Abstract

The flour obtained from germinated wheat has a low quality and may be identified by its increased content of a specific marker: a toxic lectin named wheat germ agglutinin (WGA). Quartz crystal microbalance was used to study the lectin-carbohydrate bioaffinity interactions. Sensors for two plant lectins: Concanavalin A (Con A) and WGA were obtained by immobilizing glucose on gold coated piezoelectric quartz crystals via thiol bonds. The limit of detection was 0.1 μg/mL for Con A and 0.5 μg/mL for WGA. The proposed method was sensitive enough to detect the biologically active WGA from whole meal flour samples produced using three types of wheat before and after 36 h of germination. The WGA amount in germinated wheat was increased by 17–36.9%. The obtained WGA recoveries from spiked samples were between 88.7 and 110.6%. The analysis method may be adapted for the determination of biologically active lectins from nutritional supplements based on the plant extracts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The lectins represent a class of proteins, present in most plants, especially in cereals, potatoes and beans. These proteins selectively and reversibly bind to mono- and oligosaccharide components of polysaccharide structure [1]. They were originally identified by their ability to agglutinate (clump) erythrocytes by interaction between the multiple binding sites of the lectin molecule and carbohydrate form the surface of the erythrocytes. It was demonstrated that the lectins present in food are toxic, resistant to cooking and digestive enzymes [2] and consequently they sometimes cause “food poisoning” [3]. Because of their protein-binding property, lectins can interact with a variety of cells in the body and are considered a major anti-nutrient of food [4]. They may affect the integrity of the intestinal epithelium, the absorption of dietary antigens and may also promote the release of allergic mediators from mast cells in vitro, thereby increasing the risk of food-related allergy type reactions [5].

Over the last years, many people have supplemented their diet with vitamins, minerals, plant extracts whole meal flour products, food processed avoiding high temperature, etc. One such alimentary supplement is wheat germ. Wheat germ represents ~3% of the whole grain, has a high nutritional value due to its content of vitamins B6, B9, E, a high oil content and several minerals such as zinc, magnesium and manganese [6]. Research on wheat germ has shown the presence of a particular lectin, called wheat germ agglutinin (WGA) that may be tied to wheat allergy. WGA from wheat (Triticum vulgaris) is a lectin that binds specifically to β-d-glucose (Glc), β-N-acetyl-d-glucosamine (GlcNAc) and α-N-acetyl-galactosamine (GalNAc) residues and belongs to the family of chitin-binding proteins, with a high-content of cysteine and glycine. In wheat, WGA concentrations ranged from 13 to 53 mg/kg [7]. High concentrations of WGA are found in wheat germ (≤0.5 g/kg) [8] and about 2 g/kg in unprocessed wheat germ [9]. The estimated quantity of total dietary lectins is in the range of 0–200 mg/person per day [8]. In consequence, it is important to analyze the WGA content from wheat germ-based alimentary products.

Several factors such as rainy weather during wheat harvest or too high moisture content during storage causes premature wheat germination that leads to an increase in amylases and proteases activity [10]. Germinated or partial germinated wheat produces low quality flour characterized by small falling number [11] which has a lower price and may be used only as fodder or raw material for alcohol production. One may try to use germinated wheat to produce acceptable bread by mixing with ungerminated wheat or using additives, but nevertheless significant percentages of germinated wheat flour has a negative effect on the bread quality [12]. We propose to use WGA content as an indicator to identify flour batches produced with germinated wheat.

In order to control the quality of the nutritional products that may contain or are even based on wheat germ, it is important to analyze the WGA content. Screening for the presence of WGA or other lectins in foods has been carried out using several cell-agglutination techniques to measure lectin activity [13]. These methods are semi-quantitative and interferences may occur due to the presence of colored substances, gums and other compounds present in extracts [14]. Other methods, such as affinity chromatography [15], voltammetry [16], surface plasmon resonance [17], immunoassay (ELISA) [18], have been proposed to determine WGA concentrations in foods. The quartz crystal microbalance (QCM) is a useful tool to monitor adsorption/binding processes to quartz surfaces, and is being increasingly applied in biorecognition analysis. Several analytical applications have been developed based on the bioaffinity interactions between carbohydrate and lectins described in biology/biochemistry [19, 20].

