Abstract

The lipid peroxidation inhibitory effects of cactus pear fruit (Opuntia ficus-indica) extracts (CPFE) on fish oil, fish oil-in-water emulsion and linoleic acid were studied using conjugated diene hydroperoxides (CDH), weight gaining, peroxide value (PV), and thiobabituric acid reactive substances (TBARS) assays. A modified DPPH assay was used in the characterization of CPFE antioxidants for their thermal stability. CPFE successfully controlled lipid peroxidation at different stages of the pathway in a dose-dependent manner. Inhibition of the lipid peroxidation in oils and emulsion was successfully improved by increasing the level of CPFE from 0.01 to 0.1%. CPFE controlled conjugated diene formation from lipid radicals, demonstrating lower conjugated diene hydroperoxide values than its control counterpart. Moreover, it controlled the addition of oxygen to conjugated dienes to form lipid peroxyl radicals, resulting in lower weight gain. It also recorded a lower PV than its control counterpart, indicating its inhibitory effect on peroxyl radical formation. Such multiple and integrated effects controlled the overall lipid peroxidation, resulting in lower TBARS values than the control. Characterization of the CPFE antioxidants proved that those antioxidants are heat-resistant, although the color of the CPFE pigments disappeared rapidly.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Exposing lipids and lipid-containing foods to unfavorable environmental conditions such as oxygen, temperature, and light leads to the production of lipid oxidation products (LOP). Lipid peroxidation during the storage of oils, fats and fat-containing foods not only affects the nutritional and organoleptic properties of foods, but may also make them toxic to human health. The highly unsaturated nature of fatty acids makes them prone to oxidation to a variety of LOPs, including toxic compounds capable of damaging DNA, as well as proteins and lipids which cause metabolic disorders such as ageing mutagenesis, carcinogenesis, neurological and circulatory disorders [1, 2, 3, 4, 5, 6]. Moreover, the LOPs that form in foods and oils impart rancid flavors, strong off-odors and discoloration in foods, which is detrimental to their marketability.

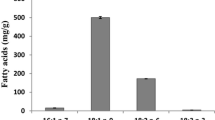

Fatty acids are known to play an essential role in human health and nutrition. Polyunsaturated fatty acids (PUFA) of the n-6 and n-3 configurations cannot be synthesized by humans and must be obtained from the diet. Essential PUFAs like eicosapentaenoic acid (EPA, 20:5) and docosahexaenoic acid (DHA, 22:6) are important dietary fatty acids in fish oil; they are the precursors of effective anti-aggregatory substances that can potentially reduce the risks of cardiovascular diseases, carcinogenesis and allergies, and they also improve brain and eye functions in infants [7, 8]. Linoleic acid (C18H32O2) is a member of the essential unsaturated fatty acid family of the omega-6 series and it is a common constituent of commercially-available food oils including fish oil and most vegetable oils.

Various mechanisms have been suggested for the lipid peroxidation that produces biologically-active LOP. In them, hydrogen atoms are abstracted from the methylene groups of polyunsaturated fatty acids (PUFA), resulting in lipid radicals. The lipid radicals are partially stabilized by molecular rearrangement and form conjugated dienes, which can combine with oxygen to form peroxy radicals (ROO.). Peroxyl radicals can abstract another hydrogen from a neighboring lipid molecule leading to autocatalytic chain reactions. The lipid hydroperoxides formed are unstable, and further abstraction of hydrogen leads to the formation of a variety of secondary LOPs, including aldehydes, ketones and lactones [9].

Antioxidants provide either kinetic hindrances to excited LOP or free radicals that can initiate further chain reactions and retard lipid peroxidation. Synthetic antioxidants are being widely used in the food industry, but are becoming controversial due to concerns about their safety. Synthetic antioxidants like TBHQ (tert-butylhydroquinone), BHA (butylated hydroxyanisole), BHT (butylated hydroxytoluene), propyl gallate (PG) and ethoxyquin are suspected as being carcinogenic and responsible for a variety of unidentified health disorders [10, 11, 12]. Therefore, research on effective natural antioxidants has been performed and is currently increasing [13, 14, 15, 16, 17, 18, 19, 20, 21]. Natural antioxidants are mixtures of antioxidants (especially polyphenolic compounds and pigments), and multiple effects can be expected. Also, unlike synthetic antioxidants, natural antioxidants can be added in high enough quantities to obtain optimum efficacy.

