Abstract

Quantification of aroma compounds in an orange juice reconstituted from concentrate which had been stored at 37 °C for 4 weeks (forced storage) revealed an increase in the concentrations of, in particular, dimethyl sulphide, 2-methoxy-4-vinylphenol, α-terpineol, and 4-hydroxy-2,5-dimethyl-3(2H)-furanone (4-HDF) in comparison with the same orange juice before storage. On the other hand, clearly lower concentrations were found for octanal, decanal, (R)-α-pinene, linalool, and (E)-β-damascenone after storage, while the concentrations of vanillin and carvone remained nearly constant. Similar results were found for the same aroma compounds after storage of the orange juice at 20 °C for 1 year. Sensory experiments corroborated the importance of 2-methoxy-4-vinylphenol and dimethyl sulphide for the typical stale off-flavour of the stored orange juice, while the omission of e.g., α-terpineol in model mixtures could not be detected. Under both storage conditions (37 °C for 4 weeks or 20 °C for 1 year), the breakthrough odour thresholds of α-terpineol and 4-HDF were not reached, while the concentrations of dimethyl sulphide and 2-methoxy-4-vinylphenol clearly exceeded their breakthrough odour thresholds, thus confirming the crucial role of these odorants for the off-flavour of stored orange juice from concentrate. In addition, changes in the concentrations of selected orange juice odorants at various temperatures and times were investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

To stabilize the product, but also to save transportation costs, a major part of orange juice undergoes a vacuum concentration process in the orange-growing countries and is afterwards reconstituted in the distributing countries from the fractions obtained by juice processing [1]. Such reconstituted juice from concentrate (JFC juice) may, however, be stored in the juice trade up to a period of several months before consumption. But, it is well-known that undesirable aroma changes may occur commonly during storage of the juice bottled in clear glass [2–4].

Previous studies on orange juice off-flavours generated during storage were focused on the influence of temperature, time, oxygen content, light exposure and packaging material [5, 6], and in a recent review the current literature on aroma changes caused by storage was comprehensively summarized [7]. Therefore, only a few studies, which are more closely related to the topic of this investigation, will be discussed in more detail.

Kirchner and Miller [2] were among the first to study aroma changes on a molecular basis and compared the quantitative differences between the volatiles of stored and unstored juice. They found an increase in the concentrations of, in particular, carveol, carvone, methanol, acetic acid, furfural and α-terpineol along with a decrease in the concentrations of, e.g., terpene hydrocarbons, esters and aldehydes during juice storage. Tatum et al. [8] suggested 2-methoxy-4-vinylphenol, the caramel-like smelling 4-hydroxy-2,5-dimethyl-3(2H)-furanone (4-HDF) and α-terpineol as key contributors to the aged or ‘heated’ off-flavour arising during storage of canned orange juice at 35 °C. The formation of 2-methoxy-4-vinylphenol, eliciting a clove-like odour, during storage has been confirmed in later studies, and ferulic acid was found to be the precursor [9–11]. An increase in the concentration of the caramel-like smelling 4-HDF during storage of orange juice at room temperature was later on also reported by Walsh et al. [12]. On the other hand, Rassis and Saguy [13] reported a decrease in the concentration of the furanone in orange juice concentrate stored at 32 °C. Thus, the contribution of 4-HDF to the off-flavour of stored orange juice is still open. An increase in α-terpineol during storage was observed in many studies, and a clear influence of the storage temperature was reported [8, 14, 15]. Because the sensory evaluation of a fresh orange juice spiked with α-terpineol (3 mg/kg) revealed a terpeny, old aroma, and, also, a clearly higher concentration than 3 mg/kg of α-terpineol was found after storage, this compound was suggested as an important contributor to storage-induced off-odours. Consequently, this compound is often used as an indicator in the quality assessment of stored orange juice.

The literature survey suggests several compounds as contributors to off-odours formed during storage of orange juices from concentrate. However, up to now, no comprehensive approach, such as the concept of molecular sensory science [16], has been applied to JFC in order to clarify the contribution of the entire set of odorants to the off-flavour development.

In a previous study [1], the key aroma compounds of orange juice freshly reconstituted from concentrate were characterized by application of the aroma extract dilution analysis, quantitative measurements and aroma reconstitution experiments. Using the same authentic juice sample, the aim of this study was (a) to quantify changes in the key odour-active volatiles, previously identified in the freshly prepared JFC during juice storage, (b) to characterize and quantify odorants newly formed during storage and, finally (c) to confirm the contribution of single aroma compounds to the off-flavour on the basis of aroma reconstitutions.

Materials and methods

Materials

Orange juice was reconstituted in a German juice-producing company from three fractions previously obtained from the same batch of Pera Rio oranges (Citrosuco, Brazil): concentrate, aqueous phase and essential oil. The fractionation had been performed under supervision of a scientist in Brazil. After transport to Germany, the fractions were mixed, degassed, pasteurized and filled into clear glass bottles. The juice was either immediately used for the analysis or frozen at −60 °C (juice A).

For storage experiments, the bottled orange juice was either stored in the dark at 37 °C for 4 weeks (juice B; forced storage) or at room temperature (20 °C) for 52 weeks (juice C; long-time storage). For further storage experiments, juices were either stored at 4, 20, or at 37 °C at varying periods of time.

