Abstract

The oxidative stability of phytosterols as lipid compounds can be defined as their resistance to oxidation and thus the formation of phytosterol oxidation products. We studied the oxidative stability of phytosterols during processing and long-term storage in phytosterol-enriched milk powder and heat-treated milk, and in microcrystalline phytosterol suspensions in different fats and oils. All of these food applications were observed to be stable despite the heat treatments used in their processing and the long-term storage even at slightly elevated temperatures. The largest change in the phytosterol oxide content was determined for phytosterol-enriched milk powder stored at 38°C for 12 months. During this period the percentage of phytosterol oxidation grew from 0.03 to 0.07%. Based on our observations, we concluded that food applications tested here were unlikely to represent an important source of phytosterol oxides. Furthermore, the formation of phytosterol oxides did not seem to be limiting factor for manufacture and subsequent storage of these products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The oxidative stability of phytosterols as lipid compounds may be defined as their resistance to oxidation and the resulting deterioration that causes decreased food quality [1]. The instability of phytosterols can lead to formation of phytosterol oxidation products shown to be absorbed and accumulated in the serum, liver, and aorta of mice [2], and to have cytotoxic effects on cultured mammalian cells [3]. In one recent study, these oxides were also identified in the plasma of healthy human subjects in amounts ranging from 4.8 to 57.2 ng/ml [4].

Since sterol autoxidation is a free-radical process [5], any sterol-containing food could be potential source of oxidized sterols when exposed to oxidation-initiating and promoting factors during, for instance, technological procedures and long-term storage. Food processing conditions that could enhance lipid and thus sterol oxidation are elevated temperatures and exposure to oxygen, light, water or metals (pro-oxidants) [6]. Food processes can also lead to redistribution of lipid compounds in the food products, causing enlargement of the contact area with oxygen and reduction in the activity of natural antioxidants [7]. During long-term storage lipid oxidation in foods can be influenced by the quality of packaging and packaging materials, storage temperature, oxygen availability, water activity and exposure to light, antioxidants or pro-oxidants. Furthermore, it is important to note that oxidation of lipid compounds during storage is linked to oxidation during processing, with a higher initial oxidation level accelerating oxidation during storage [6].

To date, few studies have been conducted on phytosterol oxidation in foods. Additional research is needed since phytosterol enrichment of foods has increased enormously during the past decade because of the cholesterol-lowering property of phytosterols in humans [8]. At the moment, added phytosterols are present in a variety of foods, including dairy products and spreads, cereals and meat products [9, 10]. Phytosterols are added both in their unsaturated and saturated (phytostanols) forms, and furthermore, in free and esterified forms. The esterified form is, however, more widely used because of its increased solubility in the fat phase of foods. Recently, a special free-phytosterol-containing ingredient [11], which can be incorporated into different foods has also been developed. This ingredient comprises phytosterols, food-grade fats or oils and water, and its physical state is mainly microcrystalline.

We have previously examined phytosterol oxidation in lipid model systems [12, 13]. However, model systems can be misleading, often oversimplifying the interfacial interactions of multiple components [1]. Thus, real phytosterol-enriched food products, produced on a pilot or industrial scale, should also be examined to strengthen observations in model system studies.

The purpose of this study was to investigate changes occuring in phytosterols in phytosterol-enriched foods during processing and subsequent storage by analysing the formation of major secondary oxidation products and the amount of unoxidized phytosterols. Food applications were selected to cover a range of commercially available phytosterol ingredients, different heat treatments during food processing and different structures in multiphase foods.

