Abstract

The objective of this research was to study spontaneously fermented chestnut flour sourdough and to evaluate its effect in gluten-free bread based on corn starch and chestnut flour. Lactic acid bacteria and yeasts counts, pH and titratable acidity of chestnut flour sourdough were measured during 6 days of sourdough propagation. Chestnut flour sourdough fermented for 5 days with back-slopping every 24 h with 33 % of the ripe sourdough was selected to elaborate gluten-free bread. Control breads contained 15, 20 or 25 % of chestnut flour, and sourdough breads contained the same amount of chestnut flour added as chestnut flour sourdough. Chestnut flour sourdough improved bread specific volume, rendered breads with lighter crusts, reduced crumb hardness at day 0 and day 7 and reduced pH. However, chestnut flour sourdough had no effect on yeasts and molds growth during 7 days of bread storage and did not influence sensory characteristics perceived by consumers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Population that follows a gluten-free (GF) diet because of suffering wheat allergy, celiac disease or gluten sensitivity is growing, and therefore, demand of GF products and specially bread is also increasing [1]. Since lack of gluten impairs GF bread baking and sensory characteristics as well as its shelf life, a wide range of additives including hydrocolloids, proteins, emulsifiers, shortenings and enzymes are being used to improve GF bread quality [2–4].

Sourdough bread making is based on the fermentation of a mixture of flour and water either by native lactic acid bacteria (LAB) and yeasts or by added starters [5, 6]. Sourdough plays an important role in bread making: increases bread volume due to the improvement in CO2 retention [7]; improves bread texture as softer crumbs are obtained [8]; elongates bread shelf life by reducing staling and by generating antimicrobial substances that prevent microbial spoilage [6, 7]; enriches nutritional quality by increasing mineral biodisponibility because of phytase activity and mineral solubility and by reducing glycemic index; and enhances sensory profile [9]. These effects have also been described when sourdough is used for GF bread production [6, 7, 9]. Furthermore, Rizzello et al. [10] reported that selected sourdough lactobacilli and fungal proteases can eliminate gluten toxicity during long fermentations.

The interest in using chestnut (Castanea sativa Mill.) flour in bakery products is increasing due to its nutritional and health benefits as it contains 4–7 % of high-quality proteins with essential amino acids, 20–30 % of sugar, 50–60 % of starch, 4–10 % of fiber, 2–4 % of fat, and vitamins and minerals such as vitamin E, vitamin B group, K, P and Mg [11, 12]. As chestnut flour is a GF flour it could also contribute to improved nutritional profile of GF breads since their content in fiber and vitamin B is usually low [6]. Demirkesen et al. [13] evaluated the effect of chestnut flour to formulate GF rice bread and concluded that 30 % of chestnut flour addition was the optimum. Moreira et al. [14] studied the rheological behavior of different blends using rice flour and chestnut flour with different particle size and indicated that the blend with 30 % of chestnut flour with a particle size of 169 µm or the blend with 25 % of chestnut flour with low particle size (77 µm) performed better than other formulations evaluated.

Aponte et al. [5] developed a spontaneously fermented sourdough with chestnut flour and assessed the impact of fermentation on volatile organic compounds formation during sourdough maturation using gas chromatography coupled to mass spectrometry and identified 59 volatile compounds. However, the effect of spontaneously fermented chestnut flour sourdough on GF bread has not been evaluated yet.

The objective of this research was to study spontaneously fermented chestnut flour sourdough and to evaluate its effect in GF bread quality.

Materials and methods

Raw materials

Ingredients used for the elaboration of GF bread were: tap water, corn starch (Syral Iberia S.A.U., Zaragoza, Spain), chestnut flour (Castaña del Bierzo, Mesa del Castaño del Bierzo, León, Spain) (8.93 % moisture, 47.07 % starch, 18.9 % sugars, 15 % fiber, 5.12 % protein, 4.98 % fat and 1.89 % ash), white sugar (Azucarera Ebro S.L., Madrid, Spain), shortening (Puratos, Sils, Spain), iodized refined salt (Sal Costa S.A., Barcelona, Spain), baking powder (Panreac Química S.L.U., Castellar del Vallès, Spain), dry yeast (Lallemand Iberica S.A., Cachofarra, Portugal), xanthan gum (Degussa Texturant Systems, Paris, France) and emulsifier: citric acid esters of monoglycerides and diglycerides and sucrose fatty acid esters (Degussa Texturant Systems).