In this paper, a QCM continuous flow analysis system for whole meal flour quality evaluation r is presented based on the lectin–carbohydrate interactions. It was studied the frequency changes of a piezoelectric quartz crystal covered with 1-thio-β-d-glucose produced by selective adsorption or desorption of the lectin. The developed QCM protocol was then applied to the determination of biologically active WGA content from whole meal flour produced using ungerminated and germinated wheat seeds. During analytical system optimization, Con A was used as a model lectin instead of WGA due to its similar binding properties and lower price.

Materials and methods

Chemical and reagents

Two lectins used were Concanavalin A (Con A) (extracted from Canavalia ensiformis) and WGA (extracted from Triticum vulgaris) both from Sigma. The Con A and WGA stock solutions were prepared in PBS at a concentration of 1 mg/mL. Lower concentration working solutions were prepared just before use. Working solution of 1-thio-β-d-glucose (Aldrich) was prepared in distilled water before use. All the chemical reagents used in the experiments were of analytical grade: d(+)-mannose, methyl α-d-mannopyranoside, bovine serum albumin (BSA) fraction V hydrogen peroxide 30%, sodium phosphate disodic, potassium phosphate monobasic, sulfuric acid 98%, sodium chloride, sodium hydroxide, ethanol, phosphoric acid (Sigma).

All QCM measurements were carried out in phosphate buffer solution (PBS) (pH 7.2, 0.033 M). For the regeneration of the quartz crystal surface, it was used an alkaline solution of sodium hydroxide 0.5 M with sodium chloride 3 M.

Apparatus

Quartz crystal microbalance measurements were carried out using a QCM (QCM 922, Princeton Applied Research, USA) controlled by a computer. 9 MHz AT-cut quartz crystals (Ametek, USA) coated with mirror polished gold electrodes on both sides (surface area of 0.2 cm2, thickness gold layer of approximately 300 nm) were mounted in the flow cell provided by Princeton Applied Research. A continuous flow analysis system was set up with QCM as detector and a peristaltic pump Gilson Minipuls 3 (France). A size-exclusion NAP-10 column (Amersham Biosciences, Sweeden) was used for WGA separation from wheat samples. Spectrophotometric measurements were performed using an HR 4000 spectrometer (Ocean Optics, USA).

Carbohydrate immobilization procedure

The immobilization method consists of three successive steps: (1) quartz crystal cleaning, (2) thiolated carbohydrate binding on gold electrode and (3) non-specific adsorption blocking with BSA. The quartz crystal was cleaned with a solution of 1:1 H2SO4, 98%: H2O2, 30% v/v, for 20 min, rinsed with distilled water and dried with an argon stream. After which, the quartz crystal was immediately mounted on to the flow cell with one side in contact with the solution. To equilibrate the system, a continuous water flow at a flow rate of 1 mL/min was through out to the cell until a stable baseline was obtained <3 min. The cleaned gold electrode was subsequently coated with 1-thio-β-d-glucose by 10 mL recirculation through flow system of 1 mM aqueous solution of thiocarbohydrate until no further mass change was recorded (minimum 1 h). The obtained electrode was rinsed with distilled water for 15 min and the frequency of the quartz crystal was then measured in PBS to re-equilibrate the system to the new solution viscosity. In the next step, any remaining adsorption sites of the glucose-modified electrode surface were completely blocked by passing a solution of 10 mg/mL BSA for 15 min.

Sample preparation

Two varieties of autumn wheat seeds (Capo and Trivale) obtained from Agricultural Research and Development Station Albota-Pitesti (Romania), were used in this study. Low quality peasant wheat of no specific variety was bought from a market place from Curtea de Arges town (Romania). Seeds were germinated by incubating between two layers of water-soaked chromatography paper (Whatman) at 23 °C, until the germs size was visible (about 1 mm) then dried (metabolize all adsorbed water) at room temperature for 24 h. Only the seeds that had germinated were milled until a very fine powder was obtained (~95% of seeds for Capo and Trivale and ~80% of seeds for unknown wheat cultivar, respectively).

The WGA was extracted from milled wheat following a modified procedure [21] by magnetically stirring 1 g of whole meal flour obtained from different wheat samples with 5 mL PBS for an hour. The supernatant was centrifuged at 9,000g for 5 min. After this, 1 mL from the final supernatant was passed through an NAP-10 column preliminary equilibrated with PBS. Five fractions were collected: F1 (1 mL), F2 (2 mL), F3 (0.5 mL), F4 (0.5 mL) and F5 (0.5 mL). Only the fraction 2 was found to contain a significant WGA quantity. From each fraction, a volume of 200 μL for QCM, and 50 μL for Bradford method were diluted, respectively, with PBS to 1 mL and the resulted solution was then analyzed for WGA and for total soluble proteins, respectively.