Materials and methods

Preparation and storage of microcrystalline phytosterol suspensions in rapeseed oil, milk fat, coconut oil and palm kernel oil

Microcrystalline phytosterol suspensions in different fats/oils were kindly donated by Teriaka Ltd. (Vantaa, Finland). Suspensions were prepared as described by Christiansen et al. [11] using wood-based phytosterols (DRT, Les Dérivés Résiniques et Terpéniques, Dax cedex, France) and rapeseed oil (RSO), anhydrous milk fat (AMF), hydrogenated coconut oil (HCO) and refined palm kernel oil (RPKO) as fat/oil phases. In brief, the mixtures of fat/oil and phytosterols were heated to 100–110°C to form a clear solution and then cooled to about 90°C. During cooling boiled water was added and the suspension was stirred until it reached room temperature. Two phytosterol concentrations in these suspensions were used: 18 and 30%; the main sterols were sitosterol (77%) and campesterol (8%). All suspensions were produced on a pilot scale (13 kg). Suspensions were packed into 100-g food-grade polyethylene bags and stored in a refrigerator (4±2°C) for 12 months. Phytosterol and phytosterol oxide concentrations in these suspensions were analysed in triplicate at 3-month intervals.

Preparation and storage of phytosterol-enriched whole milk powder

Phytosterol-enriched whole milk powder was kindly donated by Teriaka Ltd. (Vantaa, Finland). Whole milk powder was produced on a pilot scale (1 kg), with a microcrystalline phytosterol suspension in anhydrous milk fat serving as the phytosterol ingredient. At first, skimmed milk powder was added to the milk with a Limitech mixer (Limitech A/S, Denmark) and pasteurized. Phytosterol ingredient was heated to 70°C and lecithin was added. This mixture was then emulsified to milk by using a Limitech mixer and a Silverson high shear mixer (Silverson Machines Ltd., UK).

Milk powder was produced by spray-drying using a Damrow Filterlab dryer (Damrow, WI, USA). In brief, concentrated milk emulsion was stirred with a Ultra Turrax T50 high shear mixer (IKA Labortechnik, Germany) and then transferred to a water jacket vessel with an agitator and heated to 50–58°C. The emulsion was pumped with a high pressure pump through the pipes to the spray nozzle. Milk was sprayed to the drying chamber, where it was introduced to hot air (165–192°C) above a bolt cloth. The milk powder was separated from the air with the bolt cloth, and cooled air was conducted below the bolt cloth back to the heater. Concentrated milk was dried until the bolt cloth was full. The Filterlab dryer was then stopped, and milk powder was scraped out of the bolt cloth. Milk powder was packed into 20-g aluminium laminate bags.

The phytosterol content in the enriched whole milk powder was approximately 7%, and the main sterols were sitosterol (73%) and campesterol (9%). Milk powders were stored at room temperature (approximately 22°C) and slightly elevated temperature (38±1°C) for 12 months. Powders were analysed for phytosterol and phytosterol oxide concentrations in triplicate at 3-month intervals.

Preparation and storage of milks enriched with free and esterified phytosterols and phytostanyl esters

Non-fat cow's milk (from MTT Agrifood Research, Jokioinen, Finland) was enriched with free phytosterols, phytosteryl esters or phytostanyl esters at a level equivalent to 0.4, 0.5, and 0.5% sterol/stanol, respectively. Free phytosterols were wood-based sterols (DRT, Les Dérivés Résiniques et Terpéniques, Dax cedex, France) consisting mainly of sitosterol (78%) and campesterol (9%). Phytosteryl and phytostanyl ester preparates were mixtures prepared by Raisio Benecol Ltd. (Raisio, Finland) from soybean oil originated sterols and rapeseed oil fatty acids. The main phytosterols in the steryl ester preparate were sitosterol (45%), campesterol (25%) and stigmasterol (18%), whereas the phytostanyl ester preparate consisted of sitostanol (65%) and campestanol (33%).

