Abstract

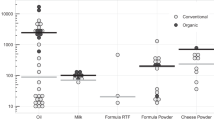

Foods with at least a few percent of free oil packed in glass jars with metal closures were analyzed for migration of additives, primarily plasticizers, from the gasket of the lid. One hundred and fifty-eight samples were collected in June 2005, i.e., some 10 months after the problem of excessive migration into oily food was communicated to the industry. In a first step, the composition of the additives in the gaskets was determined. Then the compounds found in the lid were measured in the jar content. Sixty-four percent of the gaskets contained epoxidized soy bean oil (ESBO) as principal plasticizer, 22% a phthalate, and 6% substantial amounts of di(2-ethylhexyl) adipate (DEHA). Concentrations in the food reached 1,170 mg/kg for ESBO, 270 mg/kg for diisononyl phthalate (DINP), 740 mg/kg for diisodecyl phthalate (DIDP), 825 mg/kg for di(2-ethylhexyl) phthalate (DEHP), and 180 mg/kg for DEHA. Further, elevated concentrations of plasticizers not authorized by the EU were found: diisononyl-cyclohexane-1,2-dicarboxylate (DINCH), 2-ethylhexyl palmitate and stearate, as well as epoxidized linseed oil (ELO). The few samples complying with the European rules contained little or well emulsified oil; some others were probably of very recent production (beginning of shelf life). It is concluded that there was still no lid reliably complying with the European rules (EU and national legislation).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The metal lids seal against the rim of the glass jar by means of a gasket currently consisting of plasticized PVC. A number of problems arose regarding the migration from these gaskets into the packed food. In 1998, migration of epoxidized soy bean oil (ESBO) from the gaskets into infant food was shown to sometimes exceed the tolerable daily intake (TDI) of 1 mg/kg body weight (bw) [1]. Subsequent surveys showed that the problem was not solved during the following years [2–4]. In 2003, incidentally semicarbazide was found in infant food: azodicarbonamide serving as blowing agent in the gasket released it [5]. In 2004 it was detected that frequently the non-listed 2-ethylhexanoic acid [6] was used for the Zn/Ca stabilizer soaps.

In the early summer 2004, it was noticed that the migration of plasticizers and other additives from the gaskets into oily general foods, such as sauces and products in oil, often far exceeded the legal limits: some 150–400 mg plasticized PVC is in direct food contact, typically contains 25–45% additives (primarily plasticizers), and the transfer easily approaches completeness if an oily food is in contact with the gasket [7]. As a consequence, legal limits were exceeded by far for whole ranges of products.

It has not been clarified whether the gaskets of metal closures are within the scope of the EU Directive on plastics (2002/72 EC and amendments). In case it is considered as part of a multi material, only the general Article 3 of the Framework Regulation 1935/2004 applies as harmonized European legislation and primarily national legislation is applicable, i.e., the overall migration limit (OML) would only apply as far as national legislation requires it.

Plasticizers in PVC gaskets and their legal restrictions

The compounds of concern are compiled in Table 1. ESBO is listed as an authorized substance in the plastic regulation. It was given a TDI of 1 mg/kg body weight (bw), as confirmed by the EFSA in 2004 [8]. A specific migration limit (SML) of 60 mg/kg is derived, but by convention an SML equal to or above the OML is not listed. For epoxidized linseed oil (ELO) the SCF refused to apply the toxicological data from ESBO [9], i.e., the use of ELO is not approved as safe and it will not be in the first version of the closed EU list of plastic additives. ELO is in the national list of Italy, however. The Swiss Federal Office of Public Health (SFOPH) does not accept the sale of products containing ELO as long as its safety is not ensured.

For the phthalates, there are TDIs (group TDI for diisononyl phthalate, DINP, and diisodecyl phthalate, DIDP) [10], but since exposure is from many sources, probably only a fraction of the TDI will be allocated to the food contact materials, i.e., the SMLs will probably be lower than those listed in brackets in Table 1.