Lectin analysis using QCM

The initial baseline of the QCM flow system with a piezoelectric thioglucose-modified quartz crystal was recorded by passing 1 mL/min PBS (~10 min). Then, 1 mL of different lectin samples or standard solutions were recirculated through the system until frequency stabilization (~10 min) followed by 15-min washing with PBS to remove any non-specifically adsorbed substances. During the first 50 s of lectin solution circulation through the QCM system, the waste solution was discarded and only afterwards the solution was recirculated to avoid sample dilution by PBS from the dead volume of the flow system (~0.6 mL). This allowed the use of a minimum volume of lectin solution without sample dilution. Following the lectin analysis, the quartz crystal was regenerated by removing the bounded lectins from the electrode surface by 5 min passing through the flow system a solution of 0.5 M sodium hydroxide with 3 M sodium chloride. In the end, the system was re-equilibrated with PBS and the frequency return to the initial baseline. The flow cell was kept overnight at room temperature filled with purified water.

Determination of total soluble protein content in wheat using modified Bradford method

The total protein content of each fraction was estimated by the dye-binding assay [22] using Bradford reagent and BSA as etalon protein. The Bradford reagent was prepared by dissolving 0.0125 g of Coomassie Brilliant Blue G-20 (Sigma) in 4 mL 95% methanol and then mixed with 10 mL 85% phosphoric acid. When the dye was completely dissolved, it was diluted to 100 mL with distilled water. The reagent was filtered through a filter paper (IsoLab, Germany) prior to use.

For spectrophotometric measurements, 2 mL of Bradford reagent were mixed with 1 mL of BSA standard solution or wheat extract sample and incubated at ambient temperature for 10 min, and absorbance was measured at λ = 595 nm.

Results and discussions

Quartz crystal modification with glucose

For lectin detection using bioaffinity interactions, a carbohydrate was immobilized on the quartz surface to selectively interact with lectin from sample. Clean gold electrode surface is modified in one step with 1-thio-β-d-glucose via thiol groups obtaining a carbohydrate monolayer. During quartz modification, the change of the resonant frequency was recorded as a function of time using QCM. An aqueous solution of 1 mM 1-thio-β-d-glucose was recirculated throughout the flow cell until a stable frequency was reached indicating that there is no more mass change on the quartz surface, and the thioglucose-binding process was finished. After 1-thio-β-d-glucose, water was passed through the system to remove any weak adsorbed glucose. The measured frequency variation during thioglucose binding is about −80 Hz. BSA was used as a non-glycolysed protein to block the non-specific protein adsorption sites of the thioglucose-modified quartz crystal (Fig. 1a). After system re-equilibration with PBS, a solution of 1% (m/v) BSA prepared in PBS was passed through flow cell until the surface was saturated and no more binding could be observed. In this stage, a frequency variation of approximately −130 Hz was obtained. Then, PBS was passed and only a small percentage of the weakly adsorbed BSA is washed away and the frequency is stabilized (Fig. 1b). The non-specific adsorption was completely blocked, thus when other concentrations of 1% (m/v) BSA were passed through the system no significant frequency variations were registered. A thioglucose-modified quartz was used at least 20 lectin measurements. For every five lectin analysis, another blocking of non-specific adsorption with BSA was performed.

Quartz crystal modification with thioglucose for lectine analysis: a Schematical representation of the successive steps: 1-thio-β-d-glucose binding, blocking the non-specific adsorption with BSA and specific binding of lectin to carbohydrate; b frequency changes measured during quartz crystal modification