Phytosterol/stanol enrichments of milk were performed on a pilot scale (milk volume in each batch was 5 l). Milk was heated to 70°C, and Dimodan® S-T Pel (distilled monoglycerides) (Danisco, Denmark) was added to a level of 0.4% as an emulsifier. Esterified phytosterols/stanols melted in a microwave oven and free phytosterols were then added. Finally, enriched milks were homogenized twice (190/40 bar) using an Armfield FT9 Homogenizer (Armfield Ltd., UK). To improve the durability of enriched milks, heat treatment at 127°C for 2 s was applied using an Armfield FT74 UHT/HTST System (Armfield Ltd., UK). Milks were packed into sterile 100-ml glass containers and stored in the dark at room temperature (approximately 20°C) and in a refrigerator (4±2°C) for 6 months. Milks enriched with free phytosterols and phytosteryl esters were analysed for phytosterols and phytosterol oxides at 1.5-month intervals, and milks enriched with phytostanyl esters at 3-month intervals. Two batches of milks were stored, and analyses were performed in duplicate (phytosterol oxides) or triplicate (phytosterols).

Determination of phytosterols / stanols in food samples

Phytosterol / stanol contents in food samples and raw materials were analysed by a Hewlett Packard 5890 Series II gas chromatograph (GC) (Karlsruhe, Germany) equipped with a flame ionization detector (FID) and an Rtx-5 w/ Integra Guard (crossbond 5% diphenyl – 95% dimethyl polysiloxane) capillary column (Restek, Bellefonte, PA, USA) [14]. Samples were prepared using published methods for hot saponification and extraction of unsaponifiables [14, 15] with certain modifications. The amounts of the food samples (0.1–1 g) and dihydrocholesterol (0.8–1.6 mg) (Sigma, St. Louis, MO, USA) as an internal standard were adjusted to the expected amounts of phytosterols. Samples that contained ≤40% of fat were extracted with cyclohexane (from Rathburn Chemicals, Walkerburn, Scotland) instead of hexane/diethyl ether (1/1, v/v) [14]. Heat-treated milks were also tempered at 40°C for 45 min before being subjected to phytosterol analysis. To confirm the day-to-day repeatability of the method, an in-house control sample (sitosterol-enriched rapeseed oil) was analysed in each sample batch. The coefficient of variation (CV) for the sitosterol determination in these samples was 4% (n=54).

The limit of determination for phytosterols in GC–FID analysis was 2 mg/100 g of product for samples containing >1% phytosterols, and 0.5 mg/100 g of product containing <1% phytosterols [15]. The performance of GC–FID was evaluated daily using a sterol standard mixture. The assessment of whether the performance was acceptable was based on the area ratio between cholesterol and cholestanol in the mixture. Ratios that were within two standard deviations of the mean value (n=35) were considered acceptable.

Determination of phytosterol / stanol oxides in food samples

The contents of phytosterol/stanol oxides in microcrystalline phytosterol suspensions and raw materials were analysed by the aforementioned GC–FID equipment as presented by Lampi et al. [14]. In the case of enriched milk powders and milks, some unknown impurities eluted in GC–FID analyses, interfering with the determination of phytosterol oxides. Thus, an earlier published gas chromatographic–mass spectrometric (GC–MS) method based on selected ion monitoring (SIM) [13, 16] was applied for separation, detection, and quantification of phytosterol oxides formed in these enriched dairy products. The GC–MS equipment consisted of a Hewlett Packard 6890 Series gas chromatograph (Wilmington, PA, USA) coupled to an Agilent 5973 mass spectrometer (Palo Alto, CA, USA). An Rtx-5MS w/Integra Guard (crossbond 5% diphenyl – 95% dimethyl polysiloxane) capillary column (Restek, Bellefonte, PA, USA) was used [16].

Samples for GC–FID and GC–MS analyses were prepared starting with an internal standard addition (19-hydroxycholesterol from Sigma, St. Louis, MO, USA) and direct cold saponification followed by extraction of unsaponifiables, purification of phytosterol oxides by SiOH solid phase extraction (500-mg cartridges from Varian, Harbor City, CA, USA) and conversion of oxides to trimethylsilyl ethers by procedures described previously [13, 14]. However, the following exceptions were made: the amounts of food samples (0.1–1 g) and internal standard (19-hydroxycholesterol) (1.8–20 μg) were adjusted to the expected amounts of phytosterols and possible phytosterol oxides in the sample.