Chemicals

Reference odorants

The following reference compounds needed in odorant identifications were obtained from the commercial sources given in parentheses: acetaldehyde, acetic acid, 2,3-butandione, butanoic acid, carveol, (R)-(-)-carvone, (E,E)-2,4-decadienal, dimethyl sulphide, ethyl hexanoate, ethyl 2-methylbutanoate, ethyl 2-methylpropanoate, hexanal, 4-hydroxy-2,5-dimethyl-3(2H)-furanone (4-HDF), 2-methoxy-3-isopropylpyrazine, 4-methylphenol (p-cresol), (R)-(+)-limonene, (S)-(−)-limonene, linalool, methional, 3-methylbutanal, 3-methylbutanol, 2-methylbutanoic acid, 3-methylbutanoic acid, methylpropanoic acid, myrcene, (E,E)-2,4-nonadienal, (E)-2-nonenal, octanal, 1-penten-3-one, phenylacetaldehyde, 2-phenylacetic acid, (R)-α-pinene and (S)-α-pinene (Aldrich, Sigma–Aldrich Chemie) (Taufkirchen, Germany). (Z)-4-Decenal, 2-methoxy-4-vinylphenol, nootkatone and 1-octen-3-one (Alfa Aesar, Johnson Matthey) (Karlsruhe, Germany). Ethyl butanoate, hexanoic acid, (R)-linalool, (R)-α-terpineol and (S)-α-terpineol (Fluka, Sigma–Aldrich Chemie) (Taufkirchen, Germany). 2-Methylbutanol, 4-hydroxy-3-methoxy-benzaldehyde (vanillin) (Merck) (Darmstadt, Germany). (S)-Carvone, β-ionone, nonanal and octanol (Roth) (Karlsruhe, Germany). (E)-β-Damascenone was a gift from Symrise (Holzminden, Germany).

The following reference odorants were synthesized as reported in the literature given in parentheses: trans-4,5-epoxy-(E)-2-decenal [17], 1-p-menthen-8-thiol [18], (Z)-2-nonenal [19] and (Z)-1,5-octadien-3-one [20].

Isotopically labelled internal standards

The isotopically labelled internal standards (numbering refers to the numbering of the respective analytes), labelled either with deuterium or with carbon-13, were synthesized according to the references given in the literature section of the supplementary information or in the literature cited, respectively: d-3 [S1], d-4 [S2], d-5 [S3], d-10 [S4], d-18 [1], d-21 [S5], d-23 [S6], d-27 [1], d-28 [S7], d-30 [S8], c-34 [S9], d-36 and d-40 [S10] and d-49 [S11]. [2H6]-α-terpineol was synthesized as reported in [S12].

[13C2]-Acetaldehyde was obtained from Promochem (Wesel, Germany), and [13C2]-acetic acid, [13C2]-2-phenylacetic acid and [2H6]-dimethyl sulphide were from Aldrich (Sigma–Aldrich Chemie; Taufkirchen, Germany).

Because most of the syntheses were performed on a microscale basis, it was impossible to determine the concentrations of the target compounds by weight. Thus, the following procedure was applied: defined amounts of the unlabelled compound and methyl octanoate were analysed by gas chromatography (HRGC-FID) to obtain an FID-response factor. Then, a defined amount of methyl octanoate (Merck; Darmstadt, Germany) was added to a defined volume of the solution of the synthesized labelled compound, and the mixture was analysed by HRGC-FID. The concentration of the labelled compound was calculated from the GC peak areas using the FID response factor determined for the unlabelled analyte.

Diethyl ether and n-pentane were freshly distilled before use. Silica 60 was purified as previously reported [1].

Isolation of the volatiles for aroma extract dilution analysis (AEDA)

The volatiles were isolated from orange juice (200 mL) by solvent assisted flavour evaporation (SAFE) [21] at 40 °C, followed by extraction of the aqueous distillate with diethyl ether (total volume: 200 mL). The combined extracts were dried over anhydrous sodium sulphate and concentrated to 400 μL at 37 °C using a Vigreux column (50 m × 1 cm) and a microdistillation apparatus as previously reported [22].

Enrichment of volatiles for identification

For the identification experiments, volatiles were isolated from up to 1 L of orange juice by extraction with diethyl ether. The combined extracts were washed with brine, dried over anhydrous Na2SO4 and concentrated to 100 mL using the Vigreux column described earlier before the non-volatile material was removed by SAFE distillation [21]. To separate the acidic volatiles (AF) from the neutral-basic volatiles (NBF), the distillate was extracted with an aqueous sodium carbonate solution (0.5 mol/L; total volume: 200 mL), and the organic phase was washed with saturated sodium chloride solution (2 × 50 mL). The organic phase containing the neutral/basic volatiles (NBF) was dried over anhydrous Na2SO4. The combined aqueous solutions were adjusted to pH 2 by addition of hydrochloric acid (5 mol/L), the acidic compounds were extracted with diethyl ether (4 × 50 mL) and dried over Na2SO4. Both fractions were concentrated to a final volume of 500 μL by distilling off the solvent using a Vigreux column and a microdistillation apparatus [22].