Moisture, protein, fat, sugars, fiber and ash content of chestnut flour were determined according to the official methods AOAC [15], and starch was calculated per difference.

Sourdough production and analysis

Chestnut flour and sterilized tap water (1:1) were used to start fermentation. The mixture was incubated at 25 °C and propagated by back-slopping every 24 h, adding 33 or 10 % of the previous sourdough to a new fresh mixture of chestnut flour and water, for 6 days. Aseptic conditions were guaranteed during all process working under sterile conditions.

The results of a preliminary study on different gluten-free sourdoughs showed that incubation at 25 °C with refreshments every 24 h with 33 % of the fermented sourdough were adequate conditions for chestnut flour sourdough development (results not shown). In addition, Aponte et al. [5] evaluated a chestnut flour sourdough incubated at room temperature and propagated by back-slopping every 24 h with 10 % of previous sourdough. In order to study the effect of different percentage of fermented sourdough used in the refreshments, 33 and 10 % were selected.

The LAB and yeasts counts were evaluated at the beginning of the process (day 0) and at days 1, 2, 3, 4, 5 and 6 of sourdough propagation. To count LAB, 10 g of sourdough were diluted with 90 ml of peptone water (Oxoid Ltd., Basingstocke, England) and homogenized for 30 s at 300 rpm in a Stomacher® 400 Circulator (Worthing, UK). Then, 1 ml of decimal dilutions was plated on Man Rogosa Sharpe (MRS) agar (Oxoid Ltd.) and incubated for 48 h at 30 °C. Yeasts were counted on Sabouraud dextrose agar (Oxoid Ltd.) supplemented with 0.1 g/l of chloramphenicol (Oxoid Ltd.) and incubated at 25 °C for 5 days.

Total titratable acidity (TTA) and pH were measured at the beginning of the process (day 0) and at days 1, 2, 3, 4, 5 and 6 of the sourdough propagation. The pH was directly determined with a pH meter (Crison Instruments S.A., Alella, Spain). TTA was evaluated on 10 g of sourdough homogenized with 90 ml of distilled water and expressed as the amount (ml) of 0.1 M NaOH to get a pH of 8.3, according to the method described by Coda et al. [16].

Three independent batches were elaborated to evaluate sourdough LAB and yeasts counts, pH and TTA.

Bread making

Chestnut flour sourdough fermented for 5 days with back-slopping every 24 h with 33 % of the ripe sourdough was selected to elaborate GF bread.

For bread elaboration, powder ingredients (including sourdough) were weighed and kneaded in a mixer (Sammic S.L., Gipuzkoa, Spain) at low speed (85 rpm). Water (25 °C ± 1) and melted shortening were added to powder ingredients. Batter was mixed for 2 min at low speed (85 rpm), 2 min at medium speed (222 rpm) and 30 s at high speed (385 rpm). Batter was weighed in 200-g portions in each baking pan (5 × 8 × 14 cm) and proofed in a chamber (Salva, Lezo, Spain) for 35 min at 85 % RH and 30 °C. Finally, breads were baked in a convection oven (Sveba-Dahlen AB, Fristad, Sweeden) at 160 °C for 30 min, with steam injection for 10 s at the start of baking. After 2 h of cooling, breads were stored in plastic bags at room temperature for 7 days.

Six formulations were obtained (Table 1). Control formulations C15, C20 and C25 contained 15, 20 and 25 % of chestnut flour respectively, expressed as % of flour weight (% FW) (corn starch + chestnut flour). Previous studies were performed to adjust water level of control formulations to obtain the same rheological characteristics (G*) in them. The measurement consisted of a single-frequency test performed with an angular frequency of 10 Hz and a strain of 0.01 %. A power law model was used to predict the new water level based on single-frequency measurements of complex modulus (G*) for each batter. The G* of C15, C20 and C25 with the corrected water level were 4155.33, 4501.50 and 4363.33 Pa, respectively.

Sourdough formulations S15, S20 and S25 contained the same amount of chestnut flour and water as their respective controls, but in this case chestnut flour and part of the water were added as sourdough. The content of chestnut flour sourdough in batter formulations expressed as % of total ingredients (solid ingredients + water) was: 13.1 % in S15, 17.2 % in S20 and 21.4 % in S25.

Bread analysis

Loaf volume, bake loss, water activity, crust and crumb color and crumb texture were evaluated by the methods described by Aguilar et al. [17].

Yeasts and molds counts as well as pH and TTA values of bread were measured according to the methods described in “Sourdough production and analysis” section for sourdough analysis.

