Abstract

The effects of different pectinolytic enzyme treatments on the release of phenolic compounds from blackcurrant berry mash into juice in experimental blackcurrant juice production were examined. The influence of enzyme dose (0–0.1% by weight), degree of berry crushing, maceration time, and temperature on the total phenol concentration, the juice yield, and on polysaccharide degradation were evaluated for four commercial, fungal enzyme preparations in statistically designed experimental templates. In optimal experimental conditions, treatments with Macer8 [FJ] and Pectinex Ultra SP-L released ~6500 and 6650 mg gallic acid equivalents/L of total phenols, respectively. These levels correspond to increases of 14–15% compared to the juice extracted without enzymes, and were significantly higher than those achieved with Rapidase BE Super and Grindamyl pectinase treatments. Increased enzyme dosage gave larger juice yields and higher phenol concentrations. There was a positive, linear correlation between degradation of the substrate polysaccharides and the amount of phenols released. The juice samples inhibited the oxidation of human low-density lipoproteins in vitro in a dose-dependent matter. The non-enzyme-treated sample exhibited higher antioxidant activity than the enzyme-treated juices at equimolar test levels of phenols, presumably because of differences in their phenolic profiles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is now widely recognized that the consumption of fruit and fruit products, as well as of certain plant-based beverages (including tea and wine) helps to protect against the development of cardiovascular diseases and coronary heart disease mortality [1, 2, 3]. The initiation and development of atherosclerosis and coronary heart diseases are believed to originate from the oxidative modification of human low-density lipoproteins (LDL) [4]. The literature suggests that the cardioprotective effects of plant-based foods and beverages are related to the antioxidant activities of ascorbic acid, flavonoids, and other phytochemicals present in these products [2, 5, 6]. Notably, the cardioprotective effects of moderate wine consumption have been linked to the ability of red wine phenolics to retard lipid oxidation in LDL, as demonstrated in vitro [7]. Various phenolic extracts, the juice expelled from different dark red berries, as well as individual flavonoids and other phenolic compounds present in red wines and dark red berries have also been shown to exhibit potent antioxidant activity against the oxidation of human LDL in test tube assays [8, 9, 10, 11]. Blackcurrants are among those berries that contain high amounts of phenolic compounds. Fresh blackcurrants are particularly rich in anthocyanins, notably the glucosides of delphinidin and cyanidin, which may constitute up to 2% by weight of the blackcurrant skins [12, 13]. Other principal phenolics present in blackcurrants include flavonols, procyanidins, and various phenolic acids, particularly hydroxycinnamates (chlorogenic, caffeic, and ferulic acid), and hydroxybenzoates (gallic acid) [12, 13]. Blackcurrants are also high in vitamin C content. In Europe, the annual blackcurrant harvest is around 500,000–600,000 tonnes/year [14]. Only a very small portion is consumed fresh; most is processed for juice concentrate. Therefore, a targeted focus on improving the exploitation of blackcurrants and blackcurrant products as a source of potentially health protective phytochemicals seems warranted.

Since blackcurrants contain relatively high levels of pectin (40% of the primary cell walls [15]), addition of pectinolytic enzyme preparations to degrade the pectin is a prerequisite step for efficient blackcurrant fruit pressing and extraction of high juice yields. Because of the low pH of blackcurrants (pH 2.6–2.8) and the high levels of phenolics that may inhibit the fungal pectinases employed for the maceration, relatively high pectinase dosage levels, ~0.02–0.05% by weight, are used industrially in pre-press blackcurrant juice maceration [16].

The press residues that remain from commercial blackcurrant juice-making are abundant in phenolic antioxidants, and it is possible to enhance their extraction by enzyme-catalyzed degradation of the skin cell wall material [17]. The present study was undertaken to investigate whether enzymatic release of phytochemicals from blackcurrant skins might also be exploited in the active processing of blackcurrant juices. The main objective was to investigate whether the concentration of phenols in blackcurrant juice could be enhanced—without compromising juice yields—by more forced enzymatic maceration treatment of the blackcurrants prior to pressing. A second objective was to evaluate the antioxidant activities of the differently, aggressively enzyme-macerated blackcurrant juice samples on human LDL oxidation in vitro.

The ability of four different plant cell wall-degrading enzyme preparations to increase the juice yield and to release phenols were examined in response to maceration temperature, maceration time, enzyme dosage and degree of substrate crushing in experimental design templates (factorial 24 designs). Subsequently, the influences of enzyme dosage and reaction time were evaluated in regular dose response experiments, and then the effects of extended maceration, degree of berry crushing, and enzyme dosage were examined for the two best enzyme preparations in response surface design experiments. Finally, the antioxidant activities of the juices with the highest levels of phenols were tested on human LDL in vitro, and the phenolic compositions of these juice samples were profiled by HPLC analysis.