For further fractionation, the NBF was applied onto a water-cooled glass column (30 cm × 2 cm) filled with silica gel 60 (30 g) in n-pentane. To yield fractions 1–5, the distillate was separated by eluting the column with five solvent mixtures of increasing polarity (n-pentane/diethyl ether mixtures: 100:0, 90:10, 80:20, 50:50, 0:100; 100 mL each; by vol.). After drying over Na2SO4, each fraction was concentrated to 200 μL using the Vigreux column and microdistillation apparatus [22].

High-resolution gas chromatography–olfactometry (HRGC-O); aroma extract dilution analysis

HRGC-O was performed by means of a gas chromatograph type 5300 Mega Series (Carlo Erba, Milano, Italy) with helium serving as the carrier gas at a flow rate of 2.2 mL/min. Samples were applied by the cold-on-column injection technique onto capillaries DB-5, DB-FFAP or DB-1701 (all 30 m × 0.32 mm, 0.25 μm film thickness) (J&W Scientific, Agilent Technologies) (Waldbronn, Germany). The effluent was split into two equal parts at the end of the column via two deactivated but uncoated fused silica capillaries (40 cm × 0.25 mm). One part was directed to a flame ionization detector (FID) operated at 220 °C, and the other part to a sniffing port held at 180 °C. On-column injection of the samples (0.5 μL) was performed at an oven temperature of 40 °C. After 2 min, the temperature was raised by 40 °C per min to 50 °C, held for 2 min and raised by 6 °C per min to 180 °C, then by 10 °C per min to 240 °C. The final temperature was held for 10 min. Linear retention indices (LRI) of the compounds were calculated using a series of n-alkanes.

For aroma extract dilution analysis (AEDA), the concentrated extract was stepwise diluted with diethyl ether (1:1, v/v) and analysed by HRGC-O until no odour was detectable at the respective retention index [18]. Each odorant was thus assigned a flavour dilution (FD) factor representing the last dilution in which the odorant was still detectable [22].

High-resolution gas chromatography: mass spectrometry (HRGC-MS)

For compound identification, mass spectra were recorded using a gas chromatograph 5890 series II (Hewlett Packard, Waldbronn, Germany) connected to a sector field mass spectrometer-type MAT 95 S (Finnigan) (Bremen, Germany). Mass spectra were generated in the electron ionization mode (MS-EI) at 70 eV ionization energy and in the chemical ionization mode (MS-CI) at 115 eV using isobutane as the reactant gas.

Static headspace olfactometry (SHO)

Aliquots of the orange juice (20 mL) were equilibrated in septum-sealed vessels (100 mL) for 30 min at 22 °C. Decreasing volumes (10–0.32 mL) of the headspace were taken from different vessels using a gastight syringe (Hamilton, Australia) and were analysed by headspace HRGC-olfactometry using a gas chromatograph CP 9001 with a Purge and Trap System (TCT/PTI 4001, both Chrompack, Frankfurt, Germany) as previously described [18].

Determination of enantiomeric ratios

The enantiomeric distribution in carvone and ethyl 2-methylbutanoate was determined by two-dimensional gas chromatography–mass spectrometry using a chiral column (BGB-176, 30 m × 0.25 mm, film thickness 0.25 μm) (BGB Analytik AG, Rothenfluh, Switzerland) in the second dimension. The intensities of selected ions were recorded for the calculation of enantiomeric ratios. The enantiomeric distributions in limonene, α-pinene, linalool and α-terpineol were determined on the same chiral column, but by comparison of the respective FID-peak areas.

Quantification by stable isotope dilution assays (SIDA)

For quantification, known amounts of the labelled internal standard, dissolved in diethyl ether, were added to aliquots of orange juice (10–2,000 g, respectively), depending on the amount of the respective analyte present, which was determined in preliminary experiments. The mixture was equilibrated, the volatile fraction was isolated by SAFE distillation as described earlier, and the aqueous distillate was extracted with diethyl ether. This extract was analysed by HRGC-MS and by monitoring the intensities of the respective ions given in Table S1 (see supplementary information). Mass spectrometric analyses were carried out by means of a Saturn 2000 mass spectrometer (Varian, Darmstadt, Germany) in tandem with the capillaries described earlier. Mass spectra were generated in the chemical ionization mode (MS-CI) at 115 eV using methanol as the reactant gas.

For the analysis of acidic volatile compounds, the orange juice containing the labelled internal standards was stirred with diethyl ether for 2 h, and the combined solvent extracts were used for SAFE distillation. The acidic fraction was then isolated as described earlier and analysed by HRGC-MS.

To obtain unequivocal mass spectra, e.g., in case of coeluting compounds, two-dimensional-(TD)-HRGC-MS was performed by means of the Moving Column Stream Switching system (MCSS) (Fisons Instruments, Mainz, Germany) [23]. The concentrations were calculated from the relative abundances of ions selected for the analyte and the internal standards (Table S1). The data were corrected by means of response factors, determined from mixtures containing known concentrations of the labelled and the unlabelled compound [S9].

Quantification of terpene hydrocarbons

Quantification of myrcene, α-pinene and limonene was done by HRGC-FID using trans-p-menth-2-ene as the internal standard and capillary DB-5. Calibration factors were determined by analysing mixtures containing known amounts of trans-p-menth-2-ene and each of the analytes. The FID-response factor was 0.99 for all three terpenes.