For acetyl tributyl citrate (ATBC), the safety evaluation has not been concluded [11]. As a temporary measure, a restriction (R) of 5 mg/kg in food or food simulant was set [12]. The use of 2-ethylhexyl palmitate and stearate has not been approved by any European health authority. If metabolic hydrolysis is assumed, 2-ethylhexanol and its metabolite 2-ethylhexanoic acid are of concern (see [10], p. 13). For 2-ethylhexanol, WHO/JECFA approved an acceptable daily intake (ADI) of 0.5 mg/kg bw, from which conventional transformation would result in an SML of 30 mg/kg. Diisononyl-cyclohexane-1,2-dicarboxylate (DINCH) is a rather new plasticizer, the use of which has not been approved by the EU authorities. In Germany, an SML of 5 mg/kg is applied.

The EU plastic directive 2002/72 EC specifies that the OML should always apply in terms of concentration in food or food simulant (i.e., 60 mg/kg) when the migration occurs from gaskets (Article 2). For SMLs, however, it states that for containers of less than 500 ml content the limit applies in terms of amount per contact surface area (mg/dm2, Article 7), whereby the listed SMLs expressed in mg/kg shall be divided by the conventional conversion factor of 6 in order to convert them in mg/dm2. It seems to be less clear which contact surface area is meant. While some believe it is the surface of the gasket, others understand the total internal surface, i.e., including the whole of the lid and the glass jar. In the latter case, this transformation enhances the tolerance for small packs by a factor reaching about 3.

Course of events

In July 2004, the Swiss enforcement authorities stopped the sale of one product in glass jars with ESBO far exceeding 60 mg/kg for each major distributor (totally eight). The distributors were asked to check the other oily products. This provided time for solving the problem without creating a scandal.

The average ESBO content in 86 products containing free oil from the markets of various European countries, analyzed in the second half of 2004, was 166 mg/kg; the values reached 580 mg/kg [4]. On top of this alarming result, the analysis of the lids soon revealed that ESBO was not the only plasticizer used, and it also became clear that no gasket was available which would comply with the European legal restrictions for oily foods.

A major Swiss distributor estimated the value of his products exceeding the limits to roughly 20 million euros. Extrapolated to the whole of Europe, the annual production of affected foods might be in the order of several thousand million euros. To avoid the removal of whole ranges of products from the market, primarily hitting farmers, fishers, and a broad range of food industries, it was decided that in Switzerland products exceeding the restriction for ESBO would be tolerated for 2 years (filling dates up to November 2006) [13]. This should avoid switching to more toxic plasticizer and prevent precipitated introduction of alternatives.

In November 2004, industry admitted the lack of lids for oily foods complying with the legal limits and that it needed time to develop alternatives [14]. In February 2005, Denmark required the withdrawal of several products containing high concentrations of phthalates from the market. The Swiss Federal Office of Public Health prevented the withdrawal of tomato sauces containing up to 170 mg/kg DIDP by a letter stating that there would be no health problems as long as DIDP concentrations in such sauces remained below 200 mg/kg [15]. In April 2005, German and Austrian authorities started to withdraw products from their market.

Starting in summer 2004, several European authorities required information about the composition of the gaskets, but mostly did not get any. Food distributors were in a difficult situation: they asked for specifications from the lid manufacturers, but mostly received none, meaningless (e.g., “biosilicone”) or misleading information. Present legislation does not entitle food industry or distributors obtaining information about the composition of packaging materials, despite their responsibility for the safety and compliance of their products within self-control schemes.

During June 2005, in the Canton of Zurich totally 158 oily products in glass jars with metal closures were collected from all distributors except specialty and ethnic shops. This included products immersed in oil and sauces with more than about 3% fat/oil, but excluded those of a consistency preventing contact with the lid (e.g., mustard) or with well emulsified oil, such as mayonnaise. The survey did not include infant food.

Experimental

The composition of the additives in the gasket was analyzed as described in [19]. Briefly, a portion of the gasket not in contact with the food, i.e., outside the seal against the jar rim, was dissolved in tetrahydrofurane and precipitated with ethanol. The supernatant was analyzed directly as well as after transesterification to ethyl esters using gas chromatography (GC) with flame ionization detection (FID). Transesterification enabled the detection of ESBO, ELO and polyadipates, but also confirmed the identifications of the direct analysis through the transformation products.

