Abstract

Photocatalytic activity of UV+visible-activated nitrogen-doped titanium dioxide catalyst was tested for Escherichia coli ATCC 25922 inactivation. A further aspect of this work was to evaluate the effect of selected parameters (pH, irradiation type, and nitrogen-doped TiO2 concentration) on the disinfection efficiency. The following conditions were tested: complete solar radiation (UV–visible) and visible solar radiation alone, four different concentrations of catalyst (0.0, 0.10, 0.25, and 0.5 mg/mL), and six pH values (6.0, 6.5, 7.0, 7.5, 8.0, and 8.5). Dark conditions were used as control experiments. Disinfection process was enhanced under irradiation when the nitrogen-doped photocatalyst was added into the solution. Lower accumulated energy along with higher inactivation rates was observed in the experiments testing nitrogen-doped TiO2 in comparison with the results obtained on the samples without the catalyst. The disinfection effect of the photocatalyst was found depending on the radiation type. pH value has an important role in the inactivation mechanisms that seems to be related with the cell wall permeability and with particle’s surface charge. pH values 6.5 and 8.0 improve the antimicrobial efficiency of the catalyst tested, whereas pH 7 was identified as the less favorable conditions for microbial inactivation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Availability of safe drinking water is vital for the conservation of human health, and its sustainability has become a worldwide concern. The presence of pollution (i.e., pathogenic microorganisms) represents loss of health and may cause death because of water-related diseases transmission and other human health effects. Availability of safe drinking water is therefore a necessity and a duty; especially in subtropical areas, where pathogenic bacteria transmitted through irrigation water or acquired by ingestion of contaminated water, represent severe risk to the human population [1]. Besides the use of conventional technologies for the inactivation of pathogenic species in drinking water, management has become a serious problem due to unpleasant taste, phytotoxicity, and mainly because of growing concerns regarding the toxicity of by-products of its reaction with organic matter [1, 2]. The current environmental conditions demand the evolvement of alternative technologies for water purification, and the use of free chlorine as a disinfectant will have to be limited to high-quality groundwater in order meet the disinfection by-product (DBP) regulations and to avoid its generation as secondary pollutants [3]. As a result, several approaches for the production of safe drinking water have been developed, being advanced oxidation process considered as emerging cost-effective among them.

Photocatalysis using semiconductor materials has found increasing interest in solving environmental pollution problems [4]. TiO2 is a well-analyzed, low-cost, nontoxic, stable, highly photoreactive, chemically and biologically inert photocatalyst; it means a sensitizer for light-induced redox reactions. Heterogeneous photocatalysis using titanium dioxide is a widely used advanced oxidation process considered as alternative to conventional water disinfection and air remediation technologies, such as chlorination [4–7]. This agent has proven to be highly effective in the nonselective decomposition of organic molecules and in the inactivation of microorganisms due to high decomposition and mineralization rates when used in combination with certain radiation sources [5, 6]. Furthermore, water treatment with heterogeneous photocatalysis neither requires the addition of other chemicals reactants nor generates hazardous waste by-products [2].

The process takes place when TiO2 is irradiated with near ultraviolet (UV) radiation, and photon energy is absorbed by the crystal structure of the semiconductor, transferring electrons from the valence to the conducting band [5, 7]. This photocatalytic reaction generates electron–hole pairs on the semiconductor surface [2]. It has been reported that holes in the valence bands have a positive redox potential capable of oxidizing adsorbed substrates on the catalyst surface and, in the presence of adsorbed water and oxygen, reactive oxygen species (ROS) such as superoxide radicals (O •−2 ), hydroxyl radicals (•OH), and hydrogen peroxide (H2O2) are produced by redox reactions [3]. These agents are known to be strong, nonselective oxidizing agents, thus are responsible for breaking substances and have antimicrobial effects because of their oxidation potential, being hydroxyl radicals the main reactive oxygen species involved in the photokilling process [2, 8].