Quantification of acetaldehyde and dimethyl sulphide

Both compounds were quantified by means of the headspace HRGC-O system described earlier connected to a Quadrupol-Mass Spectrometer INCOS XL (Finnigan) using the respective isotopically labelled internal standard. Mass spectra were generated in the chemical ionization mode (MS-CI) at 115 eV using methane as reactant gas.

Sensory evaluation

Ten assessors were recruited from the ‘Deutsche Forschungsanstalt für Lebensmittelchemie’ at Freising, Germany, and were trained to describe and recognize the odour qualities of over 80 odorants [24]. Sensory analyses were performed at 21 ± 1 °C in a sensory panel room equipped with single booths. The orthonasal evaluation of the orange juice aroma was performed in the following way: Panellists were asked to rate the intensities of eight odour qualities chosen in preliminary tests using a seven-point linear scale from 0 to 3 (0, 0.5, 1.0 … 3.0). The results of the aroma profile analyses obtained at three different sessions were averaged for each odour note and plotted in a spider web diagram. The values judged by the single assessors differed by not more than 20%. Orthonasal odour thresholds were determined either in water or in citrate buffer (pH 3.8) by means of triangle tests [24].

Aroma reconstitution experiments, omission tests and determination of breakthrough thresholds

A model mixture containing all odorants in the concentrations present in the stored orange juice was prepared in an aqueous solution of citric acid (4 g/L), sucrose (90 g/L) and sunflower oil (0.1 g/L, plus lecithine) [1]. The overall aroma profile of the model mixture was determined in the same way as described earlier for orange juice. In a separate session, the overall similarity of the stored orange juice aroma and the model mixture was compared. The similarity was ranked on the basis of a seven-point scale from 0 to 3.

For omission experiments, model mixtures omitting single components or groups of components from the complete model were prepared and presented to the sensory panel in comparison with the complete model using the triangle test [24].

Breakthrough odour thresholds of 2-methoxy-4-vinylphenol, dimethyl sulphide and (R)-α-terpineol were determined as performed for orthonasal odour thresholds, but in an orange juice freshly reconstituted from concentrate (juice A) as the matrix. The breakthrough threshold is defined as the concentration at which the odour of a single odorant can no longer be masked by the set of all odorants present, i.e. when the odour quality of the respective odorant can be smelled.

Results and discussion

Identification of odour-active compounds in an orange juice after forced storage (37 °C; 1 month)

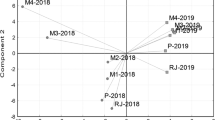

In the food trade, orange juice reconstituted from concentrate may be stored over a period of several months until it is finally consumed. Such juices, however, often show untypical odours, which have been described as ‘aged’ or ‘heated’ [7]. To evaluate the changes in important juice aroma compounds during storage, the same batch of orange juice which has been investigated in our previous study [1] was subjected to a forced storage at 37 °C for 4 weeks (juice B) immediately after reconstitution from concentrate (juice A). After storage, the overall aroma of the juice was described as untypical with smoky, mouldy and old odour notes. The evaluation of the intensities of eight selected flavour descriptors by a panel of ten trained assessors showed that the flavour notes mouldy-old and smoky were judged with high intensities in the stored juice. On the other hand, in the freshly reconstituted juice (juice A), both flavour notes were not perceivable, and the aroma was described as characteristic fruity, sweet and citrus-like (Fig. 1).

To clarify the molecular reason for the off-odour detected, the volatiles from the forced-stored juice B were isolated by direct SAFE distillation followed by solvent extraction. The resulting solvent extract elicited the smoky, mouldy-old aroma of the stored juice, when a drop of the extract was vaporized from a strip of filter paper. Application of the aroma extract dilution analysis (AEDA) on the distillate revealed 40 odour-active areas in the flavour dilution (FD) range of 4–2,048. The highest FD factor of 2,048 was found for compound 36 exhibiting a clove-like smell, followed by compound 3 with a fruity odour (FD 512).

The identification experiments comprising the comparison of retention indices, odour qualities and mass spectra of the odour-active components with reference odorants [1] identified compound 36 as 2-methoxy-4-vinylphenol and compound 3 as ethyl butanoate (Table 1). Linalool (21, flowery), (E)-β-damascenone (28, cooked apple-like), 4-hydroxy-2,5-dimethyl-3(2H)-furanone (34, caramel-like), 2-phenylacetic acid (39, honey-like) and an unknown compound (26) with a spicy, fatty odour were all assigned an FD factor of 256. With somewhat lower FD factors, (S)-ethyl 2-methylbutanoate (4, fruity) and octanal (10, citrus-like) were detected.

Thirty-eight of the 40 aroma-active compounds identified have already been identified in our previous study [1] on the freshly reconstituted orange juice (juice A), however, with differing FD factors (Table 1). In particular, a higher FD factor of 2,048 was found for the clove-like smelling 2-methoxy-4-vinylphenol (36) in the stored juice B compared to an FD factor of 128 in the freshly reconstituted juice A [1]. On the other hand, the flowery smelling linalool (21), which was one of the compounds with the highest FD factor in the freshly reconstituted juice A, was detected with a lower FD factor of 256 in the stored juice. Further components with clearly lower FD factors in the stored juice B were characterized as hexanal (5), myrcene (6), 1,5-(Z)-octadien-3-one (13) and decanal (18) (Table 1).