Materials and methods

Chemicals and enzymes

Folin-Ciocalteu phenol reagent, sodium carbonate, potassium sodium tartrate copper sulfate, and phosphate buffer salts were obtained from Merck (Darmstadt, Germany). Gallic acid, human LDL, and 3.5-dinitrosalicylic acid were purchased from Sigma-Aldrich (St. Louis, MO). Glucose was from AnalaR BKH Ltd (Poole, UK). The phenolic standard compounds catechin, rutin, and caffeic acid were purchased from Sigma-Aldrich, while cyanidin was obtained from Extrasynthese (Genay, France). Grindamyl pectinase from Aspergillus niger was obtained from Danisco-Cultor Ingredients (Brabrand, Denmark). Macer8 [FJ] from an Aspergillus strain was obtained from Biocatalysts Ltd (Pontypridd, UK). Rapidase BE Super from a selected GRAS strain of Aspergillus niger was from DSM/Gist-brocades France S.A. (Seclin, France). Pectinex Ultra SP-L from Aspergillus aculeatus was obtained from Novozymes A/S (Bagsvaerd, Denmark). Information regarding the enzyme preparations’ activities is given in Table 1. All of the enzymes were employed in liquid preparations and they were selected for this study because they are already used in the juice and wine industry.

Sample preparation

Blackcurrant berries (Ribes nigrum cv. Ben Lomond) were obtained from Vallø Saft A/S (Køge, Denmark) and kept frozen (−20 °C) until use. Prior to maceration the berries were defrosted and either gently crushed or homogenized in order to obtain two pulps that had been crushed to different extents and therefore had different particle sizes. The gentle crushing was done with a stomacher (Laboratory blender, Stomacher 400, Seward Medical, Alaska, USA) and the homogenization was done with a laboratory hammer mill (IKA-Universalmühle H20, Janke & Kunkel, Staufen, Germany). After crushing, the sample material was cooled rapidly under nitrogen, vacuum packed in portions of 10 g, and frozen (−20 °C) until further use.

Maceration

Prior to enzyme hydrolysis the pulp samples (10 g) were defrosted in a thermostatic bath at 20 °C, heated to 80 °C for 1 min, and rapidly cooled to 20 °C. Each enzyme preparation was added at a specific enzyme/substrate ratio (E/S, w/w %; in other words, g enzyme preparation/100 g wet mash) according to the experimental design (see below). Samples were mixed thoroughly and placed under nitrogen in a vibrating, thermostatically-controlled water bath, and incubated according to the reaction time and temperature given in the experimental design. Immediately after enzyme treatment the samples were heated to 100 °C for 10 min. The juice yield was extracted from the macerated blackcurrant mash by gentle pressing and vacuum assisted filtration through one layer of Whatman No. 1 filter paper (supported by a Buchner filter). The amount of juice extracted was determined by weighing.

Determination of total phenols and total water-soluble carbohydrates

Total phenols in the juices were determined by the Folin-Ciocalteu procedure, with total phenols expressed as mg/L gallic acid equivalents (GAE) [18]. The extent of cell wall hydrolysis was assessed by measuring the total water-soluble carbohydrates liberated from the sample, as described by Slominski et al [19].

HPLC

The phenolic profiles of the extracts were analyzed by means of a HPLC procedure described by Lamuela-Raventòs and Waterhouse [20]. Based on spectral identification, the areas of five different phenol classes: hydroxybenzoates (peaks at 280 nm), anthocyanins (peaks at 520 nm), flavan-3-ols (peaks at 280 nm), flavonols (peaks at 365 nm) and hydroxycinnamates (peaks at 316 nm), were quantified (mg/L equivalents) by calibration with the authentic compounds: gallic acid, cyanidin, catechin, rutin, and caffeic acid, respectively.

Inhibition of human LDL oxidation

The antioxidant power of each blackcurrant juice sample to inhibit the copper-catalyzed oxidation of human LDL (37 °C, 5 μM CuSO4) was assayed by monitoring the formation of conjugated diene hydroperoxides (234 nm) over five hours [21]. Immediately prior to assay, the extracts were diluted with doubly distilled water and tested at equimolar concentrations of 2.5 and 5 μM GAE. After triplicate analyses, the antioxidant activities of each sample were evaluated on the basis of the net lag time prolongation (the lag time minus the lag time of the control sample, which contained all of the ingredients except the juice sample).