This semiconductor photocatalyst has been employed as a suspended powder or thin film on a suitable substrate or as a coated electrode and has been found to be efficient to destroy organics and to inactivate different organisms, such as viruses, vegetative cells, and spores of organisms with a high resistance to desiccation and radiation (Escherichia coli, Lactobacillus acidophilus, Saccharomyces cerevisiae, Bacillus atrophaeus, Aspergillus niger, and Kocuria rhizophila) among others [3, 5]. However, due to its large band gap (3.2 eV), anatasa, the most efficient form of TiO2 semiconductors, exhibits photocatalytic activity only when it is irradiated with UV (λ < 400 nm) radiation [3]. This specific characteristic limits the photosensitivity to the UV part of the solar spectrum and therefore is a technological limitation [4, 6]. Since sunlight consists of about only 5% UV radiation, the enhancement of process photo efficiency is required to implement large-scale sustainable technologies based on renewable energy sources. A feasible alternative is the use of a photocatalyst excitable by the energy of photons provided by sunlight radiation (≈45% visible region) [1, 6]. TiO2 modifications have been developed in order to make it active under visible spectral irradiation, to improve the photosensitivity and quantum yield of TiO2-based photocatalysis, and to reduce the TiO2 band gap energy requirements for photocatalytic activation. It is generally accepted that this so-called daylight photocatalysis is achieved by several ways: (a) by dye sensitization, (b) by coupling TiO2 with other semiconductors possessing favorable band gaps and potentials, (c) by surface deposition of metal clusters, and (d) by doping the crystal lattice with metals (Fe, Co, Ag) and nonmetals foreign atoms (N, C, F, S), [4, 6]. Photocatalysis is enabled by light exposure, and the titanium dioxide modification determines the effective wavelength [5, 9, 10]. Substitutional nitrogen doping of TiO2 apparently contributes to band gap narrowing through mixing of nitrogen 2p states with oxygen 2p states on the top of the valence band, in the form of nitride (Ti–N), bonded to three Ti-atoms or oxynitride (Ti–O–N). On the other hand, a different arrangement in the interstitial model is the formation of oxyanion species at the interstitial lattice sites, where N is bonded to one or more O, creating localized intergap states. Both configurations change the energy photothreshold causing the redshift of the optical absorption edge toward the visible spectral region, thus absorbing a grater quantity of sunlight radiation and activating doped titania specimens to carry out surface photo-induced redox processes [6, 11].

The objective of this study was to evaluate the influence of different parameters (pH values, type of energy, and concentration of the photocatalyst) on the efficiency of the nitrogen-doped TiO2 nanopowders on the inactivation of E. coli.

Materials and methods

Reagents

All the reagents used were purchased as A.C.S. reagents and were used as received with any further purification. Nitrogen-doped TiO2 nanoparticles were provided by the Department of Civil and Environmental Engineering, University of Cincinnati.

Bacterial strains and growth conditions

The bacterial strain used in the experiments was E. coli ATCC 25922 (American Type Culture Collection). Microorganisms were acquired from the UDLAP microbial collection. The bacteria were kept frozen at −20 °C on Tryptic Soy Broth (TSB) 10% glycerol. Before each experiment, the phenotype of the culture was validated streaking on Mc Conkey agar for colony morphology and biochemical features using the 32 GN miniAPI® galleries, and the semiautomatic miniAPI® reader. E. coli was grown on TSB and Tryptic Soy Agar (TSA), as liquid and solid culture media, respectively. Cells were acquired from an overnight plate culture incubated at 37 °C under aerobic conditions. Cells were added to 10 mL of fresh culture broth and incubated at the same conditions on a rotary shaker. Bacterial growth was monitored by means of optical density measures at 620 nm, and cells growing at an exponential growth phase were collected and used immediately in the required cell density, adjusting with McFarland standard, to obtain an initial concentration of 105 CFU mL−1. For the disinfection assays, 300 mL of sterilized water containing different concentrations of nitrogen-doped TiO2 powders (0.10, 0.25, and 0.50 mg/mL) were inoculated and then exposed to solar radiation for 3 h. The catalyst and culture were maintained in suspension by magnetic stirring.

