Abstract

The effects of soy protein isolate (SPI), whey protein isolate (WPI) and egg albumen (EA) on the quality of deep-fat-fried chicken nuggets were studied. Batter without protein addition was used as a control. Batter pickup and moisture content, oil content, texture, porosity and colour of the nuggets were determined for 3, 6, 9 and 12 min of frying at 180 °C. Additionally, the rheological properties of batters were studied. SPI (3%) provided the highest apparent viscosity and coating pickup. All the batters showed shear-thinning behaviour except EA-added batter. Addition of different proteins to the batter formulation decreased the oil content of the final product. EA reduced the oil content of chicken nuggets significantly but yielded softer products. WPI (3%) was found to be the most effective ingredient on improving quality parameters of deep-fat-fried chicken nuggets. WPI (3%) added batters provided the hardest and crunchiest product with the darkest colour and also significantly reduced the oil content of the fried nuggets.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coating the surfaces of products using batters in deep-fat frying is a common and popular process. The coating adds value to the product not only by controlling moisture loss and so oil uptake during frying, but also by providing nutrition, a crisp texture and the desired colour to the fried products. The recent trend in reducing the fat content in fried foods is leading to the development of low-fat products by using batter formulations with specific ingredients.

A typical batter formulation consists of wheat flour, corn flour and a leavening agent as critical ingredients to which other flours, starches, gums, proteins, colorants and flavourings can be added as optional ingredients [1].

Proteins represent the most important class of functional ingredients because they possess a range of dynamic functional properties such as gelation, structure formation, colour, texture, thickening, emulsification, foaming and elasticity. They show versatility during processing, they can form networks and structures and they provide essential amino acids, so they fulfil functional and nutritional requirements. In addition, they interact with other components and improve quality attributes of foods [2].

There are studies reported in the literature showing the effects of different proteins used in batter formulations. Soy protein isolate (SPI) and whey protein isolate (WPI) were shown to reduce oil uptake of cereal products during frying [3]. A soy protein film coating provided fat reduction in deep-fat frying of doughnut and potato as well [4]. In a comparison of egg yolk, gluten, skimmed milk, whey and ovalbumin with respect to their effects on oil absorption and texture, ovalbumin was able to reduce oil absorption and improve the crispness of the fried batter [5]. Adhesion of a coating to food products is also an important quality parameter. Gelatin and egg albumen were found to be more effective than soy, whey and nonfat dry milk in improving adhesion [6].

Batter viscosity determines the way the batter flows on the product before it enters the fryer. The apparent viscosity of flour-based batters was positively correlated with batter adhesion [7]. Therefore, studying the rheological behaviour of different formulations of batters is important.

The properties that determine the overall quality of a fried food product include moisture content, colour, oil content, flavour, texture, yield, nutritive value and shelf-life stability [8].

The main objective of this study was to evaluate the effects of different protein types at different concentrations on the quality of deep-fat-fried chicken nuggets and to determine the best coating formulation. Another objective of this study was to investigate the effects of batter consistency on frying performance in chicken nuggets.

Materials and methods

Materials

Three types of proteins i.e., SPI (Protient, USA), WPI (Protient, USA) and egg albumen powder (EA) (Instant High Gel EAP-HG, Belovo, Belgium), were used in the experiments. Wheat flour (containing 31.5% wet gluten), corn flour, sunflower oil, chicken parts and all other ingredients used for the experiments were supplied from the local market.

Sample preparation

Breast portions of chicken were stored at -15 °C for up to 2 months prior to use. Frozen samples were thawed at 10 °C in the refrigerator before the experiments. Samples 4 cm in diameter and 1.5 cm in thickness were cut using a manually operated cutting device. The uniformity of the thickness of the samples was checked by using a micrometer (Mitutoyo, Japan). Each sample was weighed before being dipped into batter to ensure a uniform range of 0.013±0.002 kg.

