, the oxidized form of AA, during storage time.

Analysis of AA + DHA content (total ascorbic acid)

The quantification of AA + DHA was carried out similarly to that of AA, but in the presence of a reducing agent (DTT) to promote the reverse conversion of DHA into AA. At day 1, the AA + DHA content in function of the treatment followed the same pattern like as AA content. Significantly higher AA + DHA contents (p ≤ 0.05) were determined for samples treated with coating and combination of coating/ozonation (65.4 and 79.0 mg/100 g, respectively), compared to control, ozonation alone, and also irradiation alone or in combined treatments. At day 14, like as AA analysis, significantly higher AA + DHA content (p ≤ 0.05) was observed for samples treated with coating (58.3 mg/100 g), whereas no significant difference (p > 0.05) is noted between control and samples treated with ozonation and combined treatments (45.8–48.1 mg/100 g). These decrements are also significantly detected (p ≤ 0.05) in all the treatments in the presence of irradiation.

Indeed, regarding the evolution of AA + DHA content for each treatment between day 1 and day 14, significant reductions (p ≤ 0.05) are evidenced for samples treated with combined treatment of coating/ozonation, coating/irradiation and coating /ozonation/irradiation (Table 4). Highest percentages of AA + DHA reduction were determined after combined treatments (20–44.8%) compared to the other samples (range of 10.9–14.3% reduction). Therefore, as mentioned for AA analysis, these reductions suggest that combined treatments using ozonation or irradiation contributed to the higher loss of total AA + DHA.

Overall, it is important to mention that, after 14 days, the AA + DHA (total vitamin C) content in green peppers was maintained at acceptable concentrations at a biological level, notwithstanding the additional value of vitamins from the coating formulation and kind of treatment.

Analysis of DHA content (dehydroascorbic acid)

The quantification of DHA in peppers was established by calculating the difference between AA + DHA and AA measurements. Therefore, it was expected that the evolution of DHA between samples and throughout storage time would be inversely proportional to AA measurements. At day 1, the DHA content is significantly higher (p ≤ 0.05) for peppers treated with the combination of coating/ozonation (22.9 mg/100 g) compared to the other samples (4.75–9.7 mg/100 g). This higher value can be due to the oxidation after ozonation (conversion of AA into DHA). The other treatments such as coating, ozonation, and irradiation alone and in combined treatments had no effect on DHA content compared to control samples (p > 0.05). At day 14, the higher DHA content is found in peppers treated with coating (39.1 mg/100 g) significantly different (p ≤ 0.05) from control and samples treated with other treatments, but not significantly different (p > 0.05) from samples treated by coating/ozonation (33.1 mg/100 g).

Regarding the evolution of DHA content for each treatment, as a subtractive result from AA + DHA and AA analyses, significant increases (p ≤ 0.05) of DHA are reported in all samples, therefore, indicating a significant oxidation of initial AA into DHA after 14 days of storage. However, as the DHA level is measured at the same range between untreated and treated samples (30.0–39.1 mg/100 g), it can be concluded that the degree of oxidation of vitamin C in peppers has not affected by the kind of treatments. However, time and temperature of storage may have more effects. This evaluation of DHA allowed determining the oxidation level of AA, but the oxidized form (DHA) is biologically effective as AA.

Green pepper is promising source of vitamin C that can be damaged with treatments.

In general, the green tissues contain higher amounts of ascorbic acid than non-green tissues. Furthermore, vitamin C regeneration capability appears to be closely associated with stress responses of plant tissues to various conditions such as cold acclimation and ozone exposure. Dehydroascorbic acid in freshly post-harvested plants is relatively low and may vary from less than 5% or 10% of the total vitamin C content in most vegetables, but could be increased to up to 25% of the total vitamin C activity during refrigerated and frozen postharvest storage of vegetables [61].

As it was observed during storage, DHA was increased in all samples due to AA transformation. These findings confirmed the effect on freezing on AA oxidation despite of kind of treatment. These findings are in good agreement with the statements of Zhuang and Barth [61].