The main phytosterol oxides formed, 7α- and 7β-hydroxysterols, 5α, 6α- and 5β, 6β-epoxysterols and 7-ketosterols, were used as markers of phytosterol oxidation. In the GC–FID method, these oxides were quantified using a general relative response factor of 1.00 which was confirmed using commercially available cholesterol oxidation products [14]. The limits of determination in GC–FID analyses were 5 μg/g of product for 7-hydroxysterols and 5, 6-epoxysterols, and 10 μg/g of product for 7-ketosterols. In the GC–MS method, the quantification was performed indirectly via GC–FID, as described previously [13, 16], using the following target and qualifier ions: m/z 353.3 and 366.4 (19-hydroxycholesterol, internal standard), m/z 484.4 and 485.4 (7α- and 7β-hydroxysitosterol), m/z 502.5 and 412.4 (5α, 6α- and 5β, 6β-epoxysitosterol) and m/z 500.4 and 395.4 (7-ketositosterol), respectively. The determination limits for 7-hydroxysterols, 5, 6-epoxysterols and 7-ketosterols were the lowest levels on the calibration curves, with ranges of 4–8, 9–15 and 9–10 μg/g of product in milk powders, and 0.2–0.3, 0.4–0.6 and 0.4 μg/g of product in milks, respectively.

7α- and 7β-hydroxystanols, 6α-hydroxystanol and 15α-hydroxystanol [16] were used as markers of sitostanol oxidation on the basis of their separation and abundances in GC analysis [16]. The quantification of trimethylsilyl (TMS) derivatives of these compounds was achieved by SIM acquisition of the following target and qualifier ions: m/z 353.3 and 366.3 (19-hydroxycholesterol, internal standard), m/z 486.4, 487.4 and 471.3 (7α-hydroxysitostanol), m/z 486.4, 487.4 and 471.4 (7β-hydroxysitostanol), m/z 204.1, 205.1 and 191.1 (6α-hydroxysitostanol), and m/z 269.2, 270.2 and 486.4 (15α-hydroxysitostanol). The limits of determination were the lowest levels on the calibration curves, thus being 0.03 μg/g (7α-hydroxysitostanol), 0.02 μg/g (7β-hydroxysitostanol), 0.06 (6α-hydroxysitostanol) and 0.01 μg/g (15α-hydroxysitostanol) of product.

To confirm the day-to-day repeatability of the method, the in-house control sample, cholesterol oxides in whole egg powder, stored at −70°C, was analysed in each sample batch. CV value for the determinations of total amount of 7α- and 7β-hydroxycholesterols and 7-ketocholesterol in this powder was 6% (n=27). Furthermore, the performances of GC–FID and GC–MS were monitored daily using a sterol standard mixture. The assessment of whether the performances were acceptable was based on the area ratio between cholesterol and cholestanol in this mixture. Ratios that were within two standard deviations of the mean value (n=35) were considered acceptable. In the case of GC–MS, the mass spectrum of stigmasterol added in the aforementioned mixture was also monitored and evaluated daily.

Results

The main phytosterol in all studied food applications enriched with phytosterols was sitosterol. In phytostanyl ester-enriched milks, the main stanol was sitostanol. Due to these phytosterol/stanol compositions, only sitosterol or sitostanol oxides were observed in quantifiable amounts. In enriched milk powders and milks, campesterol oxides were also detected, but their amounts remained under the determination limits set.

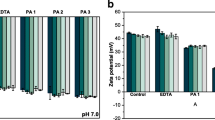

In addition to quantified sitosterol oxides, 7α- and 7β-hydroxysitosterols, 5α, 6α- and 5β, 6β-epoxysitosterols and 7-ketositosterol, also 6-ketositostanol, 25-OH-sitosterol and 3β,5, 6β-sitostanetriol were detected in enriched milk powders, 6-ketositostanol and 25-OH-sitosterol in microcrystalline phytosterol suspensions in different oils and 6-ketositostanol in milks enriched with free phytosterols (Fig. 1). All oxidation products were identified by their elution order and mass spectral properties [14, 17, 18]. Of these oxidation products, 6-ketositostanol seemed to be strongly characteristic to wood sterol preparation used here. The amount of 6-ketositostanol did not increase during storage, but its initial amount in enriched milks, milk powders and microcrystalline phytosterol suspensions was higher than that of other oxidation products.