Quartz crystal surface regeneration

In order to reuse a quartz crystal modified with thioglucose after lectin binding, a regeneration of the surface is required. The regeneration solution should satisfy two main requirements: one, it should be able to remove all the attached lectin and then it should not damage the immobilized ligand. Two strategies to remove the lectin were tested: (1) competition for the immobilized thioglucose with concentrated solutions of a carbohydrate (glucose and methyl-α-d-mannopyranoside for Con A, N-acetyl-glucosamine and N-acetyl-galactosamine for WGA) and (2) lectin denaturation using solutions with extreme pH or high salt content. The first regeneration possibility based on the affinity competition between complexes formed between lectins with immobilized thioglucose and carbohydrate from regenerating solution has not been satisfactory because there are necessary several 20 min passages regenerating solutions in order to restore the measured frequency to the original level. This difficulty to release WGA from carbohydrate bounded on heterogeneous supports using competition with 0.2 M N-acetyl-d-glucosamine was already reported [23]. For the second modified quartz regeneration option based on the physical denaturation of the bounded lectins, they tried two solutions: sodium citrate solution pH 1.54 and solution of 0.5 M sodium hydroxide with 3 M sodium chloride, respectively. It was noticed that the optimum regeneration was achieved by passing a mixture of 0.5 M sodium hydroxide with 3 M sodium chloride for 5 min. This regeneration solution has different viscoelastic properties than the PBS solution used for baseline and lectin standard solution preparation and in consequence induces a high variation of the recorded frequency during the regeneration procedure. When PBS is passed through the system following the regeneration solution, the recorded frequency is restored to the baseline. The frequency variation recorded during the binding process of Con A to immobilized thio-glucose followed by washing with PBS and regeneration is presented in Fig. 2.

The same quartz crystal can be used for at least 20 successive measurements without signal decrease (Con A concentration of 0.5 μg/mL). This regeneration treatment probably leads to the partial denaturation/removal of the immobilized 1-thio-β-d-glucose and in consequence to the decrease in the analytical signal recorded for lectin binding.

Characteristics of QCM detection

The passage via the flow system of Con A/WGA standard solution prepared in PBS led to the formation of the lectin–carbohydrate complex on the electrode surface which produced a decrease in the oscillation frequency of the crystal with a magnitude correlated with the bounded lectin mass. After every lectin solution, PBS was passed through the system and it was noticed that the resonant frequency do not return to baseline value. This suggests that the lectin-immobilized thioglucose complex is stable. An alkaline regeneration solution was then used to release, completely, the bonded lectin from gold electrode and to restore the frequency to the baseline for a new analysis.

To confirm that the recorded frequency variation corresponds to the lectin–carbohydrate binding and not to the other types of non-specific interactions, a cleaned quartz crystal was mounted in the flow system and a lectin solution was passed. In this case, it was registered no significant frequency variation, a clear indication of the absence of non-specific adsorption of the lectin on the electrode surface.

The resistance (R) and the resonant frequency of the quartz crystal were recorded simultaneously during measurements. R is given by the loss of mechanical energy in the quartz and medium. During an experiment, the R variation induced by medium may be produced by the changes in viscoelasticity occurring on the quartz surface (substance deposition in an uniform layer with rigid behavior) and variations of solution properties leading to a variation of energy dissipation (changes of viscosity, density, ionic strength) [24]. During lectin binding on quartz crystal, ΔR is very small (<2 Ω) in comparison with a starting value of ~350 Ω. This means that the lectin binding produce a rigid, rather than viscoelastic monolayer [25] well suited for QCM analysis. For proteins binding on quartz crystal, in literature, there are reported frequency variations between 10 Hz and ±45 Hz correlated with a ΔR = 1 Ω depending on layer behavior [26]. During quartz regeneration process, a regeneration solution with high-ionic strength (sodium hydroxide 0.5 M NaOH with 3 M NaCl) is used. This solution has very different properties in comparison with PBS and subsequently induces a ΔR = 75 Ω and Δf ~510 Hz. After QCM system re-equilibration with PBS, R and frequency measured return to the baseline value. The important R variation during quartz regeneration does not impede on lectin-binding measurement.

A calibration graph was made by passing through the cell system standard solutions with different concentrations of Con A from 0.1 to 2 μg/mL prepared in PBS pH 7.2. The linear part of the calibrations graph for Con A is 0.1–1 μg/mL in the concentration range with the following equation: −Δf (Hz) = 33.989 × Conc. Con A (μg/mL) + 3.5723 and R 2 = 0.9886 (n = 6). The limit of detection is 0.1 μg/mL Con A. The reproducibility of Con A analysis with the same modified quartz crystal was measured for a solution with the concentration of 0.5 μg/mL and the recorded frequency variation was −17 ± 0.44 Hz (RSD = 2.58%, n = 6). It was investigated the variation in the response for the Con A analysis using different quartz crystals. The calibration graph for Con A analysis obtained using two different resonator modified with thioglucose is presented in Fig. 3 and show only small differences that do not prevent the application of the system for real samples after a calibration.