The determination of enantiomeric ratios for the chiral compounds revealed 98% (S)-ethyl 2-methylbutanoate, 100% (R)-limonene, 100% (R)-α-pinene, as well as 50% (R)-carvone and 50% (S)-carvone. Since the same ratios were found in the freshly reconstituted juice A [1], the results indicated no changes during storage. For linalool, however, the share of (S)-linalool in the stored juice was determined with only 63% compared to 88% in the freshly reconstituted juice [1]. The racemization of linalool can be explained by the easy formation of the transient linalylkation upon an acid-catalysed loss of H2O which, after addition of water, brings about equilibrium of both enantiomers. This change in the enantiomeric ratio towards a racemate is of interest for the odour contribution, because of the lower odour threshold of (R)-linalool when compared to (S)-linalool.

The characterization of highly volatile components by means of static headspace olfactometry (Table 2) revealed acetaldehyde (41, pungent), ethanol (42, ethanolic) and dimethyl sulphide (43, sulphurous) as additional compounds in the stored orange juice B. Sniffing of decreasing headspace volumes showed that dimethyl sulphide was detected with the clearly higher FD factor of 16 in the stored juice compared to FD 2 in the freshly reconstituted juice A (Table 2). The remaining eleven odorants were already detected in the SAFE distillate and did not show substantial changes.

Quantitative analysis and calculation of odour activity values in forced stored orange juice

To confirm the results of the AEDA, 22 of the key odour-active components were quantified in the forced stored orange juice (juice B) by means of stable isotope dilution assays. The data showed (Table 3) that (R)-limonene showed the highest concentration in the stored orange juice of approx. 106 mg/kg. Relatively high concentrations (>1 mg/kg) were also found for acetaldehyde, myrcene, acetic acid and α-terpineol. In comparison with the amounts determined previously in the freshly reconstituted orange juice (juice A) [1], clearly lower concentrations were found for octanal and decanal as well as for (R)-α-pinene and linalool. Less pronounced losses were found for ethyl butanoate and (S)-ethyl 2-methylbutanoate as well as for (R)-limonene and myrcene. On the other hand, the amounts of, in particular, 2-methoxy-4-vinylphenol, dimethyl sulphide, 4-hydroxy-2,5-dimethyl-3(2H)-furanone and α-terpineol were clearly increased during storage. With somewhat lower differences, the same was true for 2- and 3-methylbutanoic acid, 2-phenylacetic acid, butanoic acid, acetic acid and hexanoic acid. The concentrations of vanillin and carvone, however, remained almost constant.

To get an idea on the influence of the single compounds on the changes in the overall juice odour profile during storage, odour activity values were calculated. In the stored juice, the highest odour activity values were calculated for (R/S)-linalool, (R)-limonene and (S)-ethyl 2-methylbutanoate, followed by dimethyl sulphide, ethyl butanoate, myrcene, octanal and (R)-α-pinene showing OAVs > 100 (Table 4).

A comparison with the data calculated for the same batch of orange juice, but determined immediately after its reconstitution (juice A) [1] indicated that the highest OAVs > 1,000 were displayed by the same three odorants in both juices, although with clearly lower OAVs for some compounds in the stored juice B (Table 4). However, with an OAV of 350, dimethyl sulphide was fourth in rank in the stored juice B due to an increase in concentration by a factor of nearly 10. Also, the clove-like smelling 2-methoxy-4-vinylphenol, which did not exceed its odour threshold in the freshly reconstituted juice A, reached an OAV of 6 after storage. These data suggested that, in particular, the increase in dimethyl sulphide and 2-methoxy-4-vinylphenol together with the decrease in key juice odorants, such as octanal, decanal, ethyl butanoate or acetaldehyde, may be responsible for the overall changes in the aroma of the juice during forced storage.

Quantitative analysis and calculation of odour activity values in orange juice after long-time storage at room temperature

To answer the question whether the results obtained for an orange juice after forced storage (juice B; 37 °C for 4 weeks) are able to simulate the storage conditions common in food trade and household, the same batch of reconstituted orange juice was stored at room temperature (20 °C) for 52 weeks (juice C).

After storage, the juice showed a similar smoky, mouldy-old off-flavour as the same batch of orange juice which had been subjected to a forced storage (B). Thus, the same 22 odour-active components were now quantified in orange juice C. The data showed (Table 5) that for most of the odorants comparable concentrations were determined in the orange juice after long-time storage (juice C) as in the orange juice after forced storage (juice B). For acetaldehyde, however, a clearly lower concentration was found in juice C, while higher concentrations were determined for acetic acid, butanoic acid, 2- and 3-methylbutanoic acid, hexanoic acid and 2-phenylacetic acid. The change in the enantiomeric ratio of linalool observed for the orange juice after forced storage was identical in the juice after long-time storage. The data showed that the conditions of forced storage (37 °C; 4 weeks) can be successfully applied to simulate a long-time storage at room temperature.

Aroma recombination and omission experiments

To clarify whether the typical smoky, mouldy-old off-flavour detected in both stored orange juices can be mimicked on the basis of the actual concentrations of the odorants in the stored juice, aroma recombination experiments were carried out.