Chauhan et al. observed that ozone treatment (10 mg/L—10 min) significantly reduced ascorbic acid and carotene content in sliced carrots [62]. However, some recent studies showed that ozonation not only has no negative impact on ascorbic acid contents of the fresh-cut lettuce and celery, but also led to extend the shelf life of fresh-cut lettuce [63, 64]. Our findings are in good agreement with these results.

Sensory analysis of green peppers

Based on the obtained results, no significant difference (p > 0.05) in sensorial properties of peppers treated with different treatments in compared to control was observed. Hedonic data indicated the ranges of 6.5–7.9 for color, 5.8–6.4 for odor, 6.1–6.4 for taste, 6.4–6.5 for texture, and 6.7–6.8 for global appreciation. It means that the trend in appreciation was like moderately/like very much for color; like slightly for odor, taste, and texture; like moderately for global appreciation which is not significantly different from control samples with the same appreciation values.

Many studies have shown that irradiation (< 1 kGy) offers considerable potential for disinfestation and also extension the shelf life of vegetables without impairing their sensory qualities [65,66,67,68].

Furthermore, in some cases, sensory evaluation tests showed that irradiated samples (mangos) were preferred in compared to the control [69].

Frimpong et al. also concluded that irradiation at 2 kGy did not have much effect on phytochemical and sensory quality of cut cabbage [70].

Akbas and Ozdemir reported that there were slight changes in flavor, appearance, and overall palatability of flaked red peppers treated with ozone between 5.0 and 9.0 ppm [71].

Selma et al. also mentioned that sensory quality was maintained in cantaloupe treated by gaseous ozone and no off flavors were developed during storage time [72]. Furthermore, Liew and Prange showed that gaseous O3 treatment did not affect the global sensory quality of fresh-cut melon after 8 day storage [73]. Based on the obtained results, our findings are in good agreement with the mentioned studies.

Conclusion

In this work, different antibacterial treatments have been tested against three target bacteria. Our results suggested a high antibacterial effect of all the tested treatments (coating, ozonation, and irradiation) on peppers. Irradiation at 0.5 kGy was the most effective treatment to reduce the studied microorganisms. The combination of ozonation and coating reduces significantly all the studied bacteria. It is important to note that the combination of ozonation, coating, and irradiation inhibits quickly and effectively L. innocua, E. coli, and S. enterica.

The results of colorimetry suggested that treatments had no effect on color parameters (L*, a*, b*, hue, and ΔE) of green peppers, and also, it can be postulated that ΔE < 4 do not indicate noticeable visual changes in green peppers. In addition, chlorophyll results showed that the use of ozonation and coating alone or in combination had no negatively effect on chlorophyll content of peppers. The effect of the coating, ozonation, irradiation, and their combined treatments on the chlorophyll content of peppers has shown no detrimental decrease of total chlorophyll at a biological level of 9.43–10.0 µg/mL of extract.

The effect of coating, ozonation, irradiation, and their combined treatment on vitamin C content of the peppers highlighted the sensitivity of vitamin C to oxidation in green peppers. However, overall, similar trends of vitamin C content were determined within all the groups (control and treated samples) at an acceptable concentration, ensuring a possible application of such treatments during storage.

Furthermore, these analyses showed some statistical differences in total vitamin C content after coating treatment (caused by coating content) and mostly after combined treatments implying ozonation and/or irradiation. However, the range of total vitamin C was measured in all samples at satisfying concentrations, ranging from 30.85 to 65.44 mg/100 g of pepper extract.

The evaluation of organoleptic attributes of samples treated with different treatments revealed no significant difference compared to control samples, suggesting that these treatments are acceptable for further commercialization as natural bio-preservative (coating) and non-residual/non-thermal treatments.