After optimization using Con A, the system based on thioglucose was also applied to WGA detection. To evaluate the interaction between the WGA and immobilized thioglucose different concentrations of WGA from 0.5 to 20 μg/mL were analyzed with a quartz crystal modified with 1-thio-β-d-glucose, and QCM frequency variation was recorded. The linearity of the curve obtained in the range 0.5–5 μg/mL presented in Fig. 4 is characterized by: −Δf (Hz) = 9.6986 × Conc. WGA (μg/mL) + 4.3452; R² = 0.9922 (n = 6). For WGA, the limit of detection is 0.5 μg/mL. The WGA concentrations were slightly higher than for Con A, but the developed system is still able to successfully detect WGA.

In literature, there are reported different analysis methods for WGA. For example, a detection limit of 8 × 10−9 M was obtained using a system based on thionine/glucose-modified magnetic microbeads [16]. Another method based on mercapto-telomere chain with many pendent glucose residues for WGA recognition reported a detection limit of 0.06 μg/mL [17]. A linearity in the concentration range 125–500 ng/ml was achieved using ELISA procedure for WGA determination in wholemeal flours [21].

Determination of biologically active WGA from whole meal flour

In the last years, the “healthier” diets containing less processed grain foods or products with whole meal four allowed followers to take advantage of an increase in nutritious food quality, but unexpectedly had resulted in the consumption of more biologically active lectins. An interesting behavior of some lectins is their ability to mimic insulin that transforms free glucose into glycogen by attaching itself to the insulin receptor found on the fat cell [27]. The insulin binds temporarily on the receptors of the fat cell that becomes more permeable to glucose and after that, the insulin hormone disconnects from its receptor. From all food that are also lectin sources (wheat, lentils, green peas, corn and potatoes) only WGA is known to bind to the insulin receptor giving the fat cell, the message, to make fat, but WGA induced a continuous message due to a lack of feedback inhibition [28]. Another effect on human metabolism is the WGA ability to bind to the receptor for cholecystokinin (CCK), a hormone involved in appetite control, suppressing its function [29] leading to an increase in appetite and eventually weight increase.

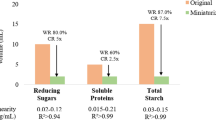

The optimized analysis method based on the QCM was applied to the determination of the biologically active WGA content from whole meal flour obtained using two varieties of wheat: Capo (fertilized N90 P80) and Trivale (not fertilized) and an unknown wheat cultivar produced by a peasant without fertilization. The moisture content was determined by drying whole meal flour at 105 °C until constant mass. For ungerminated/germinated wheat, the moisture content was 4.2%/10.2% for Capo, 10.3%/9.9% for Trivale and, 9.6%/9.8% for unknown cultivar wheat, respectively.

Germinated and ungerminated grains from wheat samples were milled to produce flour. The WGA obtained from flour was extracted using PBS; then, the PBS extract was centrifuged, and 1 mL of the supernatant was purified by size-exclusion chromatography.

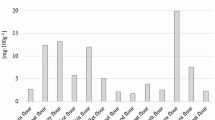

There are many varieties of wheat grown worldwide with total protein content between 9 and 12% for white wheat and between 11 and 15% for hard red wheat, respectively. Usually, higher protein content is demanded for good quality bread. The soluble protein content of each fraction collected from the size-exclusion column was determined by Bradford analysis and compared with the initial soluble protein content from the PBS supernatant injected in the column. A calibration curve with a linear working range concentration of 10–100 μg/mL BSA was made with the equation A = 0.0066 × Conc. BSA (μg/mL) + 0.0095, R 2 = 0.9958 (n = 6). The fraction 2 was found to contain the highest amount of total soluble protein, approximately 95%. By QCM analysis, WGA was identified only in fraction 2. The total soluble protein content determined using Bradford method is between 14.5 and 15.5 mg/g dry grain for ungerminated wheat and between 15.3 and 16.4 mg/g dry grain for germinated wheat, respectively (Table 1).