Sample preparations

The batch photoreactors consisted of 500 mL Pyrex flasks irradiated with solar radiation. Pyrex glass were selected because of its unique characteristics of technical glass that meets the criteria expressed in International Standards for glassware, such as transparency, optical stability, and light transmission [12]. For the doped TiO2 photocatalytic enhanced disinfection assessments, four different catalyst concentrations (0.00, 0.10, 0.25, and 0.50 mg mL−1) were tested. Photocatalyst concentration was added according to the volume of the photoreactor and sterilized. Then, the bacterial suspension was added to the suspension and subjected to solar radiation under constant stirring using a magnetic bar. Experiments were carried out always in the morning, using the highest solar radiation intensity and avoiding cloudy days. Samples were taken at different intervals (5, 10, 15, 25, 35, 60, 90, 120, and 180 min) using a micropipet (1 mL), and the antimicrobial effect of the accumulated energy was determined by count reduction test for the selected strain through serial dilution procedure. Plates were incubated overnight at 37 °C and colony-forming units per milliliter (CFU mL−1) were counted. The sterility of the materials was ensured by autoclaving at 121 °C for 20 min. All the experiments were performed by triplicate. For the experiments without UV spectra, the light of the wavelength less than 400 nm was filtered out using an Arco® acrylic cutoff filter (λ < 400 nm), as shown in Fig. 1. In order to quantify the effect of pH on the disinfection process, pH was adjusted using H2SO4 or NaOH 0.1 M.

Energy measurement

Natural sunlight arriving on the earth surface has a maximum intensity of about 1,000 Wm−2, but the actual intensity varies with the hour of day, season, geographical location, and atmospheric conditions [7]; therefore, experiments were always carried out at the same hours of the day (from 10:00 to 13:00 h), avoiding cloudy days, and at the same location, in order to use the highest solar radiation intensity. Global radiation from 300 to 1,200 nm was measured during the experiments using a LC-200SA pyranometer sensor (Li-Cor, Lincoln, NE, USA).

Catalyst shows optical activity under radiation between 300 and 480 nm; thus, a contribution of about 13.83% of radiation between 300 and 480 nm was considered for experiments with complete (UV + vis) spectra and 8.21% of radiation between 400 and 480 nm for experiments with visible spectra (Vis). The solar radiation was evaluated according to Sichel et al. [2] in terms of the accumulated energy per unit of treated water volume, Q (JL−1) as shown in Eq. 1, and is frequently used for applications in solar reactors [13, 14].

where E n−1 (Wm−2) is the accumulated energy during the experimental period, E n is the average solar radiation during Δt, Δt is the experimental period (s), X is the energy type (UV + vis or Vis), A is the illuminated collector surface (0.0036 m2), and V (0.3 L) is the total reaction volume.

Results and discussion

Bacterial inactivation by photocatalysis: effect of daylight and visible light irradiation on disinfection efficiency

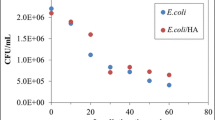

The photocatalytic efficiency of the material was evaluated by determining the apparent rate constants from the photodisinfection process of the strain by heterogeneous photocatalysis. Efficiencies of the photocatalytic disinfection processes are depicted in the Figs. 2, 3, 4, 5, 6, 7, and 8 given below as log N/N 0, which refers to the logarithmic cycles reduction in the concentration ratio of the bacterial survivors in the water measured at any time, N, compared to the initial microbial count of the untreated reference samples, N 0, as a function of the accumulated energy Q (kJL−1) by the system. The lower the calculated value, the higher the inactivation efficiency. Experiments were carried out using an inoculation level of 105 CFU/mL. It has been reported that photocatalytic treatment efficiency strongly depends on different factors including the bacterial concentration. Surviving ratio of cells increases with an increase in the initial cell concentration. Samples with high amounts of organics must be subjected to a pre-treatment, since the disinfection system with semiconductor particles is suitable for samples containing a low concentration of bacteria. The results obtained from the experiments of solar disinfection, the use of complete solar radiation alone (see Fig. 2), and heterogeneous photocatalysis testing the same radiation type (see Figs. 3, 5, 7) show that bacteria inactivation occurs in both processes, with and without the use of the photocatalyst. However, the disinfection efficiency is increased by the presence of catalyst. In agreement with the results reported by Rincón and Pulgarín (2003) in both cases, the number of surviving bacteria decreases to nondetectable levels after phototreatment and no bacterial growth was observed after illumination and then keeping in the dark for 3 h.