The cactus pear (Opunthia ficus indica) originated in tropical and sub-tropical America, and has been reported to contain a variety of bioactive compounds [22, 23, 24]. However, Jeju Island in South Korea has recently initiated the large-scale cultivation of the cactus pear for traditional folk medicine, due to its ability to cure a number of afflictions, including burns, wounds, edema, bronchial asthma, diabetes and indigestion. Its fruit is a red fleshy berry which is reported to have nutritional importance due to the presence of potential antioxidative compounds like betalains, amino acids, fiber, and ascorbic acid [25, 26]. Betalains are water-soluble nitrogenous pigments, mainly a mixture of red betacyanins and the yellow beta-xanthines. Betalain pigments can also be used as natural food colorants as well as potential free radical scavengers [27, 28].

The objective of this study was to investigate the antioxidative potential of cactus pear fruit extract (CPFE) for oils and emulsion systems. The investigation was designed to determine the multiple antioxidative effects of CPFE on various LOPs resulting from lipid oxidation in oils and emulsion systems. The thermal stability of CPFE was also investigated in order to provide characteristic information.

Materials and methods

Chemicals

Fish oil, linoleic acid, potassium iodide (KI), potassium dichromate (K2Cr2O7), sodium thiosulphate (Na2S2O3), 1,1-diphenyl-2-picrylhydrazyl (DPPH), butylated hydroxytoluene (BHT), butylated hydroxyanisole (BHA) and α-tocopherol were purchased from Sigma Co. (St Louis, USA). All of the other chemicals used were of analytical grade, and were supplied by Fluka or Sigma Co.

Extraction

Cactus pear (Opuntia ficus indica) fruits were obtained from the cactus village of Hallim in Jeju Island, South Korea. Cleaned samples were dried and ground into a fine powder. Ten grams of ground powder was mixed with 500 ml of methanol and placed in a shaking incubator for 24 h at 25 °C. The macerated mixture was filtered and concentrated in the evaporator. Half of the partially concentrated cactus pear fruit extract (CPFE) was used in the experiments with oil (fish oil and linoleic acid). The other half was vacuum dried to remove all of the methanol and then dissolved in distilled water, which was used to prepare an oil-in-water emulsion. All of the commercial antioxidants (BHA, BHT and α-tocopherol) were dissolved in methanol and added to oil at the 0.01% level.

Oxidation of oils (fish oil and linoleic acid) and emulsion

The lipid peroxidation processes of the fish and linoleic oils were accelerated according to the method explained by Abdalla and Roozen [17]. Oil samples (100 g) containing 0.01, 0.05 and 0.1% of CPFE were mixed in screw-capped glass bottles covered externally with aluminum foil and incubated at 60 °C in dark for 12 days. Initial incubation (for 6 h) was performed without closing the cap of the bottles to remove the methanol added with the CPFE and the commercial antioxidants.

Twenty percent fish oil-in-water emulsion samples were prepared with 0.01, 0.05 and 0.1% levels of CPFE. The emulsion was prepared according to the method of Abdalla and Roozen [17] by mixing 70 g of fish oil, 3.5 g of Tween 80 and 350 g of water with CPFE. The emulsions were incubated at 60 °C for 12 days in screw capped glass bottles covered with aluminum foil. During LOP measurements of the oil in the emulsion samples, a 40 ml fraction of oil was separated and thoroughly mixed (2 min) with 40 ml of dichloromethane and 10 g of salt. The dichloromethane fraction was evaporated to dryness under vacuum, and the oil fractions derived from emulsions were investigated via PV, TBARS and CDH assays. All of the commercial antioxidants (BHA, BHT and α-tocopherol) were added at the level of 0.01%.

Conjugated diene hydroperoxides (CDH)

Conjugated diene hydroperoxide content was measured every two days, as in the procedure described by Roozen [29]. Fifty milligrams of oil (oil directly from oil samples and oil separated from emulsion) was thoroughly mixed with 5 ml of cyclohexane, and the absorbance of conjugated diene hydroperoxide was recorded at 234 nm using a UV/Vis spectrophotometer (Opron 3000 Hanson Tech. Co. Ltd., Korea). The absorbance was corrected for background absorbance at 260 nm.

Weight gaining

This experiment was conducted with a slight modification of the method described by Wanasundara and Shahidi [30]. Two grams from each oil sample prepared for lipid peroxidation were separated into aluminum petri dishes and traces of water in the samples were removed by placing them in the vacuum oven at 35 °C for 12 h. Oxidation conditions of the samples were accelerated in the forced air oven at 65±1 °C, and percentage weight gaining was recorded for 12 days as in the procedure of Yan et al [31]. This investigation was not conducted for the emulsion samples.