The WGA concentrations from fraction F2 were determined by direct interpolation of the analytical signal from the calibration graph and reported to 1 g dry wheat grains. The proposed analytical method was sensitive enough to detect WGA from wheat extracts. Also, the 36-h wheat germination (until the germ is ~1-mm long) produced a significant increase in WGA content. Because the samples are separated by size-exclusion chromatography, the possible interfering effects of compounds that might be present in the crude extracts are minimized; also, soluble proteins other than WGA should not be non-specifically adsorbed on the modified quartz crystal due to adsorption sites saturation with BSA prior to sample analysis.

The results obtained for WGA analysis from whole meal flour produced using six wheat samples (3 ungerminated and 3 germinated) are presented in Table 2. Significant amounts of WGA were obtained in all types of wheat. As we expected, the WGA amount contained in each analyzed wheat sample were lower than those corresponding to the germinated wheat seeds. WGA amount in germinated wheat was increased as follows: with 36.9% in Capo, 26% in Trivale, 17% in unknown cultivar wheat, respectively. 1 mL of supernatant sample extract was fortified with 10 μg WGA, then separated through the column and fraction F2 analyzed by QCM. A 200 μL aliquots were diluted to 1 mL analyzed by QCM. The WGA recoveries were between 88.7 and 110.6%.

Conclusions

We have developed a simple analysis method to study the lectin–carbohydrate interaction using QCM. This technique has the advantage that allows the real-time monitoring of lectin-immobilized glucose complex formation in continuous flow. The quartz crystal modified with thioglucose was sufficiently stable under the working conditions, so that they could be used without significant losses of sensitivity for at least 20 measurements. The non-specific adsorption of proteins was blocked with BSA. System optimization was made with Con A and for this lectin it was obtained a better limit of detection in comparison with WGA. The method was applied for the determination of increase in biologically active WGA content in wheat after germination. The proposed method is a suitable tool for biologically active WGA or other lectin analysis and also for flour quality control in order to identify if it was produced from/or contains low quality germinated wheat. Nutritional supplements based on the unprocessed plant extracts are generally considered to have beneficial health effects, but the possible presence of toxic biologically active lectins must be verified using an analytical system based on the bioaffinities interactions, such as the one proposed in this paper.

Abbreviations

- Con A:

-

Concanavalin A

- WGA:

-

Wheat germ agglutinin

- QCM:

-

Quartz crystal microbalance

- BSA:

-

Bovine serum albumin

- PBS:

-

Phosphate buffer solution

References

Sharon N, Lis H (2004) History of lectins: from hemagglutinins to biological recognition molecules. Glycobiology 14:53R–62R

Wang Q, Yu LG, Campbell BJ, Milton J, Rhodes JM (1998) Identification of intact peanut lectin in peripheral venous blood. Lancet 352:1831–1832

Van Damme EJ, Peumans J, Pusztai A, Bardocz S (1998) Handbook of plant lectins: properties and biomedical applications. John Wiley, Chichester, pp 31–50

Putzai A, Ewen SWB, Grant G, Brown DS, Stewart JC, Peumans WJ, Van Damme EJM, Bardocz S (1993) Antinutritive effects of wheat-germ agglutinin and other N-acetylglucosamine-specific lectins. Br J Nutr 70:313–321

Watzl B, Neudecker C, Hansch GM, Rechkemmer G, Pool-Zobel BL (2001) Dietary wheat germ agglutinin modulates ovalbumin-induced immune-responses in Brown Norway rats. Br J Nutr 85:483–490

Sjovall O, Virtalaine T, Lapvetelainen A, Kallio H (2000) Development of rancidity in wheat germ analyzed by headspace gas chromatography and sensory analysis. J Agric Food Chem 48:3522–3527

Ortega-Barria E, Ward HD, Keusch GT, Pereira MEA (1994) Growth inhibition of the intestinal parasite Giardia Lamblia by a dietary lectin is associated with arrest of the cell cycle. J Clin Invest 94:2283–2288

Peumans WJ, Van Damme EJM (1996) Prevalence, biological activity and genetic manipulation of lectins in foods. Trends Food Sci Tech 7:132–138

Brady PG, Vannier AM, Banwell JG (1978) Identification of the dietary lectin, wheat germ agglutinin, in human intestinal contents. Gastroenterology 75:236–239

Marsh SJ, Annuk D, Ozsarac N, Fox DJ (1988) The effect of weather damage on wheat enzymes. J Sci Food Agric 45:175–183

AACC Method 56-81B (2000) Determination of falling number, approved methods of analysis of the American association of cereal chemists, 10th edn. AACC International, St. Paul