In phytostanyl ester-enriched milk, although only 6α-hydroxysitostanol was observed at a quantifiable level, 7α-hydroxy, 7β-hydroxy and 7-ketositostanol [16] were detected as well. However, in this study the use of 6α-hydroxysitostanol as a marker of sitostanol oxidation might be a bit controversial since as described later in this article no differences were observed in the sitostanol oxide contents of milks as compared with raw material and the stored sample. This indicates that 6α-hydroxysitostanol may have been derived from the rapeseed oil used in the esterification process of the phytostanyl ingredient. Previous studies have shown that 6-hydroxysitostanols are present in refined rapeseed oils [18, 19].

All results concerning phytosterol oxidation were calculated as “oxidized phytosterol μg/g of food product”, and also as “percentages of phytosterol oxides of unoxidized phytosterol at that time point”. As our food applications were enriched with many different phytosterol levels, the oxidation percentages enabled comparison between different food applications.

Oxidative stability of phytosterols in microcrystalline suspensions in different fats/oils

Phytosterols in microcrystalline suspensions in different fats/oils were stable at 4°C during the 12-month storage period (Tables 1 and 2). At any given time point, total contents of sitosterol oxides were virtually the same as during the initial state. Oxides were measured ranging from “not determined” to 54.2 μg/g of product in suspensions containing 18% phytosterols and from 26.7 to 108.9 μg/g of product in suspensions containing 30% phytosterols. Occasionally, a decrease in the level of total sitosterol oxides was observed (e.g. in 18% phytosterols in AMF stored for 3 months). The explanation for this likely lies in the closeness of the amounts of individual oxides to the determination limits.

Of the quantifiable oxides, the main sitosterol oxides in all suspensions studied were 7β-hydroxysitosterol and 5α, 6α- or 5β, 6β-epoxysitosterols. The amounts of 7α-hydroxysitosterol and 7-ketositosterol were slightly lower, and in the samples containing 18% phytosterols in RSO and AMF their amounts remained under determination limits throughout the storage period.

In suspensions containing 18% phytosterols, sitosterol was more oxidized in HCO and RPKO than in RSO and AMF matrices (Table 1). In suspensions containing 30% phytosterols, the situation was the opposite; sitosterol was more oxidized in RSO and AMF than in HCO and RPKO matrices (Table 2). As these results were somewhat conflicting, no conclusions about the effect of different lipid matrices on sitosterol oxidation could be made. However, since no increase in the initial sitosterol oxide contents was observed during this 12-months storage, we concluded that differences in aforementioned initial oxide contents partly derived from the phytosterol preparation used in the enrichments, although the same preparation lot was used in all products. However, different lipid matrices may also affect sterol oxidation; Nielsen et al. [20] observed that the accumulation of cholesterol oxides in dairy spread (butter/rapeseed oil mixture) was higher than in butter when these were stored at 4°C for 13 weeks. They speculated that the difference in stability was probably due to the higher unsaturation degree of lipids in dairy spread.

The aforementioned differences in initial sitosterol oxide contents indicated that the processing method used for the preparation of these phytosterol suspensions had also caused some sterol oxidation depending on the lipid matrix. However, because the measured phytosterol contents were so close to added levels (18 or 30%), we concluded that only negligible changes in initial phytosterol contents had occurred during processing. At the beginning and after 12 months of storage, the phytosterol contents were 18.5±0.4 and 18.4±0.1, 17.9±0.2 and 17.9±0.0, 18.2±0.2 and 18.8±0.0, and 18.1±0.2 and 18.4±0.6 g/100 g of product in RSO, AMF, HCO and RPKO enriched with 18% phytosterols, respectively. In suspensions containing 30% phytosterols, the corresponding contents were 30.3±0.2 and 29.8±0.1, 29.9±0.6 and 29.4±0.3, 30.5±0.1 and 30.0±0.4, and 30.4±0.1 and 29.9±0.1 g/100 g of product. These results also confirm that no loss in initial phytosterol content had occurred during the 12 months of cold storage.