Peroxide value (PV)

The PVs of oils stored under accelerated oxidation conditions was determined periodically by the iodometric determination method according to the AOAC guidelines [32].

Thiobarbituric acid-reactive substances assay (TBARS)

The assay was conducted according to the method of Madsen et al [16]. One gram of oil was dissolved in 3.5 ml of cyclohexane and 4.5 ml of TCA-TBA mixture (7.5% TCA and 0.34% TBA). The resulting mixture was shaken for 5 min and centrifuged at 2780×g for 15 min. The TCA-TBA phase was removed and heated in a boiling water bath for 10 min. The absorbance was recorded at 532 nm, and the antioxidative ability was expressed as equivalent μmol of malonaldehyde per kg oil using a tetraethoxypropane standard curve (concentration ranges from 1 mM to 20 mM).

Heat stability of CPE

This assay was based on the scavenging of 1,1-diphenyl-2-picrylhydrazyl (DPPH) radicals by the CPFE antioxidants heated at different temperatures (25, 50, 75 and 100 °C) for 2 h. A slightly modified method of that suggested by Brand-Williams [33] was used to investigate the free radical scavenging ability. DPPH solution was prepared at a concentration of 3×10−5 M using DMSO as the solvent. A 2 ml fraction of CPFE and 2 ml of freshly prepared DPPH solution were thoroughly mixed. Absorbance was measured at 517 nm using a UV-VIS spectrophotometer, and the following equation was used to calculate the percentage activity:

Here Ai is the absorbance of the CPFE mixed with DPPH solution, Aj is the absorbance of the same extract mixed with DMSO, and Ac is the absorbance of DPPH solution with added DMSO.

Statistical analysis

All experiments were conducted in triplicate and the Student’s t-test (p<0.05) was used to determine significant differences between means of LOPs formed in oils and emulsions treated with CPFE and commercial antioxidants.

Results

Preliminary studies on methanol extracts of the cactus pear fruit indicated notable antioxidant activity (88%) in DPPH radical scavenging assay. The dried methanolic extract of cactus pear fruit was readily water-soluble but not fully soluble in non-polar organic solvents like carbon tetrachloride and diethyl ether. For CPFE polyphenolics (3.4 mg/g of dried cactus pear fruit powder), the hydrophilic and hydrophobic polyphenolic contents were reported as being 80.6% and 19.4% respectively. Application of heat (100 °C for 10 min) to CPFE caused no significant antioxidative (DPPH radical scavenging) activity or smell changes, but it did induce a dramatic color change from a pink to a hay color.

Conjugated diene hydroperoxide (CDH)

The rate of CDH formation decreased significantly (p<0.05) in the fish oil, emulsions and linoleic acid treated with CPFE and synthetic antioxidants (Figs. 1, 2 and 3). The inhibitory effect of 0.1% CPFE on CDH formation in fish oil and linoleic acid was slightly higher than the effect of BHT at the twelfth day of storage, and its effect in emulsion was comparable with that of the BHA. In contrast, the inhibitory effect of 0.05% CPFE in fish oil and linoleic acid was slightly higher than the effect of BHA, while its effect on emulsion was slightly less than BHA. Moreover, there was a significant (p<0.05) difference between the effects of the 0.05 and 0.01% CPFE levels in fish oil and emulsion with CDH. The inhibitory effect of 0.01% CPFE in fish oil and linoleic acid lies in-between the effects of α-tocopherol and BHA, but its effect in the emulsion was slightly less than the α-tocopherol.

Weight gaining

Due to the practical inability to incubate the emulsion samples under forced air conditions at 65±1 °C, no weight gain evaluation was possible for the emulsions treated with the antioxidants. The presence of CPFE and synthetic antioxidants in fish oil and linoleic acid significantly (p<0.05) inhibited the weight gain in comparison to their control counterparts (Figs. 4 and 5). The inhibition of weight gain in the fish oil and linoleic acid with 0.1% CPFE was slightly less that for BHT but was considerably better than that for the BHA. The effect of 0.05% CPFE was slightly lower than for BHA but higher than for α-tocopherol, and the effect of 0.01% CPFE was comparable with that of α-tocopherol. From the results, it was observed that the inhibitory effects of 0.1, 0.05 and 0.01% CPFE on the lipid peroxidation of fish oil and linoleic acid was similar to those of BHT, BHA and α-tocopherol respectively. The rate of weight gain of both oils sharply increased within the first two days, and then followed a smooth gradual increase until the eighth day when the next rapid increase in weight gain started.