References

Gonzalez-Aguilar GA, Ayala-Zavala JF, Ruiz-Cruz S, Acedo-Felix E, Diaz-Cinco ME (2004) Effect of temperature and modified atmosphere packaging on overall quality of fresh-cut bell peppers. Lebensm Wissu Technol 37:817–826

Ketteringham L, Gausseres R, James SJ, James C (2006) Application of aqueous ozone for treating pre-cut green peppers. J Food Eng 76:104–111

Kennedy E, Meyers L, Layden W (1996) The 1995 dietary guidelines for America: an overview. J Am Diet Assoc 96:234–237

Rico D, Martin-diana AB, Barat JM, Barry-ryan C (2007) Extending and measuring the quality of fresh-cut fruit and vegetables: a review. Trends Food Sci Technol 18:373–386

Oboh G, Puntel RL, Rocha JBT (2007) Hot pepper (Capsicum annuum, Tepin and capsicum chines, Habanero) prevents Fe induced lipid peroxidation in brain—in vitro. Food Chem 102:178–185

Centers for Disease Control (2014) CDC estimates of foodborne illness in the United States. US Department of Health and Human Services, Atlanta. http://www.cdc.gov/foodborneburden/2011-foodborne-estimates.html

Hidaka T, Kirigaya T, Kamijo M, Kikawa H, Kawamura T, Kawauchi S (1992) Disappearance of residual chlorine and formation of chloroform in vegetables treated with sodium hypochlorite. J Food Hyg Soc Jpn 33:267–273

Aieta EM, Roberts PV, Hernandez M (1984) Determination of chlorine dioxide chlorine, chlorite, and chlorate in water. J AWWA 76:1–64

Beuchat LR (1992) Surface disinfection of raw produce. Dairy Food Environ Sanit 12:6–9

Brackett RE (1992) Shelf stability and safety of fresh produce as influenced by sanitation and disinfection. J Food Prot 55:808–814

Beuchat LR (1999) Survival of enterohemorrhagic Escherichia coli O157:H7 in bovine feces applied to lettuce and the effectiveness of chlorinated water as a disinfectant. J Food Prot 62:845–849

Jing L, Lei Z, Li L, Xie R, Xi W, Guan Y, Sumner LW, Zhou Z (2015) Antifungal activity of citrus essential oils: a review. J Agric Food Chem 62:3011–3033

Tripoli E, Guardia ML, Giammanco M (2007) Citrus flavonoids: molecular structure, biological activity and nutritional properties: a review. Food Chem 104:466–479

Cormier J, Scott R, Janes M (2013) Antibacterial activity of Biosecur® citrus extract surface cleaner against Vibrio vulinificus. Open Microbiol J 7:130–134

Caillet S, Côté J, Doyon GJ, Sylvain JF, Lacroix M (2011) Antioxidant and antiradical properties of cranberry juice and extracts. Food Res Int 44:1408–1413

Harich M, Maherani B, Salmieri S, Lacroix M (2016) Antibacterial activity of cranberry juice concentrate on freshness and sensory quality of ready-to-eat (RTE) foods. Food Control 75:134–144

Arvanitoyannis IS, Stratakos AC, Tsarouhas P (2009) Critical reviews in food science and nutrition irradiation applications in vegetables and fruits: a review. Crit Rev Food Sci Nutr 49:427–462

Maherani B, Hossain F, Criado P, Ben-Fadhel Y, Salmieri S, Lacroix M (2016) World market development and consumer acceptance of irradiation technology. Foods 5(4):79–100

Jeong MA, Jeong RD (2018) Applications of ionizing radiation for the control of postharvest diseases in fresh produce: recent advances. Plant Pathol 67:18–29

Oularbi S, Mansouri B (1996) Decontamination of black pepper and red pepper by gamma radiation. Radiat Phys Chem 48(3):386–386

Thayer DW, Rajkowski KT (1999) Developments in irradiation of fresh fruits and vegetables. J Food Technol 53:62–65

Zhang L, Zhaoxin L, Fengxia L, Xiaomei B (2004) Effect of ɣ-irradiation on quality-maintaining of fresh-cut lettuce. Food Control 17:225–228

Lacroix M, Ouattara B (2000) Combined industrial processes with irradiation to assure innocuity and preservation of food products—a review. Food Res Int 33:719–724

Turgis M, Millette M, Salmieri S, Lacroix M (2012) Elimination of Listeria inoculated in ready-to-eat carrots by combination of antimicrobial coating and γ-irradiation. Radiat Phys Chem 81:1170–1172