Oxidative stability of phytosterols in whole milk powder

Table 3 shows that phytosterols were stable at room temperature during the 12-months storage period. However, phytosterol oxidation was slightly affected by storage temperature. Sitosterol oxidized more rapidly at an elevated temperature (38°C) than at room temperature (22°C). During storage at 38°C, the content of sitosterol oxides increased to more than twice the initial content, i.e. from 14.0 to 33.9 μg/g of milk powder (Table 3). In addition, more phytosterol oxides were generated during storage than during spray-drying; at the beginning of storage, the level of oxidation in milk powder was 0.03%, i.e. no changes were observed when compared with initial oxidation levels of similar phytosterol ingredients (phytosterols in AMF) used in enrichment (Tables 1 and 2).

The accumulation of quantifiable sitosterol oxides in milk powders consisted of only 7α- and 7β-hydroxysitosterols the latter being the main oxide throughout the storage period at both temperatures. The amounts of 5, 6-epoxysitosterols and 7-ketositosterol remained under the determination limits.

Despite differences in sitosterol oxide contents at different storage temperatures, no differences were observed in corresponding phytosterol contents of milk powders. At the beginning of storage, the phytosterol content in milk powders was 6.9±0.1 g/100 g of powder, and after 12 months of storage 6.6±0.1 g/100 g of powder at room temperature and 6.6±0.0 g/100 g of powder at 38°C. However, a slightly higher loss in total phytosterol contents was observed in storage of milk powder than in storage of phytosterol suspensions in different fats/oils or in storage of heat-treated milks enriched with free and esterified phytosterols, as described in more detail in subsequent sections.

The observed changes in phytosterols were lower than predicted. In general, because of their large surface area, powders are known to be susceptible to lipid oxidation as an interfacial phenomenon. This may be due to greater oxygen diffusion [21] and closer contact of oxidizable lipids and metals as pro-oxidants [1]. The milk powder here was made from whole milk, and this may have affected lipid, including phytosterol, oxidation. Dried whole milk has been demonstrated to be a much more unstable product than non-fat milk products [21], and lipid oxidation, especially, is one of the main phenomena causing problems during storage of fat-containing powders [22]. Different preheat treatments of milk (low-, medium- or high-heat treatment) [23, 24], quality of packaging materials [24] and packaging conditions, e.g. use of vacuum packaging [23] or packaging under inert gas [25, 26], can also affect the rate of oxidation of sterols in milk powders.

Based on our previous studies of phytosterol oxidation, the oxidative reactions occurring during the spray-drying and subsequent storage conditions of phytosterol-enriched milk powders in this study can be considered to be rather insignificant. In our model system studies [12, 13], the oxidation percentages of phytosterols at the beginning of different heat treatments have been 0.1–0.3% indicating that more phytosterol oxides are derived from raw materials than from the food process described above.

Oxidative stability of phytosterols/stanols in heat-treated milks

Non-fat milks enriched with free or esterified phytosterols or with phytostanyl esters also contained only low levels of phytosterol/stanol oxides (Table 4). The highest oxide contents observed in these milks were 2.18, 2.37 and 0.28 μg/g of product, respectively. Taking into account the oxide contents at the beginning of storage and the rather large standard deviations due to low oxide levels, no significant changes in the amounts of sitosterol/stanol oxides could be observed during the 6-month storage at room temperature or at 4°C. Between the different phytosterol ingredients, larger differences were, however, observed in their susceptibility to oxidation. Sitostanol seemed to be much more stable than sitosterol, and sitosterol was slightly more stable in free than in esterified form. These results are consistent with our previous studies conducted with bulk lipid models [12, 13].