Feyzipour AR, Seyedain SM, Taslimi A, Mazloumi SMT (2006) The enzymic activity in flour and its effect on the quality of the Iranian traditional breads (Barbari and Lavash). Pakistan J Nutr 5:263–268

Tan L, Xie O, Yao S (2007) Electrochemical piezoelectric quartz crystal impedance study on the interaction between concanavalin A and glycogen at Au electrodes. Bioelectrochemistry 70:348–355

Calderón de la Barca AM, Vázquez-Moreno L, Robles-Burgueo MR (1991) Active soybean lectin in foods: isolation and quantitation. Food Chem 39:321–327

Honda S, Suzuki K, Suzuki S, Kakehi K (1988) High-performance affinity chromatography of carbohydrate-binding proteins by two-stage separation on a resin carrying a number of oligosaccharides. Anal Biochem 169:239–245

Sugawara K, Takayanagi T, Kamiya N, Hirabayashi G, Kuramitz H (2008) Voltammetric evaluation of the binding between wheat germ agglutinin and thionine/glucose-modified magnetic microbeads. Anal Sci 24:717–720

Kitano H, Nakada H, Mizukami K (2008) Interaction of wheat germ agglutinin with an N-acetylglucosamine-carrying telomere brush accumulated on a colloidal gold monolayer. Colloids Surf B 61:17–24

Güll I, Wirth M, Gabor F (2007) Development of a sensitive and reliable ELISA for quantification of wheat germ agglutinin. J Immunol Methods 318:20–29

Sadik OA, Yan F (2007) Electrochemical biosensors for monitoring the recognition of glycoprotein–lectin interactions. Anal Chim Acta 588:292–296

Guo CX, Boullanger P, Jiang L, Liu T (2007) Colorimetric detection of WGA in carbohydrate-functionalized polydiacetylene Langmuir–Schaefer films. Colloids Surf A 293:152–156

Matucci A, Veneri G, Pellegrina C, Ziccatelli G, Vicenzi S, Chignola R, Peruffo ADB, Rizzi C (2004) Temperature-dependent decay of wheat germ agglutinin activity and its implications for food processing and analysis. Food Control 15:391–395

Bradford MM (1976) A rapid and sensitive method for the quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Miller RC, Bowles DJ (1982) A comparative study of the localization of wheat-germ agglutinin and its potential receptors in wheat grains. Biochem J 206:571–576

Lebed K, Kulik AJ, Forro L, Lekka M (2006) Lectin-carbohydrate affinity measured using a quartz crystal microbalance. J Colloid Interface Sci 299:41–48

Zhang Y, Luo Z, Tang Y, Yu L, Ho KY, Cheng JP, Zeng X, Wang PG (2006) Carbohydrate-protein interactions by “clicked” carbohydrate self-assembled monolayers. Anal Chem 78:2001–2008

Tan L, Jia X, Jiang X, Zhang Y, Tang H, Yao S, Xie Q (2008) Real-time monitoring of the cell agglutination process with a quartz crystal microbalance. Anal Biochem 383:130–136

Shemer J, LeRoith D (1987) The interaction of brain insulin receptors with wheat germ agglutinin. Neuropeptides 9:1–8

Ebert C, Nebe B, Walzel H, Weber H, Jonas L (2009) Inhibitory effect of the lectin wheat germ agglutinin (WGA) on the proliferation of AR42J cells. Acta Histochem 111:336–343

Damm I, Mikkat U, Kirchhoff F, Böckmann S, Jonas L (2004) Inhibitory effect of the lectin wheat germ agglutinin on the binding of 125I-CCK-8s to the CCK-A and -B receptors of AR42J cells. Pancreatology 28:31–37

Acknowledgments

Capo and Trivale wheat samples were a generous gift from Dr. Maria Voica, Agricultural Research and Development Station Albota-Pitesti, Romania. This work was supported by Romanian Ministry of Education and Research through BLUEBOXSENS 82102/2008, MICROSEN 11049-02 and SAFEFOOD 61/2007 grants.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Radulescu, MC., Bucur, B., Bucur, M.P. et al. Quality control method based on quartz crystal microbalance and WGA for flour milled from germinated wheat. Eur Food Res Technol 229, 833–840 (2009). https://doi.org/10.1007/s00217-009-1120-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-009-1120-2