The batter formulations were composed of solid and water in a ratio of 3:5. The solid content of the batter formulations contained equal amounts of corn and wheat flour. In addition, 1.0% salt and 0.5% leavening agent were added to the formulation. To determine the effects of protein types on deep-fat-fried chicken nuggets, 1% or 3% of flour mix was replaced with different protein types. As a control, batter without protein addition was used. The batters were prepared by mixing the dry ingredients with water at 45±1 °C for 30 s with a mixer at the lowest speed (Arçelik ARK55 MS, Turkey) to ensure uniform mixing. Chicken samples were immersed individually into the batter suspensions for 10 s immediately after preparation of the batter and were weighed again to determine the coating mass before frying.

Analysis of batter

The water binding capacities of proteins and the corn–wheat flour mix were measured using the method of Medcalf and Gilles [9]. The amount of batter adhering to the sample during immersion coating before frying was considered as the batter pickup and was calculated as the weight of the coating picked up by a nugget divided by the uncoated nugget weight and multiplied by 100. The weight of the coating picked up by a nugget was determined from the decrease in the weight of the batter suspension after coating a chicken piece.

The flow behaviours of the batters were investigated at 45±1 °C with a parallel-plate rotational viscometer (Haake model CV20, Germany). Immediately after preparation of the batter, the sample was placed within a 1-mm gap sample load. The sample was sheared at a programmed rate linearly increasing from 0 to 200 s−1 in 300 s.

Frying

Samples were deep-fat fried at 180 °C in commercial bench-top deep-fat fryer (Moulinex, France) containing 2.5 l oil. A copper/constantan thermocouple was connected to the fryer to measure the temperature. Only four pieces were deposited into the frying oil each time. Samples were fried for 3, 6, 9 and 12 min. After each frying batch, the oil level was checked and the oil was replaced after 6-h frying.

Analysis of fried samples

The texture of the samples was analysed in terms of hardness and fracturability. Hardness is defined as the peak force during the first compression cycle, while fracturability (brittleness) is the force at the first significant break in the first positive bite area of the texture profile analysis curve. These were measured in the fried samples 40 min after frying, using a texture analyser (Lloyd Instruments, TA Plus, UK). A load cell of 50 N was used. A conical probe (D=1.6 cm, H=1.5 cm) was attached to the instrument for the penetration test. The instrument was set to a speed of 55 mm min−1 for 25% penetration of a conical probe into the fried sample.

For moisture determination, the whole fried samples were dried in a forced convection oven at 105 °C to achieve constant weight [10]. The oil content of the fried samples was determined by extracting with n-hexane using Soxhlet extraction for 6 h [10].

Porosity was estimated using bulk and particle densities of the sample [11]. The bulk density was measured by the liquid displacement method, where paraffin was used as a liquid to prevent its absorption by the samples. The particle density was determined by the gas displacement method with a nitrogen stereopycnometer (Quantachrome, USA).

The colour of the fried chicken samples was measured using a Minolta colour reader (CR-10, Japan) using the CIE Lab L*, a* and b* colour scale. Triplicate readings were carried out at room temperature on three different locations of each sample, and the mean value was recorded.

Statistical analysis

All analyses were done at least four times under each experimental condition and mean values were reported. The data were evaluated by using analysis of variance in order to determine the significant differences between the effects of protein types on quality parameters of deep-fat-fried chicken nuggets. If a significant difference was found, the treatments were compared using Duncan’s multiple comparison test (p≤0.05). Correlation was obtained to relate moisture content to oil content.

Results and discussion

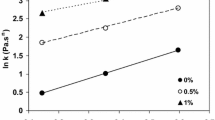

The apparent viscosities of different batter formulations are shown in Fig. 1. Experimental data provided a good fit (r2≥0.948) for the power-law model;

Changes in batter viscosity with shear rate for different protein types at different concentrations. 3% whey protein isolate (WPI) (◆), 1% WPI (□), 3% soy protein isolate (SPI) (▲), 1% SPI (+), 3% egg albumen powder (EA) (○), 1% EA (*), control (–). Markers represent the experimental data; lines represents the power-law model.