Peroxide value (PV)

Addition of CPFE and synthetic antioxidants caused a significant (p<0.05) reduction in PV compared to their control counterparts (Figs. 6, 7 and 8). The effect of 0.1% CPFE on the PV increase in fish oil and linoleic acid was comparable with the effect of BHT, while its effect in emulsion was comparable with the BHA. Unlike in fish oil and linoleic acid, the PV increase of emulsion at 0.05% CPFE was not comparable to the effect of BHA; its potency was in-between those of BHA and α-tocopherol. The PV increase of emulsion with 0.01% CPFE was even higher than that with the α-tocopherol. In oil and emulsion samples, there was a significant (p<0.05) difference between the PV reduction effects of 0.01% and 0.1% CPFE, but no such significance was observed between 0.1 and 0.05% CPFE.

Thiobarbituric acid reactive substances (TBARS)

The inhibitory effect of the CPFE on TBARS formation was significantly (p<0.05) higher than its control counterpart in all of the model systems (Figs. 9, 10 and 11). Indeed, the rate of TBARS value increase was higher than those of the CDH, weight gain and PV value increases. Addition of 0.1% CPFE, BHA and BHT produced relatively efficient, steady inhibitory performances up to the final stage compared to those of α-tocopherol, 0.05 and 0.01% CPFE which all showed sharp increases from the tenth day onwards. In the fish oil and linoleic acid, the TBARS formation inhibition effect of 0.1% CPFE was similar to that of the BHT while its effect in the emulsion was comparable with that of the BHA. The inhibitory effect of 0.05% CPFE in fish oil and linoleic acid was slightly lower than that of the BHA but considerably higher than that of the α-tocopherol. Moreover, the inhibitory effect of 0.05% CPFE in emulsion was slightly lower than the effect of α-tocopherol.

Heat stability of CPFE

The CPFE heated at 50, 75 and 100 °C up to 15 min did not show any significant reduction in its antioxidant (DPPH radical scavenging) activity (Fig. 12). Even though the pink color of the heated (75 and 100 °C) CPFE disappeared within 10 min, its antioxidative ability was measured at 70% up to 1 h afterwards, and at over 50% up to 2 h afterwards.

Discussion

In general, the CPFE- and synthetic antioxidant-treated oils and emulsion model systems showed less LOP development than that of their control counterparts. The effectiveness of synthetic antioxidants increased in the order: α-tocopherol<BHA<BHT. Also, it is known that for oils like fish oil, BHA is not very effective [37]. The comparatively low antioxidative effect recorded for α-tocopherol treated oils may be due to the consumption of α-tocopherol under accelerated storage conditions (60±1 °C) [38, 39, 40].

The antioxidative effect of CPFE was dependent upon the nature of the model system (whether it was oil or emulsion and whether it was highly saturated or not) and the LOP generation increased according to: linoleic acid<emulsion<fish oil with the same levels of added antioxidant. Moreover, the rate of oxidation of fish oil was higher than that of linoleic acid at the same levels of CPFE and synthetic antioxidants. This is mainly due to the fact that fish oil contains more highly unsaturated fatty acids than linoleic acid, which has only two double bonds per molecule. Further, Hamilton et al [9] reported that fish oil is even more unstable than sunflower and maze oil. The lipid peroxidation inhibitory effect of CPFE was found to be dose-dependent, and increasing the CPFE level from 0.01 to 0.1% significantly (p<0.05) enhanced the antioxidative effect, which was more or less comparable with the effect of adding BHT to both oils and BHA to emulsion.

Additionally, our primary studies confirmed that CPFE mainly contains hydrophilic radical scavenging antioxidants, and they are heat resistant. Previous studies on cactus pear fruit have proved this fact and reported that the major antioxidative compound in the fruit is betalain, which is a water-soluble alkaloid-type pigment [27, 36, 41, 42]. The hydrophilic antioxidants in the oils tend to orient to the air-oil interface, protecting the oil phase, whereas the hydrophobic antioxidants remain dissolved in the oil phase [34, 43]. The betalains and the majority of the polyphenolic compounds of CPFE are hydrophilic and obviously attributed to the strong antioxidative effect we found. The hydrophilic antioxidative compounds in the emulsion tend to become diluted in water and the concentration of available antioxidative compounds around the oil drops, so the emulsion becomes less stable against lipid peroxidation than for the oils. Hydrophilic polyphenolics were prominent among the small amount of polyphenolics present in the fruit (3.4 mg/g of dried cactus pear fruit powder). The antioxidative effects of betalain and polyphenolic compounds have been described in a number of studies, and positive correlations between those compounds and antioxidative effects have been resported [16, 19, 42, 44, 45].