The major sitosterol oxides found in these milk samples were 7α- and 7β-hydroxysitosterols and 7-ketositosterol. In milks enriched with free sitosterol, 7-ketositosterol was the predominant product throughout storage. In milks enriched with phytosteryl esters, the main products were 7-hydroxysitosterols. 5, 6-Epoxysitosterols were also detected in all samples, but their amounts remained under determination limits. In phytostanyl ester-enriched milks, the only sitostanol oxide found above the determination limit was 6α-hydroxysitostanol.

Interestingly, the heat treatment (127°C for 2 s) appeared to slightly enhance sitosterol oxidation. This can be concluded from the oxidation percentages calculated for raw materials used in enrichments; in free phytosterol and phytosteryl and phytostanyl ester preparates, 0.04, 0.02 and 0.01% of sitosterol/stanol was oxidized, respectively. Thus, in phytostanyl ester-enriched milk, no change in oxidation percentage was observed during heat treatment and subsequent storage, but in milks enriched with free phytosterols or phytosteryl esters, these percentages increased two-fold (0.07–0.08%) and even five-fold (0.09–0.11%), respectively (Table 4). As mentioned earlier, these results also indicate that sitosterol oxidized more in esterified than in free form.

Another aspect of the oxidative behaviour of phytosterols in enriched heat-treated milks is the changes observed in initial phytosterol contents. At the beginning of storage, phytosterol contents in milks enriched with free phytosterols, phytosteryl or phytostanyl esters were 358±8.5, 456±2.4, and 473±6.7 mg/100 g of product, respectively. After 6 months of storage, the corresponding sterol contents at room temperature were 349±0.6, 409±21.8 and 464±1.8 mg/100 g of product, and at 4°C 347±10.0, 450±2.9 and 457±5.9 mg/100 g of product, respectively. Thus, changes were rather similar at both temperatures.

Despite our samples containing much higher amounts of phytosterols than the amount of native cholesterol contained by non-fat cow's milk, one comparison was made between our results and findings in natural products. Cleveland and Harris [27] studied cholesterol oxides in pasteurized whole milk, ultra-high temperature (UHT)-treated milk, canned evaporated milk and skim milk. They found no evidence of cholesterol oxides in these products when examined immediately after purchase from the supermarket. Storage of the sterol fraction of whole milk at 5°C for 2 months, by contrast, led to formation of cholest-4-en-3-one and cholest-3,5-dien-7-one. No quantitative research was, however, conducted.

The slight changes in phytosterol oxide and initial phytosterol contents during heat treatment were predictable since milk as an oil-in-water emulsion can be susceptible to oxidation of lipid compounds due to the large interfacial area between oil and water. However, the changes observed here were rather small. We predicted that more phytosterol oxides would have been formed in phytosteryl ester-enriched milk due to the addition of unsaturated fat provided in the form of unsaturated fatty acid moieties in steryl ester molecules.

Finally, our results demonstrate that exposure to phytosterol oxides from phytosterol/stanol-enriched heat-treated milks, phytosterol-enriched whole milk powders or microcrystalline phytosterol suspensions in different fats/oils is unlikely to represent an important source of phytosterol oxides. Furthermore, the formation of phytosterol oxides does not seem to be a limiting factor for manufacture and subsequent storage of these products. Based on our observations, the deterioration of sensory quality of milks, milk powders and phytosterol suspensions in different oils, mainly in RSO and AMF, occurs long before any significant quantities of phytosterol oxides are present.