Experimental design

Individual and interactive effects on plant cell wall degradation, juice and phenol yields were first screened in two randomized, factorial 24 designs [22], the first with the enzyme preparations Macer8 [FJ] and Pectinex Ultra SP-L and the second with the enzyme preparations Grindamyl Pectinase and Rapidase BE Super. The substrate particle size was kept constant (homogenized) while the maceration time (1 h vs. 4 h), the maceration temperature (30 °C vs. 50 °C), and enzyme addition levels (0% E/S vs. 0.05% E/S) were varied according to the experimental design. The levels of maceration time and enzyme dosage in the factorial 24 designs were within the range generally used in berry juice processing [16, 23]. The effect of enzyme dosage (0% E/S, 0.0125% E/S, 0.025% E/S, 0.05% E/S, 0.075% E/S, 0.1% E/S) on plant polysaccharide degradation, juice and phenol yields were subsequently examined on homogenized blackcurrant pulp at the same hydrolysis time (1 h) and temperature (50 °C) for all four enzymes. The effects of maceration time (0 min, 1 min, 5 min, 10 min, 15 min, 30 min, 45 min, 60 min) and enzyme addition level (0.05% E/S, 0.1% E/S) on plant polysaccharide degradation, juice and phenol yields were then examined for Macer8 [FJ] and Pectinex Ultra SP-L with the homogenized pulp at the high reaction temperature (50 °C). Finally, the individual and interactive effects on plant polysaccharide degradation, juice and phenol yields of Macer8 [FJ] and Pectinex Ultra SP-L treatment were analyzed in a randomized, quadratic central composite circumscribed (CCC) response surface design with the enzyme addition (0% E/S vs. 0.05% E/S), maceration time (1 h vs. 6 h), maceration temperature (30 °C vs. 50 °C) and degree of berry crushing (mashed vs. homogenized) as experimental variables. The experimental plan of each enzyme preparation was composed of 25 different process combinations, including two star points and with three replicated centerpoints.

Statistics

The computer program Modde (Umetri AB, Umeå, Sweden) was used to aid the statistical designs of the factorial and the response surface experiments and to fit and analyze the data by multiple linear regression (factorial) or partial least squares regression (response surface). Significance of the results was established at P≤0.05. Differences in the responses in the maceration design templates and in the LDL antioxidant activities were determined by one-way analysis of variance, where the 95% confidence intervals were calculated from pooled standard deviations (Minitab Statistical Software, Addison-Wesley, Reading, MA). The statistical significance of linear correlations was tested by the dose-response F-test [24].

Results and discussion

Screening for enhanced juice yield, phenols, and polysaccharide degradation

Juice yield

For all of the four enzyme preparations (Table 1), an increased enzyme dosage in the pre-press treatment of homogenized blackcurrant pulp significantly increased the juice yield in the initial screening experiments (Table 2). This was expected, since all the enzyme preparations contained pectinolytic activities and were developed for use in the juice industry. In the production of fruit juice, the degradation of the pectin in the primary cell wall matrix and in the middle lamella is necessary to break the water binding capacity of the pectin, which in turn allows maximal juice levels to be expelled and so enhances the utilization of the press [16, 25]. Rapidase BE Super was, however, the only preparation that was fit for the very low pH range of the blackcurrant juice (pH 2.8) (Table 1). In both factorial designs the enzyme interactions (Macer8 [FJ] × Pectinex Ultra SP-L and Rapidase BE Super x Grindamyl pectinase, respectively) had a significant negative effect on the juice yield (Table 2). The four enzyme preparations were alike; they were all produced from Aspergillus strains, with two of the preparations from Aspergillus niger, and the main activities of all were pectinolytic (Table 1). Presumably the negative enzyme interactions on juice yield were a result of decreased hydrolysis rates with both enzyme preparations present, and this may be ascribable to non-productive, competitive adsorption of enzymes on the polysaccharide substrates. Competitive adsorption is a phenomenon related to the required adsorption of polysaccharide-degrading enzymes to the substrate prior to the catalytic reaction. The non-productive adsorption occurs when pectinases (and other polysaccharide-degrading activities) adsorb temporarily to sites that contain bonds that they cannot attack [26]. If too many sites are occupied in this way, for example when relatively high concentrations of mixed plant cell wall degrading enzyme preparations are employed, the non-productive adsorption sterically blocks the access for those enzymes that actually can catalyze hydrolysis at these sites, and this situation results in a lower net hydrolysis [26].

Increasing the maceration time from 1 h to 4 h did not increase the juice yield (Table 2). This indicates that the necessary enzymatic degradation of the pectin for juice release occurred within the first hour of reaction. An increase in maceration temperature from 30 °C to 50 °C only had a significant effect in the factorial design with Rapidase BE Super and Grindamyl pectinase (Table 2). This result agreed well with the temperature optima of the pectinolytic activities in these preparations (Table 1). The temperature optimum of Pectinex Ultra SP-L was 35 °C and the Macer8 [FJ] preparation was stated to have a relatively wide optimum from 40–50 °C (Table 1). Coupled with the relatively low pH in blackcurrant mash, the higher temperature optimum of the Macer8 [FJ] preparation may not have been pronounced enough to manifest as a significant effect of temperature in the factorial design.