Unlike synthetic antioxidants, CPFE antioxidative compounds are from natural edible cactus pear fruit, and its antioxidants can be added in larger quantities to get optimal effects (addition of synthetic antioxidants is limited under food laws and regulations). Therefore, lipid peroxidation can be controlled by the required amount of CPFE antioxidative compounds.

CDH are formed by rearrangements of the lipid radicals which undergo further radical formation, to molecules such as lipid peroxyl radical, lipid hydroperoxide, lipid alkoxyl radical and lipid aldehydes. The CDH formation inhibitory effect of CPFE in oils and emulsion is important during the early stages of lipid peroxidation inhibition, as it blocks any subsequent generation of reactive lipid radicals, which can undergo further chain reactions. A similar result was found in a study of different plant extracts used to evaluate the oxidative stabilities of sunflower oil and emulsion [17].

The addition of oxygen to the lipid radicals can produce lipid peroxyl radicals and weight gain. The weight gain inhibition effects we recorded suggest that CPFE antioxidative compounds retard lipid peroxidation through competitive binding of oxygen and retard further reactions [46]. The time required to achieve 0.5% weight increase for all CPFE-treated model systems was more than six days, and it was more than ten days for the 0.1% CPFE level. Evens et al [47] found that each storage day under Schaal oven conditions at 65 °C is equivalent to one month of storage at ambient temperature.

PV is a chemical indication of how much of the oil is in the early stages of oxidation, and it reflects the degree of oxidation. The obvious effect of CPFE addition on PV reduction in oils and emulsions indicates the potential of CPFE antioxidants to inhibit the lipid peroxidation in its early stages by reducing the formation of primary LOP. A study of oregano (a characteristic ingredient in Mediterranean cooking) antioxidant activity in mackeral oil showed that the effect of 0.5% oregano was comparable to that of 200 ppm BHA or 0.5% dry rosemary [13]. Also, Wanasundara and Shahidi [15] compared the antioxidant activity of dechlorophylized green tea extract (DGTE) in marine oil with commercial antioxidants and reported that the PV reduction of DGTE at ≥200 ppm was higher than that of BHT, BHA and α-tocopherol at the 200 ppm level.

Aldehydes (especially malonaldehyde) – the breakdown products (secondary LOP) of oxidized fatty acids (lipid peroxyl radicals) – produce off-flavors in oxidized oils that can be quantified through their reaction with TBA. The TBARS formation inhibitory effect indicates the total antioxidative potential of CPFE in oils and emulsion. Madesen et al [16] also reported a similar type of TBARS inhibition effect from summer savory and rosemary in dressings.

The heat stability of a natural antioxidant is important if we are to be able to use it practically at a commercial level. The heat stability of the CPFE antioxidant suggests that it could be an alternative natural antioxidant to less heat-stable natural antioxidants like α-tocopherol. Furthermore, no smell changes were encountered when the CPFE-treated oils were heated.

The multiple lipid peroxidation inhibitory effect (inhibitory effect on different stages of LPO generation such as CDH, weight gain, PV and TBARS in oils and emulsion model systems) recorded in this study is an innovative direction in the development of natural heat-stable antioxidative compounds from cactus pear fruit for the stabilization of food oils.

References

Steinberg D, Parthasarathy S, Carew TE, Khoo JC, Witztum JL (1989) New Engl J Med 320:915–924

Sevanian A, Peterson AR (1986) Food Chem Toxicol 24:1003–1110

Kubow S (1990) Trends Food Sci Tech 1:67–71

Namaki M (1990) Crit Rev Food Sci 29:273–300

Aruoma OI (1994) Food Chem Toxicol 32:671–683

Leaf A, Xiao YF, Kang XJ, Billman GE (2003) Pharmacol Therapeut 98:335–377

Kinsella JE (1987) Seafoods and fish oils in human health and disease. Marcel Dekker, New York