Graham DM (1997) Use of ozone for food processing. Food Technol 51:72–75

Xu L (1999) Use of ozone to improve the safety of fresh fruits and vegetables. Food Technol 53:58–61

Kim JG, Yousef AE, Dave S (1999) Application of ozone for enhancing the microbiological safety and quality of foods: a review. J Food Prot 62:1071–1087

Guzel-Seydim ZB, Green AK, Seydim AC (2004) Use of ozone in the food industry. Lebensm Wissu Technol 37:453–460

Gunawan M, Barringer S (2000) Green color degradation of blanched broccoli (Brassica oleracea) due to acid and microbial growth. J Food Process Preserv 24:253–263

Koca N, Karadeniz F, Burdurlu HS (2006) Effect of pH on chlorophyll degradation and colour loss in blanched green peas. Food Chem 100:609–615

Mejia LA, Hudson E, Gonzalez de Mejia E, Vasquez F (1988) Carotenoid content and vitamin A activity of some common cultivars of Mexican peppers (Capsicum annuum) as determined by HPLC. J Food Sci 53:1448–1451

Lee Y, Howard LR, Villalon B (1995) Flavonoids and antioxidant activity of fresh pepper (Capsicum annuum) cultivars. J Food Sci 60:473–476

Markus F, Daood HG, Kapitany J, Biacs PA (1999) Change in the carotenoid and antioxidant content of spice red pepper (paprika) as a function of ripening and some technological factors. J Agric Food Chem 47:100–107

Lee SK, Kader AA (2000) Preharvest and postharvest factors influencing vitamin C content of horticultural crops. Postharvest Biol Technol 20:207–220

Howard LR, Smith RT, Wagner AB, Villalon B, Burns EE (1994) Provitamin A and ascorbic acid content of fresh pepper cultivars (Capsicum annuum) and processed jalapenos. J Food Sci 59:362–365

Monacelli F, Acquarone E, Giannotti C, Borghi R, Nencioni A (2017) Vitamin C, aging and Alzheimer’s disease. Nutrients 9(7):670–695

Seung KL, Adel AK (2000) Preharvest and postharvest factors influencing vitamin C content of horticultural crops. Postharvest Biol Technol 20:207–220

Al-Dabbas M, Saleh M, Hamad H, Hamadeh W (2017) Chlorophyll color retention in green pepper preserved in natural lemon juice. J Food Process Preserv 41(4):13055–13061

Boehringer Mannheim GmbH Biochemica (1987) Methods of biochemical analysis and food analysis using test-combinations in research, production and official control. Bulletin #1087/L3-969 052-3, pp 24–26

Bermúdez-Aguirre D, Barbosa-Cánovas GV (2013) Disinfection of selected vegetables under non-thermal treatments: chlorine, acid citric, ultraviolet light and ozone. Food Control 29:82–90

Wang Z, Ma Y, Zhao G, Liao X, Chen F, Wu J et al (2006) Influence of gamma irradiation on enzyme, microorganism, and flavor of cantaloupe (Cucumis melo L.) juice. Food Microbiol Saf 71(6):M251–M220

Prakash A, Guner AR, Caporaso F, Foley DM (2000) Effect of low-dose gamma irradiation on the shelf life and quality characteristics of cut romaine lettuce packaged under modified atmosphere. J Food Sci 65:549–553

Boynton BB, Welt BA, Sims CA, Balaban MO, Brecht JK, Marshall MR (2006) Effects of low-dose electron beam irradiation on respiration, microbiology, texture, color, and sensory characteristics of fresh-cut cantaloupe stored in modified-atmosphere packages. J Food Sci 71(2):S149–S155

Daş E, Gürakan GC, Bayindirli A (2006) Effect of controlled atmosphere storage, modified atmosphere packaging and gaseous ozone treatment on the survival of Salmonella Enteritidis on cherry tomatoes. Food Microbiol 23(5):430–438

Ahn HJ, Kim JH, Kim JK, Kim DH, Yook HS, Byun MW (2005) Combined effects of irradiation and modified atmosphere packaging on minimally processed Chinese cabbage (Brassica rapa L.). Food Chem 89:589–597