To evaluate bread characteristics, three independent productions of each formulation were developed. In each experiment, three breads from each formulation were analyzed.

Sensory analysis

Sensory analysis of bread was performed 24 h after bread making by 54 volunteers recruited among university staff and students. Testers were both female and male, aged between 18 and 64 and regular bread consumers, who evaluated each sensory attribute (crust color, crumb color, porosity, crumb hardness, aroma and taste) with a seven-point intensity scale. At the end of the test, consumers were asked to select the most and the least preferred bread (results of preference test are expressed in % of preference). Control and sourdough bread samples with the same chestnut flour content were randomly codified using three digits and compared in pairs.

Statistical analysis

Results were analyzed by analysis of variance (ANOVA) using the general linear models procedure of SPSS Statistics 17.0 software. Tukey test was applied for comparison of sample data, except for sensory analysis results, which were compared by a t test. Evaluations were based on a significance level of p < 0.05.

Results and discussion

Sourdough characteristics

Figure 1 shows the evolution of chestnut flour sourdough LAB and yeasts populations. Initial LAB counts were 3.0 ± 0.1 log CFU/g and after 2 days of propagation increased to ca. 9 log CFU/g. Counts remained constant between days 2 and 5 and increased (p < 0.05) to ca. 9.5 log CFU/g at day 6. There were no differences (p > 0.05) between 10 and 33 % of sourdough used for back-slopping.

No yeasts were detected in the initial sourdough mixture at day 0. After 1 day of incubation, counts were 2.8 ± 0.5 log CFU/g. From day 1 to day 2, yeasts growth stopped in sourdough renewed at 33 % and decreased (p < 0.05) in sourdough renewed at 10 %. The pause in yeasts growth was probably caused by the pH drop observed in the same time interval (Fig. 2).

Nevertheless, yeasts rapidly adapted to new media conditions and retook growth from day 2. Moroni et al. [18] also observed a reduction in yeasts counts at day 2 in teff and buckwheat sourdoughs. At day 6, sourdough renewed at 33 % presented higher (p < 0.05) yeasts counts than sourdough renewed at 10 %, LAB/yeasts ratio being 100:1 for the first and 10,000:1 for the second. Sourdoughs evaluated in this study had cell counts similar to those of typically mature sourdoughs: >108 CFU/g LAB and yeasts counts orders of magnitude lower [7].

Figure 2 shows pH and TTA results from sourdough renewed at 10 and 33 %. Initial pH of sourdough was 5.8 ± 0.5, it slightly increased to 6.1 ± 0.1 at day 1, and at second day of propagation, it had already decreased until ca. 4.5. This pH remained constant until day 6. There were no significant differences between pH results from both sourdoughs.

The initial TTA value was 3.5 ± 0.2 and increased to ca. 16 at day 2. The maximum increase in TTA was recorded at day 2, accordingly to pH drop. Aponte et al. [5] studied chestnut flour sourdough characteristics inoculated with bakers’ yeast and renewed every 24 h with 10 % of the ripe sourdough and reported higher pH and lower TTA values compared with the present study, probably due to higher LAB counts observed in our research.

The sourdough renewed every 24 h with 33 % of the previous sourdough and propagated for 5 days was selected to elaborate gluten-free bread since it had higher yeasts counts than sourdough renewed with 10 % of the previous sourdough.

Bread characteristics

Table 2 shows results of bread characteristics. The increase in chestnut flour concentration in control breads caused a decrease in specific volume. Interestingly, this effect was not observed in sourdough breads as S20 and S25 had higher volumes than S15. In these breads, sourdough effect compensated the negative effect of chestnut flour on bread volume. The positive effect of sourdough on bread specific volume could also be observed comparing control and sourdough breads. Previous studies have also reported an increase in GF bread specific volume when sourdough was added [19–21].

Demirkesen et al. [13] reported the effect of chestnut flour mixed with rice flour at different ratios (0:100, 10:90, 20:80, 30:70, 40:60, 50:50 and 100:0) on bread specific volume and observed that bread volume increased as the chestnut:rice flour ratio increased, up to 30:70. The higher amount of fiber in the chestnut flour used in our study (15 %) compared to Demirkesen et al. [13, 22] study (9.5 %) could explain the differences observed in volume behavior, since certain amount of fiber could improve GF bread volume due to its gas retention capacity and the viscoelastic characteristics that fiber provides to dough, but too much fiber reduces bread volume. Moreover, these divergent results could also be attributed to differences in bread formulations, not only related to the flour components but also to the gums and emulsifiers used.