Carbohydrate hydrolysis and total phenols

The enzyme preparations’ ability to release soluble carbohydrates and phenols differed in the two factorial designs (Table 2). In the design with Macer8 [FJ] and Pectinex Ultra SP-L, all of the main factors except time had a significant effect on the release of soluble carbohydrates and phenols. In addition, there was a significantly negative interaction between the two enzymes on the total phenols and soluble carbohydrates. This negative interaction presumably resulted from non-productive competitive adsorption of the enzymes in these preparations, as discussed above. In the design with Rapidase BE Super and Grindamyl pectinase, the temperature was the only factor that had an effect on the release of phenols (Table 2). The significantly increased release of soluble carbohydrates and total phenols obtained with the enzyme preparations Macer8 [FJ] and Pectinex Ultra SP-L indicated an increased extent of cell wall degradation and a concomitantly elevated liberation of phenolics from the blackcurrants. In the complex structure of the plant cell wall, the location, type of bonding, and possible entrapment of the phenol compounds is basically unknown. Nevertheless, the elevated polysaccharide degradation afforded by the enzymes implied that the release of the phenols was facilitated by an increase in the substrate porosity. The high temperature (50 °C) increased the amount of soluble carbohydrates and phenols in the design with Macer8 [FJ] and Pectinex Ultra SP-L. This observation indicates that the enzymes had a higher activity at 50 °C than 30 °C and that the enzyme-catalyzed degradation of the primary cell wall polysaccharides and/or middle lamella pectin increased the phenol release. The significantly higher phenol yields obtained with the higher treatment temperature also indicate that the phenols were not significantly degraded during the enzyme treatments at 50 °C. The significant effect on the polysaccharide degradation of Macer8 [FJ] was higher than that of Pectinex Ultra SP-L, indicating that the enzyme activities of the Macer8 [FJ] preparation were more aggressive on the blackcurrant polysaccharides for the experimental conditions examined. This apparently higher activity of the Macer8 [FJ] preparation could be related to the differences in temperature optima between the two enzymes preparations: Macer8 [FJ] had the highest activity at 40–50 °C, whereas the maximum activity of Pectinex Ultra SP-L was at 35 °C (Table 1). As with the juice yield, an increase in maceration time did not increase the amount of soluble carbohydrates and phenols in the two factorial designs (Table 2). The lack of an effect of extended enzyme treatment time indicates that the decrease in viscosity taking place concomitantly with the degradation of pectin during the maceration did not affect the enzyme catalysis. Increased addition levels of Grindamyl pectinase or Rapidase BE super did not result in significantly enhanced polysaccharide degradation nor in significantly increased phenol concentrations in the juice, despite the enhancing effects of these enzyme treatments on juice yields (Table 2). A reason could be that the enzyme activities required for degradation of other polysaccharides than pectin, and therefore for phenol release, were less active under the experimental conditions and/or present at lower concentrations in these preparations compared to those present in Macer8 [FJ] and Pectinex Ultra SP-L. The main difference between these four multi-component enzyme preparations may therefore be found in the unspecified side activities. However, very little is known about synergistic effects, antagonistic effects, and non-productive absorption among fruit plant cell wall-degrading enzyme activities. The cell wall polysaccharides in blackcurrant have similar structures to those of other fruits such as apple [27], and since both Macer8 [FJ] and Pectinex Ultra SP-L are also designed to degrade the fruit pulp of apples and pears, they may have some of the same side activities that are important in the degradation of the blackcurrant cell wall and phenol release.

Dosage: response effects

A series of individual maceration treatments with each of the four enzyme preparations added at different E/S ratios were carried out in order to obtain more knowledge about the enzymatic enhancement of juice yields, soluble carbohydrates, and phenols in the maceration step of blackcurrant juice. Maceration time and temperature were selected from the results of the initial screening experiments (1 h, 50 °C). The concentrations of soluble carbohydrates in juice samples resulting from treatments with each of the four enzyme preparations as a function of the E/S ratio were basically identical (Table 3). An increased E/S ratio from 0% to 0.0125% resulted in a significant increase in the release of soluble carbohydrates, which confirmed the enzyme preparations’ ability to catalyze the breakdown of blackcurrant (cell wall) polysaccharides even at low enzyme addition levels. However, increases in the E/S ratio beyond 0.0125% E/S did not increase the levels of soluble carbohydrates (Table 3). The response in juice yield with increased E/S was also basically identical among the four enzyme preparations (Table 3) and increased with increasing E/S ratio up to 0.025% (Grindamyl pectinase and Pectinex Ultra SP-L) or 0.075% (Macer8 [FJ] and Rapidase BE Super) (Table 3). These observations are in accordance with the dependence of the reaction velocity, v, on the substrate concentration, [S], in enzyme-catalyzed reactions that follow Michaelis-Menten kinetics (Eq. 1) [28]:

where [P] is the product concentration, k+2 is the rate limiting velocity constant in the enzyme reaction, [Et] the total enzyme concentration, and Km is the Michaelis constant involving the velocity constants, k-1, k+1, k+2 for the formation and the decay of the enzyme-substrate complex (Eq. 2):