Innis SM (1991) Prog Lipid Res 30(1):39–103

Hamilton RJ, Kalu C, Prisk E, Padley FB, Pierce H (1997) Food Chem 60(2):193–197

Madsen HL, Bertelsen G (1995) Trends Food Sci Tech 6:271–277

Lindenshmidt R, Tryka A, Goad M, Witschi H (1986) Toxicolology 38:151–160

Safer AM, Al-Nughamish AJ (1999) Histol Histopathol 14:391–406

Tsimidou M, Papavergou E, Boskou D (1995) Food Res Int 28:431–433

Ghiretti GP, Zanardi E, Novelli E, Campanini G, Dazzi G, Madarena G, Chizzolini R (1997) Meat Sci 47:167–176

Wanasundara UN, Shahidi F (1998) Food Chem 63(3):355–342

Madsen HL, Sorensen B, Skibsted LH, Bertelesen G (1998) Food Chem 63(2):173–180

Abdalla AE, Roozen JP (1999) Food Chem 64:323–329

Bonilla F, Mayen M, Merida J, Medina M (1999) Food Chem 66:209–215

Siriwardhana N, Lee KW, Kim SH, Ha WJ, Jeon YJ (2003) Food Sci Technol Int 9(5):339–346

Athukorala Y, Lee KW, Song C, Ahn CB, Shin TS, Cha Y J, Shahidi F, Jeon YJ (2003) J Food Lipids 10:251–263

Heo SJ, Lee KW, Song CB, Jeon YJ (2003) Algae 7:71–81

Dok-Go H, Lee KH, Kim HJ, Lee EH, Lee J, Song YS, Lee YH, Jin C, Lee YS, Cho J (2003) Brain Res 965(1–2):130–6

Park HE, Kahng JA, Lee HS, Shin KH (2001) Fitoterapia 72:228–290

Granata G (1995) Biotic and abiotic diseases. In: Barbera G, Inglese P, Pimienta-Barrios E (eds) Agro-ecology, cultivation and uses of cactus pear (FAO Plant Production and Protection Paper 132). FAO, Rome, Italy, pp 216

Escribano J, Pereno MA, Garcia-Carmona F, Munoz R (1998) Phytochemistry 9:124–127

Stintzing FC, Schieber A, Carle R (2001) Food Res Technol Int 212:396–407

Pedreno MA, Escrebano J (2000) J Biol Educ 35(1):49–51

Strack D, Vogt T, Schliemann W (2003) Phytochemistry 62:247–269

Roozen J, Frankel E, Kinsella J (1994) Food Chem 50:33–38

Wanasundara UN, Shahidi F (1996) J Am Oil Chem Soc 73:1183–1190

Yan X, Xiancui L, Chengxu Z, Xiao F (1996) J Appl Phycol 8:201–203

AOAC (1995) Official method of analysis of the Association of Official Analytical Chemists, 15th edn. AOAC, Washington, DC

Brand-Williams W (1995) Food Sci Technol Int 28:25–30

Wettasinghe M, Shahidi F (1999) Food Chem 67:399–414

Chandler SF, Dodds JH (1993) Plant Cell Rep 2:105–110

Fernandez-Lopez JA, Almela L (2001) J Chromatogr A 13:415–420

Ke PJ, Nash DM, Ackman RG (1977) J Am Chem Soc 54:417–420

Khan MA, Shahidi F (2001) Food Chem 75:431–437

Duh PD (1999) Food Chem 66:471–476

Hras AR, Hadolin M, Knez Z, Bauman D (2000) Food Chem 71:229–223

Pavlov A, Kovatcheva P, Gerrgiev V, Kolevia I, Ilieva M (2002) Z Naturforsch 57:640–644

Piga A, Carlo AD, Pinna I, Agabbio M (2003) Lebensm-Wiss Technol 36:257–262

Kiokias S, Gordon MH (2003) Food Chem (in press)

Butera D, Tesoriere L, Di Gaudio F, Bongiorno A, Allegra M, Pintaudi AM, Kohen R, Livrea MA (2002) J Agr Food Chem 50(23):6895–6901

Duval B, Shetty K, Thomas WH (2000) J Appl Phycol 11:559–566

Halliwell B (1994) Lancet 344:721–724

Evans CD, List GR, Moser HA, Crowan JC (1973) J Am Oil Sci Soc 50:218–222

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siriwardhana, N., Jeon, YJ. Antioxidative effect of cactus pear fruit (Opuntia ficus-indica) extract on lipid peroxidation inhibition in oils and emulsion model systems. Eur Food Res Technol 219, 369–376 (2004). https://doi.org/10.1007/s00217-004-0956-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-0956-8