Chestnut flour concentration did not affect bake loss values but sourdough did, as S15, S20 and S25 had higher bake loss than C15, C20 and C25, respectively. Water activity values did not reflect bake loss results, as no differences between water activity of breads values were observed at day 0. All breads suffered a significant reduction in water activity during 7 days of storage. Wolter et al. [23] reported that sourdough (buckwheat, quinoa, sorghum, teff or wheat) fermented with Weissella cibaria MG1 did not influence water activity of bread. They also observed that quinoa and sorghum sourdoughs reduced bake loss and wheat sourdough increased it, while buckwheat and teff sourdoughs had no significant effect on bake loss. Galle et al. [24] and Moroni et al. [25] neither found differences between bake loss of GF sourdough breads and their controls.

Crust and crumb color were significantly influenced by chestnut flour % and sourdough addition (Tables 2, 3). In crumb, the increase in chestnut flour % resulted in a decrease in L* values and an increase in a* and b* values while, in crust, the increase in chestnut flour % resulted in a decrease in L* and b* values and an increase in a* values. In general, sourdough addition rendered crumbs with lower L*, a* and b* values than their controls. All sourdough bread crusts were lighter (higher L*) and less reddish (lower a* values) than their counterparts. The darkening effect of chestnut flour on bread crumb and crust was expected due to the dark color of this ingredient (L* = 85.57 ± 0.20; a* = 1.23 ± 0.01; and b* = 14.93 ± 0.09). Moreover, crust browning is explained by the high sugar content of chestnut flour, which contributes to Maillard reaction and caramelization during baking [13]. According to this, sourdough breads presented paler crusts than their controls because sugars were consumed during fermentation and could not contribute to crust browning to the same extent.

The percentage of chestnut flour did not influence crumb hardness. Demirkesen et al. [13] studied the effect of 0–100 % of chestnut flour blended with rice flour and observed that 30 % of chestnut flour rendered the softest breads and, when chestnut flour content exceeded this optimum level, a firmer texture was obtained due to the increase in fibre content.

Sourdough breads had softer crumbs than their controls at day 0 and at day 7, although all breads became harder after 7 days of storage. Novotni et al. [20], Wolter et al. [23], Moore et al. [26, 27] and Schwab et al. [28] also found that sourdough softened the crumb of GF bread. However, Moroni et al. [25] observed the opposite effect of sourdough on GF crumb hardness, and Schober et al. [21] did not find differences in crumb hardness of GF bread elaborated with sourdough. Differences in water concentration in doughs due to water adjustment did not seem to affect volume, bake loss or texture values. Water/dry ingredients ratios in doughs were: 0.88:1 for C15 and S15; 0.91:1 for C20 and S20; and 0.92:1 for C25 and S25. Probably, these small differences between doughs were not enough to explain differences between final breads.

Breads containing 25 % of chestnut flour showed lower pH than C20 and C15 although no significant differences in TTA were observed. As expected, sourdough reduced bread pH and increased TTA. Chestnut flour contains organic acids such as malic, oxalic, citric and ascorbic [29] that would explain the slight decrease in pH in control breads with 25 % of chestnut flour. GF bread pH values described in the literature range between 5.9 and 6.3, which are lower than the results of our study (7.51–7.71) probably due to formulations used as well as possible differences due to our particular sourdough microbiota. For that reason, the pH of resulting sourdough breads were higher (6.82–7.11) than those reported by other authors (4.6–5.9) [20, 23, 25–27].

No yeasts and molds could be detected at day 0. After 7 days of storage, yeasts and molds counts were slightly higher than 5 log CFU/g in all breads and no effect that could be attributed to chestnut flour % or sourdough addition was observed. It has been shown that sourdough LAB produce antifungal compounds that prevent yeasts and molds growth and improve bread shelf life [30, 31]. In GF bread, Moore et al. [27] have reported the antifungal activity of sourdough fermented with Lactobacillus plantarum FST 1.7. However, sourdough fermented with W. cibaria MG1 did not improve the microbial shelf life of GF bread [23]. LAB present in the sourdough evaluated in our study probably did not produce enough antifungal compounds to reduce yeasts and molds growth.