The flow behaviour and consistency indices of the batters are given in Table 1. All the batters show shear-thinning behaviour except EA-added batters, which showed shear-thickening. Batters to which SPI was added showed higher consistency owing to the high water binding capacity of SPI (Table 2).

SPI, which had the highest apparent viscosity, showed the highest pickup to the fried product (Fig. 2). WPI and EA addition reduced the coating pickup of deep-fat-fried chicken nuggets compared with that of the control formulation owing to their low apparent viscosities. Increasing the SPI concentration from 1 to 3% in the batter formulation increased coating pickup, while the same increase in WPI and EA concentration in the batter formulation resulted in a decrease in coating pickup. This shows that gluten is more effective than WPI and EA for increasing the consistency. Therefore, adequate consistency for batters to coat foods was lost when the corn and wheat flour mixture was replaced partly by WPI or EA.

The effects of protein types at different concentrations on the texture of deep-fat-fried chicken nuggets were examined in terms of hardness and fracturability (Figs. 3, 4). In general, both hardness and fracturability increased with increasing frying time. The initial moisture content was found to be inversely related to the force required to break the matrix [12]. Thus, the differences in the water binding capacities of the batters resulted in different texture values during frying. According to that, 3% SPI added batter was found to provide a softer texture during the initial frying period with respect to the control and other ingredients (Fig. 3). However, after 12 min of frying, it was one of the formulations giving the highest hardness value owing to its film-forming ability. Heat-induced cross-linking in the SPI structure contributed to the increase in toughness. WPI-containing batters (3%) provided significantly different hardness and fracturability values than control formulation (Figs. 3, 4). This may be due to the formation of intermolecular disulfide cross-links in whey protein.

Effects of different protein types at different concentrations on the fracturability of deep-fat-fried chicken nuggets during frying. 3% WPIa (◆), 1% WPIab (□), 3% SPIbc (▲), 1% SPIdc (+), 3% EAd (○), 1% EAd (*), controldc (–). Formulations having different letters are significantly different (p≤0.05).

The effect of protein types on the moisture content of deep-fat-fried chicken nuggets is given in Fig. 5. The control batter lost the highest amount of water during frying. Addition of EA to the batter formulation increased the moisture retention significantly compared with the control. This may be due to the more hydrophobic nature of EA. WPI (3%) added batters gave the highest moisture retention value after 12 min of frying, which can be considered as the optimum frying time for an acceptable product. The potential formation of intermolecular disulfide cross-links in whey protein films might have improved the barrier properties of the WPI-added batter for water vapour.

Effects of different protein types at different concentrations on the moisture content of deep-fat-fried chicken nuggets during frying. 3% WPIab (◆), 1% WPIab (□), 3% SPIab (▲), 1% SPIab (+), 3% EAa (○), 1% EAa (*), controlb (–). Formulations having different letters are significantly different (p≤0.05).

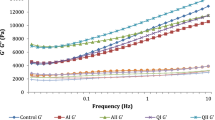

Addition of different proteins at different concentrations to the batter decreased the oil content of the final product (Fig. 6). Less oil absorption may be related to the formation of covalent links within films during heating. The reduced oil uptake may also be related to thermal gelation and the film-forming ability of proteins. The oil content was found to be correlated with the moisture content (r=0.89). Previously, a linear relationship between oil uptake and water removal had been reported [13]. WPI- and EA- added batters provided the least oily products. The improved water vapour barrier properties of WPI-added batter caused a reduction in oil absorption into the product. Ovalbumin, the main protein in egg albumen, was also reported to reduce the oil uptake of the fried product, probably owing to its lipophobic nature [14].