Food samples were homogenized using a Polytron (Kinematica, Luzern, Switzerland). When the homogenates of products immersed in oil were of insufficient stability to take representative samples, only the oil was analyzed, calculating the migration on the assumption that the component of interest would be exclusively in the oil [4]. Migration data refers to the jar content, e.g., to the sum of the oil and the product immersed in the oil.

ESBO and ELO were analyzed by on-line LC-GC-FID [16]. The homogenized sample was transesterified with methanol/sodium methoxide under conditions ruling out significant saponification by the presence of water (1 min at ambient temperature). From the methyl esters extracted from the reaction mixture, selected diepoxy esters were isolated using an HPLC column packed with a cyano phase. The whole fraction of 1 min width (300 μl) was transferred to GC using concurrent eluent evaporation with the on-column interface.

The other PVC additives/plasticizers were determined by injector-internal thermal desorption GC-mass spectrometry (MS) [17, 18], using conventional splitless injection or a similar technique based on programmed temperature vaporizing (PTV) injection. A solution of the fatty food extract or oil was deposited in the injector liner under conditions fully desorbing the solutes of interest, but leaving the bulk of the oil in the liner. A precolumn coated with a thin film of stationary phase was backflushed towards the end of every analysis. MS involved electron impact (EI) ionization and selected ion monitoring.

Results

Lid analysis

Table 2 shows the prevalence of the plasticizers in the gaskets of the 158 products analyzed. Only the main plasticizer is considered, i.e., not, e.g., a minor amount of ESBO used as HCl scavenger or phthalate present as a viscosity modifier or impurity. Six lids are listed twice since two plasticizers were present at similar concentrations. Many lids must have been from the same producer, but often the producer was not marked, the same product carried lids from different manufacturers, and some lid producers seem to use plastisols of different composition.

ESBO was the principal plasticizer in 64% of the lids, with concentrations in the gasket typically varying between 35 and 45 mg/100 mg (%). Additional six lids contained 5–10% ESBO and 14 lids 2.3-5%, presumably serving as stabilizer. Thirty-five lids (22%) contained phthalates as main additive (compared to 25% in 2004), further 26 (16%) as minor constituents, in 16 of which in concentrations below 1%. Two gaskets were plasticized with DINCH. In summer 2004, the same product carried lids containing ESBO. Then “ESBO-free” lids were used, which turned out to be with DEHP as principal plasticizer. After this was detected, DINCH was introduced. Nine lids contained 2-ethylhexanoic (EHA) acid as metal soap stabilizer.

The comparison with the data from the second half of 2004 does not show significant differences. Since many products were not the same, it does not enable to conclude on changes for given products. The proportion of the gaskets primarily plasticized with ESBO did not significantly increase. From some products we know that ESBO substituted another plasticizer, but there is a similar number of products now with “ESBO-free” lids, such as with phthalates or DINCH.

Table 3 provides some examples showing the complexity of the additives in many of the gaskets. About half of the gaskets with ESBO as principal plasticizer contained no other plasticizer. However, 28 lids also contained 0.6–3.6% DBS, 12 lids some DIDP (two with 6–7.5%, the others 0.1–1.1%), 7 were with 0.3–2.9% DINP, again others with di(2-ethylhexyl) sebacate (DEHS) or acetylated partial glycerides (acPG).

Two gaskets contained ELO as the principal plasticizer. In 10 others, ELO was mixed with ESBO. Estimated from the concentrations of diepoxy linoleic and the triepoxy linolenic acid, ELO made up 25–60% of the mixture.

DIDP was found in 26 gaskets. In 11 of them, it represented 21–33% of the gasket, in two others 6–7.5% and in 13 it ranged between 0.1 and 1.1%. In the 15 gaskets with DEHP as principal plasticizer, the concentrations varied between 28 and 45%. In another 14 gaskets, they were between 0.2 and 1.4%.

DEHA was never the principal plasticizer. It was present in nine gaskets, namely eight times in a range between 2.2 and 14% and once at 0.2%. Interestingly it was often combined with other esters of 2-ethyl hexanol, such as DEHP or Ehol-16/Ehol-18. Acetylated partial glycerides were found in 16 gaskets, namely twice as the main plasticizer beside ESBO (25 and 21%), four times between 2 and 8.5% and ten times between 0.8 and 1.3%.