This study was not designed to evaluate the enzyme kinetics. The data nevertheless indicate that the increased enzyme concentration did not necessarily increase the reaction velocity linearly, and this result is presumably explained by the dependence of the reaction velocity of the enzyme-catalyzed reactions on the substrate concentration [28]. In the case of enzymatic hydrolysis of complex polysaccharides, further issues related to competitive enzyme adsorption and access to the substrate(s) arise [26], but it was beyond the scope of the present work to investigate these issues further.

The effect of the increase in E/S ratio from 0% to 0.0125% on the phenol concentration (Table 3) demonstrated that all four enzyme preparations could release phenols during degradation of the blackcurrant polysaccharides. The phenols released at an E/S ratio 0% were probably achieved via limited thermal degradation of the blackcurrant polysaccharides during the reaction at 50 °C and during the 10 min boiling treatment which was included to halt the enzyme reactions, but also done on the non-enzyme-treated controls. At an E/S ratio of 0.1%, Macer8 [FJ] and Pectinex Ultra SP-L treatments gave the highest amount of phenols within the E/S ratios examined: 6532 and 6460 GAE mg/L, respectively (Table 3). This level was significantly higher than the amount of phenols released by Rapidase BE Super and Grindamyl pectinase at the same enzyme addition level (Table 3). The phenol release as a function of the E/S ratio resembled a straight line (not shown). In agreement with our previous study on the enzyme-assisted extraction of phenols from blackcurrant juice press residues [17], the enzyme-catalyzed polysaccharide hydrolysis therefore boosted the phenol extraction beyond what could be measured directly from the increase in liberated polysaccharides. This suggests that the enzymatic degradation of the blackcurrant polysaccharides increased the overall substrate porosity and that this—rather than direct and/or selective enzyme-catalyzed release of phenols from the cell wall matrix—facilitated the enhanced extraction of the phenols. An increase in the E/S ratio furthermore released a higher amount of phenols into a larger amount of juice yield. The increase in the juice yield therefore did not have a diluting effect on the total phenol concentration.

Effect of enzyme maceration time over the first sixty minutes

Based on the results obtained in the initial screening experiments and in the enzyme dose experiments, the enzyme preparations Macer8 [FJ] and Pectinex Ultra SP-L were selected for further examination. The ability of Macer8 [FJ] and Pectinex Ultra SP-L to induce increased yields of juice, soluble carbohydrates, and phenols as a function of maceration time (0–60 min) was examined at two dosage levels (0.05% and 0.1%) at constant reaction temperature (50 °C). The juice yield obtained by Macer8 [FJ] and Pectinex Ultra SP-L treatments at 0.05% and 0.1% enzyme addition levels were almost the same, and the juice yield generally increased with increasing maceration time (Table 4). The release of soluble carbohydrates as a function of the maceration time differed between Macer8 [FJ] and Pectinex Ultra SP-L. Pectinex Ultra SP-L degraded the substrate rapidly; the highest level of soluble carbohydrate was obtained with maceration times of 10 min. The level remained constant for the remaining maceration time. The degradation of the substrate with Macer8 [FJ] was more moderate, with the highest amounts obtained after 45 min. (Table 4). The rate of carbohydrate degradation apparently differed between the two enzyme preparations, presumably because of differences in their main activities and their undeclared side activities. In contrast to Macer8 [FJ], the Pectinex Ultra SP-L is stated to contain hemicellulotic activities (Table 1), and the presence of hemicellulases apparently boosted the pectinolytic degradation. The amounts of soluble carbohydrates released with time resembled a rectangular hyperbola curve (not shown), which, as discussed above, signified a general enzyme-catalyzed progress reaction curve. The amount of phenols released with time differed between the two E/S ratios. With a 0.05% E/S ratio, a final phenol concentration of 5644–5896 GAE mg/L was obtained after 15 min of maceration, whereas at the 0.1% E/S ratio a final phenol concentration of 6217–6532 GAE mg/L was obtained after 45 min of maceration (Table 4). A reason for this difference could be that the concentrations of side activities in the enzyme preparations may have been high enough to play a role at the 0.1% E/S addition level while the concentrations of these same side activities were too low at the 0.05% E/S ratio to have an impact. A side activity such as ferulic acid esterase could have had an effect since this enzyme catalyzes the liberation of hydroxycinnamic acids (notably ferulic acid) directly from the polysaccharides [29]. Intensified side activities at the 0.1% E/S ratio would cause the phenol profiles of the two E/S ratios to differ. It was, however, not possible to determine any differences in the profiles with the total phenol assay used. The assay was quantitative and the molar response was proportional to the amount of hydroxyl groups [30]. The correlation between total carbohydrates and total phenols (Table 4) was linear with both enzyme preparations at both E/S ratios; for instance:

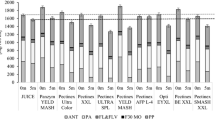

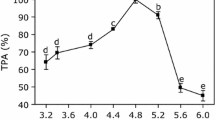

Maximal phenols release

To establish which factors resulted in the highest phenol release, the response surfaces of phenols, soluble carbohydrates, and the yield of juice were studied in response to variations in maceration reaction conditions with each of the enzyme preparations Macer8 [FJ] and Pectinex Ultra SP-L (Table 5). The influence of variations in reaction time (1 h vs. 6 h) and temperature (30 °C vs. 50 °C) of the maceration together with enzyme dose (0% vs. 0.05%) and particle size (mashed vs. homogenized) were examined. Six hours was selected as the high level of maceration time, since four hours did not have a significant effect in the initial screening experiments. With both enzyme preparations, all of the factors had a positive effect on the juice yield (Table 5). The homogenized mash gave significantly higher juice yield, and higher carbohydrate and phenol concentrations in the juice than the more gently crushed mash (Table 5). This was expected since homogenization reduces the crystallinity of cellulose, increases the surface area, and shortens the distance for extraction from the matrix [31]. It is therefore well known that enzymatic saccharifaction of complex cell wall structures is improved by a decrease in substrate particle size [32, 33]. As the temperature optimum of Pectinex Ultra SP-L was 35 °C, the effect of temperature could be due to thermal degradation of the substrate, or to undeclared side activities having a major impact. In the release of phenols and soluble carbohydrates, the particle size and the E/S ratio had, as expected, a positive effect with both enzyme preparations. With Macer8 [FJ], the maceration time and the interaction time × temperature also had a significantly positive effect on the release of phenols and soluble carbohydrates. The interaction effect may, at least partly, be due to slight thermal degradation of the substrate over time, and therefore the effect of the combination of time and temperature was more pronounced than estimated from the factors’ individual effects. With Pectinex Ultra SP-L, an increase in maceration time had a positive effect on the phenol release, but the maceration time (1 h vs. 6 h) did not affect the release of soluble carbohydrates. This may be because Pectinex Ultra SP-L rapidly (within an hour of reaction time) catalyzed the degradation of the substrate, as seen in the maceration time experiments (Table 4). Due to the differences in the temperature optima of the two enzyme preparations (Table 1), the high level of temperature (50 °C) only had a significant effect with Macer8 [FJ]. The response surfaces for phenol release for Macer8 [FJ] and Pectinex Ultra SP-L are shown in Fig. 1 and Fig. 2 respectively. The extent of substrate crushing (substrate particle size) and E/S ratio were the most significant factors and were therefore kept constant in the figures (homogenized, 0.05%). The maximum released amounts of phenols with Macer8 [FJ] and Pectinex Ultra SP-L within the experimental conditions were approximately 6500 GAE mg/L (44 °C, 5.5 h) and 6650 GAE mg/L (42 °C, 4.5 h) (Figs. 1 and 2). The response surfaces for soluble carbohydrates for Macer8 [FJ] and Pectinex Ultra SP-L (not shown) were identical, and the curves had similar shapes to those shown in Figs. 1 and 2. The correlation between total phenols and total carbohydrates was a linear function and the lines were practically the same for the two enzyme preparations (Fig. 3). The strong linear correlation between phenols and liberated carbohydrate confirmed that the phenol compounds were released as a result of the enzymatic degradation of the blackcurrant cell wall polysaccharides.