Inactivation of E. coli by visible spectra irradiation at pH6, testing three different concentrations of nitrogen-doped TiO2 and without nitrogen-doped TiO2 by complete solar spectra irradiation. Log N/N 0 values as a function of the accumulated energy per unit of water volume Q (kJL−1). Initial concentration 105 cells mL−1

No cell growth inhibition was observed for experiments carried out using visible light alone (data not shown). In the same way, experiments performed using nitrogen-doped TiO2 in the absence of radiation (dark conditions) did not lead to any significant bacterial count reduction, which indicated no loss or adsorption of microorganisms onto the catalyst surface (data not shown).

Figure 2 shows the bacteria inactivation profiles obtained in the control experiments with complete (UV + vis) solar irradiation alone, using six different pH values. Tests of disinfecting ability indicate that solar irradiation alone is capable of E. coli inactivation using accumulated energies values ranged from 708.17 to 1391.33 kJL−1 depending on the pH of the reaction mixture. Lower Q values were obtained for pH 6.5 and 8.0 tested. On the other hand, results in Fig. 2 also allowed the identification of the less favorable conditions when the inactivation process is carried out on a pH value of 6. For experiments at this pH value, the highest value of accumulated energy (1,391.33 kJL−1) was determined for a 4 log-cycles reduction.

Figure 3 shows the effect of the accumulated energy on the survival rate in the experiments performed without nitrogen-doped TiO2 and three different concentrations of the catalyst under complete solar spectra irradiation for a pH value of 6. In agreement with other reports [1, 7], TiO2 is effective in lowering the viable count and increases the effectiveness of the disinfection process. The effects of the catalyst concentration tested are analyzed below. Bacterial counts on experiments at pH 6 without nitrogen-doped TiO2 were 4 log-cycles reduced when the energy accumulated in the system reached 1,391.33 kJL−1 of complete solar irradiation alone in comparison with the 434.55 kJL−1 (over three times less) it took experiments with 0.50 mg/mL of doped TiO2 under complete irradiation. As reported by Rincón and Pulgarín [7], the effect of radiation during the first step in those experiments without the catalyst is partially diminished by the action of the self-defense mechanism induced by UV, which is not observed in the presence of N–TiO2; this may be due to the generation of radicals that rapidly overcome the self-defense and repair machineries resulting in a faster bacterial inactivation. Radiation magnitudes registered during experiments went from 530 to 1,050 Wm−2. Experimental range is consistent with the report by Rincón and Pulgarín [7] in which at magnitudes of radiation above 400 Wm−2, when TiO2 is added, the photons directly attacking the bacteria coupled with the concomitant action of radicals renders an auto-repair mechanism insufficient to protect cells and leading to replication blocking. Clearly, at higher radiation magnitudes, such as 1,000 Wm−2, self-defense and auto-repair mechanisms of bacteria are insufficient to protect cells. The different survival patterns are attributed to the individual resistance in a population, because cells are expected to have different resistance and sensitivity to lethal agents (biological variability) [15].