Nadas A, Olmo M, Garcia JM (2003) Growth of Botrytis cinerea and strawberry quality in ozone-enriched atmospheres. J Food Sci 68:1798–1802

Côté J, Caillet S, Doyon G, Sylvain JF, Lacroix M (2010) Bioactive compounds in cranberries and their biological properties. Crit Rev Food Sci Nutr 50:666–679

Mandalari G, Bennett RN, Bisignano G, Trombetta D, Saija A, Faulds CB, Gasson MJ, Narbad A (2007) Antimicrobial activity of flavonoids extracted from bergamot (Citrus bergamia Risso) peel, a byproduct of the essential oil industry. J Appl Microbiol 103:2056–2064

Rafiq S, Kaul R, Sofi SA, Bashir N, Nazir F, Ahmed NG (2016) Citrus peel as a source of functional ingredient: a review. J Saudi Soc Agric Sci. https://doi.org/10.1016/j.jssas.2016.07.006

Dussault D, Benoit C, Lacroix M (2011) Combined effect of g-irradiation and bacterial-fermented dextrose on microbiological quality of refrigerated pork sausages. Rad Phys Chem 81:1098–1102

Severino R, Vu KD, Donsì F, Salmieri S, Ferrari G, Lacroix M (2014) Antibacterial and physical effects of modified chitosan based-coating containing nanoemulsion of mandarin essential oil and three non-thermal treatments against Listeria innocua in green beans. Int J Food Microbiol 191:82–88

deSouza LP, D’AntoninoFaroni LR, Heleno FF, Cecon PR, Carvalho Gonçalves TD, daSilva JG, Figueiredo Prates LF (2018) Effects of ozone treatment on postharvest carrot quality. LWT Food Sci Tech 90:53–60

Alexandre EMC, Teresa RSB, Cristina LMS (2013) Impact of non-thermal technologies and sanitizer solutions on microbial load reduction and quality factor retention of frozen red bell peppers. Innov Food Sci Emerg Technol 17:99–105

Fan X, Peter MAT, Kathleen TR, Kimberly JBS (2003) Warm water treatment in combination with modified atmosphere packaging reduces undesirable effects of irradiation on the quality of fresh-cut iceberg lettuce. J Agric Food Chem 51:1231–1236

Marathe SA, Deshpande R, Khamesra A, Ibrahim G, Jamdar SN (2016) Effect of radiation processing on nutritional, functional, sensory and antioxidant properties of red kidney beans. Radiat Phys Chem 125:1–8

Lanfer-Marquez UM, Sinnecker P (2008) Chlorophylls in foods: sources and stability. In: Socaciu C (ed) Food colorants: chemical and functional properties. CRC Press, New York, pp 195–212

Heaton JW, Marangoni AG (1995) Chlorophyll degradation in processed foods and senescent plant tissues. Trends Food Sci Tech 7:8–15

Turkmen N, Poyrazoglu ES, Sari F, Velioglu YS (2006) Effects of cooking methods on chlorophylls, pheophytins and colour of selected green vegetables. Int J Food Sci Technol 41(3):281–288

Byun M, Jo C, Lee K, Kim K (2002) Chlorophyll breakdown by gamma irradiation in a model system containing linoleic acid. JAOCS 79(2):145–150

Saitanis CJ, Riga-Karandinos AN, Karandinos MG (2001) Effects of ozone on chlorophyll and quantum yield of tobacco (Nicotiana tabacum L.) varieties. Chemosphere 42:945–953

Zhuang H, Barth MM (2003) The physiological roles of vitamins in vegetables. In: Bartz JA, Brecht JK (eds) Postharvest physiology and pathology of vegetables. Marcel Dekker Inc, Florida, pp 374–394

Chauhan OP, Raju PS, Ravi N, Singh A, Bawa AS (2011) Effectiveness of ozone in combination with controlled atmosphere on quality characteristics including lignification of carrot sticks. J Food Eng 102(1):43–48

Beltrán D, Selma Alicia MV, Mariän, Mariä I, Gil (2005) Ozonated water extends the shelf life of fresh-cut lettuce. J Agric Food Chem 53:5654–5663