Phenolic profiles

Table 6 shows the phenol amounts and profiles of three blackcurrant juice samples pre-treated with different enzymes (0.05% E/S, 6 h, 50 °C). The enzyme-treated extracts differed in anthocyanin contents: while almost 64% of the extracted phenols were anthocyanins with Macer8 [FJ], less than 50% were anthocyanins with Pectinex Ultra SP-L. The reason for this difference may be that Pectinex Ultra SP-L possesses β-glucosidase activity, which is able to catalyze the hydrolysis of the glycosylated anthocyanin to produce unstable aglycons [34]. Macer8 [FJ] was also previously shown to contain anthocyanin-degrading enzyme activity [17], but this activity presumably did not manifest itself at the low pH of the blackcurrant mash. The sample extracted without enzyme contained relatively more flavan-3-ols than anthocyanins, whereas, somewhat surprisingly, the opposite trend was found in the samples extracted with enzymes (Table 6). At present it is uncertain whether this observation is directly due to a better extraction of anthocyanins than flavan-3-ols with enzymes. A significant antioxidant activity on human LDL oxidation in vitro was observed for the selected phenol extracts at 2.5 and 5 μM GAE (Table 7). At a concentration of 2.5 μM GAE, there was a significant difference in the antioxidant effects of the extracts, with the non-enzyme-treated sample exerting highest activity. The extracts were diluted to the same equimolar concentrations of total phenols, and the differences in the antioxidant effects were therefore presumably due to differences in the phenolic compositions of the samples. The antioxidant potencies of samples of wine, grape juices, fresh grapes and of various berry extracts on human LDL oxidation have previously been shown to correlate with the presence of distinct types of phenols, and in turn to their relative abundances in the particular samples being tested [11, 35]. The high level of flavan-3-ols (46.7%) in the sample extracted without enzymes could be the reason for higher antioxidant activity. When comparing the phenolic compositions of the enzyme-extracted samples, the Pectinex Ultra SP-L sample contained a higher level of flavan-3-ols than the Macer8 FJ-treated sample, and this might explain why the Pectinex Ultra SP-L-treated sample exerted a slightly better antioxidant effect than the Macer8 FJ-treated juice sample (Tables 6 and 7). The variation in the antioxidant effect could, however, also result from differences in the ascorbic acid content. Besides the antioxidant affect, the released phenols protect ascorbic acid from oxidation [36]. The data available on the bonding and localization of phenolics in blackcurrant does not allow any firm conclusions to be drawn about the direct influence of specific enzyme activities on the release of phenols from the blackcurrant cell wall matrix. In addition, it was beyond the scope of the present investigation to assess all of the individual enzyme activities present in the enzyme preparation and to evaluate their individual activities on the blackcurrant phenolics and in turn on antioxidant activity. Nevertheless, the results indicate that the different enzyme treatments influenced the phenolic composition of the blackcurrant juice, and furthermore that this affected the antioxidant potencies of the blackcurrant juice samples. A more detailed understanding of the influence of plant cell wall-degrading activities, for instance pectinase and β-glucosidase activities, on the release of phenols from plant cell wall polysaccharide matrices in fruits and berries—as well as an improved understanding of the action of these enzymes on the phenols—is warranted. It is therefore one of our future research priorities to provide data on these issues, as this will give a significantly improved basis for tailoring the enzymatic pre-press treatment to release the most potent antioxidant phenolics into fruit juices. Further work is also needed to translate the relative antioxidant activities of phytochemicals from in vitro observations to effects in vivo.

Conclusions

Among the four commercial pre-press preparations examined, Macer8 [FJ] and Pectinex Ultra SP-L released significantly higher amounts of phenols from blackcurrants than Rapidase BE Super and Grindamyl pectinase at optimal experimental conditions. The amount of both juice and phenols increased with the enhanced enzyme treatment, and the result was a larger juice yield with a high phenol concentration. The levels of phenols achieved with the optimal enzyme treatments were 14–15% higher than those extracted without enzymes. The variation between the pectinolytic enzyme preparations in their ability to release phenols could be due to differences in their unspecified side activities. Mixing the enzyme preparations decreased the phenol release, probably due to competitive, non-productive adsorption to the substrate polysaccharides. The correlation between the release of soluble carbohydrates (cell wall degradation) and the release of phenols was linear and mainly similar for the two enzyme preparations Macer8 [FJ] and Pectinex Ultra SP-L.

The extracts obtained with or without enzymatic hydrolysis inhibited the oxidation of LDL in vitro. The variations in antioxidant activity between the extracts were presumably based on differences in their phenolic composition, but might also result from differences in ascorbic acid content.

Among the enzyme preparations examined, Pectinex Ultra SP-L seemed to be the best enzyme preparation to use to release high amounts of phenols with potent antioxidant effects. However, relatively little is known about the side activities in commercial pectinolytic enzyme preparations, as well as the allocation, bonding type and so on of the phenols in the fruit cell wall. More information is needed to allow the rational design of enzymatic maceration treatments that both induce maximal juice yields and that release potent antioxidant phytochemicals from the fruits and berries into the juice.