For this purpose, a model mixture containing the 17 odorants of orange juice C with OAVs > 1 in their actual concentrations (Table 5) was prepared in an aqueous matrix of citric acid, saccharose and sunflower oil. Additionally, 2-methylbutanoic acid and hexanoic acid were added in their actual concentrations to investigate possible additive effects. Sensory evaluation of the eight selected flavour descriptors for the model mixture revealed a good agreement with the flavour profile of the original orange juice after long-time storage (Fig. 2), and particularly the flavour descriptors smoky and mouldy-old were judged with almost similar intensities.

To get a deeper insight into the role of single orange odorants for the overall aroma, omission experiments were finally carried out. For this purpose, the aroma of the entire model mixture containing all 21 aroma compounds was compared to the aroma of model mixtures missing either single components or groups of components. The data showed that the panel was able to detect the omission of 2-methoxy-4-vinylphenol with a high significance (α = 0.001), confirming the important role of this clove-like smelling compound for the off-flavour of the stored orange juice as previously reported [7]. The same was true for the model in which dimethyl sulphide was omitted (significance level α: 0.001). A model in which the entire set of carboxylic acids, namely acetic acid, butanoic acid, 3-methylbutanoic acid, 2-methylbutanoic acid, hexanoic acid and 2-phenylacetic acid, was also recognized, but with a lower level of significance (α = 0.05). Surprisingly, the omission of α-terpineol, a well-known indicator of the age of orange juice, was not detected by the panel (data not shown).

To check the key role of 2-methoxy-4-vinylphenol and dimethyl sulphide in off-flavour development, their concentrations were singly increased in the freshly reconstituted orange juice (juice A) by adding the respective reference compounds until a difference in the overall aroma could be detected. These “breakthrough thresholds” were determined to be 39 μg/L for 2-methoxy-4-vinylphenol and 32 μg/L for dimethyl sulphide. Because their concentrations were 208 μg/L and 54 μg/L in the stored juice, respectively, these experiments clearly showed the crucial role of both compounds in juice aroma deterioration. On the other hand, for (R)-α-terpineol, a breakthrough threshold of 6.8 mg/L juice was determined, which was far above its concentration in the stored juices.

Influence of temperature on the formation of odorants during storage

In the following experiments, the influence of the temperature on the formation of important aroma compounds was investigated in more detail.

The freshly reconstituted orange juice from concentrate (juice A) was stored for 16 weeks at 4 , 20 or at 37 °C. Quantification of fourteen selected odorants (Table 6) revealed that the storage at 4 °C for 16 weeks caused only minor changes in the concentrations of the odorants when compared to the unstored reference. Storage at 20 °C for 16 weeks, however, led to a substantial decrease in the concentrations of acetaldehyde, octanal, decanal and hexanal. While (R)-α-pinene was decreased by 50%, (R)-limonene, myrcene and linalool decreased only slightly in their concentration. On the other hand, the concentrations of 2-methoxy-4-vinylphenol and 4-hydroxy-2,5-dimethyl-3(2H)-furanone (4-HDF) increased by the factor of 4 and 3, respectively. On the other hand, the concentrations of ethyl butanoate, (S)-ethyl 2-methylbutanoate, carvone and vanillin remained nearly constant.

As to be expected, storage at 37 °C for 16 weeks led to significant changes in the concentrations of almost all odorants investigated. However, the amounts of carvone and vanillin remained nearly constant even under these drastic conditions. A clear decrease was, however, observed for all saturated aldehydes, namely hexanal, octanal and decanal, and in particular, a remarkable decrease of up to factor 10 was found for octanal and decanal, as well as for linalool. On the other hand, 2-methoxy-4-vinylphenol and 4-hydroxy-2,5-dimethyl-3(2H)-furanone increased by factors of 40 and 30, respectively, at this elevated temperature.

This result shows that carvone is not formed during storage as previously suggested in the literature, and thus, does not contribute to an off-flavour in orange juice.

Influence of storage time

To investigate the influence of storage time, freshly reconstituted orange juice from concentrate (A) was stored at a given storage temperature for up to 52 weeks, and samples were taken after several periods of time. In a first experiment, the juice was stored at 4 °C for up to 52 weeks, and samples were taken after 16, 36 and 52 weeks. Quantification of fourteen odorants (Table 7) showed that only minor changes in concentrations have taken place after 16 weeks. After storage for 36 weeks, decreases in the concentrations of the aldehydes acetaldehyde, octanal and decanal, as well as of (R)-limonene, (R)-α-pinene, and myrcene were measured. After 52 weeks of storage at 4 °C, losses were observed for nearly all compounds; however, neither 2-methoxy-4-vinylphenol nor carvone nor 4-hydroxy-2,5-dimethyl-3(2H)-furanone showed a clearly detectable increase during storage. These results indicated that a low storage temperature will keep the aroma quality of reconstituted orange juice at least for about 4 months.

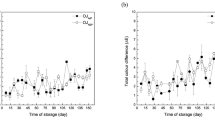

However, at room temperature, the losses of the previously mentioned odorants observed after 52 weeks already occurred after 16 weeks (Table 8). However, in contrast to the storage at 4 °C, the formation of 2-methoxy-4-vinylphenol was more pronounced, exceeding its odour threshold (30 μg/L) already after 8 weeks (Table 9).