Sensory evaluation

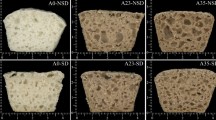

Results from sensory evaluation are shown in Table 3. Each sourdough bread was compared with its control. Although instrumental measurement of color indicated that sourdough influenced crust and crumb color, consumers could not perceive these differences. Although differences in porosity were not statistically significant, S20 and S25 breads received higher scores in this attribute than C20 and C25, respectively. Crumb porosity can be observed in digital images from Fig. 3, where it seems that adding ≥17.2 % of sourdough caused an increase in pore size. High porosity in sourdough breads is probably related to their higher volumes since sourdough helps to retain gas generated during bread fermentation, giving larger pores and resulting in a higher loaf volume [7, 26]. No differences in crumb hardness of breads elaborated with or without sourdough were perceived by consumers.

Consumers could not detect either differences between aroma and taste of control and sourdough breads. Aponte et al. [5] identified 59 volatile compounds from chestnut flour sourdough coming from microbial metabolism, lipid oxidation, caramelization, Maillard reaction and genetic and environmental factors, and concluded that the wide variety of volatile metabolites could contribute to enriched bread flavor, taste and aroma. Nevertheless, when consumers were asked to select the preferred bread comparing each sourdough bread with its control, only 32, 21 and 23 % of them preferred S15, S20 or S25, respectively, than their control counterparts. Consumers that preferred sourdough bread selected it because of its taste, aroma and texture. Control breads were mostly preferred due to the sweet taste provided by chestnut flour as it contains 18.9 % of sugars, but sourdough fermentation reduced sweet taste in bread, probably influencing consumers’ preference. Coda et al. [19] reported a decrease in sweetness in sourdough breads compared with their controls.

Conclusions

Results show that spontaneously fermented chestnut flour sourdough can contribute to improve chestnut flour bread characteristics. Sourdough increased bread specific volume, reduced crumb hardness and rendered breads with paler crusts. Chestnut flour sourdough improved bread shelf life as it provided softer crumbs than chestnut flour after 7 days of storage. However, this sourdough had no effect on yeasts and molds growth after 7 days of bread storage and it negatively affected consumers’ preference, probably due to the reduction in the characteristic sweet taste of chestnut flour caused by sourdough fermentation.

References

Rosell CM, Barro F, Sousa C, Mena MC (2014) Cereals for developing gluten-free products and analytical tools for gluten detection. J Cereal Sci 59:354–364

Aguilar N, Albanell E, Miñarro B, Capellas M (2015) Chickpea and tiger nut flours as alternatives to emulsifier and shortening in gluten-free bread. LWT Food Sci Technol 62:225–232

Hager AS, Arendt EK (2013) Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocoll 32:195–203

Martínez MM, Marcos P, Gómez M (2013) Texture development in gluten-free breads: effect of different enzymes and extruded flour. J Texture Stud 44:480–489

Aponte M, Boscaino F, Sorrentino A, Coppola R, Masi P, Romano A (2013) Volatile compounds and bacterial community dynamics of chestnut-flour-based sourdoughs. Food Chem 141:2394–2404

Moroni MM, Dal Bello F, Arend EK (2009) Sourdough in gluten-free bread-making: an ancient technology to solve a novel issue? Food Microbiol 26:676–684

Gobbetti M, De Angleis M, Di Cagno R, Rizzelo CG (2008) Sourdough/lactic acid bacteria. In: Arendt EK, Dal Bello F (eds) Gluten-free cereal products and beverages. Academic Press, San Diego

Katina K, Heiniö RL, Autio K, Poutanen K (2006) Optimization of sourdough process for improved sensory profile and texture of wheat. LWT Food Sci Technol 39:1189–1202

Katina K, Arendt EK, Liukkonen KH, Autio K, Flander L, Poutanen K (2005) Potential of sourdough for healthier cereal products. Trends Food Sci Technol 16:104–112

Rizzello CG, De Angelis MD, Di Cagno F, Camarca A, Silano M, Losito I, De Vincezi MD, De Bari MD, Palmisano F, Maurano F, Gianfrani C, Gobbetti M (2007) Highly efficient gluten degradation by lactobacilli and fungal proteases during food processing: new perspectives for celiac disease. Appl Environ Microbiol 13:4499–4507

Chenlo F, Moreira R, Pereira G, Silva CC (2007) Evaluation of the rheological behaviour of chestnut (Castanea stavia Mill) flour pastes as function of water content and temperature. Electron J Environ Agric Food Chem 6:1794–1802

Sacchetti G, Pinnavaia GG, Guidolin E, Dalla-Rosa M (2004) Effects of extrusion temperature and feed composition on the functional, physical and sensory properties of chestnut and rice flour-based snack-like products. Food Res Int 37:527–534