The development of porosity in foods, in general, depends on the initial moisture content and the composition of the material. The effect of protein addition to the batter formulations on the porosity of the samples is shown in Fig. 7. SPI addition at 3% concentration provided the most porous product, while WPI- or EA- added batters were not significantly different from the control as the batters prepared with WPI or EA were not viscous enough to keep the gas within the system. In general, porosity increased during frying.

The effect of protein types on colour development of deep-fat-fried chicken nuggets was examined in terms of CIE Lab L*, a* and b* values. As the frying time increased, the L* value decreased but the a* value increased (Figs. 8, 9). However, there was no significant trend in the variation of the b* value with respect to time. In general, proteins increased browning of the fried batter owing to the Maillard reaction. However, some proteins like EA (3%) and SPI (3%) had lighter-coloured crusts with respect to the control and other coatings. It was also reported that a high proportion of EA in batter formulations for coating chicken nuggets caused problems in colour [15]. WPI (3%) added batters had a significant effect on colour formation of deep-fat-fried chicken nuggets, and produced the darkest colour in terms of lightness and redness.

Conclusion

Addition of different protein types to batter formulations was found to affect both the rheological properties of batter and the quality attributes of deep-fat-fried chicken nuggets. All the batters showed shear-thinning behaviour except EA-added batters. SPI provided the highest apparent viscosity to the batter. Hardness, fracturability and oil content increased, whereas moisture content decreased with respect to frying time.

Batters to which SPI was added showed the highest coating pickup. WPI- and EA-added batters reduced oil absorption significantly. In addition, 3% WPI added batters were significantly effective in improving the colour and texture of deep-fat fried chicken nuggets compared with the control batters. Therefore, WPI can be recommended to be used in batter formulations of chicken nuggets.

References

Loewe R (1990) Ingredient selection for batter systems. In: Kulp K, Loewe R (eds) Batters and breadings in food processing, AAAC, St. Paul, MN, pp 11–28

Kinsella JE, Rector DJ, Phillips LG (1994) In: Yada RY, Jackman RL, Smith JL (eds) Protein structure-Function Relationships in foods. Blackie Academic and Professional, Chapman & Hall, Glasgow, pp 1–13

Albert S, Mittal GS (2002) Food Res Int 35:445–458

Rayner M, Ciolfi V, Maves B, Stedman P, Mittal GS (2000) J Sci Food Agr 80:777–782

Mohamed S, Hamid NA, Hamid MA (1998) J Sci Food Agr 78:39–45

Suderman DR, Wiker J, Cunningham FE (1981) J Food Sci 46:1010–1011

Hsia HY, Smith DM, Steffe JF (1992) J Food Sci 57:16–19, 24

Moreira RG, Castell-Perez ME, Barrufet MA (1999) Deep-Fat Frying fundamentals and applications. Aspen Publishers, Inc., Gaithersburg, Maryland, pp 111–113

Medcalf DG, Gilles KA (1965) Cereal Chem 42:558–567

AOAC 1984 Official methods of Analysis, 14th edn. Assoc of official analytical chemists, Washington, DC

Rahman S (1995) Food properties handbook. CRC Press, USA, pp 180,192

Schiffman RF (1993) The Technology of Microwaveable Coated Foods. In: Kulp K, Loewe R (eds) Batters and breadings in food processing. AAAC, St. Paul, MN, pp 153–162

Gamble MH, Rice P, Selman JD (1987) Int J Food Sci Technol 22:233–241

Kato A, Nakai S (1980) Biochimica et Biophysica Acta 624:13–20

Fiszman SM, Salvador A (2003) Food Sci Technol 14:399–407

Acknowledgements

This research was supported by the Middle East Technical University (BAP-2003-07-02-00-48). Protient is acknowledged for supplying SPI and WPI and Belovo for EA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dogan, S.F., Sahin, S. & Sumnu, G. Effects of batters containing different protein types on the quality of deep-fat-fried chicken nuggets. Eur Food Res Technol 220, 502–508 (2005). https://doi.org/10.1007/s00217-004-1099-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-1099-7