The significant decrease in concentration during storage observed for acetaldehyde, hexanal, octanal and decanal confirmed previous findings [5, 27]. Petersen et al. [28] proposed an oxidation of the aldehyde to the corresponding carboxylic acid as the reason for the decrease. However, also in our studies, the decrease of hexanal during forced storage of orange juice at 37 °C for 4 weeks was in line with an increase of hexanoic acid—this finding could not be confirmed in a model study, in which the aldehydes hexanal, octanal and decanal were stored in an aqueous solution (pH 3.8) at 37 °C for 4 weeks. Under these conditions, the concentration of hexanal as well as that of the corresponding hexanoic acid remained constant. Moreover, although the concentration of decanal decreased clearly during storage, the corresponding decanoic did not increase (data not shown). Thus, the degradation pathways of the saturated aldehydes yet remain unclear.

The terpene hydrocarbons limonene, myrcene and α-pinene also decreased in concentration during storage. On the other hand, α-terpineol clearly increased in concentration during storage at room temperature and at 37 °C. A decrease in the amount of limonene on the one hand along with an increase in the amount of α-terpineol on the other hand during storage of orange juice had already been found by Kirchner and Miller [2], and later on also the degradation of linalool to α-terpineol was reported [29, 30]. In our study, 99% (R)-α-terpineol was found in orange juice, freshly reconstituted from concentrate as well as after storage [1]. This result indicates that α-terpineol might be formed in an acid-catalysed hydration from (R)-limonene rather than from (R/S)-linalool, which would release both enantiomers.

Kirchner and Miller found carvone in canned orange juice after storage, but not in the juice before storage [2]. Our studies, however, showed that the concentration of carvone in the orange juice under investigation remained nearly constant during storage up to 52 weeks, even at 4 °C, 20 °C, or 37 °C. These findings are in agreement with results of Popken et al. [31], who reported a formation of carvone from limonene during the storage of essential oil in the presence of oxygen, but did not observe a further increase in the concentration of carvone during the storage of orange juice, which was reconstituted with this essence oil. Schieberle and Grosch [32, 33] have shown before that carvone was formed in a lemon oil containing limonene when stored in the presence of oxygen, but not during the storage of lemon oil in aqueous citric acid.

Particularly at higher storage temperatures, the concentrations of butanoic acid, 2- and 3-methylbutanoic acid and 2-phenylacetic acid increased clearly, thus reaching their odour threshold values after storage at room temperature for 52 weeks. In model studies, Hofmann et al. [34] have shown that in the Strecker reaction, the corresponding acid can be formed along with the Strecker aldehyde. It is, however, still open whether these acids are formed from the respective amino acids.

The significant increase in the concentration of 4-hydroxy-2,5-dimethyl-3(2H)-furanone during storage is in agreement with results of Tatum et al. [8], who suggested the caramel-like smelling compound as an indicator for stored orange juice. They described a suppression of the characteristic orange juice aroma when 4-HDF was present above a concentration of 50 μg/L in orange juice. However, in our study, this concentration was not surpassed during the storage of orange juice for 52 weeks at room temperature. Therefore, a contribution of 4-HDF to the aroma of stored orange juice is not likely under these storage conditions. During a forced storage at 37 °C, however, the concentration of this odorant in orange juice rapidly increased and 4-HDF exceeded its odour threshold in acidic medium (21 μg/L) already after storage time of 8 weeks, and its breakthrough threshold in orange juice (50 μg/L) after storage time of 16 weeks. This significant increase in the concentration of 4-HDF during storage at temperatures above 25 °C has also been reported in the literature [12, 35, 36]. However, it is rather unlikely that orange juice is subjected to this high temperature for several weeks in the trade.

The greatest influence of storage temperature and storage time was determined for the concentration of 2-methoxy-4-vinylphenol exceeding its odour threshold of 30 μg/L already after storage of 8 weeks at room temperature and its breakthrough threshold of 39 μg/L after storage of 16 weeks at room temperature. A contribution of the clove-like smelling odorant to the aroma of stored orange juice is, therefore, quite likely. The increase in 2-methoxy-4-vinylphenol during storage of orange juice has also been found in many studies before [8, 9, 12, 37]; however, sensory experiments were scarcely performed.

The highly volatile odorant dimethyl sulphide clearly increased during storage of orange juice. A high odour activity value was determined after storage at room temperature for 52 weeks and sensory investigations confirmed its contribution to the off-flavour of stored orange juice under these storage conditions. Under forced temperature conditions (37 °C), a similar OAV was found already after storage time of 4 weeks. The occurrence of dimethyl sulphide in pasteurized orange juice has already been described by Shaw and Wilson [38], but the influence of storage conditions on its aroma contribution has not been investigated so far. Also in strawberry juice, a clear increase in the concentration of dimethyl sulphide during storage has been reported [39]. As recently found by us, dimethyl sulphide can be formed during thermal treatment of orange juice from its precursor S-methylmethionine [40]. Whether this precursor occurs in all orange varieties is, however, not yet known.