Migration into food

In 91 out of 104 products with lids containing ESBO as principal plasticizer in the gasket, with more than 3% free oil in the food and of a consistency resulting in contact between the food and the lid, the ESBO concentration exceeded 60 mg/kg; in 34 products it exceeded 200 mg/kg. The average concentration was 216 mg/kg.

Table 4 lists the five products with the highest ESBO concentrations, all being pastes with free oil. Three of the products (but not really the two on top of the list) were in small portions, rendering the ratio of gasket material in food contact to the jar content unfavorable. The lower half of the table lists the top five products laid in oil (the olives at the bottom being at position 18 of the complete ranking). Mostly concentrations are lower because of the significantly larger jar content.

All nine foods in jars with lids with substantial amounts of DINP in the gasket contained this phthalate at concentrations above 120 mg/kg (average of 175 mg/kg). The top five are listed in Table 5. Another four products with small amounts in the gasket contained 10–55 mg/kg DINP. The bottom line shows an example: as little as 1.2% DINP in the gasket (next to 37% ESBO) was sufficient to contaminate the food at a concentration of 55 mg/kg. Hence, 9 mg/kg (SML conventionally derived from the TDI) would be reached in a product of this type with 0.2% DINP in the gasket.

Twelve products contained DIDP at concentrations above 9 mg/kg (SML from the TDI), the five highest being shown in Table 6. The lid of product 2 also contained 2.8% DEHA, which resulted in a migration of 55 mg/kg into the food. Migration into three tomato sauces from the same producer (all with 6.5% fat) varied strongly. In a first series it amounted to 150 and 170 mg/kg for two, but merely 15 mg/kg for a third (product 6). Later, however, a sample of the latter product from another shop was found with 200 mg/kg DIDP, probably showing the strong influence of the history of a product, particularly how many times the jar was shaken to result in the exchange of the (rather viscous) food adhering to the gasket.

Two more sauces are listed in which no DIDP was found (detection limit, 5 mg/kg) despite DIDP concentrations in the gasket of 24 and 29% and a labeled fat content of the sauces of 12 and 33%. They show that migration may be low when the fat is well emulsified into the product. The bottom line shows results from a 90 g jar with anchovies in oil: DIDP reached 30 mg/kg with a concentration in the gasket of merely 0.5 and 0.9% ATBC in the gasket was sufficient to result in a migration of 60 mg/kg. The main plasticizer was ESBO, which migrated at 540 mg/kg.

For two samples with a high total migration, also the slip agents oleamide (OA) and erucamide (EA, 0.9% each in the gasket) were determined: the sum of these alone reached the OML. Since their addition to the plastisol cannot be substantially reduced without rendering the jar difficult to open, other means are needed to keep their migration sufficiently low.

Seventeen products contained more than 3 mg/kg DEHP; all fifteen with substantial DEHP concentrations in the gasket exceeded 180 mg/kg and the average was as high as 387 mg/kg. The top eight products are listed in Table 7. Three (1, 2, and 5) were from the same Indian producer. Eight products were from Italy, where the use of phthalates for PVC in contact with fatty food is banned.

Eight products contained 22–180 mg/kg DEHA (Table 8). ESBO was the predominant additive in all except one lid (olive paste), where DIDP was present at 25% in the gasket. In six gaskets DEHA was combined with small amounts of still other plasticizers, such as phthalates (primarily DINP) and Ehol-16/18.

Table 9 lists products with elevated concentrations of plasticizers not reported above. The first two were with lids containing gaskets plasticized with ELO as principal plasticizer, both being oily pastes. ELO concentrations in the gaskets were 26 and 36%, which is clearly below the concentrations typically seen for ESBO. ESBO migration into the same type of products ranged from 70 to 420 mg/kg, averaging above 200 mg/kg, which might suggest that the migration of ELO is lower than that of ESBO. No attempt was made to determine the ELO migration from gaskets containing ELO/ESBO mixtures.