Akbas MY, Hülya Ö (2007) Effectiveness of organic acid, ozonated water and chlorine dippings on microbial reduction and storage quality of fresh-cut iceberg lettuce. J Sci Food Agric 87:2609–2616

Patil BS (2007) Irradiation applications to improve functional components of fruits and vegetables. In: Komolprasert V, Morehouse K (eds) Irradiation of food and packaging. M. American Chemical Society, ACS symposium series 875, Chap. 8, pp 117–137

Lacroix M, Vigneault C (2007) Irradiation treatment for increasing fruit and vegetable quality. Stewart Postharvest Rev 3(3):1–8

Park JN, Sung NK, Parka JN, Sungb NY, Byunb EH, Byuna EB, Songa BS, Kima JH, Leec KA, Sond EJ et al (2015) Microbial analysis and survey test of gamma-irradiated freeze-dried fruits for patient’s food. Radiat Phys Chem 111:57–61

Khattak KF, Rahman TU (2016) Effect of gamma irradiation on the vitamins, phytochemicals, antimicrobial and antioxidant properties of Ziziphus mauritiana Lam. leaves. Radiat Phys Chem 127:243–248

Sabato SF, da Silva JM, da Cruz JM, Salmieri S, Rela PR, Lacroix M (2009) Study of physical–chemical and sensorial properties of irradiated Tommy Atkins mangoes (Mangifera indica L.) in an international consignment. Food Control 20(3):284–288

Frimpong GK, Kottoh IS, Ofosu DO (2015) Gamma irradiation effect on the phytochemical and sensory quality of minimally processed cabbage in selected supermarkets in Accra Ghana. J Yoga Phys Ther 5:206. https://doi.org/10.4172/2157-7595.1000206

Akbas MY, Ozdemir M (2008) Effect of gaseous ozone on microbial inactivation and sensory of flaked red peppers. Int J Food Sci Tech 43:1657–1662

Selma MV, Ibáñez AM, Allende A, Cantwell M, Suslow T (2008) Effect of gaseous ozone and hot water on microbial and sensory quality of cantaloupe and potential transference of Escherichia Coli O157:H7 during cutting. Food Microbiol 25(1):162–168

Liew CL, Prange RK (1994) Effect of ozone and storage temperature on postharvest diseases and physiology of carrots (Daucus carota L.). J Am Soc Hortic Sci 119(3):563–567

Acknowledgements

RESALA Laboratories sincerely thank the Natural Science Engineering Research Council of Canada (NSERC, Discovery Program), the Ministère de l’Agriculture, des Pêcheries et de l’Alimentation du Québec (MAPAQ), the Agricultural Adaptation Council (AAC), Agriculture and Agri-Food Canada, Bonduelle Canada Inc. and Atoka Cranberries Inc. for their financial support, through the Agri-Innovation Program (AIP) Stream B of Canadian Food Innovators (CFI) recipient (Project # PAI-P298). Members of RESALA are also very thankful to M. Michel Casgrain and Dr Rony Chamoun (Bonduelle Americas Inc.) for their precious collaboration, in particular for their professional and scientific support, and the facility delivery of vegetables. Atoka Cranberries Inc. and BSA-Montréal are also acknowledged for respectively providing the concentrated cranberry juice and the fermented dextrose as bioactive components of the coating antimicrobial formulation. The authors would also like to thank Nordion Int. (Laval, QC, Canada) for irradiation treatments. Finally, the project participants are very thankful to M. Serge Pouliot (Ozone Innovations Inc.) for his availability, technical advice and development of the ozonation process throughout the project. International Atomic Energy Agency (IAEA) is also acknowledged for his financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Behnoush Maherani declares no conflict of interest. Mehdi Harich declares no conflict of interest. Stephane Salmieri declares no conflict of interest. Monique Lacroix declares no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Maherani, B., Harich, M., Salmieri, S. et al. Antibacterial properties of combined non-thermal treatments based on bioactive edible coating, ozonation, and gamma irradiation on ready-to-eat frozen green peppers: evaluation of their freshness and sensory qualities. Eur Food Res Technol 245, 1095–1111 (2019). https://doi.org/10.1007/s00217-018-3211-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-018-3211-4