Demirkesen I, Mert B, Sumnu G, Sahin S (2010) Utilization of chestnut flour in gluten-free bread formulations. J Food Eng 101:329–336

Moreira R, Chenlo F, Torres MD (2013) Rheology of gluten-free doughs from blends of chestnut and rice flours. Food Bioproc Tech 6:1476–1485

AOAC (2005) Official methods of analysis of AOAC international. Association of Official Analytical Chemists, Gaithersburg

Coda R, Di Cagno R, Rizzello CG, Nionelli L, Edema MO, Gobbetti M (2011) Utilization of African grains for sourdough bread making. J Food Sci 76:M329–M335

Aguilar N, Albanell E, Miñarro B, Guamis B, Capellas M (2015) Effect of tiger nut-derived products in gluten-free batter and bread. Food Sci Technol Int 21:323–331

Moroni MM, Arendt EK, Morrissey JP, Dal Bello F (2010) Development of buckwheat and teff sourdoughs with the use of commercial starters. Int J Food Microbiol 142:142–148

Coda R, Rizzello CG, Gobbetti M (2010) Use of sourdough fermentation and pseudo-cereals and leguminous flours for the making of a functional bread enriched of γ-aminobutyric acid (GABA). Int J Food Microbiol 137:236–245

Novotni D, Cukelj N, Smerdel B, Bituh M, Dujmic F, Curic D (2012) Glycemic index and firming kinetics of partially baked frozen gluten-free bread with sourdough. J Cereal Sci 55:120–125

Schober TJ, Bean SR, Boyle DL (2007) Gluten-free bread improved by sourdough fermentation: biochemical, rheological, and microstructural background. J Agric Food Chem 55:5137–5146

Sabanis D, Lebesi D, Tzia C (2009) Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT Food Sci Technol 42:1380–1389

Wolter A, Hager AS, Zannini E, Czerny M, Arendt EK (2014) Influence of dextran-producing Weisella cibaria on baking properties and sensory profile of gluten-free and wheat breads. Int J Food Microbiol 172:83–91

Galle S, Schwab C, Dal Bello F, Coffey A, Gänzle M, Arendt EK (2012) Influence of in situ synthesized exopolysaccharides on the quality of gluten-free sorghum sourdough bread. Int J Food Microbiol 155:105–112

Moroni AV, Dal Bello F, Zannini E, Arendt EK (2011) Impact of sourdough on buckwheat flour, batter and bread: biochemical, rheological and textural insights. J Cereal Sci 54:195–202

Moore MM, Schober TJ, Juga B, Arendt EK (2007) Effect of lactic acid bacteria on the properties of gluten-free sourdoughs, batters and the quality and ultrastructure of gluten-free bread. Cereal Chem 84:357–364

Moore MM, Dal Bello F, Arendt EK (2008) Sourdough fermented by Lactobacillus plantarum FST 1.7 improves the quality and shelf life of gluten-free bread. Eur Food Res Technol 226:1309–1316

Schwab C, Mastrangelo M, Corsetti A, Ganzle M (2008) Formation of oligosaccharides and polysaccharides by Lactobacillus reuteri LTH5448 and Weisella cibaria 10M in sorghum sourdoughs. Cereal Chem 85:679–684

Ribeiro B, Rangel J, Valentão P, Andrade PB, Pereira JA, Bölke H, Seabra RM (2007) Organic acids in two Portuguese chestnut (Castanea sativa Miller) varieties. Food Chem 100:504–508

Cizeikiene D, Joudeikiene G, Paskevicius A, Bartkiene E (2013) Antimicrobial activity of lactic acid bacteria against pathogenic and spoilage microorganism isolated from food and their control in wheat bread. Food Control 31:539–545

Rizzello CG, Cassone A, Coda R, Gobbetti M (2011) Antifungal activity of sourdough fermented wheat germ used as an ingredient for bread making. Food Chem 127:952–959

Acknowledgments

N. Aguilar acknowledges the “Ministerio de Educación y Ciencia” for her grant (AP2009-0859). We thank Mesa del Castaño del Bierzo for kindly supplying chestnut flour. We also thank Núria Garreta for her laboratory work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

We thank the consumers -all of them volunteers- that participated in the preference study.

Rights and permissions

About this article

Cite this article

Aguilar, N., Albanell, E., Miñarro, B. et al. Chestnut flour sourdough for gluten-free bread making. Eur Food Res Technol 242, 1795–1802 (2016). https://doi.org/10.1007/s00217-016-2679-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-016-2679-z