The effect of the photocatalyst was more prominent in experiments under complete solar irradiation than that performed under visible light; therefore, light type is assumed to have a positive effect on the disinfection mechanism. Figure 4 shows the results obtained in the experiments testing doped TiO2 under visible light radiation for the same pH value, 6.0, which indicated the catalyst efficiency. A 4 log-cycles reduction was achieved with an accumulated energy value of 434.55 kJL−1, under complete solar radiation, and with 539.23 kJL−1 under visible spectra only, in comparison with the results obtained from experiments with complete solar radiation and without catalyst, where the same cycles reduction took 1391.33 kJL−1, and with the results obtained from the experiments in darkness and with no catalyst, where no count reduction was achieved at all.

For all cases, the survival rate for assays under complete daylight exposure was lower than for that under visible light exposure. According to this, UV irradiation promotes a higher efficiency of the disinfection process. It has been extensively reported that sunlight inactivates microorganisms due to the synergistic effect of the UV and IR parts of sunlight [7]. The main type of UVB has a well-documented germicidal effect on the microorganisms being responsible for the DNA sequence changing as the result of copying errors introduced by the irradiation. These errors in the DNA replication process correspond to DNA lesions induced by the formation of dimeric pyrimidine photoproducts that cause the inhibition of DNA replication and bacterial mutations [7, 16]. However, visible light irradiation is also effective for bacterial inactivation by heterogeneous photocatalysis that validates that this technology strongly depends on the irradiation type. More relevant, these results validate that the nitrogen-doped titanium dioxide tested in this assays exhibits a lower band gap energy and generates reactive oxygen species (ROS) when exposed to lower energy photons provided by the visible spectra.

Process kinetics were consistent with those reported by Mitoraj et al., Muranyi et al., and Rincón and Pulgarín [5, 7, 10] in which two phases can be identified in the bactericidal effect of sunlight on the strain inactivation profiles, as shown in Table 1. The highest inactivation rates with the lowest bacterial survivals are found first when the ROS have reached the lethal concentration and its action on the bacterial cell membrane leads to the perturbation of different cellular processes [17]. In addition, DNA sequence errors accumulate because the DNA reparation systems along with cell mechanisms responding to the oxidative stress (catalase and superoxide dismutase enzymes) have been inactivated and damages necessary for death cell have occurred [16]. The synthesis of some enzymes constitutes the major self-defense mechanism against oxidation stress, resulting in the production of superoxide dismutase (SOD) enzymes, and in some cases, catalase and peroxidase. These enzymes allow bacteria to overcome the generation of ROS generating molecular oxygen and water as a result of its action. SOD accelerates the disproportionation of superoxide anion (SOD) O •−2 (precursors of •OH) into hydrogen peroxide, and molecular oxygen, see Eq. 2, catalase and peroxidase eliminate the H2O2; see Eqs. 3, 4 and 5 [3, 18].

This response to oxidative stress eliminates the reactive oxygen species. However, the photogenerated hydroxyl radical concentration increases with illumination time due to its massive production by photooxidation of adsorbed water on the surface of TiO2 [7] and oxidative damages increases. Finally, recovery of bacteria is less probable when DNA repair mechanism becomes less efficient. After this time, stabilization of the remaining bacteria with lower inactivation rates and higher concentration of survival bacteria was observed, which can be explained by the competition for the electron–hole pairs on the semiconductor surface, and surface-bound hydroxyl radicals or other ROS between the living cells and the organic compounds released to the medium after cell lyses [7]. Cell materials can also compete with the catalyst for the photons and reduce the efficiency of the photo process.

The mechanism by which TiO2 inactivates microorganisms has not been completely understood. Inactivation of microorganisms using irradiated TiO2 has been documented [1, 17, 19–21] and is attributed to the adverse influence of the oxidative species generated by the photoactivation of TiO2 on cell DNA replication and bacterial cell membrane (e.g., peroxidation of the polyunsaturated phospholipid component) that leads to the perturbation of different cellular processes and loss of essential functions, (e.g., inhibition of the cellular respiratory activity by the photoelectrochemical oxidation of intercellular coenzyme A to its dimeric form). These reactions are responsible for the breakdown of the cell membrane, loss of cell viability, and cell death [2, 3].