Small proportions of DBS were found in many gaskets. In product 1, DBS amounted to 2.2% of the gasket, in product 3 it amounted to 1.7%. The latter shows once more the high migration of a small molecular weight additive compared to ESBO: the concentrations of ESBO and DBS in the gasket amounted to 39 and 1.7%, respectively, i.e., 5.4 times more DBS migrated compared with the amount present in the gasket.

The gasket in the lid of product 4 contained 20.5% acetylated partial glycerides and 16% ESBO and is a further example for high migration of the smaller molecular weight plasticizer. DINCH (product 6) was introduced to replace the phthalates. In the two products containing DINCH, the migration was 710 and 180 mg/kg.

Conclusions

The survey showed the diversity in the composition of the gaskets in the closures. ESBO is the predominant plasticizer used, but there are numerous others, in particular phthalates. When applied in substantial amounts in the gasket and when the food contained some free oil, the restrictions provided by the EU and the national legislation were almost invariably exceeded, often drastically. We suspect that most of the complying products had a kind of favorable history: recent production and little exchange with the lid. For several of these, samples from another lot were analyzed and then often also violated the rules.

Some of the products or at least their lids may have been produced before summer 2004, but since the samples were from major distributors, where the shelf life tends to be short, most of the products were produced later. Hence, no improvement was recognized compared to the situation encountered in 2004 when this problem was pointed out. In fact it seems that there are still no lids on the market reliably respecting the legal requirements when used for oily products.

Apart from the limits for the individual components, also the OML should be met. The overall migration into the food can be approximated by adding up the concentrations of the single compounds, since PVC as the basic polymer contributes little. The slip agents alone easily claim more than half of the OML.

References

Hammarling L, Gustavsson H, Svensson K, Karlsson S, Oskarsson A (1998) Food Addit Contam 15:203–208

MAFF (1999) Food surveillance information sheet no. 196, http://www.foodstandards.gov.uk/maff/archive/food/infsheet/1999/no186/186esbo.htm

Fantoni L, Simoneau C (2003) Food Addit Contam 20:1087–1096

Fankhauser-Noti A, Fiselier K, Biedermann S, Biedermann M, Grob K, Armellini F, Rieger K, Skjevrak I (2005) Eur Food Res Technol 221:416–422

EFSA (2004) http://www.efsa.eu.int/press_room/questions_and_ answers/44_en.html

Elss S, Grünewald L, Richling E, Schreier P (2004) Food Addit Contam 21:811–814

Fankhauser-Noti A, Grob K (2005) Trends Food Sci Technol (in press)

http://europa.eu.int/comm/food/food/chemicalsafety/foodcont-act/synoptic_doc_en.pdf

http://www.efsa.eu.int/science/afc/afc_opinions/catindex_en.html

EU Scientific Committee on Toxicity, Ecotoxicity and the Environment (CSTEE). (1999)Opinion on the toxicological characteristics and risks of certain citrates and adipates used as a substitute for phthalates as plasticisers in certain soft PVC products. Opinion expressed on Sept. 28, 1999, p 11

Bundesamt für Gesundheit, Weisung 3, ESBO in Lebensmitteln. Bern, Nov. 5, 2004, http://www.bag.admin.ch/verbrau/aktuell/d/Weisung_051103_ FINAL.pdf

EU-SANCO Food Contact Materials Working Group (with representatives of all EU member states)

Bundesamt für Gesundheit, Weisung 4, Diisodecylphthalat in Lebensmitteln. Bern, March 9, 2005, http://www.bag.admin.ch/verbrau/lebensmi/weisung/d/Weisung 4.pdf

Fankhauser-Noti A, Fiselier K, Biedermann-Brem S, Grob K (2005) J Chromatogr A 1082:214–219

Biedermann M, Fiselier K, Grob K (2005) J Sep Sci 28:1550–1557

Fiselier K, Biedermann M, Grob K (2005) J Sep Sci 28:2144–2152

Biedermann-Brem S, Biedermann M, Fiselier K, Grob K (2005) Food Addit Contam 22:1274–1284

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fankhauser-Noti, A., Biedermann-Brem, S. & Grob, K. PVC plasticizers/additives migrating from the gaskets of metal closures into oily food: Swiss market survey June 2005. Eur Food Res Technol 223, 447–453 (2006). https://doi.org/10.1007/s00217-005-0223-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-005-0223-7