References

Averbeck M, Schieberle P (2009) Eur Food Res Technol 229:611–622

Kirchner JG, Miller JM (1957) J Agric Food Chem 5:283–291

Rouseff RL, Nagy S, Naim M, Zahavi U (1992) Off-flavour development in citrus juice products. In: Charalambous G (ed) Developmental Food Science, vol 28. Elsevier Science, New York, pp 211–27

Rouseff R, Naim M (2000) Citrus flavour stability. In: Risch SJ, Ho C-T (eds) Flavour chemistry. Industrial and academic research, vol 756. American Chemical Society, Washington DC, pp 101–121

Dürr P, Schobinger U, Waldvogel R (1981) Alimenta 20:91–93

Graumlich TR, Marcy JE, Adams JP (1986) J Agric Food Chem 34:402–405

Perez-Cacho P, Rouseff R (2008) J Agric Food Chem 56:9785–9796

Tatum JH, Nagy S, Berry RE (1975) J Food Sci 40:707–709

Naim M, Striem BJ, Kanner J, Peleg H (1988) J Food Sci 53:500–503 and 512

Peleg H, Naim M, Zehavi U, Rouseff RL, Nagy S (1992) J Agric Food Chem 40:764–767

Rouseff RL, Dettweiler GR, Swaine RM, Naim M, Zehavi U (1992) J Chromatogr Sci 30:383–387

Walsh M, Rouseff RL, Naim M (1997) J Agric Food Chem 45:1320–1324

Rassis D, Saguy IS (1995) Int J Food Sci Technol 30:191–198

Askar A, Bielig HJ, Treptow H (1973) Dt Lebensm Rundschau 69:162–167

Moshonas MG, Shaw PE (1989) J Agric Food Chem 37:157–161

Schieberle P, Hofmann T (2003) Auf den Geschmack gekommen. Die molekulare Welt des Lebensmittelgenusses. Chemie in unserer Zeit 37:388–401

Schieberle P, Grosch W (1991) Z Lebensm Unters Forsch 192:130–135

Hinterholzer A, Schieberle P (1998) Flavour Fragr J 13:49–55

Ullrich F, Grosch W (1988) Fat Sci Technol 90:332–336

Ullrich F, Grosch W (1988) J Am Oil Chem Soc 65:1313–1317

Engel W, Bahr W, Schieberle P (1999) Eur Food Res Technol 209:237–241

Schieberle P (1995) Recent developments in methods for analysis of flavour compounds and their precursors. In: Goankar A, (ed) Characterization of food: emerging methods. Elsevier Science, Amsterdam, pp 403–431 (Review)

Czerny M, Grosch W (2000) J Agric Food Chem 48:868–872

Czerny M, Christlbauer Ma, Christlbauer Mo, Fischer A, Granvogl M, Hammer M, Hartl C, Moran Hernandez N, Schieberle P (2008) Eur Food Res Technol 228:265–273

Rychlik M, Schieberle P, Grosch W (1998) Compilation of odour thresholds, odour qualities and retention indices of key food odorants. Deutsche Forschungsanstalt für Lebensmittelchemie und Institut für Lebensmittelchemie der TU München, Garching, Germany, ISBN: 3-9803426-5-4

Buettner A, Schieberle P (2001) J Agric Food Chem 49:2387–2394

Moshonas MG, Shaw PE (1988) Flavour evaluation of fresh and aseptically packaged orange juices. In: Charalambous G (ed) Frontiers of flavour. Elsevier Science, Amsterdam, pp 133–145

Petersen MA, Tonder D, Poll L (1998) Food Qual Pref 9:43–51

Askar A, Bielig HJ, Treptow H (1973) Dt Lebensm Rundschau 69:360–364

Haleva-Toledo E, Naim M, Zehavi U, Rouseff RL (1999) J Food Sci 64:838–841

Popken AM, Dechent HM, Gürster D (1999) Fruit Processing 9:339–341

Schieberle P, Grosch W (1988) Lebensm Wiss Technol 21:158–162

Schieberle P, Grosch W (1989) Z Lebensm Unters Forsch 189:26–31

Hofmann T, Münch P, Schieberle P (2000) J Agric Food Chem 48:434–440

Lee HS, Nagy S (1996) Chemical degradative indicators to monitor the quality of processed and stored citrus products. In: Lee TC, Kim HJ (eds) Chemical markers for processed and stored foods. ACS Symposium Series, Washington, pp 86–106

Haleva-Toledo E, Naim M, Zehavi U, Rouseff RL (1997) J Agric Food Chem 45:1314–1319

Lee HS, Nagy S (1990) J Food Sci 55:162–163, 166

Shaw PE, Wilson CW (1982) J Agric Food Chem 30:685–688

Siegmund B, Derler K, Pfannhauser W (2001) J Agric Food Chem 49:3244–3252

Scherb J, Kreissl J, Haupt S, Schieberle P (2009) J Agric Food Chem 57:9091–9096

Acknowledgments

We thank Dr. Petra Steinhaus for helpful comments and the final preparation of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Averbeck, M., Schieberle, P. Influence of different storage conditions on changes in the key aroma compounds of orange juice reconstituted from concentrate. Eur Food Res Technol 232, 129–142 (2011). https://doi.org/10.1007/s00217-010-1366-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1366-8