It can be concluded that disinfection is a consequence of both the direct action of the sunlight on the microorganisms, due to the synergistic effect of the UV (cells accumulate so many mutations, such as mismatch and excisions that DNA repair mechanisms can no longer repair and cells machinery stops functioning) and IR (heating of water), as well as the photocatalytic action of the excited catalyst particles [7, 16].

Influence of pH and catalyst concentration on the photocatalytic process

The effect of the pH value on the experiments was examined. Results related to the effect of the photocatalyst concentrations over the survival rates showed variations among pH, as shown in Figs. 5, 6, 7, and 8.

A positive inactivation effect was observed in all conditions. Changes in pH may appear to affect the efficiency of the disinfection process. Values of 6.0, 7.0, and 8.0 showed evident effect. The highest sensitivity of the microorganism was found in most experiments on pH values around 6.5 and 8.0. It appears to be a greater photocatalytic activity as pH moves away from the neutral, while the overall process effectiveness decreases, as the pH reaches a value of 7.

As for photocatalyst concentration, clear concentration-dependent effect was evident. The effect of the addition of 0.25 and 0.50 mg/mL, see Figs. 5 and 7, of photocatalyst was evident, and same results were obtained on experiments under visible light treatment, shown in Figs. 6 and 8. Based on the statistical analysis and on the accumulated energy needed to generate irreversible bacteria inactivation, the addition of 0.50 mg mL−1 of the catalyst improves the disinfection efficiency of the phototreatment as shown in Table 2.

For practical application of disinfection, it is crucial to ensure the irreversible bacterial inactivation resulting from a photocatalytic treatment. With this purpose, it is important to determine the accumulated energies required to induce bacterial death. Table 2 shows the results obtained depending on the radiation type (rt), the concentration of the catalyst (cc), and the pH value of the suspension.

Conclusions

Daylight irradiation is effective for bacterial disinfection. However, heterogeneous photocatalysis assisted by nitrogen-doped TiO2 has demonstrated to be more efficient to inactivate E. coli in aqueous suspensions under complete solar spectra irradiation. The treatment is also responsible for reducing the number of the bacteria under visible light irradiation but with a lower efficiency of inactivation. The antimicrobial inactivation rate of E. coli ATCC 25922 under heterogeneous photocatalysis with nitrogen-doped TiO2 exhibited a clear dependence on the irradiation type. Complete solar irradiation treatment shows a higher efficiency over visible light treatment. Assays validated pH near to 7 as the less favorable condition for microbial inactivation and pH 6.5 and 8.0 as the most favorable conditions. The highest catalyst load (0.50 mg/mL) shows the highest inactivation efficiency, leading to the lowest accumulative energies required in the systems. Nevertheless, lower catalyst concentrations (0.10 and 0.25 mg/mL) are also capable of improving the disinfection efficiency when comparing to the treatment without catalyst.

References

Rodrigues CP, Ziolli RL, Guimaraes JR (2007) Inactivation of Escherichia coli in water by TiO2-assisted disinfection using solar light. J Braz Chem Soc 18:126–134

Sichel C, Tello J, de Cara M, Fernández-Ibáñez P (2007) Effect of UV solar intensity and dose on the photocatalytic disinfection of bacteria and fungi. Catal Today 129:152–160

Srinivasan C, Somasundaram N (2003) Bactericidal and detoxification effects of irradiated semiconductor catalyst, TiO2. Curr Sci 85:1431–1438

Popa M, Diamandescu L, Vasiliu F, Teodorescu CM, Cosoceanu V, Baia M, Feder M, Baia L, Danciu V (2009) Synthesis, structural characterization, and photocatalytic properties of iron-doped TiO2 aerogels. J Mater Sci 44:358–364

Muranyi P, Scrami C, Wunderlich J (2009) Antimicrobial efficiency of titanium dioxide-coated surfaces. J Appl Microbiol 108:1966–1973