References

Frankel E (1998) Lipid oxidation. The Oily Press Ltd, Dundee, Scotland

Tomoyori H, Kawata Y, Higuchi T, Ichi I, Sato H, Sato M, Ikeda I, Imaizumi K (2004) J Nutr 134:1690–1696

Maguire L, Konoplyannikov M, Ford A, Maguire AR, O'Brien NM (2003) Br J Nutr 90:767–775

Grandgirard A, Martine L, Demaison L, Cordelet C, Joffre C, Berdeaux O, Semon E (2004) Br J Nutr 91:101–106

Smith LL (1987) Chem Phys Lipids 44:87–125

Lingnert (1992) Influence of food processing on lipid oxidation and flavor stability. In: St. Angelo AJ (ed) Lipid oxidation in food. American Chemical Society, Washington, DC, USA, pp 292–301

Roozen JP, Linssen JPH (1992) Factors affecting lipid autoxidation of a spray-dried milk base for baby food. In: St. Angelo AJ (ed) Lipid oxidation in food. American Chemical Society, Washington, DC, USA, pp 302–309

Katan M, Grundy S, Jones P, Law M, Miettinen T, Paoletti R (2003) Mayo Clin Proc 78:965–978

SCF (2000) Opinion of the scientific committee on food on a request for the safety assessment of the use of phytosterol esters in yellow fat spreads, SCF/CS/NF/DOS/1 Final. European Commission, Brussels, Belgium

SCF (2003) Opinion of the scientific committee on food on applications for approval of a variety of plant sterol-enriched foods, SCF/CS/NF/DOS/15 ADD 2 Final. European Commission, Brussels, Belgium

Christiansen L, Rantanen J, von Bonsdorff A, Karjalainen M, Yliruusi J (2002) Eur J Pharm Sci 15:261–269

Soupas L, Juntunen L, Lampi A-M, Piironen V (2004) J Agric Food Chem 52:6485–6491

Soupas L, Huikko L, Lampi A-M, Piironen V (2005) Eur J Lipid Sci Technol 107:107–118

Lampi A-M, Juntunen L, Toivo J, Piironen V (2002) J Chromatogr B 777: 83–92

Piironen V, Toivo J, Lampi A-M (2002) Cereal Chem 79:148–154

Soupas L, Juntunen L, Säynäjoki S, Lampi A-M, Piironen V (2004) J Am Oil Chem Soc 81:135–141

Dutta PC, Appelqvist L-Å (1997) J Am Oil Chem Soc 74:647–657

Grandgirard A, Martine L, Joffre C, Juaneda P, Berdeaux O (2004) J Chromatogr A 1040:239–250

Lambelet P, Grandgirard A, Gregoire S, Juaneda P, Sebedio J-L, Bertoli C (2003) J Agric Food Chem 51:4284–4290

Nielsen J, Olsen C, Jensen C, Skibsted L (1996) J Dairy Res 63:159–167

Labuza T (1971) Crit Rev Food Technol 2:355–405

Belitz H-D, Grosch W (1999) Food chemistry, 2nd edn. Springer-Verlag, Berlin Heidelberg, Germany

Mc Cluskey S, Connolly J, Devery R, O'Brien B, Kelly J, Harrington D, Stanton C (1997) J Food Sci 62:331–337

Tai C-Y, Chen Y, Chen B (2000) J Food Drug Anal 8:1–15

Angulo A, Romera J, Ramirez M, Gil A (1997) J Agric Food Chem 45: 4318–4323

Rose-Sallin C, Huggett A, Bosset J, Tabacchi R, Fay L (1995) J Agric Food Chem 43:935–941

Cleveland M, Harris N (1987) J Food Prot 50:867–871

Acknowledgements

The authors thank Leena Morander from Teriaka Ltd., Päivi Laakso from Raisio Benecol Ltd., Tuomo Tupasela and Juha Lundström from MTT Agrifood Research, for help in carrying out this study. We also thank Saara Jouhtimäki, Susanna Sundberg, Marjo Toivo and Katariina Usano, for technical assistance. Financial support from the National Technology Agency of Finland, four Finnish food companies, and the Finnish Graduate School on Applied Biosciences, is gratefully acknowledged

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soupas, L., Huikko, L., Lampi, AM. et al. Oxidative stability of phytosterols in some food applications. Eur Food Res Technol 222, 266–273 (2006). https://doi.org/10.1007/s00217-005-0031-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-005-0031-0