References

Criqui MH, Ringel BL (1994) Lancet 344:1719–1723

Ness AR, Powles JW (1997) Int J Epidemiol 26:1–13

Joshipura KJ, Hu FB, Manson JE, Stampfer MJ, Rimm EB, Speizer FE, Colditz G, Ascherio A, Rosner B, Spiegleman D, Willett W (2001) Ann Intern Med 134(12):1106–1114

Steinberg D (1997) J Biol Chem 272:20963–20966

Hertog MGL, Kromhout D, Aravanis C, Blackburn H, Buzina R, Fidanza F, Giampaoli S, Jansen A, Menotti A, Nedeljkovic S, Pekkarinen M, Simic BS, Toshima H, Feskens EJM, Hollman PCH, Katan MB (1995) Arch Intern Med 155:381–386

Knekt P, Järvinen R, Reunanen A, Maatela J (1996) Brit Med J 312:478–481

Frankel EN, Kanner J, German JB, Parks E, Kinsella JE (1993) Lancet 341:454–457

Teissedre PL, Frankel EN, Waterhouse AL, Peleg H, German JB (1996) J Sci Food Agr 70:55–61

Meyer A S, Yi O S, Pearson D A, Waterhouse A L, Frankel E N, (1997) J Agric Food Chem 45:1638–1643

Meyer AS, Donovan JL, Pearson DA, Waterhouse AL, Frankel EN (1998) J Agr Food Chem 46:1783–1787

Heinonen M, Meyer AS, Frankel EN, (1998) J Agr Food Chem 46:4107–4112

Koeppen BH, Herrmann K (1977) Z Lebensm Unters For 164:263–268

Schuster B, Herrmann K (1985) Phytochemistry 24:2761–2764

Hummer K E, Barney D L (2002) Horttechnology 12(3):377–387

Brett C, Waldron K (1996) Physiology and biochemistry of plant cell walls, 2nd edn. Chapman & Hall, London, pp 1–64

Grassin C, Fauquembergue P (1996) Fruit juices. In: Godfrey T, West S (ed) Industrial enzymology, 2nd edn. Macmillan, London, UK, pp 225–264

Landbo A-K, Meyer AS (2001) J Agr Food Chem 49:3169–3177

Singleton VL, Rossi JA (1965) Am J Enol Viticult 16:144–158

Slominski BA, Guenter W, Campbell LD (1993) J Agr Food Chem 41:2304–2308

Lamuela-Raventós RM, Waterhouse AL (1994) Am J Enol Viticult 45:1–5

Esterbauer H, Striegl G, Puhl H, Rotheneder M (1989) Free Radical Res Com 6:67–75

Montgomery DC (1991) Design and analysis of experiments, 3rd edn. Wiley, New York, pp 270–318

Beveridge T, Harrison JE (1995) Food Res Int 28:173–177

Berry DA, Lindgren BW (1996) Statistics: theory and methods, 2nd edn. Duxbury (Wadsworth), Belmont, CA, pp 608–609

Pilnik W, Voragen AGJ (1991) The significance of endogenous and exogenous pectic enzymes in fruit and vegetable processing. In: Fox PF (ed) Food enzymology. Elsevier, London, pp 303–336

Norsker M, Bloch L, Adler-Nissen J (1999) Nahrung 43:307–310

Hilz H, Schols HA, Voragen AGJ (2004) Characterisation of cell wall polysaccharides in black currants. Poster presented at the Annual Meeting of the German Chemists, Münich, Germany, 8–10 October 2003 (see http://www.vtt.fi/virtual/maxfun/posters/081003gdchblackcurrant.pdf)

Fullbrook P D, (1996) Practical limits and prospects (kinetics). In: Godfrey T, West S (ed) Industrial enzymology, 2nd edn. Macmillan, London, UK, pp 503–540

Faulds CB, Williamson G (1995) Biochem Soc T 23(2):253S

Frankel EN, Waterhouse AL, Teissedre PL (1995) J Agr Food Chem 43:890–894

Marsden WL, Gray PP (1986) Crit Rev Biotechnol 3:235–276

Düsterhöft E, Engels FM, Voragen AGJ (1993) Bioresource Technol 44:39–46

Mansfield SD, Mooney C, Saddler JN (1999) Biotechnol Progr 15:804–816

Jiang J, Paterson A, Piggott JR (1990) Int J Food Sci Tech 25:596–600

Ghiselli A, Nardini M, Baldi A, Scaccini C (1998) J Agr Food Chem 46:361–367

Miller NJ, Rice-Evans CA (1997) Food Chem 60:331–337

Acknowledgements

We wish to thank Vallø Saft A/S for supplying the blackcurrants, and the enzyme producers Novozymes A/S, Biocatalysts, DSM, and Danisco Cultor providing the enzyme preparations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bagger-Jørgensen, R., Meyer, A.S. Effects of different enzymatic pre-press maceration treatments on the release of phenols into blackcurrant juice. Eur Food Res Technol 219, 620–629 (2004). https://doi.org/10.1007/s00217-004-1006-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-1006-2