Pelaez M, de la Cruz AA, Stathatos E, Falaras P, Dionysiou DD (2009) Visible light-activated N-F-codoped TiO2 nanoparticles for the photocatalytic degradation of microcystin-LR in water. Catal Today 144:19–25

Rincón AG, Pulgarín C (2003) Photocatalytical inactivation of E. coli effect of (continuous-intermitent) light intensity and of (suspended-fixed) TiO2 concentration. Appl Catal 44:263–284

Kuhn KP, Chaberny IF, Massholder K, Stickler M, Benz VW, Sontag HG, Erdinger L (2003) Disinfection of surfaces by photocatalytic oxidation with titanium dioxide and UVA light. Chemosphere 53:71–77

Shanmugasundaram S, Kisch H (2003) Daylight photocatalysis by carbon-modified titanium dioxide. Angew Chem Int Ed 42:4908–4911

Mitoraj D, Janczyk A, Strus M, Lisch H, Stochel G, Heczko P, Macyk W (2007) Visible light inactivation of bacteria and fungi by modified titanium dioxide. Photochem Photobiol Sci 6:642–648

Emeline AV, Kuznetsov VN, Rybchuk VK, Serpone N (2008) Visible-light-active titania photocatalysts: the case of N-doped TiO2s-properties and some fundamental issues. Int J Photoenergy 1–19

© Pulles & Hanique B. V. Glass and Ceramics for High-Tech Applications (2006) http://www.pulleshanique.com/05_address.htm

Fernández P, Blanco J, Sichel C, Malato S (2005) Water disinfection by solar photocatalysis using compound parabolic collectors. Catal Today 101:345–356

Rincón AG, Pulgarín C (2004) Effect of pH, inorganic ions, organic matter and H2O2 on E. coli K12 photocatalytic inactivation by TiO2: implications in solar water disinfection. Appl Catal B-Environ Res 51:283–302

Rafellini S, Schenk M, Guerrero S, Alzamora SM (2011) Kinetics of Escherichia coli inactivation employing hydrogen peroxide at varying temperatures, pH and concentrations. Food Control 22:920–932

Lodish H, Berk A, Zipursky L, Matsudaira P, Baltimore D, Darnell J (2000) Molecular cell biology media connected, England

Huang Z, Maness PC, Blake DM, Wolfrum EJ, Smolinski SL, Jacoby WA (2000) Bactericidal mode of titanium dioxide photocatalysis. J Photochem Photobiol A 130:163–170

Madigan M, Martinko J, Parker J (1998) Brock Biología de los microorganismos. Prentice Hall, España

Matsunaga T, Tomoda R, Nakajima T, Wake H (1985) Photoelectrochemical sterilization of microbial cells by semiconductor powder. FEMS Microbiol Lett 29:211–214

Matsunaga T, Tomoda R, Nakajima T, Nakamura N, Komine T (1988) Continuous-sterilization system that uses photosemiconductor powders. Appl Environ Microbiol 54:1330–1333

Imlay J, Fridovich I (1992) Suppression of oxidative envelope damage by pseudoreversion of a superoxide dismutase-deficient mutant of Escherichia coli. J Bacteriol 174:953–961

Acknowledgments

This work was funded by the National Council of Science and Technology of Mexico (CONACyT) grants 91319 and VER-C01-2010-143438. J. Castillo grateful thanks CONACyT and the Universidad de las Americas Puebla (UDLAP) for providing her with a scholarship for pursuing doctoral studies. Authors gratefully thank Dionysios D. Dionysiou and Miguel Pelaez from the Department of Civil and Environmental Engineering, University of Cincinnati, for providing with the nitrogen-doped-TiO2 nanoparticles.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Castillo-Ledezma, J.H., Sánchez Salas, J.L., López-Malo, A. et al. Effect of pH, solar irradiation, and semiconductor concentration on the photocatalytic disinfection of Escherichia coli in water using nitrogen-doped TiO2 . Eur Food Res Technol 233, 825–834 (2011). https://doi.org/10.1007/s00217-011-1579-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-011-1579-5